783956dfb96fd1b6067eca23d8bb8b85.ppt

- Количество слайдов: 17

Outgassing Test and the Getter Specification Dean Walters Nuclear Engineering Division Argonne National Laboratory

Outgassing Test and the Getter Specification Dean Walters Nuclear Engineering Division Argonne National Laboratory

Gettering and Outgassing n n n System Requirements Gettering Technology Design layout Test setup Status Future Work 2

Gettering and Outgassing n n n System Requirements Gettering Technology Design layout Test setup Status Future Work 2

Situation n What are the requirements for the vacuum – Pressure for MCP – Pressure for Photocathode Cs. I and Cs. Te n Pressure limits – For cesiated Ga. N cathodes degradation occurs above 10 -7 torr – Pressures at 10 -9 torr show no degradation of QE n Cs. I is hygroscopic n Bialkali is sensitive to hydrogen and oxygen n How long does it need to be functional – Current goal is ten years 3

Situation n What are the requirements for the vacuum – Pressure for MCP – Pressure for Photocathode Cs. I and Cs. Te n Pressure limits – For cesiated Ga. N cathodes degradation occurs above 10 -7 torr – Pressures at 10 -9 torr show no degradation of QE n Cs. I is hygroscopic n Bialkali is sensitive to hydrogen and oxygen n How long does it need to be functional – Current goal is ten years 3

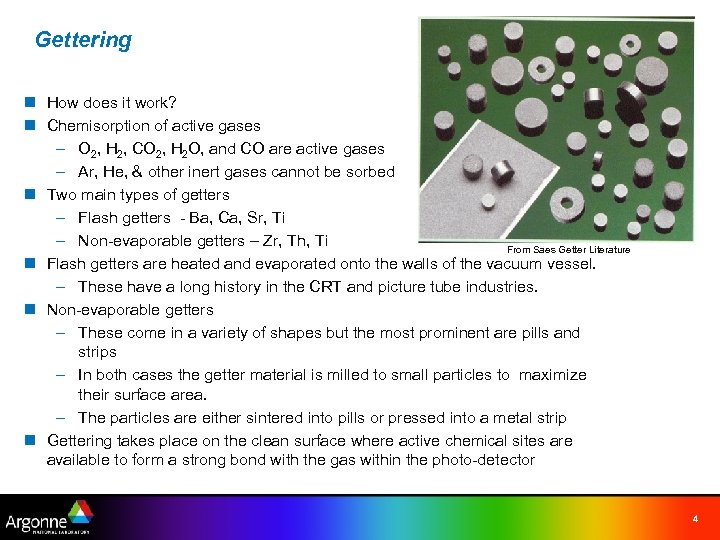

Gettering n How does it work? n Chemisorption of active gases – O 2, H 2, CO 2, H 2 O, and CO are active gases – Ar, He, & other inert gases cannot be sorbed n Two main types of getters – Flash getters - Ba, Ca, Sr, Ti – Non-evaporable getters – Zr, Th, Ti From Saes Getter Literature n Flash getters are heated and evaporated onto the walls of the vacuum vessel. – These have a long history in the CRT and picture tube industries. n Non-evaporable getters – These come in a variety of shapes but the most prominent are pills and strips – In both cases the getter material is milled to small particles to maximize their surface area. – The particles are either sintered into pills or pressed into a metal strip n Gettering takes place on the clean surface where active chemical sites are available to form a strong bond with the gas within the photo-detector 4

Gettering n How does it work? n Chemisorption of active gases – O 2, H 2, CO 2, H 2 O, and CO are active gases – Ar, He, & other inert gases cannot be sorbed n Two main types of getters – Flash getters - Ba, Ca, Sr, Ti – Non-evaporable getters – Zr, Th, Ti From Saes Getter Literature n Flash getters are heated and evaporated onto the walls of the vacuum vessel. – These have a long history in the CRT and picture tube industries. n Non-evaporable getters – These come in a variety of shapes but the most prominent are pills and strips – In both cases the getter material is milled to small particles to maximize their surface area. – The particles are either sintered into pills or pressed into a metal strip n Gettering takes place on the clean surface where active chemical sites are available to form a strong bond with the gas within the photo-detector 4

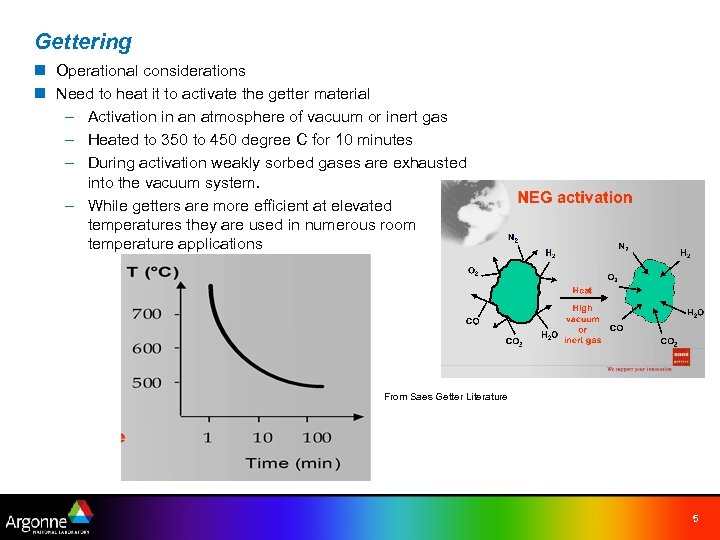

Gettering n Operational considerations n Need to heat it to activate the getter material – Activation in an atmosphere of vacuum or inert gas – Heated to 350 to 450 degree C for 10 minutes – During activation weakly sorbed gases are exhausted into the vacuum system. – While getters are more efficient at elevated temperatures they are used in numerous room temperature applications From Saes Getter Literature 5

Gettering n Operational considerations n Need to heat it to activate the getter material – Activation in an atmosphere of vacuum or inert gas – Heated to 350 to 450 degree C for 10 minutes – During activation weakly sorbed gases are exhausted into the vacuum system. – While getters are more efficient at elevated temperatures they are used in numerous room temperature applications From Saes Getter Literature 5

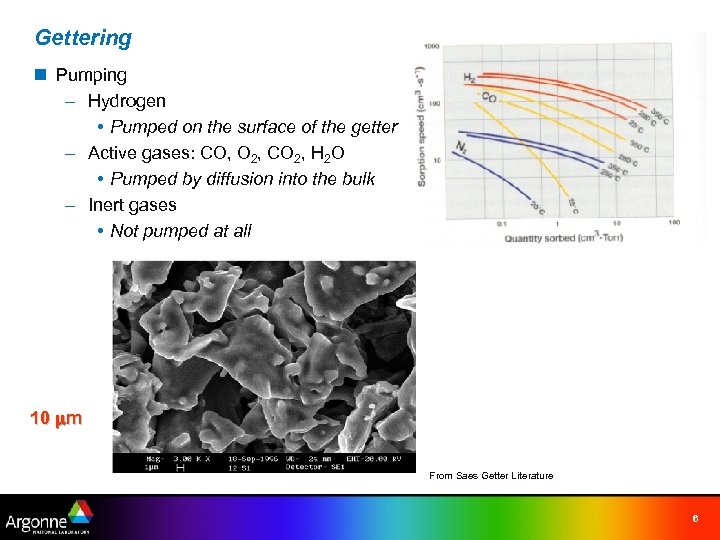

Gettering n Pumping – Hydrogen • Pumped on the surface of the getter – Active gases: CO, O 2, CO 2, H 2 O • Pumped by diffusion into the bulk – Inert gases • Not pumped at all 10 m From Saes Getter Literature 6

Gettering n Pumping – Hydrogen • Pumped on the surface of the getter – Active gases: CO, O 2, CO 2, H 2 O • Pumped by diffusion into the bulk – Inert gases • Not pumped at all 10 m From Saes Getter Literature 6

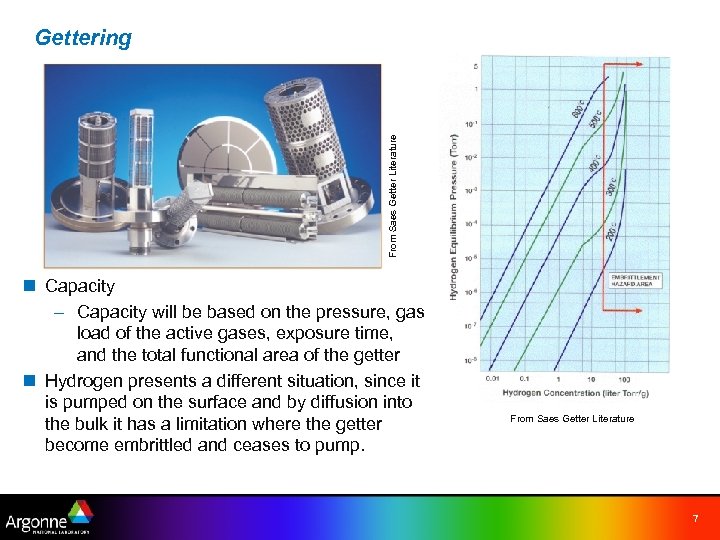

From Saes Getter Literature Gettering n Capacity – Capacity will be based on the pressure, gas load of the active gases, exposure time, and the total functional area of the getter n Hydrogen presents a different situation, since it is pumped on the surface and by diffusion into the bulk it has a limitation where the getter become embrittled and ceases to pump. From Saes Getter Literature 7

From Saes Getter Literature Gettering n Capacity – Capacity will be based on the pressure, gas load of the active gases, exposure time, and the total functional area of the getter n Hydrogen presents a different situation, since it is pumped on the surface and by diffusion into the bulk it has a limitation where the getter become embrittled and ceases to pump. From Saes Getter Literature 7

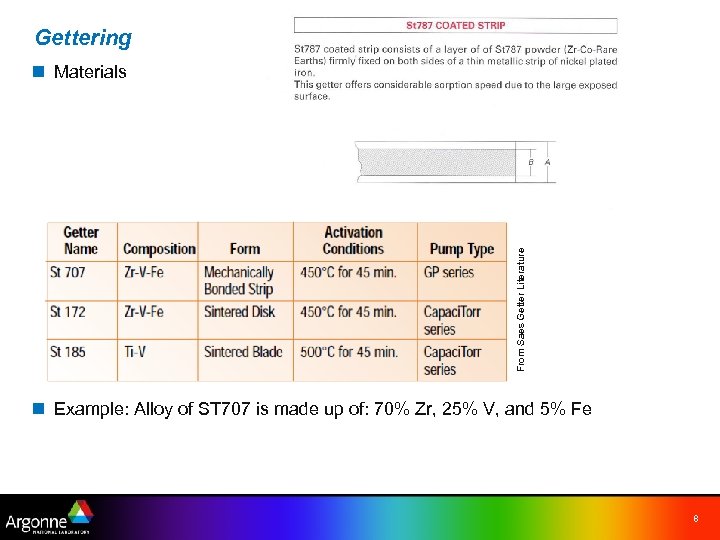

Gettering From Saes Getter Literature n Materials n Example: Alloy of ST 707 is made up of: 70% Zr, 25% V, and 5% Fe 8

Gettering From Saes Getter Literature n Materials n Example: Alloy of ST 707 is made up of: 70% Zr, 25% V, and 5% Fe 8

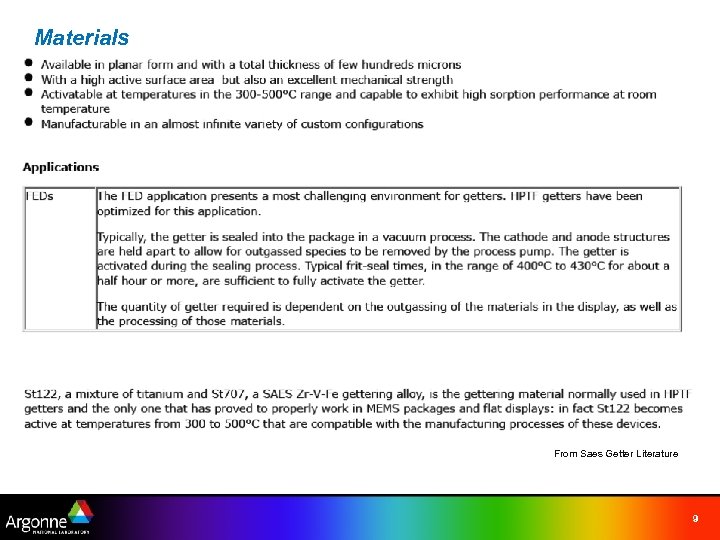

Materials From Saes Getter Literature 9

Materials From Saes Getter Literature 9

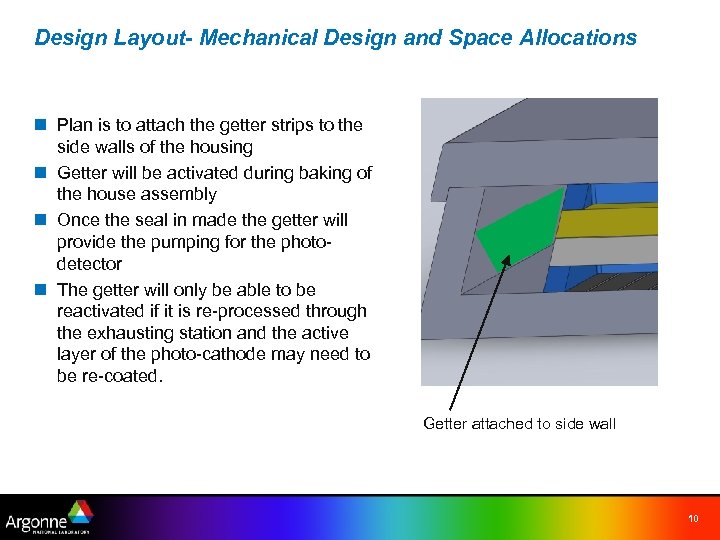

Design Layout- Mechanical Design and Space Allocations n Plan is to attach the getter strips to the side walls of the housing n Getter will be activated during baking of the house assembly n Once the seal in made the getter will provide the pumping for the photodetector n The getter will only be able to be reactivated if it is re-processed through the exhausting station and the active layer of the photo-cathode may need to be re-coated. Getter attached to side wall 10

Design Layout- Mechanical Design and Space Allocations n Plan is to attach the getter strips to the side walls of the housing n Getter will be activated during baking of the house assembly n Once the seal in made the getter will provide the pumping for the photodetector n The getter will only be able to be reactivated if it is re-processed through the exhausting station and the active layer of the photo-cathode may need to be re-coated. Getter attached to side wall 10

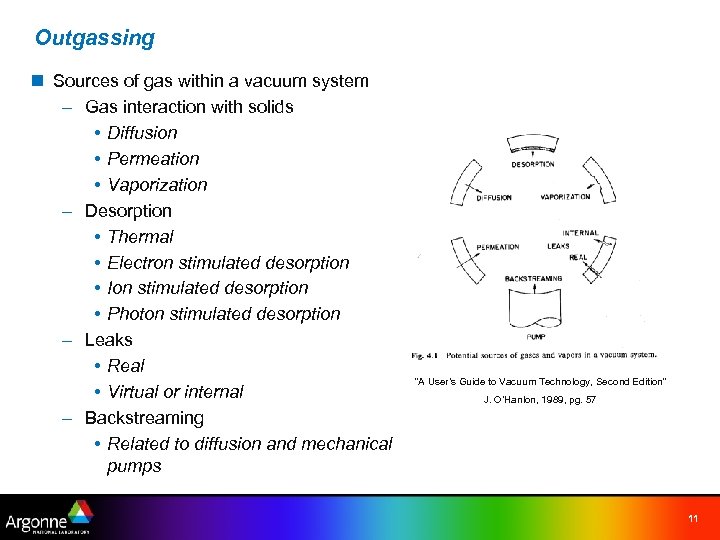

Outgassing n Sources of gas within a vacuum system – Gas interaction with solids • Diffusion • Permeation • Vaporization – Desorption • Thermal • Electron stimulated desorption • Ion stimulated desorption • Photon stimulated desorption – Leaks • Real • Virtual or internal – Backstreaming • Related to diffusion and mechanical pumps “A User’s Guide to Vacuum Technology, Second Edition” J. O’Hanlon, 1989, pg. 57 11

Outgassing n Sources of gas within a vacuum system – Gas interaction with solids • Diffusion • Permeation • Vaporization – Desorption • Thermal • Electron stimulated desorption • Ion stimulated desorption • Photon stimulated desorption – Leaks • Real • Virtual or internal – Backstreaming • Related to diffusion and mechanical pumps “A User’s Guide to Vacuum Technology, Second Edition” J. O’Hanlon, 1989, pg. 57 11

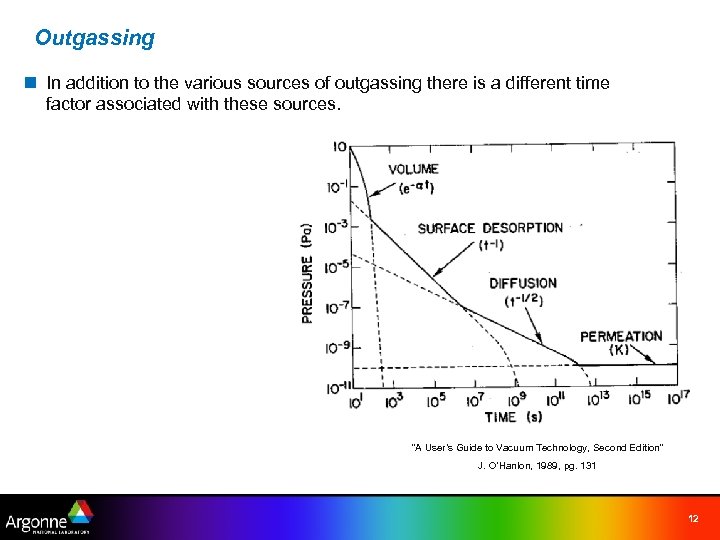

Outgassing n In addition to the various sources of outgassing there is a different time factor associated with these sources. “A User’s Guide to Vacuum Technology, Second Edition” J. O’Hanlon, 1989, pg. 131 12

Outgassing n In addition to the various sources of outgassing there is a different time factor associated with these sources. “A User’s Guide to Vacuum Technology, Second Edition” J. O’Hanlon, 1989, pg. 131 12

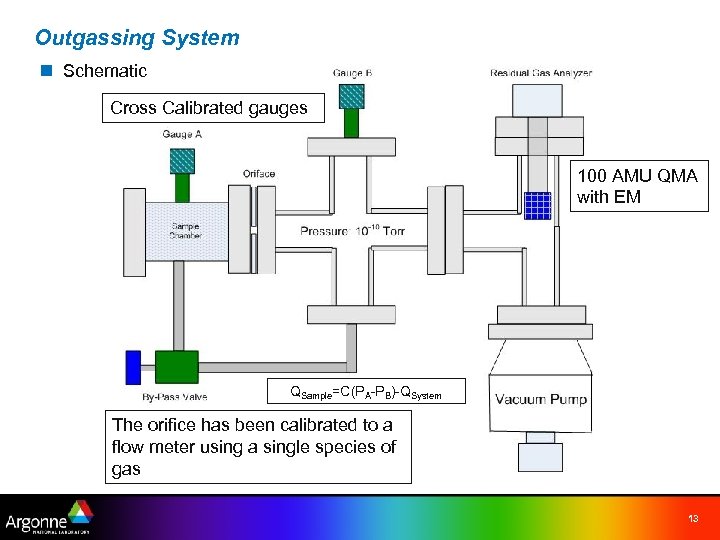

Outgassing System n Schematic Cross Calibrated gauges 100 AMU QMA with EM QSample=C(PA-PB)-QSystem The orifice has been calibrated to a flow meter using a single species of gas 13

Outgassing System n Schematic Cross Calibrated gauges 100 AMU QMA with EM QSample=C(PA-PB)-QSystem The orifice has been calibrated to a flow meter using a single species of gas 13

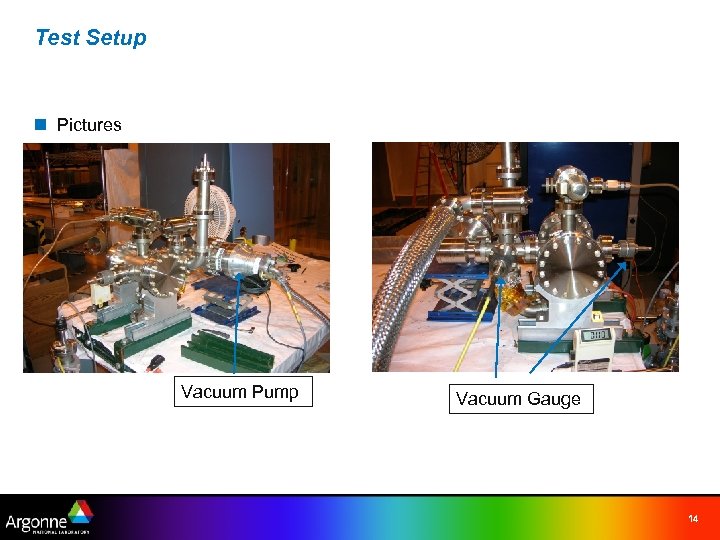

Test Setup n Pictures Vacuum Pump Vacuum Gauge 14

Test Setup n Pictures Vacuum Pump Vacuum Gauge 14

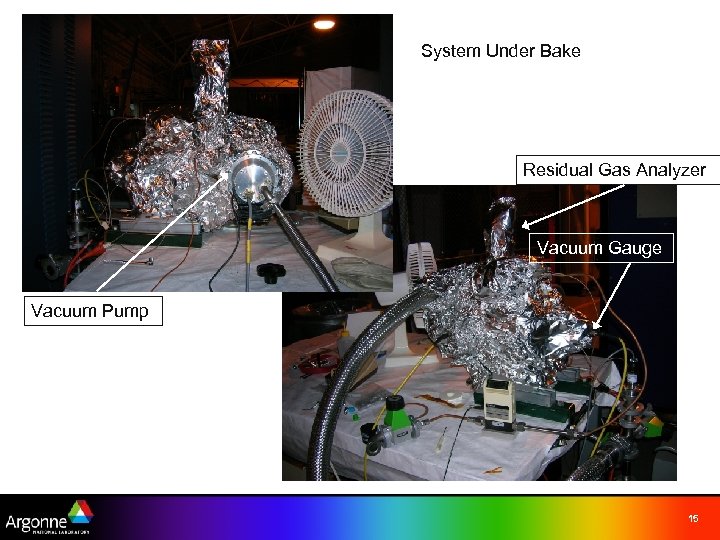

System Under Bake Residual Gas Analyzer Vacuum Gauge Vacuum Pump 15

System Under Bake Residual Gas Analyzer Vacuum Gauge Vacuum Pump 15

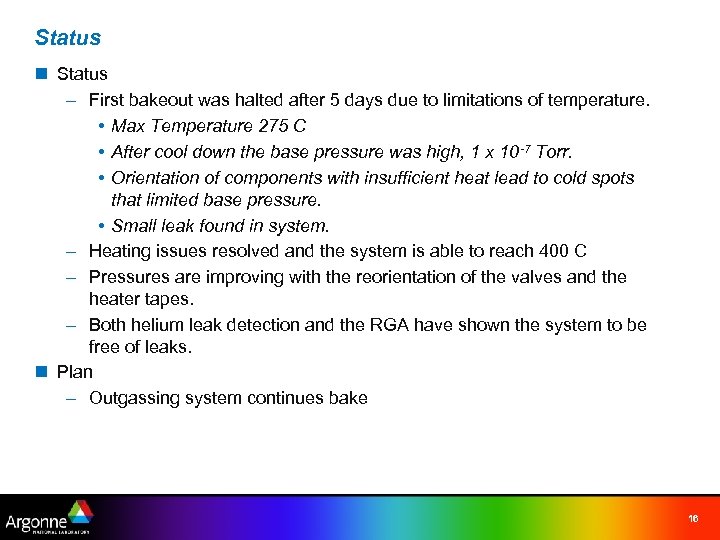

Status n Status – First bakeout was halted after 5 days due to limitations of temperature. • Max Temperature 275 C • After cool down the base pressure was high, 1 x 10 -7 Torr. • Orientation of components with insufficient heat lead to cold spots that limited base pressure. • Small leak found in system. – Heating issues resolved and the system is able to reach 400 C – Pressures are improving with the reorientation of the valves and the heater tapes. – Both helium leak detection and the RGA have shown the system to be free of leaks. n Plan – Outgassing system continues bake 16

Status n Status – First bakeout was halted after 5 days due to limitations of temperature. • Max Temperature 275 C • After cool down the base pressure was high, 1 x 10 -7 Torr. • Orientation of components with insufficient heat lead to cold spots that limited base pressure. • Small leak found in system. – Heating issues resolved and the system is able to reach 400 C – Pressures are improving with the reorientation of the valves and the heater tapes. – Both helium leak detection and the RGA have shown the system to be free of leaks. n Plan – Outgassing system continues bake 16

Future Activities n Going Forward – By measuring the outgassing rate and identifying the species of the residual gas evolving from the parts will aid in the estimation of the gas load that the getters will pump. – Will be able to experiment with different temperatures to determine the best bake out temperature. – Will be able to perform trials on some of the proposed processes. • Like Indium sealing and examples of glass frit joints. – A note of appreciation to Bob Garcia from Saes Getters for his assistance on this talk. 17

Future Activities n Going Forward – By measuring the outgassing rate and identifying the species of the residual gas evolving from the parts will aid in the estimation of the gas load that the getters will pump. – Will be able to experiment with different temperatures to determine the best bake out temperature. – Will be able to perform trials on some of the proposed processes. • Like Indium sealing and examples of glass frit joints. – A note of appreciation to Bob Garcia from Saes Getters for his assistance on this talk. 17