97bf7856b959ac2d9a5e7f390139d4fe.ppt

- Количество слайдов: 36

Operations Management Managing Quality Chapter 6 1

Operations Management Managing Quality Chapter 6 1

Outline ¨Quality and strategy. ¨Defining quality. ¨International quality standards. ¨Total quality management. ¨Tools of TQM. ¨Inspection. ¨TQM in services. 2

Outline ¨Quality and strategy. ¨Defining quality. ¨International quality standards. ¨Total quality management. ¨Tools of TQM. ¨Inspection. ¨TQM in services. 2

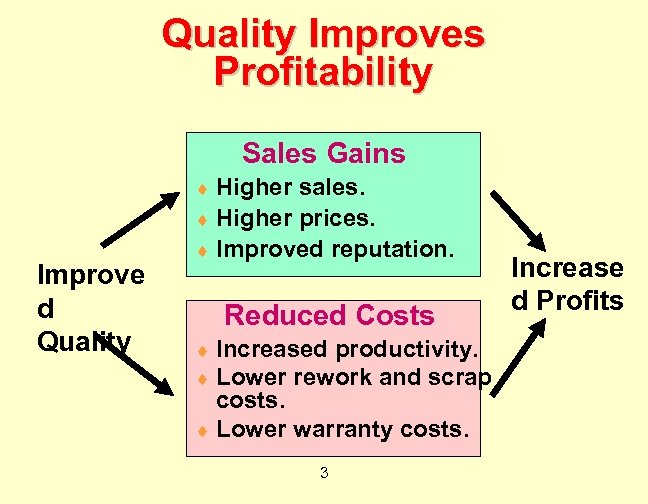

Quality Improves Profitability Sales Gains ¨ Higher Improve d Quality sales. ¨ Higher prices. ¨ Improved reputation. Reduced Costs ¨ Increased productivity. ¨ Lower rework and scrap costs. ¨ Lower warranty costs. 3 Increase d Profits

Quality Improves Profitability Sales Gains ¨ Higher Improve d Quality sales. ¨ Higher prices. ¨ Improved reputation. Reduced Costs ¨ Increased productivity. ¨ Lower rework and scrap costs. ¨ Lower warranty costs. 3 Increase d Profits

Definitions of Quality ¨ Totality of features & characteristics that bears on a product or services ability to satisfy customer needs. (American Society for Quality) ¨ User-Based: What consumer says it is. ¨ Manufacturing-Based: Degree to which a product conforms to design 4 specification.

Definitions of Quality ¨ Totality of features & characteristics that bears on a product or services ability to satisfy customer needs. (American Society for Quality) ¨ User-Based: What consumer says it is. ¨ Manufacturing-Based: Degree to which a product conforms to design 4 specification.

Dimensions of Quality for Goods ¨ Operation or Performance. ¨ Reliability. ¨ Durability. Quality ¨ Conformance. ¨ Serviceability. ¨ Appearance to senses. ¨ Perceived quality. 5

Dimensions of Quality for Goods ¨ Operation or Performance. ¨ Reliability. ¨ Durability. Quality ¨ Conformance. ¨ Serviceability. ¨ Appearance to senses. ¨ Perceived quality. 5

Implications of Quality ¨ Company reputation. ¨ Real or perceived. ¨ Product liability. ¨ Large $ can be awarded. ¨ Global implications. ¨ Company quality affects national image. 6

Implications of Quality ¨ Company reputation. ¨ Real or perceived. ¨ Product liability. ¨ Large $ can be awarded. ¨ Global implications. ¨ Company quality affects national image. 6

International Quality Standards ¨ ISO 9000 series (Europe/EC) ¨ Common quality standards for products sold in Europe (even if made in U. S. ). ¨ ISO 14000 series (Europe/EC) ¨ Standards for recycling, labeling etc. 7

International Quality Standards ¨ ISO 9000 series (Europe/EC) ¨ Common quality standards for products sold in Europe (even if made in U. S. ). ¨ ISO 14000 series (Europe/EC) ¨ Standards for recycling, labeling etc. 7

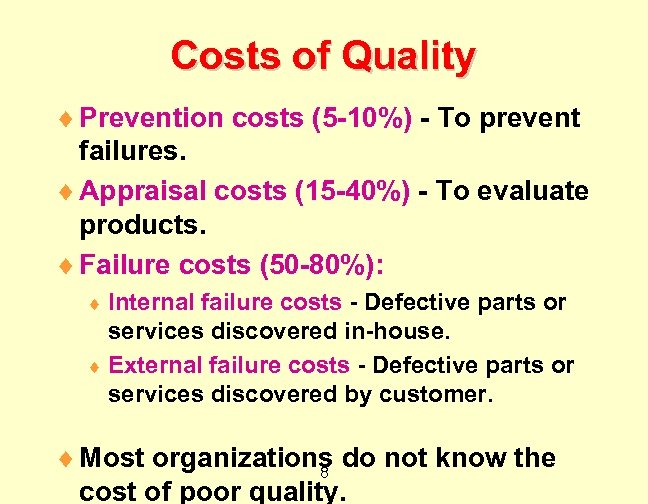

Costs of Quality ¨ Prevention costs (5 -10%) - To prevent failures. ¨ Appraisal costs (15 -40%) - To evaluate products. ¨ Failure costs (50 -80%): ¨ Internal failure costs - Defective parts or services discovered in-house. ¨ External failure costs - Defective parts or services discovered by customer. ¨ Most organizations do not know the 8 cost of poor quality.

Costs of Quality ¨ Prevention costs (5 -10%) - To prevent failures. ¨ Appraisal costs (15 -40%) - To evaluate products. ¨ Failure costs (50 -80%): ¨ Internal failure costs - Defective parts or services discovered in-house. ¨ External failure costs - Defective parts or services discovered by customer. ¨ Most organizations do not know the 8 cost of poor quality.

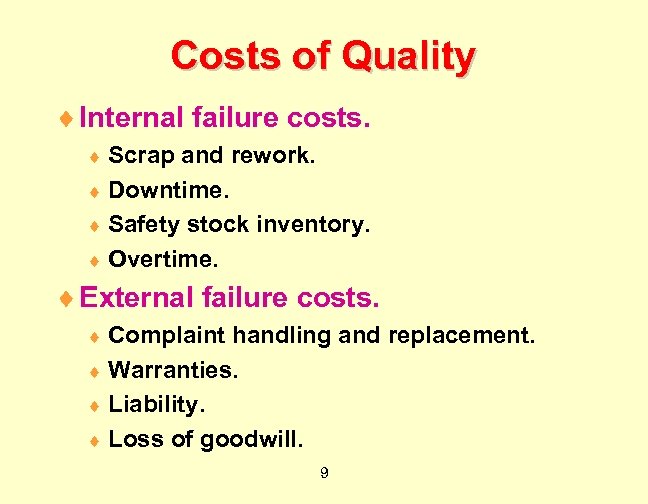

Costs of Quality ¨ Internal failure costs. ¨ Scrap and rework. ¨ Downtime. ¨ Safety stock inventory. ¨ Overtime. ¨ External failure costs. ¨ Complaint handling and replacement. ¨ Warranties. ¨ Liability. ¨ Loss of goodwill. 9

Costs of Quality ¨ Internal failure costs. ¨ Scrap and rework. ¨ Downtime. ¨ Safety stock inventory. ¨ Overtime. ¨ External failure costs. ¨ Complaint handling and replacement. ¨ Warranties. ¨ Liability. ¨ Loss of goodwill. 9

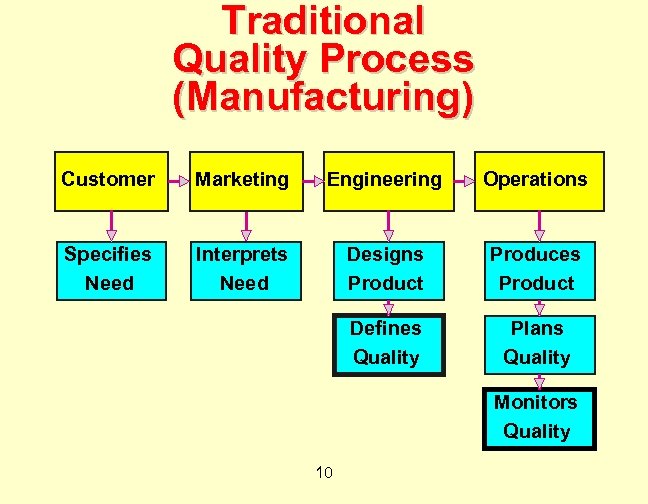

Traditional Quality Process (Manufacturing) Customer Marketing Engineering Operations Specifies Need Interprets Need Designs Product Produces Product Defines Quality Plans Quality Monitors Quality 10

Traditional Quality Process (Manufacturing) Customer Marketing Engineering Operations Specifies Need Interprets Need Designs Product Produces Product Defines Quality Plans Quality Monitors Quality 10

TQM - Total Quality Management ¨ Encompasses entire organization from supplier to customer. ¨ Commitment by management to a continuing company-wide drive toward excellence in all aspects of products and services that are important to the customer. 11

TQM - Total Quality Management ¨ Encompasses entire organization from supplier to customer. ¨ Commitment by management to a continuing company-wide drive toward excellence in all aspects of products and services that are important to the customer. 11

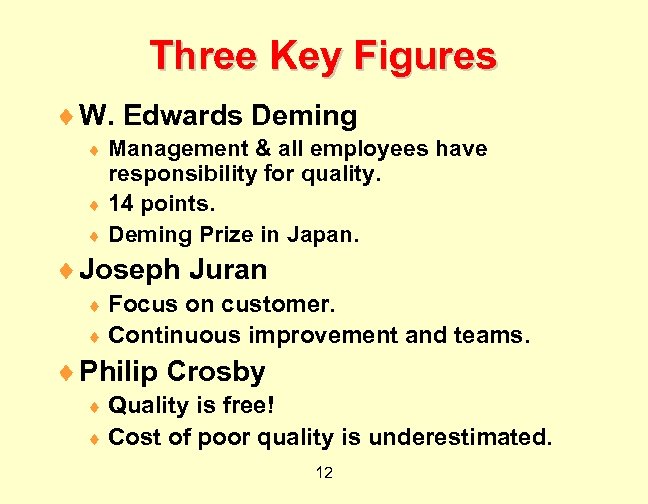

Three Key Figures ¨ W. Edwards Deming Management & all employees have responsibility for quality. ¨ 14 points. ¨ Deming Prize in Japan. ¨ ¨ Joseph Juran ¨ Focus on customer. ¨ Continuous improvement and teams. ¨ Philip Crosby ¨ Quality is free! ¨ Cost of poor quality is underestimated. 12

Three Key Figures ¨ W. Edwards Deming Management & all employees have responsibility for quality. ¨ 14 points. ¨ Deming Prize in Japan. ¨ ¨ Joseph Juran ¨ Focus on customer. ¨ Continuous improvement and teams. ¨ Philip Crosby ¨ Quality is free! ¨ Cost of poor quality is underestimated. 12

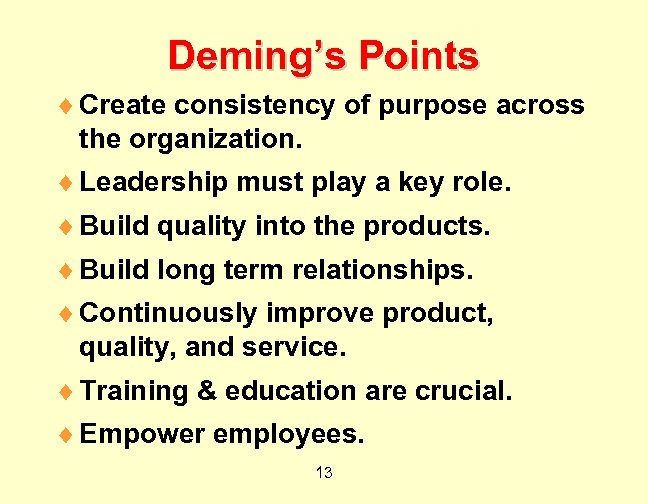

Deming’s Points ¨ Create consistency of purpose across the organization. ¨ Leadership must play a key role. ¨ Build quality into the products. ¨ Build long term relationships. ¨ Continuously improve product, quality, and service. ¨ Training & education are crucial. ¨ Empower employees. 13

Deming’s Points ¨ Create consistency of purpose across the organization. ¨ Leadership must play a key role. ¨ Build quality into the products. ¨ Build long term relationships. ¨ Continuously improve product, quality, and service. ¨ Training & education are crucial. ¨ Empower employees. 13

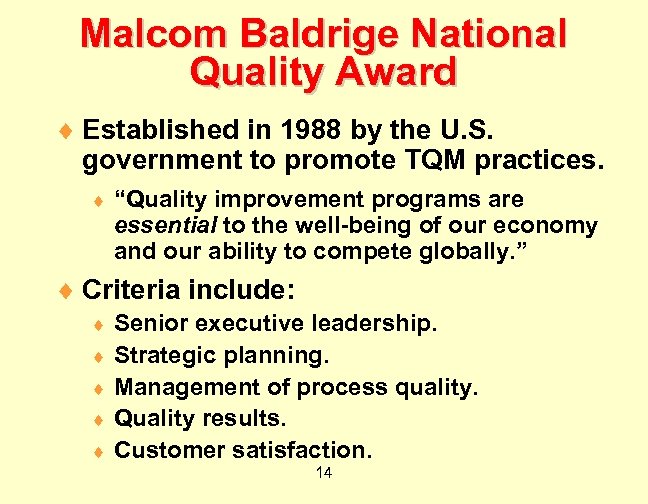

Malcom Baldrige National Quality Award ¨ Established in 1988 by the U. S. government to promote TQM practices. ¨ “Quality improvement programs are essential to the well-being of our economy and our ability to compete globally. ” ¨ Criteria include: ¨ ¨ ¨ Senior executive leadership. Strategic planning. Management of process quality. Quality results. Customer satisfaction. 14

Malcom Baldrige National Quality Award ¨ Established in 1988 by the U. S. government to promote TQM practices. ¨ “Quality improvement programs are essential to the well-being of our economy and our ability to compete globally. ” ¨ Criteria include: ¨ ¨ ¨ Senior executive leadership. Strategic planning. Management of process quality. Quality results. Customer satisfaction. 14

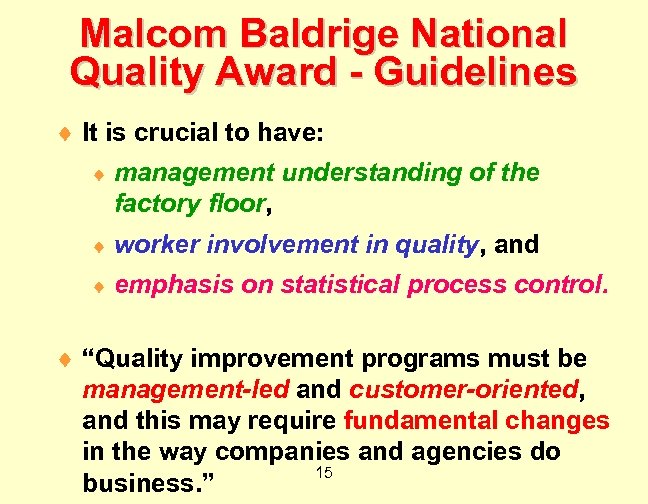

Malcom Baldrige National Quality Award - Guidelines ¨ It is crucial to have: ¨ management understanding of the factory floor, ¨ worker involvement in quality, and ¨ emphasis on statistical process control. ¨ “Quality improvement programs must be management-led and customer-oriented, and this may require fundamental changes in the way companies and agencies do 15 business. ”

Malcom Baldrige National Quality Award - Guidelines ¨ It is crucial to have: ¨ management understanding of the factory floor, ¨ worker involvement in quality, and ¨ emphasis on statistical process control. ¨ “Quality improvement programs must be management-led and customer-oriented, and this may require fundamental changes in the way companies and agencies do 15 business. ”

Concepts of TQM ¨ Top management has primary responsibility. ¨ Focus on customer. ¨ Continuous improvement. ¨ Employee empowerment. ¨ Benchmarking. ¨ Knowledge of tools for TQM. 16

Concepts of TQM ¨ Top management has primary responsibility. ¨ Focus on customer. ¨ Continuous improvement. ¨ Employee empowerment. ¨ Benchmarking. ¨ Knowledge of tools for TQM. 16

Continuous Improvement ¨ Continuously improve process & customer satisfaction. ¨ Involve all operations & work units. ¨ Other names: ¨ Kaizen (Japanese). ¨ Zero-defects. ¨ Six sigma. 17

Continuous Improvement ¨ Continuously improve process & customer satisfaction. ¨ Involve all operations & work units. ¨ Other names: ¨ Kaizen (Japanese). ¨ Zero-defects. ¨ Six sigma. 17

Employee Empowerment ¨ Involve employees in product & process improvements. ¨ 85% of quality problems are due to process & material – not employees! ¨ Techniques: ¨ Support workers; workers solve quality problems. ¨ Let workers make decisions. ¨ Train workers; provide tools for improved quality. 18

Employee Empowerment ¨ Involve employees in product & process improvements. ¨ 85% of quality problems are due to process & material – not employees! ¨ Techniques: ¨ Support workers; workers solve quality problems. ¨ Let workers make decisions. ¨ Train workers; provide tools for improved quality. 18

Benchmarking Selecting best practices to use as a standard (target) for performance. ¨ Determine what to benchmark. ¨ Consider leading organizations in similar areas. ¨ Collect and analyze benchmarking information. ¨ Quantitative measures of performance. ¨ Take action to match or exceed the 19 benchmark.

Benchmarking Selecting best practices to use as a standard (target) for performance. ¨ Determine what to benchmark. ¨ Consider leading organizations in similar areas. ¨ Collect and analyze benchmarking information. ¨ Quantitative measures of performance. ¨ Take action to match or exceed the 19 benchmark.

Tools for TQM ¨ Quality Function Deployment (QFD). ¨ Taguchi techniques. ¨ Cause-and-effect diagrams. ¨ Pareto charts. ¨ Statistical process control. ¨ Poka-yoke. 20

Tools for TQM ¨ Quality Function Deployment (QFD). ¨ Taguchi techniques. ¨ Cause-and-effect diagrams. ¨ Pareto charts. ¨ Statistical process control. ¨ Poka-yoke. 20

Quality Function Deployment (QFD) ¨ Determines what will satisfy the customer. ¨ Translates customer desires into target design. ¨ Helps determine product and process to ensure quality. 21

Quality Function Deployment (QFD) ¨ Determines what will satisfy the customer. ¨ Translates customer desires into target design. ¨ Helps determine product and process to ensure quality. 21

Taguchi Techniques ¨ Experimental design methods to improve product & process design. ¨ Identify key component & process variables affecting product variation. ¨ Taguchi Concepts: ¨ Quality robustness. ¨ Quality loss function. 22

Taguchi Techniques ¨ Experimental design methods to improve product & process design. ¨ Identify key component & process variables affecting product variation. ¨ Taguchi Concepts: ¨ Quality robustness. ¨ Quality loss function. 22

Quality Robustness ¨ Design and make products so that variations in production do not cause failure. ¨ Identify important variations. ¨ Eliminate the effect of variations rather than the cause. ¨ Allow variation, but limit its ability to reduce quality. 23

Quality Robustness ¨ Design and make products so that variations in production do not cause failure. ¨ Identify important variations. ¨ Eliminate the effect of variations rather than the cause. ¨ Allow variation, but limit its ability to reduce quality. 23

Quality Loss Function ¨ Poor quality can be viewed as deviation from a desired level. ¨ Most quality characteristics (e. g. , length, weight) have a target value. ¨ Large deviations are much more expensive than small deviations. ¨ Quality loss function shows cost of deviation and is not linear. ¨A deviation twice as large may be 10 times as expensive. 24

Quality Loss Function ¨ Poor quality can be viewed as deviation from a desired level. ¨ Most quality characteristics (e. g. , length, weight) have a target value. ¨ Large deviations are much more expensive than small deviations. ¨ Quality loss function shows cost of deviation and is not linear. ¨A deviation twice as large may be 10 times as expensive. 24

Cause and Effect Diagram ¨ Used to find problem sources/solutions. ¨ Other names: ¨ Fish-bone diagram, Ishikawa diagram. ¨ Steps: ¨ Identify ¨ Draw problem to correct. main causes for problem as ‘bones’. ¨ Ask ‘What could have caused problems in these areas? ’ Repeat for each sub-area. 25

Cause and Effect Diagram ¨ Used to find problem sources/solutions. ¨ Other names: ¨ Fish-bone diagram, Ishikawa diagram. ¨ Steps: ¨ Identify ¨ Draw problem to correct. main causes for problem as ‘bones’. ¨ Ask ‘What could have caused problems in these areas? ’ Repeat for each sub-area. 25

Cause and Effect Diagram Example Problem Too many defects 26

Cause and Effect Diagram Example Problem Too many defects 26

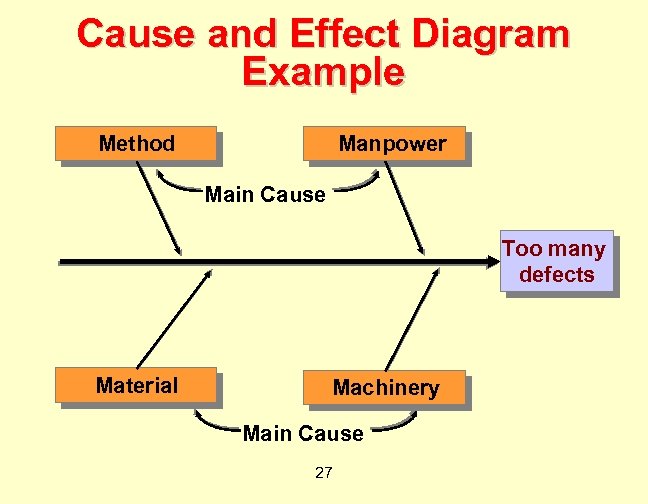

Cause and Effect Diagram Example Method Manpower Main Cause Too many defects Material Machinery Main Cause 27

Cause and Effect Diagram Example Method Manpower Main Cause Too many defects Material Machinery Main Cause 27

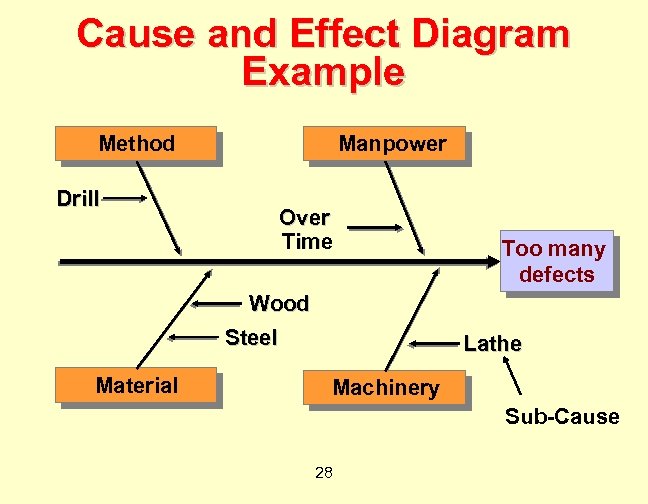

Cause and Effect Diagram Example Method Drill Manpower Over Time Wood Steel Material Too many defects Lathe Machinery Sub-Cause 28

Cause and Effect Diagram Example Method Drill Manpower Over Time Wood Steel Material Too many defects Lathe Machinery Sub-Cause 28

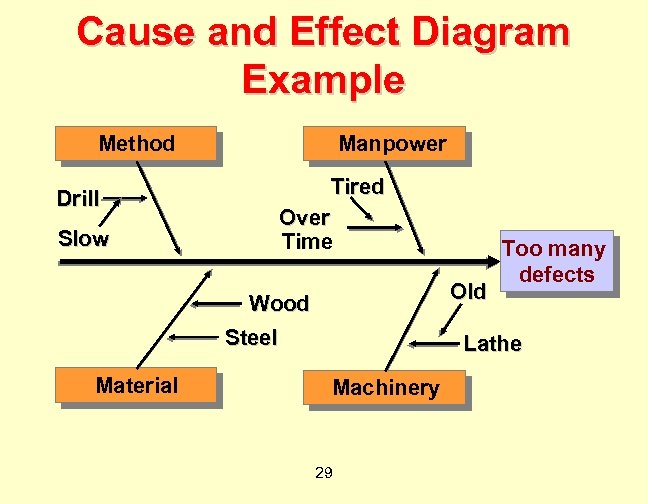

Cause and Effect Diagram Example Method Drill Slow Manpower Tired Over Time Old Wood Steel Material Too many defects Lathe Machinery 29

Cause and Effect Diagram Example Method Drill Slow Manpower Tired Over Time Old Wood Steel Material Too many defects Lathe Machinery 29

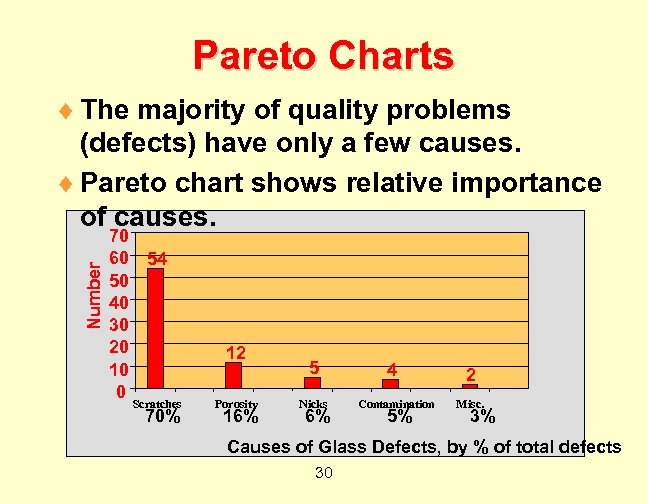

Pareto Charts Number ¨ The majority of quality problems (defects) have only a few causes. ¨ Pareto chart shows relative importance of causes. 70 60 50 40 30 20 10 0 54 12 Scratches 70% Porosity 16% 5 Nicks 6% 4 Contamination 5% 2 Misc. 3% Causes of Glass Defects, by % of total defects 30

Pareto Charts Number ¨ The majority of quality problems (defects) have only a few causes. ¨ Pareto chart shows relative importance of causes. 70 60 50 40 30 20 10 0 54 12 Scratches 70% Porosity 16% 5 Nicks 6% 4 Contamination 5% 2 Misc. 3% Causes of Glass Defects, by % of total defects 30

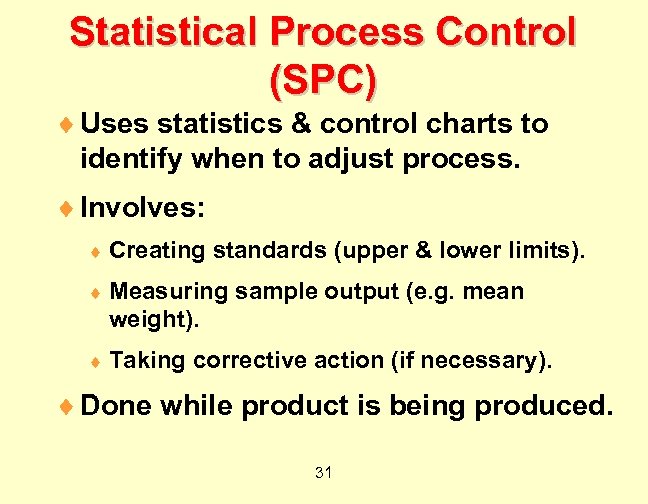

Statistical Process Control (SPC) ¨ Uses statistics & control charts to identify when to adjust process. ¨ Involves: ¨ Creating standards (upper & lower limits). ¨ Measuring sample output (e. g. mean weight). ¨ Taking corrective action (if necessary). ¨ Done while product is being produced. 31

Statistical Process Control (SPC) ¨ Uses statistics & control charts to identify when to adjust process. ¨ Involves: ¨ Creating standards (upper & lower limits). ¨ Measuring sample output (e. g. mean weight). ¨ Taking corrective action (if necessary). ¨ Done while product is being produced. 31

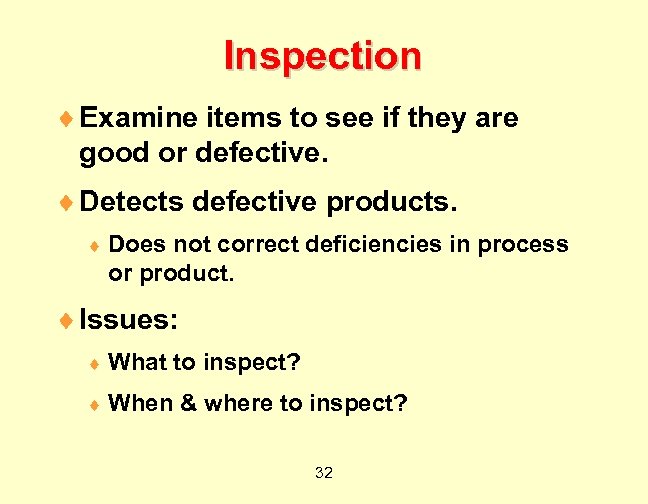

Inspection ¨ Examine items to see if they are good or defective. ¨ Detects defective products. ¨ Does not correct deficiencies in process or product. ¨ Issues: ¨ What ¨ When to inspect? & where to inspect? 32

Inspection ¨ Examine items to see if they are good or defective. ¨ Detects defective products. ¨ Does not correct deficiencies in process or product. ¨ Issues: ¨ What ¨ When to inspect? & where to inspect? 32

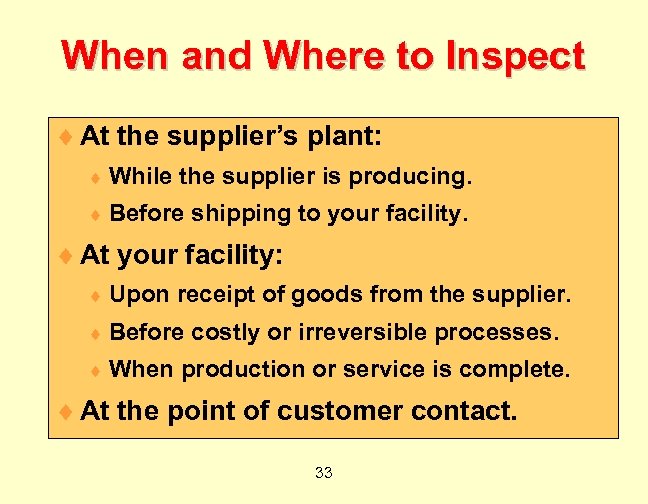

When and Where to Inspect ¨ At the supplier’s plant: ¨ While the supplier is producing. ¨ Before shipping to your facility. ¨ At your facility: ¨ Upon receipt of goods from the supplier. ¨ Before ¨ When costly or irreversible processes. production or service is complete. ¨ At the point of customer contact. 33

When and Where to Inspect ¨ At the supplier’s plant: ¨ While the supplier is producing. ¨ Before shipping to your facility. ¨ At your facility: ¨ Upon receipt of goods from the supplier. ¨ Before ¨ When costly or irreversible processes. production or service is complete. ¨ At the point of customer contact. 33

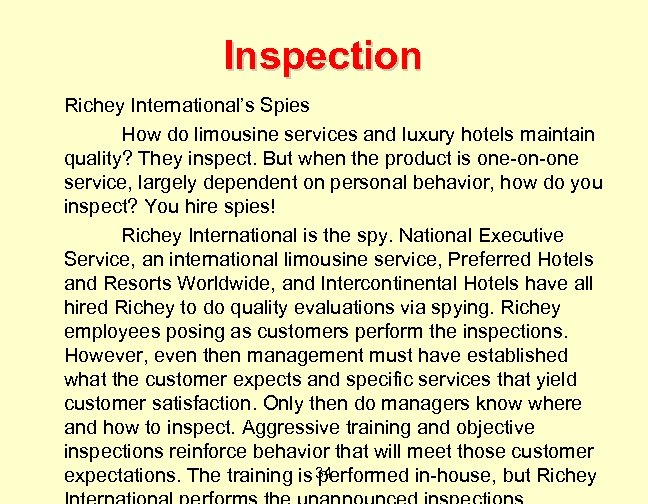

Inspection Richey International’s Spies How do limousine services and luxury hotels maintain quality? They inspect. But when the product is one-on-one service, largely dependent on personal behavior, how do you inspect? You hire spies! Richey International is the spy. National Executive Service, an international limousine service, Preferred Hotels and Resorts Worldwide, and Intercontinental Hotels have all hired Richey to do quality evaluations via spying. Richey employees posing as customers perform the inspections. However, even then management must have established what the customer expects and specific services that yield customer satisfaction. Only then do managers know where and how to inspect. Aggressive training and objective inspections reinforce behavior that will meet those customer expectations. The training is 34 performed in-house, but Richey

Inspection Richey International’s Spies How do limousine services and luxury hotels maintain quality? They inspect. But when the product is one-on-one service, largely dependent on personal behavior, how do you inspect? You hire spies! Richey International is the spy. National Executive Service, an international limousine service, Preferred Hotels and Resorts Worldwide, and Intercontinental Hotels have all hired Richey to do quality evaluations via spying. Richey employees posing as customers perform the inspections. However, even then management must have established what the customer expects and specific services that yield customer satisfaction. Only then do managers know where and how to inspect. Aggressive training and objective inspections reinforce behavior that will meet those customer expectations. The training is 34 performed in-house, but Richey

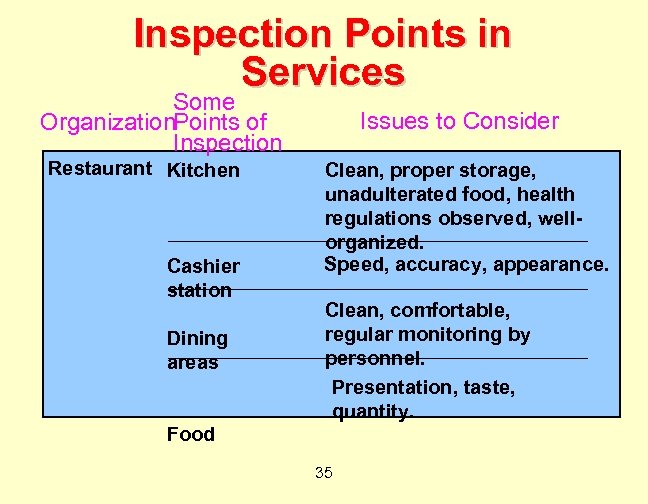

Inspection Points in Services Some Organization. Points of Inspection Restaurant Kitchen Cashier station Dining areas Issues to Consider Clean, proper storage, unadulterated food, health regulations observed, wellorganized. Speed, accuracy, appearance. Clean, comfortable, regular monitoring by personnel. Presentation, taste, quantity. Food 35

Inspection Points in Services Some Organization. Points of Inspection Restaurant Kitchen Cashier station Dining areas Issues to Consider Clean, proper storage, unadulterated food, health regulations observed, wellorganized. Speed, accuracy, appearance. Clean, comfortable, regular monitoring by personnel. Presentation, taste, quantity. Food 35

TQM In Services ¨ Customer contact is important! ¨ Service quality is more difficult to measure than for goods. ¨ Courtesy, competence, communication, etc. ¨ Service quality perceptions depend on: ¨ Expectations versus reality. ¨ Process and outcome. ¨ Type of service (normal vs. exception). ¨ Example: flight cancellation. 36

TQM In Services ¨ Customer contact is important! ¨ Service quality is more difficult to measure than for goods. ¨ Courtesy, competence, communication, etc. ¨ Service quality perceptions depend on: ¨ Expectations versus reality. ¨ Process and outcome. ¨ Type of service (normal vs. exception). ¨ Example: flight cancellation. 36