73f87d9bb103c9345f9e783e2a5a6765.ppt

- Количество слайдов: 88

OPERATIONS MANAGEMENT for MBAs Second Edition Meredith and Shafer Prepared by Scott M. Shafer Wake Forest University John Wiley and Sons, Inc. 1

Chapter 3 Quality Management Chapter 3: Quality Management 2

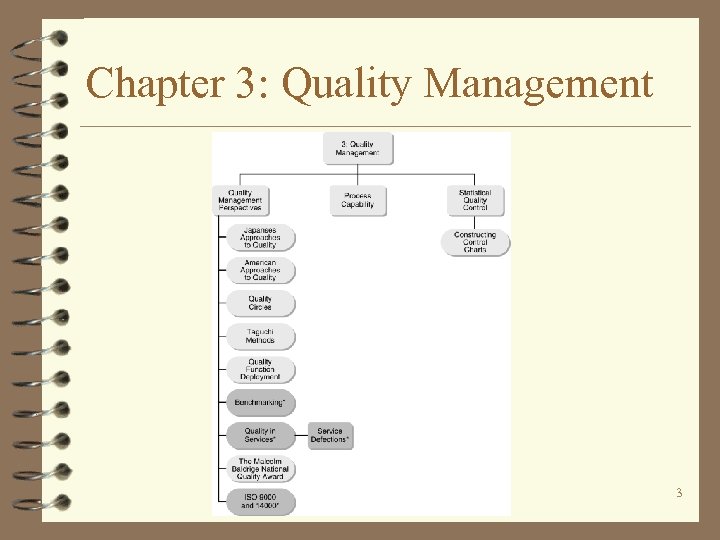

Chapter 3: Quality Management 3

Examples Chapter 3: Quality Management 4

West Babylon School District 4 Began applying continuous improvement and quality to its administrative and education processes. 4 TQE 4 Applied Deming’s 14 Points for Management to administrative process. 4 Numerous improvements made. Chapter 3: Quality Management 5

National Semiconductor 4 Early proponent of total quality – Quality circles 1981 – Preventive maintenance 1982 – Statistical process control 1983 – Design of experiment techniques 1984 – Design for manufacturing techniques 1986 Chapter 3: Quality Management 6

National Semiconductor continued 4 Second stage of quality initiatives (1990 s) – – – – Focused on customer-supplier relationships Customer satisfaction Customer score cards Process analysis Employee empowerment Team strategies Problem solving techniques – Visioning Chapter 3: Quality Management 7

National Semiconductor continued 4 Third stage – Personal mastery – Shared vision – Systems thinking – Team learning Chapter 3: Quality Management 8

NCR 4 Produces business information processing systems 4 Recognized need to continuously improve its products 4 Major component of its continuous improvement program is use of statistical techniques Chapter 3: Quality Management 9

NCR continued 4 Began using statistical process control techniques in 1985 to monitor its autoinsertion operation on its printed circuit board assembly line. – Line was producing an unacceptable number of defects. – Reasons included misinserted or broken parts, using the wrong parts and so on. Chapter 3: Quality Management 10

NCR continued 4 Quality engineering department established process averages, control limits and guidelines for action for “out-of-control” conditions. – Production was stopped when out-of-control condition detected until cause identified. – Random samples of 1000 insertions were collected each hour and the results plotted on a c chart. – Out-of-control situations were investigated to identify the assignable cause. Chapter 3: Quality Management 11

NCR concluded 4 Learned a great deal about the autoinsertion operation using the control charts. – Problem of broken parts was traced to a specific supplier. 4 Because of the success of this experiment, statistical process control was implemented across the entire assembly line. 4 NCR has since changed its approach from “inspect and repair” to “prevent and design for quality. ” Chapter 3: Quality Management 12

Timber Companies 4 Because of environmental restrictions and limited quantities of large-diameter trees, many timber companies are using statistical quality control techniques to maximize the quality and quantity of finished lumber produced Chapter 3: Quality Management 13

Converting Logs into Finished Lumber 4 Log debarked 4 Debarked log split down 4 4 4 the middle Split log resawed to create boards Ends of boards trimmed Boards are stacked Boards dried in kiln for 2 to 30 days Boards are planed Chapter 3: Quality Management 14

Applying Statistical Quality Control to the Stacking Operation 4 Important operation because this operation determines straightness of finished lumber. 4 Lumber stacked in layers. 4 Separators placed between layers to form air channels and transfer weight of wood. 4 Automated equipment used to stack lumber making it necessary to monitor the alignment of the separators. Chapter 3: Quality Management 15

Stacking Operation continued 4 Estimated cost of misplaced separator is $31. 50 owing to board warping. 4 Average sawmill handles upwards of 30, 000 separators each day. 4 Measuring board placed in front of each column of separators to monitor separator alignment. 4 Stack of lumber contains approximately 15 columns of separators and 360 separators. 16 Chapter 3: Quality Management

Stacking Operation concluded 4 Total number of misplaced separators is divided by the total number of separators in the stack of lumber and result plotted on p chart. 4 Using p chart, workers monitor the stacking equipment and identify problems before an out-of-control situation arises. Chapter 3: Quality Management 17

Quality Management Perspectives Chapter 3: Quality Management 18

Quality Costs 4 Two primary sets of costs involved in quality – Control costs – Failure costs 4 These costs are often as high as 15 to 35% of sales 4 Costs often broken down into four categories Chapter 3: Quality Management 19

Category 1: Prevention Costs 4 Costs associated with trying to prevent defects and errors – Training for quality – Educating suppliers – Designing product for quality – Designing production system for quality – Preventive maintenance Chapter 3: Quality Management 20

Category 2: Appraisal Costs 4 Costs of determining current quality – Measuring and testing parts – Running special test laboratories – Acquiring special testing equipment – Conducting statistical process control – Inspecting incoming materials Chapter 3: Quality Management 21

Category 3: Internal Costs of Defects 4 Costs incurred when defects are found before shipment/delivery to customer. – Labor and materials going into scrap – Reworking and retesting to correct defects – Downtime of equipment and labor while waiting for repairs – Yield losses Chapter 3: Quality Management 22

Category 4: External Costs of Defects 4 Costs of trying to correct defects after receipt by customer. – Lost of customer goodwill – Recalls to correct problem – Warranty, insurance, and legal suit settlements Chapter 3: Quality Management 23

Quality Management Philosophies Chapter 3: Quality Management 24

W. Edwards Deming 4 Major source of poor quality is variation 4 Quality improvement the responsibility of top management 4 All employees should be trained in use of problem solving tools and especially statistical techniques Chapter 3: Quality Management 25

Deming’s 14 Points 4 Create constancy of purpose 4 Adopt the new philosophy 4 Cease dependence on mass inspection 4 End practice of awarding business on basis of price tags 4 Improve constantly and forever 4 Institute modern methods of training Chapter 3: Quality Management 26

Deming’s 14 Points continued 4 Institute modern method of supervision 4 Drive out fear 4 Breakdown organizational barriers 4 Eliminate arbitrary numerical goals 4 Eliminate work standards and quotas 4 Remove barriers that reduce pride of workmanship Chapter 3: Quality Management 27

Deming’s 14 Points continued 4 Institute a vigorous program of education and training 4 Push the 13 points everyday Chapter 3: Quality Management 28

Joseph Juran 4 Quality Control Handbook (1951) 4 Employees speak in different languages 4 Quality Trilogy – Quality Planning – Quality Control – Quality Improvement 4 Need to place more emphasis on planning and improvement Chapter 3: Quality Management 29

Joseph Juran continued 4 Organizations progress through four phases – Minimize prevention and appraisal costs – Appraisal costs increased – Process control introduced increasing appraisal costs but lowering internal and external failure costs – Prevention costs increased in effort to lower total quality costs Chapter 3: Quality Management 30

Philip B. Crosby 4 Quality is conformance to requirements, not elegance 4 Quality problems do not exist, rather organizations have functional problems 4 Best to perform an activity right the first time 4 Zero defects only meaningful performance measure Chapter 3: Quality Management 31

Total Quality Management (TQM) 4 Better to produce item right the first time than to try to inspect quality in 4 Quality at the source - responsibility shifted from quality control department to workers Chapter 3: Quality Management 32

History of TQM 4 Dr. Shewart began using statistical control at the Bell Institute in 1930 s 4 Military standards developed in 1950 s 4 After World War II, Japanese Union of Scientist and Engineers began consulting with Deming 4 Deming Prize introduced in Japan in 1951 Chapter 3: Quality Management 33

History of TQM continued 4 Quality assurance concept proposed in 1952 4 Juran makes first trip to Japan in 1954 4 Quality becomes Japan’s national slogan in 1956 4 First quality circles created in 1957 4 10, 000 quality circles by 1966 4 100, 000 quality circles by 1977 4 First U. S. quality circle 1974 Chapter 3: Quality Management 34

Five Steps in TQM 4 Determine what customers want 4 Develop products and services 4 Develop production system 4 Monitor the system 4 Include customers and suppliers Chapter 3: Quality Management 35

New Responsibilities of Quality Control Department 4 Training employees how to control quality 4 Conducting random quality audits 4 Consulting on quality problems 4 Determining cost of quality 4 Helping implement quality control ideas 4 Overseeing final test of finished goods Chapter 3: Quality Management 36

Quality Circles 4 Focus on all problems facing workers 4 Composed of natural work groups 4 Not limited to shop employees 4 Usually spend couple hours per week on company time analyzing problems Chapter 3: Quality Management 37

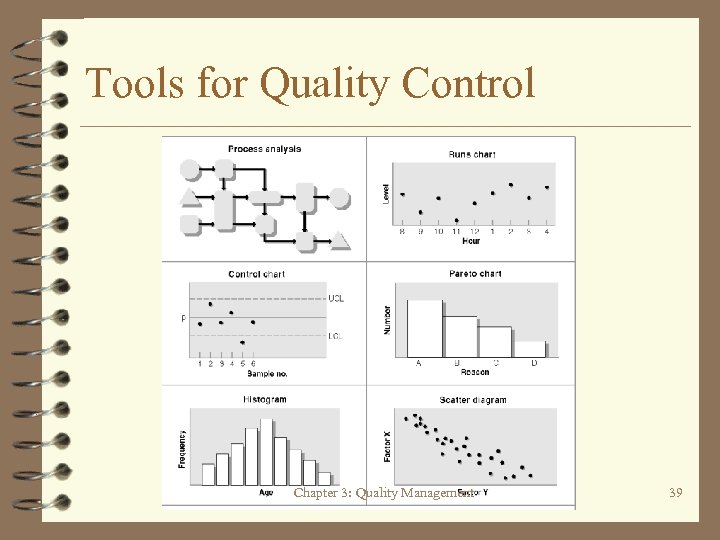

Quality Tools 4 Process analysis 4 Scatter diagram 4 Runs chart 4 Fishbone chart 4 Control chart 4 Presentation skills 4 Pareto chart 4 Analysis skills 4 Histogram 4 Brainstorming Chapter 3: Quality Management 38

Tools for Quality Control Chapter 3: Quality Management 39

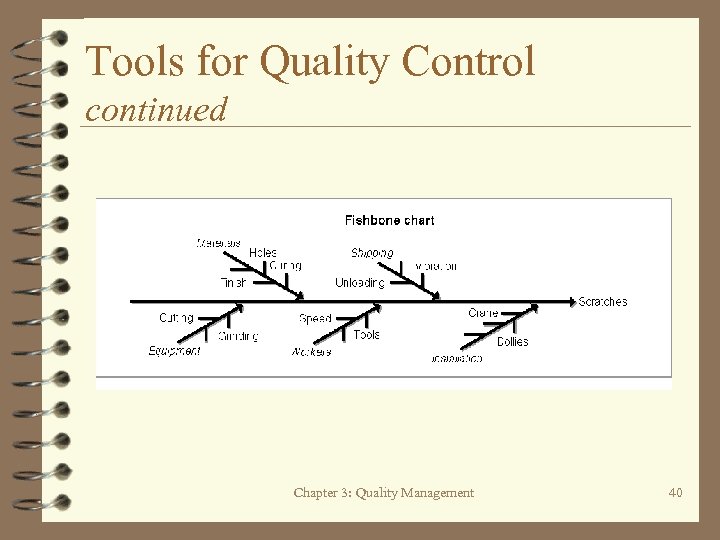

Tools for Quality Control continued Chapter 3: Quality Management 40

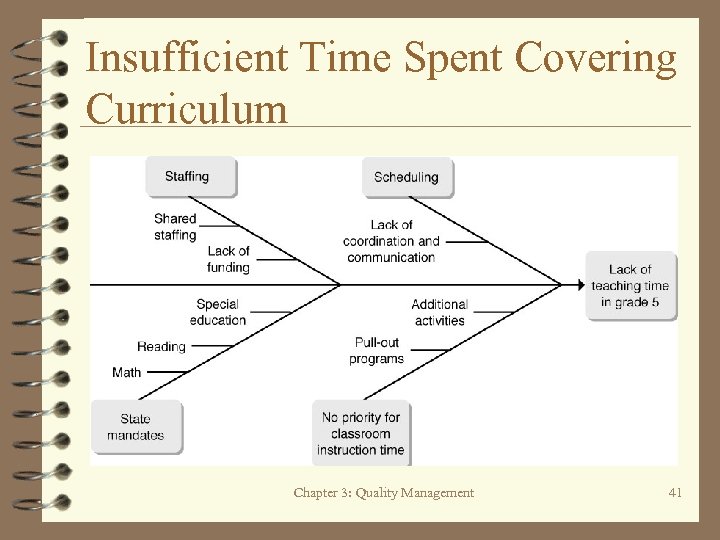

Insufficient Time Spent Covering Curriculum Chapter 3: Quality Management 41

Taguchi Methods 4 Design for Manufacturability (DFM) 4 Procedure for statistical testing to determine best combination of product and transformation system design that will make output relatively independent of normal fluctuations in the production system Chapter 3: Quality Management 42

Quality Function Deployment (QFD) 4 Tools for helping translate customer desires directly into product service attributes. Chapter 3: Quality Management 43

Benchmarking Comparing an organization’s performance to performance of other organizations. Chapter 3: Quality Management 44

Purposes for Benchmarking 4 Comparing an organization’s performance to the best organization’s performance 4 Comparing an organization’s business processes with similar processes 4 Comparing products and services 4 Identifying best practices to implement 4 Projecting trends Chapter 3: Quality Management 45

Steps in Benchmarking 4 Preparing for the study – obtaining top management support 4 Collecting data – published data – original research 4 Using what was learned to improve organizational performance Chapter 3: Quality Management 46

Benchmarking Goals 4 Learning from experiences of others 4 Determining how organization is performing relative to the best 4 Helping to prioritize improvement efforts – developing stretch goals – overcoming complacency within organization Chapter 3: Quality Management 47

Quality in Services 4 Measuring is difficult 4 Training in standard procedures often used to improve quality 4 One way to measure quality of services is to use customer satisfaction surveys 4 J. D. Power and Associates uses surveys to rate domestic airlines, hotel chains, and rental car companies. Chapter 3: Quality Management 48

Rating the Performance of Domestic Airlines 4 On-time performance (25%) 4 Airport check-in (11%) 4 Courtesy of flight attendants (11%) 4 Seating comfort (11%) Chapter 3: Quality Management 49

Service Defections 4 Organizations should monitor customer defections – feedback from defecting customers can be used to identify problem areas – can determine what is needed to win them back – changes in defection rate can be used as early warning signal Chapter 3: Quality Management 50

Quality Awards/Certifications Chapter 3: Quality Management 51

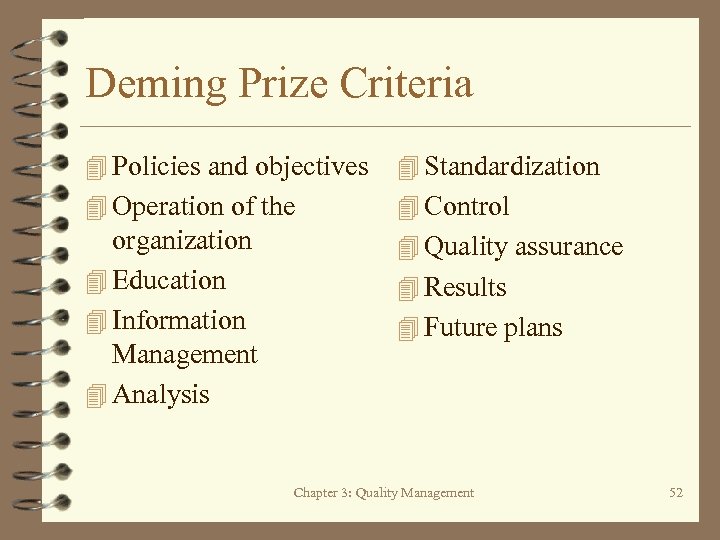

Deming Prize Criteria 4 Policies and objectives 4 Standardization 4 Operation of the 4 Control organization 4 Education 4 Information Management 4 Analysis 4 Quality assurance 4 Results 4 Future plans Chapter 3: Quality Management 52

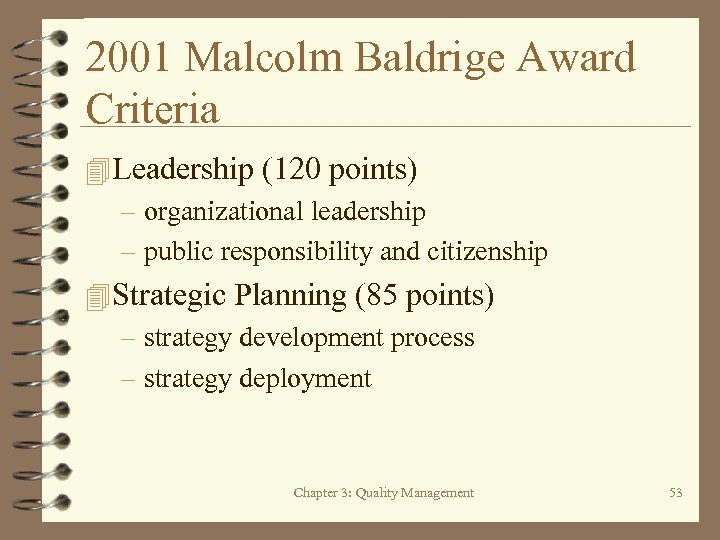

2001 Malcolm Baldrige Award Criteria 4 Leadership (120 points) – organizational leadership – public responsibility and citizenship 4 Strategic Planning (85 points) – strategy development process – strategy deployment Chapter 3: Quality Management 53

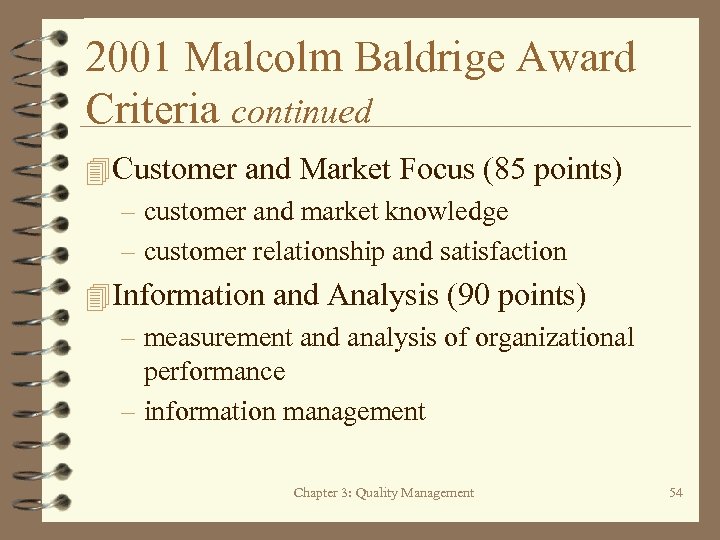

2001 Malcolm Baldrige Award Criteria continued 4 Customer and Market Focus (85 points) – customer and market knowledge – customer relationship and satisfaction 4 Information and Analysis (90 points) – measurement and analysis of organizational performance – information management Chapter 3: Quality Management 54

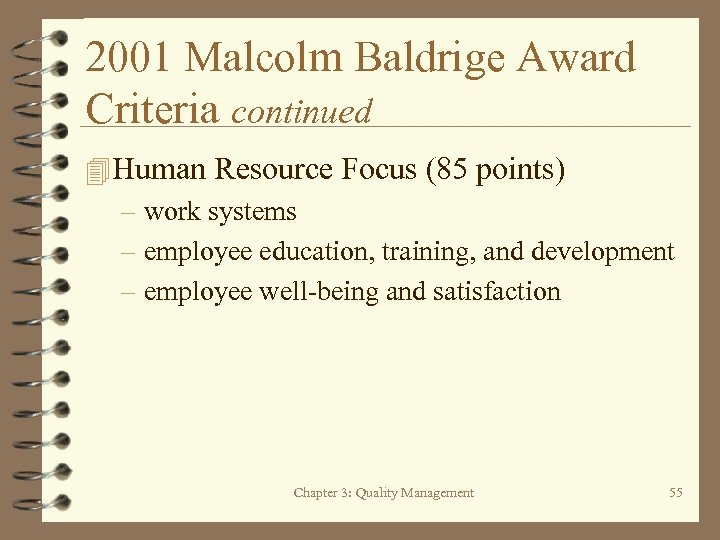

2001 Malcolm Baldrige Award Criteria continued 4 Human Resource Focus (85 points) – work systems – employee education, training, and development – employee well-being and satisfaction Chapter 3: Quality Management 55

2001 Malcolm Baldrige Award Criteria continued 4 Process Management (85) – product and service processes – business processes – support processes Chapter 3: Quality Management 56

2001 Malcolm Baldrige Award Criteria continued 4 Business Results (450 points) – Customer-focused results – financial and market results – human resource results – organizational effectiveness results Chapter 3: Quality Management 57

ISO 9000 4 Guidelines for designing, manufacturing, selling, and servicing products. 4 Selecting an ISO 9000 certified supplier provides some assurance that supplier follows accepted business practices in areas covered by the standard Chapter 3: Quality Management 58

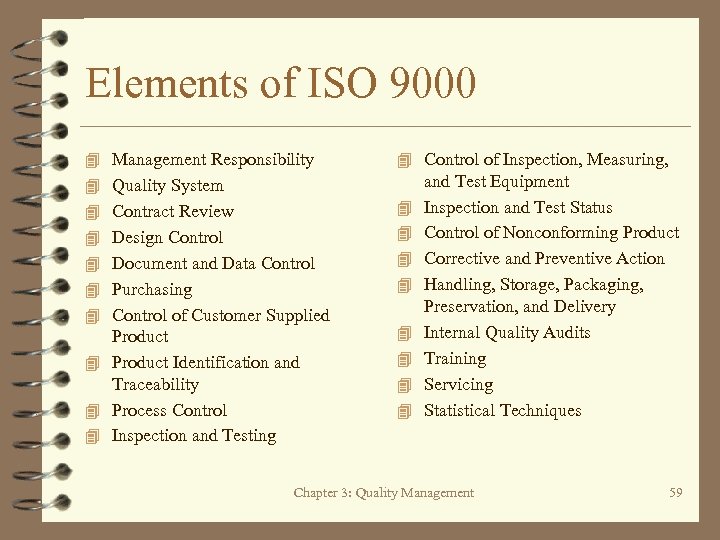

Elements of ISO 9000 4 Management Responsibility 4 Control of Inspection, Measuring, 4 Quality System 4 Contract Review 4 4 Design Control 4 4 Document and Data Control 4 4 Purchasing 4 4 Control of Customer Supplied Product 4 Product Identification and Traceability 4 Process Control 4 Inspection and Testing 4 4 and Test Equipment Inspection and Test Status Control of Nonconforming Product Corrective and Preventive Action Handling, Storage, Packaging, Preservation, and Delivery Internal Quality Audits Training Servicing Statistical Techniques Chapter 3: Quality Management 59

ISO 14000 4 Series of standards covering environmental management systems, environmental auditing, evaluation of environmental performance, environmental labeling, and life-cycle assessment. 4 Intent is to help organizations improve their environmental performance through documentation control, operational control, control of records, training, statistical techniques, and corrective and preventive actions. Chapter 3: Quality Management 60

Process Capability Chapter 3: Quality Management 61

Process Capability 4 TQM’s emphasis on “making it right the first time” has resulted in organizations emphasizing the ability of a production system to meet design specifications rather than evaluating the quality of outputs after the fact with acceptance sampling. 4 Process Capability measures the extent to which an organization’s production system can meet design specifications. Chapter 3: Quality Management 62

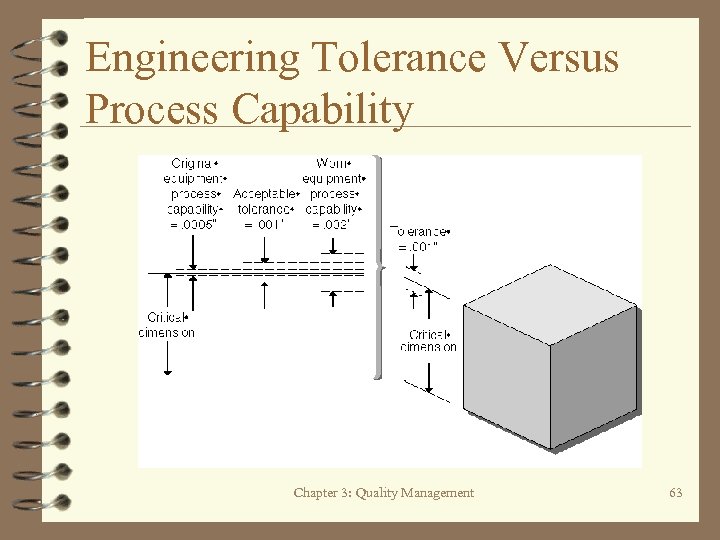

Engineering Tolerance Versus Process Capability Chapter 3: Quality Management 63

Process Capability Depends On: 4 Location of the process mean. 4 Natural variability inherent in the process. 4 Stability of the process. 4 Product’s design requirements. Chapter 3: Quality Management 64

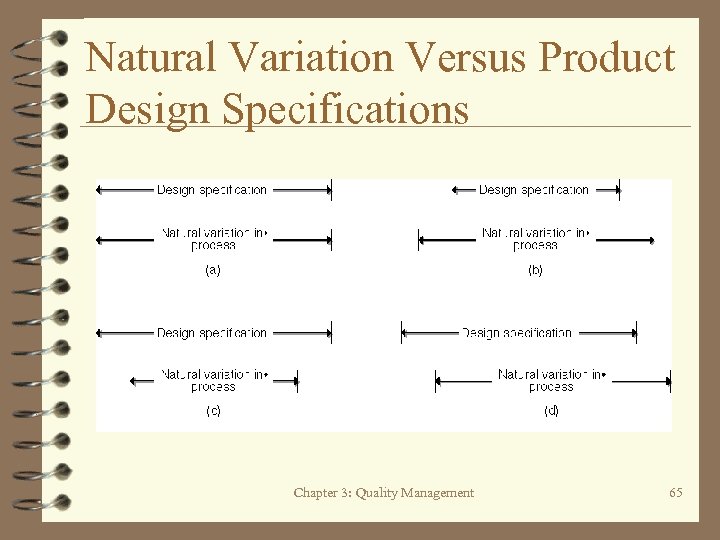

Natural Variation Versus Product Design Specifications Chapter 3: Quality Management 65

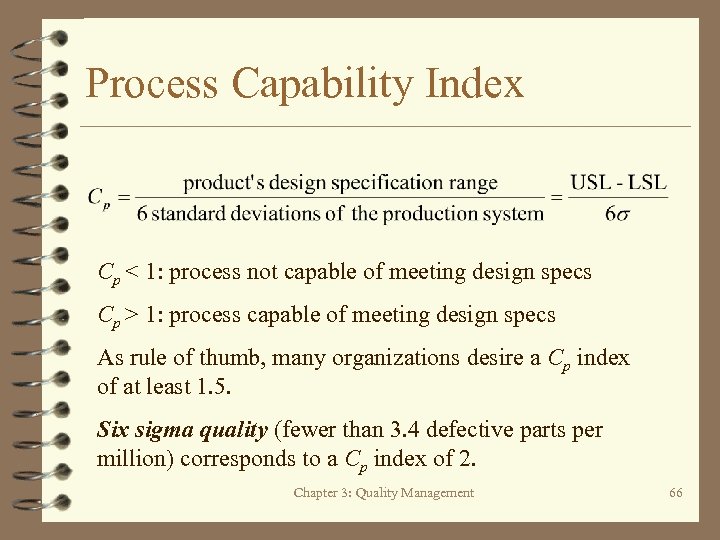

Process Capability Index Cp < 1: process not capable of meeting design specs Cp > 1: process capable of meeting design specs As rule of thumb, many organizations desire a Cp index of at least 1. 5. Six sigma quality (fewer than 3. 4 defective parts per million) corresponds to a Cp index of 2. Chapter 3: Quality Management 66

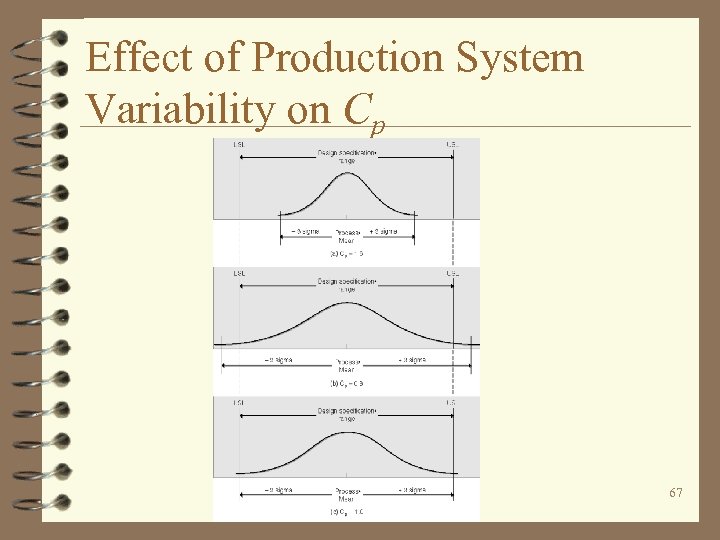

Effect of Production System Variability on Cp 67

Statistical Quality Control Chapter 3: Quality Management 68

Chance Versus Assignable Variation 4 Chance variation is variability built into the system. 4 Assignable variation occurs because some element of the system or some operating condition is out of control. 4 Quality control seeks to identify when assignable variation is present so that corrective action can be taken. Chapter 3: Quality Management 69

Control Based on Attributes and Variables 4 Inspection for Variables: measuring a variable that can be scaled such as weight, length, temperature, and diameter. 4 Inspection of Attributes: determining the existence of a characteristic such as acceptable-defective, timely-late, and rightwrong. Chapter 3: Quality Management 70

Control Charts Chapter 3: Quality Management 71

Control Charts 4 Developed in 1920 s to distinguish between chance variation in a system and variation caused by the system’s being out of control - assignable variation. Chapter 3: Quality Management 72

Control Charts continued 4 Repetitive operation will not produce exactly the same outputs. 4 Pattern of variability often described by normal distribution. 4 Random samples that fully represent the population being checked are taken. 4 Sample data plotted on control charts to determine if the process is still under control. Chapter 3: Quality Management 73

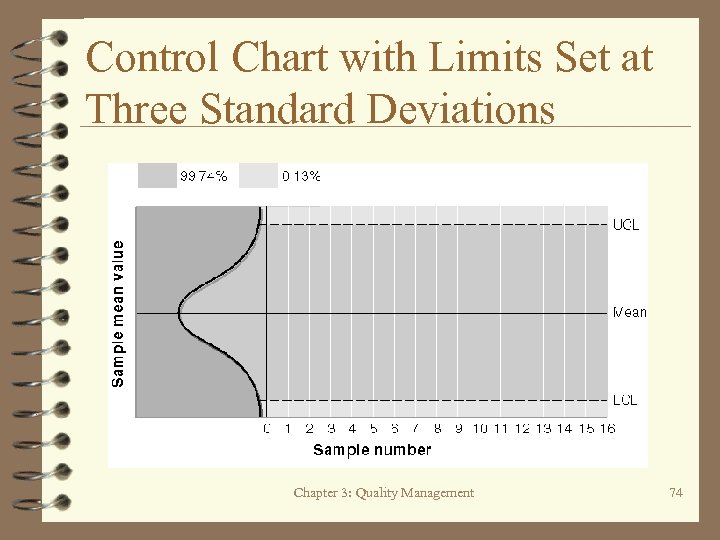

Control Chart with Limits Set at Three Standard Deviations Chapter 3: Quality Management 74

Control Charts for Variables Chapter 3: Quality Management 75

Two Control Charts 4 Sample Means Chart 4 Range Chart Chapter 3: Quality Management 76

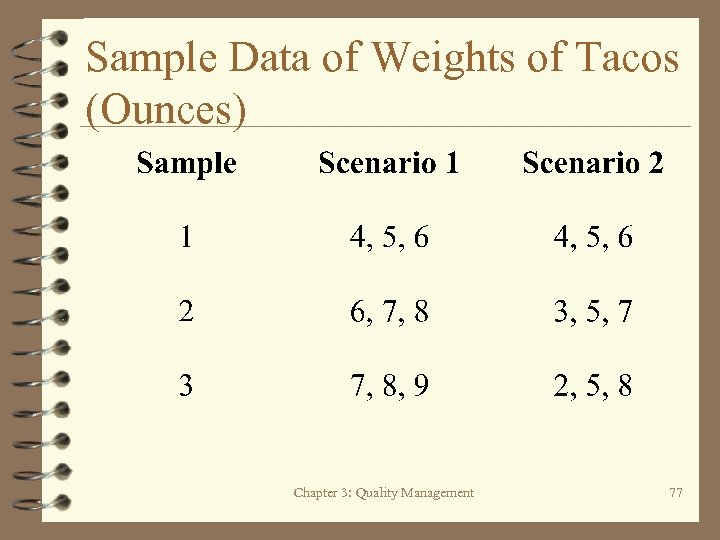

Sample Data of Weights of Tacos (Ounces) Chapter 3: Quality Management 77

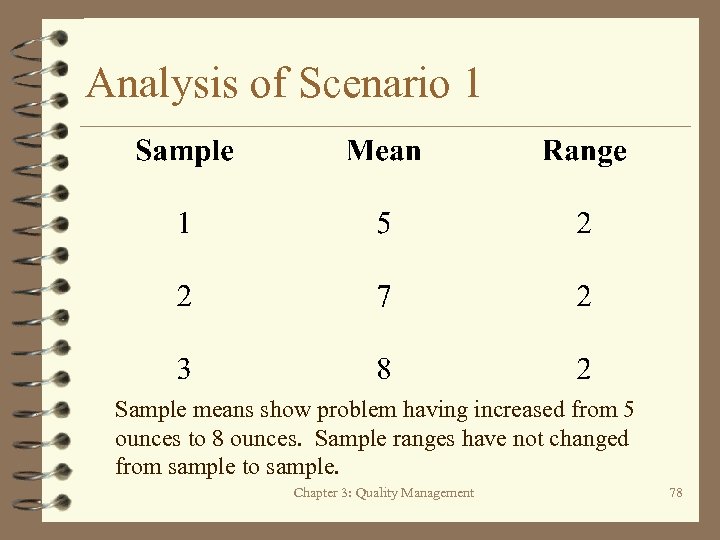

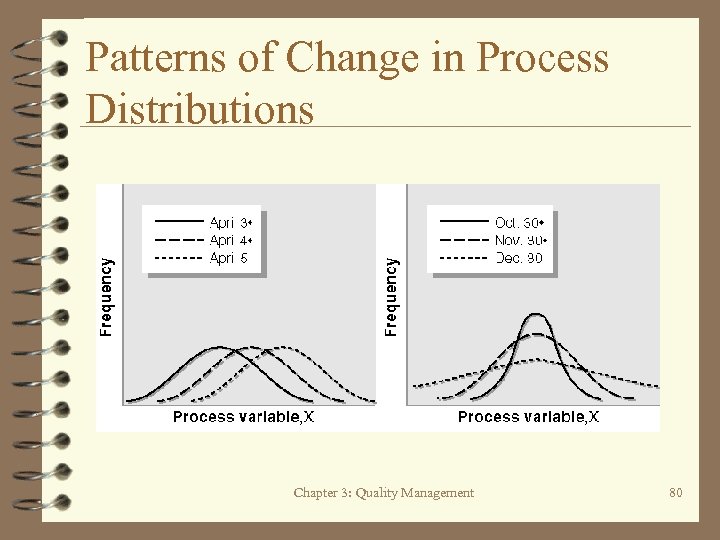

Analysis of Scenario 1 Sample means show problem having increased from 5 ounces to 8 ounces. Sample ranges have not changed from sample to sample. Chapter 3: Quality Management 78

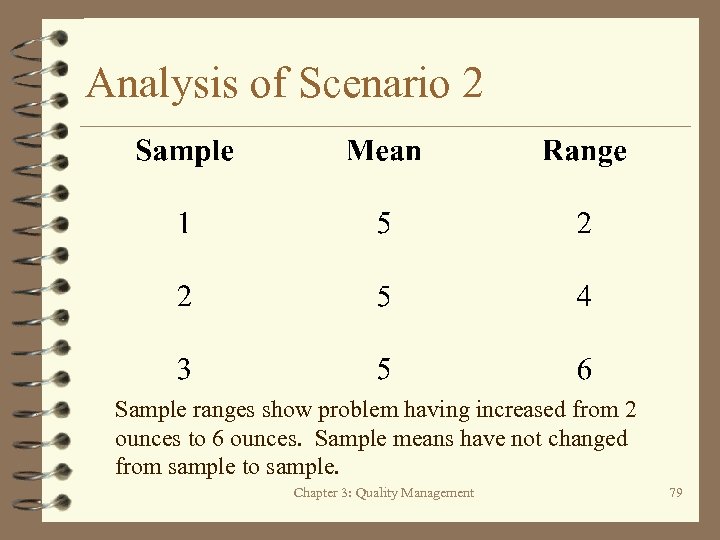

Analysis of Scenario 2 Sample ranges show problem having increased from 2 ounces to 6 ounces. Sample means have not changed from sample to sample. Chapter 3: Quality Management 79

Patterns of Change in Process Distributions Chapter 3: Quality Management 80

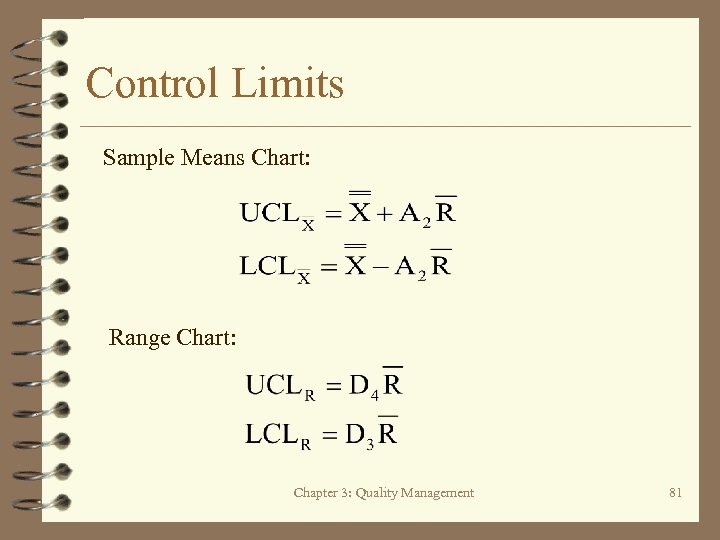

Control Limits Sample Means Chart: Range Chart: Chapter 3: Quality Management 81

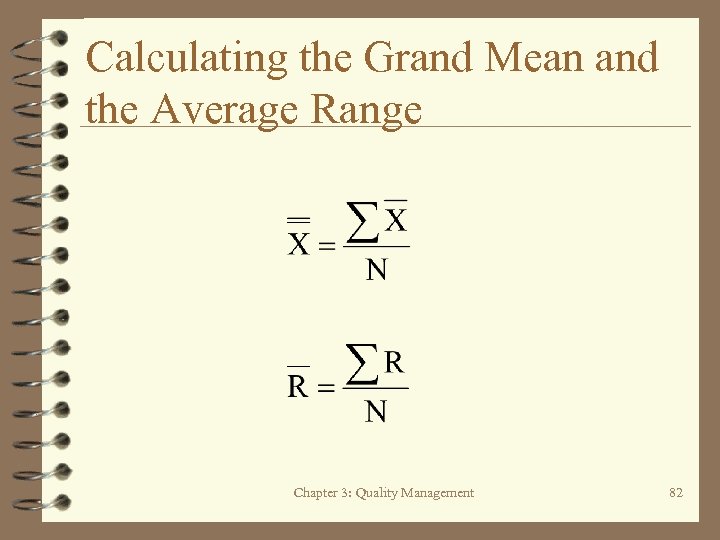

Calculating the Grand Mean and the Average Range Chapter 3: Quality Management 82

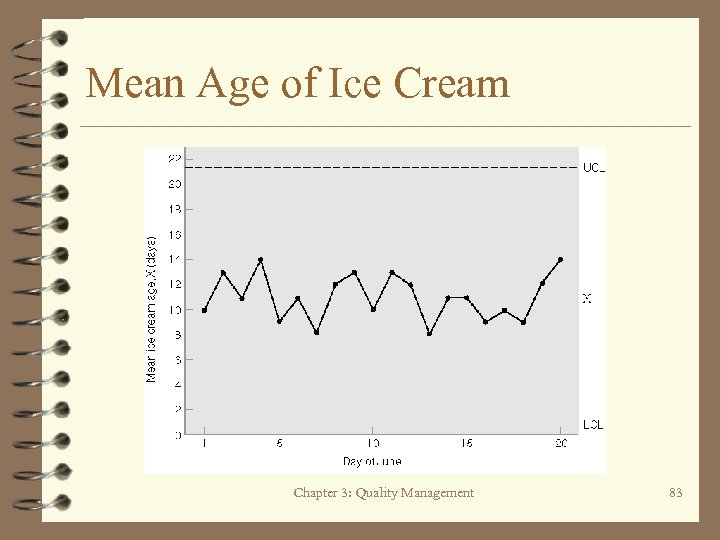

Mean Age of Ice Cream Chapter 3: Quality Management 83

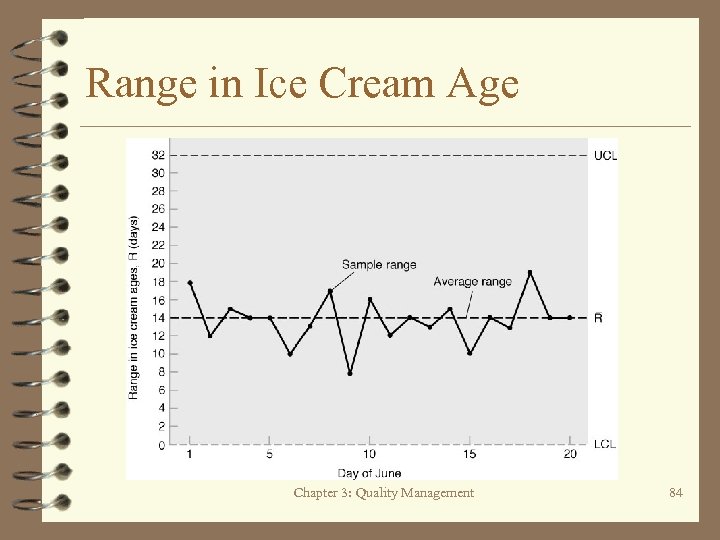

Range in Ice Cream Age Chapter 3: Quality Management 84

Control Charts for Attributes Chapter 3: Quality Management 85

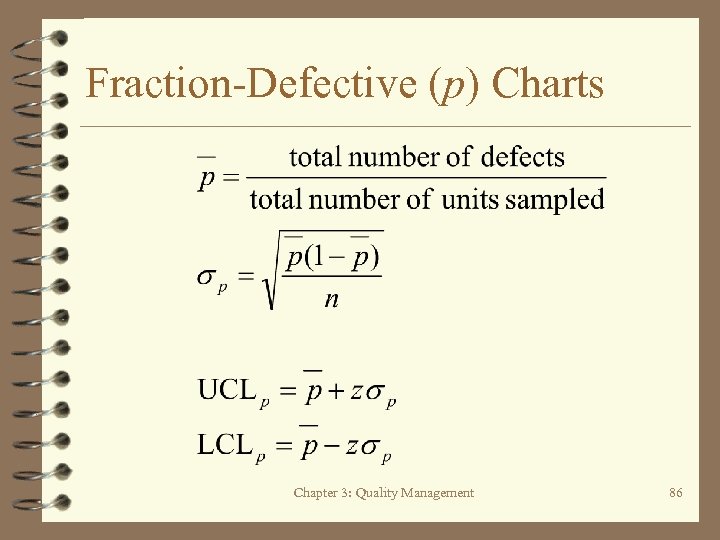

Fraction-Defective (p) Charts Chapter 3: Quality Management 86

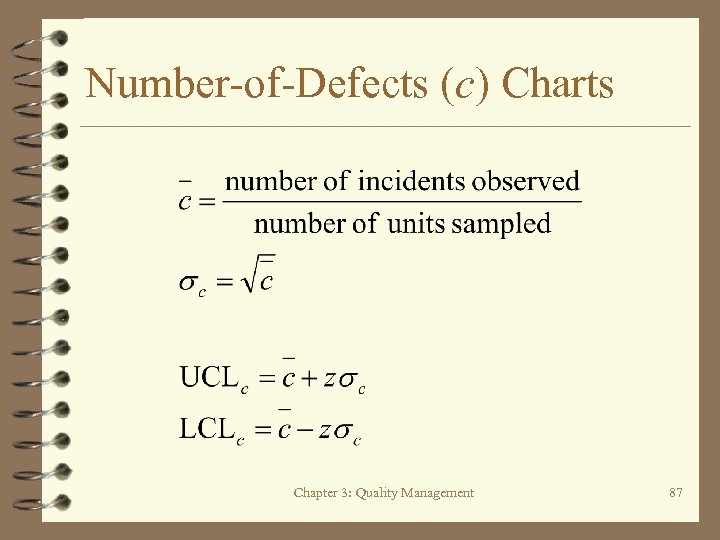

Number-of-Defects (c) Charts Chapter 3: Quality Management 87

Copyright 2002 John Wiley & Sons, Inc. All rights reserved. Reproduction or translation of this work beyond that named in Section 117 of the United States Copyright Act without the express written consent of the copyright owner is unlawful. Requests for further information should be addressed to the Permissions Department, John Wiley & Sons, Inc. Adopters of the textbook are granted permission to make back-up copies for their own use only, to make copies for distribution to students of the course the textbook is used in, and to modify this material to best suit their instructional needs. Under no circumstances can copies be made for resale. The Publisher assumes no responsibility for errors, omissions, or damages, caused by the use of these programs or from the use of the information contained herein. 88

73f87d9bb103c9345f9e783e2a5a6765.ppt