e20a1ef2b975eec79374a353a478fdcf.ppt

- Количество слайдов: 39

Operations Management Lecture 32 - Supply Chain Management - Inventory Management © 2008 Prentice Hall, Inc. Power. Point presentation to accompany Heizer/Render Principles of Operations Management, 7 e Operations Management, 9 e 11 – 1

Operations Management Lecture 32 - Supply Chain Management - Inventory Management © 2008 Prentice Hall, Inc. Power. Point presentation to accompany Heizer/Render Principles of Operations Management, 7 e Operations Management, 9 e 11 – 1

RECAP þ Location Strategy-Cost and Innovation þ Factors That Affect Location Decisions þ Methods of Evaluating Location Alternatives þ Strategic Importance of Layout Decisions þ Layout Design Considerations þ Types of Layout © 2008 Prentice Hall, Inc. 11 – 2

RECAP þ Location Strategy-Cost and Innovation þ Factors That Affect Location Decisions þ Methods of Evaluating Location Alternatives þ Strategic Importance of Layout Decisions þ Layout Design Considerations þ Types of Layout © 2008 Prentice Hall, Inc. 11 – 2

OUTLINE þ The Supply Chain’s Strategic Importance þ Supply Chain Economics þ Make-or-Buy Decisions þ Outsourcing þ Ethics in the Supply Chain þ Supply Chain Strategies þ Many Suppliers þ Few Suppliers þ Vertical Integration þ Keiretsu Networks © 2008 Prentice Hall, Inc. 11 – 3

OUTLINE þ The Supply Chain’s Strategic Importance þ Supply Chain Economics þ Make-or-Buy Decisions þ Outsourcing þ Ethics in the Supply Chain þ Supply Chain Strategies þ Many Suppliers þ Few Suppliers þ Vertical Integration þ Keiretsu Networks © 2008 Prentice Hall, Inc. 11 – 3

OUTLINE þ Inventory þ Functions of Inventory þ Types of Inventory þ Independent vs. Dependent Demand þ Holding, Ordering, and Setup Costs þ Inventory Models for Independent Demand þ The Basic Economic Order Quantity (EOQ) Model þ Minimizing Costs © 2008 Prentice Hall, Inc. 11 – 4

OUTLINE þ Inventory þ Functions of Inventory þ Types of Inventory þ Independent vs. Dependent Demand þ Holding, Ordering, and Setup Costs þ Inventory Models for Independent Demand þ The Basic Economic Order Quantity (EOQ) Model þ Minimizing Costs © 2008 Prentice Hall, Inc. 11 – 4

THE SUPPLY CHAIN’S STRATEGIC IMPORTANCE Supply chain management is the integration of the activities that procure materials and services, transform them into intermediate goods and the final product, and deliver them to customers Competition is no longer between companies; it is between supply chains © 2008 Prentice Hall, Inc. 11 – 5

THE SUPPLY CHAIN’S STRATEGIC IMPORTANCE Supply chain management is the integration of the activities that procure materials and services, transform them into intermediate goods and the final product, and deliver them to customers Competition is no longer between companies; it is between supply chains © 2008 Prentice Hall, Inc. 11 – 5

SUPPLY CHAIN MANAGEMENT Important activities include determining 1. Transportation vendors 2. Credit and cash transfers 3. Suppliers 4. Distributors 5. Accounts payable and receivable 6. Warehousing and inventory 7. Order fulfillment 8. Sharing customer, forecasting, and production information © 2008 Prentice Hall, Inc. 11 – 6

SUPPLY CHAIN MANAGEMENT Important activities include determining 1. Transportation vendors 2. Credit and cash transfers 3. Suppliers 4. Distributors 5. Accounts payable and receivable 6. Warehousing and inventory 7. Order fulfillment 8. Sharing customer, forecasting, and production information © 2008 Prentice Hall, Inc. 11 – 6

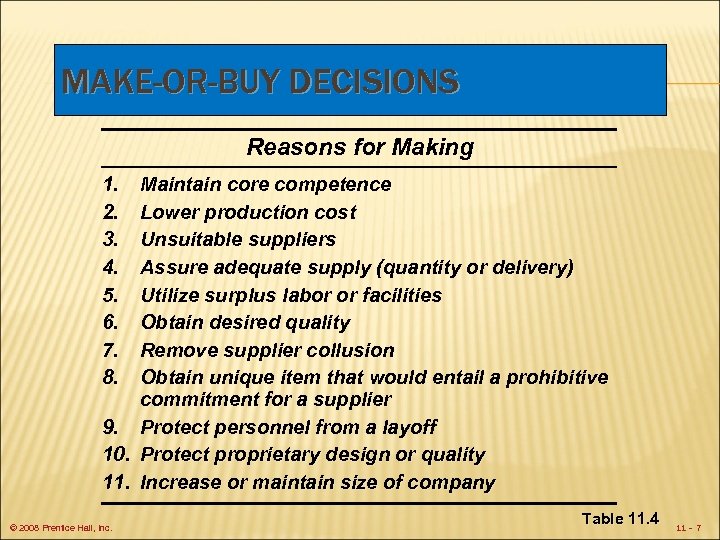

MAKE-OR-BUY DECISIONS Reasons for Making 1. 2. 3. 4. 5. 6. 7. 8. Maintain core competence Lower production cost Unsuitable suppliers Assure adequate supply (quantity or delivery) Utilize surplus labor or facilities Obtain desired quality Remove supplier collusion Obtain unique item that would entail a prohibitive commitment for a supplier 9. Protect personnel from a layoff 10. Protect proprietary design or quality 11. Increase or maintain size of company © 2008 Prentice Hall, Inc. Table 11. 4 11 – 7

MAKE-OR-BUY DECISIONS Reasons for Making 1. 2. 3. 4. 5. 6. 7. 8. Maintain core competence Lower production cost Unsuitable suppliers Assure adequate supply (quantity or delivery) Utilize surplus labor or facilities Obtain desired quality Remove supplier collusion Obtain unique item that would entail a prohibitive commitment for a supplier 9. Protect personnel from a layoff 10. Protect proprietary design or quality 11. Increase or maintain size of company © 2008 Prentice Hall, Inc. Table 11. 4 11 – 7

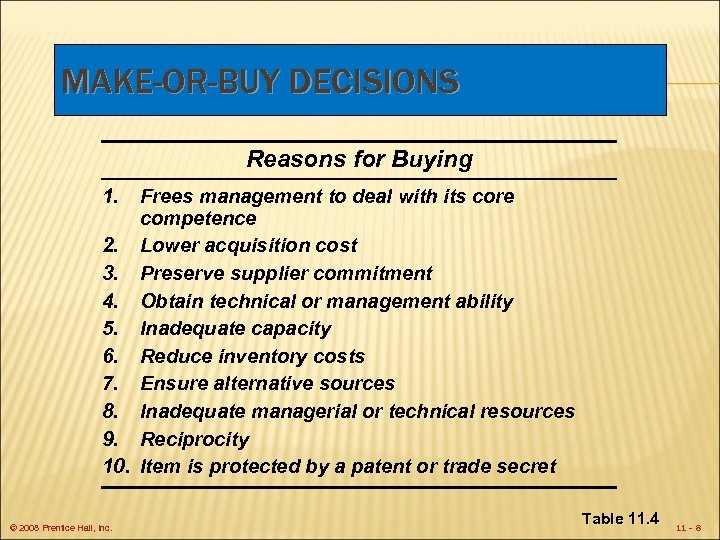

MAKE-OR-BUY DECISIONS Reasons for Buying 1. Frees management to deal with its core competence 2. Lower acquisition cost 3. Preserve supplier commitment 4. Obtain technical or management ability 5. Inadequate capacity 6. Reduce inventory costs 7. Ensure alternative sources 8. Inadequate managerial or technical resources 9. Reciprocity 10. Item is protected by a patent or trade secret © 2008 Prentice Hall, Inc. Table 11. 4 11 – 8

MAKE-OR-BUY DECISIONS Reasons for Buying 1. Frees management to deal with its core competence 2. Lower acquisition cost 3. Preserve supplier commitment 4. Obtain technical or management ability 5. Inadequate capacity 6. Reduce inventory costs 7. Ensure alternative sources 8. Inadequate managerial or technical resources 9. Reciprocity 10. Item is protected by a patent or trade secret © 2008 Prentice Hall, Inc. Table 11. 4 11 – 8

OUTSOURCING þ Transfers traditional internal activities and resources of a firm to outside vendors þ Utilizes the efficiency that comes with specialization þ Firms outsource information technology, accounting, legal, logistics, and production © 2008 Prentice Hall, Inc. 11 – 9

OUTSOURCING þ Transfers traditional internal activities and resources of a firm to outside vendors þ Utilizes the efficiency that comes with specialization þ Firms outsource information technology, accounting, legal, logistics, and production © 2008 Prentice Hall, Inc. 11 – 9

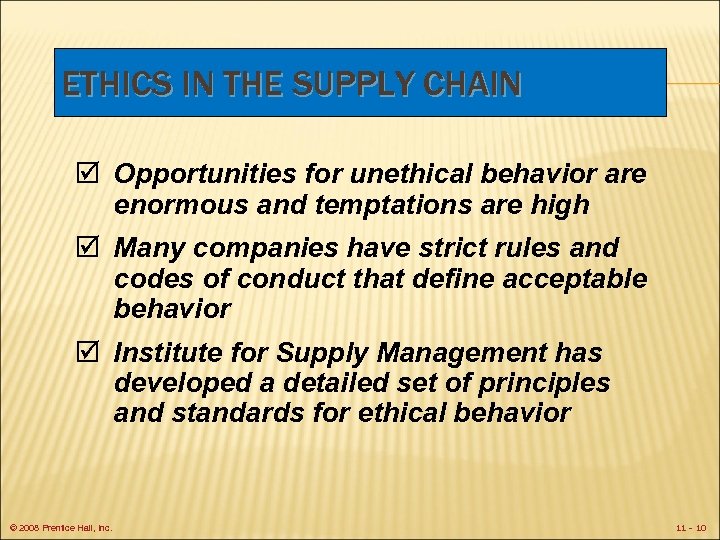

ETHICS IN THE SUPPLY CHAIN þ Opportunities for unethical behavior are enormous and temptations are high þ Many companies have strict rules and codes of conduct that define acceptable behavior þ Institute for Supply Management has developed a detailed set of principles and standards for ethical behavior © 2008 Prentice Hall, Inc. 11 – 10

ETHICS IN THE SUPPLY CHAIN þ Opportunities for unethical behavior are enormous and temptations are high þ Many companies have strict rules and codes of conduct that define acceptable behavior þ Institute for Supply Management has developed a detailed set of principles and standards for ethical behavior © 2008 Prentice Hall, Inc. 11 – 10

SUPPLY CHAIN STRATEGIES þ Negotiating with many suppliers þ Long-term partnering with few suppliers þ Vertical integration þ Keiretsu þ Virtual companies that use suppliers on an as needed basis © 2008 Prentice Hall, Inc. 11 – 11

SUPPLY CHAIN STRATEGIES þ Negotiating with many suppliers þ Long-term partnering with few suppliers þ Vertical integration þ Keiretsu þ Virtual companies that use suppliers on an as needed basis © 2008 Prentice Hall, Inc. 11 – 11

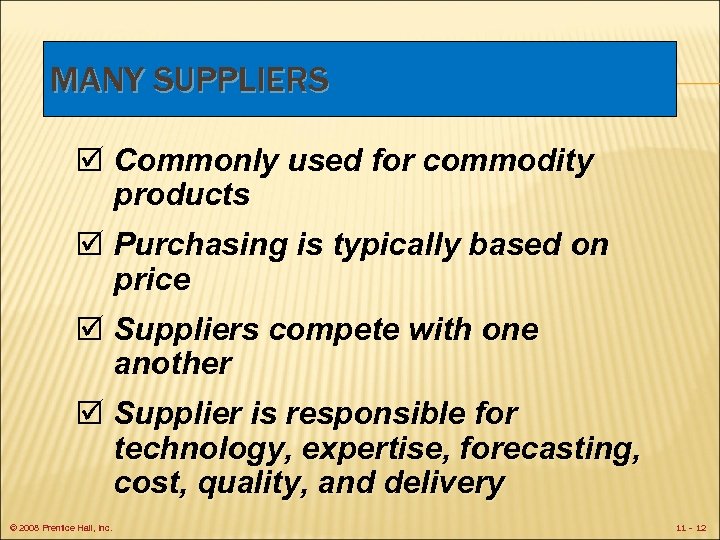

MANY SUPPLIERS þ Commonly used for commodity products þ Purchasing is typically based on price þ Suppliers compete with one another þ Supplier is responsible for technology, expertise, forecasting, cost, quality, and delivery © 2008 Prentice Hall, Inc. 11 – 12

MANY SUPPLIERS þ Commonly used for commodity products þ Purchasing is typically based on price þ Suppliers compete with one another þ Supplier is responsible for technology, expertise, forecasting, cost, quality, and delivery © 2008 Prentice Hall, Inc. 11 – 12

FEW SUPPLIERS þ Buyer forms longer term relationships with fewer suppliers þ Create value through economies of scale and learning curve improvements þ Suppliers more willing to participate in JIT programs and contribute design and technological expertise þ Cost of changing suppliers is huge © 2008 Prentice Hall, Inc. 11 – 13

FEW SUPPLIERS þ Buyer forms longer term relationships with fewer suppliers þ Create value through economies of scale and learning curve improvements þ Suppliers more willing to participate in JIT programs and contribute design and technological expertise þ Cost of changing suppliers is huge © 2008 Prentice Hall, Inc. 11 – 13

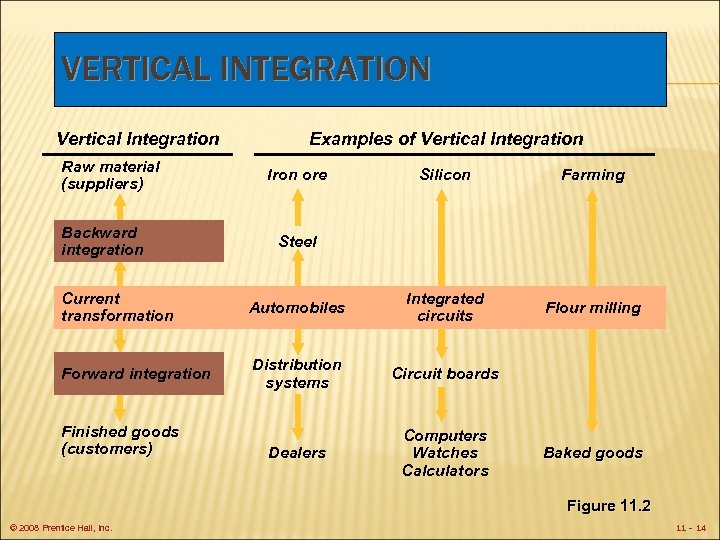

VERTICAL INTEGRATION Vertical Integration Raw material (suppliers) Backward integration Examples of Vertical Integration Iron ore Silicon Farming Flour milling Steel Current transformation Automobiles Integrated circuits Forward integration Distribution systems Circuit boards Dealers Computers Watches Calculators Finished goods (customers) Baked goods Figure 11. 2 © 2008 Prentice Hall, Inc. 11 – 14

VERTICAL INTEGRATION Vertical Integration Raw material (suppliers) Backward integration Examples of Vertical Integration Iron ore Silicon Farming Flour milling Steel Current transformation Automobiles Integrated circuits Forward integration Distribution systems Circuit boards Dealers Computers Watches Calculators Finished goods (customers) Baked goods Figure 11. 2 © 2008 Prentice Hall, Inc. 11 – 14

VERTICAL INTEGRATION þ Developing the ability to produce goods or service previously purchased þ Integration may be forward, towards the customer, or backward, towards suppliers þ Can improve cost, quality, and inventory but requires capital, managerial skills, and demand þ Risky in industries with rapid technological change © 2008 Prentice Hall, Inc. 11 – 15

VERTICAL INTEGRATION þ Developing the ability to produce goods or service previously purchased þ Integration may be forward, towards the customer, or backward, towards suppliers þ Can improve cost, quality, and inventory but requires capital, managerial skills, and demand þ Risky in industries with rapid technological change © 2008 Prentice Hall, Inc. 11 – 15

KEIRETSU NETWORKS þ A middle ground between few suppliers and vertical integration þ Supplier becomes part of the company coalition þ Often provide financial support for suppliers through ownership or loans þ Members expect long-term relationships and provide technical expertise and stable deliveries þ May extend through several levels of the supply chain © 2008 Prentice Hall, Inc. 11 – 16

KEIRETSU NETWORKS þ A middle ground between few suppliers and vertical integration þ Supplier becomes part of the company coalition þ Often provide financial support for suppliers through ownership or loans þ Members expect long-term relationships and provide technical expertise and stable deliveries þ May extend through several levels of the supply chain © 2008 Prentice Hall, Inc. 11 – 16

MANAGING THE SUPPLY CHAIN There are significant management issues in controlling a supply chain involving many independent organizations þ Mutual agreement on goals þ Trust þ Compatible organizational cultures © 2008 Prentice Hall, Inc. 11 – 17

MANAGING THE SUPPLY CHAIN There are significant management issues in controlling a supply chain involving many independent organizations þ Mutual agreement on goals þ Trust þ Compatible organizational cultures © 2008 Prentice Hall, Inc. 11 – 17

INVENTORY þ Anything that can be kept for future demand Ø Planning Ø Control (Where to buy, How much to buy? and when to buy? ) þ One of the most expensive assets of many companies representing as much as 50% of total invested capital þ Operations managers must balance inventory investment and customer service © 2008 Prentice Hall, Inc. 11 – 18

INVENTORY þ Anything that can be kept for future demand Ø Planning Ø Control (Where to buy, How much to buy? and when to buy? ) þ One of the most expensive assets of many companies representing as much as 50% of total invested capital þ Operations managers must balance inventory investment and customer service © 2008 Prentice Hall, Inc. 11 – 18

FUNCTIONS OF INVENTORY 1. To decouple or separate various parts of the production process 2. To decouple the firm from fluctuations in demand provide a stock of goods that will provide a selection for customers 3. To take advantage of quantity discounts 4. To hedge against inflation © 2008 Prentice Hall, Inc. 11 – 19

FUNCTIONS OF INVENTORY 1. To decouple or separate various parts of the production process 2. To decouple the firm from fluctuations in demand provide a stock of goods that will provide a selection for customers 3. To take advantage of quantity discounts 4. To hedge against inflation © 2008 Prentice Hall, Inc. 11 – 19

TYPES OF INVENTORY þ Raw material þ Purchased but not processed þ Work-in-process þ Undergone some change but not completed þ A function of cycle time for a product þ Maintenance/repair/operating (MRO) þ Necessary to keep machinery and processes productive þ Finished goods þ Completed product awaiting shipment © 2008 Prentice Hall, Inc. 11 – 20

TYPES OF INVENTORY þ Raw material þ Purchased but not processed þ Work-in-process þ Undergone some change but not completed þ A function of cycle time for a product þ Maintenance/repair/operating (MRO) þ Necessary to keep machinery and processes productive þ Finished goods þ Completed product awaiting shipment © 2008 Prentice Hall, Inc. 11 – 20

INVENTORY MANAGEMENT þ How inventory items can be classified þ How accurate inventory records can be maintained © 2008 Prentice Hall, Inc. 11 – 21

INVENTORY MANAGEMENT þ How inventory items can be classified þ How accurate inventory records can be maintained © 2008 Prentice Hall, Inc. 11 – 21

RECORD ACCURACY þ Accurate records are a critical ingredient in production and inventory systems þ Allows organization to focus on what is needed þ Necessary to make precise decisions about ordering, scheduling, and shipping þ Incoming and outgoing record keeping must be accurate þ Stockrooms should be secure © 2008 Prentice Hall, Inc. 11 – 22

RECORD ACCURACY þ Accurate records are a critical ingredient in production and inventory systems þ Allows organization to focus on what is needed þ Necessary to make precise decisions about ordering, scheduling, and shipping þ Incoming and outgoing record keeping must be accurate þ Stockrooms should be secure © 2008 Prentice Hall, Inc. 11 – 22

INDEPENDENT VERSUS DEPENDENT DEMAND þ Independent demand - the demand for item is independent of the demand for any other item in inventory þ Dependent demand - the demand for item is dependent upon the demand for some other item in the inventory © 2008 Prentice Hall, Inc. 11 – 23

INDEPENDENT VERSUS DEPENDENT DEMAND þ Independent demand - the demand for item is independent of the demand for any other item in inventory þ Dependent demand - the demand for item is dependent upon the demand for some other item in the inventory © 2008 Prentice Hall, Inc. 11 – 23

HOLDING, ORDERING, AND SETUP COSTS þ Holding costs - the costs of holding or “carrying” inventory over time þ Ordering costs - the costs of placing an order and receiving goods þ Setup costs - cost to prepare a machine or process for manufacturing an order © 2008 Prentice Hall, Inc. 11 – 24

HOLDING, ORDERING, AND SETUP COSTS þ Holding costs - the costs of holding or “carrying” inventory over time þ Ordering costs - the costs of placing an order and receiving goods þ Setup costs - cost to prepare a machine or process for manufacturing an order © 2008 Prentice Hall, Inc. 11 – 24

BASIC EOQ MODEL Important assumptions 1. Demand is known, constant, and independent 2. Lead time is known and constant 3. Receipt of inventory is instantaneous and complete 4. Quantity discounts are not possible 5. Only variable costs are setup and holding 6. Stockouts can be completely avoided © 2008 Prentice Hall, Inc. 11 – 25

BASIC EOQ MODEL Important assumptions 1. Demand is known, constant, and independent 2. Lead time is known and constant 3. Receipt of inventory is instantaneous and complete 4. Quantity discounts are not possible 5. Only variable costs are setup and holding 6. Stockouts can be completely avoided © 2008 Prentice Hall, Inc. 11 – 25

Inventory level INVENTORY USAGE OVER TIME Order quantity = Q (maximum inventory level) Usage rate Average inventory on hand Q 2 Minimum inventory 0 Time Figure 12. 3 © 2008 Prentice Hall, Inc. 11 – 26

Inventory level INVENTORY USAGE OVER TIME Order quantity = Q (maximum inventory level) Usage rate Average inventory on hand Q 2 Minimum inventory 0 Time Figure 12. 3 © 2008 Prentice Hall, Inc. 11 – 26

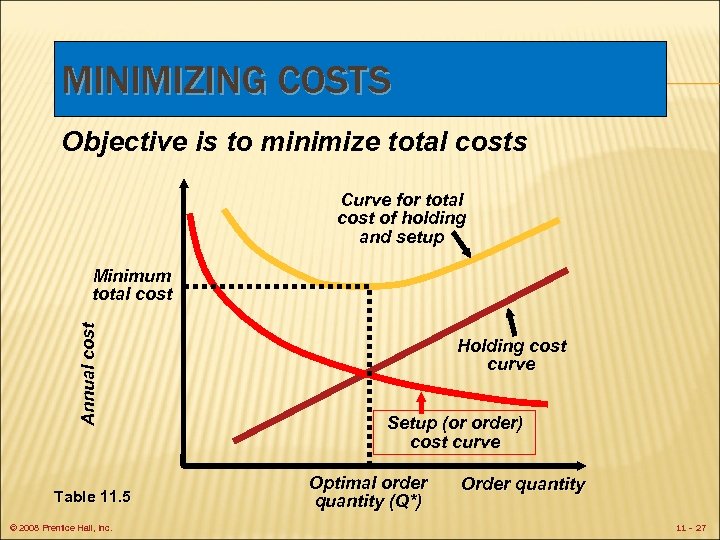

MINIMIZING COSTS Objective is to minimize total costs Curve for total cost of holding and setup Annual cost Minimum total cost Table 11. 5 © 2008 Prentice Hall, Inc. Holding cost curve Setup (or order) cost curve Optimal order quantity (Q*) Order quantity 11 – 27

MINIMIZING COSTS Objective is to minimize total costs Curve for total cost of holding and setup Annual cost Minimum total cost Table 11. 5 © 2008 Prentice Hall, Inc. Holding cost curve Setup (or order) cost curve Optimal order quantity (Q*) Order quantity 11 – 27

THE EOQ MODEL Annual setup cost = D S Q Q = Number of pieces per order (Quantity Ordered) Q* = Optimal number of pieces per order (EOQ) D = Total Annual demand (in units) for the item which is kept as inventory S = Setup or ordering cost for each order H = Holding or carrying cost per unit per year Annual setup cost = (Number of orders placed per year) (Total Annual Ordering Cost) x (Setup or order cost per order) Annual demand Setup or order = Number of units in each order cost per order = © 2008 Prentice Hall, Inc. D ( S) Q 11 – 28

THE EOQ MODEL Annual setup cost = D S Q Q = Number of pieces per order (Quantity Ordered) Q* = Optimal number of pieces per order (EOQ) D = Total Annual demand (in units) for the item which is kept as inventory S = Setup or ordering cost for each order H = Holding or carrying cost per unit per year Annual setup cost = (Number of orders placed per year) (Total Annual Ordering Cost) x (Setup or order cost per order) Annual demand Setup or order = Number of units in each order cost per order = © 2008 Prentice Hall, Inc. D ( S) Q 11 – 28

THE EOQ MODEL Q Q* D S H D S Q Q Annual holding cost = H 2 Annual setup cost = = Number of pieces per order = Optimal number of pieces per order (EOQ) = Annual demand in units for the inventory item = Setup or ordering cost for each order = Holding or carrying cost per unit per year Annual holding cost = (Average inventory level) x (Holding cost per unit per year) Order quantity = (Holding cost per unit per year) 2 = Q ( H) 2 © 2008 Prentice Hall, Inc. 11 – 29

THE EOQ MODEL Q Q* D S H D S Q Q Annual holding cost = H 2 Annual setup cost = = Number of pieces per order = Optimal number of pieces per order (EOQ) = Annual demand in units for the inventory item = Setup or ordering cost for each order = Holding or carrying cost per unit per year Annual holding cost = (Average inventory level) x (Holding cost per unit per year) Order quantity = (Holding cost per unit per year) 2 = Q ( H) 2 © 2008 Prentice Hall, Inc. 11 – 29

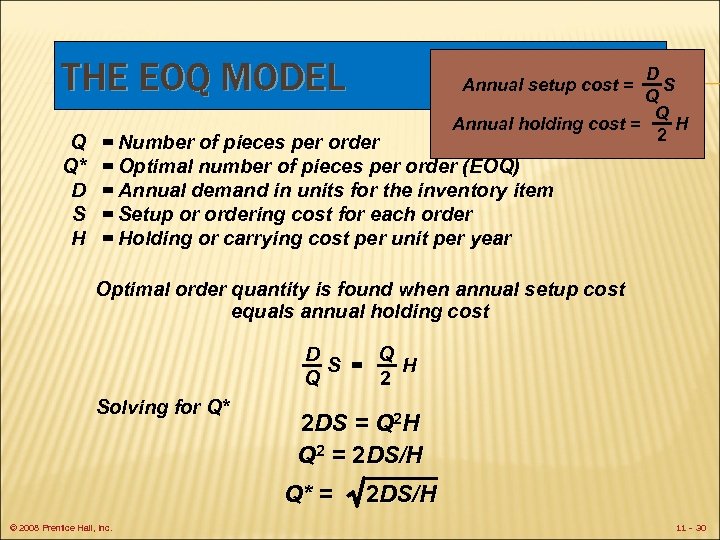

THE EOQ MODEL Q Q* D S H D S Q Q Annual holding cost = H 2 Annual setup cost = = Number of pieces per order = Optimal number of pieces per order (EOQ) = Annual demand in units for the inventory item = Setup or ordering cost for each order = Holding or carrying cost per unit per year Optimal order quantity is found when annual setup cost equals annual holding cost D Q S = H Q 2 Solving for Q* 2 DS = Q 2 H Q 2 = 2 DS/H Q* = © 2008 Prentice Hall, Inc. 2 DS/H 11 – 30

THE EOQ MODEL Q Q* D S H D S Q Q Annual holding cost = H 2 Annual setup cost = = Number of pieces per order = Optimal number of pieces per order (EOQ) = Annual demand in units for the inventory item = Setup or ordering cost for each order = Holding or carrying cost per unit per year Optimal order quantity is found when annual setup cost equals annual holding cost D Q S = H Q 2 Solving for Q* 2 DS = Q 2 H Q 2 = 2 DS/H Q* = © 2008 Prentice Hall, Inc. 2 DS/H 11 – 30

AN EOQ EXAMPLE Determine optimal number of needles to order D = 1, 000 units S = $10 per order H = $. 50 per unit per year Q* = 2 DS H Q* = 2(1, 000)(10) = 0. 50 © 2008 Prentice Hall, Inc. 40, 000 = 200 units 11 – 31

AN EOQ EXAMPLE Determine optimal number of needles to order D = 1, 000 units S = $10 per order H = $. 50 per unit per year Q* = 2 DS H Q* = 2(1, 000)(10) = 0. 50 © 2008 Prentice Hall, Inc. 40, 000 = 200 units 11 – 31

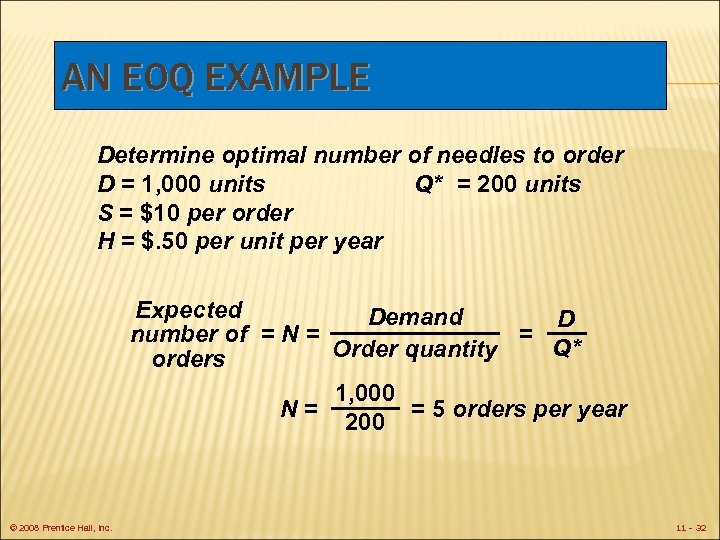

AN EOQ EXAMPLE Determine optimal number of needles to order D = 1, 000 units Q* = 200 units S = $10 per order H = $. 50 per unit per year Expected Demand D number of = N = = Q* Order quantity orders 1, 000 N= = 5 orders per year 200 © 2008 Prentice Hall, Inc. 11 – 32

AN EOQ EXAMPLE Determine optimal number of needles to order D = 1, 000 units Q* = 200 units S = $10 per order H = $. 50 per unit per year Expected Demand D number of = N = = Q* Order quantity orders 1, 000 N= = 5 orders per year 200 © 2008 Prentice Hall, Inc. 11 – 32

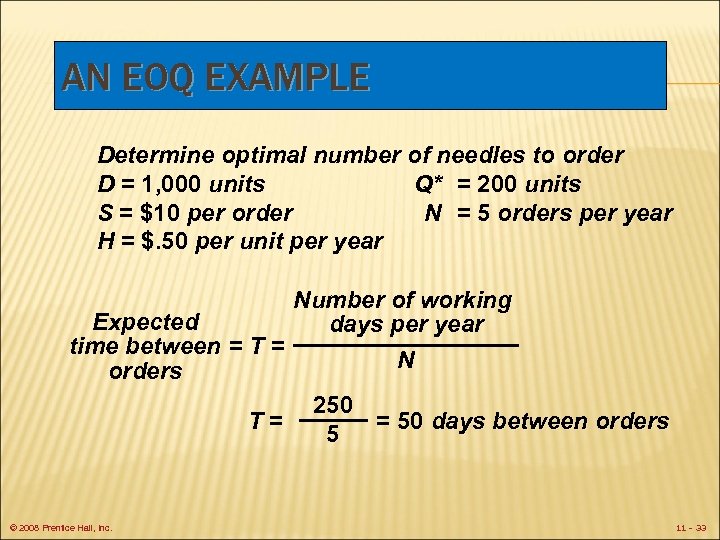

AN EOQ EXAMPLE Determine optimal number of needles to order D = 1, 000 units Q* = 200 units S = $10 per order N = 5 orders per year H = $. 50 per unit per year Number of working Expected days per year time between = T = N orders T= © 2008 Prentice Hall, Inc. 250 = 50 days between orders 5 11 – 33

AN EOQ EXAMPLE Determine optimal number of needles to order D = 1, 000 units Q* = 200 units S = $10 per order N = 5 orders per year H = $. 50 per unit per year Number of working Expected days per year time between = T = N orders T= © 2008 Prentice Hall, Inc. 250 = 50 days between orders 5 11 – 33

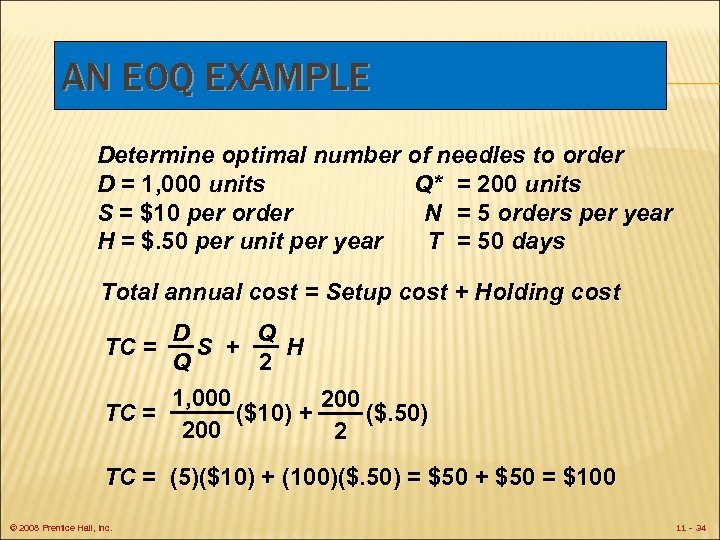

AN EOQ EXAMPLE Determine optimal number of needles to order D = 1, 000 units Q* = 200 units S = $10 per order N = 5 orders per year H = $. 50 per unit per year T = 50 days Total annual cost = Setup cost + Holding cost Q D S + H 2 Q 1, 000 200 TC = ($10) + ($. 50) 200 2 TC = (5)($10) + (100)($. 50) = $50 + $50 = $100 © 2008 Prentice Hall, Inc. 11 – 34

AN EOQ EXAMPLE Determine optimal number of needles to order D = 1, 000 units Q* = 200 units S = $10 per order N = 5 orders per year H = $. 50 per unit per year T = 50 days Total annual cost = Setup cost + Holding cost Q D S + H 2 Q 1, 000 200 TC = ($10) + ($. 50) 200 2 TC = (5)($10) + (100)($. 50) = $50 + $50 = $100 © 2008 Prentice Hall, Inc. 11 – 34

ROBUST MODEL þ The EOQ model is robust þ It works even if all parameters and assumptions are not met þ The total cost curve is relatively flat in the area of the EOQ © 2008 Prentice Hall, Inc. 11 – 35

ROBUST MODEL þ The EOQ model is robust þ It works even if all parameters and assumptions are not met þ The total cost curve is relatively flat in the area of the EOQ © 2008 Prentice Hall, Inc. 11 – 35

AN EOQ EXAMPLE Management underestimated demand by 50% D = 1, 000 units 1, 500 units Q* = 200 units S = $10 per order N = 5 orders per year H = $. 50 per unit per year T = 50 days D Q TC = S + H Q 2 1, 500 200 TC = ($10) + ($. 50) = $75 + $50 = $125 200 2 Total annual cost increases by only 25% © 2008 Prentice Hall, Inc. 11 – 36

AN EOQ EXAMPLE Management underestimated demand by 50% D = 1, 000 units 1, 500 units Q* = 200 units S = $10 per order N = 5 orders per year H = $. 50 per unit per year T = 50 days D Q TC = S + H Q 2 1, 500 200 TC = ($10) + ($. 50) = $75 + $50 = $125 200 2 Total annual cost increases by only 25% © 2008 Prentice Hall, Inc. 11 – 36

AN EOQ EXAMPLE Actual EOQ for new demand is 244. 9 units D = 1, 000 units 1, 500 units Q* = 244. 9 units S = $10 per order N = 5 orders per year H = $. 50 per unit per year T = 50 days D Q TC = S + H Q 2 1, 500 244. 9 TC = ($10) + ($. 50) 244. 9 2 TC = $61. 24 + $61. 24 = $122. 48 © 2008 Prentice Hall, Inc. Only 2% less than the total cost of $125 when the order quantity was 200 11 – 37

AN EOQ EXAMPLE Actual EOQ for new demand is 244. 9 units D = 1, 000 units 1, 500 units Q* = 244. 9 units S = $10 per order N = 5 orders per year H = $. 50 per unit per year T = 50 days D Q TC = S + H Q 2 1, 500 244. 9 TC = ($10) + ($. 50) 244. 9 2 TC = $61. 24 + $61. 24 = $122. 48 © 2008 Prentice Hall, Inc. Only 2% less than the total cost of $125 when the order quantity was 200 11 – 37

REORDER POINTS þ þ EOQ answers the “how much” question The reorder point (ROP) tells when to order Lead time for a Demand ROP = per day new order in days =dx. L D d = Number of working days in a year © 2008 Prentice Hall, Inc. 11 – 38

REORDER POINTS þ þ EOQ answers the “how much” question The reorder point (ROP) tells when to order Lead time for a Demand ROP = per day new order in days =dx. L D d = Number of working days in a year © 2008 Prentice Hall, Inc. 11 – 38

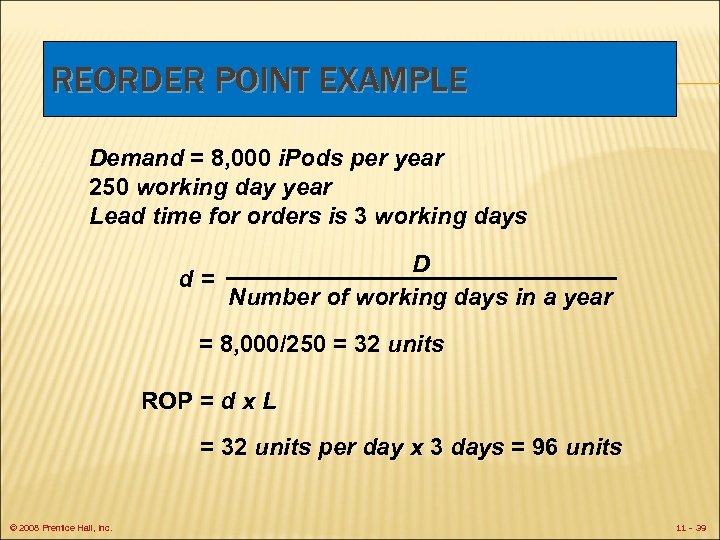

REORDER POINT EXAMPLE Demand = 8, 000 i. Pods per year 250 working day year Lead time for orders is 3 working days D d= Number of working days in a year = 8, 000/250 = 32 units ROP = d x L = 32 units per day x 3 days = 96 units © 2008 Prentice Hall, Inc. 11 – 39

REORDER POINT EXAMPLE Demand = 8, 000 i. Pods per year 250 working day year Lead time for orders is 3 working days D d= Number of working days in a year = 8, 000/250 = 32 units ROP = d x L = 32 units per day x 3 days = 96 units © 2008 Prentice Hall, Inc. 11 – 39