dbb92b370fe64200e35b2bd988f1aa1b.ppt

- Количество слайдов: 38

Operations Management Design of Goods and Services Chapter 5 1

Operations Management Design of Goods and Services Chapter 5 1

Outline ¨ Product Strategies & Selection. ¨ Life Cycle. ¨ Product Development Stages. ¨ Concurrent design. ¨ Quality Function Deployment (QFD). ¨ Design Issues. ¨ Documents. ¨ Service Design. 2

Outline ¨ Product Strategies & Selection. ¨ Life Cycle. ¨ Product Development Stages. ¨ Concurrent design. ¨ Quality Function Deployment (QFD). ¨ Design Issues. ¨ Documents. ¨ Service Design. 2

Goals ¨ Find new products to design, develop and market. ¨ Develop and implement a product strategy that: Meets demands of the marketplace. · Provides a competitive advantage. · Differentiation. · Low cost. · Rapid response. · 3

Goals ¨ Find new products to design, develop and market. ¨ Develop and implement a product strategy that: Meets demands of the marketplace. · Provides a competitive advantage. · Differentiation. · Low cost. · Rapid response. · 3

Product Strategy ¨ Product strategy includes: ¨ Selection - What good or service should be offered. ¨ Development - From product concept to introduction. ¨ Design (and redesign) - To define and redefine product. 4

Product Strategy ¨ Product strategy includes: ¨ Selection - What good or service should be offered. ¨ Development - From product concept to introduction. ¨ Design (and redesign) - To define and redefine product. 4

Product Selection ¨ Deciding which products (goods and services) to provide. ¨ Customers buy satisfaction, not parts. ¨ What is a Product? ¨ Need-satisfying offering of an organization. ¨ Example: Procter & Gamble (P&G) ¨ P&G does not sell laundry detergent. ¨ P&G sells the benefit of clean clothes. 5

Product Selection ¨ Deciding which products (goods and services) to provide. ¨ Customers buy satisfaction, not parts. ¨ What is a Product? ¨ Need-satisfying offering of an organization. ¨ Example: Procter & Gamble (P&G) ¨ P&G does not sell laundry detergent. ¨ P&G sells the benefit of clean clothes. 5

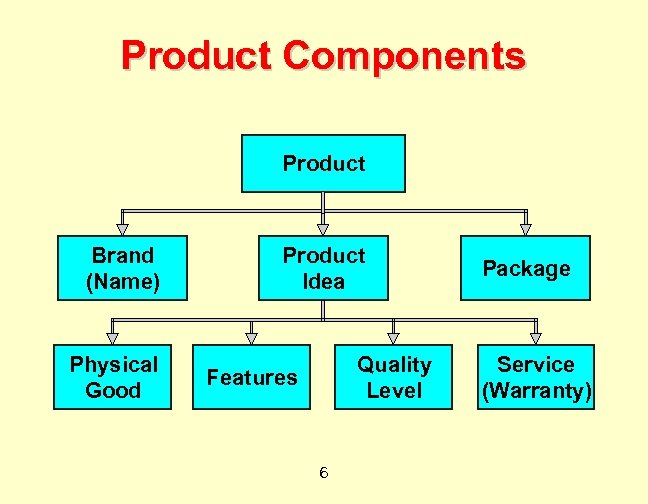

Product Components Product Brand (Name) Physical Good Product Idea Quality Level Features 6 Package Service (Warranty)

Product Components Product Brand (Name) Physical Good Product Idea Quality Level Features 6 Package Service (Warranty)

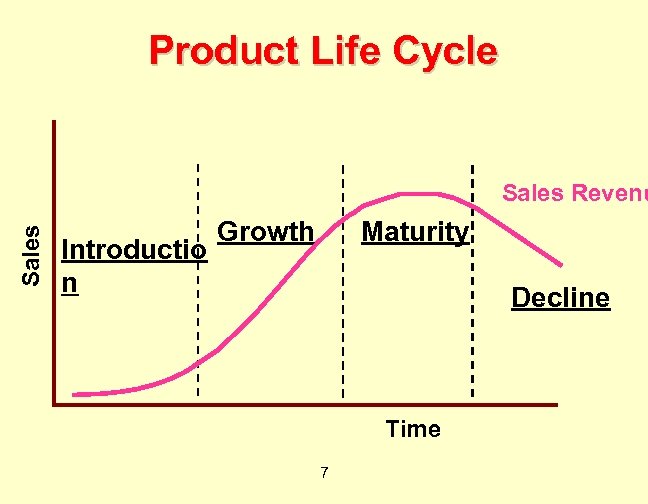

Product Life Cycle Sales Revenu Introductio n Growth Maturity Decline Time 7

Product Life Cycle Sales Revenu Introductio n Growth Maturity Decline Time 7

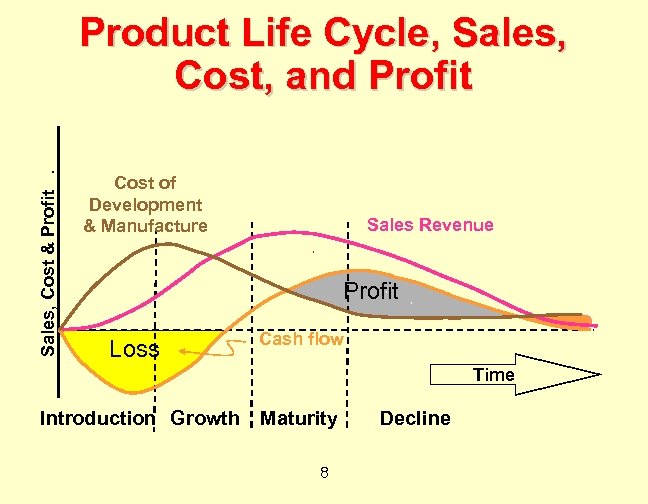

Sales, Cost & Profit. Product Life Cycle, Sales, Cost, and Profit Cost of Development & Manufacture Sales Revenue Profit Loss Cash flow Time Introduction Growth Maturity 8 Decline

Sales, Cost & Profit. Product Life Cycle, Sales, Cost, and Profit Cost of Development & Manufacture Sales Revenue Profit Loss Cash flow Time Introduction Growth Maturity 8 Decline

Product Life Cycle Introduction ¨ Initial designs. ¨ Product development. ¨ Process modification and enhancement. ¨ Supplier development. ¨ Increasing costs and revenues. ¨ Generally cost>revenue. 9

Product Life Cycle Introduction ¨ Initial designs. ¨ Product development. ¨ Process modification and enhancement. ¨ Supplier development. ¨ Increasing costs and revenues. ¨ Generally cost>revenue. 9

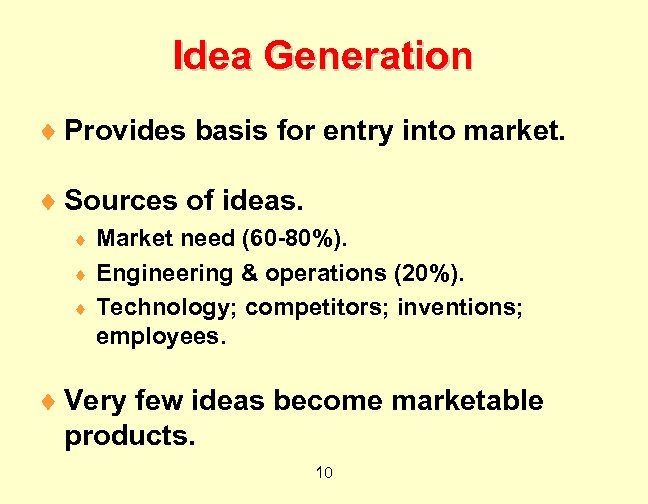

Idea Generation ¨ Provides basis for entry into market. ¨ Sources of ideas. Market need (60 -80%). ¨ Engineering & operations (20%). ¨ Technology; competitors; inventions; employees. ¨ ¨ Very few ideas become marketable products. 10

Idea Generation ¨ Provides basis for entry into market. ¨ Sources of ideas. Market need (60 -80%). ¨ Engineering & operations (20%). ¨ Technology; competitors; inventions; employees. ¨ ¨ Very few ideas become marketable products. 10

Need Very Many Ideas for Successful New Products Number 2000 1500 1000 500 0 Ideas 1750 Design review, Market Testing, Introduction requiremen t 1000 Functional specification Product s 500 specificatio One n 100 25 succes s! Development Stage 11

Need Very Many Ideas for Successful New Products Number 2000 1500 1000 500 0 Ideas 1750 Design review, Market Testing, Introduction requiremen t 1000 Functional specification Product s 500 specificatio One n 100 25 succes s! Development Stage 11

Assess Abilty to Offer Product ¨ Can the firm provide the product/service? ¨ Should the firm provide the product/service? ¨ Make vs. Buy ¨ A firm may be able to purchase the product 12 as a “standard item” from another

Assess Abilty to Offer Product ¨ Can the firm provide the product/service? ¨ Should the firm provide the product/service? ¨ Make vs. Buy ¨ A firm may be able to purchase the product 12 as a “standard item” from another

Product Development Stages ¨ Customer Requirements. ¨ Functional Specification. ¨ Product Specifications. ¨ Design Review. ¨ Test Market. ¨ Transition to Production. 13

Product Development Stages ¨ Customer Requirements. ¨ Functional Specification. ¨ Product Specifications. ¨ Design Review. ¨ Test Market. ¨ Transition to Production. 13

Customer Requirements ¨ Identifies & positions key product benefits. ¨ Example: Long lasting with more power. (Sears’ detailed Battery) ¨ Identifies Die Hardlist of product attributes desired by customer. ¨ Customer focus groups or interviews. 14

Customer Requirements ¨ Identifies & positions key product benefits. ¨ Example: Long lasting with more power. (Sears’ detailed Battery) ¨ Identifies Die Hardlist of product attributes desired by customer. ¨ Customer focus groups or interviews. 14

Functional Specification ¨ Defines product in terms of how the product would meet desired attributes. ¨ Identifies product’s engineering characteristics. ¨ Example: printer noise (d. B). ¨ Prioritizes engineering characteristics. ¨ May rate product compared to competition. 15

Functional Specification ¨ Defines product in terms of how the product would meet desired attributes. ¨ Identifies product’s engineering characteristics. ¨ Example: printer noise (d. B). ¨ Prioritizes engineering characteristics. ¨ May rate product compared to competition. 15

Product Specifications ¨ Determines how product will be made. ¨ Gives product’s physical specifications. ¨ Example: Dimensions, material etc. ¨ Defined by engineering drawing. ¨ Done often on computer. ¨ Computer-Aided Design (CAD). 16

Product Specifications ¨ Determines how product will be made. ¨ Gives product’s physical specifications. ¨ Example: Dimensions, material etc. ¨ Defined by engineering drawing. ¨ Done often on computer. ¨ Computer-Aided Design (CAD). 16

Design Review ¨ Review design from multiple perspectives. ¨ Evaluate in terms of: ¨ Customer requirements. ¨ Ability to produce product or deliver service. ¨ Revise design if needed. 17

Design Review ¨ Review design from multiple perspectives. ¨ Evaluate in terms of: ¨ Customer requirements. ¨ Ability to produce product or deliver service. ¨ Revise design if needed. 17

Quality Function Deployment - QFD ¨ Technique to help: ¨ Identify customer requirements. ¨ Translate these into functional specifications and product specifications. ¨ Also helps focus quality efforts. ¨ Involves creating 4 tabular ‘Matrices’ or ‘Houses’. ¨ Breakdown product design into increasing levels of detail. 18

Quality Function Deployment - QFD ¨ Technique to help: ¨ Identify customer requirements. ¨ Translate these into functional specifications and product specifications. ¨ Also helps focus quality efforts. ¨ Involves creating 4 tabular ‘Matrices’ or ‘Houses’. ¨ Breakdown product design into increasing levels of detail. 18

House of Quality Sequence Specific Components Production Process Customer Requirement s Design Characteristics Specific Components House 2 House 1 19 House 3 Production Process Quality Plan House 4

House of Quality Sequence Specific Components Production Process Customer Requirement s Design Characteristics Specific Components House 2 House 1 19 House 3 Production Process Quality Plan House 4

Test Marketing & Transition to Production ¨ Test market product to assess design and market. ¨ Transition to production. ¨ Use a trial period to work the bugs out and revise product and process design. ¨ Refine supplier selections. ¨ Transfer responsibility from design group to production group. 20

Test Marketing & Transition to Production ¨ Test market product to assess design and market. ¨ Transition to production. ¨ Use a trial period to work the bugs out and revise product and process design. ¨ Refine supplier selections. ¨ Transfer responsibility from design group to production group. 20

Design Issues ¨ Concurrent design. ¨ Manufacturability & Value Engineering. ¨ Modular Design. ¨ Robust Design. ¨ Computer-aided design. ¨ Environmentally friendly design. ¨ Time-based competition. 21

Design Issues ¨ Concurrent design. ¨ Manufacturability & Value Engineering. ¨ Modular Design. ¨ Robust Design. ¨ Computer-aided design. ¨ Environmentally friendly design. ¨ Time-based competition. 21

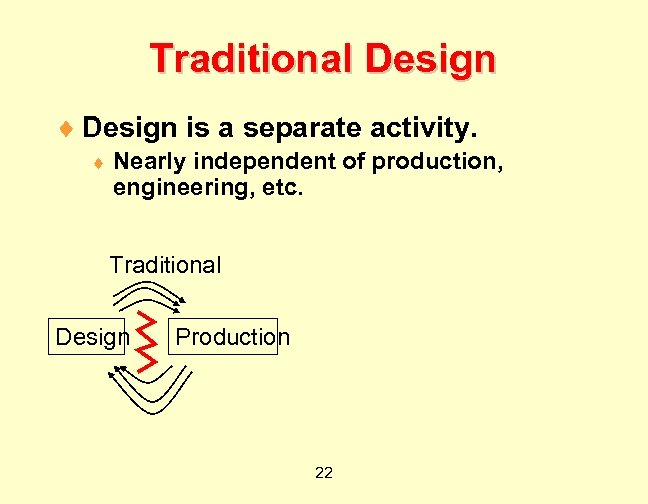

Traditional Design ¨ Design is a separate activity. ¨ Nearly independent of production, engineering, etc. Traditional Design Production 22

Traditional Design ¨ Design is a separate activity. ¨ Nearly independent of production, engineering, etc. Traditional Design Production 22

Concurrent Design ¨ Design product using cross-functional teams. ¨ Production, engineering, marketing, customers, etc. Traditional Design Concurrent design Production Design & Production & other units 23

Concurrent Design ¨ Design product using cross-functional teams. ¨ Production, engineering, marketing, customers, etc. Traditional Design Concurrent design Production Design & Production & other units 23

Manufacturability and Value Engineering ¨ Key is to simplify. ¨ Minimize parts. ¨ Use common components in different products. ¨ Use standard off-the-shelf components. ¨ Simplify ¨ Use and mistake-proof assembly. modules to add variety. ¨ Design for robustness. 24

Manufacturability and Value Engineering ¨ Key is to simplify. ¨ Minimize parts. ¨ Use common components in different products. ¨ Use standard off-the-shelf components. ¨ Simplify ¨ Use and mistake-proof assembly. modules to add variety. ¨ Design for robustness. 24

Modular & Robust Design ¨ Modular design. ¨ Design in easily segmented components. ¨ Modules add flexibility to both production and marketing. ¨ Design for robustness. ¨ Design so small variations in production or assembly do not adversely affect the product. 25

Modular & Robust Design ¨ Modular design. ¨ Design in easily segmented components. ¨ Modules add flexibility to both production and marketing. ¨ Design for robustness. ¨ Design so small variations in production or assembly do not adversely affect the product. 25

Computer Aided Design (CAD) ¨ Designing products at a computer work station. ¨ Design engineer uses computer to draw product. ¨ Often used with CAM (Computer Aided Manufacturing). 26

Computer Aided Design (CAD) ¨ Designing products at a computer work station. ¨ Design engineer uses computer to draw product. ¨ Often used with CAM (Computer Aided Manufacturing). 26

Environmentally Friendly Design ¨ Make products recyclable. ¨ Use recycled materials. ¨ Use less harmful (toxic) ingredients. ¨ Use lighter components. ¨ Less weight lowers transportation cost. ¨ Use less energy and material. 27

Environmentally Friendly Design ¨ Make products recyclable. ¨ Use recycled materials. ¨ Use less harmful (toxic) ingredients. ¨ Use lighter components. ¨ Less weight lowers transportation cost. ¨ Use less energy and material. 27

Time-based Competition ¨ Product life cycles are becoming shorter. ¨ Faster developers of new products gain on slower developers and obtain a competitive advantage. ¨ First to market is often market leader. 28

Time-based Competition ¨ Product life cycles are becoming shorter. ¨ Faster developers of new products gain on slower developers and obtain a competitive advantage. ¨ First to market is often market leader. 28

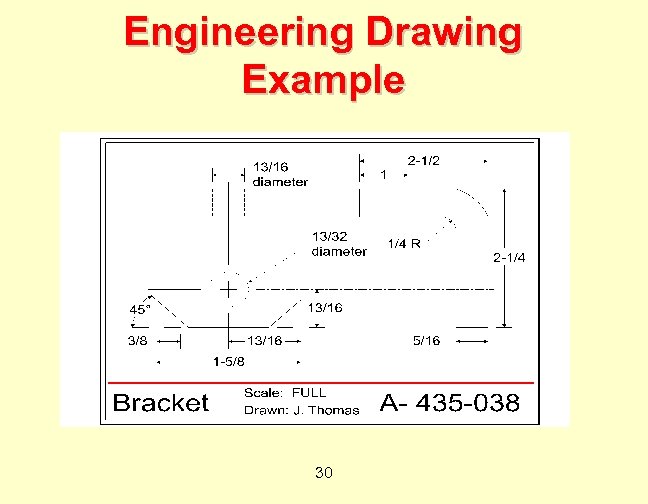

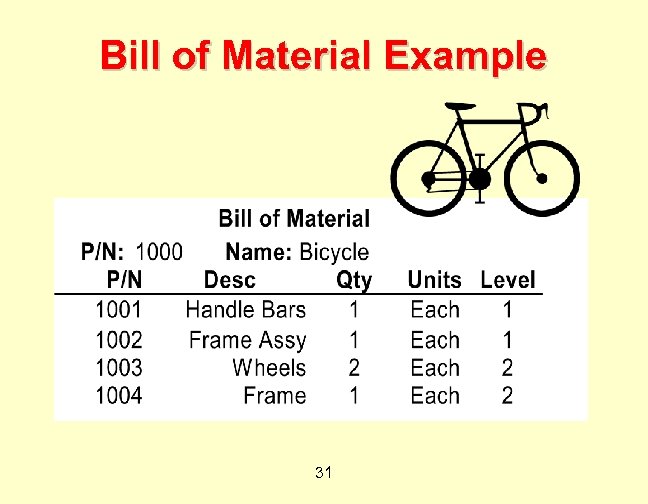

Product Documents ¨ Engineering drawing. ¨ Shows dimensions, tolerances, & materials. ¨ Bill of Material. Lists components, quantities & where used. ¨ Shows product structure. ¨ 29

Product Documents ¨ Engineering drawing. ¨ Shows dimensions, tolerances, & materials. ¨ Bill of Material. Lists components, quantities & where used. ¨ Shows product structure. ¨ 29

Engineering Drawing Example 30

Engineering Drawing Example 30

Bill of Material Example 31

Bill of Material Example 31

Production Documents ¨ Assembly drawings. ¨ Assembly chart. ¨ Route sheet. ¨ Work order. 32

Production Documents ¨ Assembly drawings. ¨ Assembly chart. ¨ Route sheet. ¨ Work order. 32

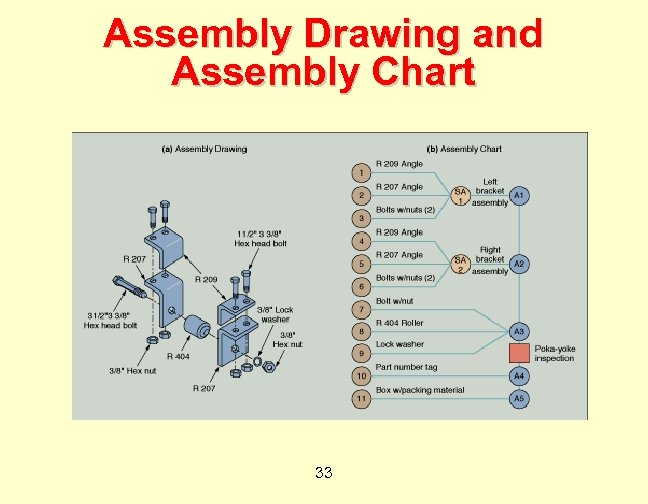

Assembly Drawing and Assembly Chart 33

Assembly Drawing and Assembly Chart 33

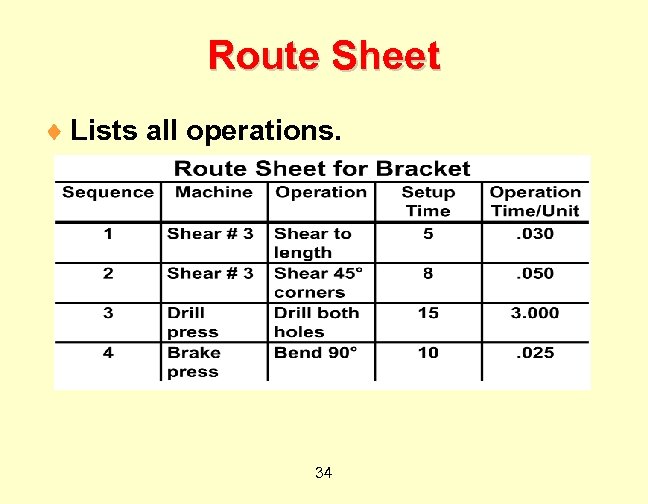

Route Sheet ¨ Lists all operations. 34

Route Sheet ¨ Lists all operations. 34

Work Order Authorizes producing a given item, usually to a sche g Wor Orde ufacturin Man Date r k pt Oper e D : roved App JM 35

Work Order Authorizes producing a given item, usually to a sche g Wor Orde ufacturin Man Date r k pt Oper e D : roved App JM 35

Service Design Principles ¨ Simplify! ¨ Minimize number of steps. ¨ Minimize repetition. ¨ Reduce waiting time for customer. ¨ Use modularity to create variety. ¨ Example: Hospital, University certificate programs. ¨ Design for robustness. ¨ Accommodate large variation, since all people are different. 36

Service Design Principles ¨ Simplify! ¨ Minimize number of steps. ¨ Minimize repetition. ¨ Reduce waiting time for customer. ¨ Use modularity to create variety. ¨ Example: Hospital, University certificate programs. ¨ Design for robustness. ¨ Accommodate large variation, since all people are different. 36

Service Design Principles ¨ Consider range of services offered. ¨ Customized vs standard services (Medical clinics). ¨ Full service vs. self service (Gasoline station). ¨ Manage expectations. ¨ Gourmet restaurant vs. fast food. ¨ Schedule staff to match demand. ¨ Use appointments. ¨ Provide distractions to ease waiting. 37

Service Design Principles ¨ Consider range of services offered. ¨ Customized vs standard services (Medical clinics). ¨ Full service vs. self service (Gasoline station). ¨ Manage expectations. ¨ Gourmet restaurant vs. fast food. ¨ Schedule staff to match demand. ¨ Use appointments. ¨ Provide distractions to ease waiting. 37

Decision Trees for Product Design ¨ Useful with a series of decisions and outcomes. ¨ Example: Select design from several options that produces largest expected profit. ¨ Different costs. ¨ Different benefits: Benefits depend on future (unknown) market. 38

Decision Trees for Product Design ¨ Useful with a series of decisions and outcomes. ¨ Example: Select design from several options that produces largest expected profit. ¨ Different costs. ¨ Different benefits: Benefits depend on future (unknown) market. 38