6c8841fc3ab0d14454a299bf5b489512.ppt

- Количество слайдов: 72

Operations Management MSOM 306. 001 Lecture 6 – Product and Service Design Al Baharmast, Ph. D.

Operations Management MSOM 306. 001 Lecture 6 – Product and Service Design Al Baharmast, Ph. D.

Regal Marine þ Global market þ 3 -dimensional CAD system þ Reduced product development time þ Reduced problems with tooling þ Reduced problems in production þ Assembly line production þ JIT Some lecture content courtesy of Prentice Hall, Rights Reserved

Regal Marine þ Global market þ 3 -dimensional CAD system þ Reduced product development time þ Reduced problems with tooling þ Reduced problems in production þ Assembly line production þ JIT Some lecture content courtesy of Prentice Hall, Rights Reserved

Product Decision þ The good or service the organization provides society þ Top organizations typically focus on core products þ Customers buy satisfaction, not just a physical good or particular service þ Fundamental to an organization's strategy with implications throughout the operations function Some lecture content courtesy of Prentice Hall, Rights Reserved

Product Decision þ The good or service the organization provides society þ Top organizations typically focus on core products þ Customers buy satisfaction, not just a physical good or particular service þ Fundamental to an organization's strategy with implications throughout the operations function Some lecture content courtesy of Prentice Hall, Rights Reserved

Product Strategy Options þ Differentiation þ Shouldice Hospital þ Low cost þ Taco Bell þ Rapid response þ Toyota Some lecture content courtesy of Prentice Hall, Rights Reserved

Product Strategy Options þ Differentiation þ Shouldice Hospital þ Low cost þ Taco Bell þ Rapid response þ Toyota Some lecture content courtesy of Prentice Hall, Rights Reserved

Product Life Cycles þ May be any length from a few hours to decades þ The operations function must be able to introduce new products successfully Some lecture content courtesy of Prentice Hall, Rights Reserved

Product Life Cycles þ May be any length from a few hours to decades þ The operations function must be able to introduce new products successfully Some lecture content courtesy of Prentice Hall, Rights Reserved

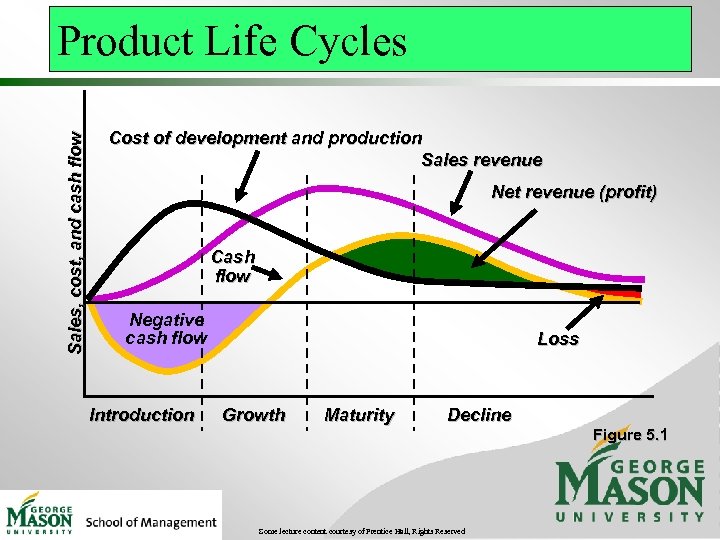

Sales, cost, and cash flow Product Life Cycles Cost of development and production Sales revenue Net revenue (profit) Cash flow Negative cash flow Introduction Loss Growth Maturity Decline Some lecture content courtesy of Prentice Hall, Rights Reserved Figure 5. 1

Sales, cost, and cash flow Product Life Cycles Cost of development and production Sales revenue Net revenue (profit) Cash flow Negative cash flow Introduction Loss Growth Maturity Decline Some lecture content courtesy of Prentice Hall, Rights Reserved Figure 5. 1

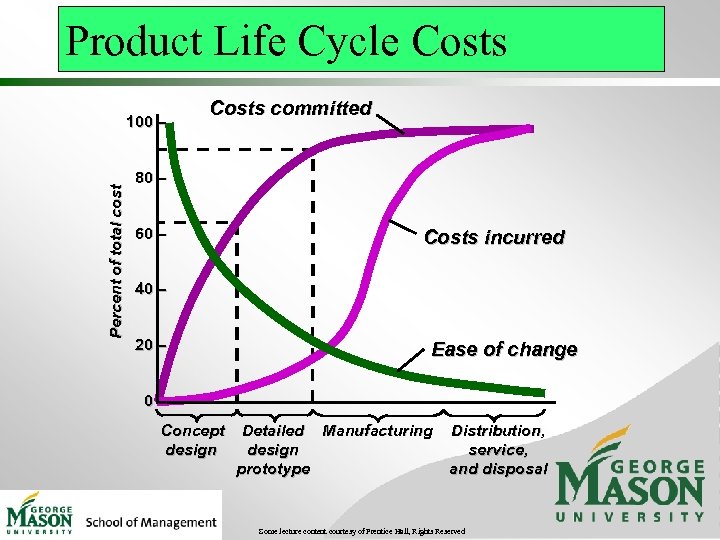

Product Life Cycle Costs Percent of total cost 100 – Costs committed 80 – 60 – Costs incurred 40 – 20 – Ease of change 0– Concept design Detailed Manufacturing design prototype Distribution, service, and disposal Some lecture content courtesy of Prentice Hall, Rights Reserved

Product Life Cycle Costs Percent of total cost 100 – Costs committed 80 – 60 – Costs incurred 40 – 20 – Ease of change 0– Concept design Detailed Manufacturing design prototype Distribution, service, and disposal Some lecture content courtesy of Prentice Hall, Rights Reserved

Product Life Cycle Introduction þ Fine tuning þ Research þ Product development þ Process modification and enhancement þ Supplier development Some lecture content courtesy of Prentice Hall, Rights Reserved

Product Life Cycle Introduction þ Fine tuning þ Research þ Product development þ Process modification and enhancement þ Supplier development Some lecture content courtesy of Prentice Hall, Rights Reserved

Product Life Cycle Growth þ Product design begins to stabilize þ Effective forecasting of capacity becomes necessary þ Adding or enhancing capacity may be necessary Some lecture content courtesy of Prentice Hall, Rights Reserved

Product Life Cycle Growth þ Product design begins to stabilize þ Effective forecasting of capacity becomes necessary þ Adding or enhancing capacity may be necessary Some lecture content courtesy of Prentice Hall, Rights Reserved

Product Life Cycle Maturity þ Competitors now established þ High volume, innovative production may be needed þ Improved cost control, reduction in options, paring down of product line Some lecture content courtesy of Prentice Hall, Rights Reserved

Product Life Cycle Maturity þ Competitors now established þ High volume, innovative production may be needed þ Improved cost control, reduction in options, paring down of product line Some lecture content courtesy of Prentice Hall, Rights Reserved

Product Life Cycle Decline þ Unless product makes a special contribution to the organization, must plan to terminate offering Some lecture content courtesy of Prentice Hall, Rights Reserved

Product Life Cycle Decline þ Unless product makes a special contribution to the organization, must plan to terminate offering Some lecture content courtesy of Prentice Hall, Rights Reserved

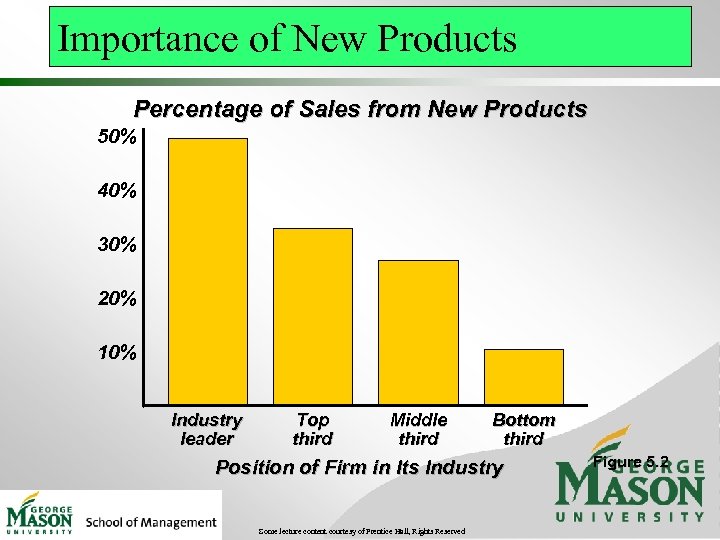

Importance of New Products Percentage of Sales from New Products 50% 40% 30% 20% 10% Industry leader Top third Middle third Bottom third Position of Firm in Its Industry Some lecture content courtesy of Prentice Hall, Rights Reserved Figure 5. 2

Importance of New Products Percentage of Sales from New Products 50% 40% 30% 20% 10% Industry leader Top third Middle third Bottom third Position of Firm in Its Industry Some lecture content courtesy of Prentice Hall, Rights Reserved Figure 5. 2

Product-by-Value Analysis þ Lists products in descending order of their individual dollar contribution to the firm þ Lists the total annual dollar contribution of the product þ Helps management evaluate alternative strategies Some lecture content courtesy of Prentice Hall, Rights Reserved

Product-by-Value Analysis þ Lists products in descending order of their individual dollar contribution to the firm þ Lists the total annual dollar contribution of the product þ Helps management evaluate alternative strategies Some lecture content courtesy of Prentice Hall, Rights Reserved

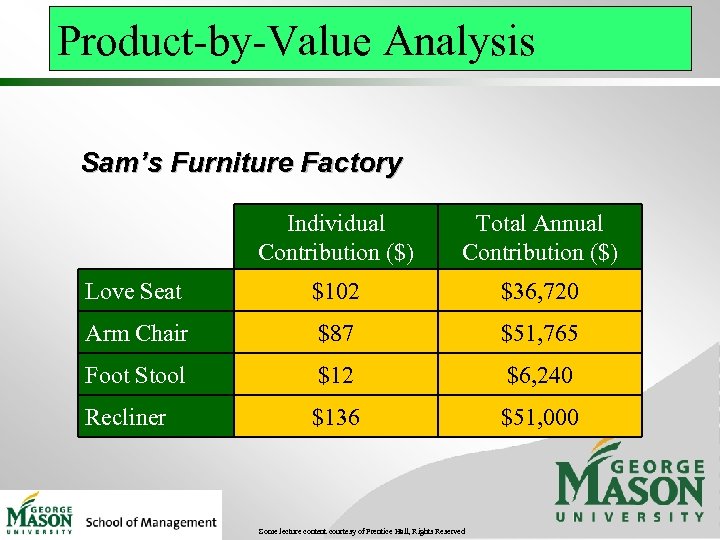

Product-by-Value Analysis Sam’s Furniture Factory Individual Contribution ($) Total Annual Contribution ($) Love Seat $102 $36, 720 Arm Chair $87 $51, 765 Foot Stool $12 $6, 240 Recliner $136 $51, 000 Some lecture content courtesy of Prentice Hall, Rights Reserved

Product-by-Value Analysis Sam’s Furniture Factory Individual Contribution ($) Total Annual Contribution ($) Love Seat $102 $36, 720 Arm Chair $87 $51, 765 Foot Stool $12 $6, 240 Recliner $136 $51, 000 Some lecture content courtesy of Prentice Hall, Rights Reserved

New Product Opportunities 1. Understanding the customer 2. Economic change 3. Sociological and demographic change Brainstorming 4. Technological change is a useful tool 5. Political/legal change 6. Market practice, professional standards, suppliers, distributors Some lecture content courtesy of Prentice Hall, Rights Reserved

New Product Opportunities 1. Understanding the customer 2. Economic change 3. Sociological and demographic change Brainstorming 4. Technological change is a useful tool 5. Political/legal change 6. Market practice, professional standards, suppliers, distributors Some lecture content courtesy of Prentice Hall, Rights Reserved

Quality Function Deployment þ Identify customer wants þ Identify how the good/service will satisfy customer wants þ Relate customer wants to product hows þ Identify relationships between the firm’s hows þ Develop importance ratings þ Evaluate competing products Some lecture content courtesy of Prentice Hall, Rights Reserved

Quality Function Deployment þ Identify customer wants þ Identify how the good/service will satisfy customer wants þ Relate customer wants to product hows þ Identify relationships between the firm’s hows þ Develop importance ratings þ Evaluate competing products Some lecture content courtesy of Prentice Hall, Rights Reserved

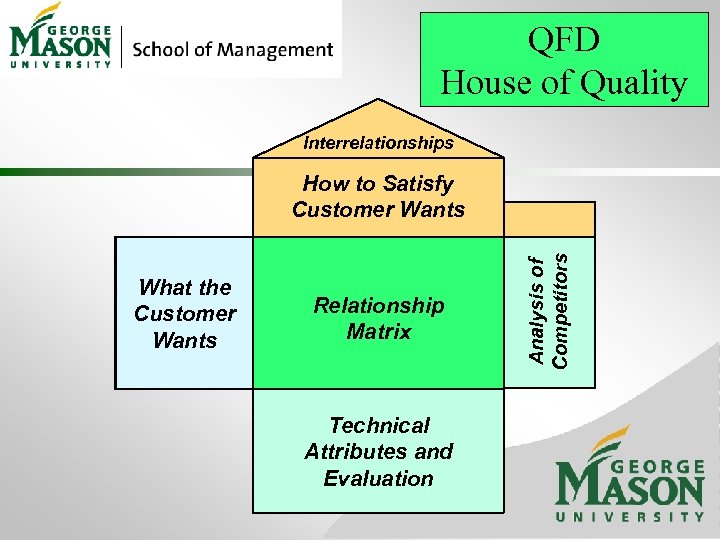

QFD House of Quality Interrelationships What the Customer Wants Relationship Matrix Technical Attributes and Evaluation Analysis of Competitors How to Satisfy Customer Wants

QFD House of Quality Interrelationships What the Customer Wants Relationship Matrix Technical Attributes and Evaluation Analysis of Competitors How to Satisfy Customer Wants

House of Quality Example Your team has been charged with designing a new camera for Great Cameras, Inc. The first action is to construct a House of Quality Some lecture content courtesy of Prentice Hall, Rights Reserved

House of Quality Example Your team has been charged with designing a new camera for Great Cameras, Inc. The first action is to construct a House of Quality Some lecture content courtesy of Prentice Hall, Rights Reserved

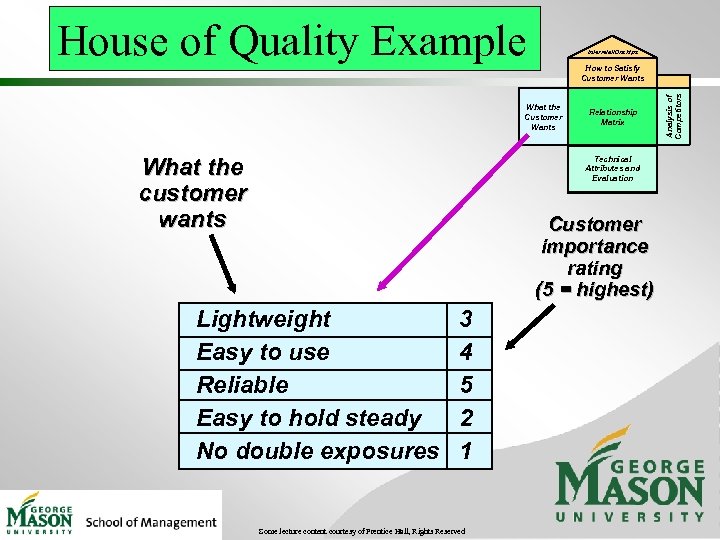

House of Quality Example Interrelationships What the Customer Wants What the customer wants Relationship Matrix Technical Attributes and Evaluation Customer importance rating (5 = highest) Lightweight Easy to use Reliable Easy to hold steady No double exposures 3 4 5 2 1 Some lecture content courtesy of Prentice Hall, Rights Reserved Analysis of Competitors How to Satisfy Customer Wants

House of Quality Example Interrelationships What the Customer Wants What the customer wants Relationship Matrix Technical Attributes and Evaluation Customer importance rating (5 = highest) Lightweight Easy to use Reliable Easy to hold steady No double exposures 3 4 5 2 1 Some lecture content courtesy of Prentice Hall, Rights Reserved Analysis of Competitors How to Satisfy Customer Wants

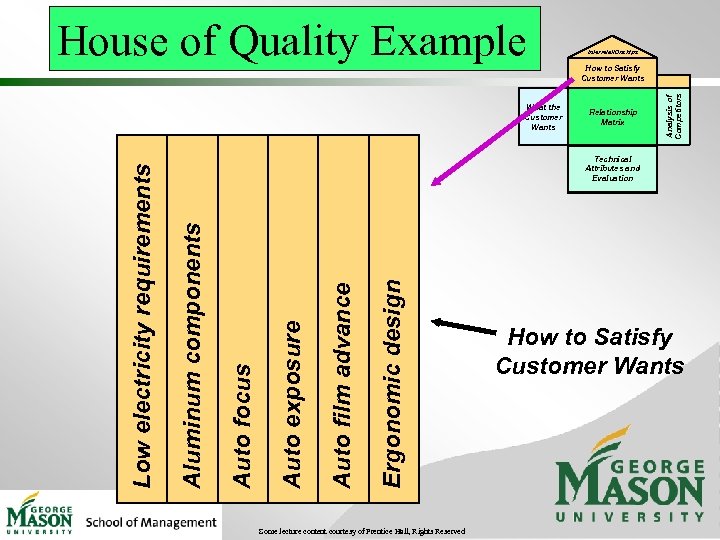

How to Satisfy Customer Wants Relationship Matrix Ergonomic design Auto film advance Auto exposure Auto focus Technical Attributes and Evaluation Aluminum components Low electricity requirements What the Customer Wants Interrelationships Analysis of Competitors House of Quality Example Some lecture content courtesy of Prentice Hall, Rights Reserved How to Satisfy Customer Wants

How to Satisfy Customer Wants Relationship Matrix Ergonomic design Auto film advance Auto exposure Auto focus Technical Attributes and Evaluation Aluminum components Low electricity requirements What the Customer Wants Interrelationships Analysis of Competitors House of Quality Example Some lecture content courtesy of Prentice Hall, Rights Reserved How to Satisfy Customer Wants

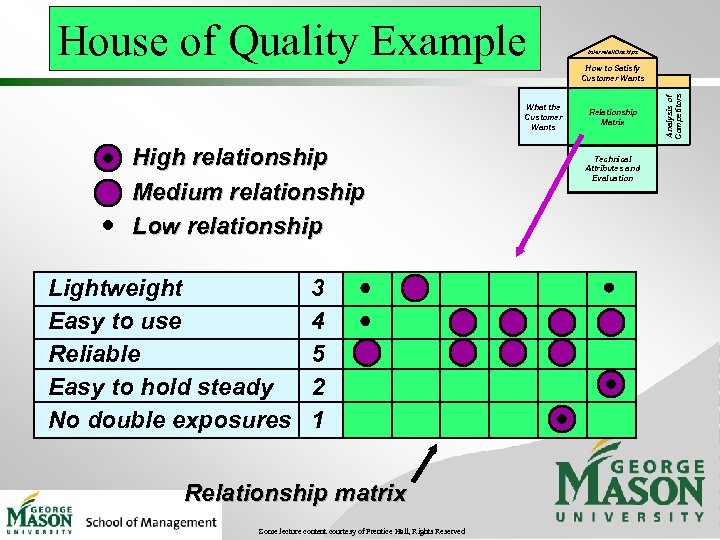

What the Customer Wants High relationship Medium relationship Low relationship Lightweight Easy to use Reliable Easy to hold steady No double exposures 3 4 5 2 1 Relationship matrix Some lecture content courtesy of Prentice Hall, Rights Reserved Interrelationships How to Satisfy Customer Wants Relationship Matrix Technical Attributes and Evaluation Analysis of Competitors House of Quality Example

What the Customer Wants High relationship Medium relationship Low relationship Lightweight Easy to use Reliable Easy to hold steady No double exposures 3 4 5 2 1 Relationship matrix Some lecture content courtesy of Prentice Hall, Rights Reserved Interrelationships How to Satisfy Customer Wants Relationship Matrix Technical Attributes and Evaluation Analysis of Competitors House of Quality Example

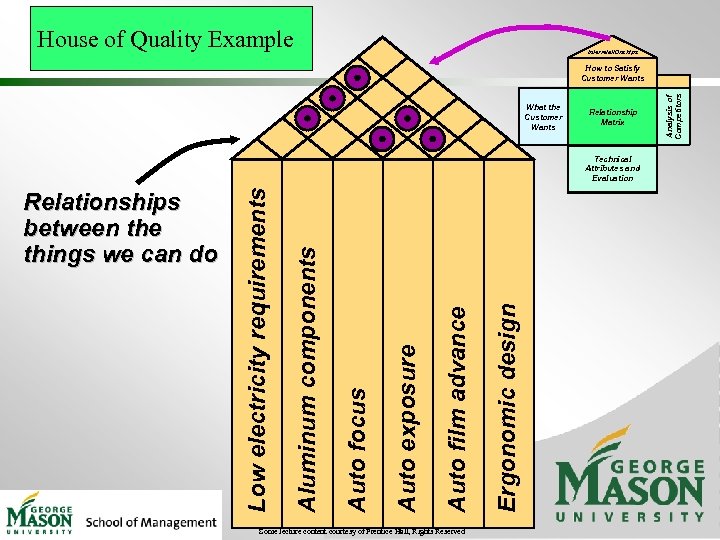

House of Quality Example Interrelationships What the Customer Wants Relationship Matrix Some lecture content courtesy of Prentice Hall, Rights Reserved Ergonomic design Auto film advance Auto exposure Auto focus Aluminum components Relationships between the things we can do Low electricity requirements Technical Attributes and Evaluation Analysis of Competitors How to Satisfy Customer Wants

House of Quality Example Interrelationships What the Customer Wants Relationship Matrix Some lecture content courtesy of Prentice Hall, Rights Reserved Ergonomic design Auto film advance Auto exposure Auto focus Aluminum components Relationships between the things we can do Low electricity requirements Technical Attributes and Evaluation Analysis of Competitors How to Satisfy Customer Wants

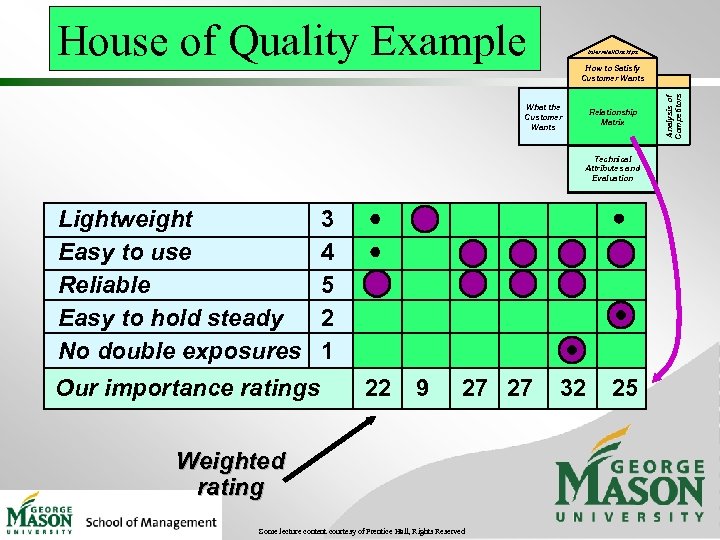

House of Quality Example Interrelationships What the Customer Wants Relationship Matrix Technical Attributes and Evaluation Lightweight Easy to use Reliable Easy to hold steady No double exposures Our importance ratings 3 4 5 2 1 22 9 27 27 Weighted rating Some lecture content courtesy of Prentice Hall, Rights Reserved 32 25 Analysis of Competitors How to Satisfy Customer Wants

House of Quality Example Interrelationships What the Customer Wants Relationship Matrix Technical Attributes and Evaluation Lightweight Easy to use Reliable Easy to hold steady No double exposures Our importance ratings 3 4 5 2 1 22 9 27 27 Weighted rating Some lecture content courtesy of Prentice Hall, Rights Reserved 32 25 Analysis of Competitors How to Satisfy Customer Wants

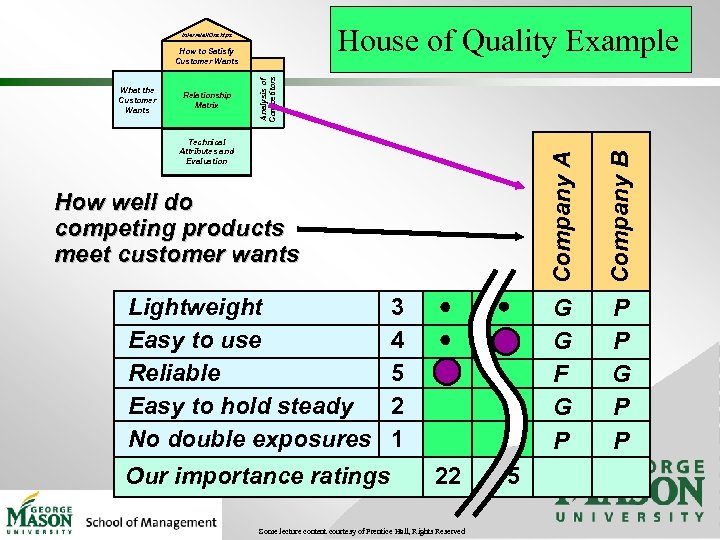

House of Quality Example Interrelationships Relationship Matrix Company A Technical Attributes and Evaluation G G F G P How well do competing products meet customer wants Lightweight Easy to use Reliable Easy to hold steady No double exposures Our importance ratings 3 4 5 2 1 22 Some lecture content courtesy of Prentice Hall, Rights Reserved 5 Company B What the Customer Wants Analysis of Competitors How to Satisfy Customer Wants P P G P P

House of Quality Example Interrelationships Relationship Matrix Company A Technical Attributes and Evaluation G G F G P How well do competing products meet customer wants Lightweight Easy to use Reliable Easy to hold steady No double exposures Our importance ratings 3 4 5 2 1 22 Some lecture content courtesy of Prentice Hall, Rights Reserved 5 Company B What the Customer Wants Analysis of Competitors How to Satisfy Customer Wants P P G P P

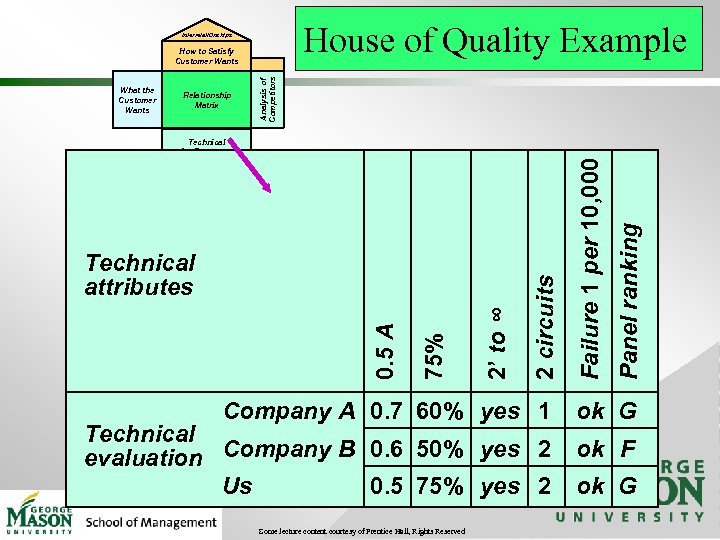

House of Quality Example Interrelationships 2’ to ∞ 75% 0. 5 A Technical attributes 2 circuits Technical Attributes and Evaluation Company A 0. 7 60% yes 1 Technical evaluation Company B 0. 6 50% yes 2 Us 0. 5 75% yes 2 Some lecture content courtesy of Prentice Hall, Rights Reserved Panel ranking Relationship Matrix Failure 1 per 10, 000 What the Customer Wants Analysis of Competitors How to Satisfy Customer Wants ok G ok F ok G

House of Quality Example Interrelationships 2’ to ∞ 75% 0. 5 A Technical attributes 2 circuits Technical Attributes and Evaluation Company A 0. 7 60% yes 1 Technical evaluation Company B 0. 6 50% yes 2 Us 0. 5 75% yes 2 Some lecture content courtesy of Prentice Hall, Rights Reserved Panel ranking Relationship Matrix Failure 1 per 10, 000 What the Customer Wants Analysis of Competitors How to Satisfy Customer Wants ok G ok F ok G

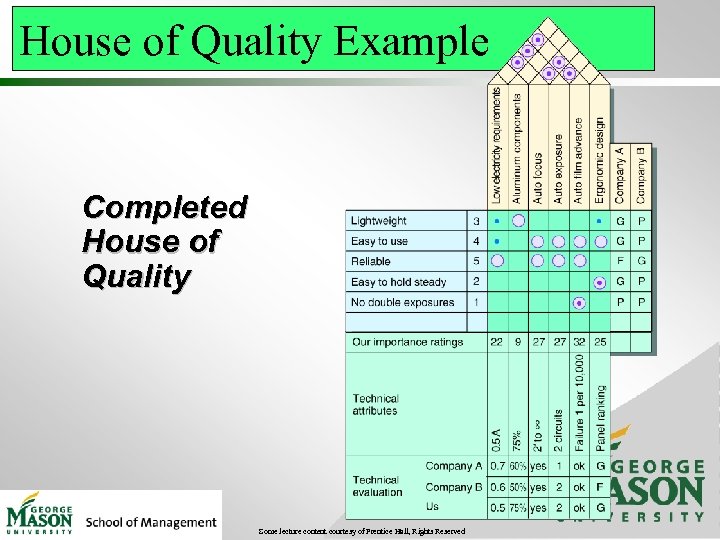

House of Quality Example Completed House of Quality Some lecture content courtesy of Prentice Hall, Rights Reserved

House of Quality Example Completed House of Quality Some lecture content courtesy of Prentice Hall, Rights Reserved

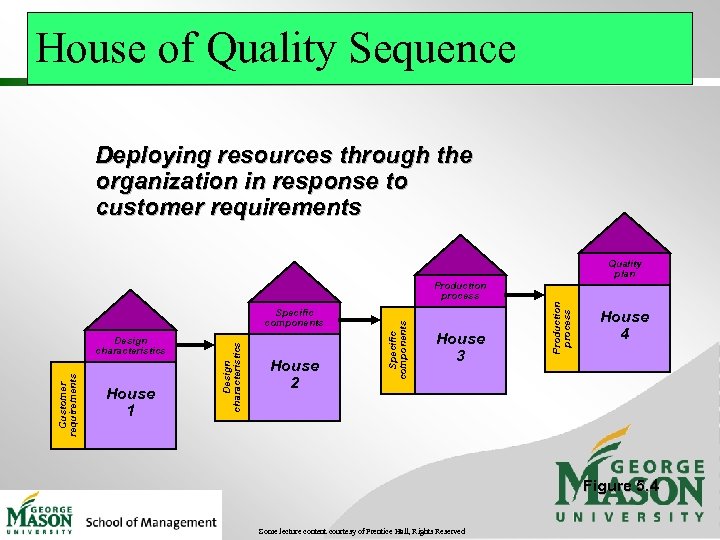

House of Quality Sequence Deploying resources through the organization in response to customer requirements Quality plan Customer requirements House 1 House 2 House 3 Production process Design characteristics Specific components Production process House 4 Figure 5. 4 Some lecture content courtesy of Prentice Hall, Rights Reserved

House of Quality Sequence Deploying resources through the organization in response to customer requirements Quality plan Customer requirements House 1 House 2 House 3 Production process Design characteristics Specific components Production process House 4 Figure 5. 4 Some lecture content courtesy of Prentice Hall, Rights Reserved

Organizing for Product Development Historically – distinct departments þ Duties and responsibilities are defined þ Difficult to foster forward thinking Today – team approach þ Cross functional – representatives from all disciplines or functions þ Concurrent engineering – cross functional team Some lecture content courtesy of Prentice Hall, Rights Reserved

Organizing for Product Development Historically – distinct departments þ Duties and responsibilities are defined þ Difficult to foster forward thinking Today – team approach þ Cross functional – representatives from all disciplines or functions þ Concurrent engineering – cross functional team Some lecture content courtesy of Prentice Hall, Rights Reserved

Manufacturability and Value Engineering Benefits: 1. 2. 3. 4. 5. 6. Reduced complexity of products Additional standardization of products Improved functional aspects of product Improved job design and job safety Improved maintainability of the product Robust design Some lecture content courtesy of Prentice Hall, Rights Reserved

Manufacturability and Value Engineering Benefits: 1. 2. 3. 4. 5. 6. Reduced complexity of products Additional standardization of products Improved functional aspects of product Improved job design and job safety Improved maintainability of the product Robust design Some lecture content courtesy of Prentice Hall, Rights Reserved

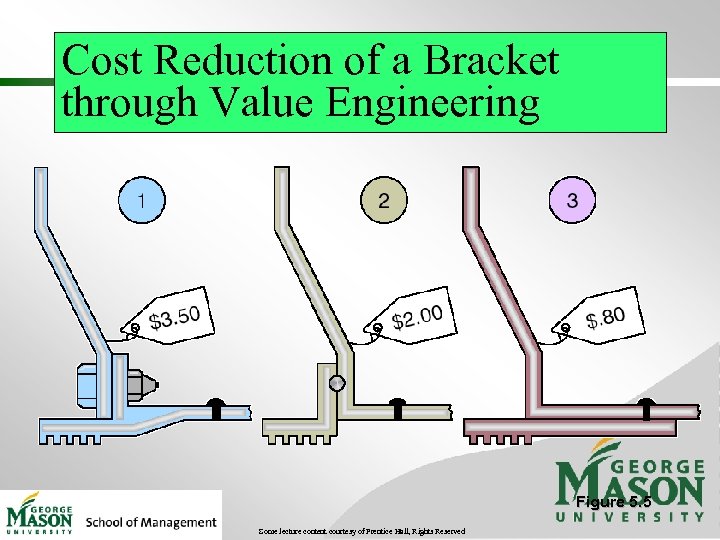

Cost Reduction of a Bracket through Value Engineering Figure 5. 5 Some lecture content courtesy of Prentice Hall, Rights Reserved

Cost Reduction of a Bracket through Value Engineering Figure 5. 5 Some lecture content courtesy of Prentice Hall, Rights Reserved

Issues for Product Development þ þ þ þ Robust design Modular design Computer-aided design (CAD) Computer-aided manufacturing (CAM) Virtual reality technology Value analysis Environmentally friendly design Some lecture content courtesy of Prentice Hall, Rights Reserved

Issues for Product Development þ þ þ þ Robust design Modular design Computer-aided design (CAD) Computer-aided manufacturing (CAM) Virtual reality technology Value analysis Environmentally friendly design Some lecture content courtesy of Prentice Hall, Rights Reserved

Robust Design þ Product is designed so that small variations in production or assembly do not adversely affect the product þ Typically results in lower cost and higher quality Some lecture content courtesy of Prentice Hall, Rights Reserved

Robust Design þ Product is designed so that small variations in production or assembly do not adversely affect the product þ Typically results in lower cost and higher quality Some lecture content courtesy of Prentice Hall, Rights Reserved

Modular Design Products designed in easily segmented components Adds flexibility to both production and marketing Improved ability to satisfy customer requirements Some lecture content courtesy of Prentice Hall, Rights Reserved

Modular Design Products designed in easily segmented components Adds flexibility to both production and marketing Improved ability to satisfy customer requirements Some lecture content courtesy of Prentice Hall, Rights Reserved

Computer Aided Design (CAD) Using computers to design products and prepare engineering documentation Shorter development cycles, improved accuracy, lower cost Information and designs can be deployed worldwide Some lecture content courtesy of Prentice Hall, Rights Reserved

Computer Aided Design (CAD) Using computers to design products and prepare engineering documentation Shorter development cycles, improved accuracy, lower cost Information and designs can be deployed worldwide Some lecture content courtesy of Prentice Hall, Rights Reserved

Extensions of CAD Design for Manufacturing and Assembly (DFMA) þSolve manufacturing problems during the design stage 3 -D Object Modeling þSmall prototype development International data exchange through STEP Some lecture content courtesy of Prentice Hall, Rights Reserved

Extensions of CAD Design for Manufacturing and Assembly (DFMA) þSolve manufacturing problems during the design stage 3 -D Object Modeling þSmall prototype development International data exchange through STEP Some lecture content courtesy of Prentice Hall, Rights Reserved

Computer-Aided Manufacturing (CAM) þ Utilizing specialized computers and program to control manufacturing equipment þ Often driven by the CAD system Some lecture content courtesy of Prentice Hall, Rights Reserved

Computer-Aided Manufacturing (CAM) þ Utilizing specialized computers and program to control manufacturing equipment þ Often driven by the CAD system Some lecture content courtesy of Prentice Hall, Rights Reserved

Virtual Reality Technology þ Computer technology used to develop an interactive, 3 -D model of a product from the basic CAD data þ Allows people to ‘see’ the finished design before a physical model is built þ Very effective in large-scale designs such as plant layout Some lecture content courtesy of Prentice Hall, Rights Reserved

Virtual Reality Technology þ Computer technology used to develop an interactive, 3 -D model of a product from the basic CAD data þ Allows people to ‘see’ the finished design before a physical model is built þ Very effective in large-scale designs such as plant layout Some lecture content courtesy of Prentice Hall, Rights Reserved

Ethics and Environmentally Friendly Designs It is possible to enhance productivity, drive down costs, and preserve resources The Ethical Approach 1. View product design from a systems perspective 2. Consider the entire life cycle of the product Some lecture content courtesy of Prentice Hall, Rights Reserved

Ethics and Environmentally Friendly Designs It is possible to enhance productivity, drive down costs, and preserve resources The Ethical Approach 1. View product design from a systems perspective 2. Consider the entire life cycle of the product Some lecture content courtesy of Prentice Hall, Rights Reserved

Goals for Ethical and Environmentally Friendly Designs 1. Develop safe and more environmentally sound products 2. Minimize waste of raw materials and energy 3. Reduce environmental liabilities 4. Increase cost-effectiveness of complying with environmental regulations 5. Be recognized as a good corporate citizen Some lecture content courtesy of Prentice Hall, Rights Reserved

Goals for Ethical and Environmentally Friendly Designs 1. Develop safe and more environmentally sound products 2. Minimize waste of raw materials and energy 3. Reduce environmental liabilities 4. Increase cost-effectiveness of complying with environmental regulations 5. Be recognized as a good corporate citizen Some lecture content courtesy of Prentice Hall, Rights Reserved

Legal and Industry Standards For Design … þ þ Federal Drug Administration þ þ National Highway Safety Administration Consumer Products Safety Commission Children’s Product Safety Act Some lecture content courtesy of Prentice Hall, Rights Reserved

Legal and Industry Standards For Design … þ þ Federal Drug Administration þ þ National Highway Safety Administration Consumer Products Safety Commission Children’s Product Safety Act Some lecture content courtesy of Prentice Hall, Rights Reserved

Legal and Industry Standards For Manufacture/Assembly … þ Occupational Safety and Health Administration þ Environmental Protection Agency þ Professional ergonomic standards þ State and local laws dealing with employment standards, discrimination, etc. Some lecture content courtesy of Prentice Hall, Rights Reserved

Legal and Industry Standards For Manufacture/Assembly … þ Occupational Safety and Health Administration þ Environmental Protection Agency þ Professional ergonomic standards þ State and local laws dealing with employment standards, discrimination, etc. Some lecture content courtesy of Prentice Hall, Rights Reserved

Legal and Industry Standards For Disassembly/Disposal … þ Vehicle Recycling Partnership þ Increasingly rigid laws worldwide Some lecture content courtesy of Prentice Hall, Rights Reserved

Legal and Industry Standards For Disassembly/Disposal … þ Vehicle Recycling Partnership þ Increasingly rigid laws worldwide Some lecture content courtesy of Prentice Hall, Rights Reserved

Time-Based Competition þ Product life cycles are becoming shorter and the rate of technological change is increasing þ Developing new products faster can result in a competitive advantage Some lecture content courtesy of Prentice Hall, Rights Reserved

Time-Based Competition þ Product life cycles are becoming shorter and the rate of technological change is increasing þ Developing new products faster can result in a competitive advantage Some lecture content courtesy of Prentice Hall, Rights Reserved

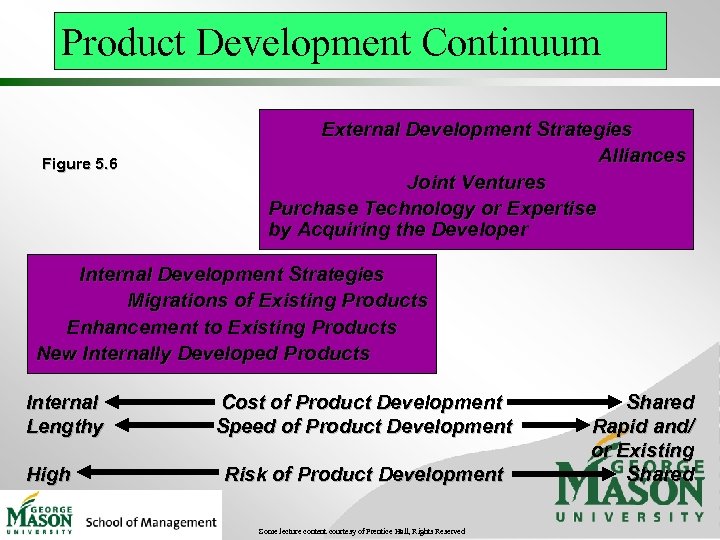

Product Development Continuum Figure 5. 6 External Development Strategies Alliances Joint Ventures Purchase Technology or Expertise by Acquiring the Developer Internal Development Strategies Migrations of Existing Products Enhancement to Existing Products New Internally Developed Products Internal Lengthy High Cost of Product Development Speed of Product Development Risk of Product Development Some lecture content courtesy of Prentice Hall, Rights Reserved Shared Rapid and/ or Existing Shared

Product Development Continuum Figure 5. 6 External Development Strategies Alliances Joint Ventures Purchase Technology or Expertise by Acquiring the Developer Internal Development Strategies Migrations of Existing Products Enhancement to Existing Products New Internally Developed Products Internal Lengthy High Cost of Product Development Speed of Product Development Risk of Product Development Some lecture content courtesy of Prentice Hall, Rights Reserved Shared Rapid and/ or Existing Shared

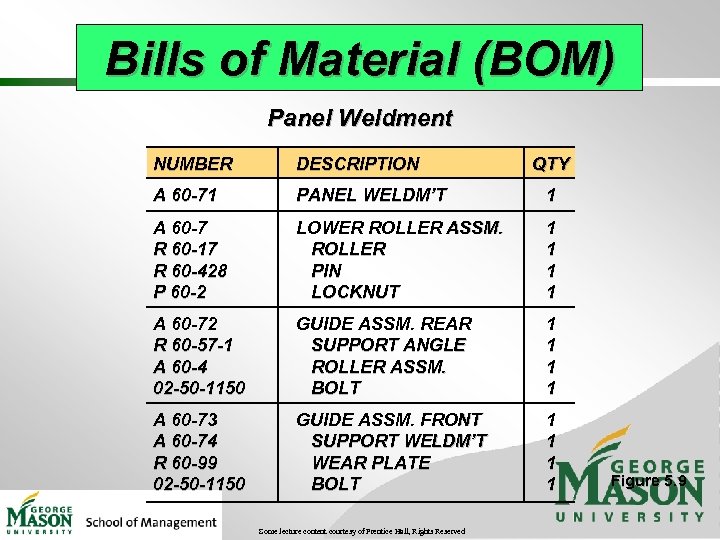

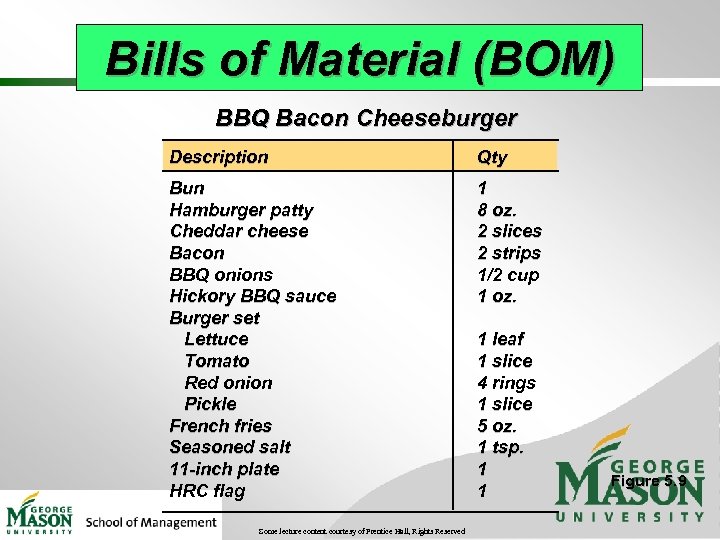

Defining The Product þ First definition is in terms of functions þ Rigorous specifications are developed during the design phase þ Manufactured products will have an engineering drawing þ Bill of material (BOM) lists the components of a product Some lecture content courtesy of Prentice Hall, Rights Reserved

Defining The Product þ First definition is in terms of functions þ Rigorous specifications are developed during the design phase þ Manufactured products will have an engineering drawing þ Bill of material (BOM) lists the components of a product Some lecture content courtesy of Prentice Hall, Rights Reserved

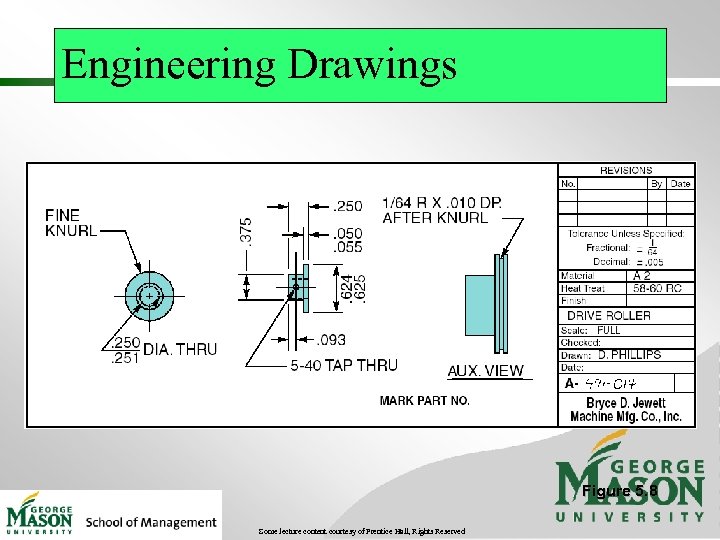

Product Documents Engineering drawing þ Shows dimensions, tolerances, and materials þ Shows codes for Group Technology Bill of Material þ Lists components, quantities and where used þ Shows product structure Some lecture content courtesy of Prentice Hall, Rights Reserved

Product Documents Engineering drawing þ Shows dimensions, tolerances, and materials þ Shows codes for Group Technology Bill of Material þ Lists components, quantities and where used þ Shows product structure Some lecture content courtesy of Prentice Hall, Rights Reserved

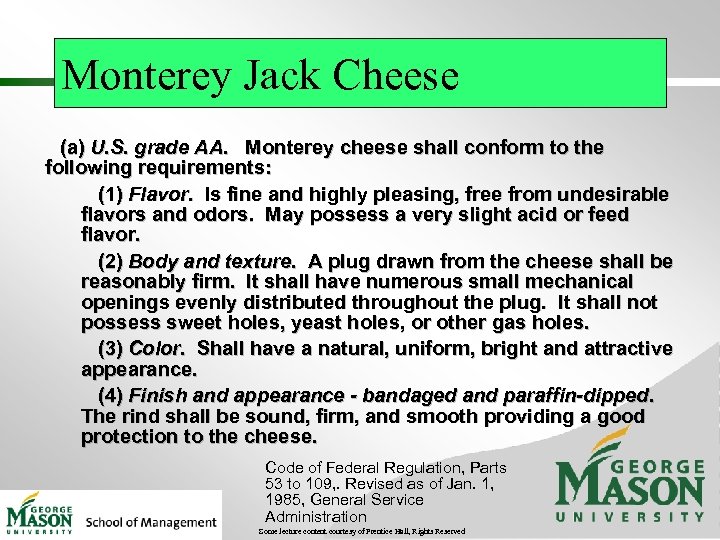

Monterey Jack Cheese (a) U. S. grade AA. Monterey cheese shall conform to the following requirements: (1) Flavor. Is fine and highly pleasing, free from undesirable flavors and odors. May possess a very slight acid or feed flavor. (2) Body and texture. A plug drawn from the cheese shall be reasonably firm. It shall have numerous small mechanical openings evenly distributed throughout the plug. It shall not possess sweet holes, yeast holes, or other gas holes. (3) Color. Shall have a natural, uniform, bright and attractive appearance. (4) Finish and appearance - bandaged and paraffin-dipped. The rind shall be sound, firm, and smooth providing a good protection to the cheese. Code of Federal Regulation, Parts 53 to 109, . Revised as of Jan. 1, 1985, General Service Administration Some lecture content courtesy of Prentice Hall, Rights Reserved

Monterey Jack Cheese (a) U. S. grade AA. Monterey cheese shall conform to the following requirements: (1) Flavor. Is fine and highly pleasing, free from undesirable flavors and odors. May possess a very slight acid or feed flavor. (2) Body and texture. A plug drawn from the cheese shall be reasonably firm. It shall have numerous small mechanical openings evenly distributed throughout the plug. It shall not possess sweet holes, yeast holes, or other gas holes. (3) Color. Shall have a natural, uniform, bright and attractive appearance. (4) Finish and appearance - bandaged and paraffin-dipped. The rind shall be sound, firm, and smooth providing a good protection to the cheese. Code of Federal Regulation, Parts 53 to 109, . Revised as of Jan. 1, 1985, General Service Administration Some lecture content courtesy of Prentice Hall, Rights Reserved

Engineering Drawings Figure 5. 8 Some lecture content courtesy of Prentice Hall, Rights Reserved

Engineering Drawings Figure 5. 8 Some lecture content courtesy of Prentice Hall, Rights Reserved

Bills of Material (BOM) Panel Weldment NUMBER DESCRIPTION A 60 -71 PANEL WELDM’T 1 A 60 -7 R 60 -17 R 60 -428 P 60 -2 LOWER ROLLER ASSM. ROLLER PIN LOCKNUT 1 1 A 60 -72 R 60 -57 -1 A 60 -4 02 -50 -1150 GUIDE ASSM. REAR SUPPORT ANGLE ROLLER ASSM. BOLT 1 1 A 60 -73 A 60 -74 R 60 -99 02 -50 -1150 GUIDE ASSM. FRONT SUPPORT WELDM’T WEAR PLATE BOLT 1 1 Some lecture content courtesy of Prentice Hall, Rights Reserved QTY Figure 5. 9

Bills of Material (BOM) Panel Weldment NUMBER DESCRIPTION A 60 -71 PANEL WELDM’T 1 A 60 -7 R 60 -17 R 60 -428 P 60 -2 LOWER ROLLER ASSM. ROLLER PIN LOCKNUT 1 1 A 60 -72 R 60 -57 -1 A 60 -4 02 -50 -1150 GUIDE ASSM. REAR SUPPORT ANGLE ROLLER ASSM. BOLT 1 1 A 60 -73 A 60 -74 R 60 -99 02 -50 -1150 GUIDE ASSM. FRONT SUPPORT WELDM’T WEAR PLATE BOLT 1 1 Some lecture content courtesy of Prentice Hall, Rights Reserved QTY Figure 5. 9

Bills of Material (BOM) BBQ Bacon Cheeseburger Description Qty Bun Hamburger patty Cheddar cheese Bacon BBQ onions Hickory BBQ sauce Burger set Lettuce Tomato Red onion Pickle French fries Seasoned salt 11 -inch plate HRC flag 1 8 oz. 2 slices 2 strips 1/2 cup 1 oz. Some lecture content courtesy of Prentice Hall, Rights Reserved 1 leaf 1 slice 4 rings 1 slice 5 oz. 1 tsp. 1 1 Figure 5. 9

Bills of Material (BOM) BBQ Bacon Cheeseburger Description Qty Bun Hamburger patty Cheddar cheese Bacon BBQ onions Hickory BBQ sauce Burger set Lettuce Tomato Red onion Pickle French fries Seasoned salt 11 -inch plate HRC flag 1 8 oz. 2 slices 2 strips 1/2 cup 1 oz. Some lecture content courtesy of Prentice Hall, Rights Reserved 1 leaf 1 slice 4 rings 1 slice 5 oz. 1 tsp. 1 1 Figure 5. 9

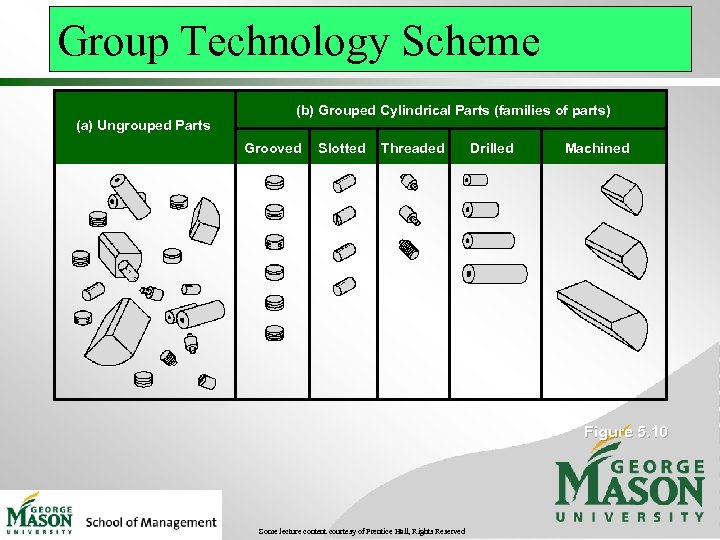

Group Technology þ Parts grouped into families with similar characteristics þ Coding system describes processing and physical characteristics þ Part families can be produced in dedicated manufacturing cells Some lecture content courtesy of Prentice Hall, Rights Reserved

Group Technology þ Parts grouped into families with similar characteristics þ Coding system describes processing and physical characteristics þ Part families can be produced in dedicated manufacturing cells Some lecture content courtesy of Prentice Hall, Rights Reserved

Group Technology Scheme (a) Ungrouped Parts (b) Grouped Cylindrical Parts (families of parts) Grooved Slotted Threaded Drilled Machined Figure 5. 10 Some lecture content courtesy of Prentice Hall, Rights Reserved

Group Technology Scheme (a) Ungrouped Parts (b) Grouped Cylindrical Parts (families of parts) Grooved Slotted Threaded Drilled Machined Figure 5. 10 Some lecture content courtesy of Prentice Hall, Rights Reserved

Group Technology Benefits • • Improved design Reduced raw material and purchases Simplified production planning and control Improved layout, routing, and machine loading • Reduced tooling setup time, work-inprocess, and production time Some lecture content courtesy of Prentice Hall, Rights Reserved

Group Technology Benefits • • Improved design Reduced raw material and purchases Simplified production planning and control Improved layout, routing, and machine loading • Reduced tooling setup time, work-inprocess, and production time Some lecture content courtesy of Prentice Hall, Rights Reserved

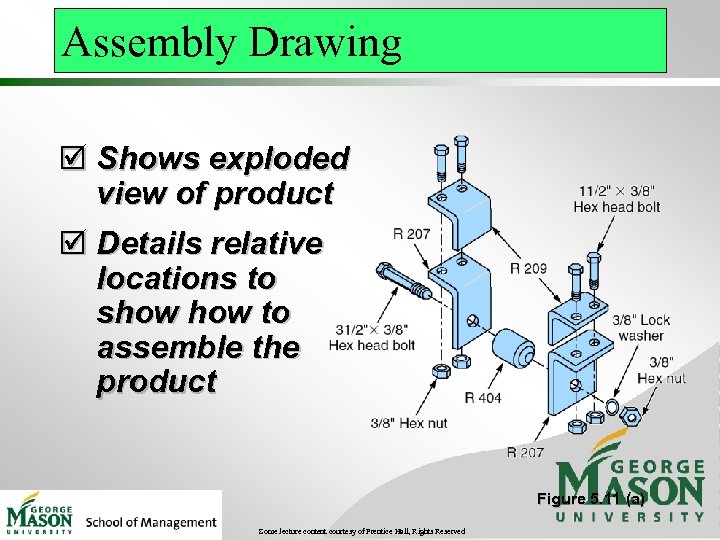

Documents for Production Assembly drawing Assembly chart Route sheet Work order Engineering change notices (ECNs) Some lecture content courtesy of Prentice Hall, Rights Reserved

Documents for Production Assembly drawing Assembly chart Route sheet Work order Engineering change notices (ECNs) Some lecture content courtesy of Prentice Hall, Rights Reserved

Assembly Drawing þ Shows exploded view of product þ Details relative locations to show to assemble the product Figure 5. 11 (a) Some lecture content courtesy of Prentice Hall, Rights Reserved

Assembly Drawing þ Shows exploded view of product þ Details relative locations to show to assemble the product Figure 5. 11 (a) Some lecture content courtesy of Prentice Hall, Rights Reserved

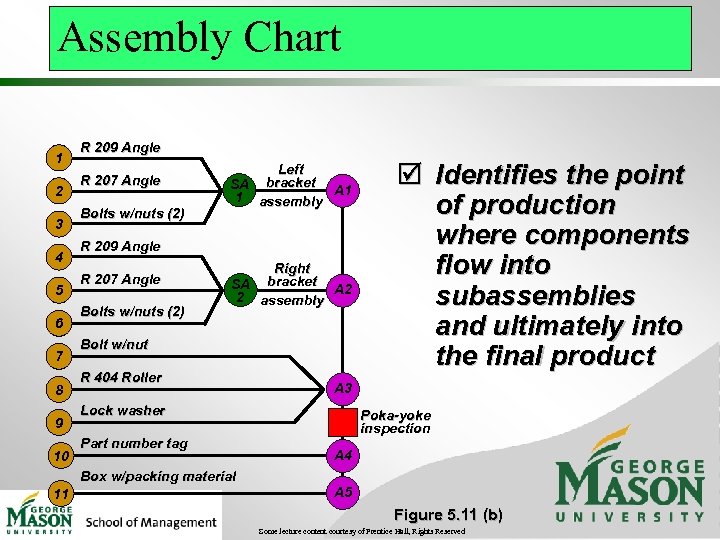

Assembly Chart 1 2 3 4 5 6 7 8 9 10 R 209 Angle R 207 Angle Bolts w/nuts (2) Left bracket SA A 1 1 assembly R 209 Angle R 207 Angle Bolts w/nuts (2) Right bracket SA A 2 2 assembly Bolt w/nut R 404 Roller A 3 Lock washer Part number tag þ Identifies the point of production where components flow into subassemblies and ultimately into the final product Poka-yoke inspection A 4 Box w/packing material 11 A 5 Figure 5. 11 (b) Some lecture content courtesy of Prentice Hall, Rights Reserved

Assembly Chart 1 2 3 4 5 6 7 8 9 10 R 209 Angle R 207 Angle Bolts w/nuts (2) Left bracket SA A 1 1 assembly R 209 Angle R 207 Angle Bolts w/nuts (2) Right bracket SA A 2 2 assembly Bolt w/nut R 404 Roller A 3 Lock washer Part number tag þ Identifies the point of production where components flow into subassemblies and ultimately into the final product Poka-yoke inspection A 4 Box w/packing material 11 A 5 Figure 5. 11 (b) Some lecture content courtesy of Prentice Hall, Rights Reserved

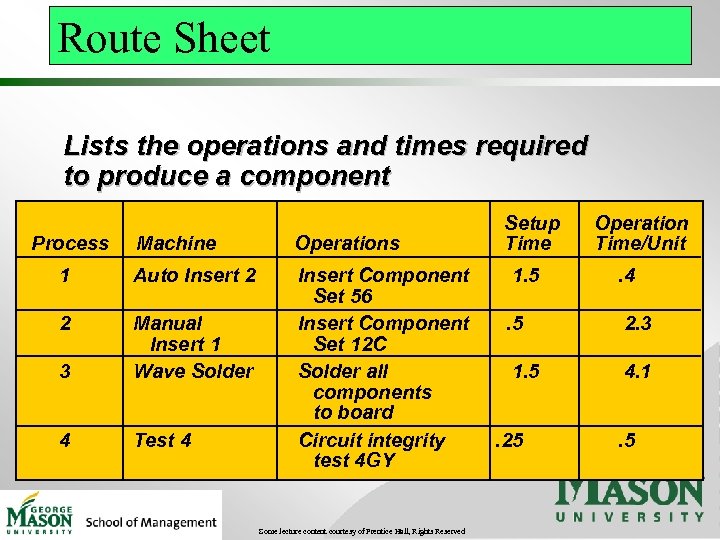

Route Sheet Lists the operations and times required to produce a component Process Machine Operations 1 Auto Insert 2 2 3 Manual Insert 1 Wave Solder 4 Test 4 Insert Component Set 56 Insert Component Set 12 C Solder all components to board Circuit integrity test 4 GY Some lecture content courtesy of Prentice Hall, Rights Reserved Setup Time Operation Time/Unit 1. 5 . 4 . 5 2. 3 1. 5 4. 1 . 25 . 5

Route Sheet Lists the operations and times required to produce a component Process Machine Operations 1 Auto Insert 2 2 3 Manual Insert 1 Wave Solder 4 Test 4 Insert Component Set 56 Insert Component Set 12 C Solder all components to board Circuit integrity test 4 GY Some lecture content courtesy of Prentice Hall, Rights Reserved Setup Time Operation Time/Unit 1. 5 . 4 . 5 2. 3 1. 5 4. 1 . 25 . 5

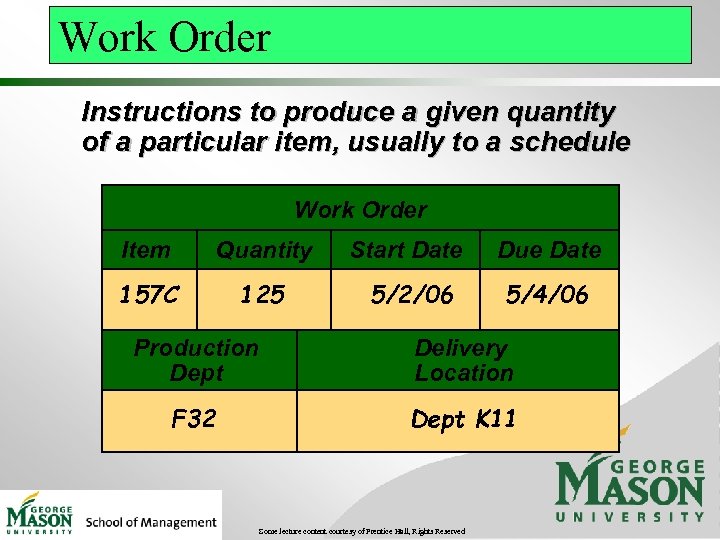

Work Order Instructions to produce a given quantity of a particular item, usually to a schedule Work Order Item Quantity Start Date Due Date 157 C 125 5/2/06 5/4/06 Production Dept Delivery Location F 32 Dept K 11 Some lecture content courtesy of Prentice Hall, Rights Reserved

Work Order Instructions to produce a given quantity of a particular item, usually to a schedule Work Order Item Quantity Start Date Due Date 157 C 125 5/2/06 5/4/06 Production Dept Delivery Location F 32 Dept K 11 Some lecture content courtesy of Prentice Hall, Rights Reserved

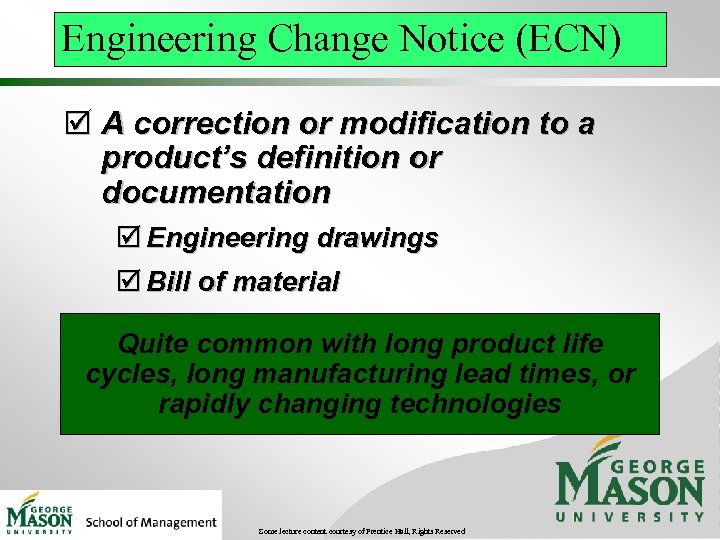

Engineering Change Notice (ECN) þ A correction or modification to a product’s definition or documentation þ Engineering drawings þ Bill of material Quite common with long product life cycles, long manufacturing lead times, or rapidly changing technologies Some lecture content courtesy of Prentice Hall, Rights Reserved

Engineering Change Notice (ECN) þ A correction or modification to a product’s definition or documentation þ Engineering drawings þ Bill of material Quite common with long product life cycles, long manufacturing lead times, or rapidly changing technologies Some lecture content courtesy of Prentice Hall, Rights Reserved

Configuration Management þ The need to manage ECNs has led to the development of configuration management systems þ A product’s planned and changing components are accurately identified and control and accountability for change are identified and maintained Some lecture content courtesy of Prentice Hall, Rights Reserved

Configuration Management þ The need to manage ECNs has led to the development of configuration management systems þ A product’s planned and changing components are accurately identified and control and accountability for change are identified and maintained Some lecture content courtesy of Prentice Hall, Rights Reserved

Product Lifecycle Management þ Integrated software that brings together most, if not all, elements of product design and manufacture þ Product design þ CAD/CAM, DFMA þ Product routing þ Materials þ Assembly þ Environmental Some lecture content courtesy of Prentice Hall, Rights Reserved

Product Lifecycle Management þ Integrated software that brings together most, if not all, elements of product design and manufacture þ Product design þ CAD/CAM, DFMA þ Product routing þ Materials þ Assembly þ Environmental Some lecture content courtesy of Prentice Hall, Rights Reserved

Service Design þ Service typically includes direct interaction with the customer þ Increased opportunity for customization þ Reduced productivity þ Cost and quality are still determined at the design stage þ Delay customization þ Modularization þ Reduce customer interaction, often through automation Some lecture content courtesy of Prentice Hall, Rights Reserved

Service Design þ Service typically includes direct interaction with the customer þ Increased opportunity for customization þ Reduced productivity þ Cost and quality are still determined at the design stage þ Delay customization þ Modularization þ Reduce customer interaction, often through automation Some lecture content courtesy of Prentice Hall, Rights Reserved

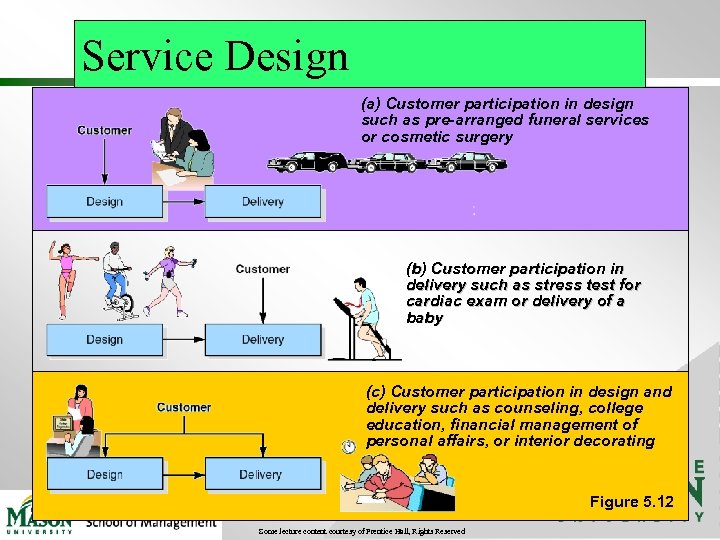

Service Design (a) Customer participation in design such as pre-arranged funeral services or cosmetic surgery (b) Customer participation in delivery such as stress test for cardiac exam or delivery of a baby (c) Customer participation in design and delivery such as counseling, college education, financial management of personal affairs, or interior decorating Figure 5. 12 Some lecture content courtesy of Prentice Hall, Rights Reserved

Service Design (a) Customer participation in design such as pre-arranged funeral services or cosmetic surgery (b) Customer participation in delivery such as stress test for cardiac exam or delivery of a baby (c) Customer participation in design and delivery such as counseling, college education, financial management of personal affairs, or interior decorating Figure 5. 12 Some lecture content courtesy of Prentice Hall, Rights Reserved

Moments of Truth þ Concept created by Jan Carlzon of Scandinavian Airways þ Critical moments between the customer and the organization that determine customer satisfaction þ There may be many of these moments þ These are opportunities to gain or lose business Some lecture content courtesy of Prentice Hall, Rights Reserved

Moments of Truth þ Concept created by Jan Carlzon of Scandinavian Airways þ Critical moments between the customer and the organization that determine customer satisfaction þ There may be many of these moments þ These are opportunities to gain or lose business Some lecture content courtesy of Prentice Hall, Rights Reserved

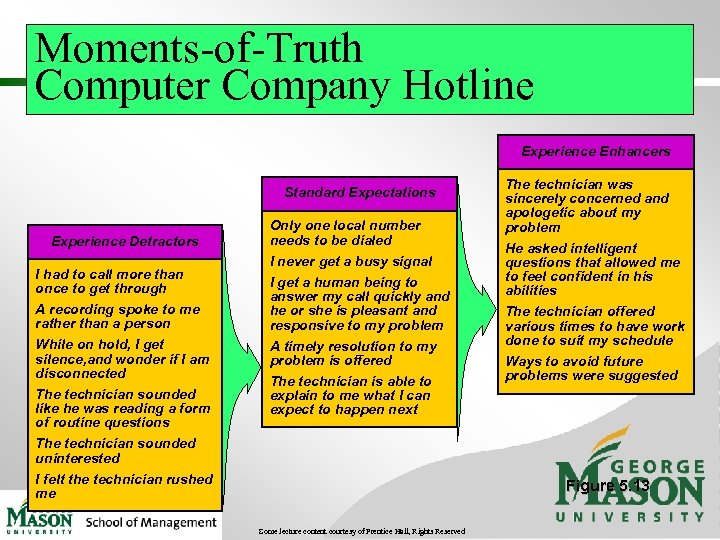

Moments-of-Truth Computer Company Hotline Experience Enhancers Standard Expectations Experience Detractors I had to call more than once to get through A recording spoke to me rather than a person While on hold, I get silence, and wonder if I am disconnected The technician sounded like he was reading a form of routine questions The technician sounded uninterested I felt the technician rushed me Only one local number needs to be dialed I never get a busy signal I get a human being to answer my call quickly and he or she is pleasant and responsive to my problem A timely resolution to my problem is offered The technician is able to explain to me what I can expect to happen next The technician was sincerely concerned and apologetic about my problem He asked intelligent questions that allowed me to feel confident in his abilities The technician offered various times to have work done to suit my schedule Ways to avoid future problems were suggested Figure 5. 13 Some lecture content courtesy of Prentice Hall, Rights Reserved

Moments-of-Truth Computer Company Hotline Experience Enhancers Standard Expectations Experience Detractors I had to call more than once to get through A recording spoke to me rather than a person While on hold, I get silence, and wonder if I am disconnected The technician sounded like he was reading a form of routine questions The technician sounded uninterested I felt the technician rushed me Only one local number needs to be dialed I never get a busy signal I get a human being to answer my call quickly and he or she is pleasant and responsive to my problem A timely resolution to my problem is offered The technician is able to explain to me what I can expect to happen next The technician was sincerely concerned and apologetic about my problem He asked intelligent questions that allowed me to feel confident in his abilities The technician offered various times to have work done to suit my schedule Ways to avoid future problems were suggested Figure 5. 13 Some lecture content courtesy of Prentice Hall, Rights Reserved

Documents for Services þ High levels of customer interaction necessitates different documentation þ Often explicit job instructions for moments-of-truth þ Scripts and storyboards are other techniques Some lecture content courtesy of Prentice Hall, Rights Reserved

Documents for Services þ High levels of customer interaction necessitates different documentation þ Often explicit job instructions for moments-of-truth þ Scripts and storyboards are other techniques Some lecture content courtesy of Prentice Hall, Rights Reserved

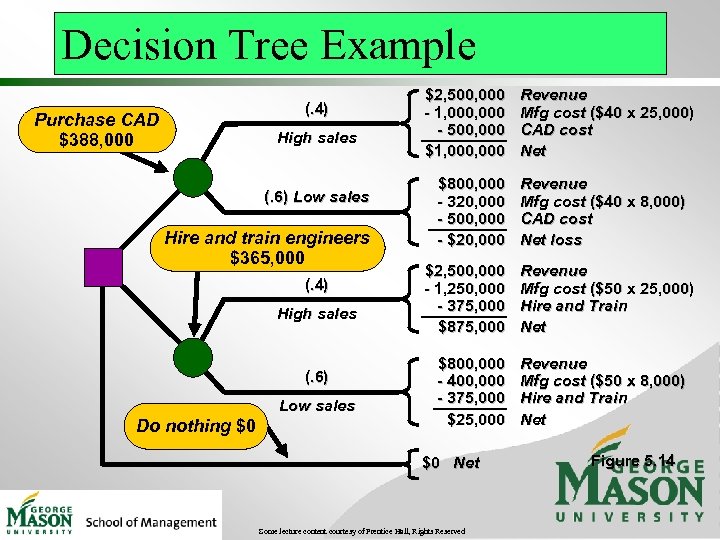

Application of Decision Trees to Product Design þ Particularly useful when there a series of decisions and outcomes which lead to other decisions and outcomes Some lecture content courtesy of Prentice Hall, Rights Reserved

Application of Decision Trees to Product Design þ Particularly useful when there a series of decisions and outcomes which lead to other decisions and outcomes Some lecture content courtesy of Prentice Hall, Rights Reserved

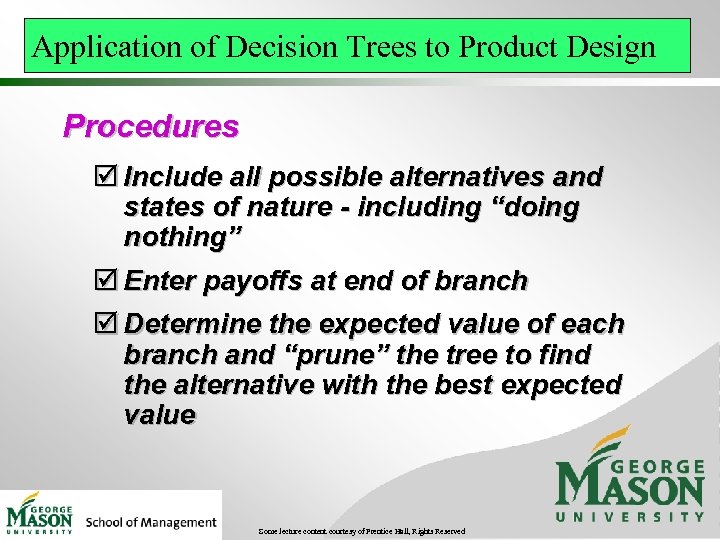

Application of Decision Trees to Product Design Procedures þ Include all possible alternatives and states of nature - including “doing nothing” þ Enter payoffs at end of branch þ Determine the expected value of each branch and “prune” the tree to find the alternative with the best expected value Some lecture content courtesy of Prentice Hall, Rights Reserved

Application of Decision Trees to Product Design Procedures þ Include all possible alternatives and states of nature - including “doing nothing” þ Enter payoffs at end of branch þ Determine the expected value of each branch and “prune” the tree to find the alternative with the best expected value Some lecture content courtesy of Prentice Hall, Rights Reserved

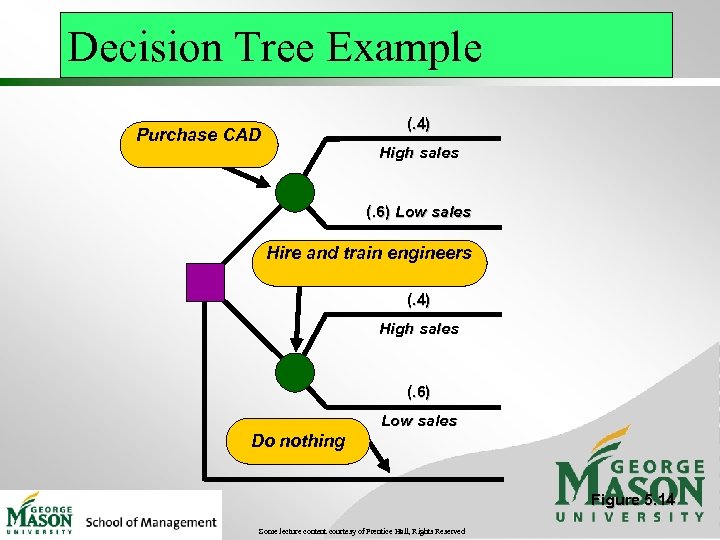

Decision Tree Example (. 4) Purchase CAD High sales (. 6) Low sales Hire and train engineers (. 4) High sales (. 6) Low sales Do nothing Figure 5. 14 Some lecture content courtesy of Prentice Hall, Rights Reserved

Decision Tree Example (. 4) Purchase CAD High sales (. 6) Low sales Hire and train engineers (. 4) High sales (. 6) Low sales Do nothing Figure 5. 14 Some lecture content courtesy of Prentice Hall, Rights Reserved

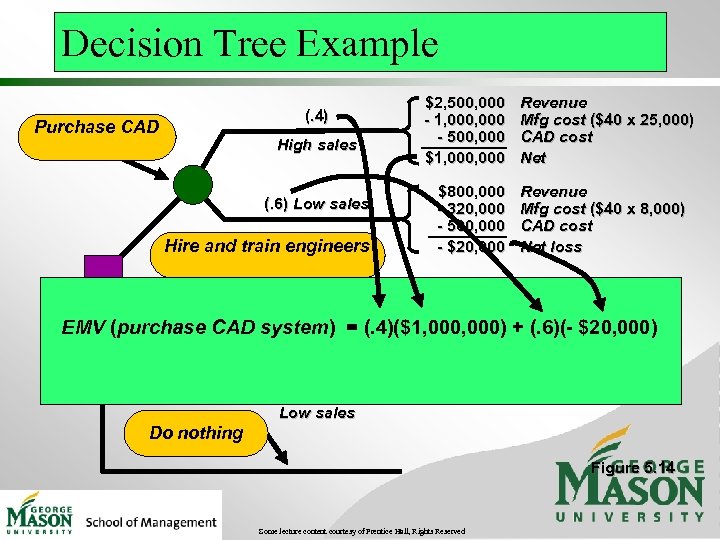

Decision Tree Example (. 4) Purchase CAD High sales (. 6) Low sales Hire and train engineers $2, 500, 000 - 1, 000 - 500, 000 $1, 000 $800, 000 - 320, 000 - 500, 000 - $20, 000 Revenue Mfg cost ($40 x 25, 000) CAD cost Net Revenue Mfg cost ($40 x 8, 000) CAD cost Net loss (. 4) High sales EMV (purchase CAD system) = (. 4)($1, 000) + (. 6)(- $20, 000) (. 6) Low sales Do nothing Figure 5. 14 Some lecture content courtesy of Prentice Hall, Rights Reserved

Decision Tree Example (. 4) Purchase CAD High sales (. 6) Low sales Hire and train engineers $2, 500, 000 - 1, 000 - 500, 000 $1, 000 $800, 000 - 320, 000 - 500, 000 - $20, 000 Revenue Mfg cost ($40 x 25, 000) CAD cost Net Revenue Mfg cost ($40 x 8, 000) CAD cost Net loss (. 4) High sales EMV (purchase CAD system) = (. 4)($1, 000) + (. 6)(- $20, 000) (. 6) Low sales Do nothing Figure 5. 14 Some lecture content courtesy of Prentice Hall, Rights Reserved

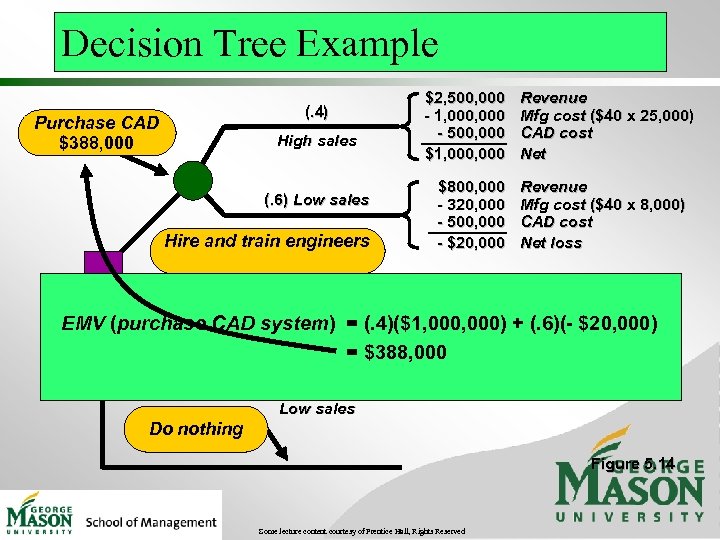

Decision Tree Example (. 4) Purchase CAD $388, 000 High sales (. 6) Low sales Hire and train engineers $2, 500, 000 - 1, 000 - 500, 000 $1, 000 $800, 000 - 320, 000 - 500, 000 - $20, 000 Revenue Mfg cost ($40 x 25, 000) CAD cost Net Revenue Mfg cost ($40 x 8, 000) CAD cost Net loss (. 4) High sales EMV (purchase CAD system) = (. 4)($1, 000) + (. 6)(- $20, 000) = $388, 000 (. 6) Low sales Do nothing Figure 5. 14 Some lecture content courtesy of Prentice Hall, Rights Reserved

Decision Tree Example (. 4) Purchase CAD $388, 000 High sales (. 6) Low sales Hire and train engineers $2, 500, 000 - 1, 000 - 500, 000 $1, 000 $800, 000 - 320, 000 - 500, 000 - $20, 000 Revenue Mfg cost ($40 x 25, 000) CAD cost Net Revenue Mfg cost ($40 x 8, 000) CAD cost Net loss (. 4) High sales EMV (purchase CAD system) = (. 4)($1, 000) + (. 6)(- $20, 000) = $388, 000 (. 6) Low sales Do nothing Figure 5. 14 Some lecture content courtesy of Prentice Hall, Rights Reserved

Decision Tree Example (. 4) Purchase CAD $388, 000 High sales (. 6) Low sales Hire and train engineers $365, 000 (. 4) High sales (. 6) Low sales Do nothing $0 $2, 500, 000 - 1, 000 - 500, 000 $1, 000 $800, 000 - 320, 000 - 500, 000 - $20, 000 $2, 500, 000 - 1, 250, 000 - 375, 000 $800, 000 - 400, 000 - 375, 000 $25, 000 $0 Net Some lecture content courtesy of Prentice Hall, Rights Reserved Revenue Mfg cost ($40 x 25, 000) CAD cost Net Revenue Mfg cost ($40 x 8, 000) CAD cost Net loss Revenue Mfg cost ($50 x 25, 000) Hire and Train Net Revenue Mfg cost ($50 x 8, 000) Hire and Train Net Figure 5. 14

Decision Tree Example (. 4) Purchase CAD $388, 000 High sales (. 6) Low sales Hire and train engineers $365, 000 (. 4) High sales (. 6) Low sales Do nothing $0 $2, 500, 000 - 1, 000 - 500, 000 $1, 000 $800, 000 - 320, 000 - 500, 000 - $20, 000 $2, 500, 000 - 1, 250, 000 - 375, 000 $800, 000 - 400, 000 - 375, 000 $25, 000 $0 Net Some lecture content courtesy of Prentice Hall, Rights Reserved Revenue Mfg cost ($40 x 25, 000) CAD cost Net Revenue Mfg cost ($40 x 8, 000) CAD cost Net loss Revenue Mfg cost ($50 x 25, 000) Hire and Train Net Revenue Mfg cost ($50 x 8, 000) Hire and Train Net Figure 5. 14