ec714b45313fa28a3546c1cd49eaeba9.ppt

- Количество слайдов: 69

Organic Poultry Production in the U. S. Anne Fanatico National Center for Appropriate Technology

Organic Poultry Production in the U. S. Anne Fanatico National Center for Appropriate Technology

Organic Broiler Market Meat/fish/poultry category was fastest-growing organic category at 29% in 2006 OTA’s Manufacturer Survey, 2006 and 2007

Organic Broiler Market Meat/fish/poultry category was fastest-growing organic category at 29% in 2006 OTA’s Manufacturer Survey, 2006 and 2007

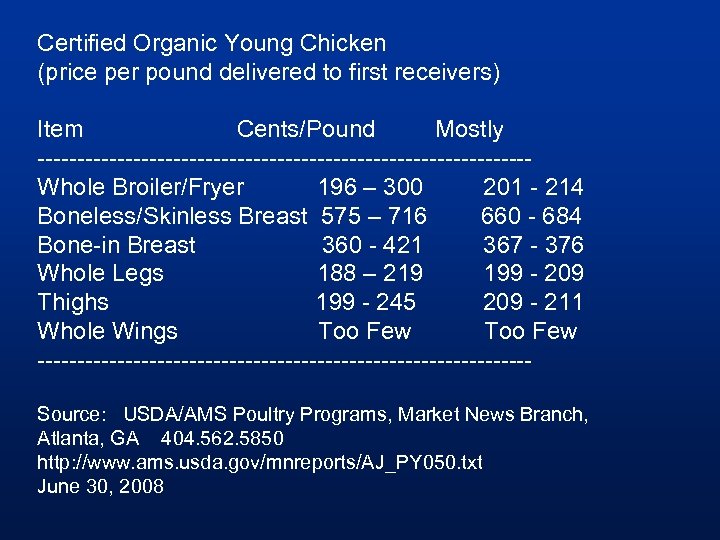

Certified Organic Young Chicken (price per pound delivered to first receivers) Item Cents/Pound Mostly -------------------------------Whole Broiler/Fryer 196 – 300 201 - 214 Boneless/Skinless Breast 575 – 716 660 - 684 Bone-in Breast 360 - 421 367 - 376 Whole Legs 188 – 219 199 - 209 Thighs 199 - 245 209 - 211 Whole Wings Too Few -------------------------------Source: USDA/AMS Poultry Programs, Market News Branch, Atlanta, GA 404. 562. 5850 http: //www. ams. usda. gov/mnreports/AJ_PY 050. txt June 30, 2008

Certified Organic Young Chicken (price per pound delivered to first receivers) Item Cents/Pound Mostly -------------------------------Whole Broiler/Fryer 196 – 300 201 - 214 Boneless/Skinless Breast 575 – 716 660 - 684 Bone-in Breast 360 - 421 367 - 376 Whole Legs 188 – 219 199 - 209 Thighs 199 - 245 209 - 211 Whole Wings Too Few -------------------------------Source: USDA/AMS Poultry Programs, Market News Branch, Atlanta, GA 404. 562. 5850 http: //www. ams. usda. gov/mnreports/AJ_PY 050. txt June 30, 2008

Organic Chicken Prices, Retail Product Year Whole Fryers $ per pound, fresh tray pack $2. 71 BS Breast $7. 99 Split bone-in breast Whole wings $4. 99 Dec 2007 $2. 49 2006 Thighs $2. 49 2006 Drums $2. 49 2006 Source: http: //www. ams. usda. gov/poultry/pymn. htm 2006

Organic Chicken Prices, Retail Product Year Whole Fryers $ per pound, fresh tray pack $2. 71 BS Breast $7. 99 Split bone-in breast Whole wings $4. 99 Dec 2007 $2. 49 2006 Thighs $2. 49 2006 Drums $2. 49 2006 Source: http: //www. ams. usda. gov/poultry/pymn. htm 2006

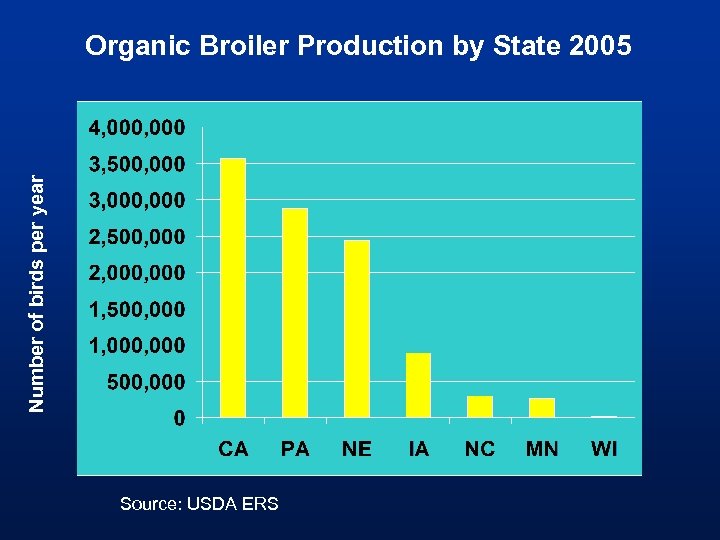

Number of birds per year Organic Broiler Production by State 2005 Source: USDA ERS

Number of birds per year Organic Broiler Production by State 2005 Source: USDA ERS

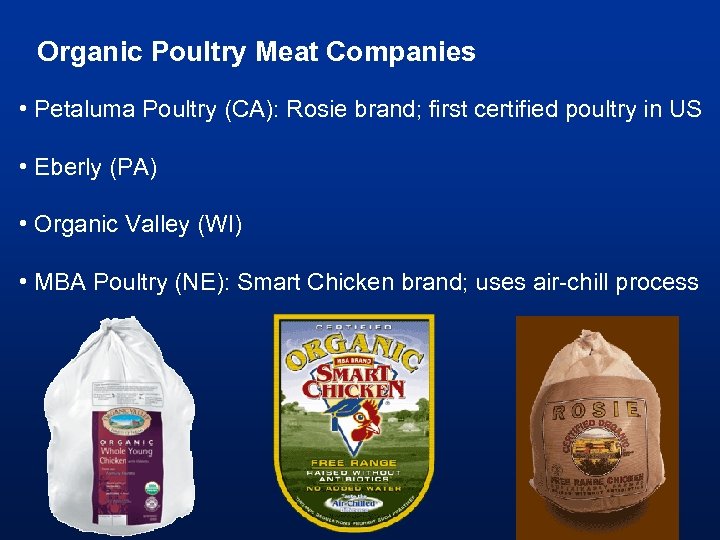

Organic Poultry Meat Companies • Petaluma Poultry (CA): Rosie brand; first certified poultry in US • Eberly (PA) • Organic Valley (WI) • MBA Poultry (NE): Smart Chicken brand; uses air-chill process

Organic Poultry Meat Companies • Petaluma Poultry (CA): Rosie brand; first certified poultry in US • Eberly (PA) • Organic Valley (WI) • MBA Poultry (NE): Smart Chicken brand; uses air-chill process

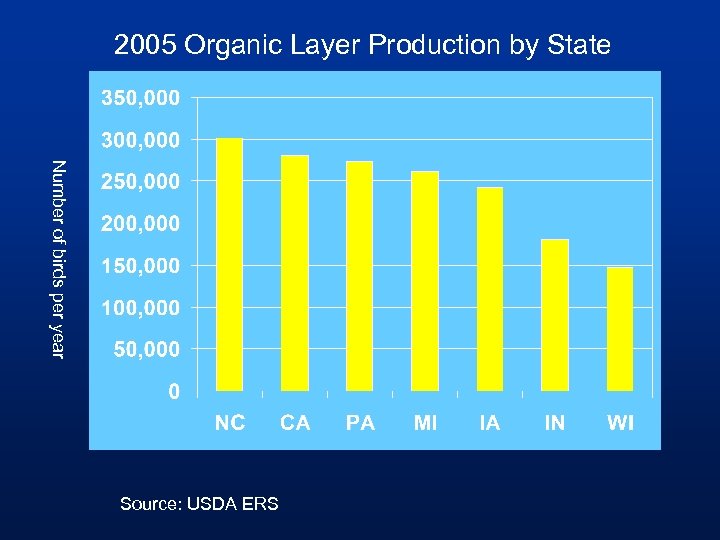

2005 Organic Layer Production by State Number of birds per year Source: USDA ERS

2005 Organic Layer Production by State Number of birds per year Source: USDA ERS

Organic Egg Companies Braswell Foods Horizon Organic Valley Eggland’s Best Chino Valley Ranchers Egg Innovations

Organic Egg Companies Braswell Foods Horizon Organic Valley Eggland’s Best Chino Valley Ranchers Egg Innovations

Organic Processed Egg Companies Braswell Farmer’s Organic Food Chino Valley Ranchers Whites Yolks Whole egg Frozen salted yolks Frozen sugared yolks Dried products

Organic Processed Egg Companies Braswell Farmer’s Organic Food Chino Valley Ranchers Whites Yolks Whole egg Frozen salted yolks Frozen sugared yolks Dried products

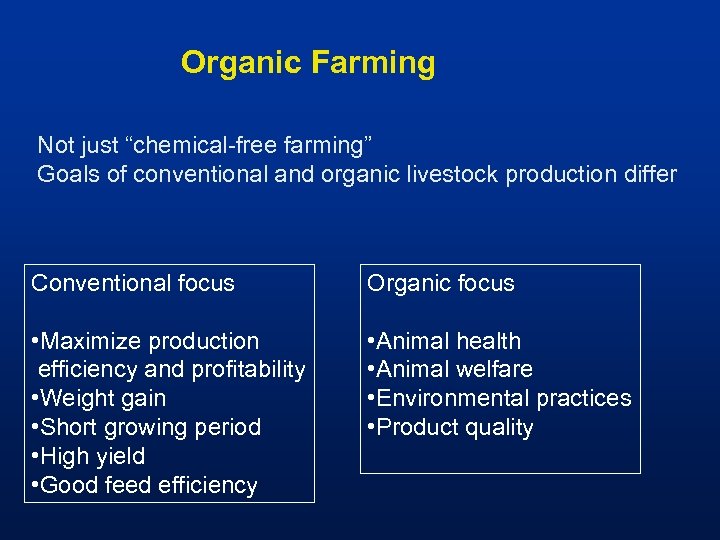

Organic Farming Not just “chemical-free farming” Goals of conventional and organic livestock production differ Conventional focus Organic focus • Maximize production efficiency and profitability • Weight gain • Short growing period • High yield • Good feed efficiency • Animal health • Animal welfare • Environmental practices • Product quality

Organic Farming Not just “chemical-free farming” Goals of conventional and organic livestock production differ Conventional focus Organic focus • Maximize production efficiency and profitability • Weight gain • Short growing period • High yield • Good feed efficiency • Animal health • Animal welfare • Environmental practices • Product quality

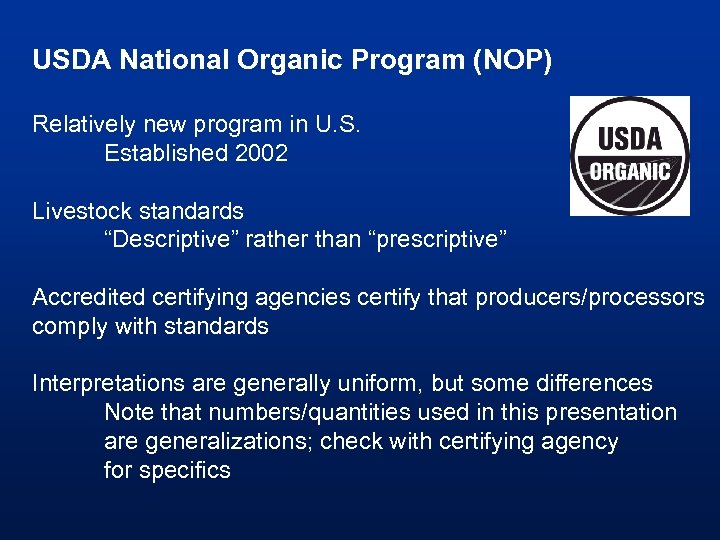

USDA National Organic Program (NOP) Relatively new program in U. S. Established 2002 Livestock standards “Descriptive” rather than “prescriptive” Accredited certifying agencies certify that producers/processors comply with standards Interpretations are generally uniform, but some differences Note that numbers/quantities used in this presentation are generalizations; check with certifying agency for specifics

USDA National Organic Program (NOP) Relatively new program in U. S. Established 2002 Livestock standards “Descriptive” rather than “prescriptive” Accredited certifying agencies certify that producers/processors comply with standards Interpretations are generally uniform, but some differences Note that numbers/quantities used in this presentation are generalizations; check with certifying agency for specifics

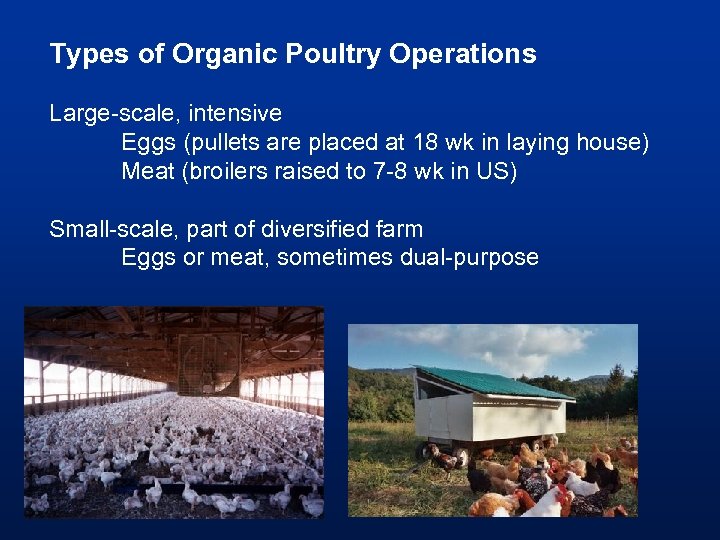

Types of Organic Poultry Operations Large-scale, intensive Eggs (pullets are placed at 18 wk in laying house) Meat (broilers raised to 7 -8 wk in US) Small-scale, part of diversified farm Eggs or meat, sometimes dual-purpose

Types of Organic Poultry Operations Large-scale, intensive Eggs (pullets are placed at 18 wk in laying house) Meat (broilers raised to 7 -8 wk in US) Small-scale, part of diversified farm Eggs or meat, sometimes dual-purpose

Vertically Integrated Companies • Most conventional broilers, layers, and turkeys are raised by vertically integrated companies or “integrators” in US • One company owns hatcheries, production flocks, feed mill, processing plant, etc. • Production is usually contracted to contract growers who own houses (high capital) and provide labor • Vertical integration is common in large-scale organic production Independent Operations • Small operations are independent

Vertically Integrated Companies • Most conventional broilers, layers, and turkeys are raised by vertically integrated companies or “integrators” in US • One company owns hatcheries, production flocks, feed mill, processing plant, etc. • Production is usually contracted to contract growers who own houses (high capital) and provide labor • Vertical integration is common in large-scale organic production Independent Operations • Small operations are independent

Housing and Living Conditions Environment that accommodates health and natural behavior of animals, shade, shelter, exercise areas, fresh air, direct sunlight No cages Access to outdoors No stocking density limit or restriction on flock size However, certifying agencies usually look for low density (at least 1. 5 ft 2 per bird)* * Check with certifying agency for specifics

Housing and Living Conditions Environment that accommodates health and natural behavior of animals, shade, shelter, exercise areas, fresh air, direct sunlight No cages Access to outdoors No stocking density limit or restriction on flock size However, certifying agencies usually look for low density (at least 1. 5 ft 2 per bird)* * Check with certifying agency for specifics

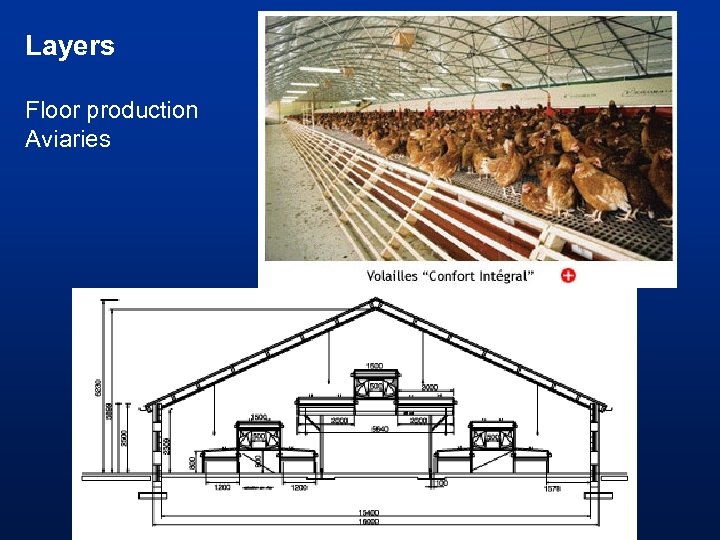

Layers Floor production Aviaries

Layers Floor production Aviaries

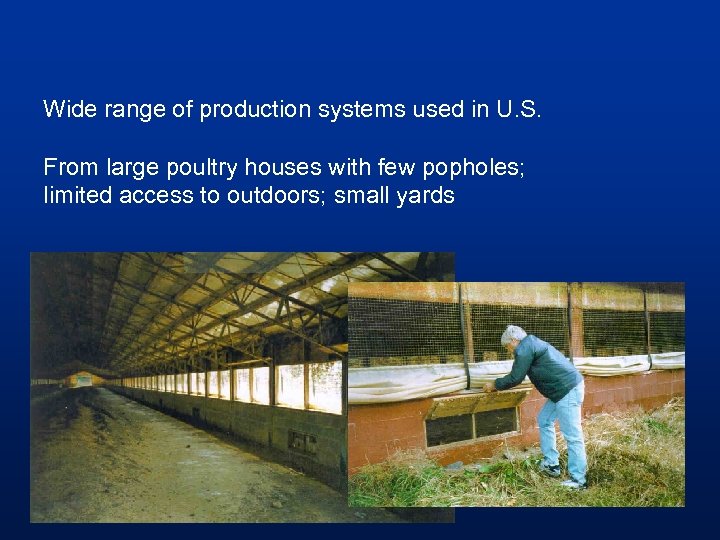

Wide range of production systems used in U. S. From large poultry houses with few popholes; limited access to outdoors; small yards

Wide range of production systems used in U. S. From large poultry houses with few popholes; limited access to outdoors; small yards

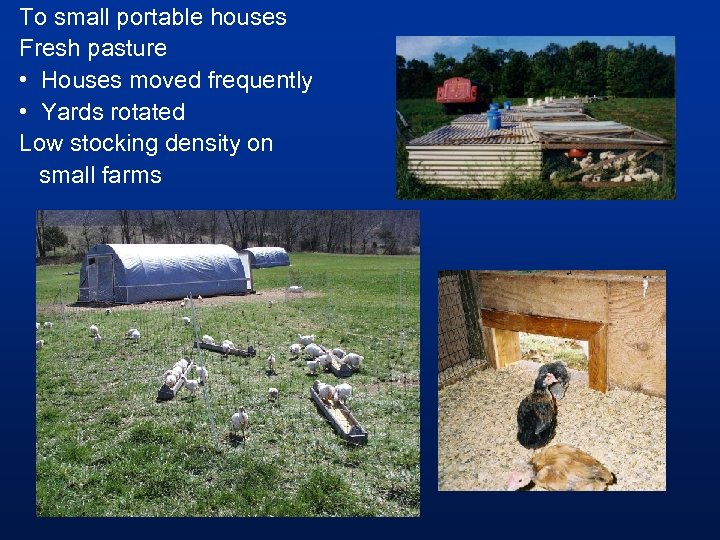

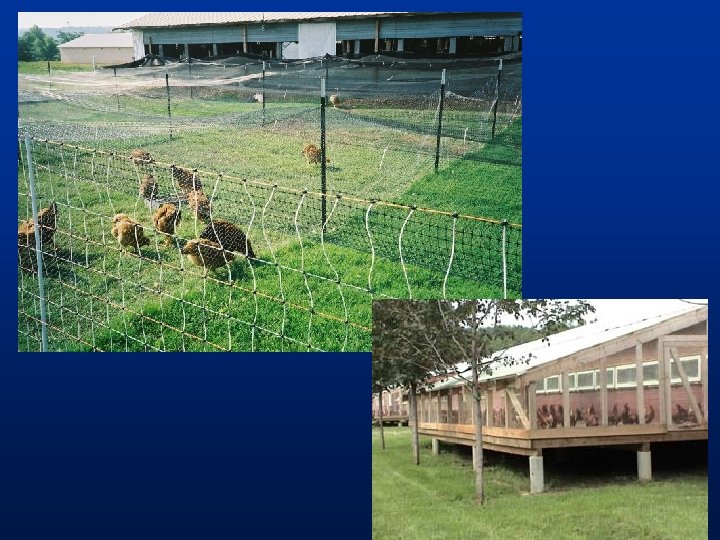

To small portable houses Fresh pasture • Houses moved frequently • Yards rotated Low stocking density on small farms

To small portable houses Fresh pasture • Houses moved frequently • Yards rotated Low stocking density on small farms

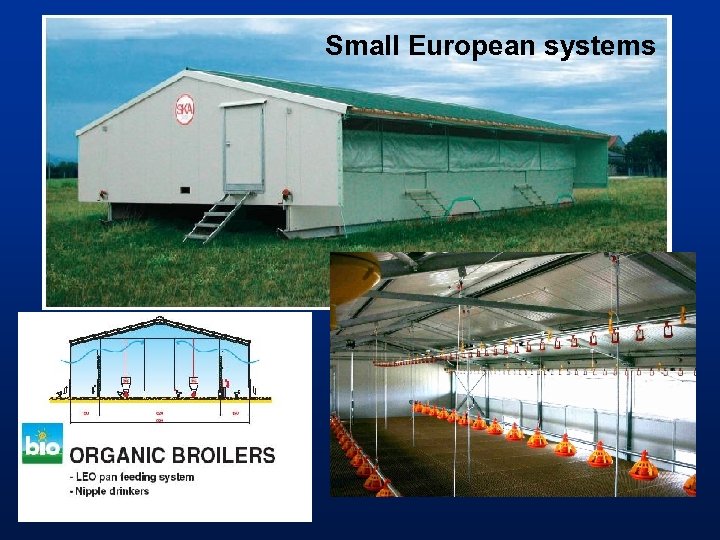

Small European systems

Small European systems

Outdoor Access Temporary confinement is allowed For inclement weather, stage of production, conditions under which health or safety are jeopardized, or risk to soil or water quality NOP does not specify length of time birds require outdoor access NOP does not specify type of surface in outdoor area

Outdoor Access Temporary confinement is allowed For inclement weather, stage of production, conditions under which health or safety are jeopardized, or risk to soil or water quality NOP does not specify length of time birds require outdoor access NOP does not specify type of surface in outdoor area

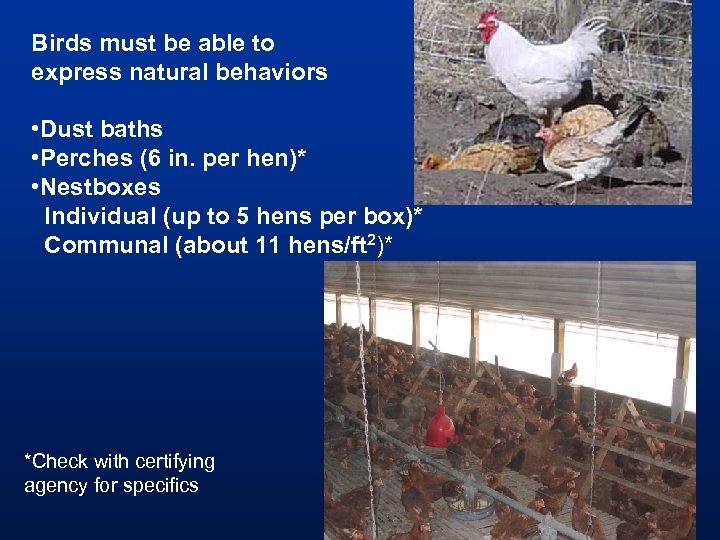

Birds must be able to express natural behaviors • Dust baths • Perches (6 in. per hen)* • Nestboxes Individual (up to 5 hens per box)* Communal (about 11 hens/ft 2)* *Check with certifying agency for specifics

Birds must be able to express natural behaviors • Dust baths • Perches (6 in. per hen)* • Nestboxes Individual (up to 5 hens per box)* Communal (about 11 hens/ft 2)* *Check with certifying agency for specifics

Ventilation is often natural due to open bird doorways Lighting • Limits on the use of artificial lighting • NOP has no specific requirements for dark period • Most certifiers look for 8 h of dark* Light intensity • Many certifiers require a relatively high level of light • High welfare standards require at least 2 footcandles* (Humane Farm Animal Care, 2004) Natural light *Check with certifying agency for specifics

Ventilation is often natural due to open bird doorways Lighting • Limits on the use of artificial lighting • NOP has no specific requirements for dark period • Most certifiers look for 8 h of dark* Light intensity • Many certifiers require a relatively high level of light • High welfare standards require at least 2 footcandles* (Humane Farm Animal Care, 2004) Natural light *Check with certifying agency for specifics

Litter does not have to be organic, unless birds eat it Waste must not contribute to environmental contamination Poultry manure • Composting poultry litter: • Must meet NOP compost requirements to be applied to organic crops If allowing poultry to forage in crops, orchards, restrictions apply Raw manure cannot be applied to crops Within 90 days of harvest Within 120 days if edible part of crop not in contact with soil

Litter does not have to be organic, unless birds eat it Waste must not contribute to environmental contamination Poultry manure • Composting poultry litter: • Must meet NOP compost requirements to be applied to organic crops If allowing poultry to forage in crops, orchards, restrictions apply Raw manure cannot be applied to crops Within 90 days of harvest Within 120 days if edible part of crop not in contact with soil

Poultry Health Use proactive practices Reduce stress and maintain immune system Provide adequate housing and space, ventilation, and good nutrition Vaccines are allowed to prevent disease Prevent the introduction of disease Biosecurity Sanitation All-in, all-out with 2 -week downtime Treatment used as a last resort Alternatives

Poultry Health Use proactive practices Reduce stress and maintain immune system Provide adequate housing and space, ventilation, and good nutrition Vaccines are allowed to prevent disease Prevent the introduction of disease Biosecurity Sanitation All-in, all-out with 2 -week downtime Treatment used as a last resort Alternatives

• Attention to animal welfare practices; many organic broiler companies also participate in welfare assurance programs • Mortality often higher in organic broiler production in US than conventional; necrotic enteritis can be a problem

• Attention to animal welfare practices; many organic broiler companies also participate in welfare assurance programs • Mortality often higher in organic broiler production in US than conventional; necrotic enteritis can be a problem

Vaccination Programs Broilers (meat birds) Marek’s Newcastle Infectious bronchitis Infectious bursal disease Coccidiosis Administered at hatch and/or 10 -14 days of age Make sure eggs or chicks are not injected with antibiotics Broiler Breeders and Layers Combination of modified live vaccines Followed by injectable inactivated vaccines

Vaccination Programs Broilers (meat birds) Marek’s Newcastle Infectious bronchitis Infectious bursal disease Coccidiosis Administered at hatch and/or 10 -14 days of age Make sure eggs or chicks are not injected with antibiotics Broiler Breeders and Layers Combination of modified live vaccines Followed by injectable inactivated vaccines

Coccidiosis Management focus Sanitation, separate older/ younger birds, expose young birds gradually Pasture should be clean Rotate pasture with fencing or by moving house Anti-coccidial drugs not permitted; coccidial vaccines used Necropsy dead or sick poultry for information

Coccidiosis Management focus Sanitation, separate older/ younger birds, expose young birds gradually Pasture should be clean Rotate pasture with fencing or by moving house Anti-coccidial drugs not permitted; coccidial vaccines used Necropsy dead or sick poultry for information

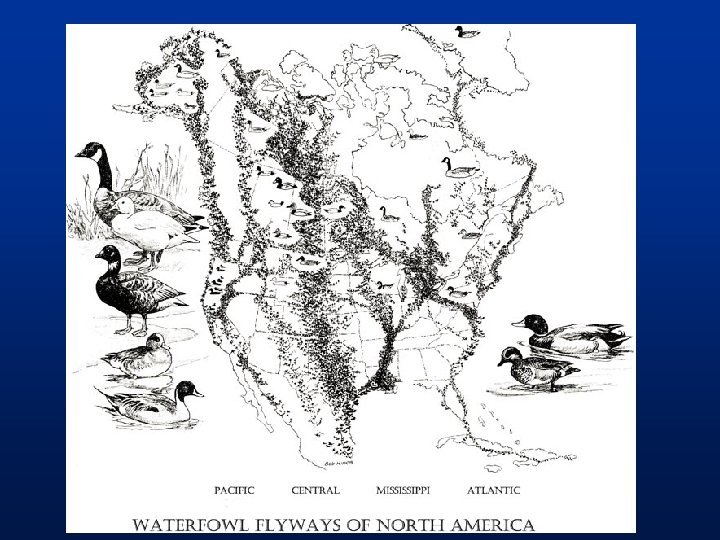

Biosecurity Special considerations with birds with outdoor access, especially concerning avian influenza (AI) Key: Reduce contact with wild waterfowl • Birds with outdoor access should not share areas with wild ducks, geese, or shorebirds • Being close to wetlands or flyways is a risk factor • Make sure free-range areas do not have attractions for wild waterfowl (i. e. pond). Use feeders that do not attract wild waterfowl • Consider covering feed area with netting or keeping feeders/waterers inside • In extreme situations, be prepared to cover entire yard with netting or to enclose birds under roofed cover

Biosecurity Special considerations with birds with outdoor access, especially concerning avian influenza (AI) Key: Reduce contact with wild waterfowl • Birds with outdoor access should not share areas with wild ducks, geese, or shorebirds • Being close to wetlands or flyways is a risk factor • Make sure free-range areas do not have attractions for wild waterfowl (i. e. pond). Use feeders that do not attract wild waterfowl • Consider covering feed area with netting or keeping feeders/waterers inside • In extreme situations, be prepared to cover entire yard with netting or to enclose birds under roofed cover

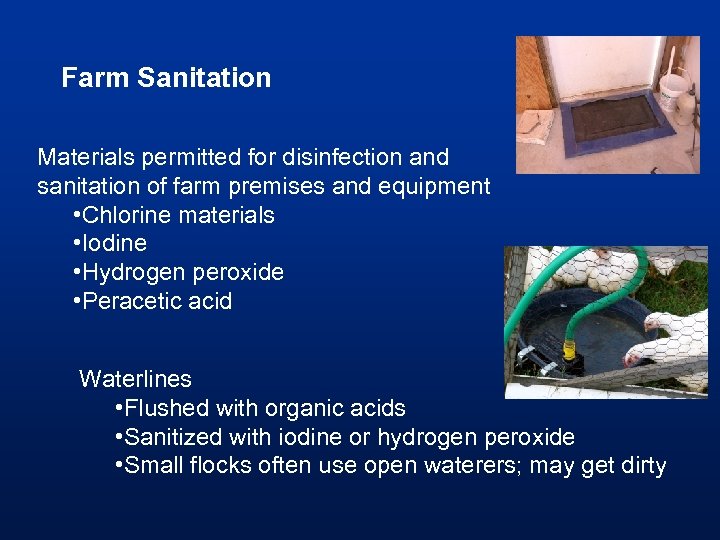

Farm Sanitation Materials permitted for disinfection and sanitation of farm premises and equipment • Chlorine materials • Iodine • Hydrogen peroxide • Peracetic acid Waterlines • Flushed with organic acids • Sanitized with iodine or hydrogen peroxide • Small flocks often use open waterers; may get dirty

Farm Sanitation Materials permitted for disinfection and sanitation of farm premises and equipment • Chlorine materials • Iodine • Hydrogen peroxide • Peracetic acid Waterlines • Flushed with organic acids • Sanitized with iodine or hydrogen peroxide • Small flocks often use open waterers; may get dirty

Rodent Control Habitat reduction • Physical exclusion from facilities and feed • Trapping • Predators • Limited rodenticides • Cholecalciferol • Sulfur dioxide as underground smoke bomb

Rodent Control Habitat reduction • Physical exclusion from facilities and feed • Trapping • Predators • Limited rodenticides • Cholecalciferol • Sulfur dioxide as underground smoke bomb

External Parasite Control Preventative measures Provide dustbathing substrates: dirt, wood ashes, diatomaceous earth Apply natural oils (i. e. linseed oil) to roosts Treat with natural insecticides Pyrethrum and components pyrethrins are botanical extracts

External Parasite Control Preventative measures Provide dustbathing substrates: dirt, wood ashes, diatomaceous earth Apply natural oils (i. e. linseed oil) to roosts Treat with natural insecticides Pyrethrum and components pyrethrins are botanical extracts

Enteric diseases Replacing antibiotic growth promotants (AGP) Probiotics Beneficial microbes that use competitive exclusion to outcompete pathogens Salmonella and E. coli Prebiotics • Nondigestible feed ingredients for beneficial microbes (lactose) • Prevent pathogens from adhering to enterocytes (mannooligosaccharides or MOS) Organic acids

Enteric diseases Replacing antibiotic growth promotants (AGP) Probiotics Beneficial microbes that use competitive exclusion to outcompete pathogens Salmonella and E. coli Prebiotics • Nondigestible feed ingredients for beneficial microbes (lactose) • Prevent pathogens from adhering to enterocytes (mannooligosaccharides or MOS) Organic acids

Alternative Treatments Immune enhancement Antioxidants Botanicals Oregano Rosemary Garlic

Alternative Treatments Immune enhancement Antioxidants Botanicals Oregano Rosemary Garlic

Physical Alterations Allowed if essential to welfare Make sure layers do not have bare patches that indicate pecking Beak Trimming If necessary: Welfare programs require beak trimming be done before 10 days of age, using humane methods: • Hot blade method • New methods: microwave (beak exposed to short burst of high intensity light)

Physical Alterations Allowed if essential to welfare Make sure layers do not have bare patches that indicate pecking Beak Trimming If necessary: Welfare programs require beak trimming be done before 10 days of age, using humane methods: • Hot blade method • New methods: microwave (beak exposed to short burst of high intensity light)

Prevent Feather Pecking Pullets that feather peck during rearing will continue as layers Raise pullets on litter (not in cages or slats) Provide perches Scatter grain as pecking incentive Roughage, hung or in baskets Use low stocking density, including first weeks of life Flocks that feather pecked were at a density of 3. 2 chick/ft 2 (flocks that did not were at only 2 chicks/ft 2) Outdoor access should be provided as soon as possible (Bestman and Wagenaar, 2006)

Prevent Feather Pecking Pullets that feather peck during rearing will continue as layers Raise pullets on litter (not in cages or slats) Provide perches Scatter grain as pecking incentive Roughage, hung or in baskets Use low stocking density, including first weeks of life Flocks that feather pecked were at a density of 3. 2 chick/ft 2 (flocks that did not were at only 2 chicks/ft 2) Outdoor access should be provided as soon as possible (Bestman and Wagenaar, 2006)

Molt • Molt extends productive lives of layers; fewer layers needed • Molt can be forced with molt diet and dark • NOP has no specific standards on forced molting; generally certifiers do not permit • Natural molt is not as efficient as forced molt but maintains high welfare • Ideally, layers should be kept for 2 -3 years (Thear, 1997)

Molt • Molt extends productive lives of layers; fewer layers needed • Molt can be forced with molt diet and dark • NOP has no specific standards on forced molting; generally certifiers do not permit • Natural molt is not as efficient as forced molt but maintains high welfare • Ideally, layers should be kept for 2 -3 years (Thear, 1997)

Broilers Birds should be able to walk Gait score (0 to 5): 4 s and 5 s culled Incidence of metabolic problems should be low Mortality should not be over 5 -10% in broilers

Broilers Birds should be able to walk Gait score (0 to 5): 4 s and 5 s culled Incidence of metabolic problems should be low Mortality should not be over 5 -10% in broilers

Animal Welfare Cornerstone of organic philosophy Independent programs • Certified Humane (Humane Farm Animal Care) • American Humane Certified (American Humane Association) • Animal Welfare Approved (Animal Welfare Institute) Industry programs also

Animal Welfare Cornerstone of organic philosophy Independent programs • Certified Humane (Humane Farm Animal Care) • American Humane Certified (American Humane Association) • Animal Welfare Approved (Animal Welfare Institute) Industry programs also

Stock Origin of poultry There are no organic hatcheries in U. S. Chicks must be raised under organic management from day 2 Breeds should be chosen for resistance to disease and appropriateness to site However, conventional genetics usually used in U. S. Birds grow to market weight in less than 8 wk High breast yield High-yielding meat birds may be subject to metabolic and leg problems

Stock Origin of poultry There are no organic hatcheries in U. S. Chicks must be raised under organic management from day 2 Breeds should be chosen for resistance to disease and appropriateness to site However, conventional genetics usually used in U. S. Birds grow to market weight in less than 8 wk High breast yield High-yielding meat birds may be subject to metabolic and leg problems

In EU organic, slow-growing meat birds are used Minimum age at slaughter: Chicken: 81 days Turkey: 140 days

In EU organic, slow-growing meat birds are used Minimum age at slaughter: Chicken: 81 days Turkey: 140 days

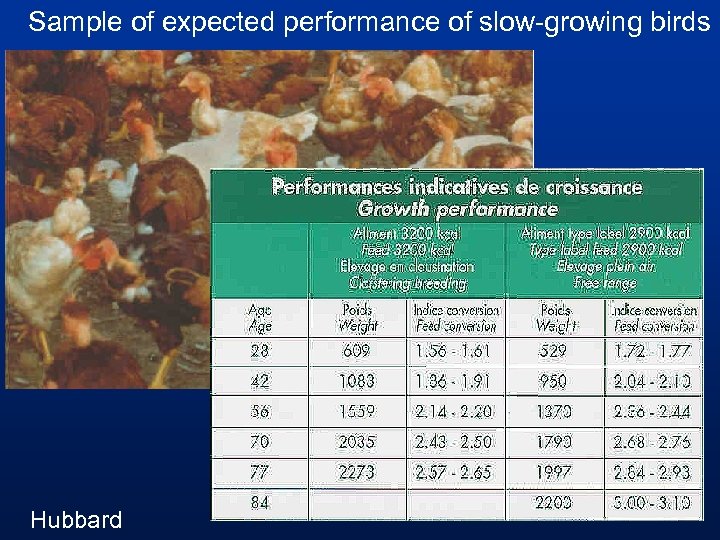

Sample of expected performance of slow-growing birds Hubbard

Sample of expected performance of slow-growing birds Hubbard

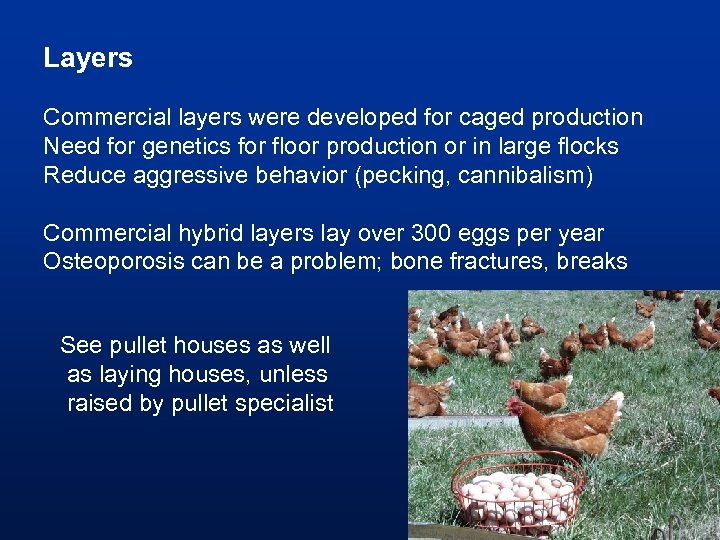

Layers Commercial layers were developed for caged production Need for genetics for floor production or in large flocks Reduce aggressive behavior (pecking, cannibalism) Commercial hybrid layers lay over 300 eggs per year Osteoporosis can be a problem; bone fractures, breaks See pullet houses as well as laying houses, unless raised by pullet specialist

Layers Commercial layers were developed for caged production Need for genetics for floor production or in large flocks Reduce aggressive behavior (pecking, cannibalism) Commercial hybrid layers lay over 300 eggs per year Osteoporosis can be a problem; bone fractures, breaks See pullet houses as well as laying houses, unless raised by pullet specialist

Standard Breeds Used by small producers Ex. Barred Rock Cornish

Standard Breeds Used by small producers Ex. Barred Rock Cornish

University of Arkansas Trial Fast-growing were more efficient meat producers with higher weight gains, better feed efficiency, higher carcass and breast yield Slow-growing had better livability with lower mortality, better leg health, more active Meat had more vitamins; more flavor Fanatico et al. (2007; 2008)

University of Arkansas Trial Fast-growing were more efficient meat producers with higher weight gains, better feed efficiency, higher carcass and breast yield Slow-growing had better livability with lower mortality, better leg health, more active Meat had more vitamins; more flavor Fanatico et al. (2007; 2008)

Feed • Feed rations must provide levels of protein, energy, minerals and vitamins appropriate to type of bird and age/stage of development; Important in monogastrics to prevent nutritional deficiencies • In US, usually corn/soy based • Only 100% organic feeds allowed § No antibiotics, animal slaughter by-products, or genetically-modified organisms are allowed §Feed processing must be in certified organic mill

Feed • Feed rations must provide levels of protein, energy, minerals and vitamins appropriate to type of bird and age/stage of development; Important in monogastrics to prevent nutritional deficiencies • In US, usually corn/soy based • Only 100% organic feeds allowed § No antibiotics, animal slaughter by-products, or genetically-modified organisms are allowed §Feed processing must be in certified organic mill

• Feed Additives Synthetic substances can be used in micro amounts (i. e. , vitamins, minerals) • Feed Supplements Natural substances used in larger amounts to improve nutrient balance; examples: • Fishmeal • Oyster shell • Enzymes • Probiotics Do not have to be organic; but cannot be GMO or have prohibited substances (ethoxyquine)

• Feed Additives Synthetic substances can be used in micro amounts (i. e. , vitamins, minerals) • Feed Supplements Natural substances used in larger amounts to improve nutrient balance; examples: • Fishmeal • Oyster shell • Enzymes • Probiotics Do not have to be organic; but cannot be GMO or have prohibited substances (ethoxyquine)

Forage and Pasture Must be organic Pasture must be free of synthetic materials for at least 3 years Seeded with organic seeds Weeds managed with cultural practices not synthetics Any roughage or sprouted grains must be organic

Forage and Pasture Must be organic Pasture must be free of synthetic materials for at least 3 years Seeded with organic seeds Weeds managed with cultural practices not synthetics Any roughage or sprouted grains must be organic

Feeding Organic Poultry Organic feed is expensive; up to triple the cost of conventional Feed is about 2/3 of the production costs 100 hens eat 25 lb feed per day Broiler feed conversion ratio is 2: 1

Feeding Organic Poultry Organic feed is expensive; up to triple the cost of conventional Feed is about 2/3 of the production costs 100 hens eat 25 lb feed per day Broiler feed conversion ratio is 2: 1

Outdoor feeding Covered, bulk feeders Sometimes whole grains

Outdoor feeding Covered, bulk feeders Sometimes whole grains

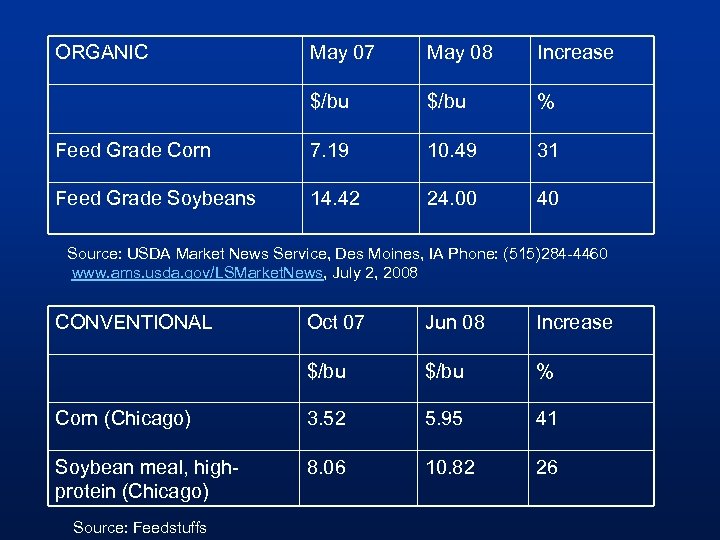

ORGANIC May 07 May 08 Increase $/bu % Feed Grade Corn 7. 19 10. 49 31 Feed Grade Soybeans 14. 42 24. 00 40 Source: USDA Market News Service, Des Moines, IA Phone: (515)284 -4460 www. ams. usda. gov/LSMarket. News, July 2, 2008 CONVENTIONAL Oct 07 Jun 08 Increase $/bu % Corn (Chicago) 3. 52 5. 95 41 Soybean meal, highprotein (Chicago) 8. 06 10. 82 26 Source: Feedstuffs

ORGANIC May 07 May 08 Increase $/bu % Feed Grade Corn 7. 19 10. 49 31 Feed Grade Soybeans 14. 42 24. 00 40 Source: USDA Market News Service, Des Moines, IA Phone: (515)284 -4460 www. ams. usda. gov/LSMarket. News, July 2, 2008 CONVENTIONAL Oct 07 Jun 08 Increase $/bu % Corn (Chicago) 3. 52 5. 95 41 Soybean meal, highprotein (Chicago) 8. 06 10. 82 26 Source: Feedstuffs

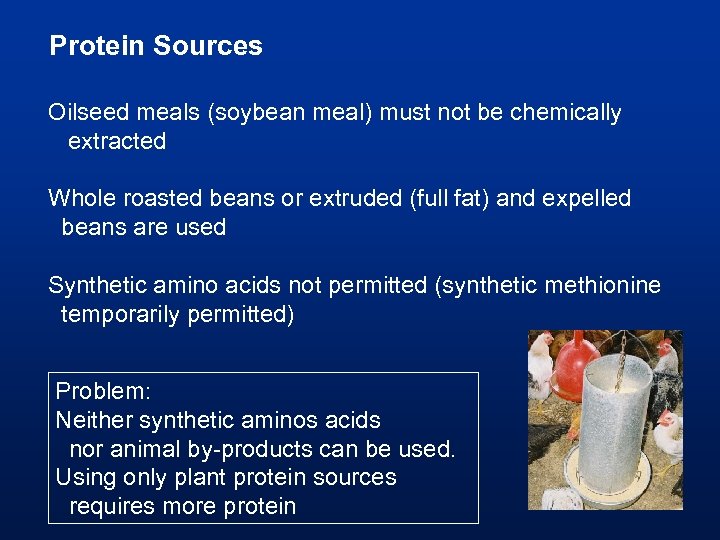

Protein Sources Oilseed meals (soybean meal) must not be chemically extracted Whole roasted beans or extruded (full fat) and expelled beans are used Synthetic amino acids not permitted (synthetic methionine temporarily permitted) Problem: Neither synthetic aminos acids nor animal by-products can be used. Using only plant protein sources requires more protein

Protein Sources Oilseed meals (soybean meal) must not be chemically extracted Whole roasted beans or extruded (full fat) and expelled beans are used Synthetic amino acids not permitted (synthetic methionine temporarily permitted) Problem: Neither synthetic aminos acids nor animal by-products can be used. Using only plant protein sources requires more protein

Methionine Issue • Methionine is most limiting amino acid in corn/soy diets • Synthetic methionine currently allowed only in poultry production until 2010; No natural methionine product currently available • Solution may be alternative feeding or genetics

Methionine Issue • Methionine is most limiting amino acid in corn/soy diets • Synthetic methionine currently allowed only in poultry production until 2010; No natural methionine product currently available • Solution may be alternative feeding or genetics

Protein Feeds • Fish meal: use limited due to nonavailability, off-flavor, or “veg-fed” practice of company • Milk powder • Corn gluten meal (however, none with organic status exists) • Alternative proteins such as algae, earthworms, larvae

Protein Feeds • Fish meal: use limited due to nonavailability, off-flavor, or “veg-fed” practice of company • Milk powder • Corn gluten meal (however, none with organic status exists) • Alternative proteins such as algae, earthworms, larvae

West Virginia University Research Organic poultry/sheep farm Concluded synthetic MET is not needed for growing organic broiler chickens (research conducted in grower period; not starter Fast-growing genotypes outperformed slow-growing genotypes Moritz (2008) personal comm.

West Virginia University Research Organic poultry/sheep farm Concluded synthetic MET is not needed for growing organic broiler chickens (research conducted in grower period; not starter Fast-growing genotypes outperformed slow-growing genotypes Moritz (2008) personal comm.

Alternative Genetics • Low-yielding genotypes have lower protein requirements than high-yielding (Sundrum, 2005) • Research at Univ. of Arkansas has not shown slow-growing genotypes to have lower methionine requirements (Fanatico et al, 2006; 2007)

Alternative Genetics • Low-yielding genotypes have lower protein requirements than high-yielding (Sundrum, 2005) • Research at Univ. of Arkansas has not shown slow-growing genotypes to have lower methionine requirements (Fanatico et al, 2006; 2007)

Processing Poultry • Catching, transport, and slaughter should be humane, but no specific standards (not measured) • Common gap in organic standards world-wide (Lockeretz and Merrigan, 2006)

Processing Poultry • Catching, transport, and slaughter should be humane, but no specific standards (not measured) • Common gap in organic standards world-wide (Lockeretz and Merrigan, 2006)

Small operations may do on-farm processing of meat and eggs (may be part of organic livestock plan) Off-farm processing facility must be certified organic (processing plan needed)

Small operations may do on-farm processing of meat and eggs (may be part of organic livestock plan) Off-farm processing facility must be certified organic (processing plan needed)

Organic Processing requires • Use approved organic detergents and sanitizers, including chill water and pest control methods • Preventing contamination from prohibited substances • Need to ensure that organic products are segregated from non-organic • Organic usually scheduled first run of the day in split plants • Good audit trail

Organic Processing requires • Use approved organic detergents and sanitizers, including chill water and pest control methods • Preventing contamination from prohibited substances • Need to ensure that organic products are segregated from non-organic • Organic usually scheduled first run of the day in split plants • Good audit trail

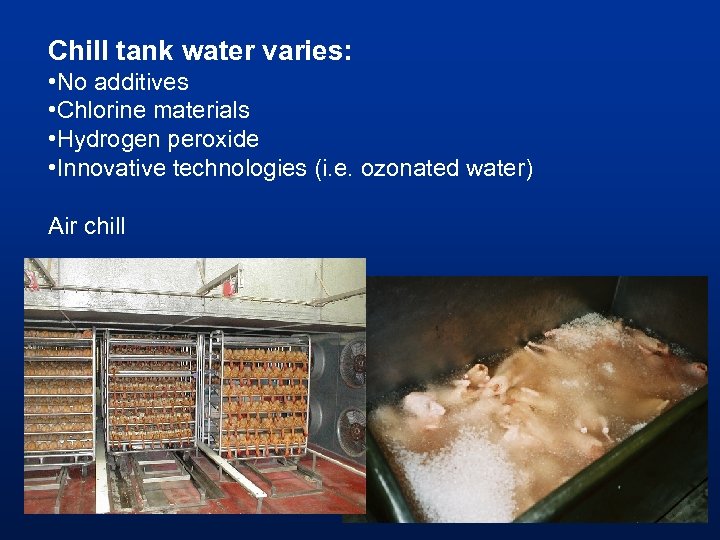

Chill tank water varies: • No additives • Chlorine materials • Hydrogen peroxide • Innovative technologies (i. e. ozonated water) Air chill

Chill tank water varies: • No additives • Chlorine materials • Hydrogen peroxide • Innovative technologies (i. e. ozonated water) Air chill

Shell Egg Detergents and Sanitizers Detergents are usually alkaline Sanitizers are often chlorine-based Also include hydrogen peroxide and organic acids (i. e. lactic acid and acetic acid)

Shell Egg Detergents and Sanitizers Detergents are usually alkaline Sanitizers are often chlorine-based Also include hydrogen peroxide and organic acids (i. e. lactic acid and acetic acid)

Control of Facility Pests Rodents and insects must be controlled First use sanitation practices, barriers, environmental management Then mechanical and physical traps Then approved substances

Control of Facility Pests Rodents and insects must be controlled First use sanitation practices, barriers, environmental management Then mechanical and physical traps Then approved substances

Packaging must be free of prohibited substances such as preservatives. Separate storage area for finished organic products to prevent Co-mingling

Packaging must be free of prohibited substances such as preservatives. Separate storage area for finished organic products to prevent Co-mingling

NOP National List • Generally natural substances are permitted and synthetic substances are prohibited in organic production • National List specifies synthetics that are allowed and naturals that are prohibited • Must be permitted by FDA • Listed by crops, livestock, and processing • Petition process to add substances

NOP National List • Generally natural substances are permitted and synthetic substances are prohibited in organic production • National List specifies synthetics that are allowed and naturals that are prohibited • Must be permitted by FDA • Listed by crops, livestock, and processing • Petition process to add substances

Organic Poultry Inspection See IFOAM/IOIA International Organic Inspection Manual for livestock inspection details; also applicable to poultry Biosecurity requirements (check company policy) • Usually 48 hours away from other poultry/birds • Use proper gear (disposible booties, coveralls, gloves hair net) • Even on a small farm, use clean booties and gloves when entering poultry area

Organic Poultry Inspection See IFOAM/IOIA International Organic Inspection Manual for livestock inspection details; also applicable to poultry Biosecurity requirements (check company policy) • Usually 48 hours away from other poultry/birds • Use proper gear (disposible booties, coveralls, gloves hair net) • Even on a small farm, use clean booties and gloves when entering poultry area

Organic System Plans See producer’s organic livestock plan which describes practices in compliance with standards Animal health plan may be part of it Verify farm practices match plan Organic crop plan and organic handling plan may also be needed depending on operation

Organic System Plans See producer’s organic livestock plan which describes practices in compliance with standards Animal health plan may be part of it Verify farm practices match plan Organic crop plan and organic handling plan may also be needed depending on operation

Poultry Records Review of records important part of audit trail. Ask how flock is identified; see Production records (egg production, market weights, FCR, mortality) Monitoring records (daily inspections, environment including temperature, litter, air quality conditions, outdoor access) (usually posted in the house) Health Input records and other inputs (vaccines, probiotics, botanicals, litter treatments) Feed tags (confirm organic ingredients, adequate formulation, confirm no prohibited feeds or substances) Slaughter records or egg process records (condemnations) Sales records Choose random samples of product to track

Poultry Records Review of records important part of audit trail. Ask how flock is identified; see Production records (egg production, market weights, FCR, mortality) Monitoring records (daily inspections, environment including temperature, litter, air quality conditions, outdoor access) (usually posted in the house) Health Input records and other inputs (vaccines, probiotics, botanicals, litter treatments) Feed tags (confirm organic ingredients, adequate formulation, confirm no prohibited feeds or substances) Slaughter records or egg process records (condemnations) Sales records Choose random samples of product to track

Organic Poultry Inspection Report Similar to Organic Livestock Inspect Report • Housing and Outdoor Access (ventilation, stocking density, amount of outdoor access, conditions of outdoor area) • Manure Management • Health Management (Describe health plan, vaccination program, physical alternations, molting practices) • Condition of birds • Feed (source, storage) • Water • Breeds and source • Processing Meat or Eggs (on-farm processing) • Labels • Poultry Audit Control (make sure you can track birds/eggs from placement through slaughter • Recommended sampling (water, meat or egg products) • Management

Organic Poultry Inspection Report Similar to Organic Livestock Inspect Report • Housing and Outdoor Access (ventilation, stocking density, amount of outdoor access, conditions of outdoor area) • Manure Management • Health Management (Describe health plan, vaccination program, physical alternations, molting practices) • Condition of birds • Feed (source, storage) • Water • Breeds and source • Processing Meat or Eggs (on-farm processing) • Labels • Poultry Audit Control (make sure you can track birds/eggs from placement through slaughter • Recommended sampling (water, meat or egg products) • Management

Resources USDA National Organic Program www. ams. usda. gov/nop/ IOIA www. ioia. net ATTRA, www. attra. ncat. org; 800 -346 -9140 • Organic Certification materials • Alternative Poultry Production and Outdoor Access • Poultry House Management in Alternative Production • Poultry Equipment for Alternative Production • Parasites: Coccidiosis Control in Natural and Organic Poultry • Organic Poultry Production (draft) www. sustainablepoultry. ncat. org see Images/Presentations

Resources USDA National Organic Program www. ams. usda. gov/nop/ IOIA www. ioia. net ATTRA, www. attra. ncat. org; 800 -346 -9140 • Organic Certification materials • Alternative Poultry Production and Outdoor Access • Poultry House Management in Alternative Production • Poultry Equipment for Alternative Production • Parasites: Coccidiosis Control in Natural and Organic Poultry • Organic Poultry Production (draft) www. sustainablepoultry. ncat. org see Images/Presentations