627045744ad5e208b0443d6627b7daa2.ppt

- Количество слайдов: 46

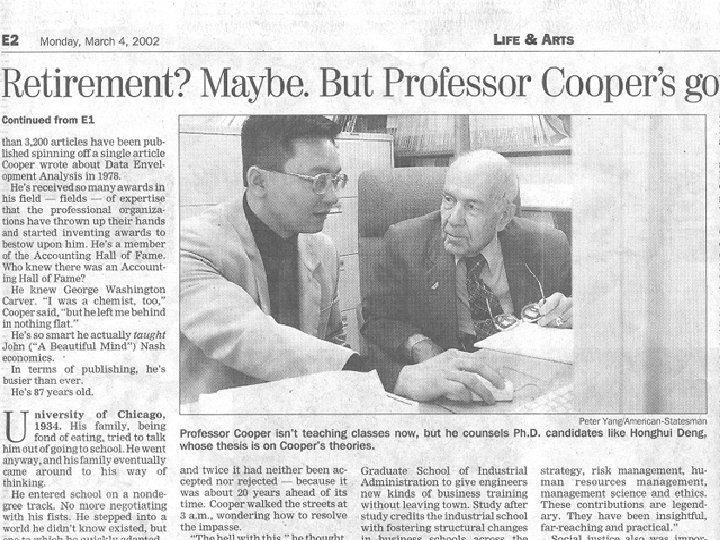

OPERATIONS MANAGEMENT Honghui (Henry) Deng Ph. D of BA, Red Mc. Combs School of Business, The University of Texas at Austin Assistant Professor, Business School, The University of Nevada, Las Vegas

OPERATIONS MANAGEMENT Honghui (Henry) Deng Ph. D of BA, Red Mc. Combs School of Business, The University of Texas at Austin Assistant Professor, Business School, The University of Nevada, Las Vegas

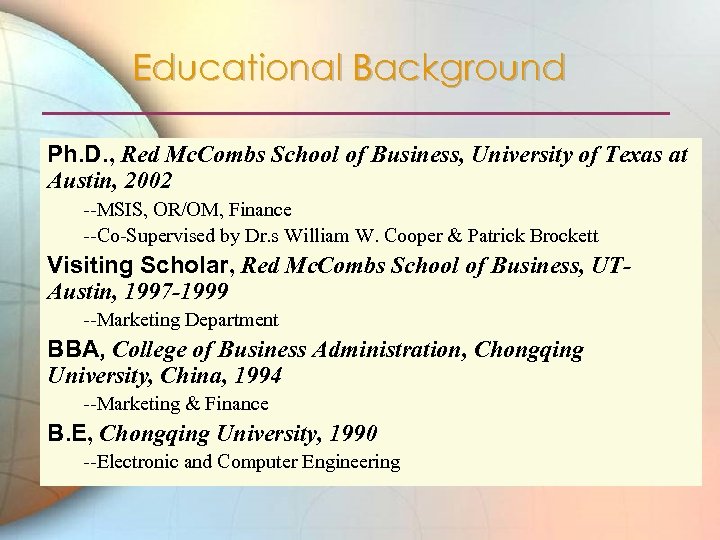

Educational Background Ph. D. , Red Mc. Combs School of Business, University of Texas at Austin, 2002 --MSIS, OR/OM, Finance --Co-Supervised by Dr. s William W. Cooper & Patrick Brockett Visiting Scholar, Red Mc. Combs School of Business, UTAustin, 1997 -1999 --Marketing Department BBA, College of Business Administration, Chongqing University, China, 1994 --Marketing & Finance B. E, Chongqing University, 1990 --Electronic and Computer Engineering

Educational Background Ph. D. , Red Mc. Combs School of Business, University of Texas at Austin, 2002 --MSIS, OR/OM, Finance --Co-Supervised by Dr. s William W. Cooper & Patrick Brockett Visiting Scholar, Red Mc. Combs School of Business, UTAustin, 1997 -1999 --Marketing Department BBA, College of Business Administration, Chongqing University, China, 1994 --Marketing & Finance B. E, Chongqing University, 1990 --Electronic and Computer Engineering

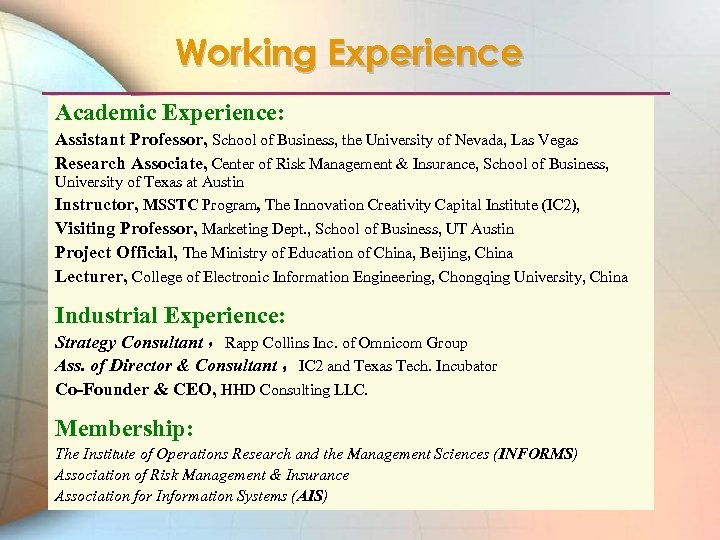

Working Experience Academic Experience: Assistant Professor, School of Business, the University of Nevada, Las Vegas Research Associate, Center of Risk Management & Insurance, School of Business, University of Texas at Austin Instructor, MSSTC Program, The Innovation Creativity Capital Institute (IC 2), Visiting Professor, Marketing Dept. , School of Business, UT Austin Project Official, The Ministry of Education of China, Beijing, China Lecturer, College of Electronic Information Engineering, Chongqing University, China Industrial Experience: Strategy Consultant ,Rapp Collins Inc. of Omnicom Group Ass. of Director & Consultant ,IC 2 and Texas Tech. Incubator Co-Founder & CEO, HHD Consulting LLC. Membership: The Institute of Operations Research and the Management Sciences (INFORMS) Association of Risk Management & Insurance Association for Information Systems (AIS)

Working Experience Academic Experience: Assistant Professor, School of Business, the University of Nevada, Las Vegas Research Associate, Center of Risk Management & Insurance, School of Business, University of Texas at Austin Instructor, MSSTC Program, The Innovation Creativity Capital Institute (IC 2), Visiting Professor, Marketing Dept. , School of Business, UT Austin Project Official, The Ministry of Education of China, Beijing, China Lecturer, College of Electronic Information Engineering, Chongqing University, China Industrial Experience: Strategy Consultant ,Rapp Collins Inc. of Omnicom Group Ass. of Director & Consultant ,IC 2 and Texas Tech. Incubator Co-Founder & CEO, HHD Consulting LLC. Membership: The Institute of Operations Research and the Management Sciences (INFORMS) Association of Risk Management & Insurance Association for Information Systems (AIS)

Current Research – – – – Operations Research/Management IT Strategy & Organization Knowledge Management Science Risk Management and Insurance Decision Science Data Communication & Networks

Current Research – – – – Operations Research/Management IT Strategy & Organization Knowledge Management Science Risk Management and Insurance Decision Science Data Communication & Networks

Teaching Experience * * * * Supply Chain Management & Operation Strategy Management Information Systems Commercialization Strategy Risk Management Statistics I Applied Information Technology Data Communications & Networks

Teaching Experience * * * * Supply Chain Management & Operation Strategy Management Information Systems Commercialization Strategy Risk Management Statistics I Applied Information Technology Data Communications & Networks

Today’s Schedule v v v Operation Research/Management landscape Introduction of Operations Management Overview of syllabus and course objectives Student information sheet Introduction of Forecasting Group Assignment

Today’s Schedule v v v Operation Research/Management landscape Introduction of Operations Management Overview of syllabus and course objectives Student information sheet Introduction of Forecasting Group Assignment

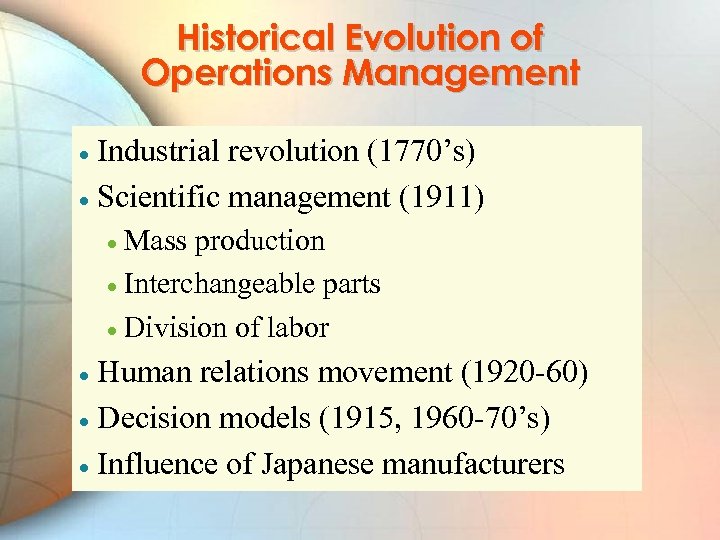

Historical Evolution of Operations Management Industrial revolution (1770’s) · Scientific management (1911) · Mass production · Interchangeable parts · Division of labor · Human relations movement (1920 -60) · Decision models (1915, 1960 -70’s) · Influence of Japanese manufacturers ·

Historical Evolution of Operations Management Industrial revolution (1770’s) · Scientific management (1911) · Mass production · Interchangeable parts · Division of labor · Human relations movement (1920 -60) · Decision models (1915, 1960 -70’s) · Influence of Japanese manufacturers ·

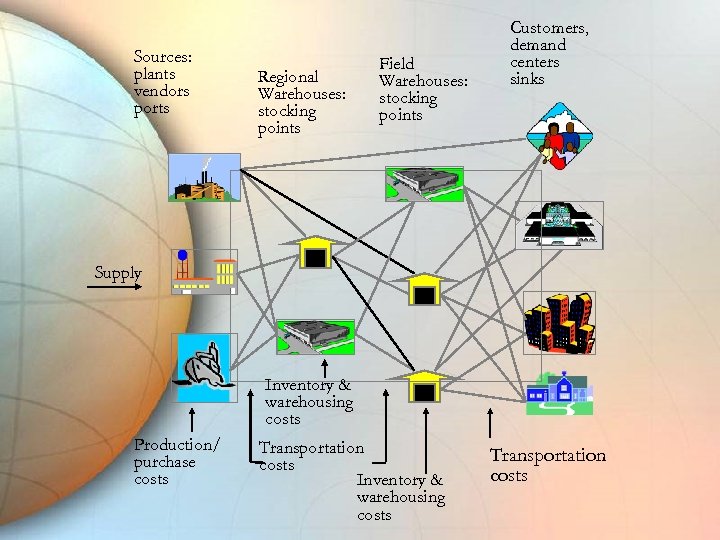

Sources: plants vendors ports Regional Warehouses: stocking points Field Warehouses: stocking points Customers, demand centers sinks Supply Inventory & warehousing costs Production/ purchase costs Transportation costs Inventory & warehousing costs Transportation costs

Sources: plants vendors ports Regional Warehouses: stocking points Field Warehouses: stocking points Customers, demand centers sinks Supply Inventory & warehousing costs Production/ purchase costs Transportation costs Inventory & warehousing costs Transportation costs

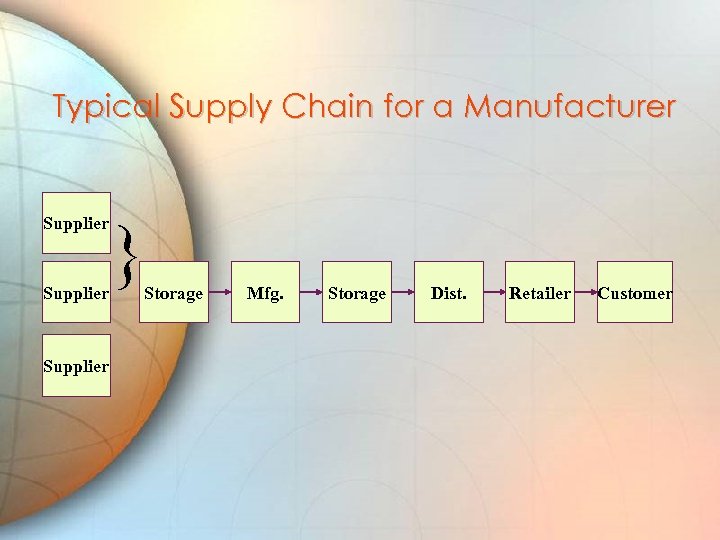

Typical Supply Chain for a Manufacturer Supplier } Storage Mfg. Storage Dist. Retailer Customer

Typical Supply Chain for a Manufacturer Supplier } Storage Mfg. Storage Dist. Retailer Customer

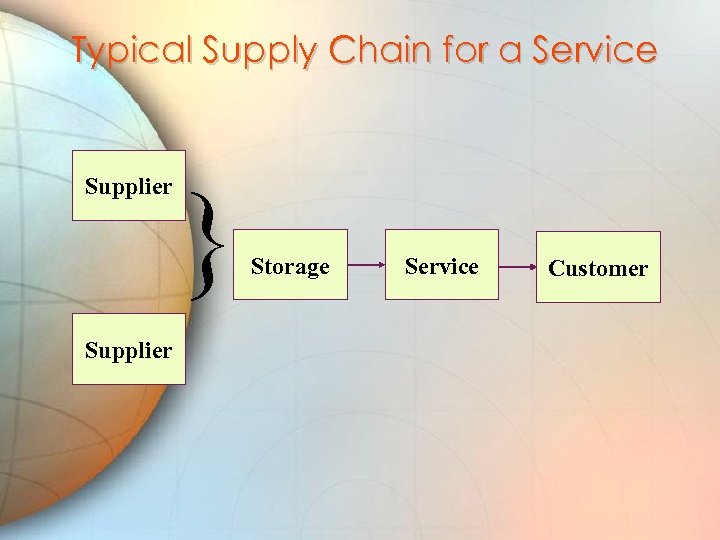

Typical Supply Chain for a Service Supplier } Storage Service Customer

Typical Supply Chain for a Service Supplier } Storage Service Customer

In the first half of the twentieth century industry replaced agriculture, in the second half of the twentieth century –“service” has replaced “manufacturing” -and right now, the knowledge industry is beginning to replace the others. −−George Kotzmetzk

In the first half of the twentieth century industry replaced agriculture, in the second half of the twentieth century –“service” has replaced “manufacturing” -and right now, the knowledge industry is beginning to replace the others. −−George Kotzmetzk

1 -13 George Kotzmetzk

1 -13 George Kotzmetzk

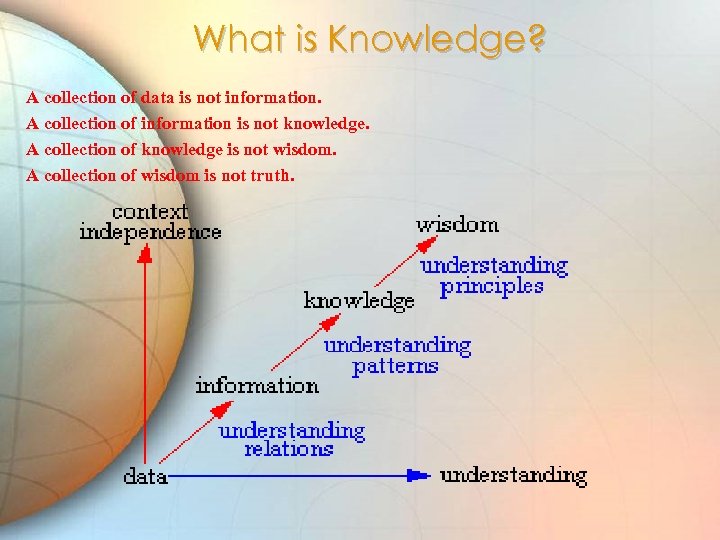

What is Knowledge? A collection of data is not information. A collection of information is not knowledge. A collection of knowledge is not wisdom. A collection of wisdom is not truth.

What is Knowledge? A collection of data is not information. A collection of information is not knowledge. A collection of knowledge is not wisdom. A collection of wisdom is not truth.

1 -15 CHAPTER 1 Introduction to Operations Management

1 -15 CHAPTER 1 Introduction to Operations Management

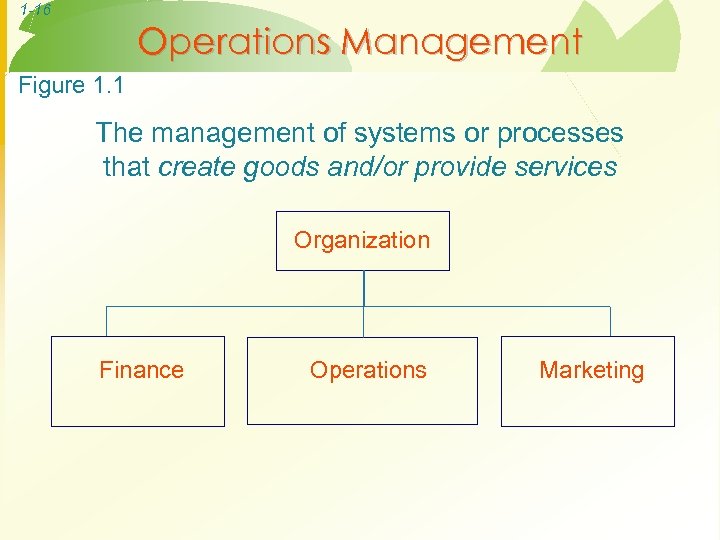

1 -16 Operations Management Figure 1. 1 The management of systems or processes that create goods and/or provide services Organization Finance Operations Marketing

1 -16 Operations Management Figure 1. 1 The management of systems or processes that create goods and/or provide services Organization Finance Operations Marketing

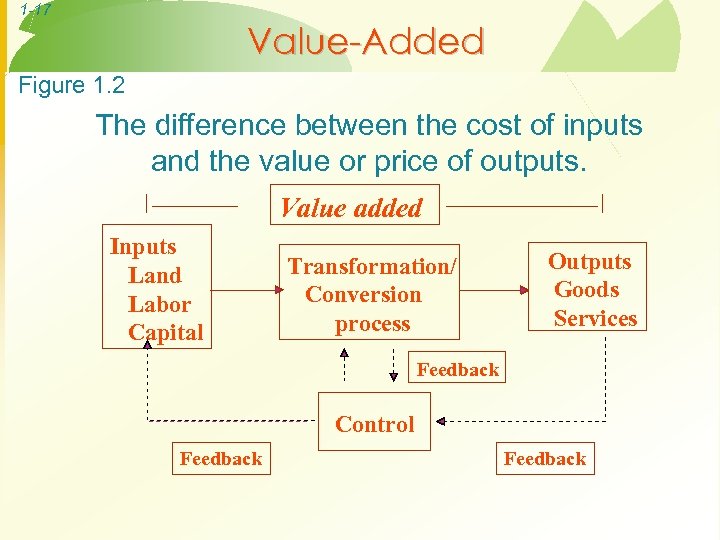

1 -17 Value-Added Figure 1. 2 The difference between the cost of inputs and the value or price of outputs. Value added Inputs Land Labor Capital Transformation/ Conversion process Outputs Goods Services Feedback Control Feedback

1 -17 Value-Added Figure 1. 2 The difference between the cost of inputs and the value or price of outputs. Value added Inputs Land Labor Capital Transformation/ Conversion process Outputs Goods Services Feedback Control Feedback

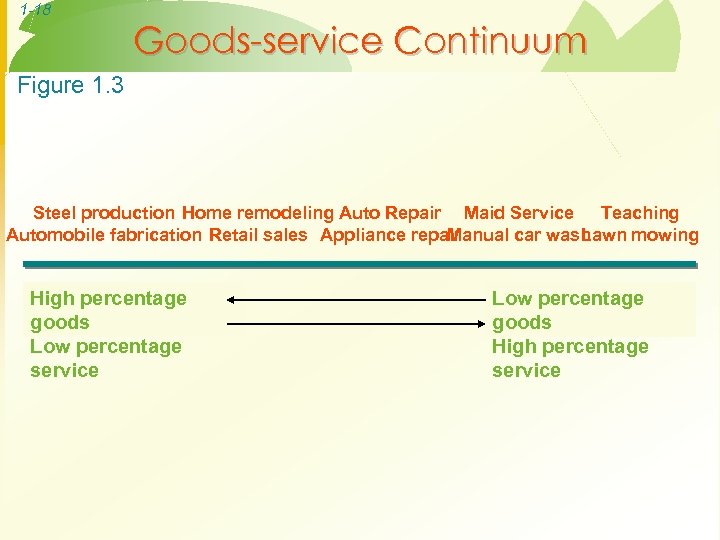

1 -18 Goods-service Continuum Figure 1. 3 Steel production Home remodeling Auto Repair Maid Service Teaching Automobile fabrication Retail sales Appliance repair Manual car wash Lawn mowing High percentage goods Low percentage service Low percentage goods High percentage service

1 -18 Goods-service Continuum Figure 1. 3 Steel production Home remodeling Auto Repair Maid Service Teaching Automobile fabrication Retail sales Appliance repair Manual car wash Lawn mowing High percentage goods Low percentage service Low percentage goods High percentage service

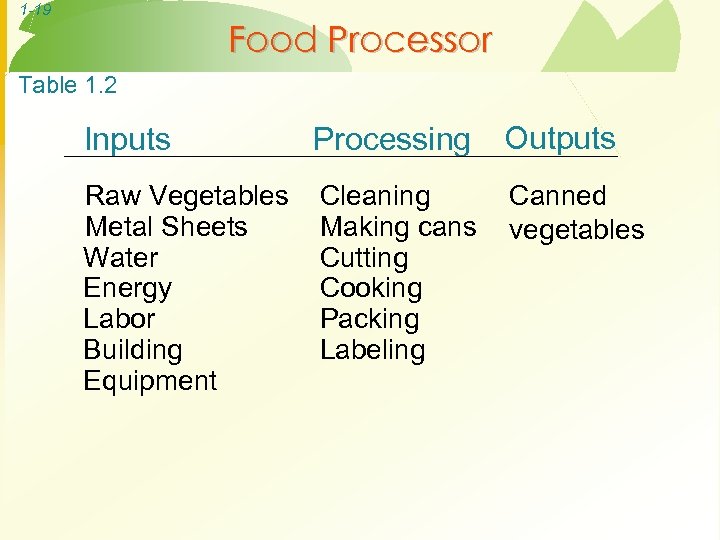

1 -19 Food Processor Table 1. 2 Inputs Processing Outputs Raw Vegetables Metal Sheets Water Energy Labor Building Equipment Cleaning Making cans Cutting Cooking Packing Labeling Canned vegetables

1 -19 Food Processor Table 1. 2 Inputs Processing Outputs Raw Vegetables Metal Sheets Water Energy Labor Building Equipment Cleaning Making cans Cutting Cooking Packing Labeling Canned vegetables

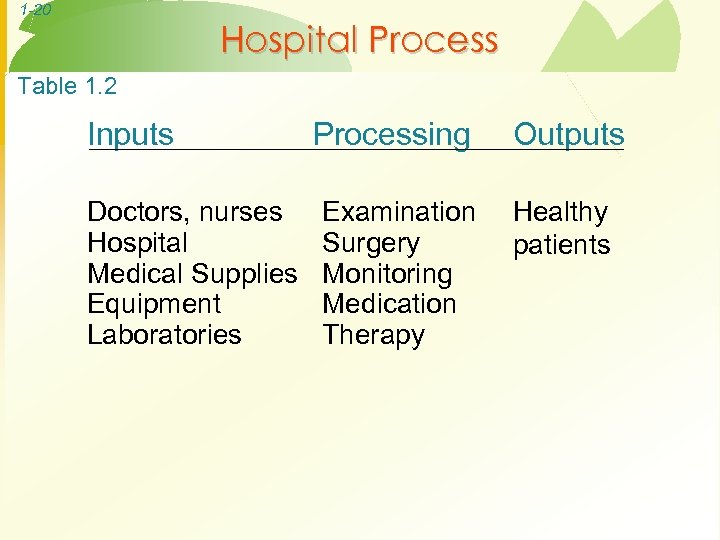

1 -20 Hospital Process Table 1. 2 Inputs Doctors, nurses Hospital Medical Supplies Equipment Laboratories Processing Outputs Examination Surgery Monitoring Medication Therapy Healthy patients

1 -20 Hospital Process Table 1. 2 Inputs Doctors, nurses Hospital Medical Supplies Equipment Laboratories Processing Outputs Examination Surgery Monitoring Medication Therapy Healthy patients

1 -21 Manufacturing or Service? Tangible Act

1 -21 Manufacturing or Service? Tangible Act

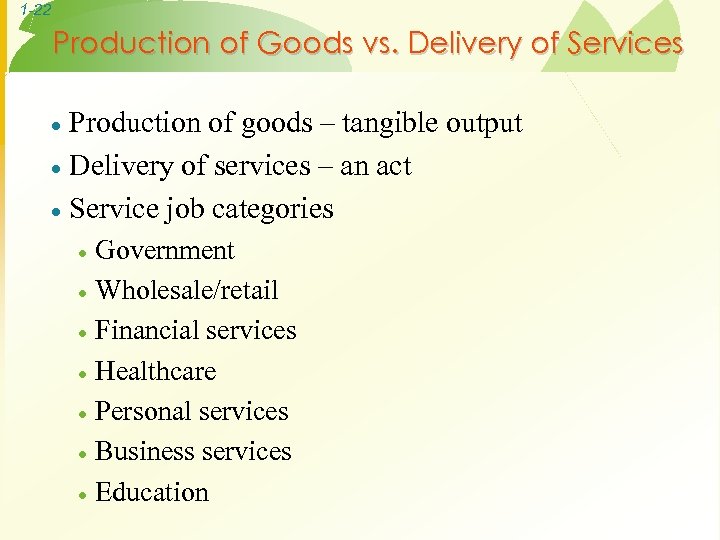

1 -22 Production of Goods vs. Delivery of Services Production of goods – tangible output · Delivery of services – an act · Service job categories · Government · Wholesale/retail · Financial services · Healthcare · Personal services · Business services · Education ·

1 -22 Production of Goods vs. Delivery of Services Production of goods – tangible output · Delivery of services – an act · Service job categories · Government · Wholesale/retail · Financial services · Healthcare · Personal services · Business services · Education ·

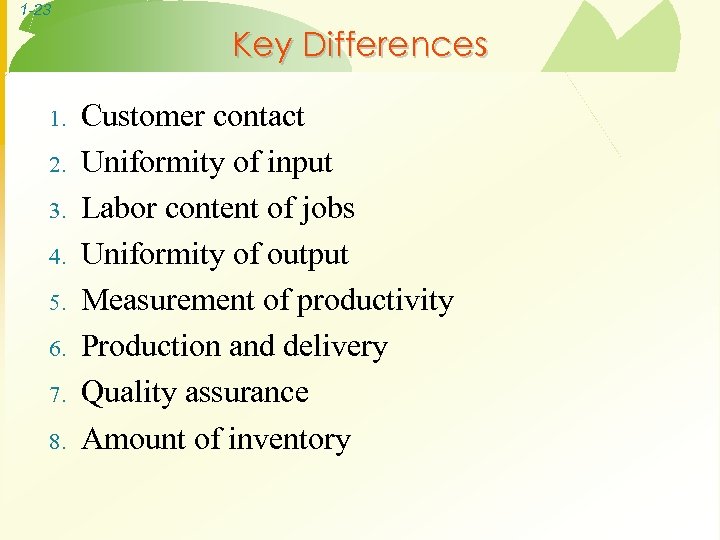

1 -23 Key Differences 1. 2. 3. 4. 5. 6. 7. 8. Customer contact Uniformity of input Labor content of jobs Uniformity of output Measurement of productivity Production and delivery Quality assurance Amount of inventory

1 -23 Key Differences 1. 2. 3. 4. 5. 6. 7. 8. Customer contact Uniformity of input Labor content of jobs Uniformity of output Measurement of productivity Production and delivery Quality assurance Amount of inventory

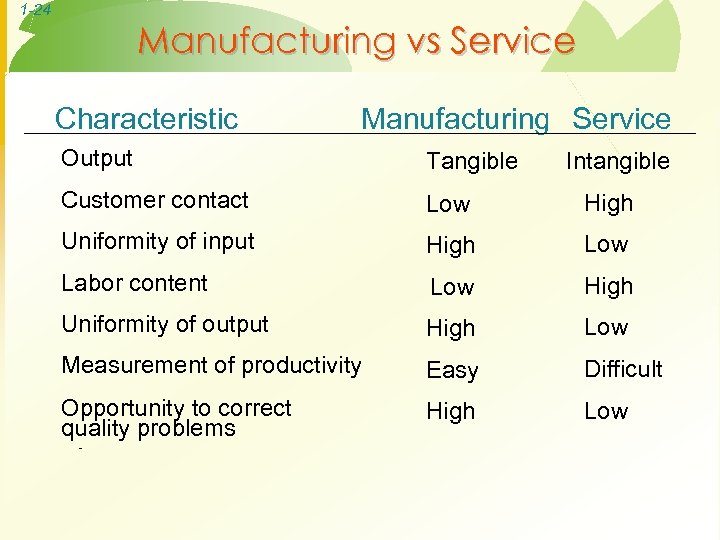

1 -24 Manufacturing vs Service Characteristic Manufacturing Service Output Tangible Customer contact Low High Uniformity of input High Low Labor content Low High Uniformity of output High Low Measurement of productivity Easy Difficult Opportunity to correct quality problems High Low High Intangible

1 -24 Manufacturing vs Service Characteristic Manufacturing Service Output Tangible Customer contact Low High Uniformity of input High Low Labor content Low High Uniformity of output High Low Measurement of productivity Easy Difficult Opportunity to correct quality problems High Low High Intangible

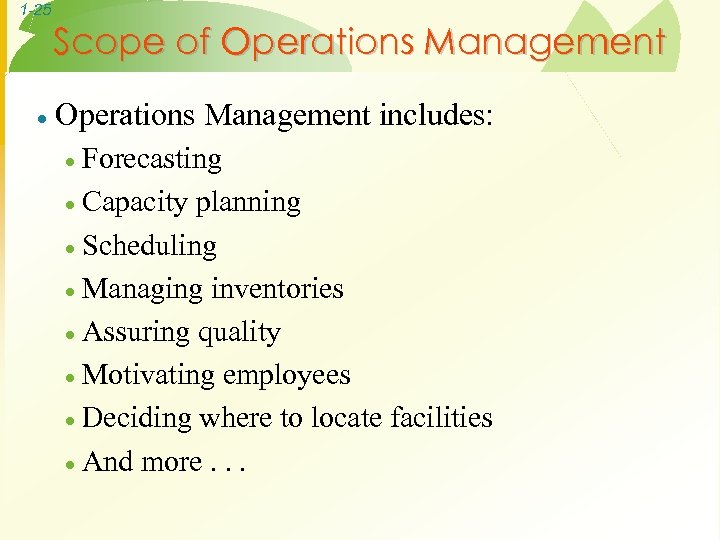

1 -25 Scope of Operations Management · Operations Management includes: Forecasting · Capacity planning · Scheduling · Managing inventories · Assuring quality · Motivating employees · Deciding where to locate facilities · And more. . . ·

1 -25 Scope of Operations Management · Operations Management includes: Forecasting · Capacity planning · Scheduling · Managing inventories · Assuring quality · Motivating employees · Deciding where to locate facilities · And more. . . ·

1 -26 · The operations function · Consists of all activities directly related to producing goods or providing services

1 -26 · The operations function · Consists of all activities directly related to producing goods or providing services

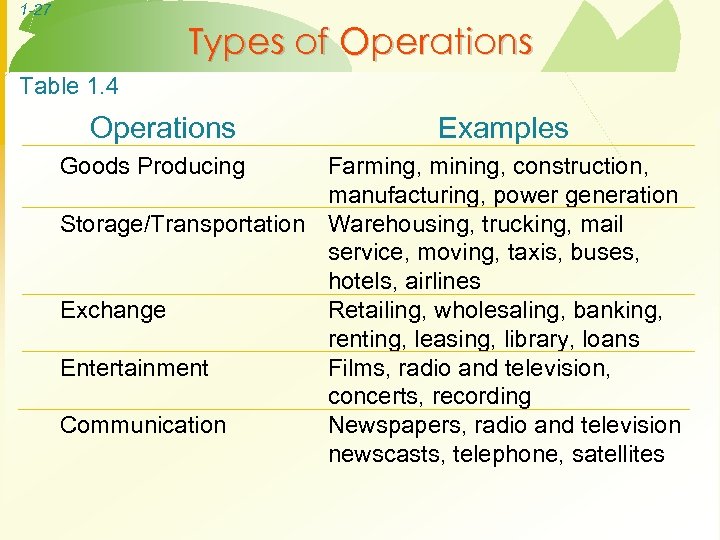

1 -27 Types of Operations Table 1. 4 Operations Goods Producing Examples Farming, mining, construction, manufacturing, power generation Storage/Transportation Warehousing, trucking, mail service, moving, taxis, buses, hotels, airlines Exchange Retailing, wholesaling, banking, renting, leasing, library, loans Entertainment Films, radio and television, concerts, recording Communication Newspapers, radio and television newscasts, telephone, satellites

1 -27 Types of Operations Table 1. 4 Operations Goods Producing Examples Farming, mining, construction, manufacturing, power generation Storage/Transportation Warehousing, trucking, mail service, moving, taxis, buses, hotels, airlines Exchange Retailing, wholesaling, banking, renting, leasing, library, loans Entertainment Films, radio and television, concerts, recording Communication Newspapers, radio and television newscasts, telephone, satellites

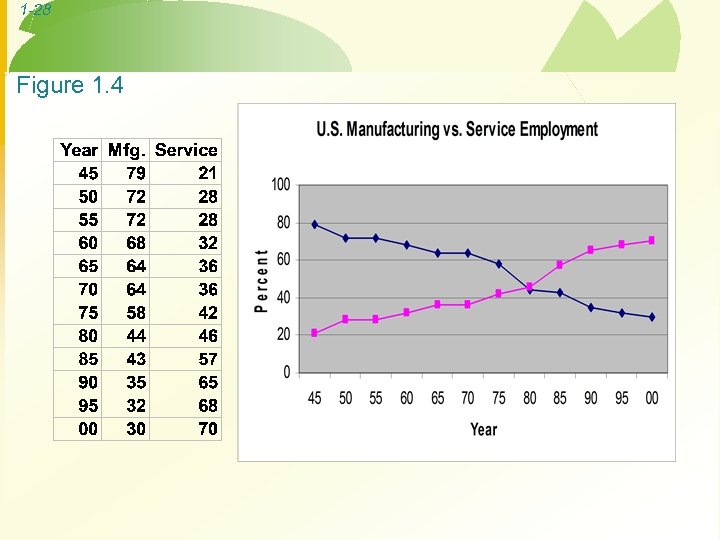

1 -28 Figure 1. 4

1 -28 Figure 1. 4

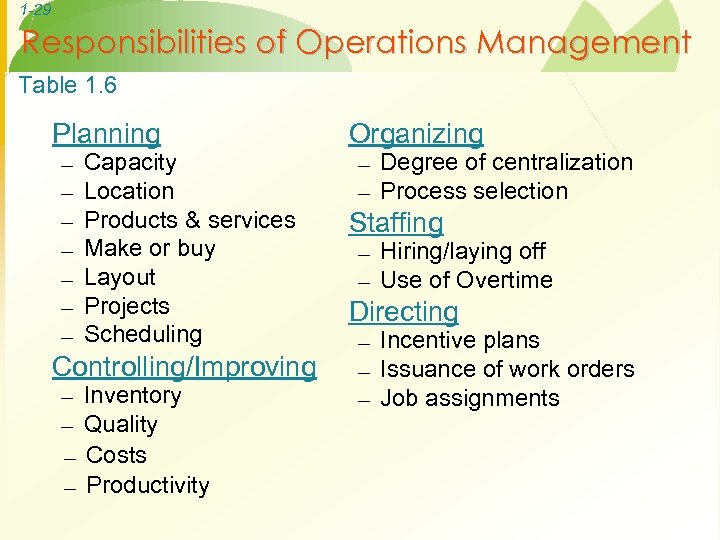

1 -29 Responsibilities of Operations Management Table 1. 6 Planning – – – – Capacity Location Products & services Make or buy Layout Projects Scheduling Controlling/Improving – – Inventory Quality Costs Productivity Organizing – Degree of centralization – Process selection Staffing – Hiring/laying off – Use of Overtime Directing – Incentive plans – Issuance of work orders – Job assignments

1 -29 Responsibilities of Operations Management Table 1. 6 Planning – – – – Capacity Location Products & services Make or buy Layout Projects Scheduling Controlling/Improving – – Inventory Quality Costs Productivity Organizing – Degree of centralization – Process selection Staffing – Hiring/laying off – Use of Overtime Directing – Incentive plans – Issuance of work orders – Job assignments

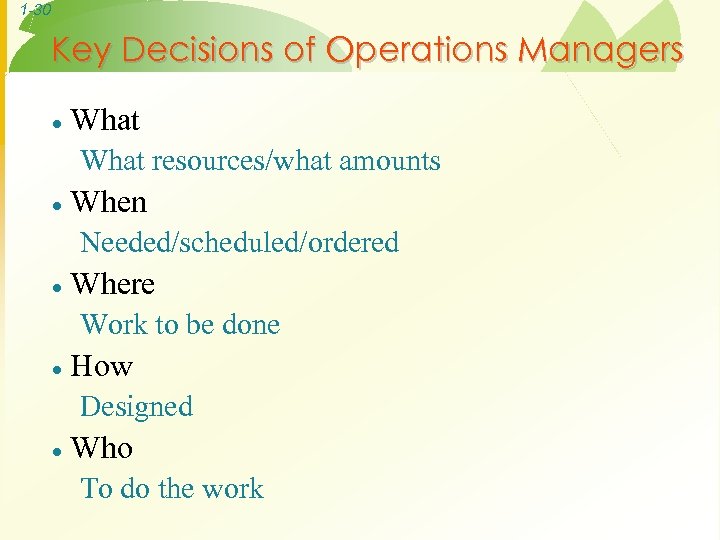

1 -30 Key Decisions of Operations Managers · What resources/what amounts · When Needed/scheduled/ordered · Where Work to be done · How Designed · Who To do the work

1 -30 Key Decisions of Operations Managers · What resources/what amounts · When Needed/scheduled/ordered · Where Work to be done · How Designed · Who To do the work

1 -31 Decision Making System Design – – – capacity location arrangement of departments product and service planning acquisition and placement of equipment

1 -31 Decision Making System Design – – – capacity location arrangement of departments product and service planning acquisition and placement of equipment

1 -32 Decision Making System operation personnel inventory scheduling project management – quality assurance – –

1 -32 Decision Making System operation personnel inventory scheduling project management – quality assurance – –

1 -33 Decision Making Models · Quantitative approaches · Analysis of trade-offs · Systems approach ·

1 -33 Decision Making Models · Quantitative approaches · Analysis of trade-offs · Systems approach ·

1 -34 Models A model is an abstraction of reality. – Physical – Schematic – Mathematical Tradeoffs What are the pros and cons of models?

1 -34 Models A model is an abstraction of reality. – Physical – Schematic – Mathematical Tradeoffs What are the pros and cons of models?

1 -35 Models Are Beneficial Easy to use, less expensive · Require users to organize · Systematic approach to problem solving · Increase understanding of the problem · Enable “what if” questions · Specific objectives · Consistent tool · Power of mathematics · Standardized format ·

1 -35 Models Are Beneficial Easy to use, less expensive · Require users to organize · Systematic approach to problem solving · Increase understanding of the problem · Enable “what if” questions · Specific objectives · Consistent tool · Power of mathematics · Standardized format ·

1 -36 Quantitative Approaches • Linear programming • Queuing Techniques • Inventory models • Project models • Statistical models

1 -36 Quantitative Approaches • Linear programming • Queuing Techniques • Inventory models • Project models • Statistical models

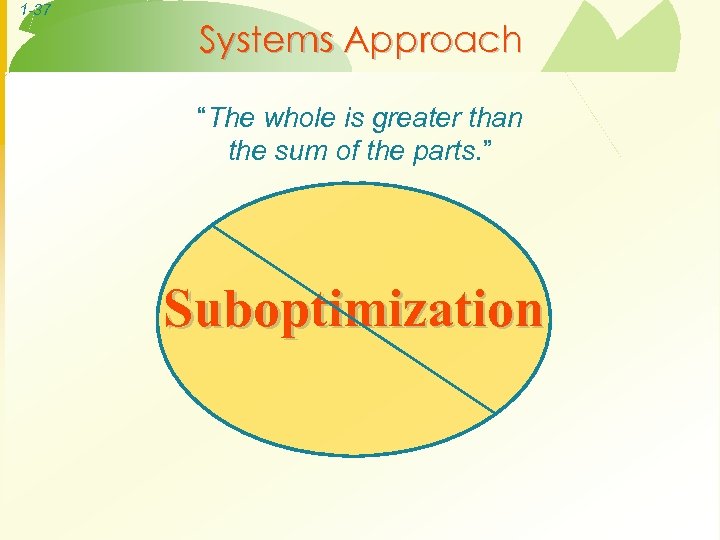

1 -37 Systems Approach “The whole is greater than the sum of the parts. ” Suboptimization

1 -37 Systems Approach “The whole is greater than the sum of the parts. ” Suboptimization

1 -38 Pareto Phenomenon • A few factors account for a high percentage of the occurrence of some event(s). • 80/20 Rule - 80% of problems are caused by 20% of the activities. How do we identify the vital few?

1 -38 Pareto Phenomenon • A few factors account for a high percentage of the occurrence of some event(s). • 80/20 Rule - 80% of problems are caused by 20% of the activities. How do we identify the vital few?

1 -39 Business Operations Overlap Figure 1. 5 Operations Marketing Finance

1 -39 Business Operations Overlap Figure 1. 5 Operations Marketing Finance

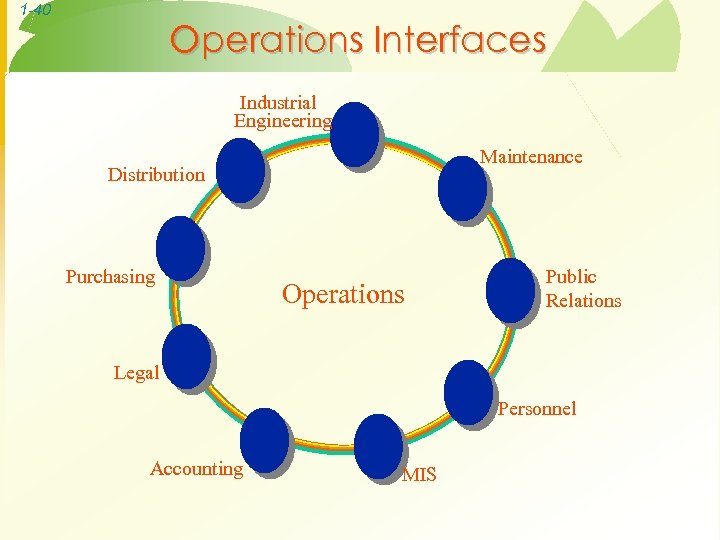

1 -40 Operations Interfaces Industrial Engineering Maintenance Distribution Purchasing Operations Public Relations Legal Personnel Accounting MIS

1 -40 Operations Interfaces Industrial Engineering Maintenance Distribution Purchasing Operations Public Relations Legal Personnel Accounting MIS

1 -41 Trends in Business · Major trends The Internet, e-commerce, e-business · Management technology · Globalization · Management of supply chains · Agility ·

1 -41 Trends in Business · Major trends The Internet, e-commerce, e-business · Management technology · Globalization · Management of supply chains · Agility ·

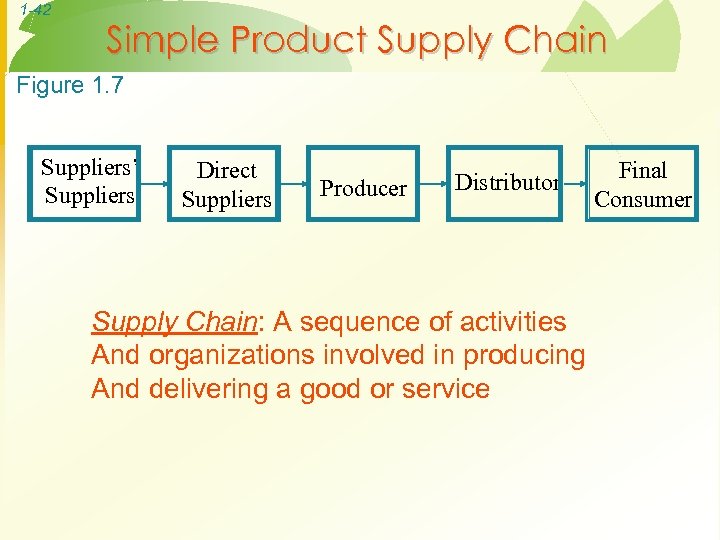

1 -42 Simple Product Supply Chain Figure 1. 7 Suppliers’ Suppliers Direct Suppliers Producer Distributor Supply Chain: A sequence of activities And organizations involved in producing And delivering a good or service Final Consumer

1 -42 Simple Product Supply Chain Figure 1. 7 Suppliers’ Suppliers Direct Suppliers Producer Distributor Supply Chain: A sequence of activities And organizations involved in producing And delivering a good or service Final Consumer

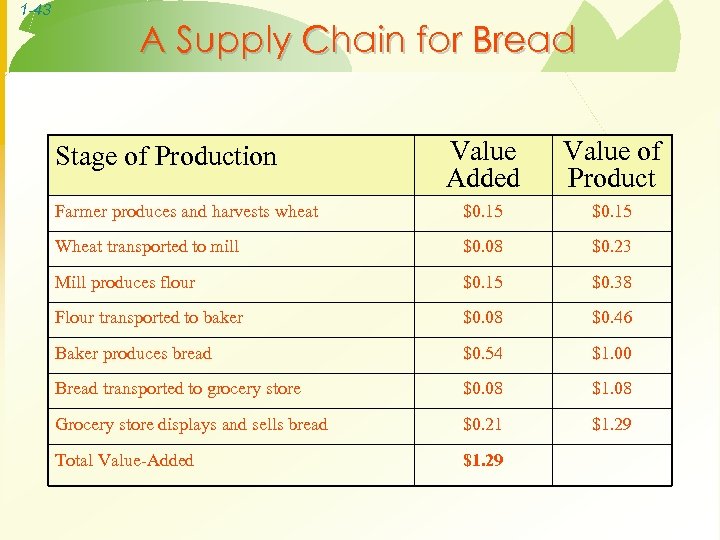

1 -43 A Supply Chain for Bread Value Added Value of Product Farmer produces and harvests wheat $0. 15 Wheat transported to mill $0. 08 $0. 23 Mill produces flour $0. 15 $0. 38 Flour transported to baker $0. 08 $0. 46 Baker produces bread $0. 54 $1. 00 Bread transported to grocery store $0. 08 $1. 08 Grocery store displays and sells bread $0. 21 $1. 29 Total Value-Added $1. 29 Stage of Production

1 -43 A Supply Chain for Bread Value Added Value of Product Farmer produces and harvests wheat $0. 15 Wheat transported to mill $0. 08 $0. 23 Mill produces flour $0. 15 $0. 38 Flour transported to baker $0. 08 $0. 46 Baker produces bread $0. 54 $1. 00 Bread transported to grocery store $0. 08 $1. 08 Grocery store displays and sells bread $0. 21 $1. 29 Total Value-Added $1. 29 Stage of Production

1 -44 Other Important Trends Ethical behavior · Operations strategy · Working with fewer resources · Cost control and productivity · Quality and process improvement · Increased regulation and product liability · Lean production ·

1 -44 Other Important Trends Ethical behavior · Operations strategy · Working with fewer resources · Cost control and productivity · Quality and process improvement · Increased regulation and product liability · Lean production ·

1 -45 Value/Dimensions VD 2 Performance=speed x quality x flexibility

1 -45 Value/Dimensions VD 2 Performance=speed x quality x flexibility

1 -46 Value/Definition VD 1 Trek bike example

1 -46 Value/Definition VD 1 Trek bike example