abddaea0023f520a29e4c239ce7bda32.ppt

- Количество слайдов: 22

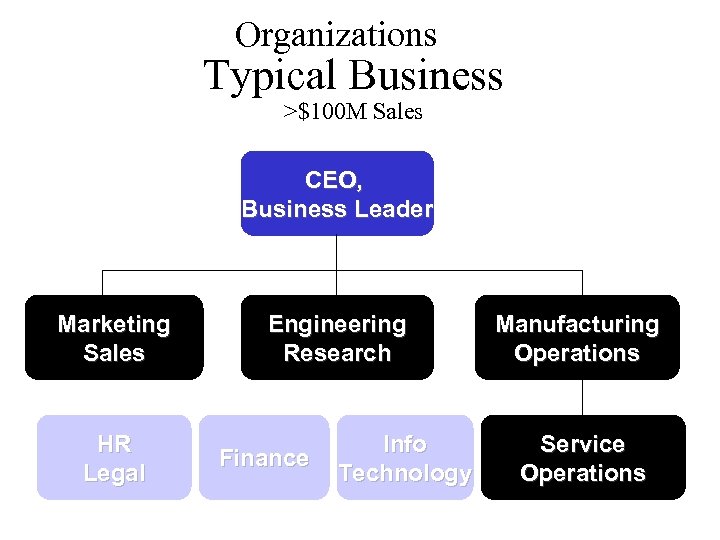

Organizations Typical Business >$100 M Sales CEO, Business Leader Marketing Sales HR Legal Engineering Research Finance Info Technology Manufacturing Operations Service Operations

Roles Typical Business • CEO – Chief Executive Officer • Sets Strategic Direction • Formulates and Drives overall Operating Plan • Allocates Funding to Supporting Functions • Sets/Approves Supporting Function Annual Goals • Company Image and Morale • Meets Strategic Commitments: OM, Cash, Net Income, etc • Ultimate Responsibility for Quality

Roles Typical Business • Marketing & Sales • Assess Customer Needs & Satisfaction • Determine Market Size, Demographics • Transform Customer Needs into High Level Product Definitions • Communicate Product Definitions to Eng • Drive Promotion and Advertising • Assess Competitive Product Features • Set Sales Prices • Determine Suitable Distribution with Mfg • Predict/Communicate Sales Volume & $ for each Product on Annual Basis

Roles Typical Business • Engineering • Transform High Level Product Definition into Quantifiable and Verifiable System Requirements • Estimate Resources Required for Proposed Product Development • Provide Technology and Design Solutions to System Requirements • Develop System Architecture, Requirement Flowdown, and Detailed Design Solutions • Integrate and Verify Block and System Level Requirements • Provide Mfg with all documentation to produce the product • Provide/Integrate Competitive New Technology

Roles Typical Business • Manufacturing & Operations • Purchase & Procurement of Materials • MRP (Material-Resource Planning) • Build, Produce, Distribute the Products • Develop Automated and Manual Assembly • Develop Automated and Manual Processes • Drive for Lower Cycle Time, Inventory, Defects, Rework, Variable Costs, Safety • Drive Promotion and Advertising • Justify Equipment Expenditures, ROI • Maintain Product Mfg Records • Shipping and Receiving

Roles Typical Business • Info Technology (Supporting Function) • Provide Computer Automation of Manual Functions including Order Entry, Purchase Orders, Shop Orders, Inventory, Payments, and Shipping Orders • Support e. Business Transactions • Provide Basic Computer Platforms to Departments including HW, OS, Email, Internet, Word Processing, Spreadsheet, Charting, E-CAD, etc • Provide Networking, File Storage and Server Infrastructures

Roles Typical Business • Finance (Supporting Function) • Manage Accounts Payable • Manage Accounts Receivable • Provide Periodic Accounting Summary of Base Cost, Var Cost, OM, CM, Net Inc & Cash • Provide Operating Plan Assessment • Allocate Depreciation • Provide Tax Justification and Payment • Drive Controllership, Identify and Reduce Unnecessary Costs • Manage Company Payroll

Roles Typical Business • Human Resources & Legal (Supporting Functions) • Find Qualified New Hire Candidates • Drive Periodic Performance Assessments and Salary Actions • Drive Compliant & Legal Operations • Formulate and Communicate Company Policies including vacation, work rules, sick leave, disability, bereavement, internal job posting, seniority, use of company assets, job elimination • Provide Employee Complaint & Appeal Systems • Manage Intellectual Property Usage/Ownership • Manage Company Legal Actions

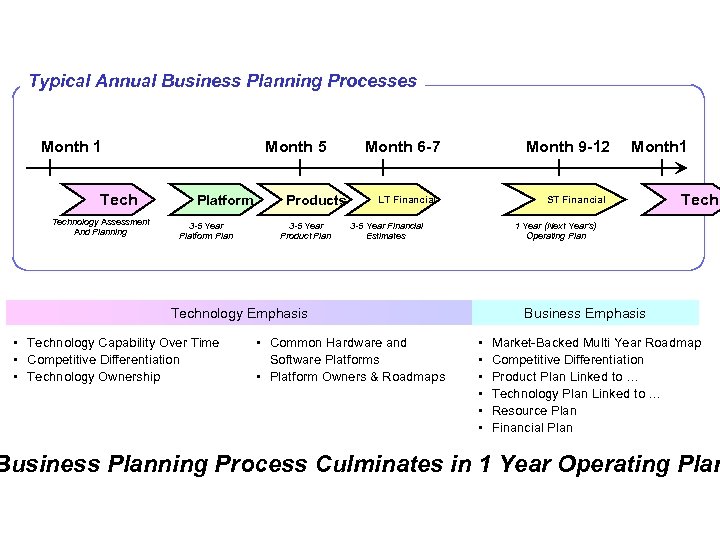

Typical Annual Business Planning Processes Month 1 Technology Assessment And Planning Month 5 Platform 3 -5 Year Platform Plan Products 3 -5 Year Product Plan Month 6 -7 Month 9 -12 LT Financial ST Financial 3 -5 Year Financial Estimates • Common Hardware and Software Platforms • Platform Owners & Roadmaps Tech 1 Year (Next Year’s) Operating Plan Technology Emphasis • Technology Capability Over Time • Competitive Differentiation • Technology Ownership Month 1 Business Emphasis • • • Market-Backed Multi Year Roadmap Competitive Differentiation Product Plan Linked to … Technology Plan Linked to … Resource Plan Financial Plan Business Planning Process Culminates in 1 Year Operating Plan

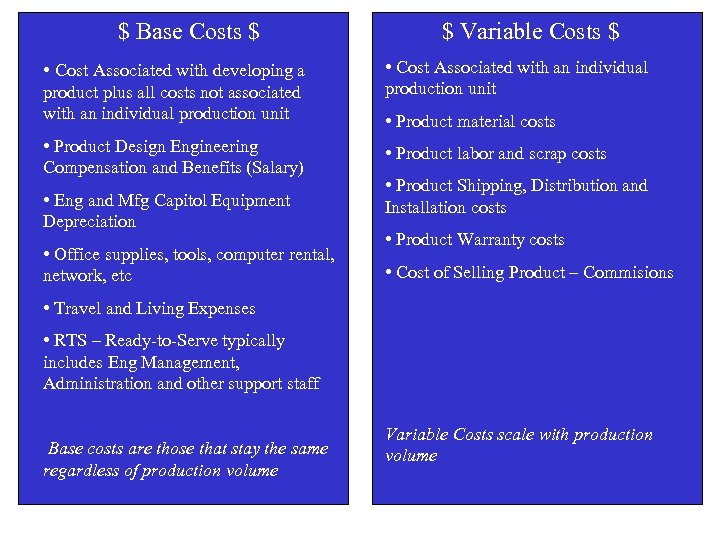

$ Base Costs $ • Cost Associated with developing a product plus all costs not associated with an individual production unit • Product Design Engineering Compensation and Benefits (Salary) • Eng and Mfg Capitol Equipment Depreciation • Office supplies, tools, computer rental, network, etc $ Variable Costs $ • Cost Associated with an individual production unit • Product material costs • Product labor and scrap costs • Product Shipping, Distribution and Installation costs • Product Warranty costs • Cost of Selling Product – Commisions • Travel and Living Expenses • RTS – Ready-to-Serve typically includes Eng Management, Administration and other support staff Base costs are those that stay the same regardless of production volume Variable Costs scale with production volume

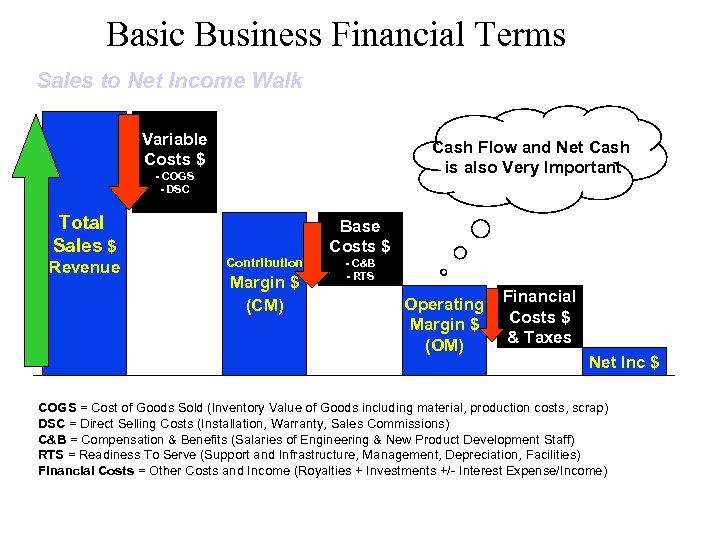

Basic Business Financial Terms Sales to Net Income Walk Variable Costs $ Cash Flow and Net Cash is also Very Important - COGS - DSC Total Sales $ Revenue Contribution Margin $ (CM) Base Costs $ - C&B - RTS Operating Margin $ (OM) Financial Costs $ & Taxes Net Inc $ COGS = Cost of Goods Sold (Inventory Value of Goods including material, production costs, scrap) DSC = Direct Selling Costs (Installation, Warranty, Sales Commissions) C&B = Compensation & Benefits (Salaries of Engineering & New Product Development Staff) RTS = Readiness To Serve (Support and Infrastructure, Management, Depreciation, Facilities) Financial Costs = Other Costs and Income (Royalties + Investments +/- Interest Expense/Income)

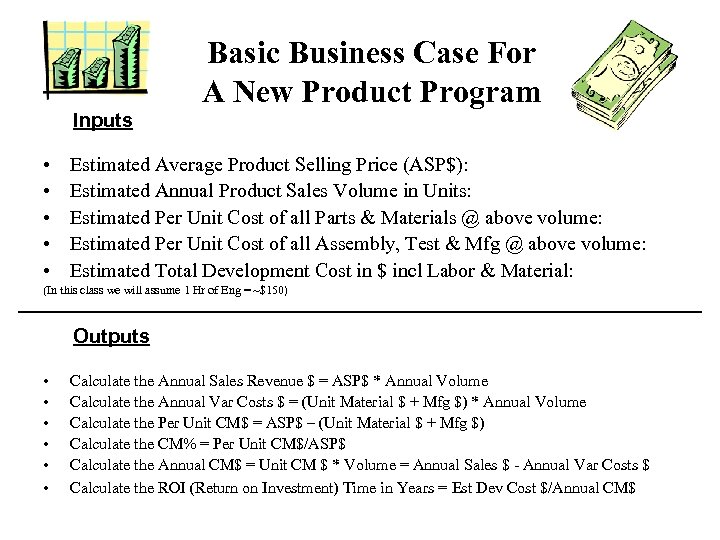

Basic Business Case For A New Product Program Inputs • • • Estimated Average Product Selling Price (ASP$): Estimated Annual Product Sales Volume in Units: Estimated Per Unit Cost of all Parts & Materials @ above volume: Estimated Per Unit Cost of all Assembly, Test & Mfg @ above volume: Estimated Total Development Cost in $ incl Labor & Material: (In this class we will assume 1 Hr of Eng = ~$150) Outputs • • • Calculate the Annual Sales Revenue $ = ASP$ * Annual Volume Calculate the Annual Var Costs $ = (Unit Material $ + Mfg $) * Annual Volume Calculate the Per Unit CM$ = ASP$ – (Unit Material $ + Mfg $) Calculate the CM% = Per Unit CM$/ASP$ Calculate the Annual CM$ = Unit CM $ * Volume = Annual Sales $ - Annual Var Costs $ Calculate the ROI (Return on Investment) Time in Years = Est Dev Cost $/Annual CM$

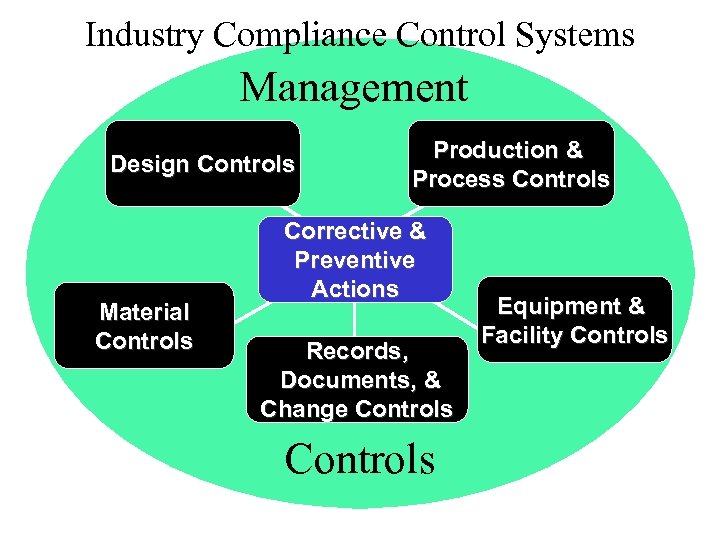

Industry Compliance Control Systems Management Design Controls Material Controls Production & Process Controls Corrective & Preventive Actions Records, Documents, & Change Controls Equipment & Facility Controls

Terms and Definitions • Design Inputs • Requirements, Constraints and other information which is needed to formulate a set of design outputs for a given product. • Design Inputs must include customer (user) level as well as product/system level. • Design Outputs • All drawings, documents and other information necessary to describe the constituent parts, assembly, manufacturing process, service and disposal processes for a product. • Design outputs from one team often become the design inputs to another team. All Design Inputs/Outputs Must Be Reviewed in Many Industries… …. ie Aerospace, Transportation, Medical, etc

Terms and Definitions • Reviews • Peer review of design inputs and design outputs are a mandatory part of many industry product development processes. • Reviews must include objective evidence of attendees, documented issue list with dispensation actions, signatures and dates. • Reviews must include appropriate stake holders (management, customers, other design teams) plus at least 1 unbiased, knowledgeable external reviewer

Terms and Definitions • Verification • Design analysis, simulation or prototype testing which provides objective evidence that a design meets all of its block or product level requirements. • Verification is used to prove that a design meets all of its specifications. • Is performed at component, block and product levels • Validation • Product field, clinical or customer trial which provides objective evidence that a product meets its customer (user) requirements. • Intended use is an important part of the product labeling. • Is only performed at the product level

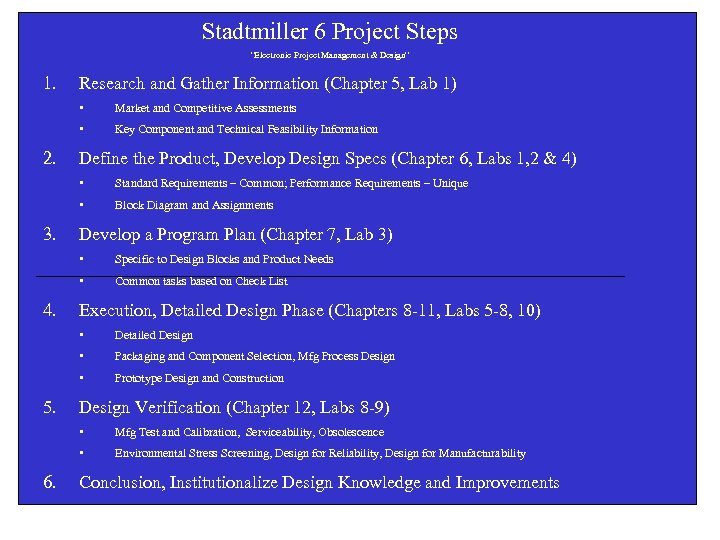

Stadtmiller 6 Project Steps “Electronic Project Management & Design” 1. Research and Gather Information (Chapter 5, Lab 1) • • 2. Market and Competitive Assessments Key Component and Technical Feasibility Information Define the Product, Develop Design Specs (Chapter 6, Labs 1, 2 & 4) • • 3. Standard Requirements – Common; Performance Requirements – Unique Block Diagram and Assignments Develop a Program Plan (Chapter 7, Lab 3) • • 4. Specific to Design Blocks and Product Needs Common tasks based on Check List Execution, Detailed Design Phase (Chapters 8 -11, Labs 5 -8, 10) • • Packaging and Component Selection, Mfg Process Design • 5. Detailed Design Prototype Design and Construction Design Verification (Chapter 12, Labs 8 -9) • • 6. Mfg Test and Calibration, Serviceability, Obsolescence Environmental Stress Screening, Design for Reliability, Design for Manufacturability Conclusion, Institutionalize Design Knowledge and Improvements

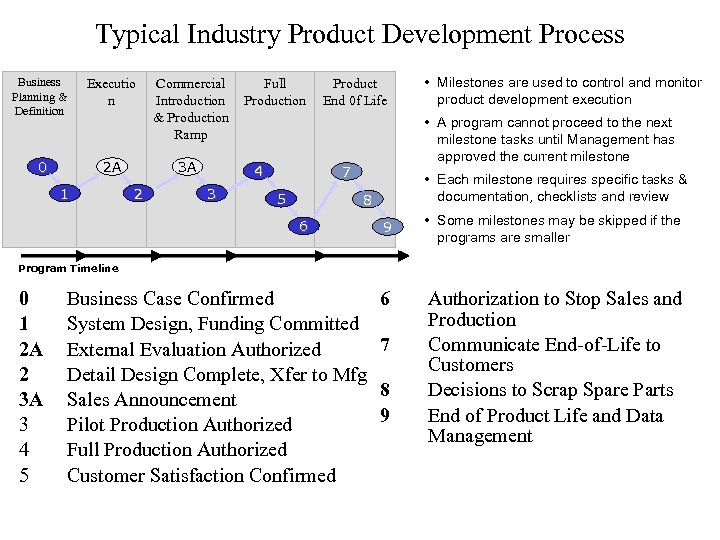

Typical Industry Product Development Process Business Planning & Definition Executio n 0 2 A 1 Commercial Introduction & Production Ramp 3 A 2 Full Production 4 3 Product End 0 f Life • A program cannot proceed to the next milestone tasks until Management has approved the current milestone 7 5 • Milestones are used to control and monitor product development execution • Each milestone requires specific tasks & documentation, checklists and review 8 6 9 • Some milestones may be skipped if the programs are smaller 6 Authorization to Stop Sales and Production Communicate End-of-Life to Customers Decisions to Scrap Spare Parts End of Product Life and Data Management Program Timeline 0 1 2 A 2 3 A 3 4 5 Business Case Confirmed System Design, Funding Committed External Evaluation Authorized Detail Design Complete, Xfer to Mfg Sales Announcement Pilot Production Authorized Full Production Authorized Customer Satisfaction Confirmed 7 8 9

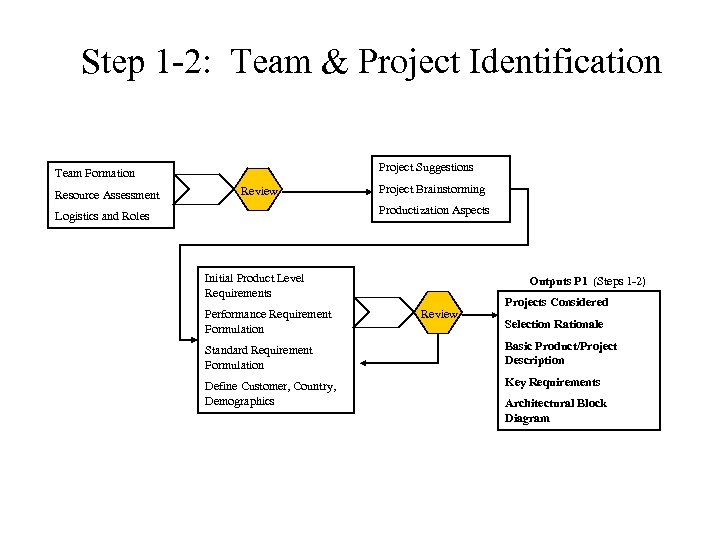

Step 1 -2: Team & Project Identification Project Suggestions Team Formation Resource Assessment Review Project Brainstorming Productization Aspects Logistics and Roles Initial Product Level Requirements Performance Requirement Formulation Outputs P 1 (Steps 1 -2) Review Projects Considered Selection Rationale Standard Requirement Formulation Basic Product/Project Description Define Customer, Country, Demographics Key Requirements Architectural Block Diagram

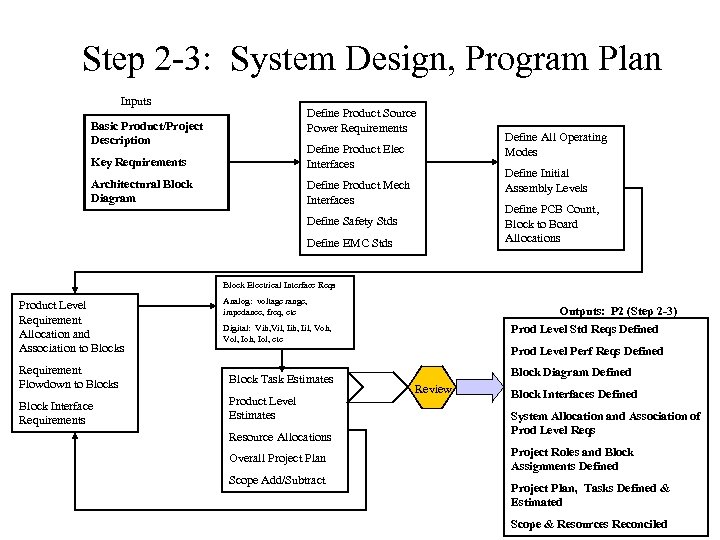

Step 2 -3: System Design, Program Plan Inputs Define Product Source Power Requirements Basic Product/Project Description Key Requirements Define Product Elec Interfaces Architectural Block Diagram Define Product Mech Interfaces Define All Operating Modes Define Initial Assembly Levels Define PCB Count, Block to Board Allocations Define Safety Stds Define EMC Stds Block Electrical Interface Reqs Product Level Requirement Allocation and Association to Blocks Analog: voltage range, impedance, freq, etc Outputs: P 2 (Step 2 -3) Prod Level Std Reqs Defined Digital: Vih, Vil, Iih, Iil, Voh, Vol, Ioh, Iol, etc Requirement Flowdown to Blocks Block Task Estimates Block Interface Requirements Product Level Estimates Resource Allocations Overall Project Plan Scope Add/Subtract Prod Level Perf Reqs Defined Block Diagram Defined Review Block Interfaces Defined System Allocation and Association of Prod Level Reqs Project Roles and Block Assignments Defined Project Plan, Tasks Defined & Estimated Scope & Resources Reconciled

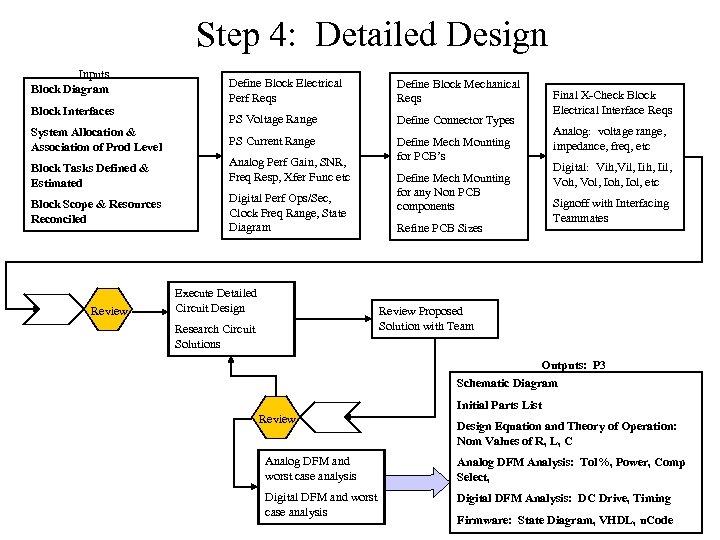

Step 4: Detailed Design Inputs Block Diagram Block Interfaces System Allocation & Association of Prod Level Define Block Electrical Perf Reqs Define Block Mechanical Reqs PS Voltage Range Define Connector Types PS Current Range Define Mech Mounting for PCB’s Block Tasks Defined & Estimated Analog Perf Gain, SNR, Freq Resp, Xfer Func etc Block Scope & Resources Reconciled Digital Perf Ops/Sec, Clock Freq Range, State Diagram Review Execute Detailed Circuit Design Define Mech Mounting for any Non PCB components Refine PCB Sizes Final X-Check Block Electrical Interface Reqs Analog: voltage range, impedance, freq, etc Digital: Vih, Vil, Iih, Iil, Voh, Vol, Ioh, Iol, etc Signoff with Interfacing Teammates Review Proposed Solution with Team Research Circuit Solutions Outputs: P 3 Schematic Diagram Initial Parts List Review Design Equation and Theory of Operation: Nom Values of R, L, C Analog DFM and worst case analysis Analog DFM Analysis: Tol%, Power, Comp Select, Digital DFM and worst case analysis Digital DFM Analysis: DC Drive, Timing Firmware: State Diagram, VHDL, u. Code

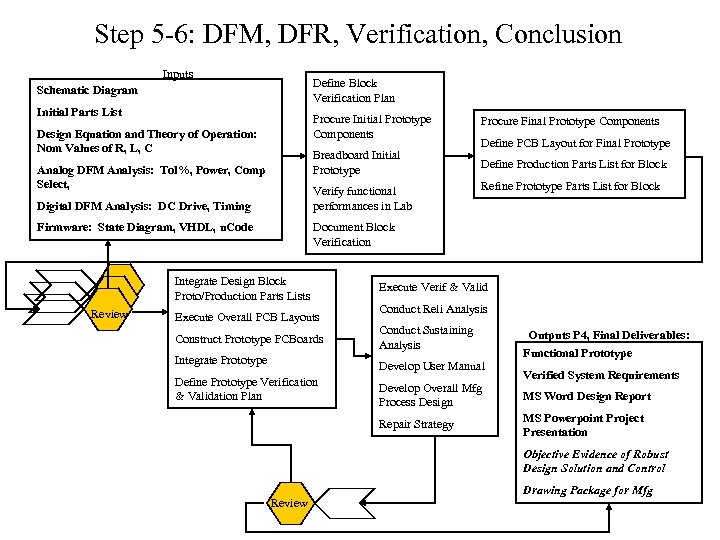

Step 5 -6: DFM, DFR, Verification, Conclusion Inputs Define Block Verification Plan Schematic Diagram Initial Parts List Procure Initial Prototype Components Analog DFM Analysis: Tol%, Power, Comp Select, Procure Final Prototype Components Breadboard Initial Prototype Design Equation and Theory of Operation: Nom Values of R, L, C Define Production Parts List for Block Verify functional performances in Lab Digital DFM Analysis: DC Drive, Timing Refine Prototype Parts List for Block Document Block Verification Firmware: State Diagram, VHDL, u. Code Integrate Design Block Proto/Production Parts Lists Review Define PCB Layout for Final Prototype Execute Overall PCB Layouts Execute Verif & Valid Conduct Reli Analysis Construct Prototype PCBoards Conduct Sustaining Analysis Integrate Prototype Develop User Manual Define Prototype Verification & Validation Plan Develop Overall Mfg Process Design Repair Strategy Outputs P 4, Final Deliverables: Functional Prototype Verified System Requirements MS Word Design Report MS Powerpoint Project Presentation Objective Evidence of Robust Design Solution and Control Drawing Package for Mfg Review

abddaea0023f520a29e4c239ce7bda32.ppt