e73da430b70d4fa1195a419657bba678.ppt

- Количество слайдов: 65

OPERATIONS Management Operations Higher Business Management

OPERATIONS Management Role and importance of operations Operations is concerned with: the purchase and storage of raw materials the production and storage of finished goods the distribution of the finished goods quality measures to ensure goods are of a suitable standard. Operations needs the right materials to be in the right place at the right time.

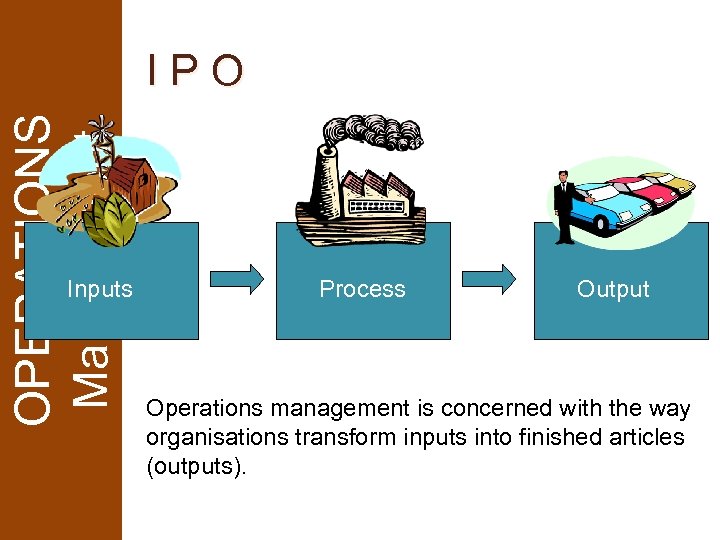

OPERATIONS Management IPO Inputs Process Output Operations management is concerned with the way organisations transform inputs into finished articles (outputs).

OPERATIONS Management Production planning Planning is crucial in helping a firm achieve its objectives. In ideal circumstances, production should be at a constant, set level that would never deviate. This would mean it would be easy to calculate how many workers are needed, what materials to buy, and what equipment and machinery to operate. However, employees can be off, machines can break down and consumer demand can be fickle.

OPERATIONS Management Production systems Nature of the final product Market size Resources available Stage of development of the business Labour-intensive vs capital-intensive production Availability of technology – automation

OPERATIONS Management Production systems – key factors The nature of the product: producing different products requires different production systems as the finished goods are very different. The quantity to be produced: large volume favours standardised production, whereas a one-off product needs a customised approach. The resources available: the system chosen will depend on the availability of materials, people, buildings and equipment, finance and time.

OPERATIONS Management Production systems – key factors Labour: a labour-intensive system is one where the organisation relies more heavily on its workforce than on machinery to complete production. Capital: where the production system places more emphasis on machinery and other capital equipment than it does on labour, then it is said to be capital-intensive.

OPERATIONS Management Purchasing – materials management The purchasing mix: suppliers delivery time price quality quantity storage facilities. Click for clip

OPERATIONS Management Purchasing mix Suppliers – Are suppliers dependable? Local or national suppliers? Additional costs? Delivery time – Lead times long or short? Reliability and keeping promises. Price – Discounts and bulk buying vs cost of keeping stock. Credit terms vs discounts.

OPERATIONS Management Purchasing mix Quality – Supplier guarantee of consistent quality materials Quantity – Storage adds 15– 30% on to cost of purchasing. Storage facilities – Storage capacity? Safety, security, other conditions of storage?

OPERATIONS Management Answer a question Describe five factors an organisation might take into account before choosing a supplier of raw materials. (5 marks) 2010 10 minutes

OPERATIONS Management Peer marking You Has are going to swap answers. your partner answered well? Does the answer make sense? Is it worth a mark?

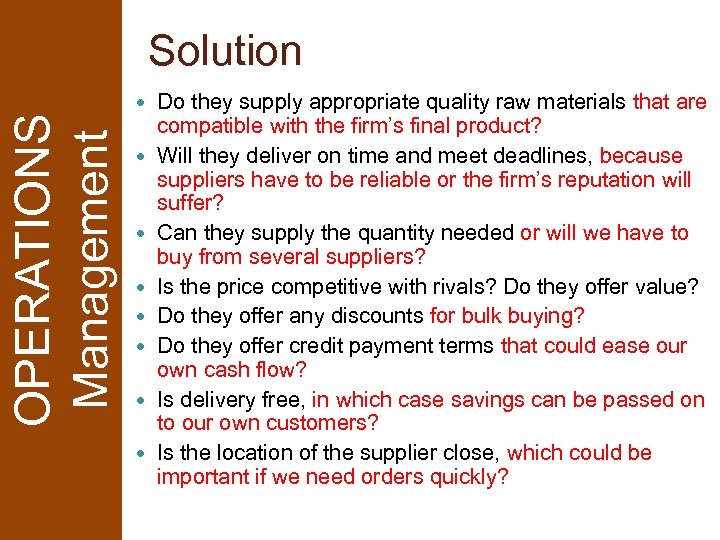

OPERATIONS Management Solution Do they supply appropriate quality raw materials that are compatible with the firm’s final product? Will they deliver on time and meet deadlines, because suppliers have to be reliable or the firm’s reputation will suffer? Can they supply the quantity needed or will we have to buy from several suppliers? Is the price competitive with rivals? Do they offer value? Do they offer any discounts for bulk buying? Do they offer credit payment terms that could ease our own cash flow? Is delivery free, in which case savings can be passed on to our own customers? Is the location of the supplier close, which could be important if we need orders quickly?

OPERATIONS Management Job production concentrates on producing one product from start to finish. Once one product is complete, another can begin. It is extremely labour intensive. Some examples: wedding dress painting a boat house extension.

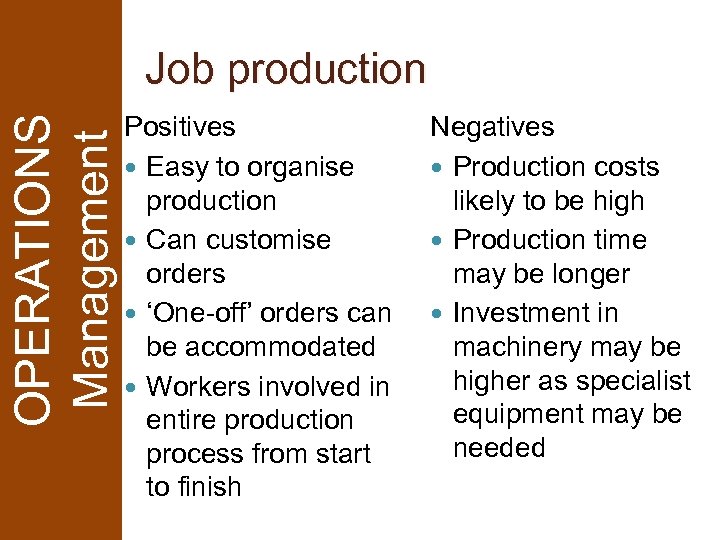

OPERATIONS Management Job production Positives Easy to organise production Can customise orders ‘One-off’ orders can be accommodated Workers involved in entire production process from start to finish Negatives Production costs likely to be high Production time may be longer Investment in machinery may be higher as specialist equipment may be needed

OPERATIONS Management Batch production enables items to be created in bulk (‘a batch’). General purpose equipment and methods are used to produce small quantities of items that will be made and sold for a limited time only. Commonly used in food production: ◦ Big Mac ◦ Gregg’s rolls

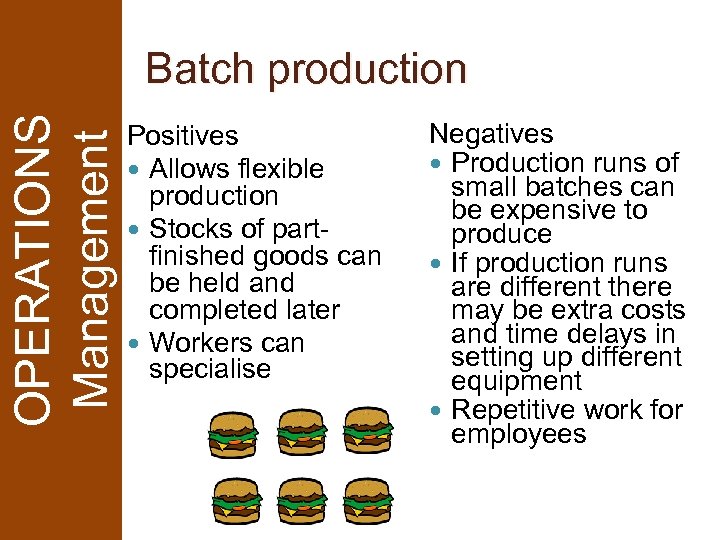

OPERATIONS Management Batch production Positives Allows flexible production Stocks of partfinished goods can be held and completed later Workers can specialise Negatives Production runs of small batches can be expensive to produce If production runs are different there may be extra costs and time delays in setting up different equipment Repetitive work for employees

OPERATIONS Management Flow production Also known as continuous production, flow production enables products to be created in a series of steps. Large quantities of goods produced and highly capital intensive (machinery, automation). Cars are mass-produced for a large market using flow production. Click for clip

OPERATIONS Management Flow production Positives 24/7 production Economies of scale Automated production lines save time and money Quality systems can be built into the production Click for clip Negatives Standard product produced (opposite of customised) High set-up costs of automated lines Repetitive and boring work Long production runs may produce more than is needed

OPERATIONS Management Answer a question Describe three methods of production. (3 marks) 2008 6 minutes

OPERATIONS Management Peer marking You Has are going to swap answers. your partner answered well? Does the answer make sense? Is it worth a mark?

OPERATIONS Management Solution Batch production is when a group of similar products are made at the same time. Many foods such as rolls and burgers are made by batch production. Flow production is when each product moves continuously along a production line from one process to the next, enabling many units to be produced by automated assembly lines. Job production is when an individual product is made to a customer’s specification and is created by one person.

OPERATIONS Management Importance of quality Quality is ensuring that the finished good satisfies the customer. Quality focuses on reducing errors and faults, and cutting out flaws. Employees need to be aware of the standard of quality expected by the end user.

OPERATIONS Management Quality standards British ISO Standards Institute Kite Mark 9000 ABTA Investors in People

OPERATIONS Management Quality control There are three approaches to attempting to improve on quality: 1. quality control 2. quality assurance 3. total quality management (TQM).

OPERATIONS Management Quality control The traditional method of quality control, where quality inspectors conduct spot checks on the final products. If a flaw or defect is discovered, the item is rejected. This high wastage is costly to a firm. Workers are not involved in the quality process.

OPERATIONS Management Quality assurance makes workers aware of the quality standard expected. Quality checks are conducted at each stage of production. The workers work in teams to check the progress of production. Quality assurance is based on prevention.

OPERATIONS Management Total quality management The main principle of TQM is that every employee has a responsibility to ensure that a quality product leaves the workplace. To encourage and motivate workers, management ask for workers’ opinions and feedback on how to improve quality standards. Zero errors are tolerated, so tasks must be completed correctly first time! Click for clip

OPERATIONS Management Total quality management (cont’d) In order for TQM to be effective the following factors must be implemented: ◦ A quality policy is produced. ◦ Every employee is focused on customer satisfaction. ◦ Working in teams should be encouraged. ◦ Employees must be highly trained in order to achieve the quality level striven for. ◦ Feedback and evaluation on the quality process are ongoing

OPERATIONS Management TQM - Kaizen The Japanese have perfected the concept of total involvement in the life of the organisation. Workers are part of a team; there are team songs and team competitions. Kaizen means continuous improvement.

OPERATIONS Management Benchmarking is when the best example of a product or service in a market is taken apart and reengineered by a rival. This allows other firms to make cheaper, close imitations of the market leader and offer customers more choice.

Quality circles A group of 6– 12 people who meet to identify quality problems, consider solutions and recommend suitable outcomes to management. Members are drawn from the factory floor but include engineers, quality inspectors and salesmen to offer different viewpoints. (Managers may or may not be included. ) OPERATIONS Management Why use quality circles? No-one knows production problems better than the workers. Workers appreciate the chance to display their knowledge and skill.

OPERATIONS Management How can quality circles be used in an organisation? Increase productivity Improve quality Boost employee morale

OPERATIONS Management Answer a question Explain measures organisations can take to ensure they produce a quality product or service. (9 marks) 2007 15 minutes

OPERATIONS Management Peer marking You Has are going to swap answers. your partner answered well? Does the answer make sense? Is it worth a mark?

Solution OPERATIONS Management Benchmarking is when the best method is identified through best practice in industry and then imitated. Quality assurance is when products are checked at certain points in the production process. Unacceptable products are discarded. Quality circles are groups of workers, possibly including managers, who meet to discuss the best methods and where improvements can be made. This allows the actual workers doing the job to make suggestions. TQM focuses on creating quality products every time. Zero defects are aimed for. TQM must have the commitment of the whole organisation and all workers. It also requires clearly defined standards and policies, which are implemented to ensure quality at all times. Products are scrutinised at all stages of the production process. Quality standards/marks, eg BSI awards, are used to show a product’s quality has been approved. Quality control is when products are checked at the end of the process. This can result in high wastage or reworks.

OPERATIONS Management Stock is a resource that is stored in a warehouse ready for use. Storing stock is very expensive, as a warehouse with overheads has to be kept and employees who work in the warehouse have to be paid a wage. There are three basic categories of stock: ◦ raw materials: components used to produce a product ◦ work-in-progress: goods which are unfinished ◦ finished goods: end product awaiting distribution to customer.

OPERATIONS Management Why is it important to control stock? Stock control has to be managed to lower costs and avoid unnecessary waste Effective stock control has the following features: ◦ a process for regular inventory checks ◦ costs minimised (overheads and labour) ◦ security systems in place to prevent theft.

OPERATIONS Management Levels of stock A business which holds stock will implement the following stock levels in order to meet customer demand at all times. ◦ Minimum level: ensures that there will always be stocks for production, allowing for ordering and delivery times. ◦ Maximum level: the firm’s full capacity in terms of physical storage space. ◦ Re-order level: the level at which new stock should be ordered.

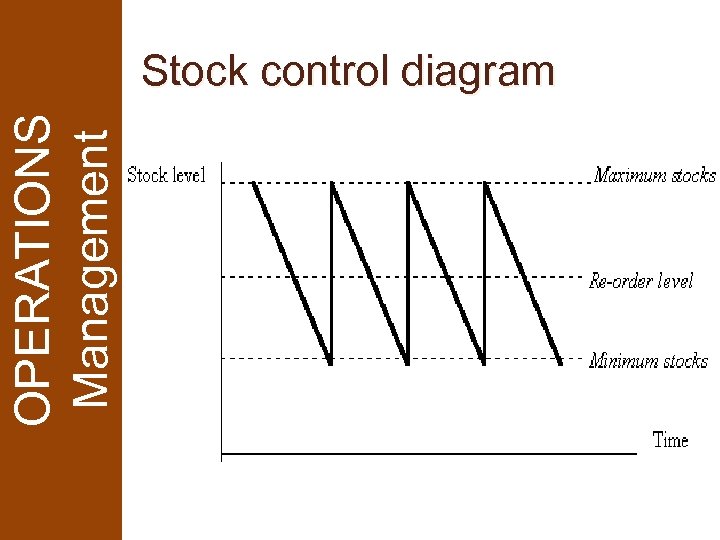

OPERATIONS Management Stock control diagram

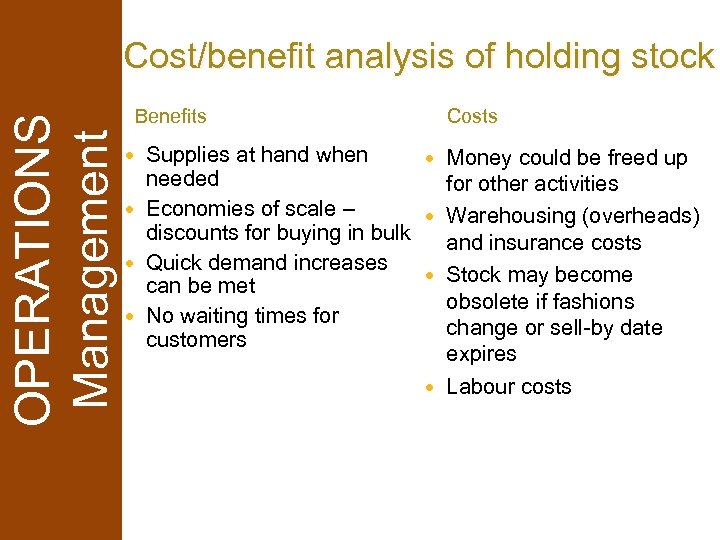

OPERATIONS Management Cost/benefit analysis of holding stock Benefits Costs Supplies at hand when Money could be freed up needed for other activities Economies of scale – Warehousing (overheads) discounts for buying in bulk and insurance costs Quick demand increases Stock may become can be met obsolete if fashions No waiting times for change or sell-by date customers expires Labour costs

OPERATIONS Management Answer a question Describe different stages in setting an appropriate stock level. (4 marks) 2009 8 minutes

OPERATIONS Management Self-marking You are going to answer on your own! Have you answered well? Does the answer make sense? Is it worth a mark?

Solution OPERATIONS Management Maximum stock level: the level of stock that should be held to minimise costs, which involves examining storage space available and finance required for this level. Minimum stock level: level that stock should not fall below, as shortages could result and production could be halted. Re-order level: the level at which stock should be re-ordered, taking into account usage and lead times. Re-order quantity: the amount that is ordered to take the stock back up to maximum level once it is delivered. Lead time: the time taken between ordering new stock and it arriving at the organisation.

OPERATIONS Management Just-in-time (JIT) production JIT production is a Japanese approach to production that involves keeping the stock inventory to a minimum. Stocks arrive just in time to be used in production. As a result, costs are cut by reducing the quantity of stocks held by the business. Goods are not produced unless the business has an order from the customer. JIT strives to eliminate waste by producing the right part in the right place at the right time! Click for clip

OPERATIONS Management Effective JIT In order to be effective and efficient JIT requires the following factors to be in place: ◦ highly skilled and flexible workforce that is able to respond to the challenges of JIT ◦ absolute certainty regarding delivery times, to ensure that production runs to schedule (if the delivery was late this would halt production) ◦ if suppliers provide sub-standard items the whole system fails as there isn’t an alternative resource waiting in stock.

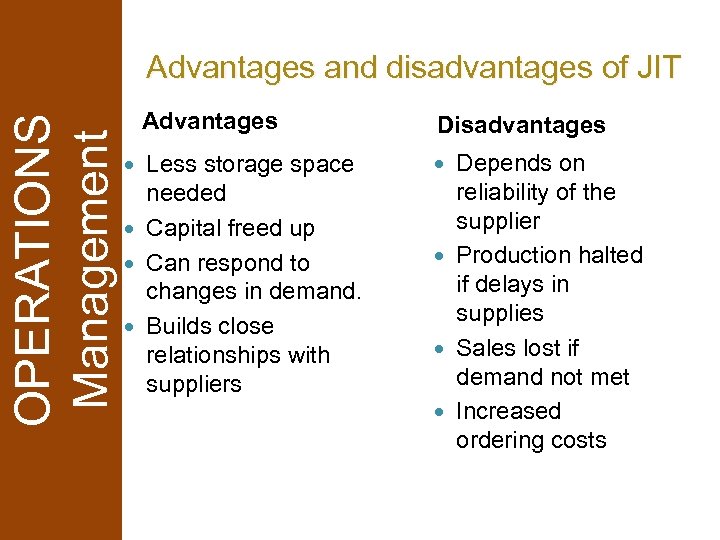

OPERATIONS Management Advantages and disadvantages of JIT Advantages Less storage space needed Capital freed up Can respond to changes in demand. Builds close relationships with suppliers Disadvantages Depends on reliability of the supplier Production halted if delays in supplies Sales lost if demand not met Increased ordering costs

OPERATIONS Management Answer a question Describe the advantages and disadvantages of using JIT production (5 marks) 2008 10 minutes

OPERATIONS Management Peer marking You Has are going to swap answers. your partner answered well? Does the answer make sense? Is it worth a mark?

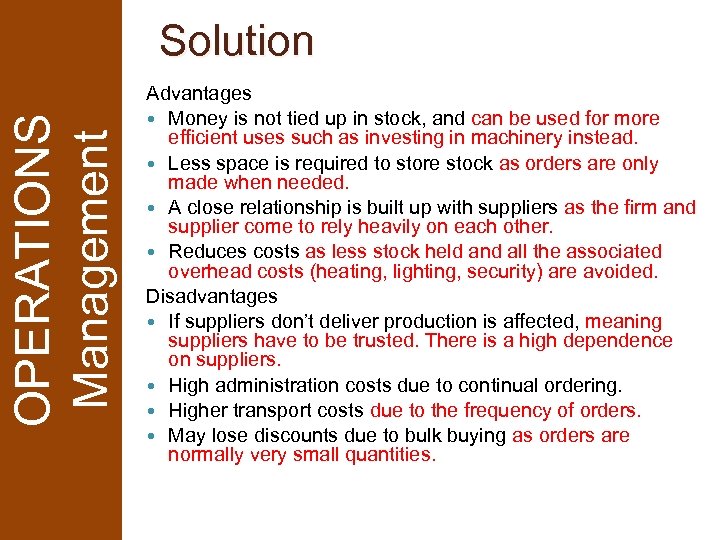

OPERATIONS Management Solution Advantages Money is not tied up in stock, and can be used for more efficient uses such as investing in machinery instead. Less space is required to store stock as orders are only made when needed. A close relationship is built up with suppliers as the firm and supplier come to rely heavily on each other. Reduces costs as less stock held and all the associated overhead costs (heating, lighting, security) are avoided. Disadvantages If suppliers don’t deliver production is affected, meaning suppliers have to be trusted. There is a high dependence on suppliers. High administration costs due to continual ordering. Higher transport costs due to the frequency of orders. May lose discounts due to bulk buying as orders are normally very small quantities.

OPERATIONS Management Payment systems Flat rate Overtime Piecework PRP Profit sharing Share save/share options

OPERATIONS Management Flat rate This payment method involves the employee receiving a basic rate of pay per time period that he/she works (eg £ 5 per hour, £ 50 per day, £ 400 per week). The pay is not related to output or productivity.

OPERATIONS Management Overtime Any time that the employee works above the agreed number of hours per week may make them eligible for overtime payments, often at ‘time and a half’ (eg £ 7. 50 per hour instead of £ 5 per hour). Double time is paid after a certain number of hours of overtime and would be £ 10 per hour in this example.

OPERATIONS Management Piecework This payment method involves the employee receiving an amount of money per unit (or per ‘piece’) that he/she produces. Pay is linked to productivity level. However, quality may suffer as employees hurry work to increase productivity.

OPERATIONS Management Performance-related pay (PRP) This method consists of pay rises to individual workers based on meeting agreed targets. This is common with managerial and professional workers. Appraisals may be linked to PRP.

OPERATIONS Management Profit sharing Employees receiving a share of the profit of the business. The aim is to increase employee effort, motivation and productivity. However, if the business makes low profits (or even a loss) then employees are demotivated!

OPERATIONS Management Share/save options Some PLCs offer share options. Employees receive a part of each month’s salary in the form of shares at a discounted price. Employees can use this as a pension plan or savings, although they can sell the shares for profit after a time. Employees may be more motivated as their productivity and effort result in a higher share price for the firm and potential gain for them.

OPERATIONS Management Answer a question Describe the types of payment systems for employees. (4 marks) 2007 8 minutes

OPERATIONS Management Peer marking You Has are going to swap answers. your partner answered well? Does the answer make sense? Is it worth a mark?

Solution OPERATIONS Management Time rate is when workers are paid per hour, eg £ 10 per hour, for each hour they work. This is used in manual jobs and is simple to calculate. It pays for the actual time spent at work and not for output. Piece rate is when employees are paid for the amount of work they do. They are paid an agreed rate for every item they produce – it is payment by result. It is an incentive to produce more items. However, employees have no basic pay if machinery fails and employees may sacrifice quality for output. Commission is a reward for the amount of a product or service sold to customers. This is usually paid on top of a basic salary and is paid as a percentage of the product’s sale value. Overtime is the normal hourly rate plus an increase for extra hours worked. It is an incentive to work more than the contracted hours. Bonus rate is when employees are paid a basic rate with a bonus on top for meeting agreed targets. It is an incentive to produce more or work harder.

OPERATIONS Management Distribution and delivery Design and layout Mechanical handling Transportation Scheduling

OPERATIONS Management Design and layout Warehouses on one level to reduce handling times. Goods used most often must have easy access.

OPERATIONS Management Mechanical handling Automation is faster than using employees. Automated systems are cost-efficient in the long run.

OPERATIONS Management Transportation How is the firm going to distribute the goods to the retailer or customer? What methods will be used? Does the firm have its own delivery vans and drivers or do they use a third party?

OPERATIONS Management Scheduling is the process of coordinating all the varied aspects of the production process from ordering raw materials to distribution to the customer.

e73da430b70d4fa1195a419657bba678.ppt