Oracle Industry Solutions Complex Equipment Manufacturing Information Age Applications </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="High Technology Segments Complex Equipment Semiconductor Ÿ Products – Semicon fab equipment, servers, test" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-2.jpg" alt="High Technology Segments Complex Equipment Semiconductor Ÿ Products – Semicon fab equipment, servers, test" />

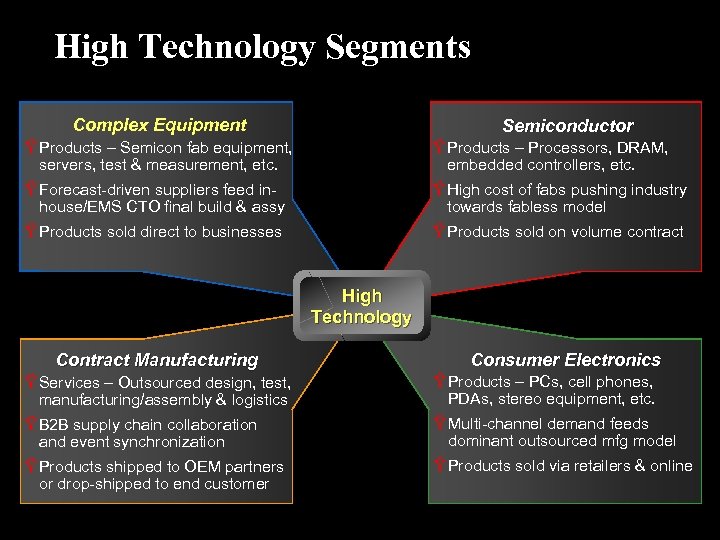

High Technology Segments Complex Equipment Semiconductor Ÿ Products – Semicon fab equipment, servers, test & measurement, etc. Ÿ Products – Processors, DRAM, embedded controllers, etc. Ÿ Forecast-driven suppliers feed inhouse/EMS CTO final build & assy Ÿ High cost of fabs pushing industry towards fabless model Ÿ Products sold direct to businesses Ÿ Products sold on volume contract High Technology Contract Manufacturing Consumer Electronics Ÿ Services – Outsourced design, test, manufacturing/assembly & logistics Ÿ Products – PCs, cell phones, PDAs, stereo equipment, etc. Ÿ B 2 B supply chain collaboration and event synchronization Ÿ Multi-channel demand feeds dominant outsourced mfg model Ÿ Products shipped to OEM partners or drop-shipped to end customer Ÿ Products sold via retailers & online </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="The Complex Equipment Value Chain Silicon Source Component Mfg Tiered Supply Base Contract Mfg" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-3.jpg" alt="The Complex Equipment Value Chain Silicon Source Component Mfg Tiered Supply Base Contract Mfg" />

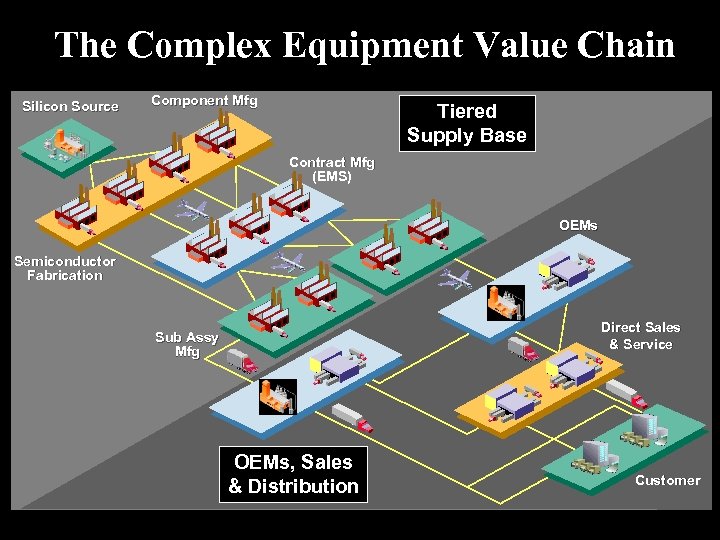

The Complex Equipment Value Chain Silicon Source Component Mfg Tiered Supply Base Contract Mfg (EMS) OEMs Semiconductor Fabrication Direct Sales & Service Sub Assy Mfg OEMs, Sales & Distribution Customer </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="Complex Equipment Industry Drivers Design Complexity Supply Variability • How can I reduce design" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-4.jpg" alt="Complex Equipment Industry Drivers Design Complexity Supply Variability • How can I reduce design" />

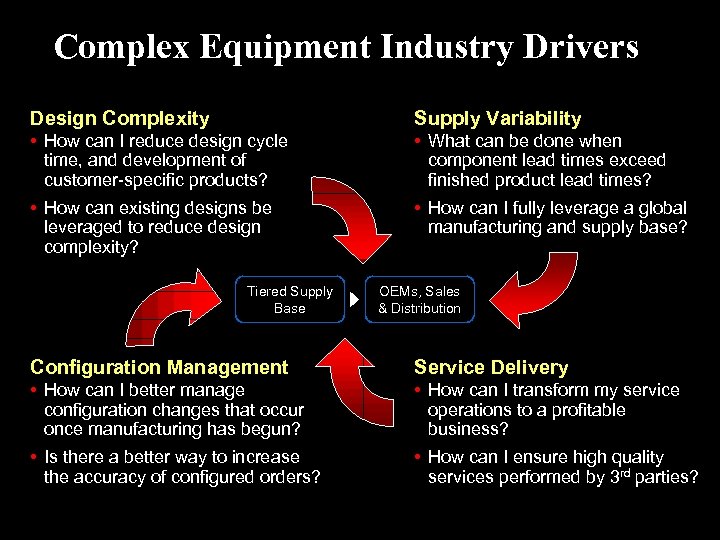

Complex Equipment Industry Drivers Design Complexity Supply Variability • How can I reduce design cycle time, and development of customer-specific products? • What can be done when component lead times exceed finished product lead times? • How can existing designs be leveraged to reduce design complexity? • How can I fully leverage a global manufacturing and supply base? Tiered Supply Base OEMs, Sales & Distribution Configuration Management Service Delivery • How can I better manage configuration changes that occur once manufacturing has begun? • How can I transform my service operations to a profitable business? • Is there a better way to increase the accuracy of configured orders? • How can I ensure high quality services performed by 3 rd parties? </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="A Need for Change Leading Business Trends • Simultaneous optimization of supply & build" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-5.jpg" alt="A Need for Change Leading Business Trends • Simultaneous optimization of supply & build" />

A Need for Change Leading Business Trends • Simultaneous optimization of supply & build strategies • Outsourcing with complete visibility across multiple tiers • Integration of configure-to-order processes and service • Emergence of customer service as a strategic differentiator • Lean initiatives to reduce cycle time and waste </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="A Need for Change Extend Lean Initiatives Across the Enterprise Sales & Mktg Sales" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-6.jpg" alt="A Need for Change Extend Lean Initiatives Across the Enterprise Sales & Mktg Sales" />

A Need for Change Extend Lean Initiatives Across the Enterprise Sales & Mktg Sales & Operational Planning Finance Common Areas of Waste Engineering • • Poor Quality & Excess WIP High Material & Supply Costs Lengthy ECO Approval Process Error Prone Order Processing Supply Management • • Incorrect Resource Dispatching Conflicting Demand Signals Duplicate & Erroneous Data Isolated Departmental Systems Production Information Technology Continually Improve Quality, Cost and Cycle Time Service </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="Oracle in High Technology Did You Know? ŸAll of the top 25 Electronic OEMs" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-7.jpg" alt="Oracle in High Technology Did You Know? ŸAll of the top 25 Electronic OEMs" />

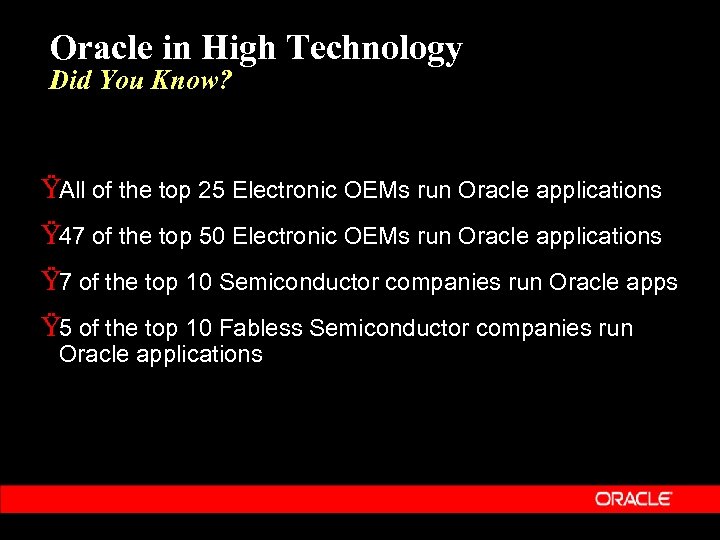

Oracle in High Technology Did You Know? ŸAll of the top 25 Electronic OEMs run Oracle applications Ÿ 47 of the top 50 Electronic OEMs run Oracle applications Ÿ 7 of the top 10 Semiconductor companies run Oracle apps Ÿ 5 of the top 10 Fabless Semiconductor companies run Oracle applications </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="What Analysts are Saying… “Oracle is well positioned to drive innovation to the high" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-8.jpg" alt="What Analysts are Saying… “Oracle is well positioned to drive innovation to the high" />

What Analysts are Saying… “Oracle is well positioned to drive innovation to the high tech industry. The company’s belief that it needs to maintain leadership across the high tech sector in order to stay in touch with innovative manufacturing developments for the rest of its business helps ensure Oracle’s commitment to this industry. ” -- Meredith Whalen, Vice President, US Vertical Industry Research “Firms in high tech manufacturing, where customer service spans both front- and back-office processes, should consider Oracle, especially if they have already made investments in other Oracle modules, like financials. Oracle applications are also a good fit for midsized companies looking to implement a single vendor apps suite and for firms thinking about outsourcing. ” -- Eric Schmitt, Senior Analyst </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="What Customers are Saying… “We selected Oracle for three reasons. First, we knew we" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-9.jpg" alt="What Customers are Saying… “We selected Oracle for three reasons. First, we knew we" />

What Customers are Saying… “We selected Oracle for three reasons. First, we knew we wanted an integrated solution. Second, we wanted software that did not require any customization. Oracle excelled over its competitors on both of these counts. The final reason we chose Oracle was its proven success as a solution provider. ” --Tami Brown, Purchasing Manager “Mc. DATA's challenge of growing international business operations can only be met with a flexible open system like Oracle E-Business Suite. Buying disparate "best-of-breed" applications requires costly and time-consuming integration services. Oracle offers a seamless, fully integrated, modular business solution. ” -- Don Wenninger, CIO “We now have electronic communication and commerce with both outsourced manufacturers and 3 PL providers. We have all of our core back office activities directly linked to the front-end systems that support our new direct order fulfillment model. ” -- Saeed Hosseiniyar, VP of IT </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="What Customers are Achieving… decreased planning cycle time by 75% reduced engineering change order" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-10.jpg" alt="What Customers are Achieving… decreased planning cycle time by 75% reduced engineering change order" />

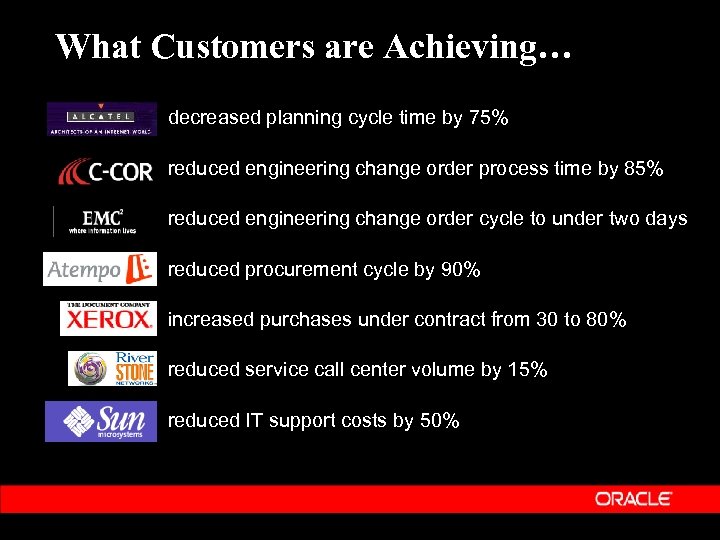

What Customers are Achieving… decreased planning cycle time by 75% reduced engineering change order process time by 85% reduced engineering change order cycle to under two days reduced procurement cycle by 90% increased purchases under contract from 30 to 80% reduced service call center volume by 15% reduced IT support costs by 50% </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="A Few More Customers… " src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-11.jpg" alt="A Few More Customers… " />

A Few More Customers… </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="Oracle E-Business Suite Built on a Unified Information Architecture • Common data model Develop" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-12.jpg" alt="Oracle E-Business Suite Built on a Unified Information Architecture • Common data model Develop" />

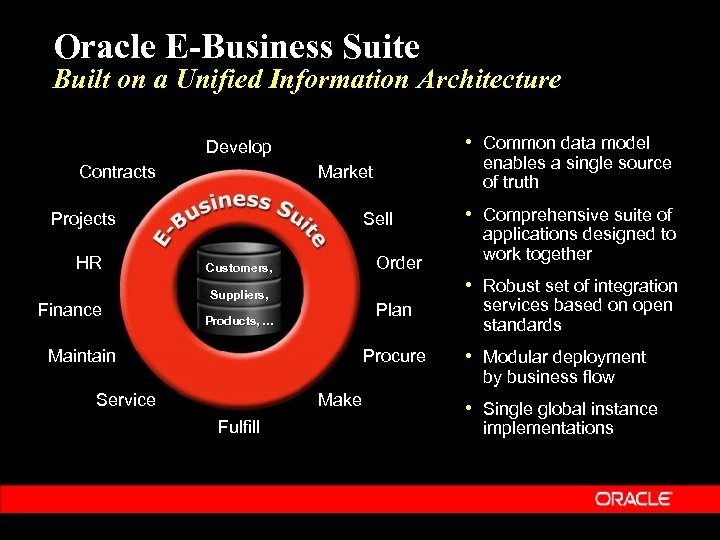

Oracle E-Business Suite Built on a Unified Information Architecture • Common data model Develop Contracts Projects HR Finance enables a single source of truth Market Sell Order Customers, Suppliers, Plan Products, … Maintain Procure • Comprehensive suite of applications designed to work together • Robust set of integration services based on open standards • Modular deployment by business flow Service Make Fulfill • Single global instance implementations </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="Tailored to the Complex Equip. Industry Support for Key Processes Business Intelligence Product Lifecycle" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-13.jpg" alt="Tailored to the Complex Equip. Industry Support for Key Processes Business Intelligence Product Lifecycle" />

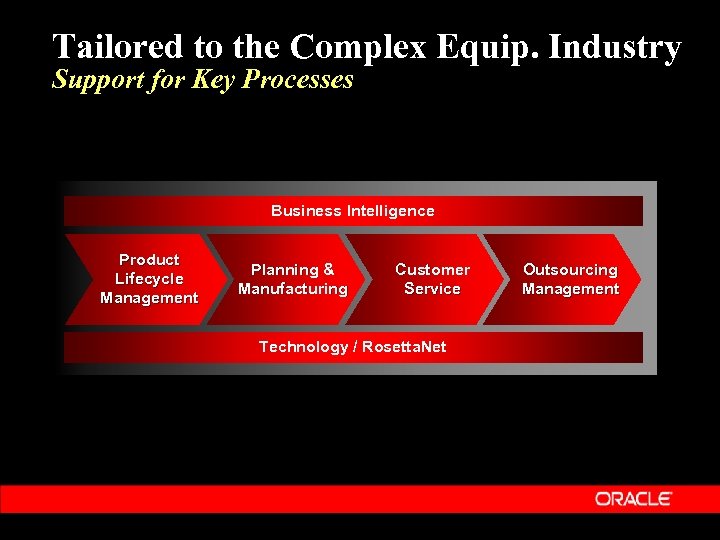

Tailored to the Complex Equip. Industry Support for Key Processes Business Intelligence Product Lifecycle Management Planning & Manufacturing Customer Service Technology / Rosetta. Net Outsourcing Management </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="Tailored to the Complex Equip. Industry Key Processes: Complete Design-to-Service Flow Opportunity Definition Automatic" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-14.jpg" alt="Tailored to the Complex Equip. Industry Key Processes: Complete Design-to-Service Flow Opportunity Definition Automatic" />

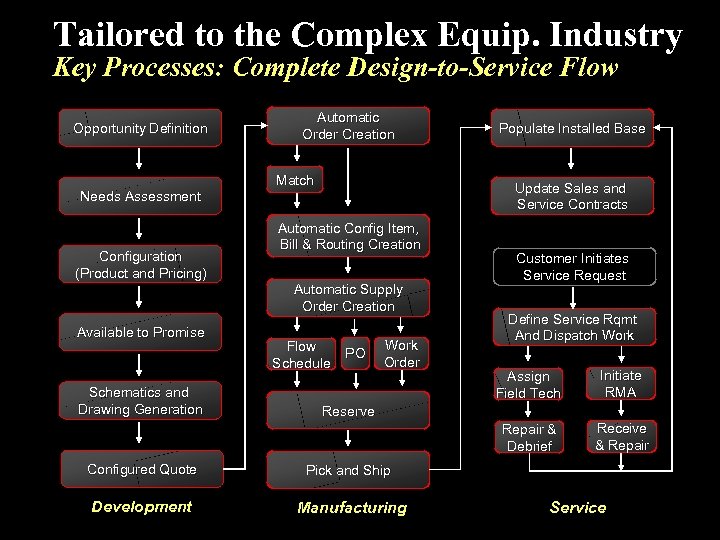

Tailored to the Complex Equip. Industry Key Processes: Complete Design-to-Service Flow Opportunity Definition Automatic Order Creation Match Update Sales and Service Contracts Needs Assessment Configuration (Product and Pricing) Automatic Config Item, Bill & Routing Creation Automatic Supply Order Creation Available to Promise Populate Installed Base Flow Schedule PO Work Order Customer Initiates Service Request Define Service Rqmt And Dispatch Work Initiate RMA Repair & Debrief Schematics and Drawing Generation Assign Field Tech Receive & Repair Reserve Configured Quote Pick and Ship Development Manufacturing Service </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="Oracle Complex Equipment Solutions Business Intelligence Product Planning & Lifecycle Manufacturing Management Customer Service" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-15.jpg" alt="Oracle Complex Equipment Solutions Business Intelligence Product Planning & Lifecycle Manufacturing Management Customer Service" />

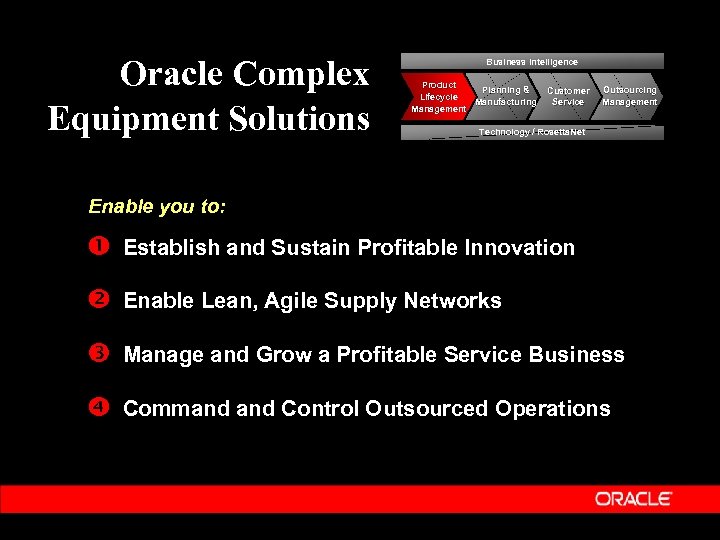

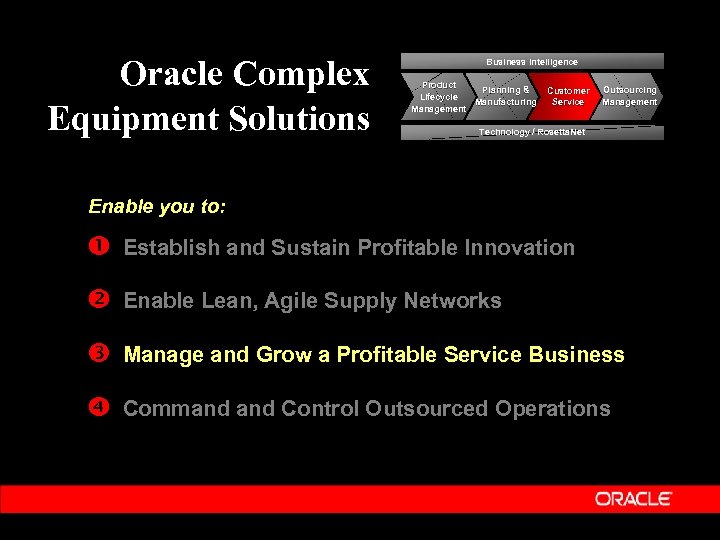

Oracle Complex Equipment Solutions Business Intelligence Product Planning & Lifecycle Manufacturing Management Customer Service Outsourcing Management Technology / Rosetta. Net Enable you to: Establish and Sustain Profitable Innovation Enable Lean, Agile Supply Networks Manage and Grow a Profitable Service Business Command Control Outsourced Operations </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="Product Design and Development Accelerate Creation of Base Platform Internal Portfolio Management Engineering Manufacturing" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-16.jpg" alt="Product Design and Development Accelerate Creation of Base Platform Internal Portfolio Management Engineering Manufacturing" />

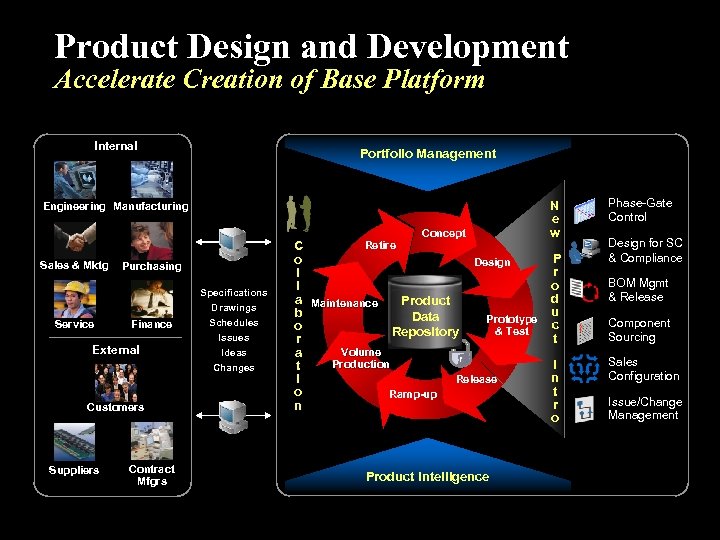

Product Design and Development Accelerate Creation of Base Platform Internal Portfolio Management Engineering Manufacturing Concept Sales & Mktg Purchasing Specifications Drawings Service Finance External Customers Suppliers Contract Mfgrs Schedules Issues Ideas Changes N e w Retire C P o Design r l o l d a Maintenance Product u b Data Prototype c o & Test Repository t r Volume a Production I t n Release i t o Ramp-up r n o Product Intelligence Phase-Gate Control Design for SC & Compliance BOM Mgmt & Release Component Sourcing Sales Configuration Issue/Change Management </p>

</div>

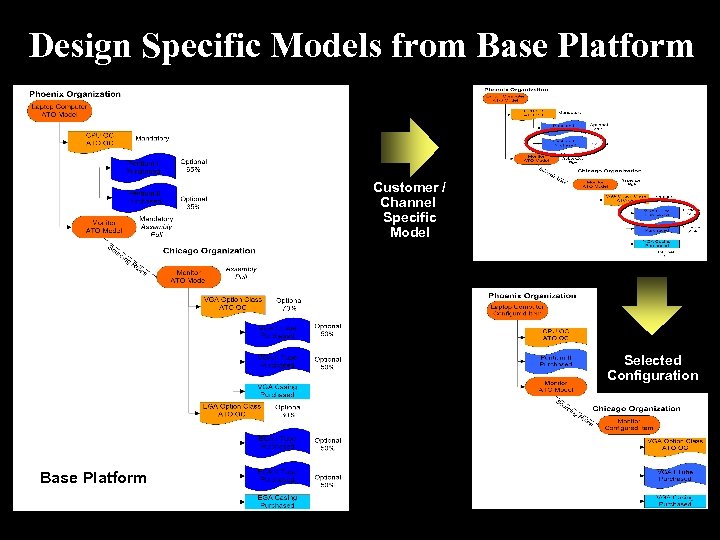

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="Design Specific Models from Base Platform Customer / Channel Specific Model Selected Configuration Base" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-17.jpg" alt="Design Specific Models from Base Platform Customer / Channel Specific Model Selected Configuration Base" />

Design Specific Models from Base Platform Customer / Channel Specific Model Selected Configuration Base Platform </p>

</div>

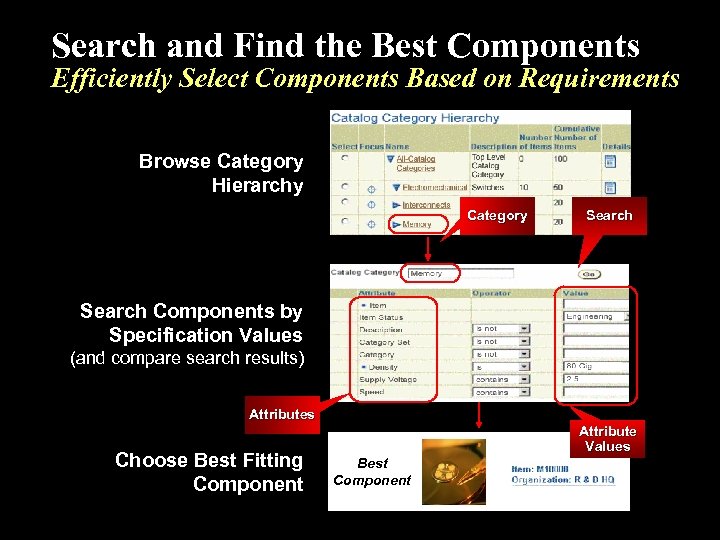

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="Search and Find the Best Components Efficiently Select Components Based on Requirements Browse Category" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-18.jpg" alt="Search and Find the Best Components Efficiently Select Components Based on Requirements Browse Category" />

Search and Find the Best Components Efficiently Select Components Based on Requirements Browse Category Hierarchy Category Search Components by Specification Values (and compare search results) Attributes Choose Best Fitting Component Attribute Values Best Component </p>

</div>

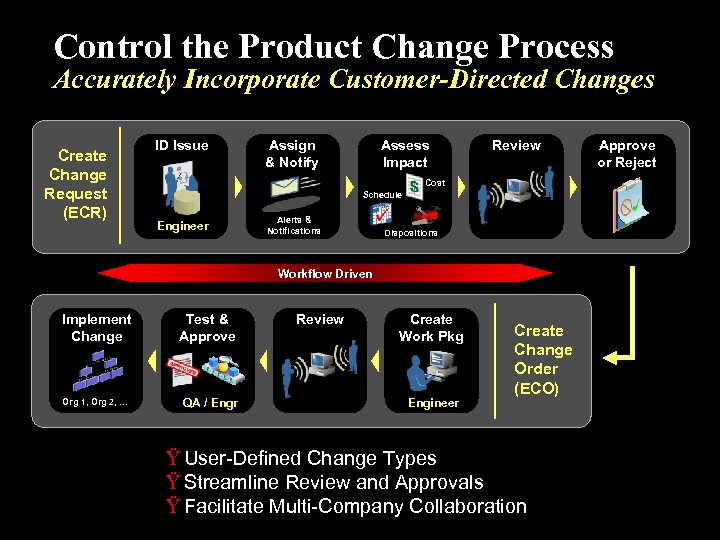

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="Control the Product Change Process Accurately Incorporate Customer-Directed Changes Create Change Request (ECR) ID" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-19.jpg" alt="Control the Product Change Process Accurately Incorporate Customer-Directed Changes Create Change Request (ECR) ID" />

Control the Product Change Process Accurately Incorporate Customer-Directed Changes Create Change Request (ECR) ID Issue Assign & Notify Assess Impact Review Cost Schedule Engineer Alerts & Notifications Dispositions Workflow Driven Implement Change Test & Approve Org 1, Org 2, … QA / Engr Review Create Work Pkg Engineer Create Change Order (ECO) Ÿ User-Defined Change Types Ÿ Streamline Review and Approvals Ÿ Facilitate Multi-Company Collaboration Approve or Reject </p>

</div>

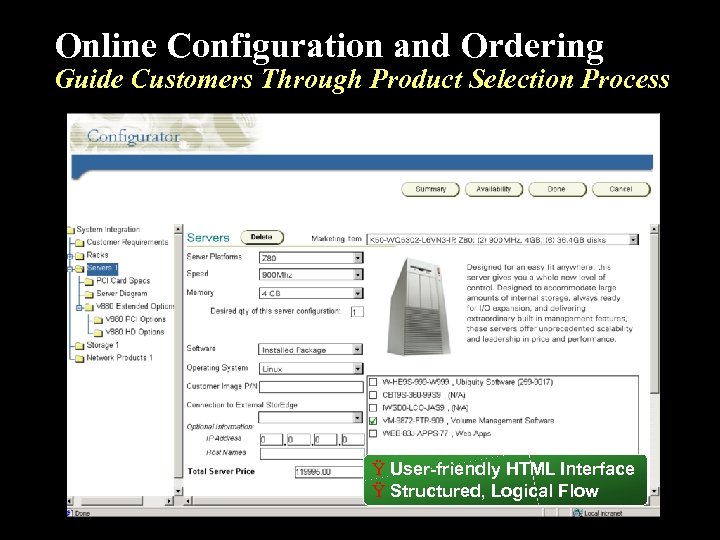

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="Online Configuration and Ordering Guide Customers Through Product Selection Process Ÿ User-friendly HTML Interface" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-20.jpg" alt="Online Configuration and Ordering Guide Customers Through Product Selection Process Ÿ User-friendly HTML Interface" />

Online Configuration and Ordering Guide Customers Through Product Selection Process Ÿ User-friendly HTML Interface Ÿ Structured, Logical Flow </p>

</div>

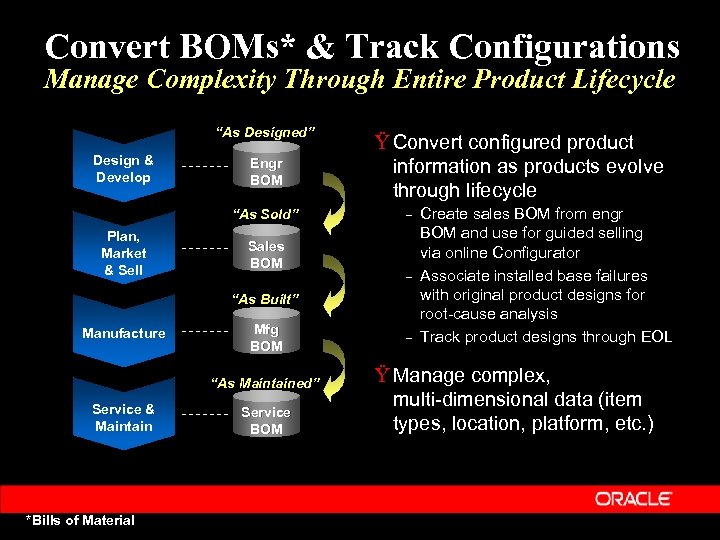

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="Convert BOMs* & Track Configurations Manage Complexity Through Entire Product Lifecycle “As Designed” Design" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-21.jpg" alt="Convert BOMs* & Track Configurations Manage Complexity Through Entire Product Lifecycle “As Designed” Design" />

Convert BOMs* & Track Configurations Manage Complexity Through Entire Product Lifecycle “As Designed” Design & Develop Engr BOM “As Sold” Plan, Market & Sell Sales BOM Ÿ Convert configured product information as products evolve through lifecycle – – “As Built” Manufacture Mfg BOM “As Maintained” Service & Maintain *Bills of Material Service BOM – Create sales BOM from engr BOM and use for guided selling via online Configurator Associate installed base failures with original product designs for root-cause analysis Track product designs through EOL Ÿ Manage complex, multi-dimensional data (item types, location, platform, etc. ) </p>

</div>

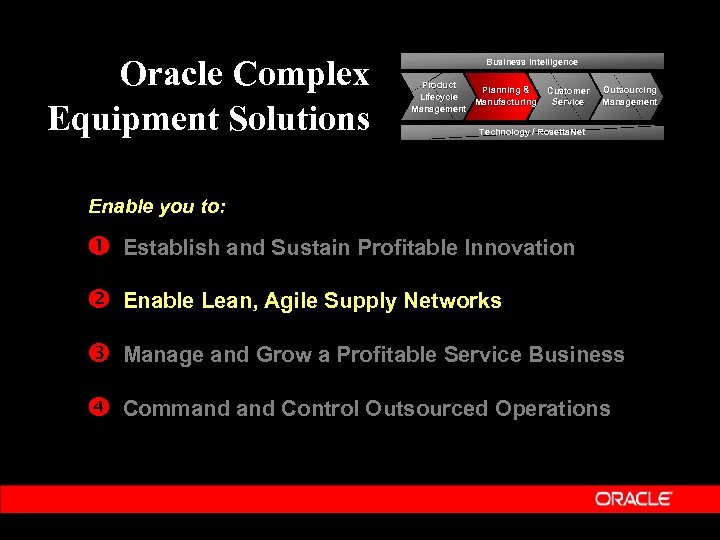

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="Oracle Complex Equipment Solutions Business Intelligence Product Planning & Lifecycle Manufacturing Management Customer Service" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-22.jpg" alt="Oracle Complex Equipment Solutions Business Intelligence Product Planning & Lifecycle Manufacturing Management Customer Service" />

Oracle Complex Equipment Solutions Business Intelligence Product Planning & Lifecycle Manufacturing Management Customer Service Outsourcing Management Technology / Rosetta. Net Enable you to: Establish and Sustain Profitable Innovation Enable Lean, Agile Supply Networks Manage and Grow a Profitable Service Business Command Control Outsourced Operations </p>

</div>

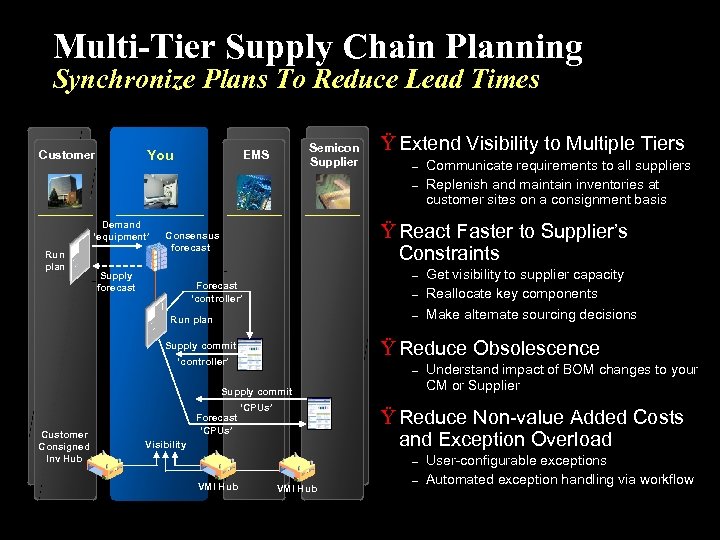

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="Multi-Tier Supply Chain Planning Synchronize Plans To Reduce Lead Times You Customer Semicon Supplier" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-23.jpg" alt="Multi-Tier Supply Chain Planning Synchronize Plans To Reduce Lead Times You Customer Semicon Supplier" />

Multi-Tier Supply Chain Planning Synchronize Plans To Reduce Lead Times You Customer Semicon Supplier EMS Ÿ Extend Visibility to Multiple Tiers – – Demand ‘equipment’ Run plan Ÿ React Faster to Supplier’s Constraints Consensus forecast Supply forecast – Forecast ‘controller’ – – Run plan ‘controller’ – Supply commit Forecast ‘CPUs’ Understand impact of BOM changes to your CM or Supplier Ÿ Reduce Non-value Added Costs and Exception Overload Visibility – VMI Hub Get visibility to supplier capacity Reallocate key components Make alternate sourcing decisions Ÿ Reduce Obsolescence Supply commit Customer Consigned Inv Hub Communicate requirements to all suppliers Replenish and maintain inventories at customer sites on a consignment basis VMI Hub – User-configurable exceptions Automated exception handling via workflow </p>

</div>

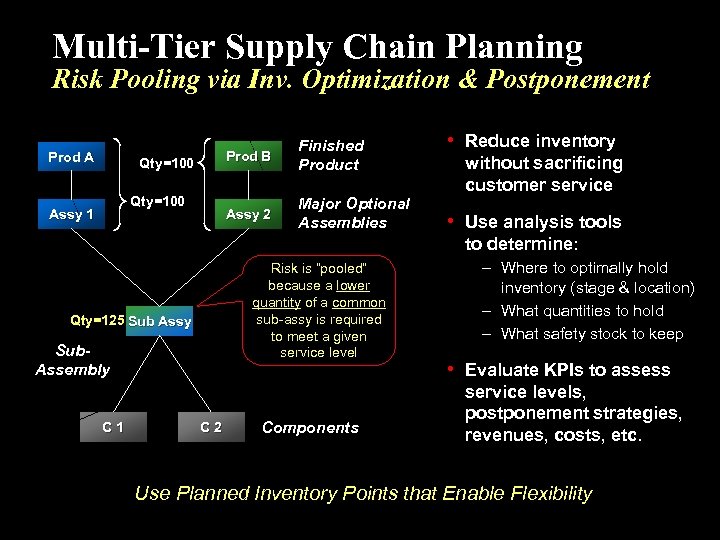

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="Multi-Tier Supply Chain Planning Risk Pooling via Inv. Optimization & Postponement Prod A Prod" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-24.jpg" alt="Multi-Tier Supply Chain Planning Risk Pooling via Inv. Optimization & Postponement Prod A Prod" />

Multi-Tier Supply Chain Planning Risk Pooling via Inv. Optimization & Postponement Prod A Prod B Assy 2 Qty=100 Assy 1 Finished Product Major Optional Assemblies • Reduce inventory without sacrificing customer service • Use analysis tools to determine: Risk is “pooled” because a lower quantity of a common sub-assy is required to meet a given service level Qty=125 Sub Assy Sub. Assembly C 1 C 2 Components - Where to optimally hold inventory (stage & location) - What quantities to hold - What safety stock to keep • Evaluate KPIs to assess service levels, postponement strategies, revenues, costs, etc. Use Planned Inventory Points that Enable Flexibility </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="CTO and MTS Manufacturing Minimize Inventories & Increase Customer Satisfaction Standard Product (MTS) Customers" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-25.jpg" alt="CTO and MTS Manufacturing Minimize Inventories & Increase Customer Satisfaction Standard Product (MTS) Customers" />

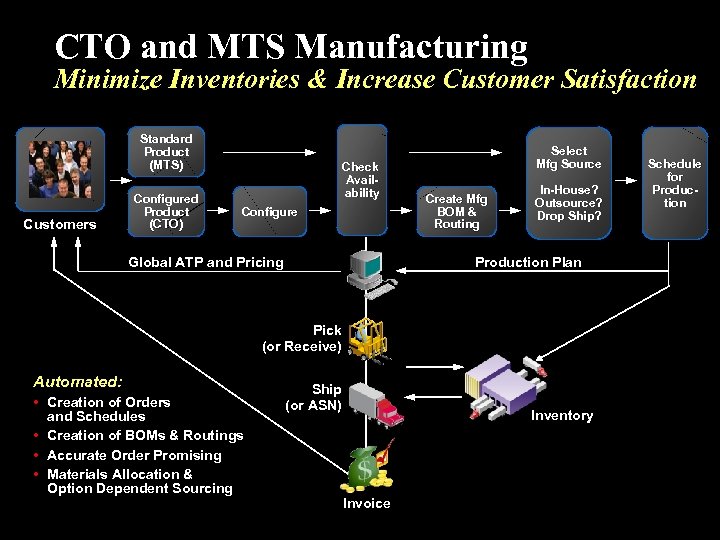

CTO and MTS Manufacturing Minimize Inventories & Increase Customer Satisfaction Standard Product (MTS) Customers Configured Product (CTO) Check Availability Configure Global ATP and Pricing Select Mfg Source Create Mfg BOM & Routing In-House? Outsource? Drop Ship? Production Plan Pick (or Receive) Automated: • Creation of Orders and Schedules • Creation of BOMs & Routings • Accurate Order Promising • Materials Allocation & Option Dependent Sourcing Ship (or ASN) Inventory Invoice Schedule for Production </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="Multi-Mode Manufacturing Demand Variability Integrated Intelligence Cost Analysis Planning ATO Discrete Flow Substitutes •" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-26.jpg" alt="Multi-Mode Manufacturing Demand Variability Integrated Intelligence Cost Analysis Planning ATO Discrete Flow Substitutes •" />

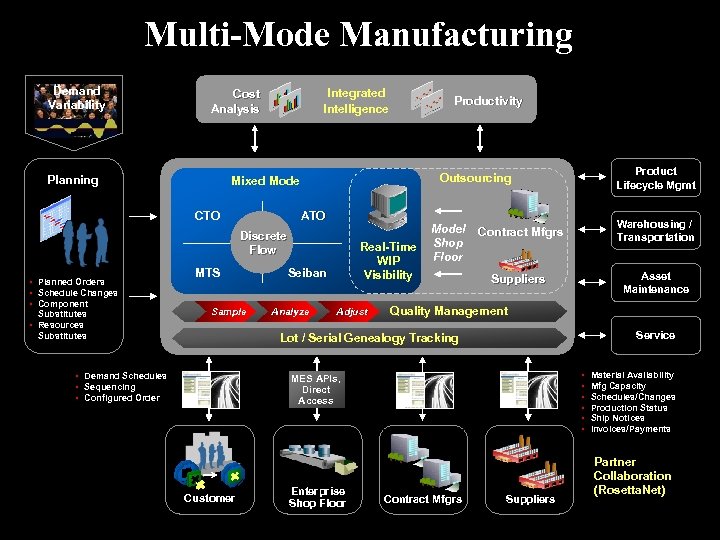

Multi-Mode Manufacturing Demand Variability Integrated Intelligence Cost Analysis Planning ATO Discrete Flow Substitutes • Resources Substitutes MTS Sample Product Lifecycle Mgmt Outsourcing Mixed Mode CTO • Planned Orders • Schedule Changes • Component Productivity Real-Time WIP Visibility Seiban Analyze Adjust Model Shop Floor Contract Mfgrs Warehousing / Transportation Suppliers Asset Maintenance Quality Management Service Lot / Serial Genealogy Tracking • Demand Schedules • Sequencing • Configured Order • • • MES APIs, Direct Access Customer Enterprise Shop Floor Contract Mfgrs Suppliers Material Availability Mfg Capacity Schedules/Changes Production Status Ship Notices Invoices/Payments Partner Collaboration (Rosetta. Net) </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="Flow Mfg for Cost Effective Production Build a Mix of Models and Configurations on" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-27.jpg" alt="Flow Mfg for Cost Effective Production Build a Mix of Models and Configurations on" />

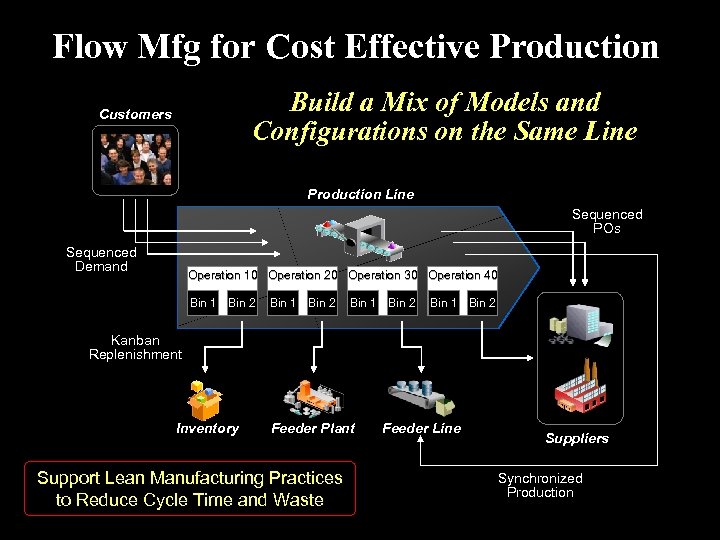

Flow Mfg for Cost Effective Production Build a Mix of Models and Configurations on the Same Line Customers Production Line Sequenced POs Sequenced Demand Operation 10 Operation 20 Operation 30 Operation 40 Bin 1 Bin 2 Kanban Replenishment Inventory Feeder Plant Support Lean Manufacturing Practices to Reduce Cycle Time and Waste Feeder Line Suppliers Synchronized Production </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="Manufacturing & Logistics Integration Efficiently Move Products from Assembly to Customers Warehouse Management Integration" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-28.jpg" alt="Manufacturing & Logistics Integration Efficiently Move Products from Assembly to Customers Warehouse Management Integration" />

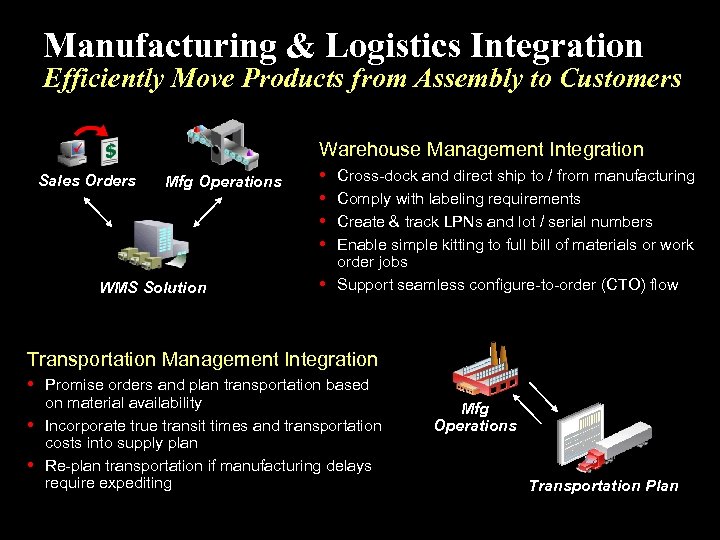

Manufacturing & Logistics Integration Efficiently Move Products from Assembly to Customers Warehouse Management Integration Sales Orders Mfg Operations WMS Solution • • Cross-dock and direct ship to / from manufacturing Comply with labeling requirements Create & track LPNs and lot / serial numbers Enable simple kitting to full bill of materials or work order jobs • Support seamless configure-to-order (CTO) flow Transportation Management Integration • Promise orders and plan transportation based on material availability • Incorporate true transit times and transportation costs into supply plan • Re-plan transportation if manufacturing delays require expediting Mfg Operations Transportation Plan </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="Oracle Complex Equipment Solutions Business Intelligence Product Planning & Lifecycle Manufacturing Management Customer Service" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-29.jpg" alt="Oracle Complex Equipment Solutions Business Intelligence Product Planning & Lifecycle Manufacturing Management Customer Service" />

Oracle Complex Equipment Solutions Business Intelligence Product Planning & Lifecycle Manufacturing Management Customer Service Outsourcing Management Technology / Rosetta. Net Enable you to: Establish and Sustain Profitable Innovation Enable Lean, Agile Supply Networks Manage and Grow a Profitable Service Business Command Control Outsourced Operations </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="Automatically Verify Entitlements Accelerate Response via Seamless Contract Integration • Define service coverage and" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-30.jpg" alt="Automatically Verify Entitlements Accelerate Response via Seamless Contract Integration • Define service coverage and" />

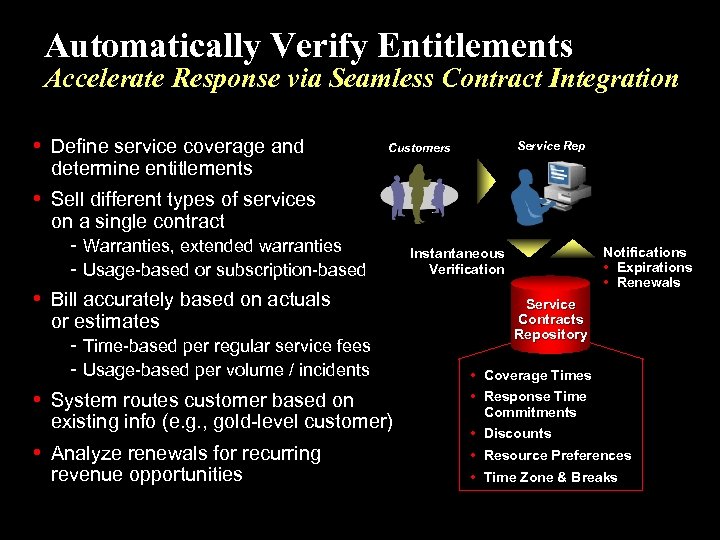

Automatically Verify Entitlements Accelerate Response via Seamless Contract Integration • Define service coverage and Service Rep Customers determine entitlements • Sell different types of services on a single contract - Warranties, extended warranties - Usage-based or subscription-based • Bill accurately based on actuals or estimates - Time-based per regular service fees - Usage-based per volume / incidents • System routes customer based on existing info (e. g. , gold-level customer) • Analyze renewals for recurring revenue opportunities Notifications • Expirations • Renewals Instantaneous Verification Service Contracts Repository • Coverage Times • Response Time Commitments • Discounts • Resource Preferences • Time Zone & Breaks </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="Know Installed Base Configurations Capture Information From Inception to Retirement Design Specs Ÿ Record" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-31.jpg" alt="Know Installed Base Configurations Capture Information From Inception to Retirement Design Specs Ÿ Record" />

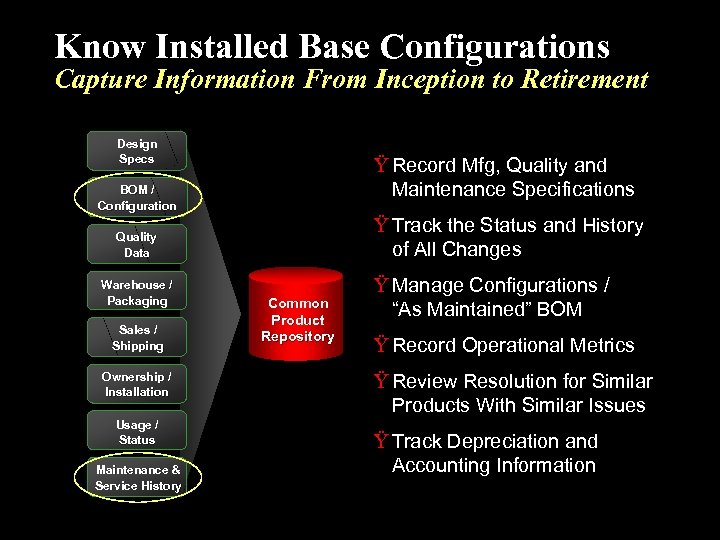

Know Installed Base Configurations Capture Information From Inception to Retirement Design Specs Ÿ Record Mfg, Quality and Maintenance Specifications BOM / Configuration Ÿ Track the Status and History of All Changes Quality Data Warehouse / Packaging Sales / Shipping Ownership / Installation Usage / Status Maintenance & Service History Common Product Repository Ÿ Manage Configurations / “As Maintained” BOM Ÿ Record Operational Metrics Ÿ Review Resolution for Similar Products With Similar Issues Ÿ Track Depreciation and Accounting Information </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="Field Service Resource Planning Increase Productivity and Service Quality Issues • • • General" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-32.jpg" alt="Field Service Resource Planning Increase Productivity and Service Quality Issues • • • General" />

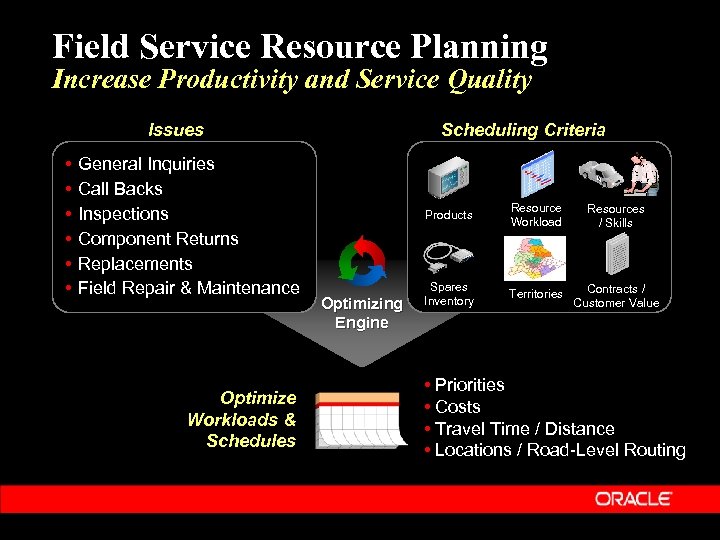

Field Service Resource Planning Increase Productivity and Service Quality Issues • • • General Inquiries Call Backs Inspections Component Returns Replacements Field Repair & Maintenance Optimize Workloads & Schedules Scheduling Criteria Products Optimizing Engine Resource Workload Resources / Skills Spares Inventory Territories Contracts / Customer Value • Priorities • Costs • Travel Time / Distance • Locations / Road-Level Routing </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="Field Service Deployment Reduce Repair Time & Cost, Leverage Mobile Capabilities Spare Parts Identify" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-33.jpg" alt="Field Service Deployment Reduce Repair Time & Cost, Leverage Mobile Capabilities Spare Parts Identify" />

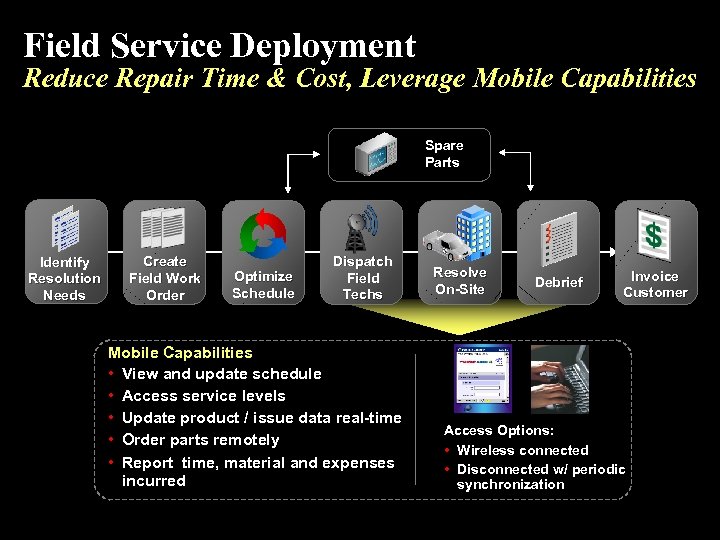

Field Service Deployment Reduce Repair Time & Cost, Leverage Mobile Capabilities Spare Parts Identify Resolution Needs Create Field Work Order Optimize Schedule Dispatch Field Techs Mobile Capabilities • View and update schedule • Access service levels • Update product / issue data real-time • Order parts remotely • Report time, material and expenses incurred Resolve On-Site Debrief Invoice Customer Access Options: • Wireless connected • Disconnected w/ periodic synchronization </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="Manage Product Returns Support Complete Logistics & Repair Processing Needs Direct Product Return Identify" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-34.jpg" alt="Manage Product Returns Support Complete Logistics & Repair Processing Needs Direct Product Return Identify" />

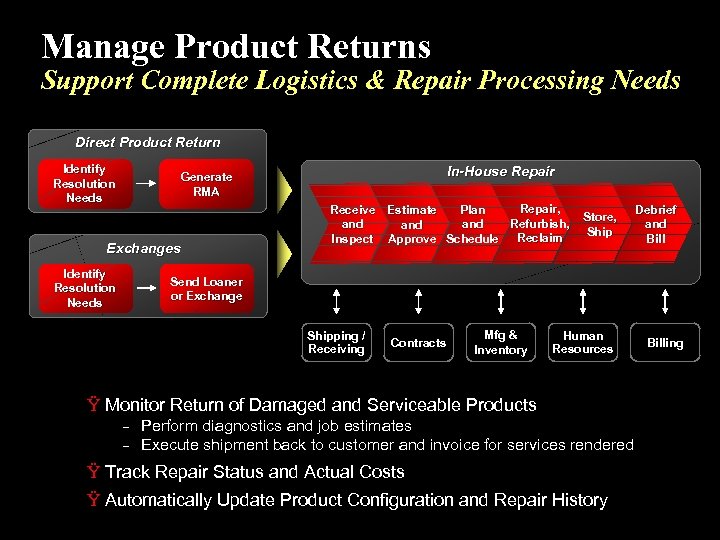

Manage Product Returns Support Complete Logistics & Repair Processing Needs Direct Product Return Identify Resolution Needs In-House Repair Generate RMA Exchanges Identify Resolution Needs Repair, Receive Estimate Plan Refurbish, and and Inspect Approve Schedule Reclaim Store, Ship Debrief and Bill Send Loaner or Exchange Shipping / Receiving Contracts Mfg & Inventory Human Resources Ÿ Monitor Return of Damaged and Serviceable Products – – Perform diagnostics and job estimates Execute shipment back to customer and invoice for services rendered Ÿ Track Repair Status and Actual Costs Ÿ Automatically Update Product Configuration and Repair History Billing </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="Installed Base Preventive Maintenance Support Planned Maintenance & Reduce Breakdowns • Define programs, including" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-35.jpg" alt="Installed Base Preventive Maintenance Support Planned Maintenance & Reduce Breakdowns • Define programs, including" />

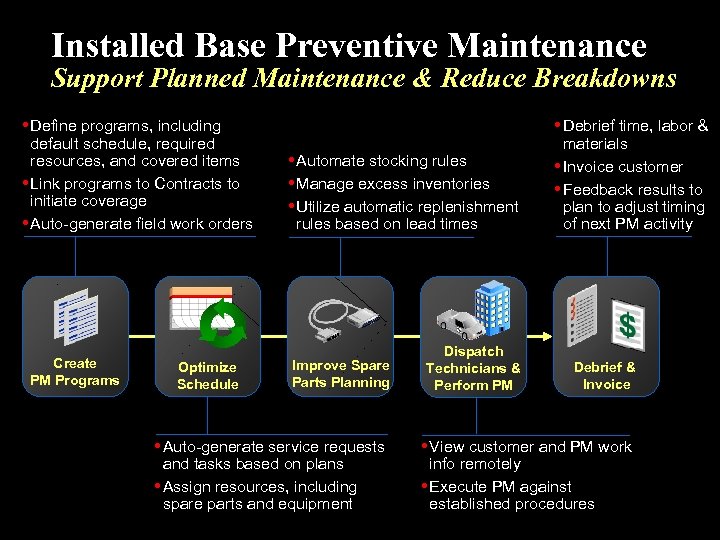

Installed Base Preventive Maintenance Support Planned Maintenance & Reduce Breakdowns • Define programs, including default schedule, required resources, and covered items • Link programs to Contracts to initiate coverage • Auto-generate field work orders Create PM Programs Optimize Schedule • Debrief time, labor & • Automate stocking rules • Manage excess inventories • Utilize automatic replenishment rules based on lead times Improve Spare Parts Planning • Auto-generate service requests and tasks based on plans • Assign resources, including spare parts and equipment Dispatch Technicians & Perform PM materials • Invoice customer • Feedback results to plan to adjust timing of next PM activity Debrief & Invoice • View customer and PM work info remotely • Execute PM against established procedures </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="Oracle Complex Equipment Solutions Business Intelligence Product Planning & Lifecycle Manufacturing Management Customer Service" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-36.jpg" alt="Oracle Complex Equipment Solutions Business Intelligence Product Planning & Lifecycle Manufacturing Management Customer Service" />

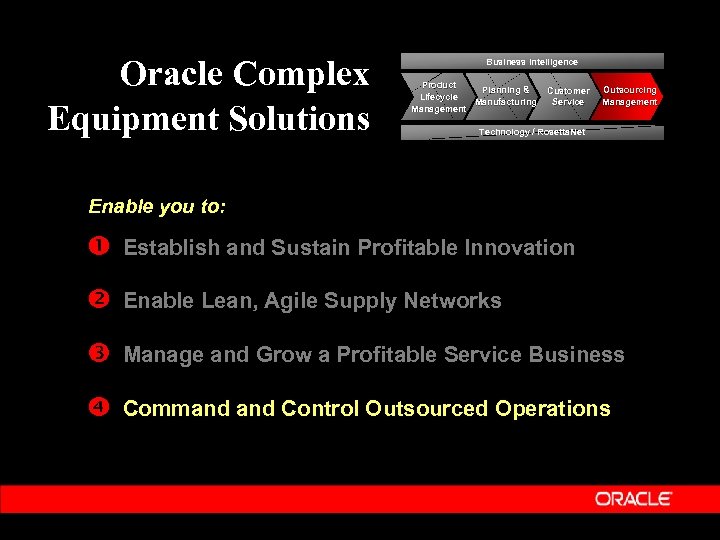

Oracle Complex Equipment Solutions Business Intelligence Product Planning & Lifecycle Manufacturing Management Customer Service Outsourcing Management Technology / Rosetta. Net Enable you to: Establish and Sustain Profitable Innovation Enable Lean, Agile Supply Networks Manage and Grow a Profitable Service Business Command Control Outsourced Operations </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="Outsourced Manufacturing Challenges Less Visibility, Less Control, Conflicting Information ATP based on supplier capacity" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-37.jpg" alt="Outsourced Manufacturing Challenges Less Visibility, Less Control, Conflicting Information ATP based on supplier capacity" />

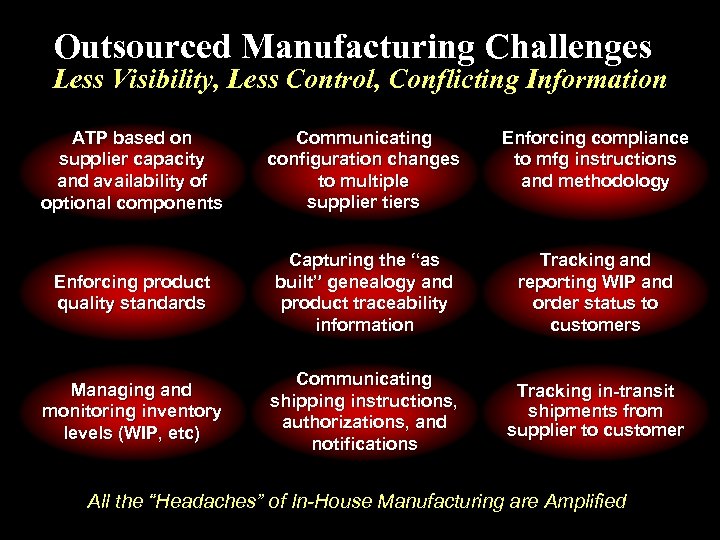

Outsourced Manufacturing Challenges Less Visibility, Less Control, Conflicting Information ATP based on supplier capacity and availability of optional components Communicating configuration changes to multiple supplier tiers Enforcing compliance to mfg instructions and methodology Enforcing product quality standards Capturing the “as built” genealogy and product traceability information Tracking and reporting WIP and order status to customers Managing and monitoring inventory levels (WIP, etc) Communicating shipping instructions, authorizations, and notifications Tracking in-transit shipments from supplier to customer All the “Headaches” of In-House Manufacturing are Amplified </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="Example: Drop Ship from Partner to Customer OEM Order A Place PO for Component" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-38.jpg" alt="Example: Drop Ship from Partner to Customer OEM Order A Place PO for Component" />

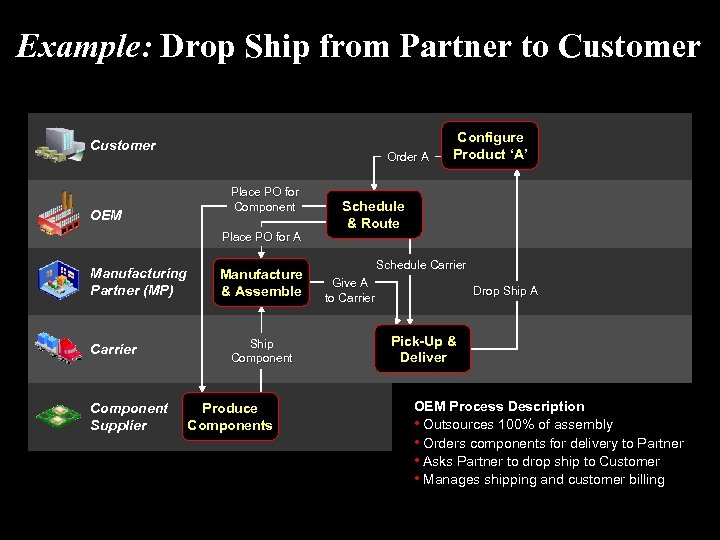

Example: Drop Ship from Partner to Customer OEM Order A Place PO for Component Place PO for A Manufacturing Partner (MP) Carrier Component Supplier Manufacture & Assemble Ship Component Produce Components Configure Product ‘A’ Schedule & Route Schedule Carrier Give A to Carrier Drop Ship A Pick-Up & Deliver OEM Process Description • Outsources 100% of assembly • Orders components for delivery to Partner • Asks Partner to drop ship to Customer • Manages shipping and customer billing </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="Outsource with Confidence Achieve Total Visibility to Outsourced Mfg & Logistics – Partner Setup" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-39.jpg" alt="Outsource with Confidence Achieve Total Visibility to Outsourced Mfg & Logistics – Partner Setup" />

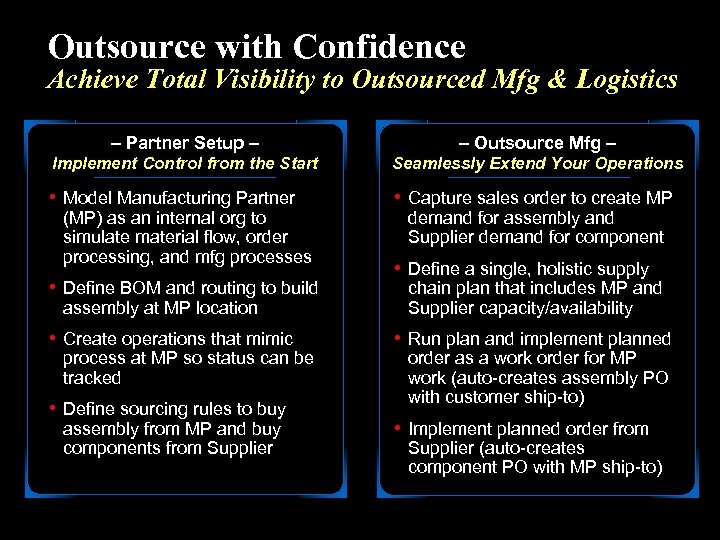

Outsource with Confidence Achieve Total Visibility to Outsourced Mfg & Logistics – Partner Setup – – Outsource Mfg – Implement Control from the Start Seamlessly Extend Your Operations • Model Manufacturing Partner • Capture sales order to create MP (MP) as an internal org to simulate material flow, order processing, and mfg processes • Define BOM and routing to build assembly at MP location • Create operations that mimic process at MP so status can be tracked • Define sourcing rules to buy assembly from MP and buy components from Supplier demand for assembly and Supplier demand for component • Define a single, holistic supply chain plan that includes MP and Supplier capacity/availability • Run plan and implement planned order as a work order for MP work (auto-creates assembly PO with customer ship-to) • Implement planned order from Supplier (auto-creates component PO with MP ship-to) </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="Outsource with Confidence Achieve Total Visibility to Outsourced Mfg & Logistics – Shipping –" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-40.jpg" alt="Outsource with Confidence Achieve Total Visibility to Outsourced Mfg & Logistics – Shipping –" />

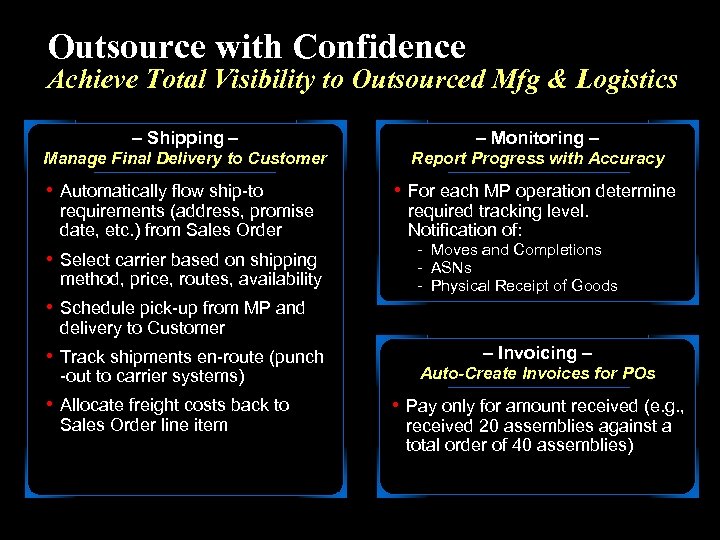

Outsource with Confidence Achieve Total Visibility to Outsourced Mfg & Logistics – Shipping – – Monitoring – Manage Final Delivery to Customer Report Progress with Accuracy • Automatically flow ship-to requirements (address, promise date, etc. ) from Sales Order • Select carrier based on shipping method, price, routes, availability • For each MP operation determine required tracking level. Notification of: - Moves and Completions - ASNs - Physical Receipt of Goods • Schedule pick-up from MP and delivery to Customer • Track shipments en-route (punch -out to carrier systems) • Allocate freight costs back to Sales Order line item – Invoicing – Auto-Create Invoices for POs • Pay only for amount received (e. g. , received 20 assemblies against a total order of 40 assemblies) </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="Facilitated Supplier Communications Enable Suppliers to have Easy Access to Critical Info OEMs Send:" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-41.jpg" alt="Facilitated Supplier Communications Enable Suppliers to have Easy Access to Critical Info OEMs Send:" />

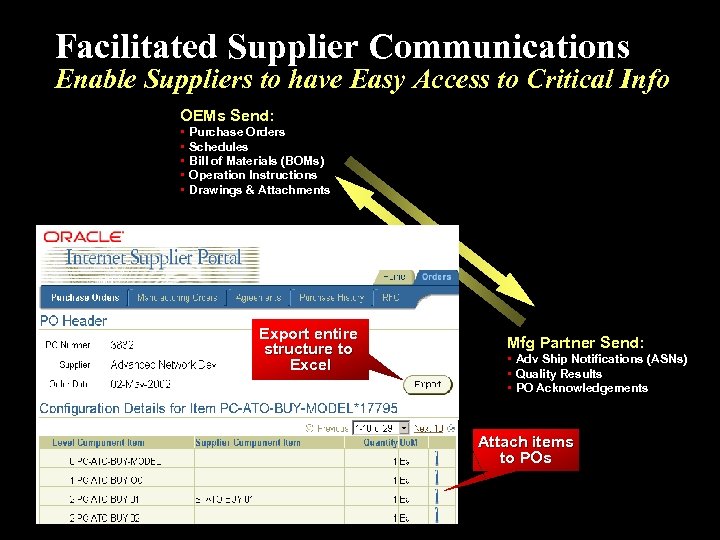

Facilitated Supplier Communications Enable Suppliers to have Easy Access to Critical Info OEMs Send: • • • Purchase Orders Schedules Bill of Materials (BOMs) Operation Instructions Drawings & Attachments Export entire structure to Excel Mfg Partner Send: • Adv Ship Notifications (ASNs) • Quality Results • PO Acknowledgements Attach items to POs </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="Serial / Lot Genealogy and Tracking Always Know the Source and Placement of Each" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-42.jpg" alt="Serial / Lot Genealogy and Tracking Always Know the Source and Placement of Each" />

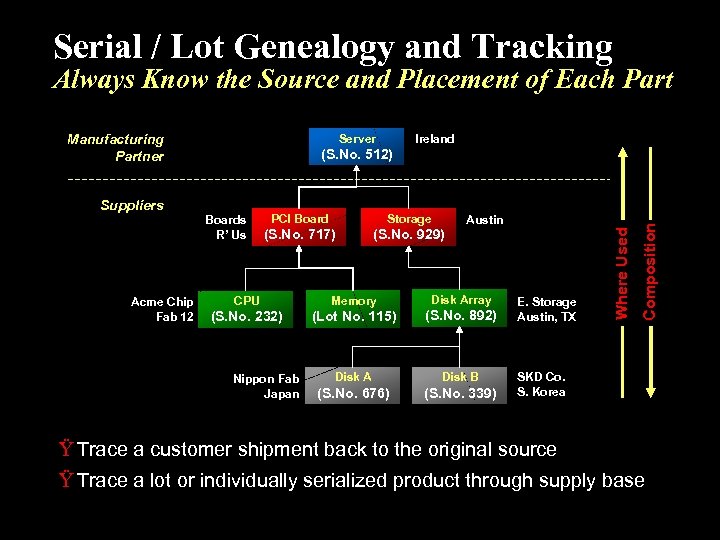

Serial / Lot Genealogy and Tracking Always Know the Source and Placement of Each Part Manufacturing Partner Server PCI Board Storage (S. No. 717) (S. No. 929) Austin CPU Memory Disk Array (S. No. 232) (Lot No. 115) (S. No. 892) Disk A Disk B (S. No. 676) (S. No. 339) Nippon Fab Japan E. Storage Austin, TX Where Used Boards R’ Us Composition (S. No. 512) Suppliers Acme Chip Fab 12 Ireland SKD Co. S. Korea Ÿ Trace a customer shipment back to the original source Ÿ Trace a lot or individually serialized product through supply base </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="Extend Reach Through 3 rd Party Services Control Scheduling and Meet Contractual Obligations Personalized" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-43.jpg" alt="Extend Reach Through 3 rd Party Services Control Scheduling and Meet Contractual Obligations Personalized" />

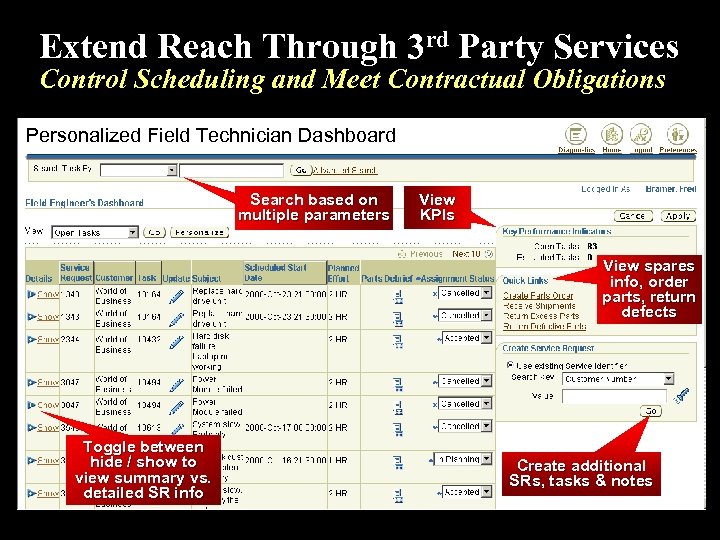

Extend Reach Through 3 rd Party Services Control Scheduling and Meet Contractual Obligations Personalized Field Technician Dashboard Search based on multiple parameters View KPIs View spares info, order parts, return defects Toggle between hide / show to view summary vs. detailed SR info Create additional SRs, tasks & notes </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="Integrated Throughout Entire Offering… Business Intelligence and Corporate Governance " src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-44.jpg" alt="Integrated Throughout Entire Offering… Business Intelligence and Corporate Governance " />

Integrated Throughout Entire Offering… Business Intelligence and Corporate Governance </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="Foundation: Common Data Model A Single Source of Truth 3 rd Party & Legacy" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-45.jpg" alt="Foundation: Common Data Model A Single Source of Truth 3 rd Party & Legacy" />

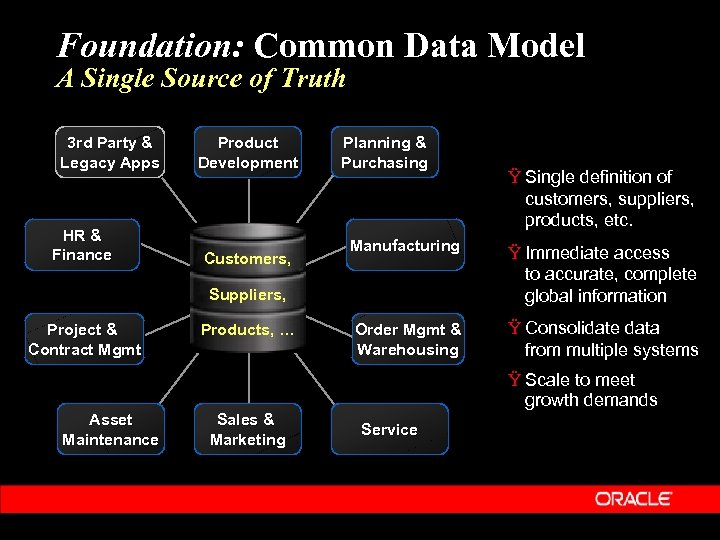

Foundation: Common Data Model A Single Source of Truth 3 rd Party & Legacy Apps HR & Finance Product Development Customers, Planning & Purchasing Manufacturing Ÿ Immediate access to accurate, complete global information Order Mgmt & Warehousing Ÿ Consolidate data from multiple systems Suppliers, Project & Contract Mgmt Products, … Ÿ Single definition of customers, suppliers, products, etc. Ÿ Scale to meet growth demands Asset Maintenance Sales & Marketing Service </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="Deliver Daily Business Intelligence Real-Time Access to Complete Business Information What are the project" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-46.jpg" alt="Deliver Daily Business Intelligence Real-Time Access to Complete Business Information What are the project" />

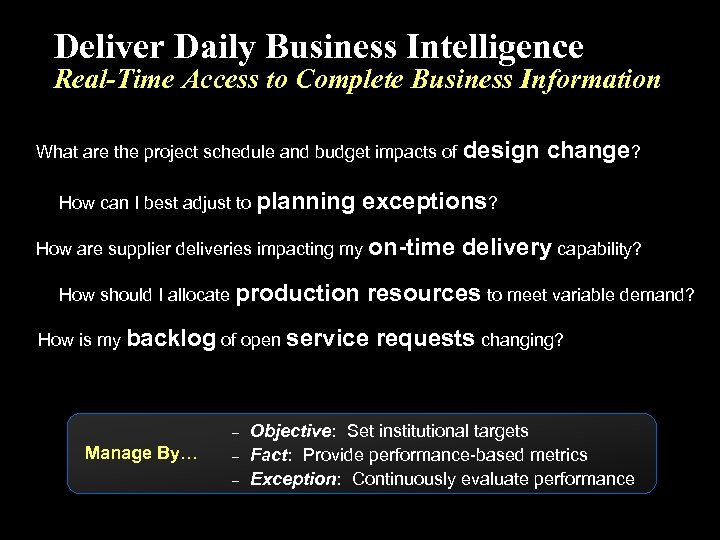

Deliver Daily Business Intelligence Real-Time Access to Complete Business Information What are the project schedule and budget impacts of design change? How can I best adjust to planning exceptions? How are supplier deliveries impacting my on-time delivery capability? How should I allocate production resources to meet variable demand? How is my backlog of open service requests changing? – Manage By… – – Objective: Set institutional targets Fact: Provide performance-based metrics Exception: Continuously evaluate performance </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="Business Intelligence: Timely, Accurate, Relevant Flexible Time Periods Flexible Comparisons Real-Time Results • Actionable" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-47.jpg" alt="Business Intelligence: Timely, Accurate, Relevant Flexible Time Periods Flexible Comparisons Real-Time Results • Actionable" />

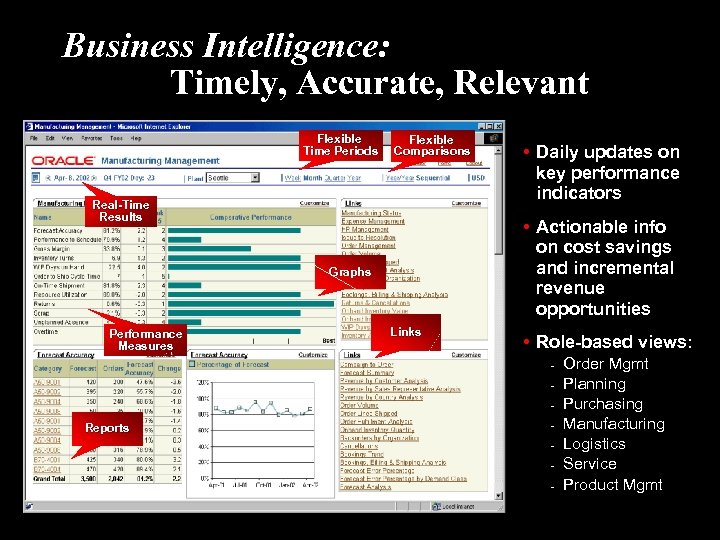

Business Intelligence: Timely, Accurate, Relevant Flexible Time Periods Flexible Comparisons Real-Time Results • Actionable info on cost savings and incremental revenue opportunities Graphs Performance Measures • Daily updates on key performance indicators Links • Role-based views: - Reports - Order Mgmt Planning Purchasing Manufacturing Logistics Service Product Mgmt </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="Corporate Governance A heightened business focus on accuracy in reporting to investors brought on" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-48.jpg" alt="Corporate Governance A heightened business focus on accuracy in reporting to investors brought on" />

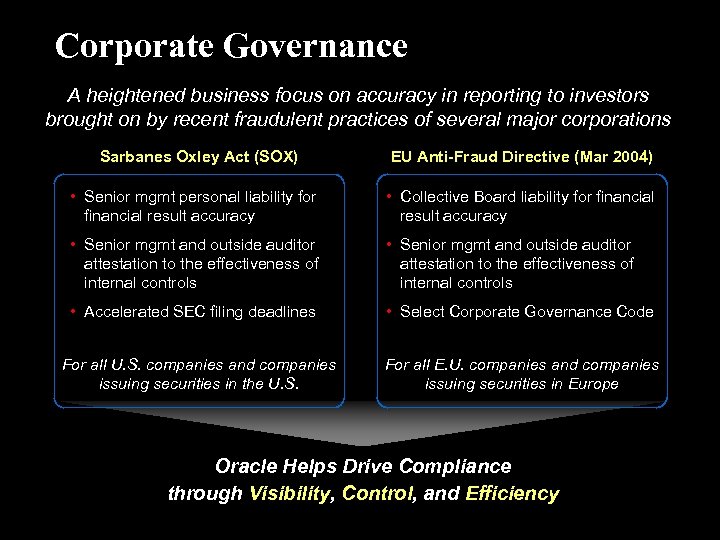

Corporate Governance A heightened business focus on accuracy in reporting to investors brought on by recent fraudulent practices of several major corporations Sarbanes Oxley Act (SOX) EU Anti-Fraud Directive (Mar 2004) • Senior mgmt personal liability for financial result accuracy • Collective Board liability for financial result accuracy • Senior mgmt and outside auditor attestation to the effectiveness of internal controls • Accelerated SEC filing deadlines • Select Corporate Governance Code For all U. S. companies and companies issuing securities in the U. S. For all E. U. companies and companies issuing securities in Europe Oracle Helps Drive Compliance through Visibility, Control, and Efficiency </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="Corporate Governance: Visibility, Control, Efficiency Control Visibility • Identify issues early • Enable real-time" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-49.jpg" alt="Corporate Governance: Visibility, Control, Efficiency Control Visibility • Identify issues early • Enable real-time" />

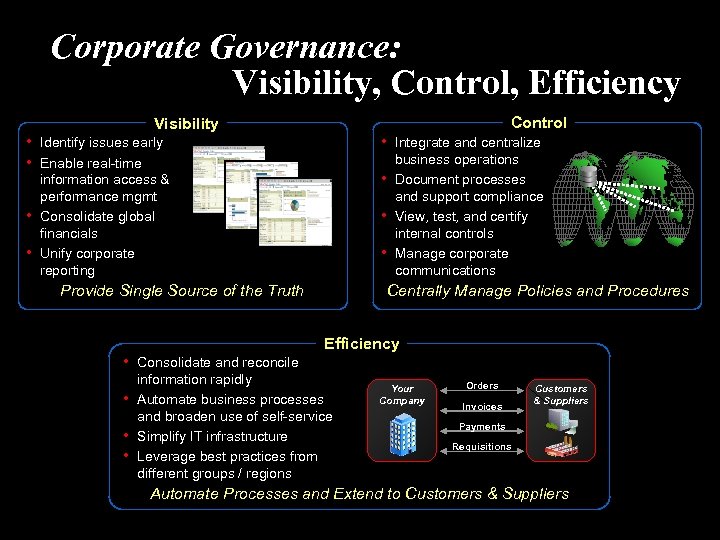

Corporate Governance: Visibility, Control, Efficiency Control Visibility • Identify issues early • Enable real-time • • • Integrate and centralize • information access & performance mgmt Consolidate global financials Unify corporate reporting • • Centrally Manage Policies and Procedures Provide Single Source of the Truth • Consolidate and reconcile • • • business operations Document processes and support compliance View, test, and certify internal controls Manage corporate communications Efficiency information rapidly Automate business processes and broaden use of self-service Simplify IT infrastructure Leverage best practices from different groups / regions Your Company Orders Invoices Customers & Suppliers Payments Requisitions Automate Processes and Extend to Customers & Suppliers </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="All Built on Leading Technology Database Server Application Server " src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-50.jpg" alt="All Built on Leading Technology Database Server Application Server " />

All Built on Leading Technology Database Server Application Server </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="Oracle Complex Equipment Solutions Collaborative development with integrated BOM management and controlled ECR /" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-51.jpg" alt="Oracle Complex Equipment Solutions Collaborative development with integrated BOM management and controlled ECR /" />

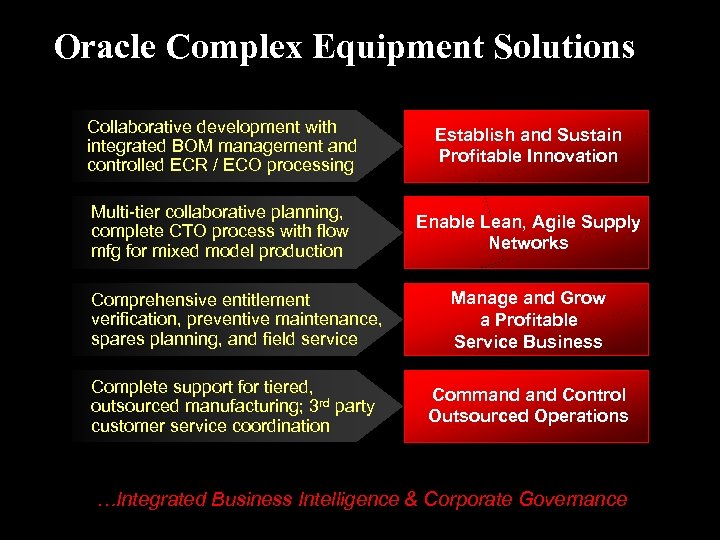

Oracle Complex Equipment Solutions Collaborative development with integrated BOM management and controlled ECR / ECO processing Establish and Sustain Profitable Innovation Multi-tier collaborative planning, complete CTO process with flow mfg for mixed model production Enable Lean, Agile Supply Networks Comprehensive entitlement verification, preventive maintenance, spares planning, and field service Manage and Grow a Profitable Service Business Complete support for tiered, outsourced manufacturing; 3 rd party customer service coordination Command Control Outsourced Operations …Integrated Business Intelligence & Corporate Governance </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="Footprint: High Tech - Complex Equipment Establish and Sustain Profitable Innovation Drivers • Inability" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-52.jpg" alt="Footprint: High Tech - Complex Equipment Establish and Sustain Profitable Innovation Drivers • Inability" />

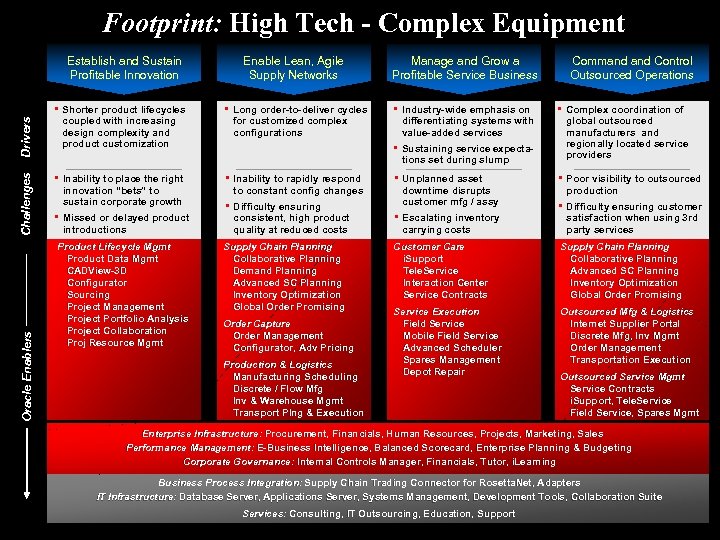

Footprint: High Tech - Complex Equipment Establish and Sustain Profitable Innovation Drivers • Inability to place the right Oracle Enablers coupled with increasing design complexity and product customization Challenges • Shorter product lifecycles Enable Lean, Agile Supply Networks Manage and Grow a Profitable Service Business • Long order-to-deliver cycles • Industry-wide emphasis on for customized complex configurations differentiating systems with value-added services • Sustaining service expectations set during slump innovation “bets” to sustain corporate growth • Missed or delayed product introductions Product Lifecycle Mgmt Product Data Mgmt CADView-3 D CADView -3 D Configurator Sourcing Project Management Project Portfolio Analysis Project Collaboration Proj Resource Mgmt • Inability to rapidly respond to constant config changes • Difficulty ensuring consistent, high product quality at reduced costs Supply Chain Planning Collaborative Planning Demand Planning Advanced SC Planning Inventory Optimization Global Order Promising Order Capture Order Management Configurator, Adv Pricing Production & Logistics Manufacturing Scheduling Discrete / Flow Mfg Inv & Warehouse Mgmt Transport Plng & Execution • Unplanned asset downtime disrupts customer mfg / assy • Escalating inventory carrying costs Command Control Outsourced Operations • Complex coordination of global outsourced manufacturers and regionally located service providers • Poor visibility to outsourced production • Difficulty ensuring customer satisfaction when using 3 rd party services Customer Care i. Support Tele. Service Interaction Center Service Contracts Supply Chain Planning Collaborative Planning Advanced SC Planning Inventory Optimization Global Order Promising Service Execution Field Service Mobile Field Service Advanced Scheduler Spares Management Depot Repair Outsourced Mfg & Logistics Internet Supplier Portal Discrete Mfg, Inv Mgmt Order Management Transportation Execution Outsourced Service Mgmt Service Contracts i. Support, Tele. Service i. Support , Tele. Service Field Service, Spares Mgmt Infrastructure: Procurement, Financials, Human Resources, Projects, Marketing, Sales Enterprise Infrastructure: Procurement, Financials, Human Resources, Projects, Marketing, Sales Management: E-Business Intelligence, Balanced Scorecard, Enterprise Planning & Budgeting Performance Management: E-Business Intelligence, Balanced Scorecard, Enterprise Planning & Budgeting Governance: Internal Controls Manager, Financials, Tutor, i. Learning Corporate Governance: Internal Controls Manager, Financials, Tutor, i. Learning Integration: Supply Chain Trading Connector for Rosetta. Net, Adapters Business Process Integration: Supply Chain Trading Connector for Rosetta. Net, Adapters Infrastructure: Database Server, Applications Server, Systems Management, Development Tools, Collaboration Suite IT Infrastructure: Database Server, Applications Server, Systems Management, Development Tools, Collaboration Suite Services: Consulting, IT Outsourcing, Education, Support </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="High Technology Capabilities Evolution of Oracle Applications in High Tech Base Differentiators… New in" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-53.jpg" alt="High Technology Capabilities Evolution of Oracle Applications in High Tech Base Differentiators… New in" />

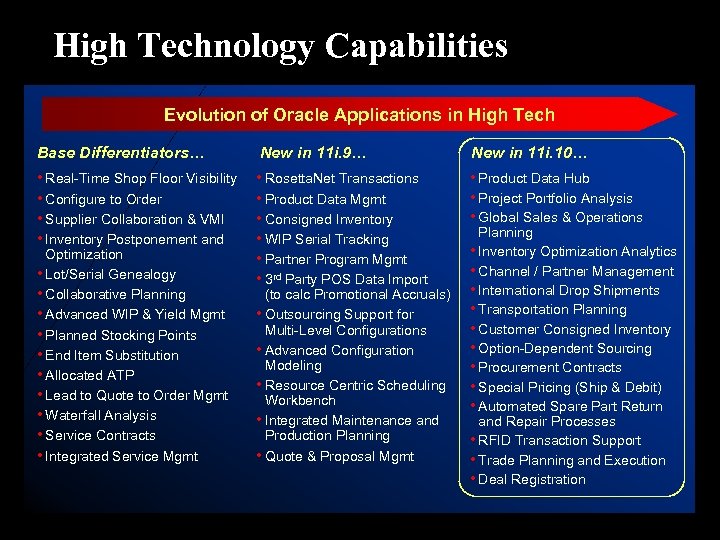

High Technology Capabilities Evolution of Oracle Applications in High Tech Base Differentiators… New in 11 i. 9… New in 11 i. 10… • Real-Time Shop Floor Visibility • Configure to Order • Supplier Collaboration & VMI • Inventory Postponement and • Rosetta. Net Transactions • Product Data Mgmt • Consigned Inventory • WIP Serial Tracking • Partner Program Mgmt • 3 rd Party POS Data Import • Product Data Hub • Project Portfolio Analysis • Global Sales & Operations Optimization • Lot/Serial Genealogy • Collaborative Planning • Advanced WIP & Yield Mgmt • Planned Stocking Points • End Item Substitution • Allocated ATP • Lead to Quote to Order Mgmt • Waterfall Analysis • Service Contracts • Integrated Service Mgmt (to calc Promotional Accruals) • Outsourcing Support for Multi-Level Configurations • Advanced Configuration Modeling • Resource Centric Scheduling Workbench • Integrated Maintenance and Production Planning • Quote & Proposal Mgmt Planning • Inventory Optimization Analytics • Channel / Partner Management • International Drop Shipments • Transportation Planning • Customer Consigned Inventory • Option-Dependent Sourcing • Procurement Contracts • Special Pricing (Ship & Debit) • Automated Spare Part Return and Repair Processes • RFID Transaction Support • Trade Planning and Execution • Deal Registration </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="Lower Total Cost of Ownership (TCO) Run on a Single Global Instance E-Business On" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-54.jpg" alt="Lower Total Cost of Ownership (TCO) Run on a Single Global Instance E-Business On" />

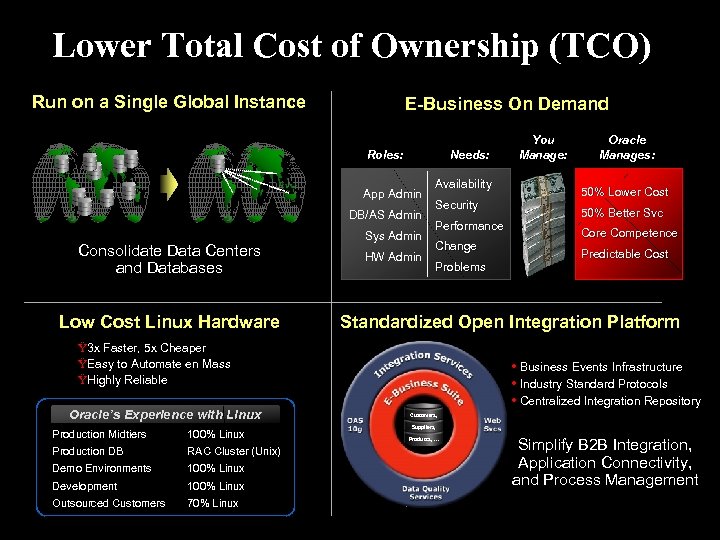

Lower Total Cost of Ownership (TCO) Run on a Single Global Instance E-Business On Demand Roles: Needs: App Admin DB/AS Admin Consolidate Data Centers and Databases Low Cost Linux Hardware Sys Admin HW Admin Availability Security Performance Change Problems Production Midtiers 100% Linux Production DB RAC Cluster (Unix) Demo Environments 100% Linux Development 100% Linux Outsourced Customers 70% Linux Oracle Manages: 50% Lower Cost 50% Better Svc Core Competence Predictable Cost Standardized Open Integration Platform Ÿ 3 x Faster, 5 x Cheaper ŸEasy to Automate en Mass ŸHighly Reliable Oracle’s Experience with Linux You Manage: • Business Events Infrastructure • Industry Standard Protocols • Centralized Integration Repository Customers, Suppliers, Products, … Simplify B 2 B Integration, Application Connectivity, and Process Management </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="Lower Total Cost of Ownership Run on a Single Global Instance Support Global Operations" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-55.jpg" alt="Lower Total Cost of Ownership Run on a Single Global Instance Support Global Operations" />

Lower Total Cost of Ownership Run on a Single Global Instance Support Global Operations Ÿ 30 Languages Ÿ Multiple Currencies Ÿ Customers in 100+ Countries Ÿ All Languages Installable in Same Unicode Instance Ÿ Support for Statutory and Customary Local Requirements </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="Lower Total Cost of Ownership Standardized Open Integration Platform Ÿ Provide a unified view" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-56.jpg" alt="Lower Total Cost of Ownership Standardized Open Integration Platform Ÿ Provide a unified view" />

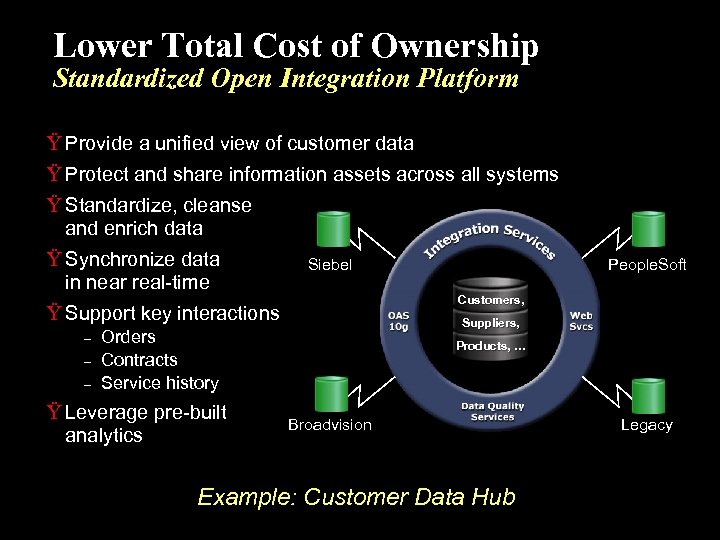

Lower Total Cost of Ownership Standardized Open Integration Platform Ÿ Provide a unified view of customer data Ÿ Protect and share information assets across all systems Ÿ Standardize, cleanse and enrich data Ÿ Synchronize data in near real-time Siebel Customers, Ÿ Support key interactions – – – Suppliers, Orders Contracts Service history Ÿ Leverage pre-built analytics People. Soft Products, … Broadvision Example: Customer Data Hub Legacy </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="Customer Case Studies " src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-57.jpg" alt="Customer Case Studies " />

Customer Case Studies </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="ŸLeader in test devices, semiconductors, and chemical analysis tools – $ 7. 18 B" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-58.jpg" alt="ŸLeader in test devices, semiconductors, and chemical analysis tools – $ 7. 18 B" />

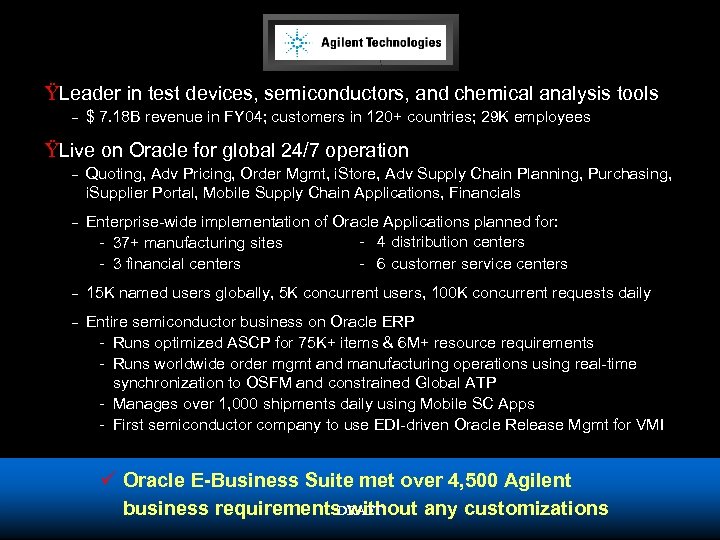

ŸLeader in test devices, semiconductors, and chemical analysis tools – $ 7. 18 B revenue in FY 04; customers in 120+ countries; 29 K employees ŸLive on Oracle for global 24/7 operation – Quoting, Adv Pricing, Order Mgmt, i. Store, Adv Supply Chain Planning, Purchasing, i. Supplier Portal, Mobile Supply Chain Applications, Financials – Enterprise-wide implementation of Oracle Applications planned for: - 4 distribution centers - 37+ manufacturing sites - 6 customer service centers - 3 financial centers – 15 K named users globally, 5 K concurrent users, 100 K concurrent requests daily – Entire semiconductor business on Oracle ERP - Runs optimized ASCP for 75 K+ items & 6 M+ resource requirements - Runs worldwide order mgmt and manufacturing operations using real-time synchronization to OSFM and constrained Global ATP - Manages over 1, 000 shipments daily using Mobile SC Apps - First semiconductor company to use EDI-driven Oracle Release Mgmt for VMI ü Oracle E-Business Suite met over 4, 500 Agilent DRAFT business requirements without any customizations </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="American Power Conversion Corp. Ÿ $1. 4 B world leader in IT equipment power" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-59.jpg" alt="American Power Conversion Corp. Ÿ $1. 4 B world leader in IT equipment power" />

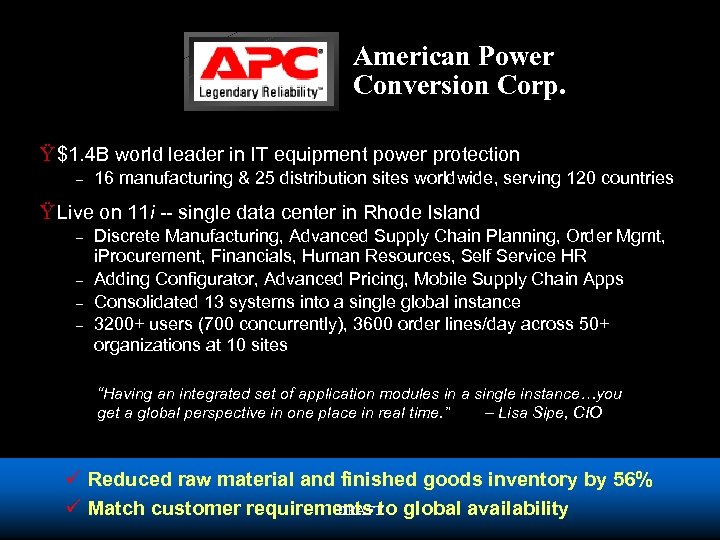

American Power Conversion Corp. Ÿ $1. 4 B world leader in IT equipment power protection – 16 manufacturing & 25 distribution sites worldwide, serving 120 countries Ÿ Live on 11 i -- single data center in Rhode Island – – Discrete Manufacturing, Advanced Supply Chain Planning, Order Mgmt, i. Procurement, Financials, Human Resources, Self Service HR Adding Configurator, Advanced Pricing, Mobile Supply Chain Apps Consolidated 13 systems into a single global instance 3200+ users (700 concurrently), 3600 order lines/day across 50+ organizations at 10 sites “Having an integrated set of application modules in a single instance…you get a global perspective in one place in real time. ” – Lisa Sipe, CIO ü Reduced raw material and finished goods inventory by 56% ü Match customer requirements to global availability DRAFT </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="Ÿ $419 M worldwide leader in high-performance open storage networking solutions – – 1020" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-60.jpg" alt="Ÿ $419 M worldwide leader in high-performance open storage networking solutions – – 1020" />

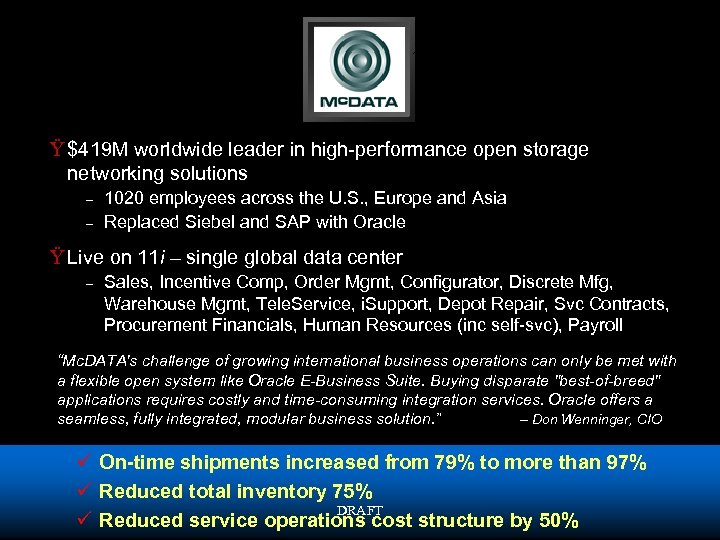

Ÿ $419 M worldwide leader in high-performance open storage networking solutions – – 1020 employees across the U. S. , Europe and Asia Replaced Siebel and SAP with Oracle Ÿ Live on 11 i – single global data center – Sales, Incentive Comp, Order Mgmt, Configurator, Discrete Mfg, Warehouse Mgmt, Tele. Service, i. Support, Depot Repair, Svc Contracts, Procurement Financials, Human Resources (inc self-svc), Payroll “Mc. DATA's challenge of growing international business operations can only be met with a flexible open system like Oracle E-Business Suite. Buying disparate "best-of-breed" applications requires costly and time-consuming integration services. Oracle offers a seamless, fully integrated, modular business solution. ” – Don Wenninger, CIO ü On-time shipments increased from 79% to more than 97% ü Reduced total inventory 75% DRAFT ü Reduced service operations cost structure by 50% </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="Ÿ Leading provider of standards-based IP communications solutions – Alcatel e-Business Networking Division is" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-61.jpg" alt="Ÿ Leading provider of standards-based IP communications solutions – Alcatel e-Business Networking Division is" />

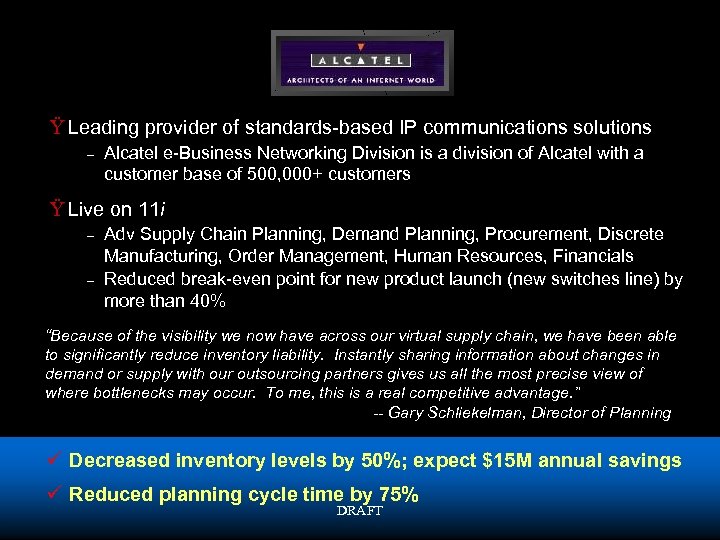

Ÿ Leading provider of standards-based IP communications solutions – Alcatel e-Business Networking Division is a division of Alcatel with a customer base of 500, 000+ customers Ÿ Live on 11 i – – Adv Supply Chain Planning, Demand Planning, Procurement, Discrete Manufacturing, Order Management, Human Resources, Financials Reduced break-even point for new product launch (new switches line) by more than 40% “Because of the visibility we now have across our virtual supply chain, we have been able to significantly reduce inventory liability. Instantly sharing information about changes in demand or supply with our outsourcing partners gives us all the most precise view of where bottlenecks may occur. To me, this is a real competitive advantage. ” -- Gary Schliekelman, Director of Planning ü Decreased inventory levels by 50%; expect $15 M annual savings ü Reduced planning cycle time by 75% DRAFT </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="Oracle Complex Equipment Solutions Establish and Sustain Profitable Innovation Enable Lean, Agile Supply Networks" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-62.jpg" alt="Oracle Complex Equipment Solutions Establish and Sustain Profitable Innovation Enable Lean, Agile Supply Networks" />

Oracle Complex Equipment Solutions Establish and Sustain Profitable Innovation Enable Lean, Agile Supply Networks Manage and Grow a Profitable Service Business Command Control Outsourced Operations </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="Information Age Applications " src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-63.jpg" alt="Information Age Applications " />

Information Age Applications </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="Appendix: Rosetta. Net Offering " src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-64.jpg" alt="Appendix: Rosetta. Net Offering " />

Appendix: Rosetta. Net Offering </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="Current Integration Shortcomings Latent, Linear Information Flow Sub Assy Fab Comp Mfg EMS Comp" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-65.jpg" alt="Current Integration Shortcomings Latent, Linear Information Flow Sub Assy Fab Comp Mfg EMS Comp" />

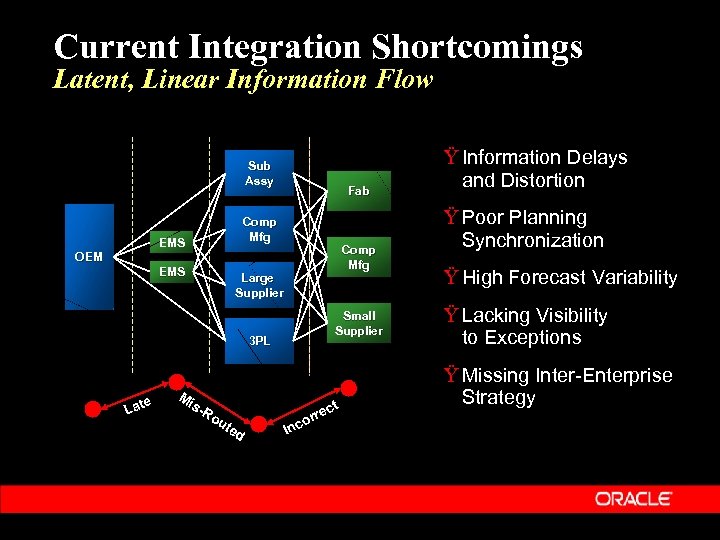

Current Integration Shortcomings Latent, Linear Information Flow Sub Assy Fab Comp Mfg EMS Comp Mfg OEM EMS Large Supplier 3 PL e Lat Mi s-R ou ted Small Supplier ct rre o Inc Ÿ Information Delays and Distortion Ÿ Poor Planning Synchronization Ÿ High Forecast Variability Ÿ Lacking Visibility to Exceptions Ÿ Missing Inter-Enterprise Strategy </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="Rosetta. Net At-a-Glance Developed by High Tech for Fast-Paced Business Ÿ Agreed-Upon, Processes for" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-66.jpg" alt="Rosetta. Net At-a-Glance Developed by High Tech for Fast-Paced Business Ÿ Agreed-Upon, Processes for" />

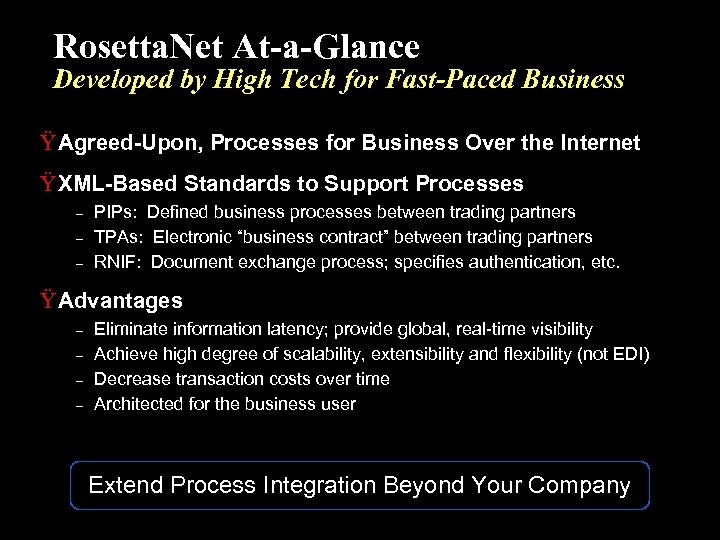

Rosetta. Net At-a-Glance Developed by High Tech for Fast-Paced Business Ÿ Agreed-Upon, Processes for Business Over the Internet Ÿ XML-Based Standards to Support Processes – – – PIPs: Defined business processes between trading partners TPAs: Electronic “business contract” between trading partners RNIF: Document exchange process; specifies authentication, etc. Ÿ Advantages – – Eliminate information latency; provide global, real-time visibility Achieve high degree of scalability, extensibility and flexibility (not EDI) Decrease transaction costs over time Architected for the business user Extend Process Integration Beyond Your Company </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="Oracle’s Rosetta. Net Solution Your Company Customers Business Process Management Real Time Trading Partner" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-67.jpg" alt="Oracle’s Rosetta. Net Solution Your Company Customers Business Process Management Real Time Trading Partner" />

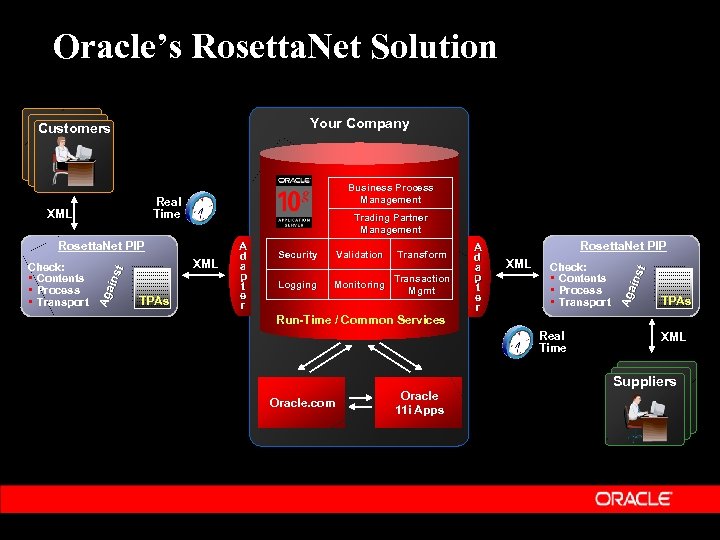

Oracle’s Rosetta. Net Solution Your Company Customers Business Process Management Real Time Trading Partner Management Check: • Contents • Process • Transport Ag ain st Rosetta. Net PIP XML TPAs A d a p t e r Security Validation Transform Logging Transaction Monitoring Mgmt A d a p t e r Rosetta. Net PIP XML Check: • Contents • Process • Transport Ag ain st XML TPAs Run-Time / Common Services Real Time Oracle. com Oracle 11 i Apps XML Suppliers </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="Oracle Trading Partner Solution Adaptive Infrastructure for Dynamic Businesses • Seamless Connectivity Between Public" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-68.jpg" alt="Oracle Trading Partner Solution Adaptive Infrastructure for Dynamic Businesses • Seamless Connectivity Between Public" />

Oracle Trading Partner Solution Adaptive Infrastructure for Dynamic Businesses • Seamless Connectivity Between Public & Private Processes – – – Private processes trigger public processes Pre-built mappings for in and outbound process integration Support for existing IT infrastructure • Rapidly Achieve Critical Mass with Trading Partners – – Empower business users to initiate and manage relationships Leverage same PIP for multiple partners Integrate to legacy / 3 rd party systems via adapters Small-to-medium enterprise focus; self-service and affordability </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="Oracle Trading Partner Solution Complete on Integrated Technology Stack Ÿ Integrated tools for easy" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-69.jpg" alt="Oracle Trading Partner Solution Complete on Integrated Technology Stack Ÿ Integrated tools for easy" />

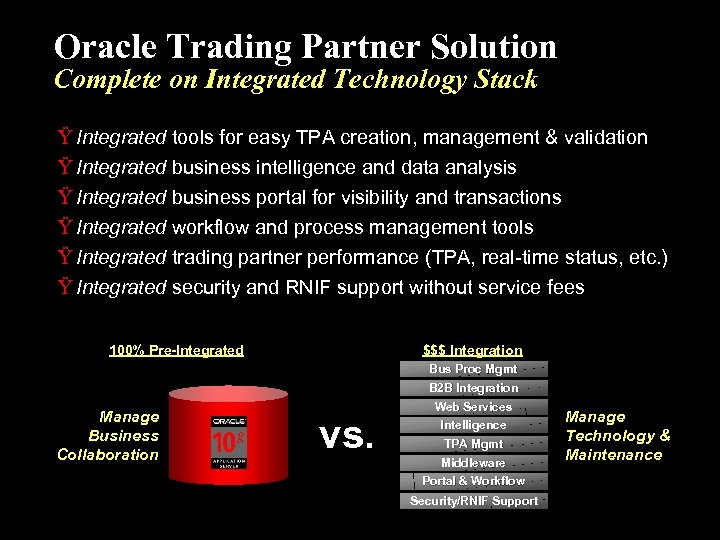

Oracle Trading Partner Solution Complete on Integrated Technology Stack Ÿ Integrated tools for easy TPA creation, management & validation Ÿ Integrated business intelligence and data analysis Ÿ Integrated business portal for visibility and transactions Ÿ Integrated workflow and process management tools Ÿ Integrated trading partner performance (TPA, real-time status, etc. ) Ÿ Integrated security and RNIF support without service fees 100% Pre-Integrated $$$ Integration Bus Proc Mgmt B 2 B Integration Manage Business Collaboration vs. Web Services Intelligence TPA Mgmt Middleware Portal & Workflow Security/RNIF Support Manage Technology & Maintenance </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="Sample Product Info Flow 2 A 12 PIP Capability: Supplier (OEM) Buyer (Customer) Workflow" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-70.jpg" alt="Sample Product Info Flow 2 A 12 PIP Capability: Supplier (OEM) Buyer (Customer) Workflow" />

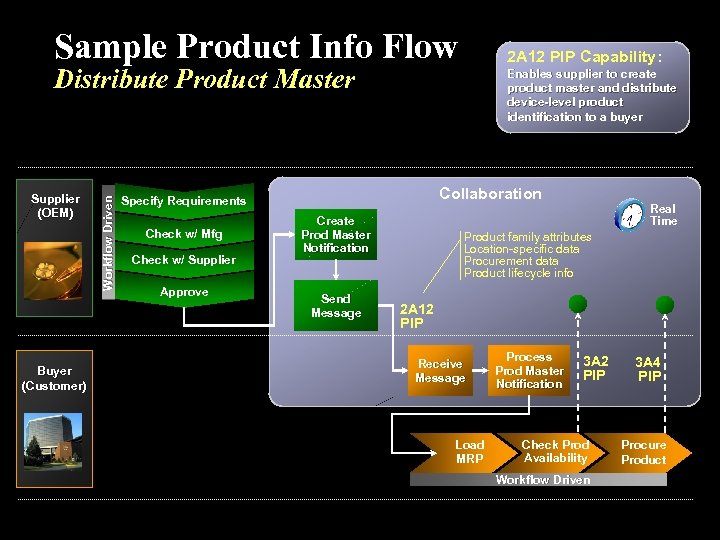

Sample Product Info Flow 2 A 12 PIP Capability: Supplier (OEM) Buyer (Customer) Workflow Driven Distribute Product Master Enables supplier to create product master and distribute device-level product identification to a buyer Collaboration Specify Requirements Check w/ Mfg Check w/ Supplier Approve Create Prod Master Notification Send Message Real Time Product family attributes Location-specific data Procurement data Product lifecycle info 2 A 12 PIP Receive Message Load MRP Process Prod Master Notification 3 A 2 PIP Check Prod Availability Workflow Driven 3 A 4 PIP Procure Product </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="Sample Planning Flow 4 Ax PIP Capability: Buyer (OEM) Workflow Driven Collaborative Forecasting Check" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-71.jpg" alt="Sample Planning Flow 4 Ax PIP Capability: Buyer (OEM) Workflow Driven Collaborative Forecasting Check" />

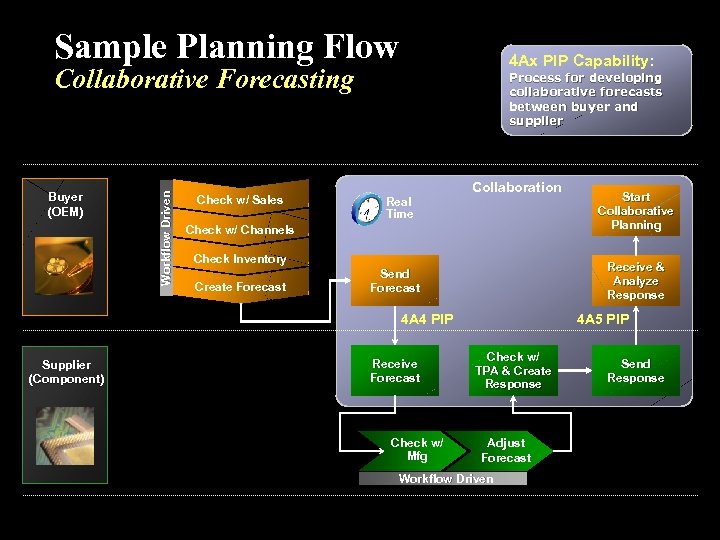

Sample Planning Flow 4 Ax PIP Capability: Buyer (OEM) Workflow Driven Collaborative Forecasting Check w/ Sales Process for developing collaborative forecasts between buyer and supplier Real Time Collaboration Check w/ Channels Check Inventory Create Forecast Receive & Analyze Response Send Forecast 4 A 4 PIP Supplier (Component) Receive Forecast Check w/ Mfg Start Collaborative Planning 4 A 5 PIP Check w/ TPA & Create Response Adjust Forecast Workflow Driven Send Response </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="Sample Manufacturing Flow Work In Process (WIP) Reporting 7 Bx PIP Capability: Supplier (Component)" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-72.jpg" alt="Sample Manufacturing Flow Work In Process (WIP) Reporting 7 Bx PIP Capability: Supplier (Component)" />

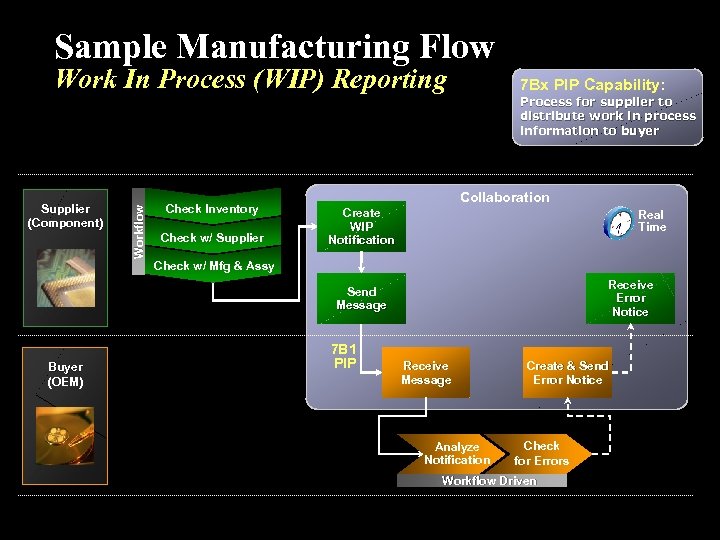

Sample Manufacturing Flow Work In Process (WIP) Reporting 7 Bx PIP Capability: Supplier (Component) Workflow Process for supplier to distribute work in process information to buyer Check Inventory Check w/ Supplier Collaboration Create WIP Notification Real Time Check w/ Mfg & Assy Receive Error Notice Send Message Buyer (OEM) 7 B 1 PIP Receive Message Analyze Notification Create & Send Error Notice Check for Errors Workflow Driven </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="" src="" alt="" />

</p>

</div>

</div>

<div id="inputform">

<script>$("#inputform").load("https://present5.com/wp-content/plugins/report-content/inc/report-form-aj.php");

</script>

</div>

</p>

<!--end entry-content-->

</div>

</article><!-- .post -->

</section><!-- #content -->

<div class="three columns">

<div class="widget-entry">

</div>

</div>

</div>

</div>

<!-- #content-wrapper -->

<footer id="footer" style="padding: 5px 0 5px;">

<div class="container">

<div class="columns twelve">

<!--noindex-->

<!--LiveInternet counter--><script type="text/javascript"><!--

document.write("<img src='//counter.yadro.ru/hit?t26.10;r"+

escape(document.referrer)+((typeof(screen)=="undefined")?"":

";s"+screen.width+"*"+screen.height+"*"+(screen.colorDepth?

screen.colorDepth:screen.pixelDepth))+";u"+escape(document.URL)+

";"+Math.random()+

"' alt='' title='"+" ' "+

"border='0' width='1' height='1'><\/a>")

//--></script><!--/LiveInternet-->

<a href="https://slidetodoc.com/" alt="Наш международный проект SlideToDoc.com!" target="_blank"><img src="https://present5.com/SlideToDoc.png"></a> <script>

$(window).load(function() {

var owl = document.getElementsByClassName('owl-carousel owl-theme owl-loaded owl-drag')[0];

document.getElementById("owlheader").insertBefore(owl, null);

$('#owlheader').css('display', 'inline-block');

});

</script>

<script type="text/javascript">

var yaParams = {'typepage': '1000_top_300k',

'author': '1000_top_300k'

};

</script>

<!-- Yandex.Metrika counter --> <script type="text/javascript" > (function(m,e,t,r,i,k,a){m[i]=m[i]||function(){(m[i].a=m[i].a||[]).push(arguments)}; m[i].l=1*new Date(); for (var j = 0; j < document.scripts.length; j++) {if (document.scripts[j].src === r) { return; }} k=e.createElement(t),a=e.getElementsByTagName(t)[0],k.async=1,k.src=r,a.parentNode.insertBefore(k,a)}) (window, document, "script", "https://mc.yandex.ru/metrika/tag.js", "ym"); ym(32395810, "init", { clickmap:true, trackLinks:true, accurateTrackBounce:true, webvisor:true }); </script> <noscript><div><img src="https://mc.yandex.ru/watch/32395810" style="position:absolute; left:-9999px;" alt="" /></div></noscript> <!-- /Yandex.Metrika counter -->

<!--/noindex-->

<nav id="top-nav">

<ul id="menu-top" class="top-menu clearfix">

</ul> </nav>

</div>

</div><!--.container-->

</footer>

<script type='text/javascript'>

/* <![CDATA[ */

var wpcf7 = {"apiSettings":{"root":"https:\/\/present5.com\/wp-json\/contact-form-7\/v1","namespace":"contact-form-7\/v1"}};

/* ]]> */

</script>

<script type='text/javascript' src='https://present5.com/wp-content/plugins/contact-form-7/includes/js/scripts.js?ver=5.1.4'></script>

<script type='text/javascript' src='https://present5.com/wp-content/themes/sampression-lite/lib/js/jquery.shuffle.js?ver=4.9.26'></script>

<script type='text/javascript' src='https://present5.com/wp-content/themes/sampression-lite/lib/js/scripts.js?ver=1.13'></script>

<script type='text/javascript' src='https://present5.com/wp-content/themes/sampression-lite/lib/js/shuffle.js?ver=4.9.26'></script>

<!--[if lt IE 9]>

<script type='text/javascript' src='https://present5.com/wp-content/themes/sampression-lite/lib/js/selectivizr.js?ver=1.0.2'></script>

<![endif]-->

<script type='text/javascript' src='https://present5.com/wp-content/themes/sampression-lite/lib/js/notify.js?ver=1770463528'></script>

<script type='text/javascript'>

/* <![CDATA[ */

var my_ajax_object = {"ajax_url":"https:\/\/present5.com\/wp-admin\/admin-ajax.php","nonce":"7a6d1b761a"};

/* ]]> */

</script>

<script type='text/javascript' src='https://present5.com/wp-content/themes/sampression-lite/lib/js/filer.js?ver=1770463528'></script>

</body>

</html>

Oracle Industry Solutions Complex Equipment Manufacturing Information Age Applications </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="High Technology Segments Complex Equipment Semiconductor Ÿ Products – Semicon fab equipment, servers, test" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-2.jpg" alt="High Technology Segments Complex Equipment Semiconductor Ÿ Products – Semicon fab equipment, servers, test" />

High Technology Segments Complex Equipment Semiconductor Ÿ Products – Semicon fab equipment, servers, test & measurement, etc. Ÿ Products – Processors, DRAM, embedded controllers, etc. Ÿ Forecast-driven suppliers feed inhouse/EMS CTO final build & assy Ÿ High cost of fabs pushing industry towards fabless model Ÿ Products sold direct to businesses Ÿ Products sold on volume contract High Technology Contract Manufacturing Consumer Electronics Ÿ Services – Outsourced design, test, manufacturing/assembly & logistics Ÿ Products – PCs, cell phones, PDAs, stereo equipment, etc. Ÿ B 2 B supply chain collaboration and event synchronization Ÿ Multi-channel demand feeds dominant outsourced mfg model Ÿ Products shipped to OEM partners or drop-shipped to end customer Ÿ Products sold via retailers & online </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="The Complex Equipment Value Chain Silicon Source Component Mfg Tiered Supply Base Contract Mfg" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-3.jpg" alt="The Complex Equipment Value Chain Silicon Source Component Mfg Tiered Supply Base Contract Mfg" />

The Complex Equipment Value Chain Silicon Source Component Mfg Tiered Supply Base Contract Mfg (EMS) OEMs Semiconductor Fabrication Direct Sales & Service Sub Assy Mfg OEMs, Sales & Distribution Customer </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="Complex Equipment Industry Drivers Design Complexity Supply Variability • How can I reduce design" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-4.jpg" alt="Complex Equipment Industry Drivers Design Complexity Supply Variability • How can I reduce design" />

Complex Equipment Industry Drivers Design Complexity Supply Variability • How can I reduce design cycle time, and development of customer-specific products? • What can be done when component lead times exceed finished product lead times? • How can existing designs be leveraged to reduce design complexity? • How can I fully leverage a global manufacturing and supply base? Tiered Supply Base OEMs, Sales & Distribution Configuration Management Service Delivery • How can I better manage configuration changes that occur once manufacturing has begun? • How can I transform my service operations to a profitable business? • Is there a better way to increase the accuracy of configured orders? • How can I ensure high quality services performed by 3 rd parties? </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="A Need for Change Leading Business Trends • Simultaneous optimization of supply & build" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-5.jpg" alt="A Need for Change Leading Business Trends • Simultaneous optimization of supply & build" />

A Need for Change Leading Business Trends • Simultaneous optimization of supply & build strategies • Outsourcing with complete visibility across multiple tiers • Integration of configure-to-order processes and service • Emergence of customer service as a strategic differentiator • Lean initiatives to reduce cycle time and waste </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="A Need for Change Extend Lean Initiatives Across the Enterprise Sales & Mktg Sales" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-6.jpg" alt="A Need for Change Extend Lean Initiatives Across the Enterprise Sales & Mktg Sales" />

A Need for Change Extend Lean Initiatives Across the Enterprise Sales & Mktg Sales & Operational Planning Finance Common Areas of Waste Engineering • • Poor Quality & Excess WIP High Material & Supply Costs Lengthy ECO Approval Process Error Prone Order Processing Supply Management • • Incorrect Resource Dispatching Conflicting Demand Signals Duplicate & Erroneous Data Isolated Departmental Systems Production Information Technology Continually Improve Quality, Cost and Cycle Time Service </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="Oracle in High Technology Did You Know? ŸAll of the top 25 Electronic OEMs" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-7.jpg" alt="Oracle in High Technology Did You Know? ŸAll of the top 25 Electronic OEMs" />

Oracle in High Technology Did You Know? ŸAll of the top 25 Electronic OEMs run Oracle applications Ÿ 47 of the top 50 Electronic OEMs run Oracle applications Ÿ 7 of the top 10 Semiconductor companies run Oracle apps Ÿ 5 of the top 10 Fabless Semiconductor companies run Oracle applications </p>

</div>

<div style="width: auto;" class="description columns twelve"><p><img class="imgdescription" title="What Analysts are Saying… “Oracle is well positioned to drive innovation to the high" src="https://present5.com/presentation/11df9464798cab20d3930ace90d83485/image-8.jpg" alt="What Analysts are Saying… “Oracle is well positioned to drive innovation to the high" />

What Analysts are Saying… “Oracle is well positioned to drive innovation to the high tech industry. The company’s belief that it needs to maintain leadership across the high tech sector in order to stay in touch with innovative manufacturing developments for the rest of its business helps ensure Oracle’s commitment to this industry. ” -- Meredith Whalen, Vice President, US Vertical Industry Research “Firms in high tech manufacturing, where customer service spans both front- and back-office processes, should consider Oracle, especially if they have already made investments in other Oracle modules, like financials. Oracle applications are also a good fit for midsized companies looking to implement a single vendor apps suite and for firms thinking about outsourcing. ” -- Eric Schmitt, Senior Analyst </p>

</div>