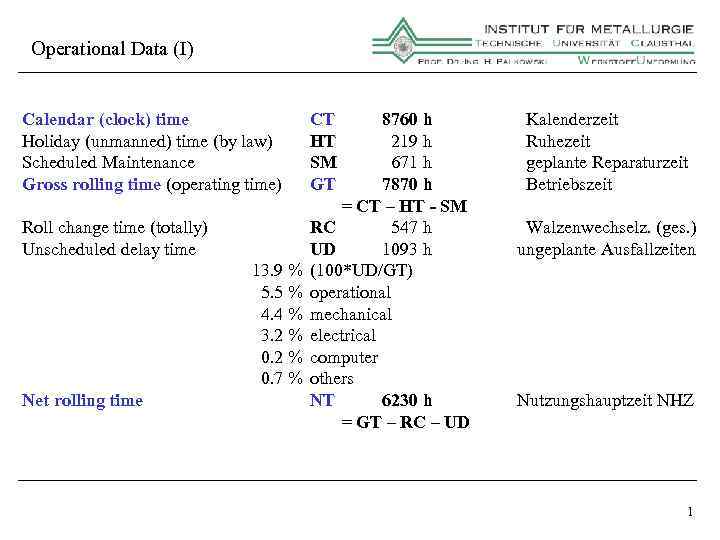

Operational Data (I) Calendar (clock) time Holiday (unmanned) time (by law) Scheduled Maintenance Gross rolling time (operating time) Roll change time (totally) Unscheduled delay time 13. 9 % 5. 5 % 4. 4 % 3. 2 % 0. 7 % Net rolling time CT HT SM GT 8760 h 219 h 671 h 7870 h = CT – HT - SM RC 547 h UD 1093 h (100*UD/GT) operational mechanical electrical computer others NT 6230 h = GT – RC – UD Kalenderzeit Ruhezeit geplante Reparaturzeit Betriebszeit Walzenwechselz. (ges. ) ungeplante Ausfallzeiten Nutzungshauptzeit NHZ 1

Operational Data (I) Calendar (clock) time Holiday (unmanned) time (by law) Scheduled Maintenance Gross rolling time (operating time) Roll change time (totally) Unscheduled delay time 13. 9 % 5. 5 % 4. 4 % 3. 2 % 0. 7 % Net rolling time CT HT SM GT 8760 h 219 h 671 h 7870 h = CT – HT - SM RC 547 h UD 1093 h (100*UD/GT) operational mechanical electrical computer others NT 6230 h = GT – RC – UD Kalenderzeit Ruhezeit geplante Reparaturzeit Betriebszeit Walzenwechselz. (ges. ) ungeplante Ausfallzeiten Nutzungshauptzeit NHZ 1

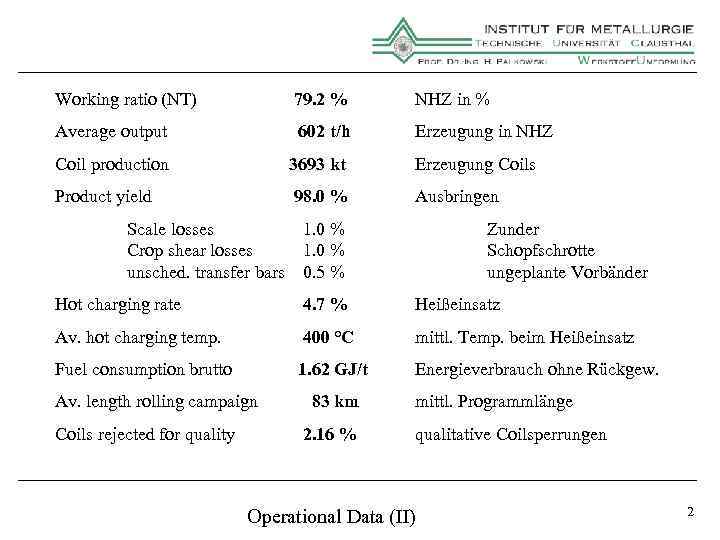

Working ratio (NT) 79. 2 % NHZ in % Average output 602 t/h Erzeugung in NHZ Coil production 3693 kt Erzeugung Coils Product yield 98. 0 % Ausbringen Scale losses Crop shear losses unsched. transfer bars 1. 0 % 0. 5 % Zunder Schopfschrotte ungeplante Vorbänder Hot charging rate 4. 7 % Heißeinsatz Av. hot charging temp. 400 °C mittl. Temp. beim Heißeinsatz Fuel consumption brutto 1. 62 GJ/t Energieverbrauch ohne Rückgew. Av. length rolling campaign Coils rejected for quality 83 km 2. 16 % mittl. Programmlänge qualitative Coilsperrungen Operational Data (II) 2

Working ratio (NT) 79. 2 % NHZ in % Average output 602 t/h Erzeugung in NHZ Coil production 3693 kt Erzeugung Coils Product yield 98. 0 % Ausbringen Scale losses Crop shear losses unsched. transfer bars 1. 0 % 0. 5 % Zunder Schopfschrotte ungeplante Vorbänder Hot charging rate 4. 7 % Heißeinsatz Av. hot charging temp. 400 °C mittl. Temp. beim Heißeinsatz Fuel consumption brutto 1. 62 GJ/t Energieverbrauch ohne Rückgew. Av. length rolling campaign Coils rejected for quality 83 km 2. 16 % mittl. Programmlänge qualitative Coilsperrungen Operational Data (II) 2

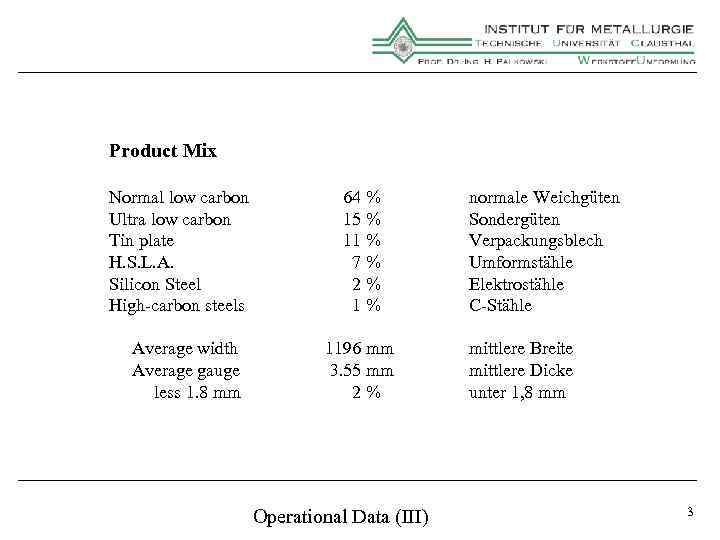

Product Mix Normal low carbon Ultra low carbon Tin plate H. S. L. A. Silicon Steel High-carbon steels Average width Average gauge less 1. 8 mm 64 % 15 % 11 % 7% 2% 1% 1196 mm 3. 55 mm 2% Operational Data (III) normale Weichgüten Sondergüten Verpackungsblech Umformstähle Elektrostähle C-Stähle mittlere Breite mittlere Dicke unter 1, 8 mm 3

Product Mix Normal low carbon Ultra low carbon Tin plate H. S. L. A. Silicon Steel High-carbon steels Average width Average gauge less 1. 8 mm 64 % 15 % 11 % 7% 2% 1% 1196 mm 3. 55 mm 2% Operational Data (III) normale Weichgüten Sondergüten Verpackungsblech Umformstähle Elektrostähle C-Stähle mittlere Breite mittlere Dicke unter 1, 8 mm 3