564326148a54b305a89a66c328181f58.ppt

- Количество слайдов: 21

Opportunities & limits to recycle critical metals for clean energies Christian Hagelüken, Mark Caffarey - Umicore Trans-Atlantic Workshop on Rare Earth Elements and Other Critical Materials for a Clean Energy Future MIT Boston, 3. Dec. 2010

Opportunities & limits to recycle critical metals for clean energies Christian Hagelüken, Mark Caffarey - Umicore Trans-Atlantic Workshop on Rare Earth Elements and Other Critical Materials for a Clean Energy Future MIT Boston, 3. Dec. 2010

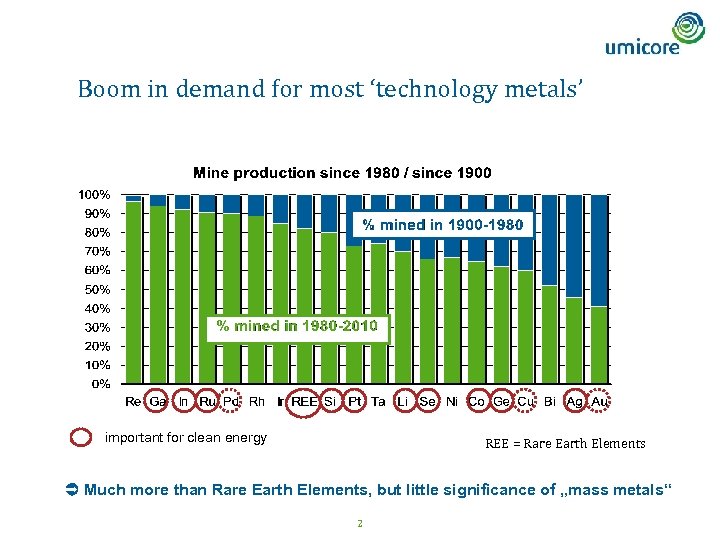

Boom in demand for most ‘technology metals’ % mined in 1900 -1980 % mined in 1980 -2010 important for clean energy REE = Rare Earth Elements Much more than Rare Earth Elements, but little significance of „mass metals“ 2

Boom in demand for most ‘technology metals’ % mined in 1900 -1980 % mined in 1980 -2010 important for clean energy REE = Rare Earth Elements Much more than Rare Earth Elements, but little significance of „mass metals“ 2

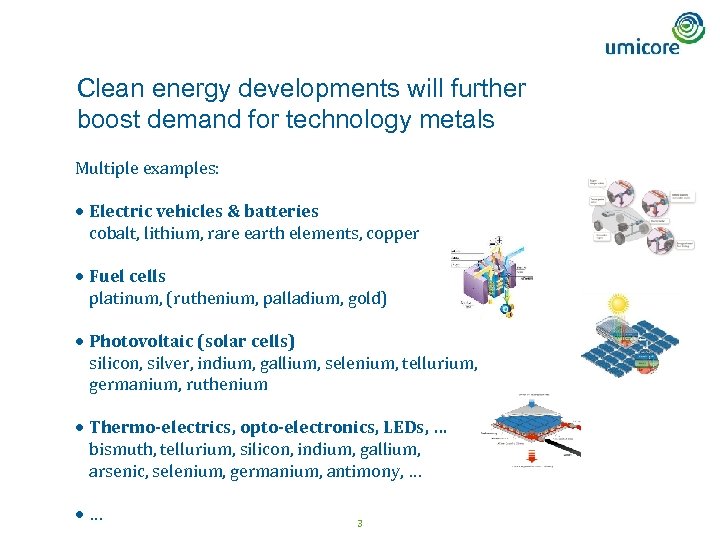

Clean energy developments will further boost demand for technology metals Multiple examples: · Electric vehicles & batteries cobalt, lithium, rare earth elements, copper · Fuel cells platinum, (ruthenium, palladium, gold) · Photovoltaic (solar cells) silicon, silver, indium, gallium, selenium, tellurium, germanium, ruthenium · Thermo-electrics, opto-electronics, LEDs, … bismuth, tellurium, silicon, indium, gallium, arsenic, selenium, germanium, antimony, … ·… 3

Clean energy developments will further boost demand for technology metals Multiple examples: · Electric vehicles & batteries cobalt, lithium, rare earth elements, copper · Fuel cells platinum, (ruthenium, palladium, gold) · Photovoltaic (solar cells) silicon, silver, indium, gallium, selenium, tellurium, germanium, ruthenium · Thermo-electrics, opto-electronics, LEDs, … bismuth, tellurium, silicon, indium, gallium, arsenic, selenium, germanium, antimony, … ·… 3

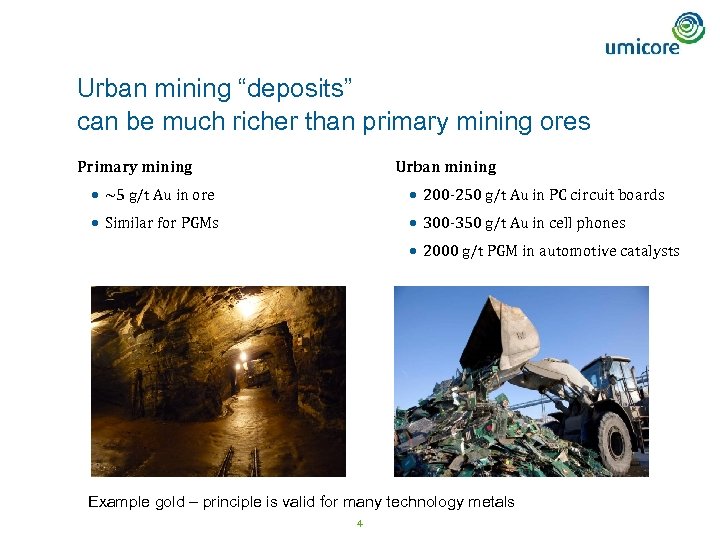

Urban mining “deposits” can be much richer than primary mining ores Primary mining Urban mining · ~5 g/t Au in ore · 200 -250 g/t Au in PC circuit boards · Similar for PGMs · 300 -350 g/t Au in cell phones · 2000 g/t PGM in automotive catalysts Example gold – principle is valid for many technology metals 4

Urban mining “deposits” can be much richer than primary mining ores Primary mining Urban mining · ~5 g/t Au in ore · 200 -250 g/t Au in PC circuit boards · Similar for PGMs · 300 -350 g/t Au in cell phones · 2000 g/t PGM in automotive catalysts Example gold – principle is valid for many technology metals 4

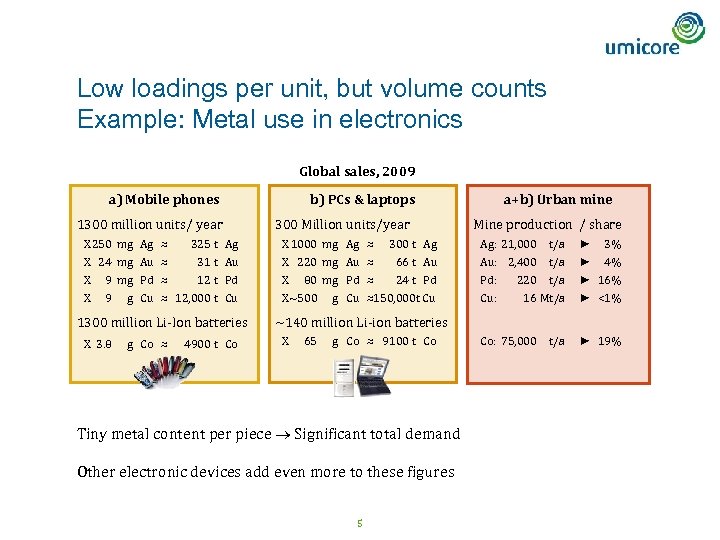

Low loadings per unit, but volume counts Example: Metal use in electronics Global sales, 2009 a) Mobile phones b) PCs & laptops 1300 million units/ year X 250 mg Ag ≈ 325 t X 24 mg Au ≈ 31 t X 9 mg Pd ≈ 12 t X 9 g Cu ≈ 12, 000 t 300 Million units/year Ag Au Pd Cu 1300 million Li-Ion batteries X 3. 8 g Co ≈ 4900 t Co X 1000 mg Ag ≈ 300 t Ag X 220 mg Au ≈ 66 t Au X 80 mg Pd ≈ 24 t Pd X~500 g Cu ≈150, 000 t Cu a+b) Urban mine Mine production / share Ag: 21, 000 t/a Au: 2, 400 t/a Pd: 220 t/a Cu: 16 Mt/a ► 3% ► 4% ► 16% ► <1% Co: 75, 000 ► 19% ~140 million Li-ion batteries X 65 g Co ≈ 9100 t Co Tiny metal content per piece Significant total demand Other electronic devices add even more to these figures 5 t/a

Low loadings per unit, but volume counts Example: Metal use in electronics Global sales, 2009 a) Mobile phones b) PCs & laptops 1300 million units/ year X 250 mg Ag ≈ 325 t X 24 mg Au ≈ 31 t X 9 mg Pd ≈ 12 t X 9 g Cu ≈ 12, 000 t 300 Million units/year Ag Au Pd Cu 1300 million Li-Ion batteries X 3. 8 g Co ≈ 4900 t Co X 1000 mg Ag ≈ 300 t Ag X 220 mg Au ≈ 66 t Au X 80 mg Pd ≈ 24 t Pd X~500 g Cu ≈150, 000 t Cu a+b) Urban mine Mine production / share Ag: 21, 000 t/a Au: 2, 400 t/a Pd: 220 t/a Cu: 16 Mt/a ► 3% ► 4% ► 16% ► <1% Co: 75, 000 ► 19% ~140 million Li-ion batteries X 65 g Co ≈ 9100 t Co Tiny metal content per piece Significant total demand Other electronic devices add even more to these figures 5 t/a

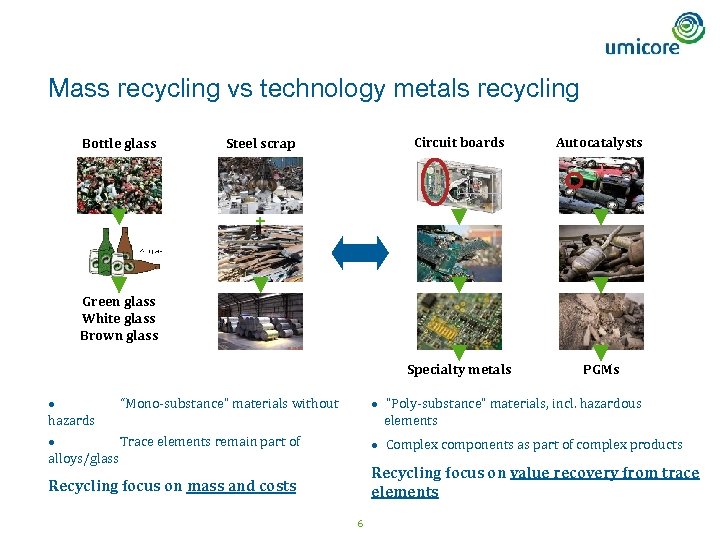

Mass recycling vs technology metals recycling Circuit boards Steel scrap Autocatalysts Specialty metals Bottle glass PGMs + Green glass White glass Brown glass · “Mono-substance” materials without hazards · Trace elements remain part of alloys/glass · ”Poly-substance” materials, incl. hazardous elements · Complex components as part of complex products Recycling focus on value recovery from trace elements Recycling focus on mass and costs 6

Mass recycling vs technology metals recycling Circuit boards Steel scrap Autocatalysts Specialty metals Bottle glass PGMs + Green glass White glass Brown glass · “Mono-substance” materials without hazards · Trace elements remain part of alloys/glass · ”Poly-substance” materials, incl. hazardous elements · Complex components as part of complex products Recycling focus on value recovery from trace elements Recycling focus on mass and costs 6

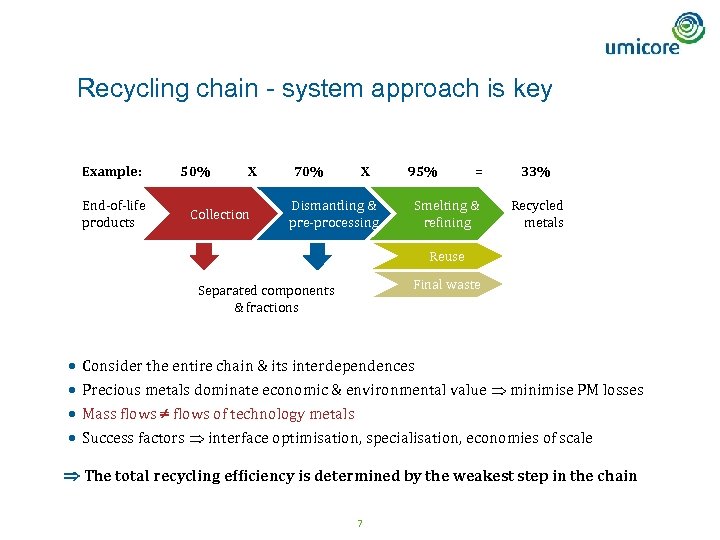

Recycling chain - system approach is key Example: End-of-life products 50% X Collection 70% X Dismantling & pre-processing 95% = Smelting & refining 33% Recycled metals Reuse Final waste Separated components & fractions · · Consider the entire chain & its interdependences Precious metals dominate economic & environmental value minimise PM losses Mass flows of technology metals Success factors interface optimisation, specialisation, economies of scale The total recycling efficiency is determined by the weakest step in the chain 7

Recycling chain - system approach is key Example: End-of-life products 50% X Collection 70% X Dismantling & pre-processing 95% = Smelting & refining 33% Recycled metals Reuse Final waste Separated components & fractions · · Consider the entire chain & its interdependences Precious metals dominate economic & environmental value minimise PM losses Mass flows of technology metals Success factors interface optimisation, specialisation, economies of scale The total recycling efficiency is determined by the weakest step in the chain 7

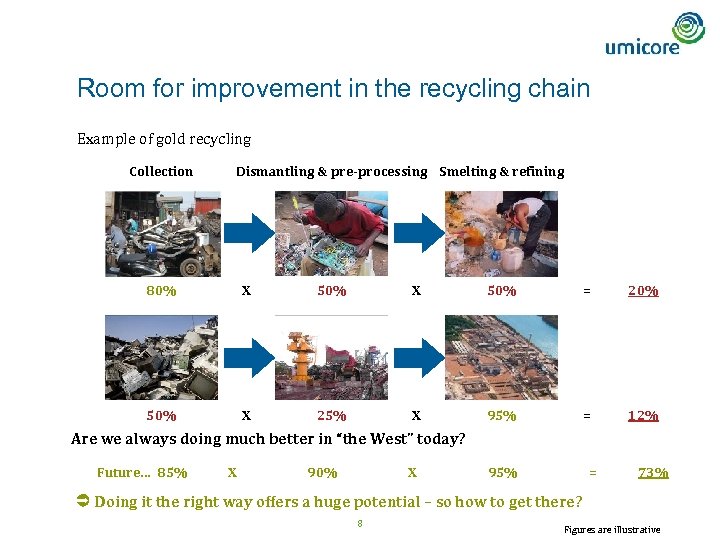

Room for improvement in the recycling chain Example of gold recycling Collection Dismantling & pre-processing Smelting & refining 80% X 50% = 20% 50% X 25% X 95% = 12% Are we always doing much better in “the West” today? Future… 85% X 90% X 95% = 73% Doing it the right way offers a huge potential – so how to get there? 8 Figures are illustrative

Room for improvement in the recycling chain Example of gold recycling Collection Dismantling & pre-processing Smelting & refining 80% X 50% = 20% 50% X 25% X 95% = 12% Are we always doing much better in “the West” today? Future… 85% X 90% X 95% = 73% Doing it the right way offers a huge potential – so how to get there? 8 Figures are illustrative

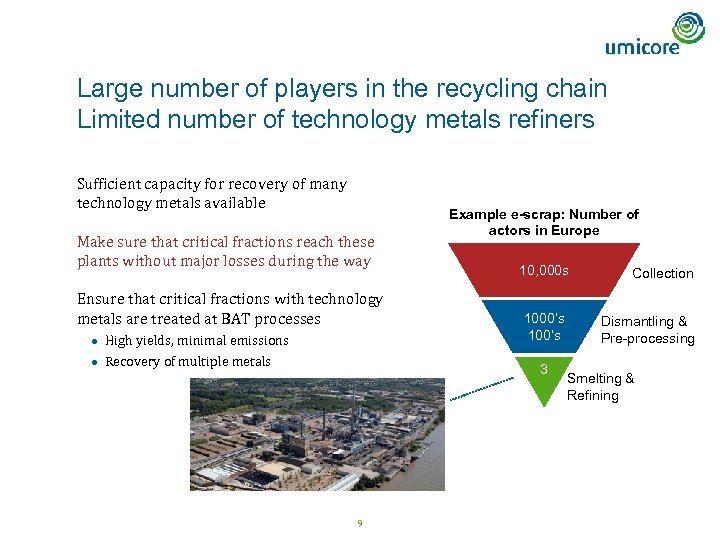

Large number of players in the recycling chain Limited number of technology metals refiners Sufficient capacity for recovery of many technology metals available Make sure that critical fractions reach these plants without major losses during the way Ensure that critical fractions with technology metals are treated at BAT processes · High yields, minimal emissions · Recovery of multiple metals Example e-scrap: Number of actors in Europe 10, 000 s 1000’s 100’s 3 9 Collection Dismantling & Pre-processing Smelting & Refining

Large number of players in the recycling chain Limited number of technology metals refiners Sufficient capacity for recovery of many technology metals available Make sure that critical fractions reach these plants without major losses during the way Ensure that critical fractions with technology metals are treated at BAT processes · High yields, minimal emissions · Recovery of multiple metals Example e-scrap: Number of actors in Europe 10, 000 s 1000’s 100’s 3 9 Collection Dismantling & Pre-processing Smelting & Refining

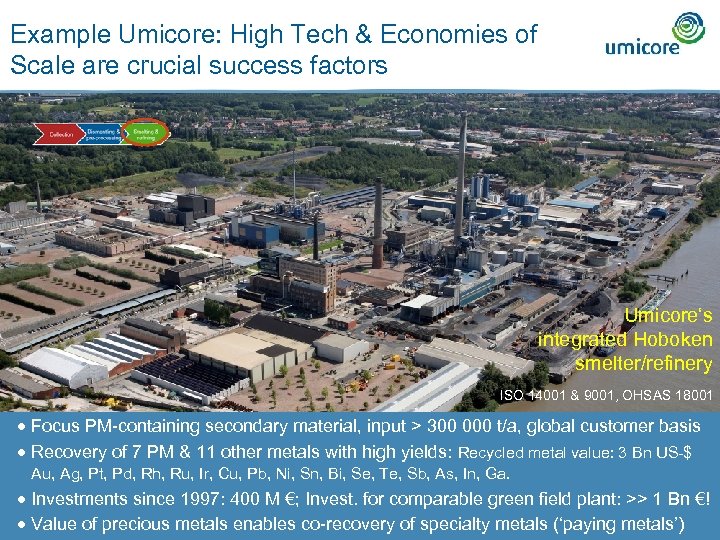

Example Umicore: High Tech & Economies of Scale are crucial success factors Umicore‘s integrated Hoboken smelter/refinery ISO 14001 & 9001, OHSAS 18001 · Focus PM-containing secondary material, input > 300 000 t/a, global customer basis · Recovery of 7 PM & 11 other metals with high yields: Recycled metal value: 3 Bn US-$ Au, Ag, Pt, Pd, Rh, Ru, Ir, Cu, Pb, Ni, Sn, Bi, Se, Te, Sb, As, In, Ga. · Investments since 1997: 400 M €; Invest. for comparable green field plant: >> 1 Bn €! · Value of precious metals enables co-recovery of specialty metals (‘paying metals’)

Example Umicore: High Tech & Economies of Scale are crucial success factors Umicore‘s integrated Hoboken smelter/refinery ISO 14001 & 9001, OHSAS 18001 · Focus PM-containing secondary material, input > 300 000 t/a, global customer basis · Recovery of 7 PM & 11 other metals with high yields: Recycled metal value: 3 Bn US-$ Au, Ag, Pt, Pd, Rh, Ru, Ir, Cu, Pb, Ni, Sn, Bi, Se, Te, Sb, As, In, Ga. · Investments since 1997: 400 M €; Invest. for comparable green field plant: >> 1 Bn €! · Value of precious metals enables co-recovery of specialty metals (‘paying metals’)

Technology metals recycling is more complex than in the movies Technical accessibility of relevant components · E. g. electronics in modern cars, REE-magnets in electric motors, … · Need for “Design for disassembly”, sorting & “pre-shredder” separation technologies Thermodynamic challenges & difficult metal combinations for “trace elements” · Laws of Nature cannot be broken · E. g. rare earth elements, tantalum, gallium, beryllium in electronics, lithium in batteries · Need for recyclability consideration in development of new material combinations Quality/composition of feed streams need to match with capability of recycling process 11 From: Disney/Pixar www. wall-e. com

Technology metals recycling is more complex than in the movies Technical accessibility of relevant components · E. g. electronics in modern cars, REE-magnets in electric motors, … · Need for “Design for disassembly”, sorting & “pre-shredder” separation technologies Thermodynamic challenges & difficult metal combinations for “trace elements” · Laws of Nature cannot be broken · E. g. rare earth elements, tantalum, gallium, beryllium in electronics, lithium in batteries · Need for recyclability consideration in development of new material combinations Quality/composition of feed streams need to match with capability of recycling process 11 From: Disney/Pixar www. wall-e. com

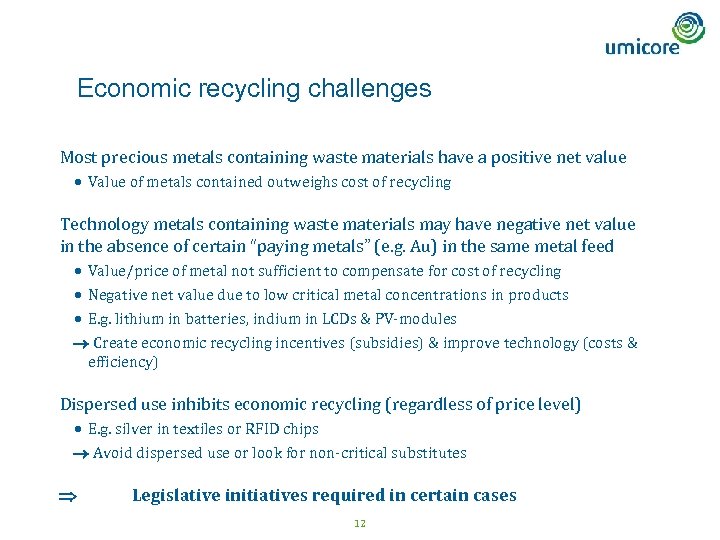

Economic recycling challenges Most precious metals containing waste materials have a positive net value · Value of metals contained outweighs cost of recycling Technology metals containing waste materials may have negative net value in the absence of certain “paying metals” (e. g. Au) in the same metal feed · Value/price of metal not sufficient to compensate for cost of recycling · Negative net value due to low critical metal concentrations in products · E. g. lithium in batteries, indium in LCDs & PV-modules Create economic recycling incentives (subsidies) & improve technology (costs & efficiency) Dispersed use inhibits economic recycling (regardless of price level) · E. g. silver in textiles or RFID chips Avoid dispersed use or look for non-critical substitutes Legislative initiatives required in certain cases 12

Economic recycling challenges Most precious metals containing waste materials have a positive net value · Value of metals contained outweighs cost of recycling Technology metals containing waste materials may have negative net value in the absence of certain “paying metals” (e. g. Au) in the same metal feed · Value/price of metal not sufficient to compensate for cost of recycling · Negative net value due to low critical metal concentrations in products · E. g. lithium in batteries, indium in LCDs & PV-modules Create economic recycling incentives (subsidies) & improve technology (costs & efficiency) Dispersed use inhibits economic recycling (regardless of price level) · E. g. silver in textiles or RFID chips Avoid dispersed use or look for non-critical substitutes Legislative initiatives required in certain cases 12

Main flaws in EU WEEE recycling Poor collection Deviation of collected materials dubious exports backyard treatment ► : 13

Main flaws in EU WEEE recycling Poor collection Deviation of collected materials dubious exports backyard treatment ► : 13

To what extent does current (EU-) legislation help? Legislation helps · Awareness raising, supportive legal framework · Development of take-back infrastructure, collection targets, EU wide reporting · Resource aspect of recycling is on the radar screen now, beyond the traditional waste/environmental aspects Legislation can be improved · Weak enforcement of legislation - Poor monitoring of end-of-life flows - Illegal exports · Collection targets not ambitious enough, collection remains well below potential - Mass based targets do not help for technology metals (“trace elements”) · Neither clear definitions nor reliable supervision of recycling standards exist 14

To what extent does current (EU-) legislation help? Legislation helps · Awareness raising, supportive legal framework · Development of take-back infrastructure, collection targets, EU wide reporting · Resource aspect of recycling is on the radar screen now, beyond the traditional waste/environmental aspects Legislation can be improved · Weak enforcement of legislation - Poor monitoring of end-of-life flows - Illegal exports · Collection targets not ambitious enough, collection remains well below potential - Mass based targets do not help for technology metals (“trace elements”) · Neither clear definitions nor reliable supervision of recycling standards exist 14

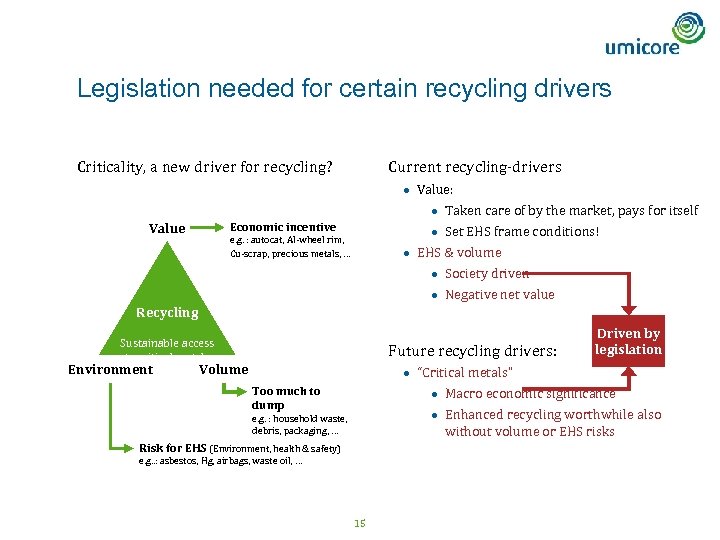

Legislation needed for certain recycling drivers Criticality, a new driver for recycling? Current recycling-drivers · Value: · Taken care of by the market, pays for itself · Set EHS frame conditions! · EHS & volume · Society driven · Negative net value Economic incentive Value e. g. : autocat, Al-wheel rim, Cu-scrap, precious metals, … Recycling Sustainable access to critical metals Environment Future recycling drivers: Volume Driven by legislation · “Critical metals” · Macro economic significance · Enhanced recycling worthwhile also without volume or EHS risks Too much to dump e. g. : household waste, debris, packaging, … Risk for EHS (Environment, health & safety) e. g. . : asbestos, Hg, airbags, waste oil, … 15

Legislation needed for certain recycling drivers Criticality, a new driver for recycling? Current recycling-drivers · Value: · Taken care of by the market, pays for itself · Set EHS frame conditions! · EHS & volume · Society driven · Negative net value Economic incentive Value e. g. : autocat, Al-wheel rim, Cu-scrap, precious metals, … Recycling Sustainable access to critical metals Environment Future recycling drivers: Volume Driven by legislation · “Critical metals” · Macro economic significance · Enhanced recycling worthwhile also without volume or EHS risks Too much to dump e. g. : household waste, debris, packaging, … Risk for EHS (Environment, health & safety) e. g. . : asbestos, Hg, airbags, waste oil, … 15

Next steps: Time for fundamental changes · Attitude: from waste management to resource management · Targets: from focus on mass to focus on quality & critical substances · Practice: from traditional waste business to high-tech recycling · Vision (OEMs): from burden to recycling as opportunity Recycling requires a holistic and interdisciplinary approach Ensure consistency between different policies

Next steps: Time for fundamental changes · Attitude: from waste management to resource management · Targets: from focus on mass to focus on quality & critical substances · Practice: from traditional waste business to high-tech recycling · Vision (OEMs): from burden to recycling as opportunity Recycling requires a holistic and interdisciplinary approach Ensure consistency between different policies

Ready for questions Mark. Caffarey@am. umicore. com, Christian. Hagelueken@eu. umicore. com 17 www. preciousmetals. umicore. com

Ready for questions Mark. Caffarey@am. umicore. com, Christian. Hagelueken@eu. umicore. com 17 www. preciousmetals. umicore. com

Recycling recommendations developed by the RMI critical metals group Undertake policy actions to make recycling of critical raw materials more efficient, in particular by: Ø Mobilising relevant Eo. L products for proper collection instead of stocking, landfill or incineration Ø Improving overall organisation, logistics & efficiency of recycling chains by focussing on interfaces and system approach Ø Preventing illegal exports of relevant Eo. L products & increasing transparency in flows Ø Promoting research on system optimisation & recycling of technically challenging products & substances Source: DEFINING CRITICAL RAW MATERIALS FOR THE EU: A Report from the Raw Materials Supply Group ad hoc working group defining critical raw materials; July 30, 2010 18

Recycling recommendations developed by the RMI critical metals group Undertake policy actions to make recycling of critical raw materials more efficient, in particular by: Ø Mobilising relevant Eo. L products for proper collection instead of stocking, landfill or incineration Ø Improving overall organisation, logistics & efficiency of recycling chains by focussing on interfaces and system approach Ø Preventing illegal exports of relevant Eo. L products & increasing transparency in flows Ø Promoting research on system optimisation & recycling of technically challenging products & substances Source: DEFINING CRITICAL RAW MATERIALS FOR THE EU: A Report from the Raw Materials Supply Group ad hoc working group defining critical raw materials; July 30, 2010 18

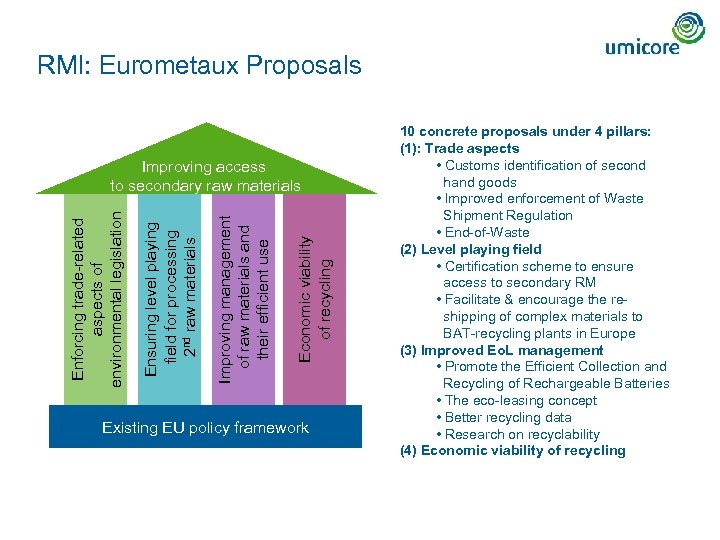

RMI: Eurometaux Proposals Economic viability of recycling Improving management of raw materials and their efficient use Ensuring level playing field for processing 2 nd raw materials Enforcing trade-related aspects of environmental legislation Improving access to secondary raw materials Existing EU policy framework 10 concrete proposals under 4 pillars: (1): Trade aspects • Customs identification of second hand goods • Improved enforcement of Waste Shipment Regulation • End-of-Waste (2) Level playing field • Certification scheme to ensure access to secondary RM • Facilitate & encourage the reshipping of complex materials to BAT-recycling plants in Europe (3) Improved Eo. L management • Promote the Efficient Collection and Recycling of Rechargeable Batteries • The eco-leasing concept • Better recycling data • Research on recyclability (4) Economic viability of recycling

RMI: Eurometaux Proposals Economic viability of recycling Improving management of raw materials and their efficient use Ensuring level playing field for processing 2 nd raw materials Enforcing trade-related aspects of environmental legislation Improving access to secondary raw materials Existing EU policy framework 10 concrete proposals under 4 pillars: (1): Trade aspects • Customs identification of second hand goods • Improved enforcement of Waste Shipment Regulation • End-of-Waste (2) Level playing field • Certification scheme to ensure access to secondary RM • Facilitate & encourage the reshipping of complex materials to BAT-recycling plants in Europe (3) Improved Eo. L management • Promote the Efficient Collection and Recycling of Rechargeable Batteries • The eco-leasing concept • Better recycling data • Research on recyclability (4) Economic viability of recycling

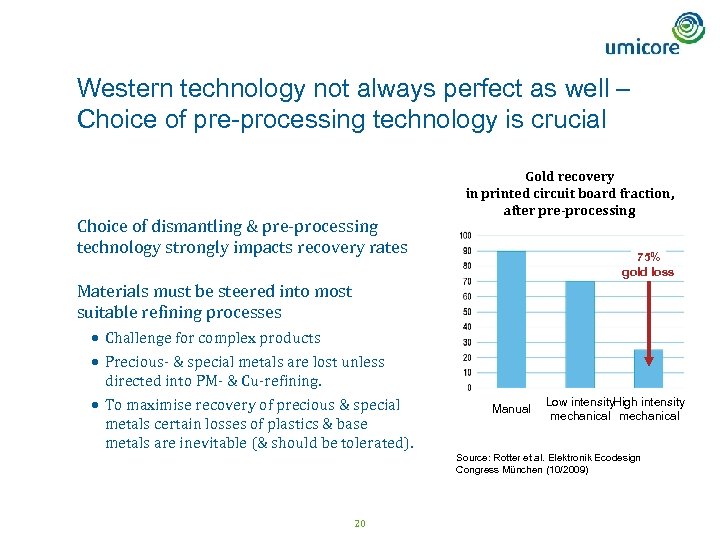

Western technology not always perfect as well – Choice of pre-processing technology is crucial Choice of dismantling & pre-processing technology strongly impacts recovery rates Gold recovery in printed circuit board fraction, after pre-processing 75% gold loss Materials must be steered into most suitable refining processes · Challenge for complex products · Precious- & special metals are lost unless directed into PM- & Cu-refining. · To maximise recovery of precious & special metals certain losses of plastics & base metals are inevitable (& should be tolerated). Manual Low intensity. High intensity mechanical Source: Rotter et al. Elektronik Ecodesign Congress München (10/2009) 20

Western technology not always perfect as well – Choice of pre-processing technology is crucial Choice of dismantling & pre-processing technology strongly impacts recovery rates Gold recovery in printed circuit board fraction, after pre-processing 75% gold loss Materials must be steered into most suitable refining processes · Challenge for complex products · Precious- & special metals are lost unless directed into PM- & Cu-refining. · To maximise recovery of precious & special metals certain losses of plastics & base metals are inevitable (& should be tolerated). Manual Low intensity. High intensity mechanical Source: Rotter et al. Elektronik Ecodesign Congress München (10/2009) 20

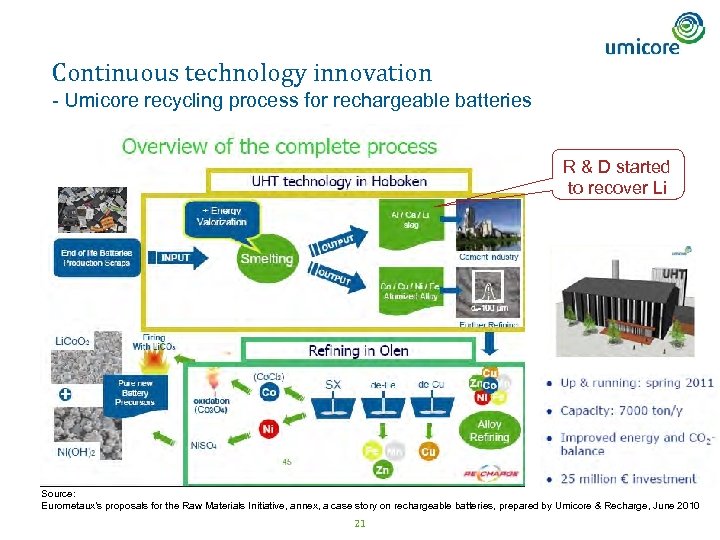

Continuous technology innovation - Umicore recycling process for rechargeable batteries R & D started to recover Li Source: Eurometaux’s proposals for the Raw Materials Initiative, annex, a case story on rechargeable batteries, prepared by Umicore & Recharge, June 2010 21

Continuous technology innovation - Umicore recycling process for rechargeable batteries R & D started to recover Li Source: Eurometaux’s proposals for the Raw Materials Initiative, annex, a case story on rechargeable batteries, prepared by Umicore & Recharge, June 2010 21