83a1ad94415d0403a89753a449f47507.ppt

- Количество слайдов: 17

Operations Management and Technology Ross L. Fink

Operations Management and Technology Ross L. Fink

Design Technology Computer-Aided Design (CAD) o Refers to the use of computers to interactively design products and prepare engineering documentation http: //www. swissspecialties. com/product 2. htm

Design Technology Computer-Aided Design (CAD) o Refers to the use of computers to interactively design products and prepare engineering documentation http: //www. swissspecialties. com/product 2. htm

Design Technology Computer-Aided Manufacturing (CAM) q Refers to the use of specialized computer programs to direct and control manufacturing equipment

Design Technology Computer-Aided Manufacturing (CAM) q Refers to the use of specialized computer programs to direct and control manufacturing equipment

Design Technology Benefits of CAD and CAM q q q Product quality Shorter design time Production cost reductions Database availability New range of capabilities Reduces need for “similar” parts

Design Technology Benefits of CAD and CAM q q q Product quality Shorter design time Production cost reductions Database availability New range of capabilities Reduces need for “similar” parts

Production Technology q Numerically controlled machines q q q q q Numerical control Computer numerical control Direct numerical control Process control Vision systems Robots Automated storage and retrieval systems Automated guided vehicles Flexible manufacturing systems Computer integrated manufacturing

Production Technology q Numerically controlled machines q q q q q Numerical control Computer numerical control Direct numerical control Process control Vision systems Robots Automated storage and retrieval systems Automated guided vehicles Flexible manufacturing systems Computer integrated manufacturing

Production Technology Process Control - Operation q q q Sensors, often analog devices, collect data Analog devices read data on some periodic basis, perhaps once a minute or once a second Measurements are translated into digital signals, and transmitted to a digital computer Computer programs read the file (the digital data) and analyze the data Output may be a: message on printer or console, signal to a motor to change a value setting, warning light or horn, process control chart, etc.

Production Technology Process Control - Operation q q q Sensors, often analog devices, collect data Analog devices read data on some periodic basis, perhaps once a minute or once a second Measurements are translated into digital signals, and transmitted to a digital computer Computer programs read the file (the digital data) and analyze the data Output may be a: message on printer or console, signal to a motor to change a value setting, warning light or horn, process control chart, etc.

Photo S 7. 7

Photo S 7. 7

Production Technology Robots q q q Machines that hold, move, or grasp items Perform monotonous or dangerous tasks Used when speed, accuracy, or strength are needed © 1984 -1994 T/Maker Co.

Production Technology Robots q q q Machines that hold, move, or grasp items Perform monotonous or dangerous tasks Used when speed, accuracy, or strength are needed © 1984 -1994 T/Maker Co.

Automated Storage and Retrieval System (ASRS) q Provide for automatic placement and withdrawal of parts and products into and from designated places in a warehouse.

Automated Storage and Retrieval System (ASRS) q Provide for automatic placement and withdrawal of parts and products into and from designated places in a warehouse.

Production Technology Automatic Guided Vehicles (AGV) q q q Material handling machines Used to move parts & equipment in manufacturing May be used to deliver mail & meals in service facilities © 1984 -1994 T/Maker Co.

Production Technology Automatic Guided Vehicles (AGV) q q q Material handling machines Used to move parts & equipment in manufacturing May be used to deliver mail & meals in service facilities © 1984 -1994 T/Maker Co.

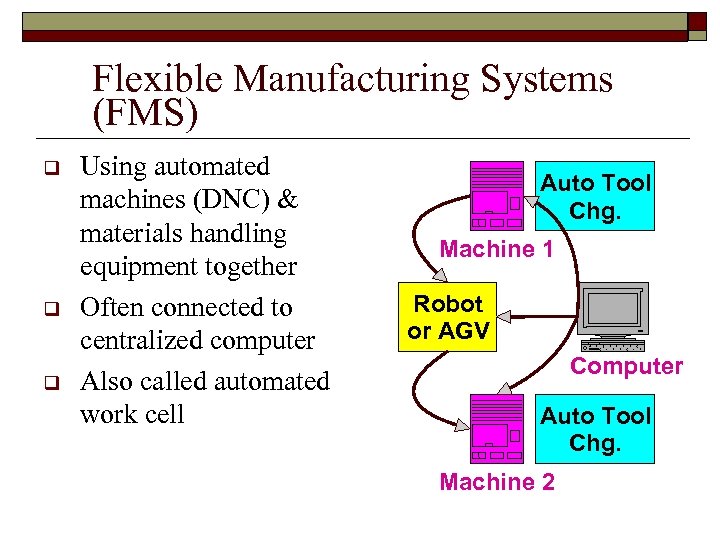

Flexible Manufacturing Systems (FMS) q q q Using automated machines (DNC) & materials handling equipment together Often connected to centralized computer Also called automated work cell Auto Tool Chg. Machine 1 Robot or AGV Computer Auto Tool Chg. Machine 2

Flexible Manufacturing Systems (FMS) q q q Using automated machines (DNC) & materials handling equipment together Often connected to centralized computer Also called automated work cell Auto Tool Chg. Machine 1 Robot or AGV Computer Auto Tool Chg. Machine 2

Production Technology FMS - Pros & Cons q q Advantages q Faster, lower-cost changes from one part to another q Lower direct labor costs q Reduced inventory q Consistent, and perhaps better quality Disadvantages q Limited ability to adapt to product or product mix changes q Requires substantial preplanning and capital expenditures q Technological problems of exact component positioning and precise timing q Tooling and fixture requirements

Production Technology FMS - Pros & Cons q q Advantages q Faster, lower-cost changes from one part to another q Lower direct labor costs q Reduced inventory q Consistent, and perhaps better quality Disadvantages q Limited ability to adapt to product or product mix changes q Requires substantial preplanning and capital expenditures q Technological problems of exact component positioning and precise timing q Tooling and fixture requirements

Enterprise Resource Planning (ERP) q Packaged business software systems that allow companies to: q q q Automate and integrate the majority of their business processes Share common data and practices across the entire enterprise Produce and access information in a real-time environment

Enterprise Resource Planning (ERP) q Packaged business software systems that allow companies to: q q q Automate and integrate the majority of their business processes Share common data and practices across the entire enterprise Produce and access information in a real-time environment

Advantages of ERP q q q q Provides integration of supply-chain, production and administrative processes Creates commonality of databases Can incorporate improved, redesigned, “best processes: Increases communication and collaboration worldwide Helps integrate multiple sites and business units Is packaged with a software core that is off-the-shelf coding Can provide a strategic advantage over competitors

Advantages of ERP q q q q Provides integration of supply-chain, production and administrative processes Creates commonality of databases Can incorporate improved, redesigned, “best processes: Increases communication and collaboration worldwide Helps integrate multiple sites and business units Is packaged with a software core that is off-the-shelf coding Can provide a strategic advantage over competitors

Disadvantages of ERP q q q Is very expensive to purchase, and even more costly to customize Requires major changes in the company and its processes to implement Is such a complex program that many companies cannot adjust to it Involves an ongoing process for implementation, which is often never completed Expertise in ERP is limited, with staffing an ongoing problem

Disadvantages of ERP q q q Is very expensive to purchase, and even more costly to customize Requires major changes in the company and its processes to implement Is such a complex program that many companies cannot adjust to it Involves an ongoing process for implementation, which is often never completed Expertise in ERP is limited, with staffing an ongoing problem

Internet Uses q Supply Chain Management -- Business Networking q q Exchange of information Purchasing q q q Transactions Identifying vendors Qualifying vendors Order tracking Price negotiation Feedback

Internet Uses q Supply Chain Management -- Business Networking q q Exchange of information Purchasing q q q Transactions Identifying vendors Qualifying vendors Order tracking Price negotiation Feedback

Internet Uses q q q q Interface with legacy systems Design Order fulfillment Scheduling (Production or Personnel) Project management Quality control Inventory management Capacity

Internet Uses q q q q Interface with legacy systems Design Order fulfillment Scheduling (Production or Personnel) Project management Quality control Inventory management Capacity