08a7274b65a09c34fdec455aa0472eac.ppt

- Количество слайдов: 31

Operations Management Session 4: Kristine Cookies Case

Operations Management Session 4: Kristine Cookies Case

Last Class in Process Analysis Module w What did we learn? w Throughput rate w Capacity n w w w What’s the difference between capacity and throughput rate? Bottleneck resource Utilization rate Throughput time WIP Little’s Law: n Session 4 Throughput Time = (Average) WIP / Throughput Rate Operations Management 2

Last Class in Process Analysis Module w What did we learn? w Throughput rate w Capacity n w w w What’s the difference between capacity and throughput rate? Bottleneck resource Utilization rate Throughput time WIP Little’s Law: n Session 4 Throughput Time = (Average) WIP / Throughput Rate Operations Management 2

Today w Team Presentations w Lecture (Kristen’s cookies and additional comments on capacity management) Session 4 Operations Management 3

Today w Team Presentations w Lecture (Kristen’s cookies and additional comments on capacity management) Session 4 Operations Management 3

Team Presentations Session 4 Operations Management 4

Team Presentations Session 4 Operations Management 4

What is it all about? w Process Characteristics w Capacity of a System n How much can you process in a week/day? w Response Time n Session 4 How quickly can you meet demand? Operations Management 5

What is it all about? w Process Characteristics w Capacity of a System n How much can you process in a week/day? w Response Time n Session 4 How quickly can you meet demand? Operations Management 5

Process Flow w What are the inputs? w What are the outputs? w What are the activities? Session 4 Operations Management 6

Process Flow w What are the inputs? w What are the outputs? w What are the activities? Session 4 Operations Management 6

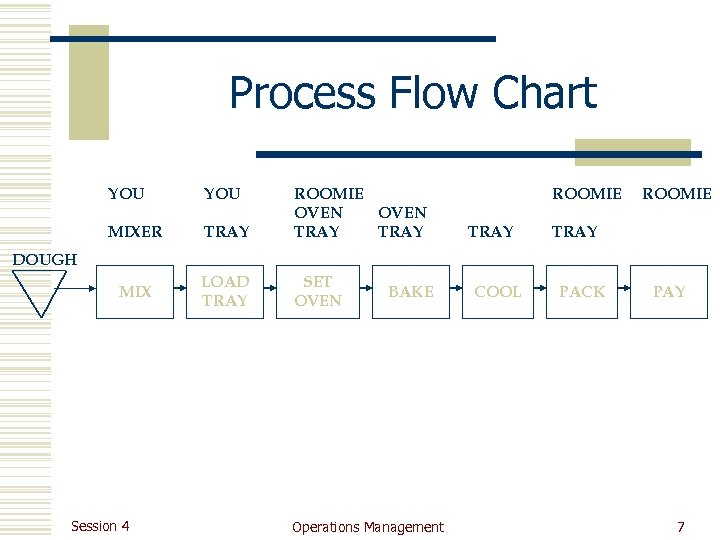

Process Flow Chart YOU MIXER TRAY ROOMIE OVEN TRAY MIX LOAD TRAY SET OVEN ROOMIE TRAY DOUGH Session 4 BAKE Operations Management COOL PACK PAY 7

Process Flow Chart YOU MIXER TRAY ROOMIE OVEN TRAY MIX LOAD TRAY SET OVEN ROOMIE TRAY DOUGH Session 4 BAKE Operations Management COOL PACK PAY 7

Activity 8 12 16 20 24 28 32 Time Resource 4 Operations Management 8 36

Activity 8 12 16 20 24 28 32 Time Resource 4 Operations Management 8 36

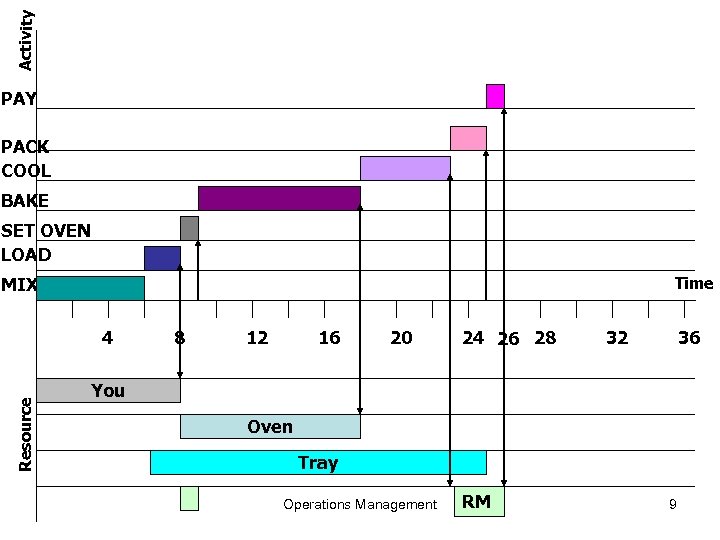

Activity PAY PACK COOL BAKE SET OVEN LOAD MIX Time Resource 4 8 12 16 20 24 26 28 32 36 You Oven Tray Operations Management RM 9

Activity PAY PACK COOL BAKE SET OVEN LOAD MIX Time Resource 4 8 12 16 20 24 26 28 32 36 You Oven Tray Operations Management RM 9

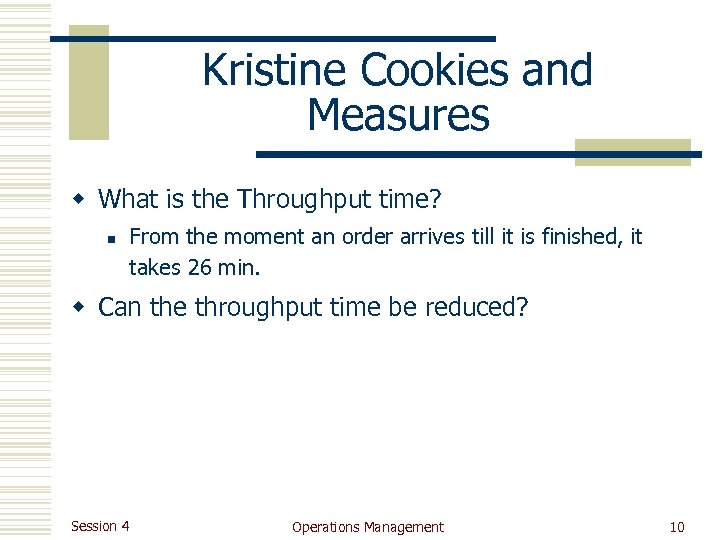

Kristine Cookies and Measures w What is the Throughput time? n From the moment an order arrives till it is finished, it takes 26 min. w Can the throughput time be reduced? Session 4 Operations Management 10

Kristine Cookies and Measures w What is the Throughput time? n From the moment an order arrives till it is finished, it takes 26 min. w Can the throughput time be reduced? Session 4 Operations Management 10

Activity PAY PACK COOL BAKE SET OVEN LOAD MIX Time Resource 4 8 12 16 20 24 26 28 32 36 You Oven Tray Operations Management RM 11

Activity PAY PACK COOL BAKE SET OVEN LOAD MIX Time Resource 4 8 12 16 20 24 26 28 32 36 You Oven Tray Operations Management RM 11

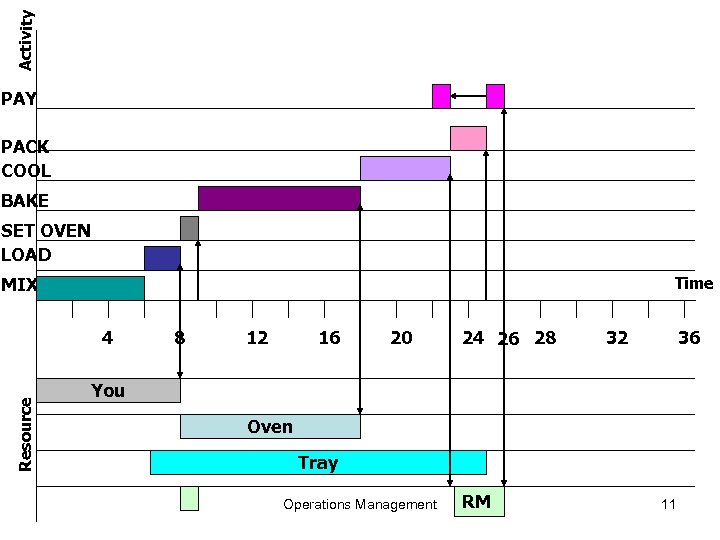

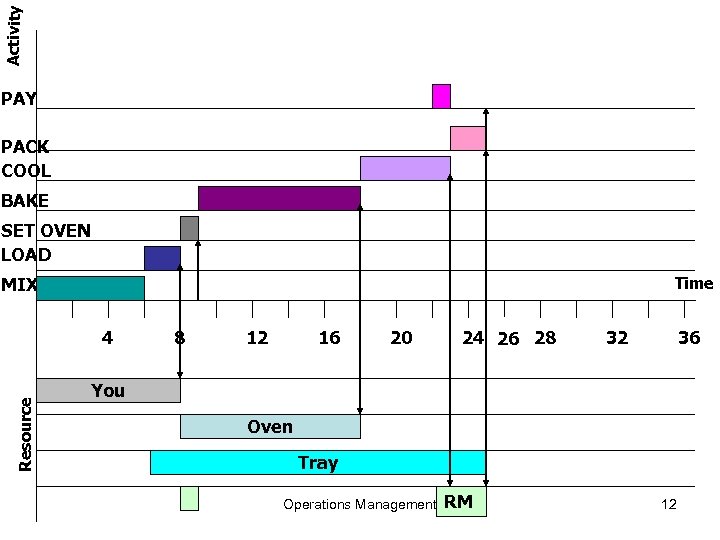

Activity PAY PACK COOL BAKE SET OVEN LOAD MIX Time Resource 4 8 12 16 20 24 26 28 32 36 You Oven Tray Operations Management RM 12

Activity PAY PACK COOL BAKE SET OVEN LOAD MIX Time Resource 4 8 12 16 20 24 26 28 32 36 You Oven Tray Operations Management RM 12

Kristine Cookies and Measures w What is the capacity of the system? w What is the slowest resource? (Assume that the we have enough trays. ) Session 4 Operations Management 13

Kristine Cookies and Measures w What is the capacity of the system? w What is the slowest resource? (Assume that the we have enough trays. ) Session 4 Operations Management 13

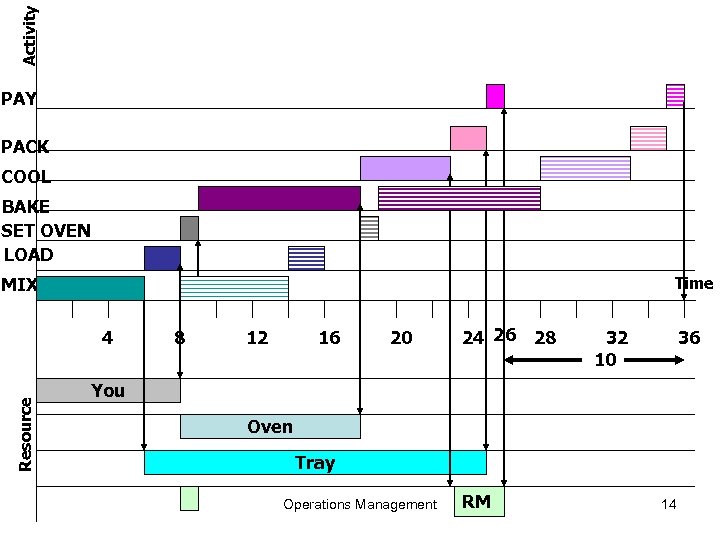

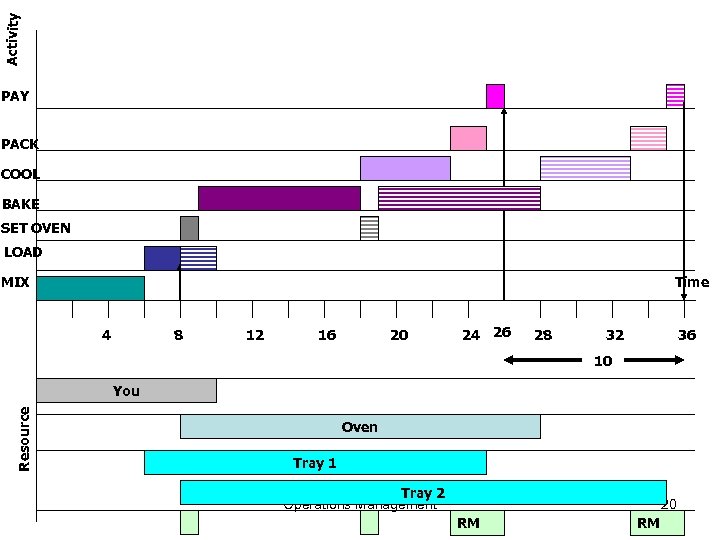

Activity PAY PACK COOL BAKE SET OVEN LOAD MIX Time Resource 4 8 12 16 20 24 26 28 32 10 36 You Oven Tray Operations Management RM 14

Activity PAY PACK COOL BAKE SET OVEN LOAD MIX Time Resource 4 8 12 16 20 24 26 28 32 10 36 You Oven Tray Operations Management RM 14

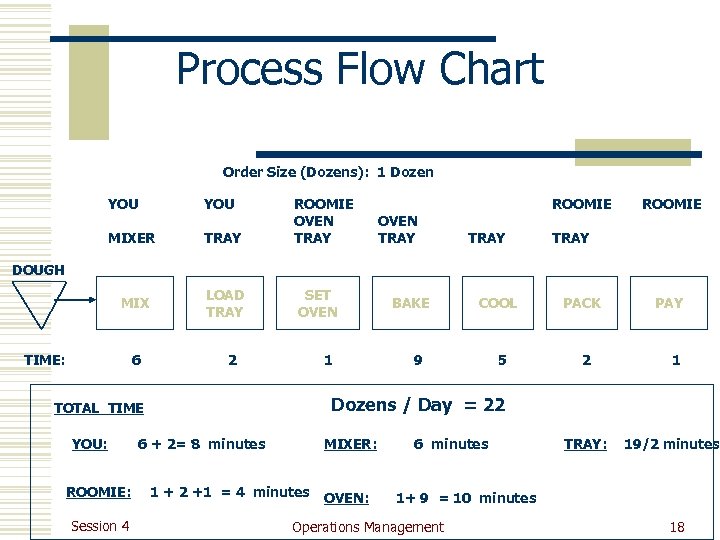

Bottleneck Analysis w It is clear that the bottleneck is the Oven n n Session 4 It is the only resource that once we start producing is not idle. It is the slowest resource: One dozen every 10 min. Operations Management 15

Bottleneck Analysis w It is clear that the bottleneck is the Oven n n Session 4 It is the only resource that once we start producing is not idle. It is the slowest resource: One dozen every 10 min. Operations Management 15

Capacity w It seems that if they have enough trays they can produce a dozen of cookies every 10 min. n 1. 2 cookies per min. n In 4 hours (240 min) you can finish 22 trays: l 240 – 26 = 214 l 214 / 10 = 21. 4 or 21 trays. w Given the bottleneck is the oven, to maximize capacity we must ensure that the oven runs continuously: once every 10 min. Session 4 Operations Management 16

Capacity w It seems that if they have enough trays they can produce a dozen of cookies every 10 min. n 1. 2 cookies per min. n In 4 hours (240 min) you can finish 22 trays: l 240 – 26 = 214 l 214 / 10 = 21. 4 or 21 trays. w Given the bottleneck is the oven, to maximize capacity we must ensure that the oven runs continuously: once every 10 min. Session 4 Operations Management 16

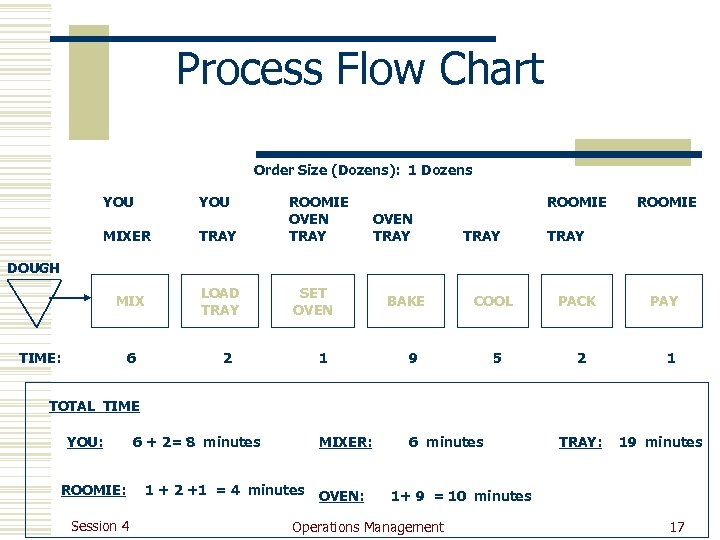

Process Flow Chart Order Size (Dozens): 1 Dozens YOU MIXER TRAY ROOMIE OVEN TRAY MIX LOAD TRAY SET OVEN TRAY ROOMIE TRAY DOUGH TIME: 6 2 BAKE COOL 1 9 MIXER: 6 minutes 5 PACK 2 PAY 1 TOTAL TIME YOU: ROOMIE: Session 4 6 + 2= 8 minutes 1 + 2 +1 = 4 minutes OVEN: TRAY: 19 minutes 1+ 9 = 10 minutes Operations Management 17

Process Flow Chart Order Size (Dozens): 1 Dozens YOU MIXER TRAY ROOMIE OVEN TRAY MIX LOAD TRAY SET OVEN TRAY ROOMIE TRAY DOUGH TIME: 6 2 BAKE COOL 1 9 MIXER: 6 minutes 5 PACK 2 PAY 1 TOTAL TIME YOU: ROOMIE: Session 4 6 + 2= 8 minutes 1 + 2 +1 = 4 minutes OVEN: TRAY: 19 minutes 1+ 9 = 10 minutes Operations Management 17

Process Flow Chart Order Size (Dozens): 1 Dozen YOU MIXER TRAY ROOMIE OVEN TRAY MIX LOAD TRAY SET OVEN TRAY ROOMIE TRAY DOUGH TIME: 6 2 1 ROOMIE: Session 4 COOL 9 5 PACK 2 PAY 1 Dozens / Day = 22 TOTAL TIME YOU: BAKE 6 + 2= 8 minutes MIXER: 1 + 2 +1 = 4 minutes OVEN: 6 minutes TRAY: 19/2 minutes 1+ 9 = 10 minutes Operations Management 18

Process Flow Chart Order Size (Dozens): 1 Dozen YOU MIXER TRAY ROOMIE OVEN TRAY MIX LOAD TRAY SET OVEN TRAY ROOMIE TRAY DOUGH TIME: 6 2 1 ROOMIE: Session 4 COOL 9 5 PACK 2 PAY 1 Dozens / Day = 22 TOTAL TIME YOU: BAKE 6 + 2= 8 minutes MIXER: 1 + 2 +1 = 4 minutes OVEN: 6 minutes TRAY: 19/2 minutes 1+ 9 = 10 minutes Operations Management 18

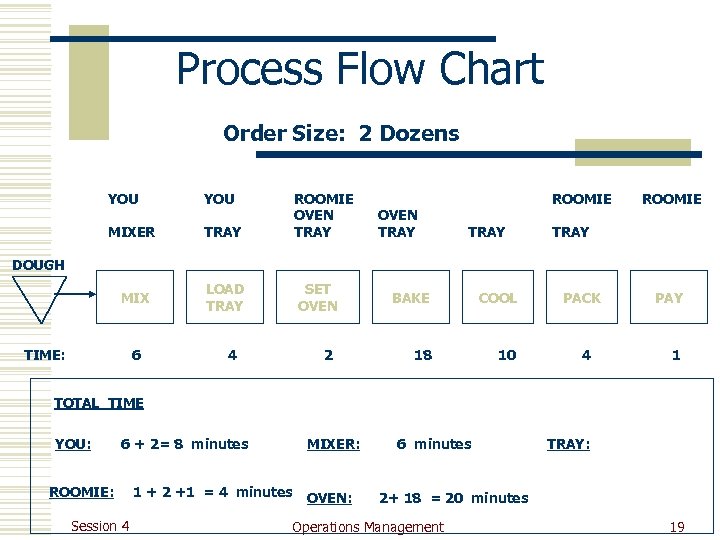

Process Flow Chart Order Size: 2 Dozens YOU MIXER TRAY ROOMIE OVEN TRAY MIX LOAD TRAY SET OVEN TRAY ROOMIE TRAY DOUGH TIME: 6 4 2 BAKE COOL 18 10 PACK 4 PAY 1 TOTAL TIME YOU: 6 + 2= 8 minutes ROOMIE: Session 4 MIXER: 1 + 2 +1 = 4 minutes OVEN: 6 minutes TRAY: 2+ 18 = 20 minutes Operations Management 19

Process Flow Chart Order Size: 2 Dozens YOU MIXER TRAY ROOMIE OVEN TRAY MIX LOAD TRAY SET OVEN TRAY ROOMIE TRAY DOUGH TIME: 6 4 2 BAKE COOL 18 10 PACK 4 PAY 1 TOTAL TIME YOU: 6 + 2= 8 minutes ROOMIE: Session 4 MIXER: 1 + 2 +1 = 4 minutes OVEN: 6 minutes TRAY: 2+ 18 = 20 minutes Operations Management 19

Activity PAY PACK COOL BAKE SET OVEN LOAD MIX Time 4 8 12 16 20 24 26 28 32 36 10 Resource You Oven Tray 1 Tray 2 Operations Management 20 RM RM

Activity PAY PACK COOL BAKE SET OVEN LOAD MIX Time 4 8 12 16 20 24 26 28 32 36 10 Resource You Oven Tray 1 Tray 2 Operations Management 20 RM RM

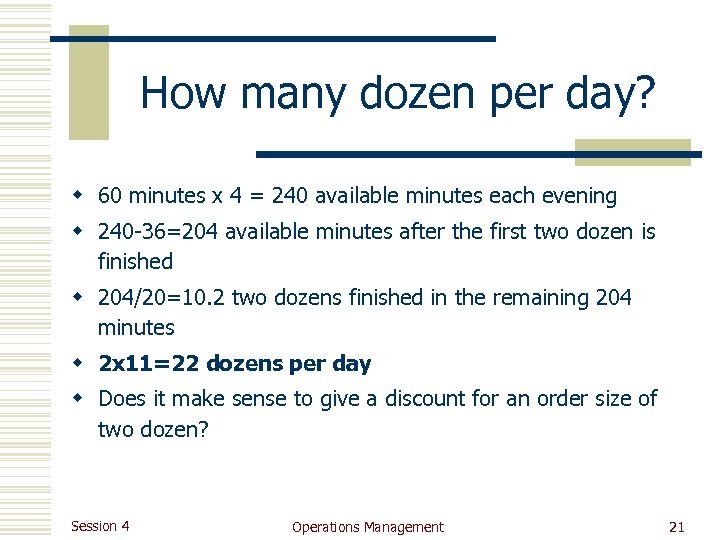

How many dozen per day? w 60 minutes x 4 = 240 available minutes each evening w 240 -36=204 available minutes after the first two dozen is finished w 204/20=10. 2 two dozens finished in the remaining 204 minutes w 2 x 11=22 dozens per day w Does it make sense to give a discount for an order size of two dozen? Session 4 Operations Management 21

How many dozen per day? w 60 minutes x 4 = 240 available minutes each evening w 240 -36=204 available minutes after the first two dozen is finished w 204/20=10. 2 two dozens finished in the remaining 204 minutes w 2 x 11=22 dozens per day w Does it make sense to give a discount for an order size of two dozen? Session 4 Operations Management 21

Capacity Investment w Should we invest in a second Oven? Session 4 Operations Management 22

Capacity Investment w Should we invest in a second Oven? Session 4 Operations Management 22

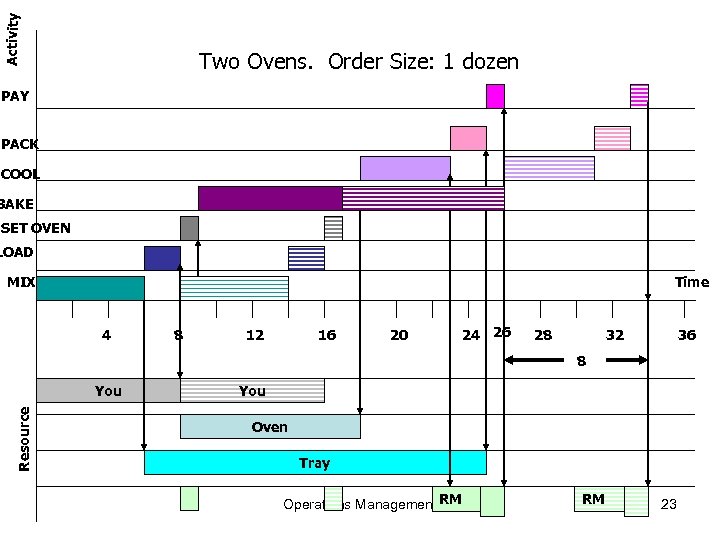

Activity Two Ovens. Order Size: 1 dozen PAY PACK COOL BAKE SET OVEN LOAD MIX Time 4 8 12 16 20 24 26 28 32 36 8 Resource You Oven Tray Operations Management RM RM 23

Activity Two Ovens. Order Size: 1 dozen PAY PACK COOL BAKE SET OVEN LOAD MIX Time 4 8 12 16 20 24 26 28 32 36 8 Resource You Oven Tray Operations Management RM RM 23

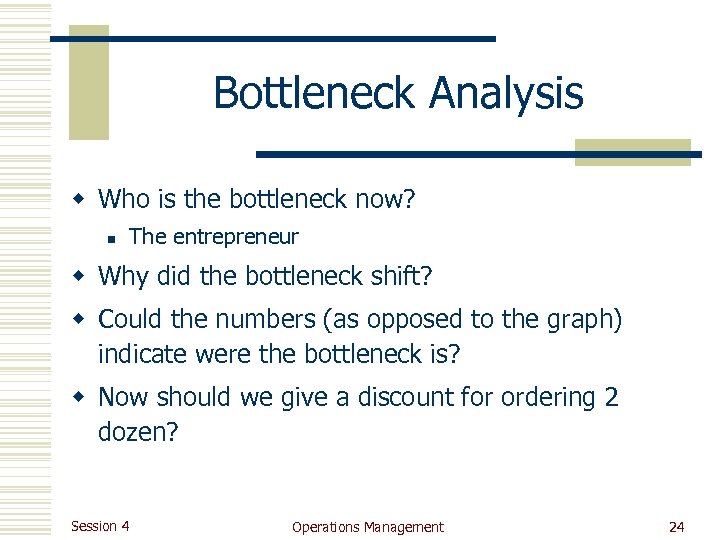

Bottleneck Analysis w Who is the bottleneck now? n The entrepreneur w Why did the bottleneck shift? w Could the numbers (as opposed to the graph) indicate were the bottleneck is? w Now should we give a discount for ordering 2 dozen? Session 4 Operations Management 24

Bottleneck Analysis w Who is the bottleneck now? n The entrepreneur w Why did the bottleneck shift? w Could the numbers (as opposed to the graph) indicate were the bottleneck is? w Now should we give a discount for ordering 2 dozen? Session 4 Operations Management 24

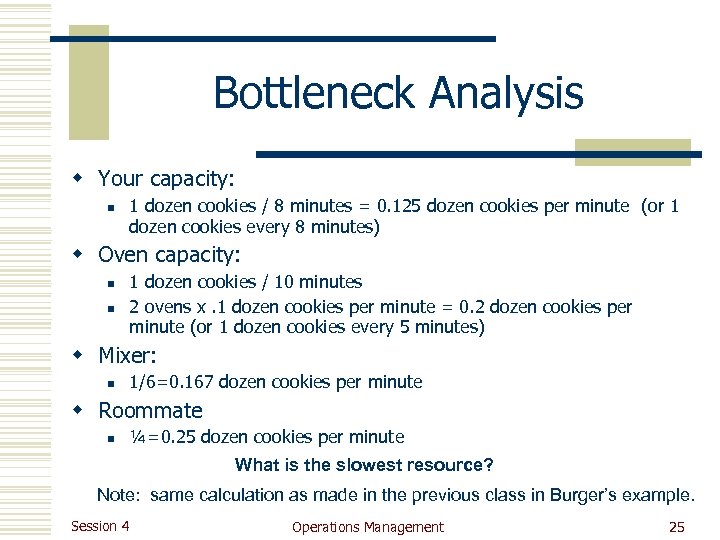

Bottleneck Analysis w Your capacity: n 1 dozen cookies / 8 minutes = 0. 125 dozen cookies per minute (or 1 dozen cookies every 8 minutes) w Oven capacity: n n 1 dozen cookies / 10 minutes 2 ovens x. 1 dozen cookies per minute = 0. 2 dozen cookies per minute (or 1 dozen cookies every 5 minutes) w Mixer: n 1/6=0. 167 dozen cookies per minute w Roommate n ¼=0. 25 dozen cookies per minute What is the slowest resource? Note: same calculation as made in the previous class in Burger’s example. Session 4 Operations Management 25

Bottleneck Analysis w Your capacity: n 1 dozen cookies / 8 minutes = 0. 125 dozen cookies per minute (or 1 dozen cookies every 8 minutes) w Oven capacity: n n 1 dozen cookies / 10 minutes 2 ovens x. 1 dozen cookies per minute = 0. 2 dozen cookies per minute (or 1 dozen cookies every 5 minutes) w Mixer: n 1/6=0. 167 dozen cookies per minute w Roommate n ¼=0. 25 dozen cookies per minute What is the slowest resource? Note: same calculation as made in the previous class in Burger’s example. Session 4 Operations Management 25

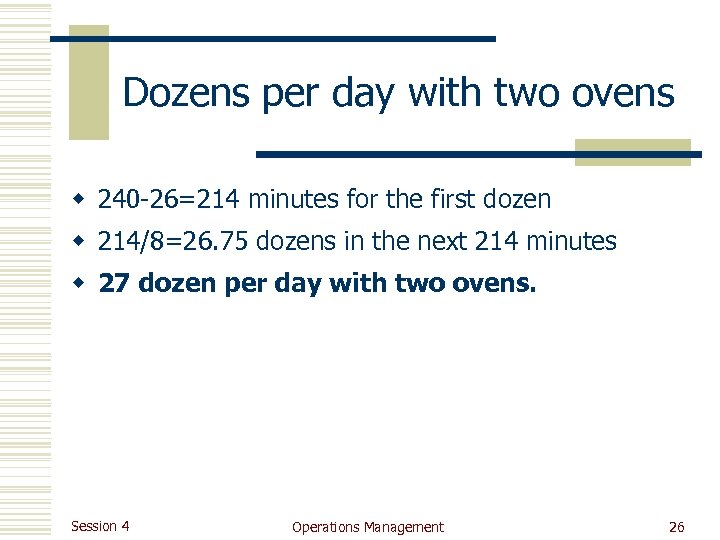

Dozens per day with two ovens w 240 -26=214 minutes for the first dozen w 214/8=26. 75 dozens in the next 214 minutes w 27 dozen per day with two ovens. Session 4 Operations Management 26

Dozens per day with two ovens w 240 -26=214 minutes for the first dozen w 214/8=26. 75 dozens in the next 214 minutes w 27 dozen per day with two ovens. Session 4 Operations Management 26

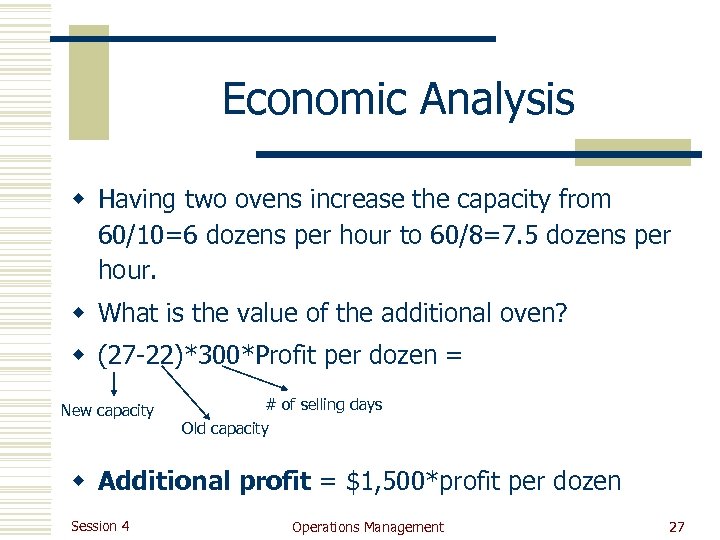

Economic Analysis w Having two ovens increase the capacity from 60/10=6 dozens per hour to 60/8=7. 5 dozens per hour. w What is the value of the additional oven? w (27 -22)*300*Profit per dozen = New capacity # of selling days Old capacity w Additional profit = $1, 500*profit per dozen Session 4 Operations Management 27

Economic Analysis w Having two ovens increase the capacity from 60/10=6 dozens per hour to 60/8=7. 5 dozens per hour. w What is the value of the additional oven? w (27 -22)*300*Profit per dozen = New capacity # of selling days Old capacity w Additional profit = $1, 500*profit per dozen Session 4 Operations Management 27

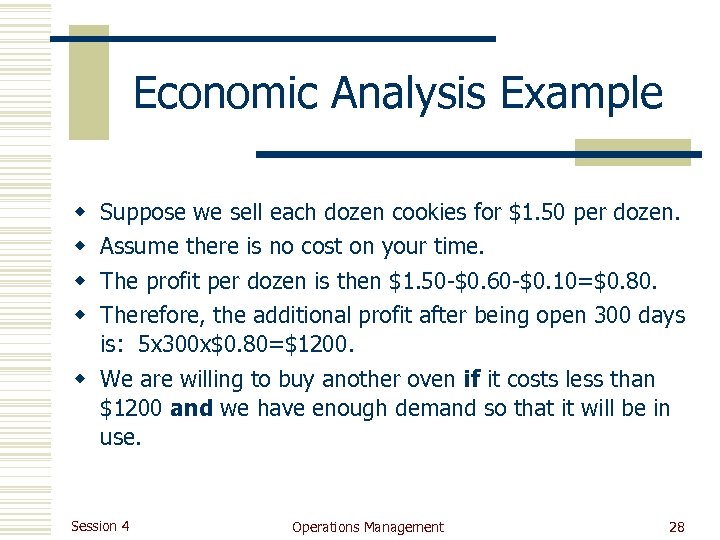

Economic Analysis Example w w Suppose we sell each dozen cookies for $1. 50 per dozen. Assume there is no cost on your time. The profit per dozen is then $1. 50 -$0. 60 -$0. 10=$0. 80. Therefore, the additional profit after being open 300 days is: 5 x 300 x$0. 80=$1200. w We are willing to buy another oven if it costs less than $1200 and we have enough demand so that it will be in use. Session 4 Operations Management 28

Economic Analysis Example w w Suppose we sell each dozen cookies for $1. 50 per dozen. Assume there is no cost on your time. The profit per dozen is then $1. 50 -$0. 60 -$0. 10=$0. 80. Therefore, the additional profit after being open 300 days is: 5 x 300 x$0. 80=$1200. w We are willing to buy another oven if it costs less than $1200 and we have enough demand so that it will be in use. Session 4 Operations Management 28

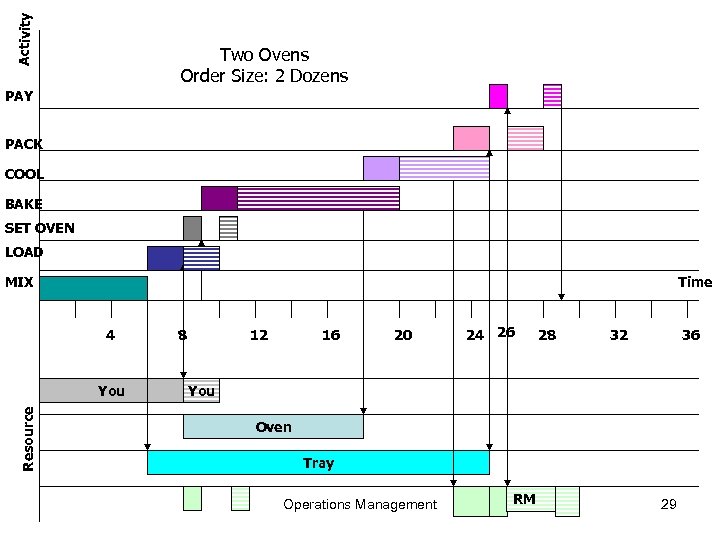

Activity Two Ovens Order Size: 2 Dozens PAY PACK COOL BAKE SET OVEN LOAD MIX Time 4 Resource You 8 12 16 20 24 26 28 32 36 You Oven Tray Operations Management RM 29

Activity Two Ovens Order Size: 2 Dozens PAY PACK COOL BAKE SET OVEN LOAD MIX Time 4 Resource You 8 12 16 20 24 26 28 32 36 You Oven Tray Operations Management RM 29

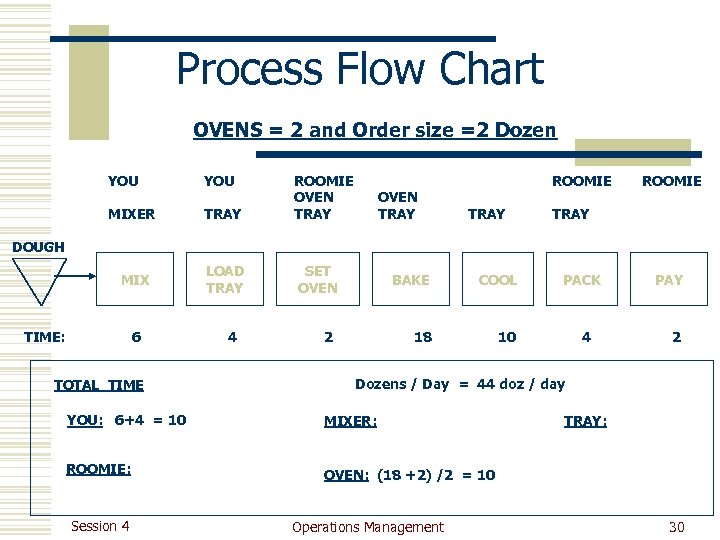

Process Flow Chart OVENS = 2 and Order size =2 Dozen YOU MIXER TRAY ROOMIE OVEN TRAY MIX LOAD TRAY SET OVEN TRAY ROOMIE TRAY DOUGH TIME: 6 TOTAL TIME 4 BAKE 18 2 COOL PACK 10 4 PAY 2 Dozens / Day = 44 doz / day YOU: 6+4 = 10 MIXER: ROOMIE: OVEN: (18 +2) /2 = 10 Session 4 Operations Management TRAY: 30

Process Flow Chart OVENS = 2 and Order size =2 Dozen YOU MIXER TRAY ROOMIE OVEN TRAY MIX LOAD TRAY SET OVEN TRAY ROOMIE TRAY DOUGH TIME: 6 TOTAL TIME 4 BAKE 18 2 COOL PACK 10 4 PAY 2 Dozens / Day = 44 doz / day YOU: 6+4 = 10 MIXER: ROOMIE: OVEN: (18 +2) /2 = 10 Session 4 Operations Management TRAY: 30

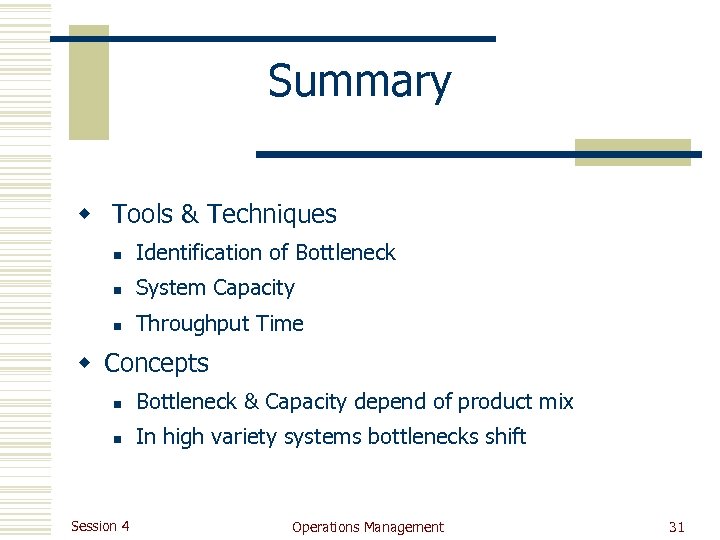

Summary w Tools & Techniques n Identification of Bottleneck n System Capacity n Throughput Time w Concepts n Bottleneck & Capacity depend of product mix n In high variety systems bottlenecks shift Session 4 Operations Management 31

Summary w Tools & Techniques n Identification of Bottleneck n System Capacity n Throughput Time w Concepts n Bottleneck & Capacity depend of product mix n In high variety systems bottlenecks shift Session 4 Operations Management 31