Completion Fluids Module.ppt

- Количество слайдов: 71

® ONE-TRAX Version 1. 3 Completion Fluids Module

® ONE-TRAX Version 1. 3 Completion Fluids Module

ONE-TRAX® 1. 3 Completion Fluids Module Illustrated instructions on using ONE-TRAX for Completion Fluids Reporting

ONE-TRAX® 1. 3 Completion Fluids Module Illustrated instructions on using ONE-TRAX for Completion Fluids Reporting

To Start a new well. . . Click on the “New Well” button.

To Start a new well. . . Click on the “New Well” button.

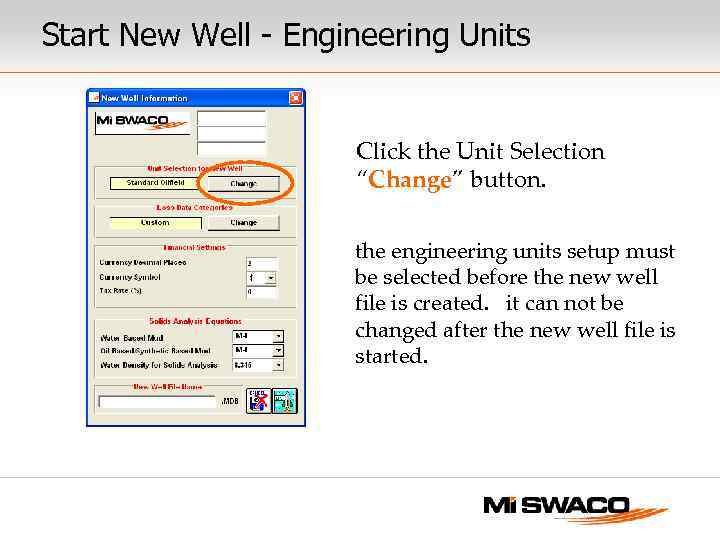

Start New Well - Engineering Units Click the Unit Selection “Change” button. the engineering units setup must be selected before the new well file is created. it can not be changed after the new well file is started.

Start New Well - Engineering Units Click the Unit Selection “Change” button. the engineering units setup must be selected before the new well file is created. it can not be changed after the new well file is started.

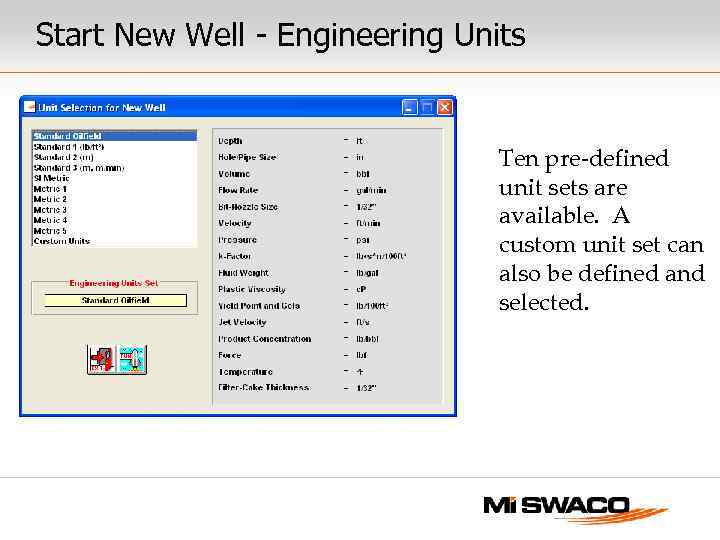

Start New Well - Engineering Units Ten pre-defined unit sets are available. A custom unit set can also be defined and selected.

Start New Well - Engineering Units Ten pre-defined unit sets are available. A custom unit set can also be defined and selected.

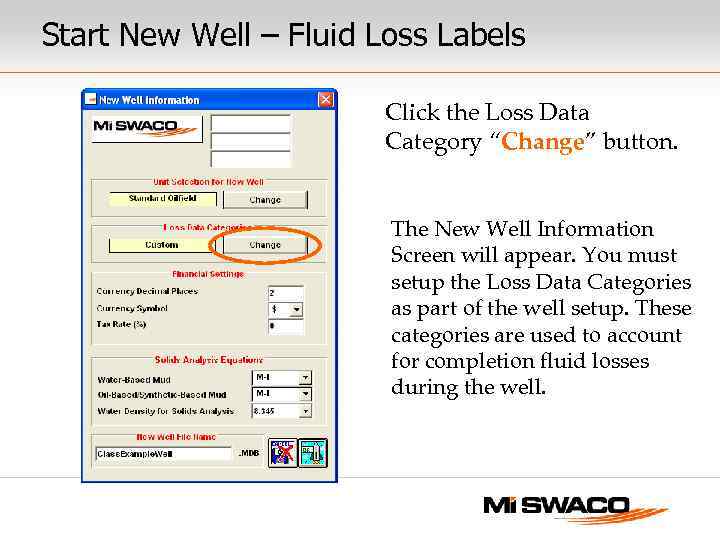

Start New Well – Fluid Loss Labels Click the Loss Data Category “Change” button. The New Well Information Screen will appear. You must setup the Loss Data Categories as part of the well setup. These categories are used to account for completion fluid losses during the well.

Start New Well – Fluid Loss Labels Click the Loss Data Category “Change” button. The New Well Information Screen will appear. You must setup the Loss Data Categories as part of the well setup. These categories are used to account for completion fluid losses during the well.

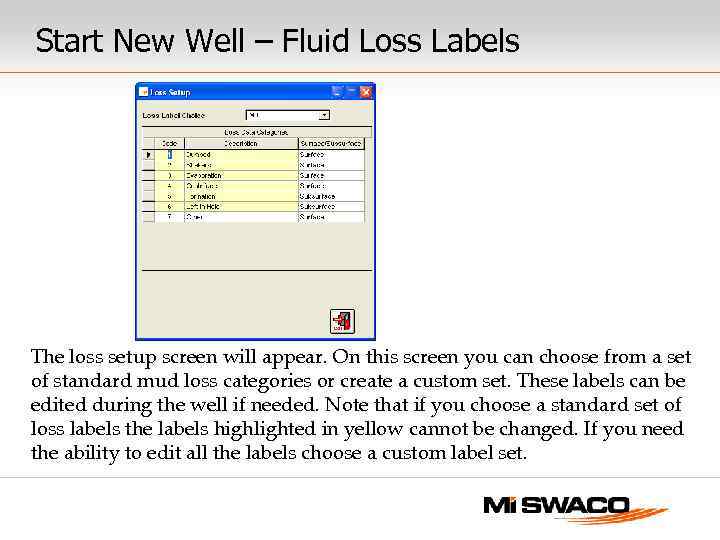

Start New Well – Fluid Loss Labels The loss setup screen will appear. On this screen you can choose from a set of standard mud loss categories or create a custom set. These labels can be edited during the well if needed. Note that if you choose a standard set of loss labels the labels highlighted in yellow cannot be changed. If you need the ability to edit all the labels choose a custom label set.

Start New Well – Fluid Loss Labels The loss setup screen will appear. On this screen you can choose from a set of standard mud loss categories or create a custom set. These labels can be edited during the well if needed. Note that if you choose a standard set of loss labels the labels highlighted in yellow cannot be changed. If you need the ability to edit all the labels choose a custom label set.

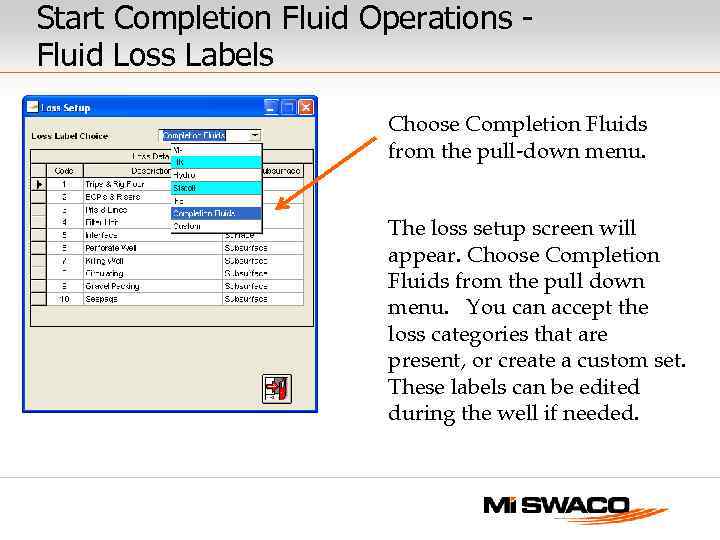

Start Completion Fluid Operations Fluid Loss Labels Choose Completion Fluids from the pull-down menu. The loss setup screen will appear. Choose Completion Fluids from the pull down menu. You can accept the loss categories that are present, or create a custom set. These labels can be edited during the well if needed.

Start Completion Fluid Operations Fluid Loss Labels Choose Completion Fluids from the pull-down menu. The loss setup screen will appear. Choose Completion Fluids from the pull down menu. You can accept the loss categories that are present, or create a custom set. These labels can be edited during the well if needed.

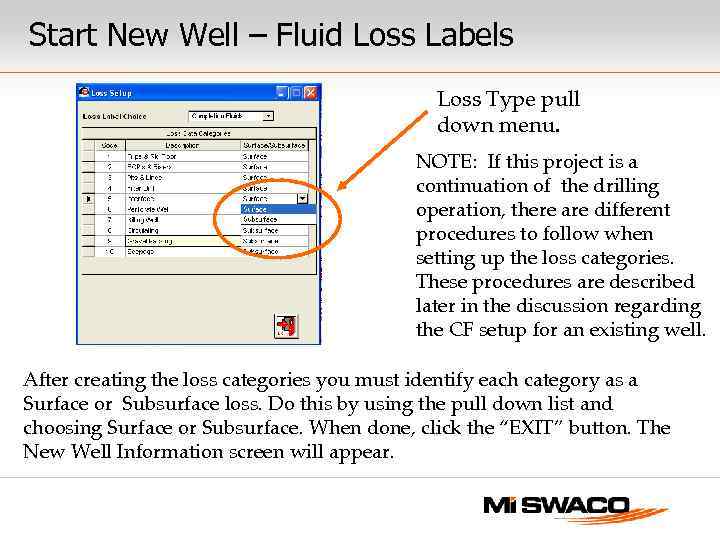

Start New Well – Fluid Loss Labels Loss Type pull down menu. NOTE: If this project is a continuation of the drilling operation, there are different procedures to follow when setting up the loss categories. These procedures are described later in the discussion regarding the CF setup for an existing well. After creating the loss categories you must identify each category as a Surface or Subsurface loss. Do this by using the pull down list and choosing Surface or Subsurface. When done, click the “EXIT” button. The New Well Information screen will appear.

Start New Well – Fluid Loss Labels Loss Type pull down menu. NOTE: If this project is a continuation of the drilling operation, there are different procedures to follow when setting up the loss categories. These procedures are described later in the discussion regarding the CF setup for an existing well. After creating the loss categories you must identify each category as a Surface or Subsurface loss. Do this by using the pull down list and choosing Surface or Subsurface. When done, click the “EXIT” button. The New Well Information screen will appear.

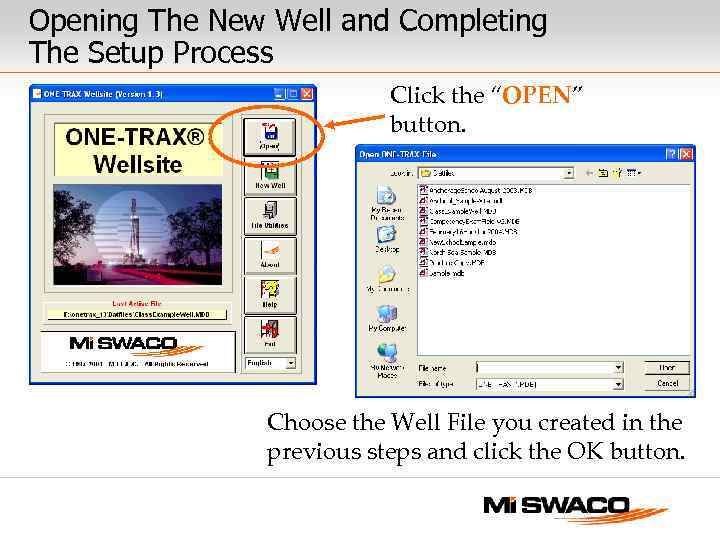

Opening The New Well and Completing The Setup Process Click the “OPEN” button. Choose the Well File you created in the previous steps and click the OK button.

Opening The New Well and Completing The Setup Process Click the “OPEN” button. Choose the Well File you created in the previous steps and click the OK button.

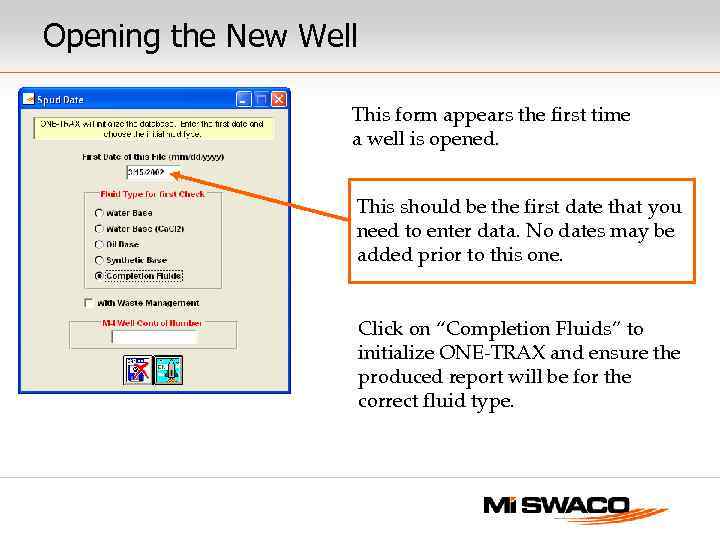

Opening the New Well This form appears the first time a well is opened. This should be the first date that you need to enter data. No dates may be added prior to this one. Click on “Completion Fluids” to initialize ONE-TRAX and ensure the produced report will be for the correct fluid type.

Opening the New Well This form appears the first time a well is opened. This should be the first date that you need to enter data. No dates may be added prior to this one. Click on “Completion Fluids” to initialize ONE-TRAX and ensure the produced report will be for the correct fluid type.

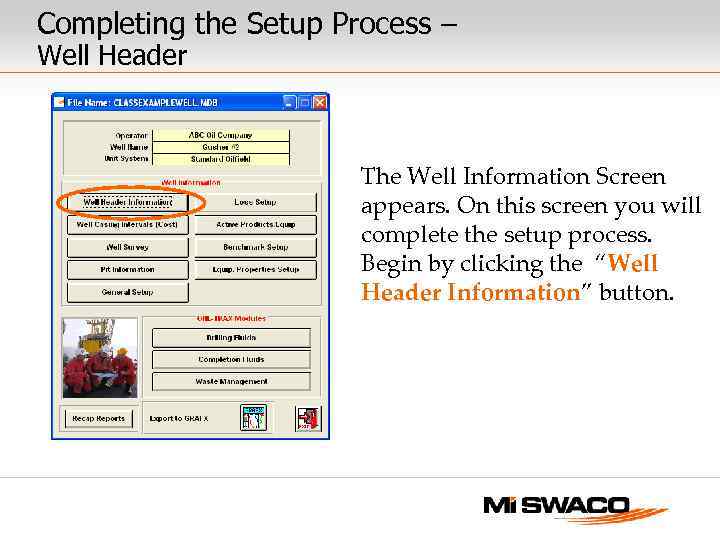

Completing the Setup Process – Well Header The Well Information Screen appears. On this screen you will complete the setup process. Begin by clicking the “Well Header Information” button.

Completing the Setup Process – Well Header The Well Information Screen appears. On this screen you will complete the setup process. Begin by clicking the “Well Header Information” button.

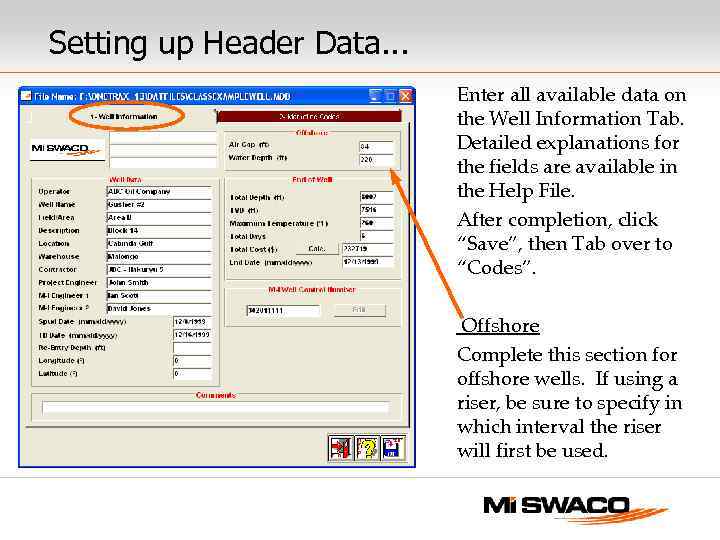

Setting up Header Data. . . Enter all available data on the Well Information Tab. Detailed explanations for the fields are available in the Help File. After completion, click “Save”, then Tab over to “Codes”. Offshore Complete this section for offshore wells. If using a riser, be sure to specify in which interval the riser will first be used.

Setting up Header Data. . . Enter all available data on the Well Information Tab. Detailed explanations for the fields are available in the Help File. After completion, click “Save”, then Tab over to “Codes”. Offshore Complete this section for offshore wells. If using a riser, be sure to specify in which interval the riser will first be used.

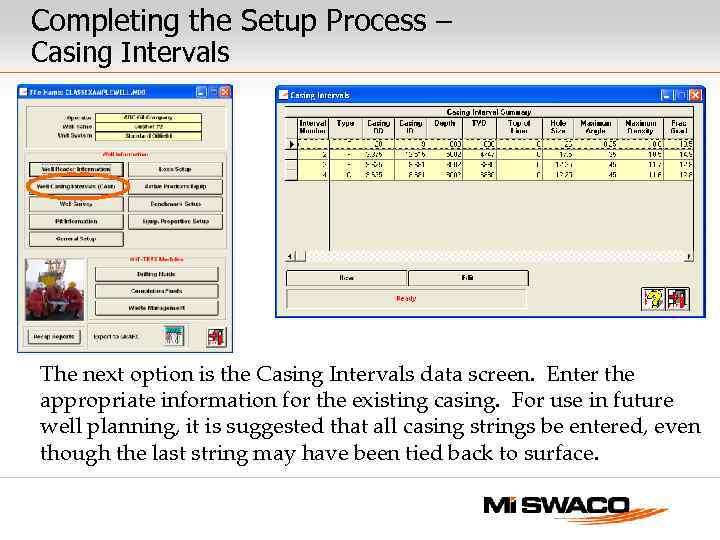

Completing the Setup Process – Casing Intervals The next option is the Casing Intervals data screen. Enter the appropriate information for the existing casing. For use in future well planning, it is suggested that all casing strings be entered, even though the last string may have been tied back to surface.

Completing the Setup Process – Casing Intervals The next option is the Casing Intervals data screen. Enter the appropriate information for the existing casing. For use in future well planning, it is suggested that all casing strings be entered, even though the last string may have been tied back to surface.

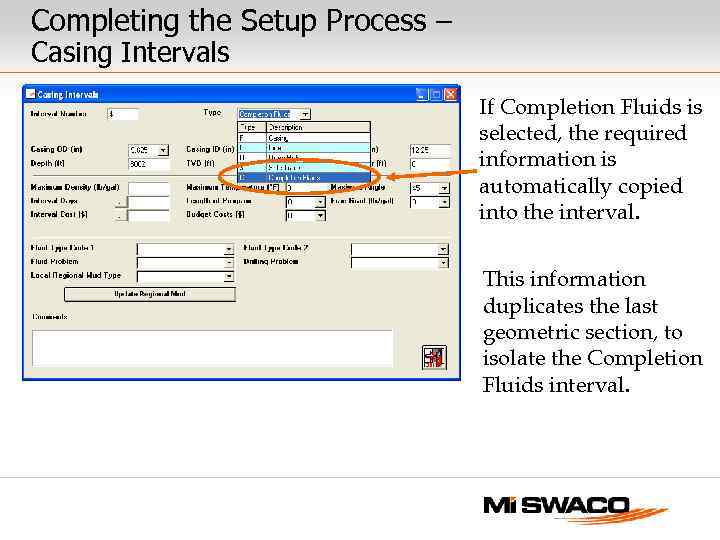

Completing the Setup Process – Casing Intervals If Completion Fluids is selected, the required information is automatically copied into the interval. This information duplicates the last geometric section, to isolate the Completion Fluids interval.

Completing the Setup Process – Casing Intervals If Completion Fluids is selected, the required information is automatically copied into the interval. This information duplicates the last geometric section, to isolate the Completion Fluids interval.

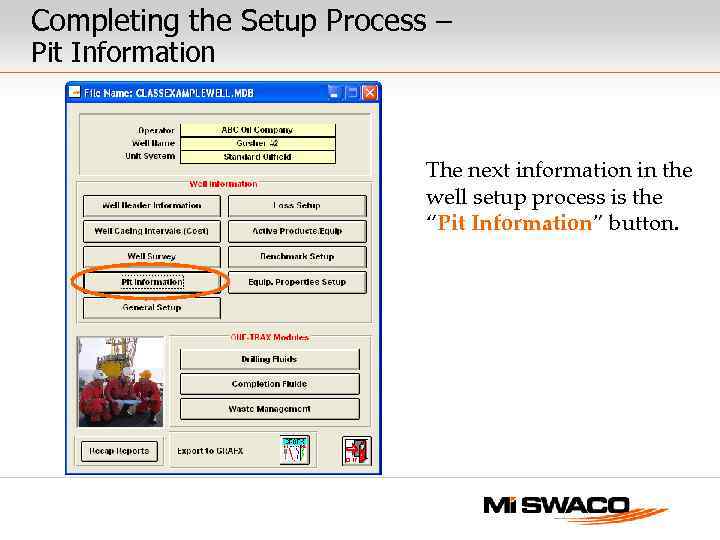

Completing the Setup Process – Pit Information The next information in the well setup process is the “Pit Information” button.

Completing the Setup Process – Pit Information The next information in the well setup process is the “Pit Information” button.

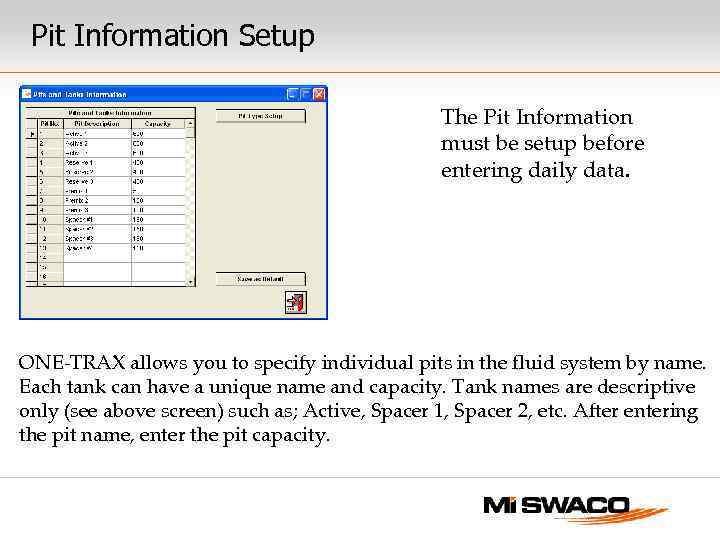

Pit Information Setup The Pit Information must be setup before entering daily data. ONE-TRAX allows you to specify individual pits in the fluid system by name. Each tank can have a unique name and capacity. Tank names are descriptive only (see above screen) such as; Active, Spacer 1, Spacer 2, etc. After entering the pit name, enter the pit capacity.

Pit Information Setup The Pit Information must be setup before entering daily data. ONE-TRAX allows you to specify individual pits in the fluid system by name. Each tank can have a unique name and capacity. Tank names are descriptive only (see above screen) such as; Active, Spacer 1, Spacer 2, etc. After entering the pit name, enter the pit capacity.

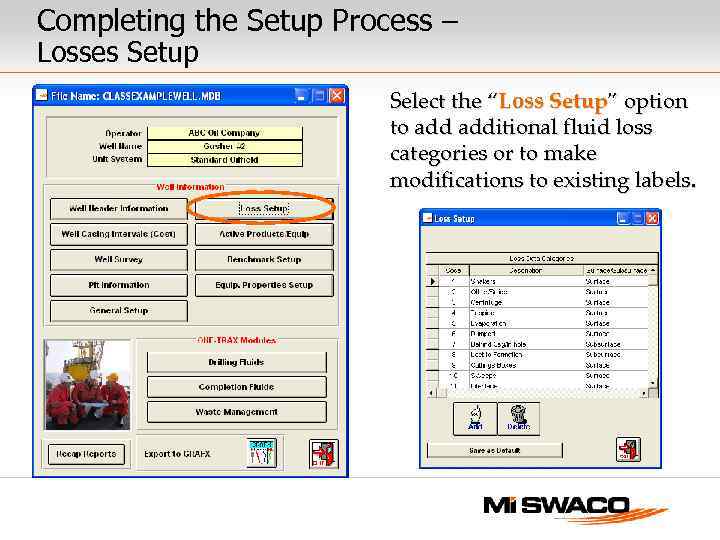

Completing the Setup Process – Losses Setup Select the “Loss Setup” option to additional fluid loss categories or to make modifications to existing labels.

Completing the Setup Process – Losses Setup Select the “Loss Setup” option to additional fluid loss categories or to make modifications to existing labels.

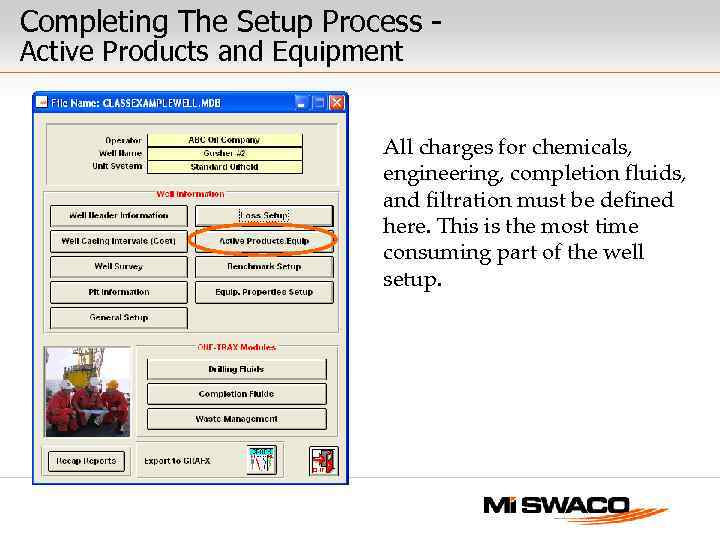

Completing The Setup Process Active Products and Equipment All charges for chemicals, engineering, completion fluids, and filtration must be defined here. This is the most time consuming part of the well setup.

Completing The Setup Process Active Products and Equipment All charges for chemicals, engineering, completion fluids, and filtration must be defined here. This is the most time consuming part of the well setup.

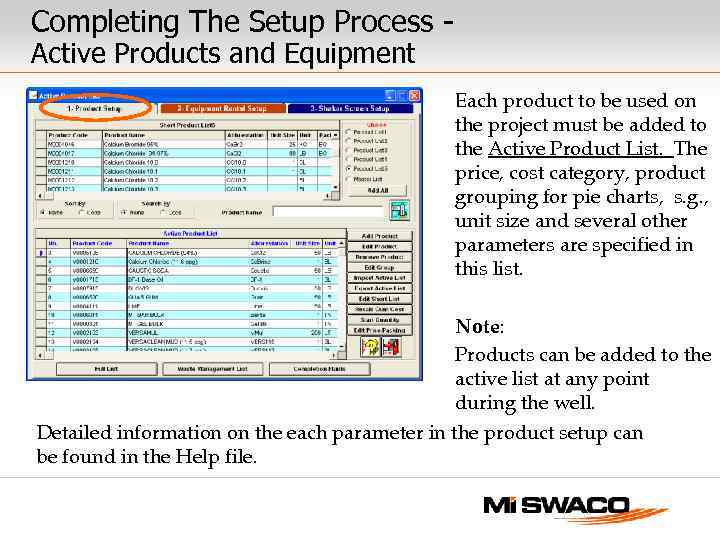

Completing The Setup Process Active Products and Equipment Each product to be used on the project must be added to the Active Product List. The price, cost category, product grouping for pie charts, s. g. , unit size and several other parameters are specified in this list. Note: Products can be added to the active list at any point during the well. Detailed information on the each parameter in the product setup can be found in the Help file.

Completing The Setup Process Active Products and Equipment Each product to be used on the project must be added to the Active Product List. The price, cost category, product grouping for pie charts, s. g. , unit size and several other parameters are specified in this list. Note: Products can be added to the active list at any point during the well. Detailed information on the each parameter in the product setup can be found in the Help file.

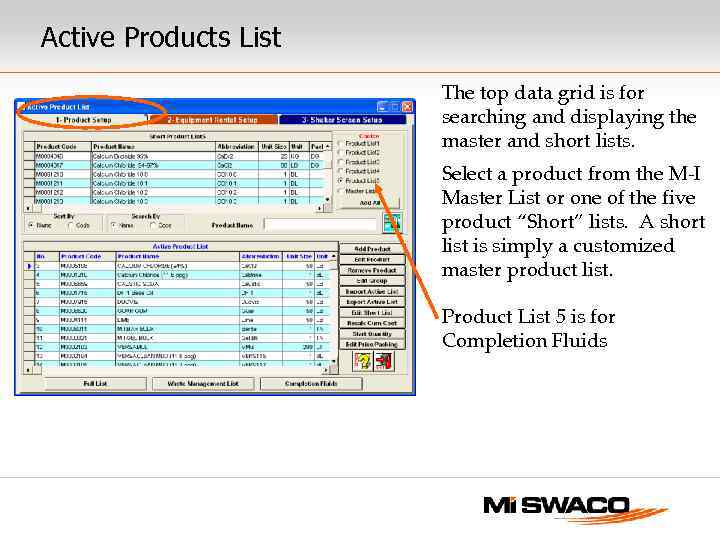

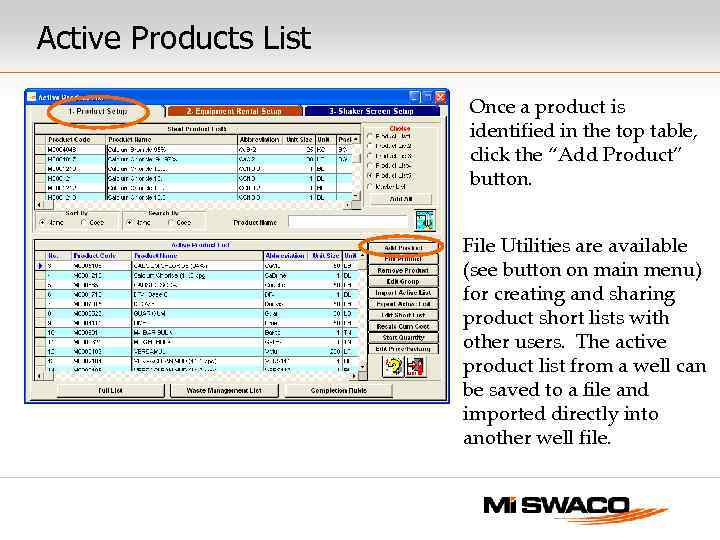

Active Products List The top data grid is for searching and displaying the master and short lists. Select a product from the M-I Master List or one of the five product “Short” lists. A short list is simply a customized master product list. Product List 5 is for Completion Fluids

Active Products List The top data grid is for searching and displaying the master and short lists. Select a product from the M-I Master List or one of the five product “Short” lists. A short list is simply a customized master product list. Product List 5 is for Completion Fluids

Active Products List Once a product is identified in the top table, click the “Add Product” button. File Utilities are available (see button on main menu) for creating and sharing product short lists with other users. The active product list from a well can be saved to a file and imported directly into another well file.

Active Products List Once a product is identified in the top table, click the “Add Product” button. File Utilities are available (see button on main menu) for creating and sharing product short lists with other users. The active product list from a well can be saved to a file and imported directly into another well file.

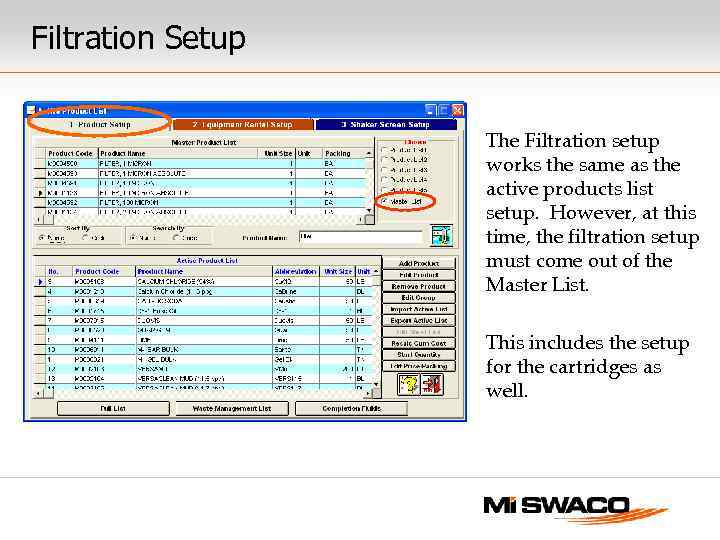

Filtration Setup The Filtration setup works the same as the active products list setup. However, at this time, the filtration setup must come out of the Master List. This includes the setup for the cartridges as well.

Filtration Setup The Filtration setup works the same as the active products list setup. However, at this time, the filtration setup must come out of the Master List. This includes the setup for the cartridges as well.

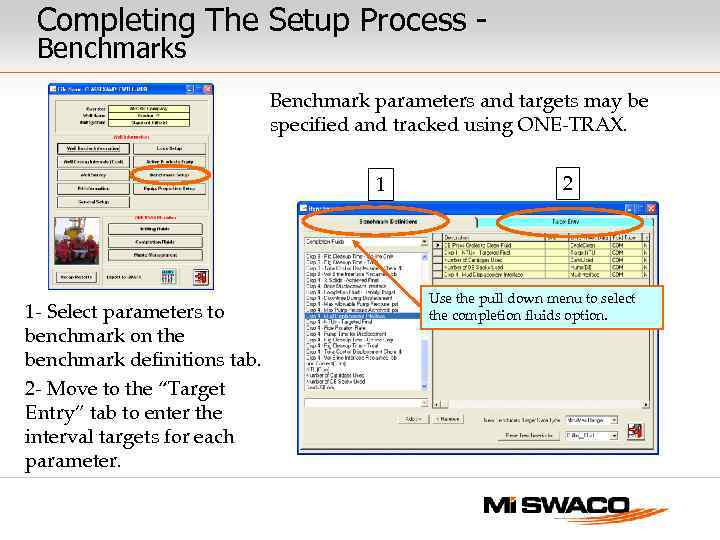

Completing The Setup Process Benchmark parameters and targets may be specified and tracked using ONE-TRAX. 1 1 - Select parameters to benchmark on the benchmark definitions tab. 2 - Move to the “Target Entry” tab to enter the interval targets for each parameter. 2 Use the pull down menu to select the completion fluids option.

Completing The Setup Process Benchmark parameters and targets may be specified and tracked using ONE-TRAX. 1 1 - Select parameters to benchmark on the benchmark definitions tab. 2 - Move to the “Target Entry” tab to enter the interval targets for each parameter. 2 Use the pull down menu to select the completion fluids option.

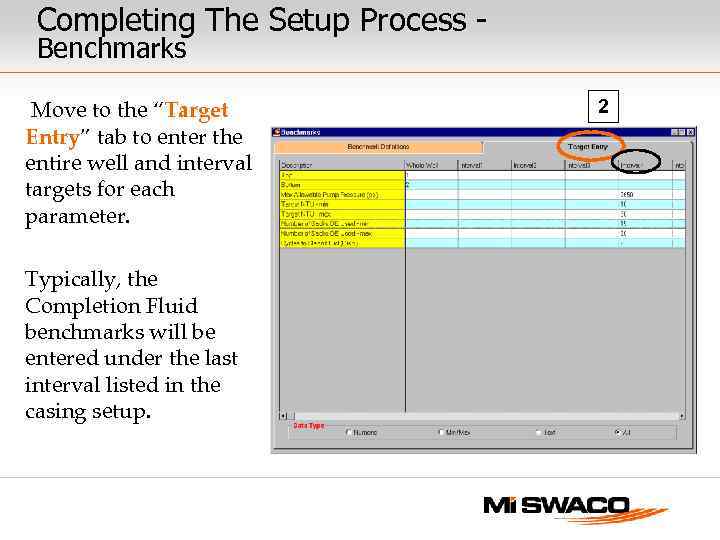

Completing The Setup Process Benchmarks Move to the “Target Entry” tab to enter the entire well and interval targets for each parameter. Typically, the Completion Fluid benchmarks will be entered under the last interval listed in the casing setup. 2

Completing The Setup Process Benchmarks Move to the “Target Entry” tab to enter the entire well and interval targets for each parameter. Typically, the Completion Fluid benchmarks will be entered under the last interval listed in the casing setup. 2

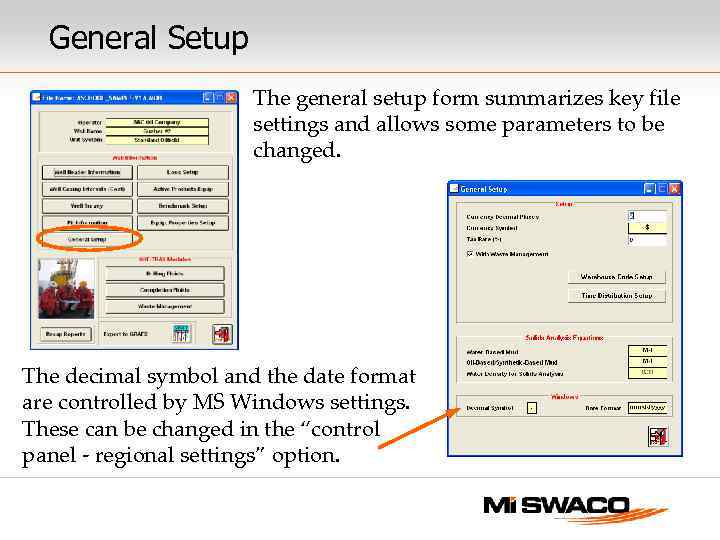

General Setup The general setup form summarizes key file settings and allows some parameters to be changed. The decimal symbol and the date format are controlled by MS Windows settings. These can be changed in the “control panel - regional settings” option.

General Setup The general setup form summarizes key file settings and allows some parameters to be changed. The decimal symbol and the date format are controlled by MS Windows settings. These can be changed in the “control panel - regional settings” option.

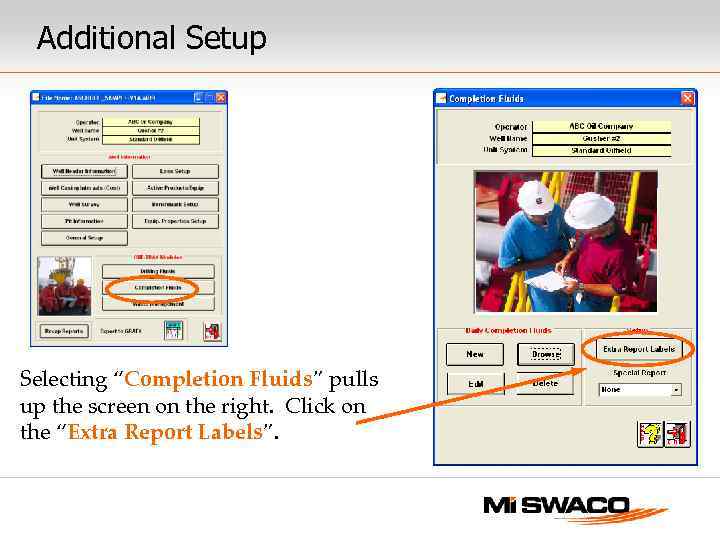

Additional Setup Selecting “Completion Fluids” pulls up the screen on the right. Click on the “Extra Report Labels”.

Additional Setup Selecting “Completion Fluids” pulls up the screen on the right. Click on the “Extra Report Labels”.

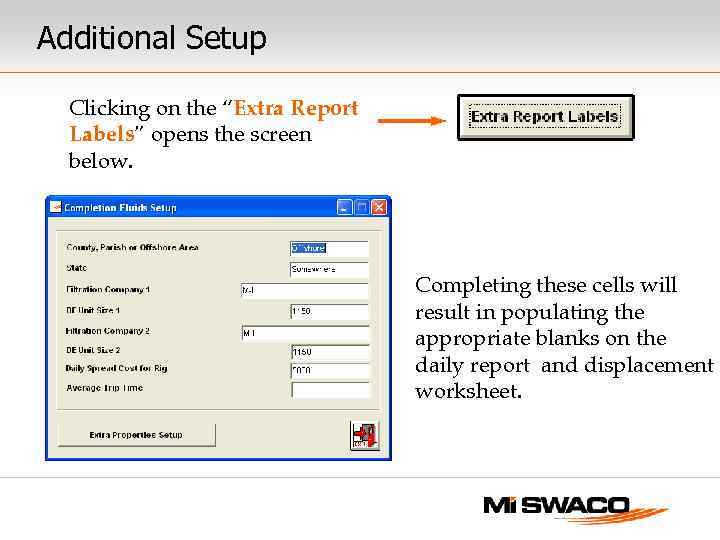

Additional Setup Clicking on the “Extra Report Labels” opens the screen below. Completing these cells will result in populating the appropriate blanks on the daily report and displacement worksheet.

Additional Setup Clicking on the “Extra Report Labels” opens the screen below. Completing these cells will result in populating the appropriate blanks on the daily report and displacement worksheet.

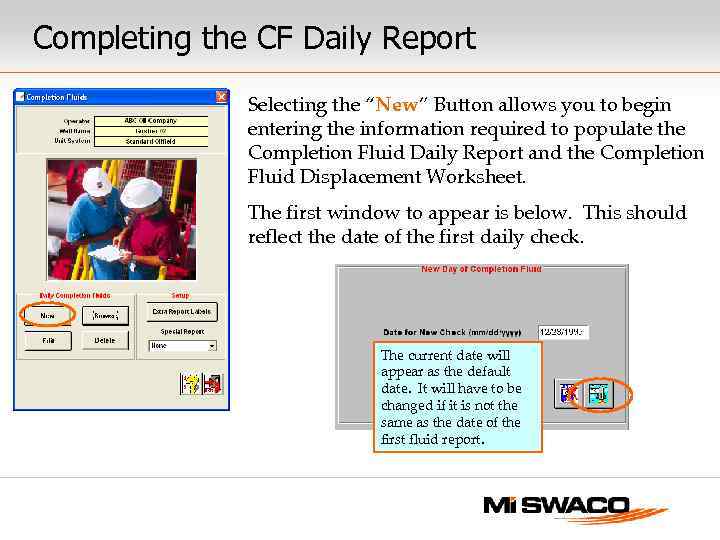

Completing the CF Daily Report Selecting the “New” Button allows you to begin entering the information required to populate the Completion Fluid Daily Report and the Completion Fluid Displacement Worksheet. The first window to appear is below. This should reflect the date of the first daily check. The current date will appear as the default date. It will have to be changed if it is not the same as the date of the first fluid report.

Completing the CF Daily Report Selecting the “New” Button allows you to begin entering the information required to populate the Completion Fluid Daily Report and the Completion Fluid Displacement Worksheet. The first window to appear is below. This should reflect the date of the first daily check. The current date will appear as the default date. It will have to be changed if it is not the same as the date of the first fluid report.

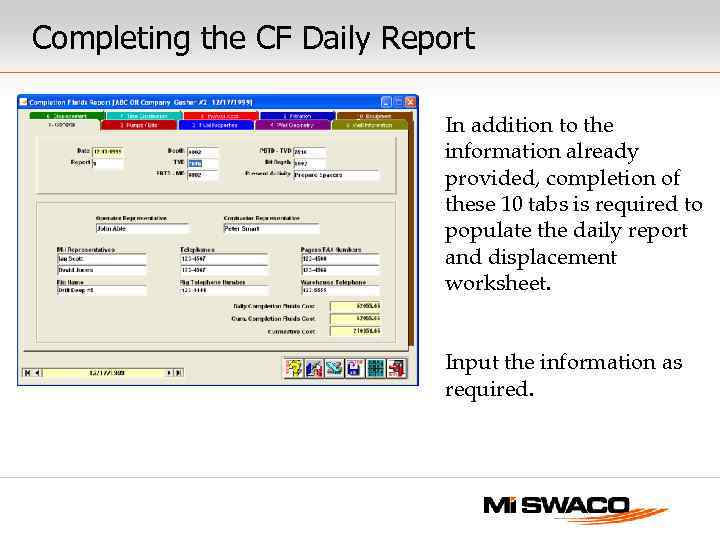

Completing the CF Daily Report In addition to the information already provided, completion of these 10 tabs is required to populate the daily report and displacement worksheet. Input the information as required.

Completing the CF Daily Report In addition to the information already provided, completion of these 10 tabs is required to populate the daily report and displacement worksheet. Input the information as required.

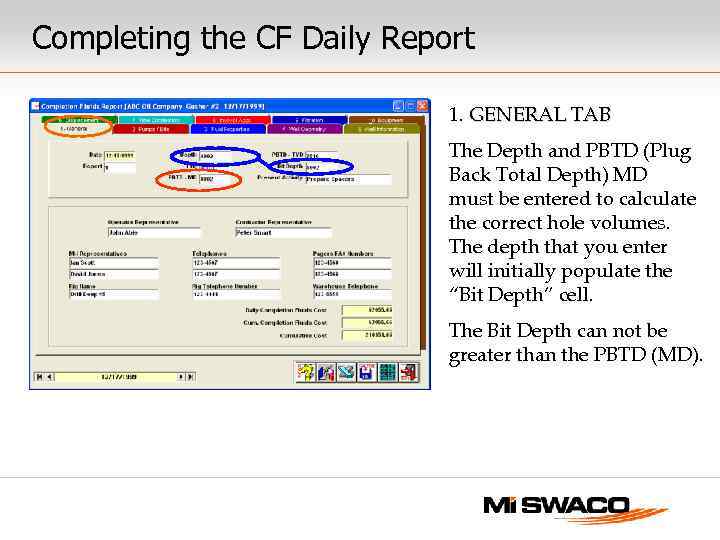

Completing the CF Daily Report 1. GENERAL TAB The Depth and PBTD (Plug Back Total Depth) MD must be entered to calculate the correct hole volumes. The depth that you enter will initially populate the “Bit Depth” cell. The Bit Depth can not be greater than the PBTD (MD).

Completing the CF Daily Report 1. GENERAL TAB The Depth and PBTD (Plug Back Total Depth) MD must be entered to calculate the correct hole volumes. The depth that you enter will initially populate the “Bit Depth” cell. The Bit Depth can not be greater than the PBTD (MD).

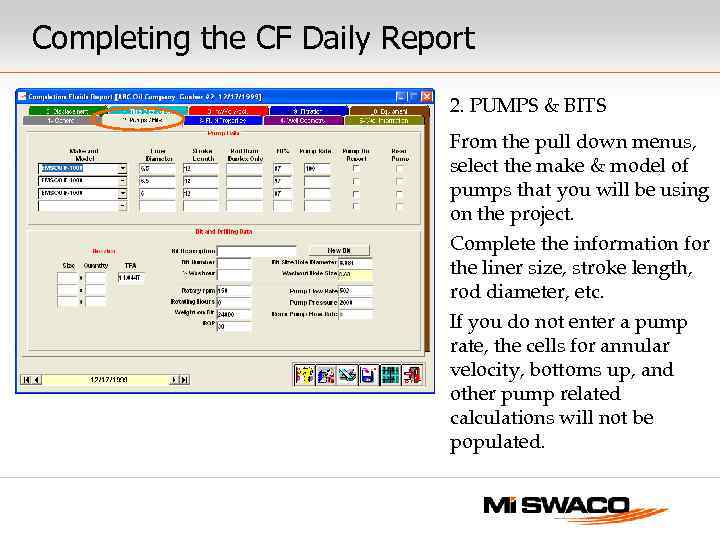

Completing the CF Daily Report 2. PUMPS & BITS From the pull down menus, select the make & model of pumps that you will be using on the project. Complete the information for the liner size, stroke length, rod diameter, etc. If you do not enter a pump rate, the cells for annular velocity, bottoms up, and other pump related calculations will not be populated.

Completing the CF Daily Report 2. PUMPS & BITS From the pull down menus, select the make & model of pumps that you will be using on the project. Complete the information for the liner size, stroke length, rod diameter, etc. If you do not enter a pump rate, the cells for annular velocity, bottoms up, and other pump related calculations will not be populated.

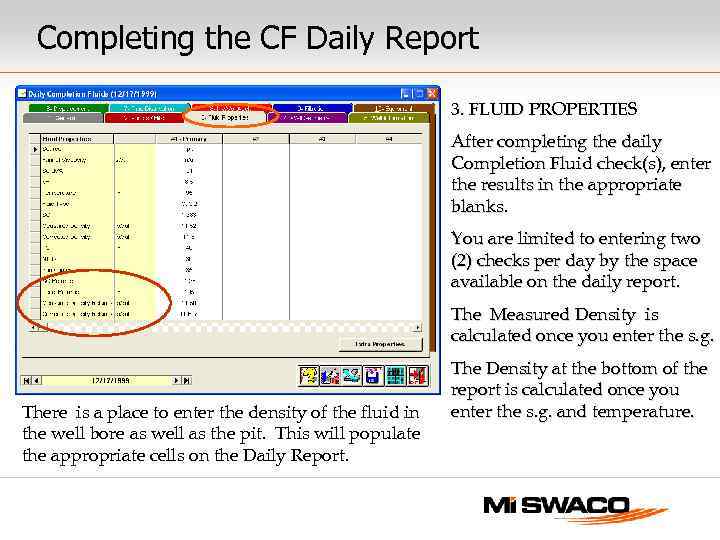

Completing the CF Daily Report 3. FLUID PROPERTIES After completing the daily Completion Fluid check(s), enter the results in the appropriate blanks. You are limited to entering two (2) checks per day by the space available on the daily report. The Measured Density is calculated once you enter the s. g. There is a place to enter the density of the fluid in the well bore as well as the pit. This will populate the appropriate cells on the Daily Report. The Density at the bottom of the report is calculated once you enter the s. g. and temperature.

Completing the CF Daily Report 3. FLUID PROPERTIES After completing the daily Completion Fluid check(s), enter the results in the appropriate blanks. You are limited to entering two (2) checks per day by the space available on the daily report. The Measured Density is calculated once you enter the s. g. There is a place to enter the density of the fluid in the well bore as well as the pit. This will populate the appropriate cells on the Daily Report. The Density at the bottom of the report is calculated once you enter the s. g. and temperature.

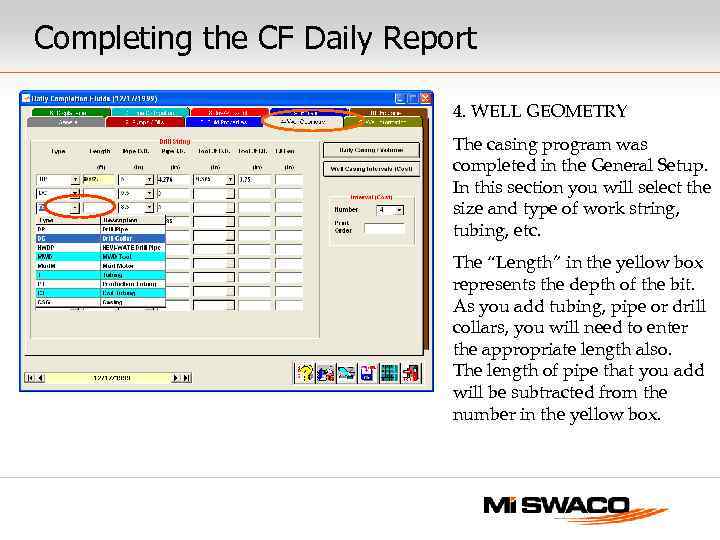

Completing the CF Daily Report 4. WELL GEOMETRY The casing program was completed in the General Setup. In this section you will select the size and type of work string, tubing, etc. The “Length” in the yellow box represents the depth of the bit. As you add tubing, pipe or drill collars, you will need to enter the appropriate length also. The length of pipe that you add will be subtracted from the number in the yellow box.

Completing the CF Daily Report 4. WELL GEOMETRY The casing program was completed in the General Setup. In this section you will select the size and type of work string, tubing, etc. The “Length” in the yellow box represents the depth of the bit. As you add tubing, pipe or drill collars, you will need to enter the appropriate length also. The length of pipe that you add will be subtracted from the number in the yellow box.

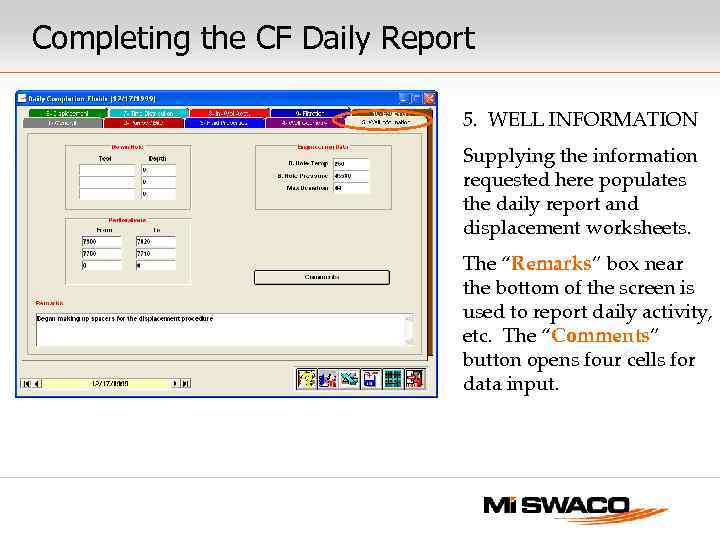

Completing the CF Daily Report 5. WELL INFORMATION Supplying the information requested here populates the daily report and displacement worksheets. The “Remarks” box near the bottom of the screen is used to report daily activity, etc. The “Comments” button opens four cells for data input.

Completing the CF Daily Report 5. WELL INFORMATION Supplying the information requested here populates the daily report and displacement worksheets. The “Remarks” box near the bottom of the screen is used to report daily activity, etc. The “Comments” button opens four cells for data input.

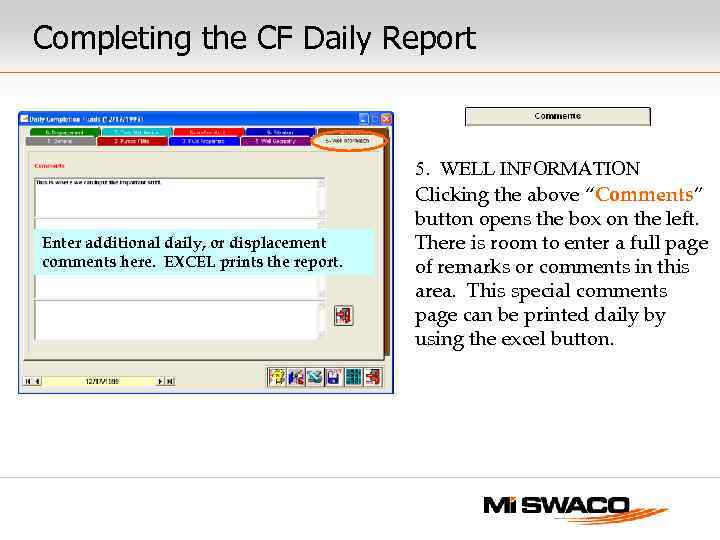

Completing the CF Daily Report Enter additional daily, or displacement comments here. EXCEL prints the report. 5. WELL INFORMATION Clicking the above “Comments” button opens the box on the left. There is room to enter a full page of remarks or comments in this area. This special comments page can be printed daily by using the excel button.

Completing the CF Daily Report Enter additional daily, or displacement comments here. EXCEL prints the report. 5. WELL INFORMATION Clicking the above “Comments” button opens the box on the left. There is room to enter a full page of remarks or comments in this area. This special comments page can be printed daily by using the excel button.

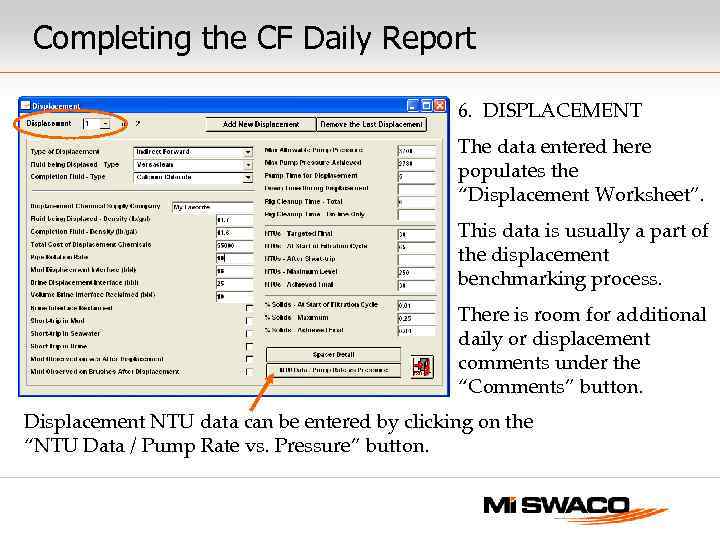

Completing the CF Daily Report 6. DISPLACEMENT The data entered here populates the “Displacement Worksheet”. This data is usually a part of the displacement benchmarking process. There is room for additional daily or displacement comments under the “Comments” button. Displacement NTU data can be entered by clicking on the “NTU Data / Pump Rate vs. Pressure” button.

Completing the CF Daily Report 6. DISPLACEMENT The data entered here populates the “Displacement Worksheet”. This data is usually a part of the displacement benchmarking process. There is room for additional daily or displacement comments under the “Comments” button. Displacement NTU data can be entered by clicking on the “NTU Data / Pump Rate vs. Pressure” button.

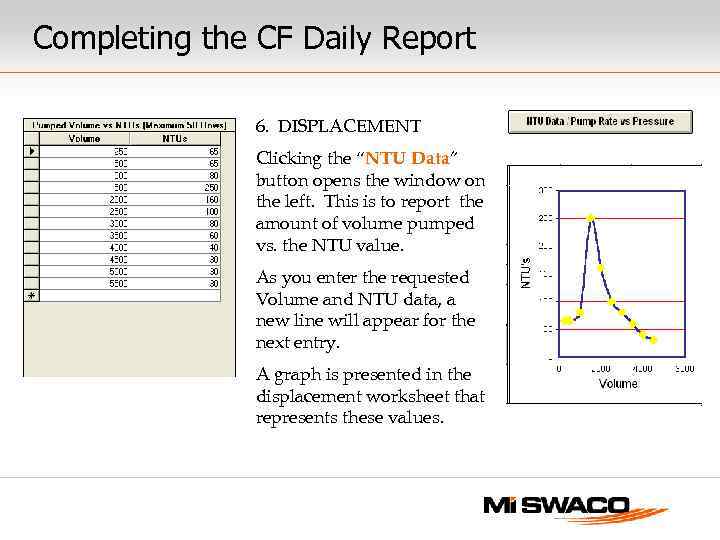

Completing the CF Daily Report 6. DISPLACEMENT Clicking the “NTU Data” button opens the window on the left. This is to report the amount of volume pumped vs. the NTU value. As you enter the requested Volume and NTU data, a new line will appear for the next entry. A graph is presented in the displacement worksheet that represents these values.

Completing the CF Daily Report 6. DISPLACEMENT Clicking the “NTU Data” button opens the window on the left. This is to report the amount of volume pumped vs. the NTU value. As you enter the requested Volume and NTU data, a new line will appear for the next entry. A graph is presented in the displacement worksheet that represents these values.

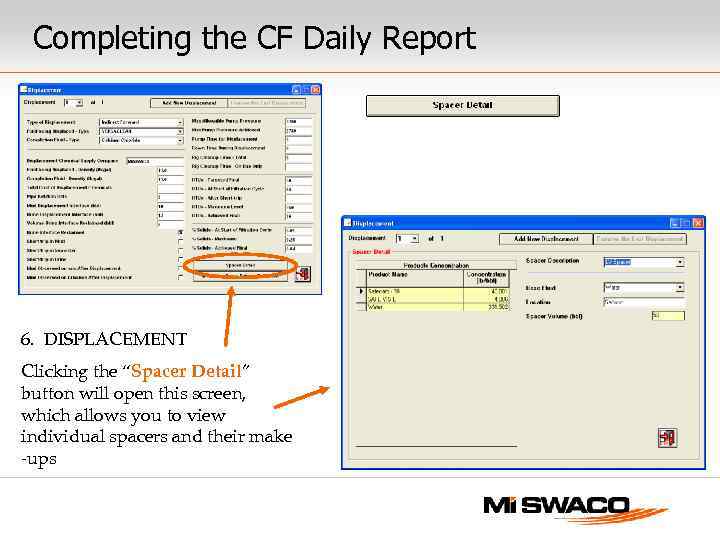

Completing the CF Daily Report 6. DISPLACEMENT Clicking the “Spacer Detail” button will open this screen, which allows you to view individual spacers and their make -ups

Completing the CF Daily Report 6. DISPLACEMENT Clicking the “Spacer Detail” button will open this screen, which allows you to view individual spacers and their make -ups

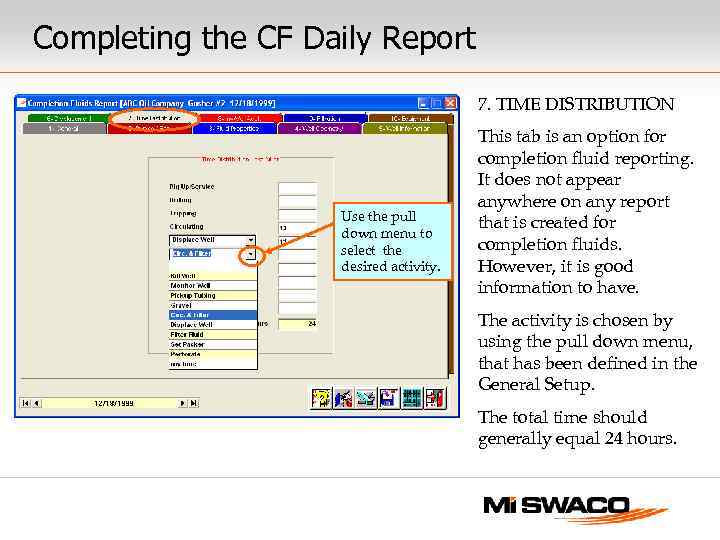

Completing the CF Daily Report 7. TIME DISTRIBUTION Use the pull down menu to select the desired activity. This tab is an option for completion fluid reporting. It does not appear anywhere on any report that is created for completion fluids. However, it is good information to have. The activity is chosen by using the pull down menu, that has been defined in the General Setup. The total time should generally equal 24 hours.

Completing the CF Daily Report 7. TIME DISTRIBUTION Use the pull down menu to select the desired activity. This tab is an option for completion fluid reporting. It does not appear anywhere on any report that is created for completion fluids. However, it is good information to have. The activity is chosen by using the pull down menu, that has been defined in the General Setup. The total time should generally equal 24 hours.

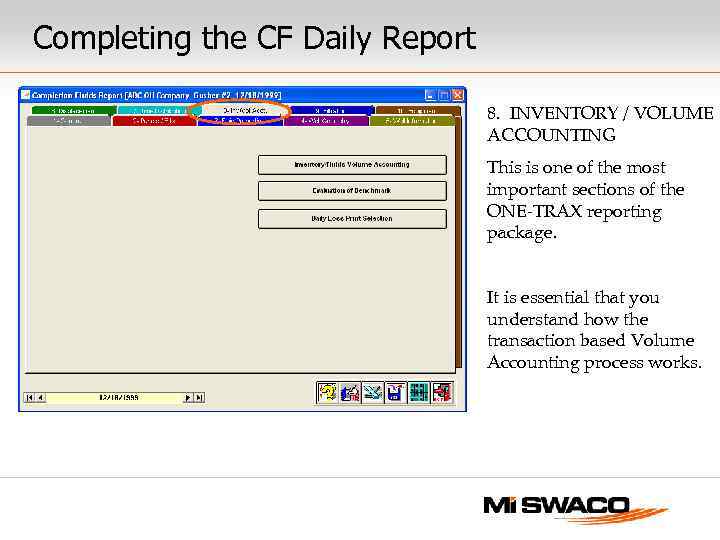

Completing the CF Daily Report 8. INVENTORY / VOLUME ACCOUNTING This is one of the most important sections of the ONE-TRAX reporting package. It is essential that you understand how the transaction based Volume Accounting process works.

Completing the CF Daily Report 8. INVENTORY / VOLUME ACCOUNTING This is one of the most important sections of the ONE-TRAX reporting package. It is essential that you understand how the transaction based Volume Accounting process works.

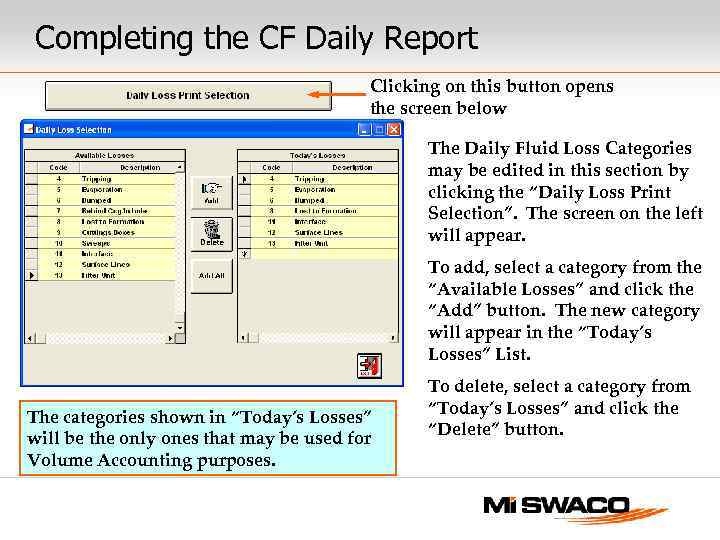

Completing the CF Daily Report Clicking on this button opens the screen below The Daily Fluid Loss Categories may be edited in this section by clicking the “Daily Loss Print Selection”. The screen on the left will appear. To add, select a category from the “Available Losses” and click the “Add” button. The new category will appear in the “Today’s Losses” List. The categories shown in “Today’s Losses” will be the only ones that may be used for Volume Accounting purposes. To delete, select a category from “Today’s Losses” and click the “Delete” button.

Completing the CF Daily Report Clicking on this button opens the screen below The Daily Fluid Loss Categories may be edited in this section by clicking the “Daily Loss Print Selection”. The screen on the left will appear. To add, select a category from the “Available Losses” and click the “Add” button. The new category will appear in the “Today’s Losses” List. The categories shown in “Today’s Losses” will be the only ones that may be used for Volume Accounting purposes. To delete, select a category from “Today’s Losses” and click the “Delete” button.

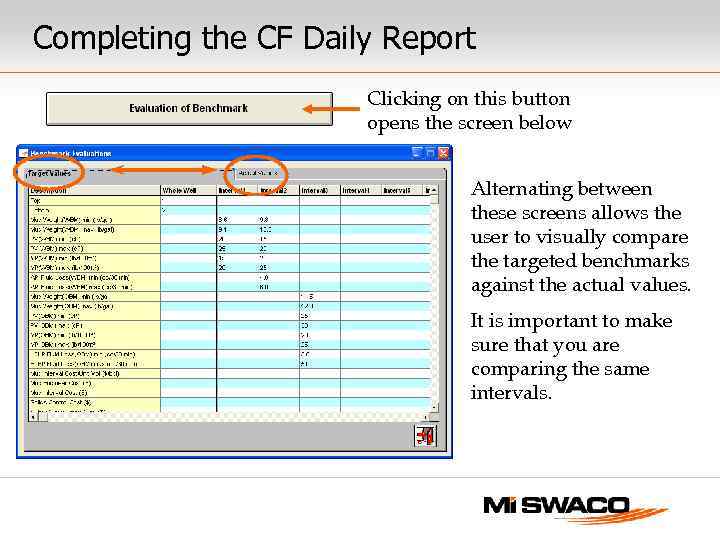

Completing the CF Daily Report Clicking on this button opens the screen below Alternating between these screens allows the user to visually compare the targeted benchmarks against the actual values. It is important to make sure that you are comparing the same intervals.

Completing the CF Daily Report Clicking on this button opens the screen below Alternating between these screens allows the user to visually compare the targeted benchmarks against the actual values. It is important to make sure that you are comparing the same intervals.

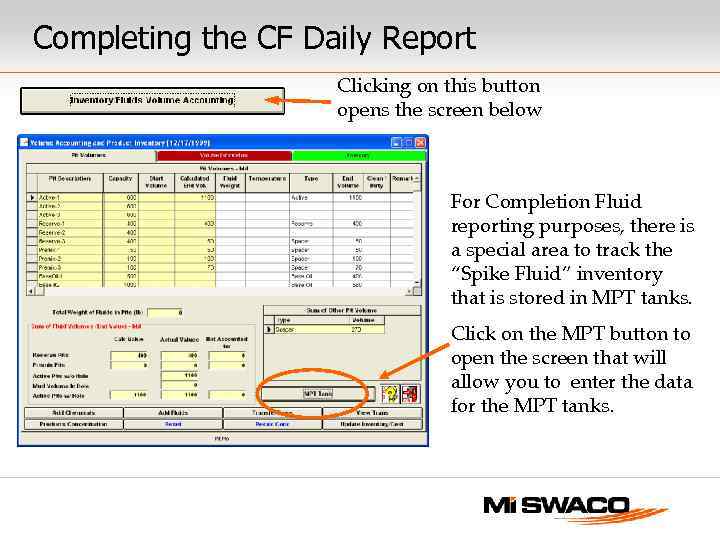

Completing the CF Daily Report Clicking on this button opens the screen below For Completion Fluid reporting purposes, there is a special area to track the “Spike Fluid” inventory that is stored in MPT tanks. Click on the MPT button to open the screen that will allow you to enter the data for the MPT tanks.

Completing the CF Daily Report Clicking on this button opens the screen below For Completion Fluid reporting purposes, there is a special area to track the “Spike Fluid” inventory that is stored in MPT tanks. Click on the MPT button to open the screen that will allow you to enter the data for the MPT tanks.

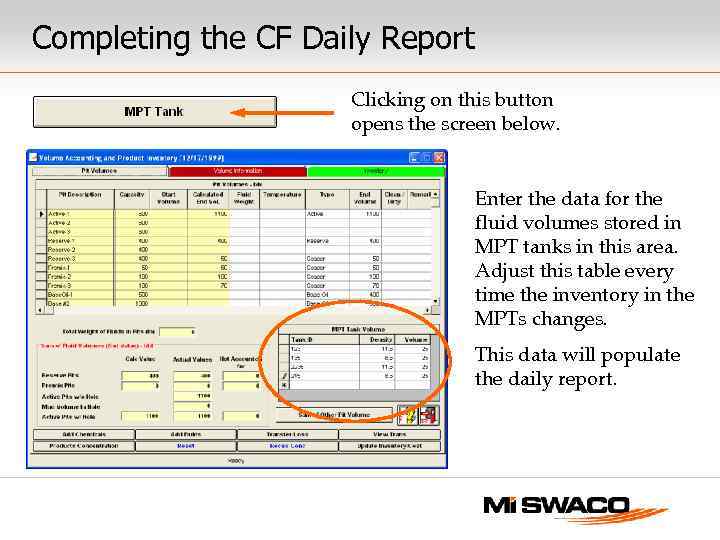

Completing the CF Daily Report Clicking on this button opens the screen below. Enter the data for the fluid volumes stored in MPT tanks in this area. Adjust this table every time the inventory in the MPTs changes. This data will populate the daily report.

Completing the CF Daily Report Clicking on this button opens the screen below. Enter the data for the fluid volumes stored in MPT tanks in this area. Adjust this table every time the inventory in the MPTs changes. This data will populate the daily report.

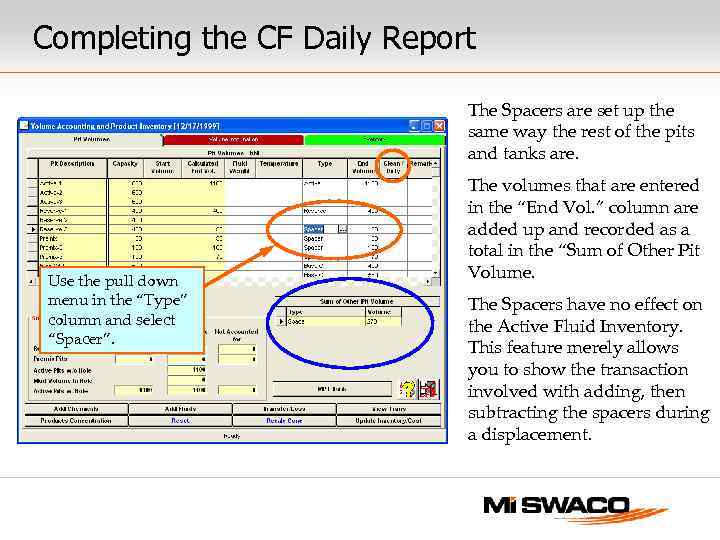

Completing the CF Daily Report The Spacers are set up the same way the rest of the pits and tanks are. Use the pull down menu in the “Type” column and select “Spacer”. The volumes that are entered in the “End Vol. ” column are added up and recorded as a total in the “Sum of Other Pit Volume. The Spacers have no effect on the Active Fluid Inventory. This feature merely allows you to show the transaction involved with adding, then subtracting the spacers during a displacement.

Completing the CF Daily Report The Spacers are set up the same way the rest of the pits and tanks are. Use the pull down menu in the “Type” column and select “Spacer”. The volumes that are entered in the “End Vol. ” column are added up and recorded as a total in the “Sum of Other Pit Volume. The Spacers have no effect on the Active Fluid Inventory. This feature merely allows you to show the transaction involved with adding, then subtracting the spacers during a displacement.

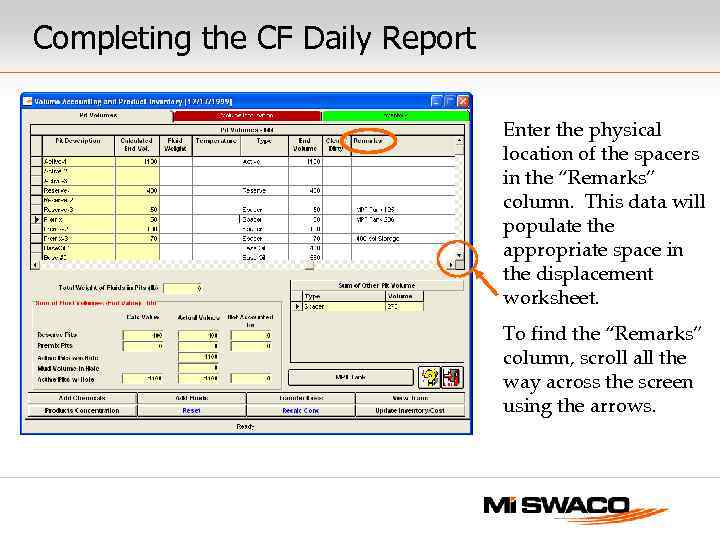

Completing the CF Daily Report Enter the physical location of the spacers in the “Remarks” column. This data will populate the appropriate space in the displacement worksheet. To find the “Remarks” column, scroll all the way across the screen using the arrows.

Completing the CF Daily Report Enter the physical location of the spacers in the “Remarks” column. This data will populate the appropriate space in the displacement worksheet. To find the “Remarks” column, scroll all the way across the screen using the arrows.

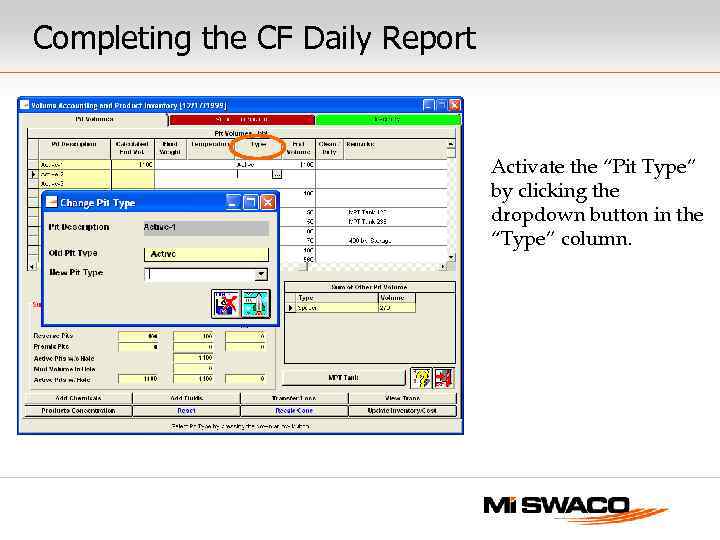

Completing the CF Daily Report Activate the “Pit Type” by clicking the dropdown button in the “Type” column.

Completing the CF Daily Report Activate the “Pit Type” by clicking the dropdown button in the “Type” column.

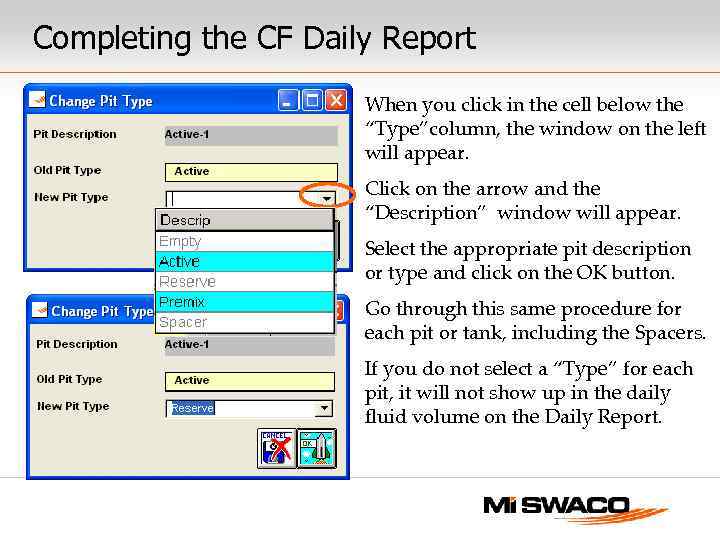

Completing the CF Daily Report When you click in the cell below the “Type”column, the window on the left will appear. Click on the arrow and the “Description” window will appear. Select the appropriate pit description or type and click on the OK button. Go through this same procedure for each pit or tank, including the Spacers. If you do not select a “Type” for each pit, it will not show up in the daily fluid volume on the Daily Report.

Completing the CF Daily Report When you click in the cell below the “Type”column, the window on the left will appear. Click on the arrow and the “Description” window will appear. Select the appropriate pit description or type and click on the OK button. Go through this same procedure for each pit or tank, including the Spacers. If you do not select a “Type” for each pit, it will not show up in the daily fluid volume on the Daily Report.

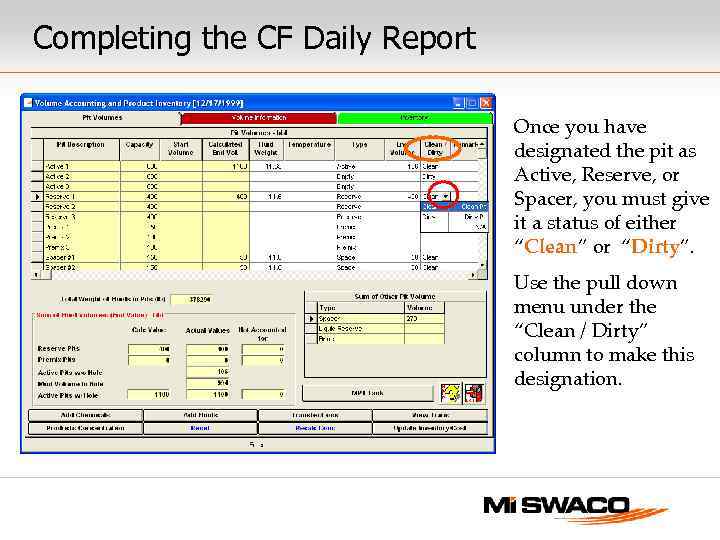

Completing the CF Daily Report Once you have designated the pit as Active, Reserve, or Spacer, you must give it a status of either “Clean” or “Dirty”. Use the pull down menu under the “Clean / Dirty” column to make this designation.

Completing the CF Daily Report Once you have designated the pit as Active, Reserve, or Spacer, you must give it a status of either “Clean” or “Dirty”. Use the pull down menu under the “Clean / Dirty” column to make this designation.

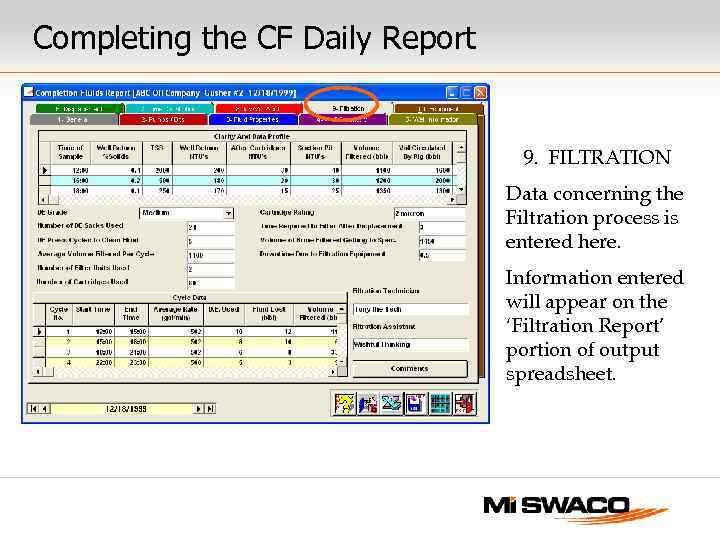

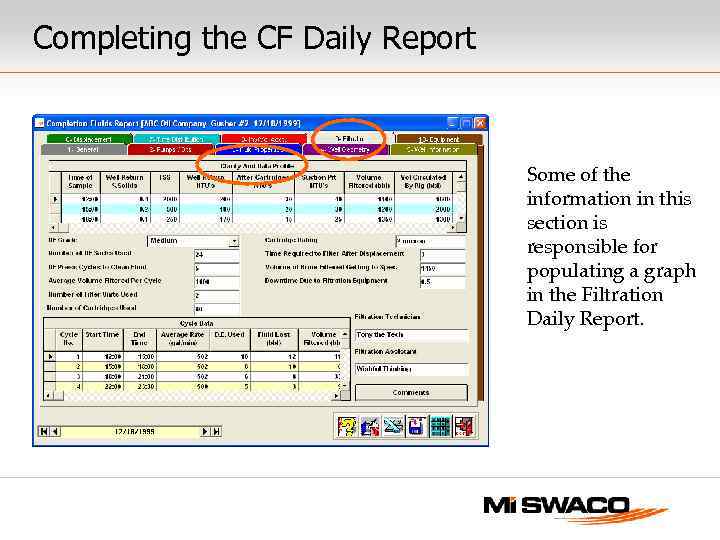

Completing the CF Daily Report 9. FILTRATION Data concerning the Filtration process is entered here. Information entered will appear on the ‘Filtration Report’ portion of output spreadsheet.

Completing the CF Daily Report 9. FILTRATION Data concerning the Filtration process is entered here. Information entered will appear on the ‘Filtration Report’ portion of output spreadsheet.

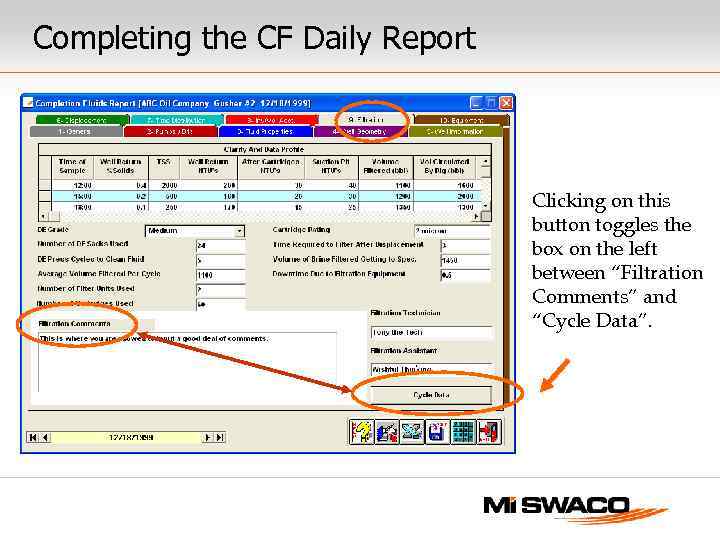

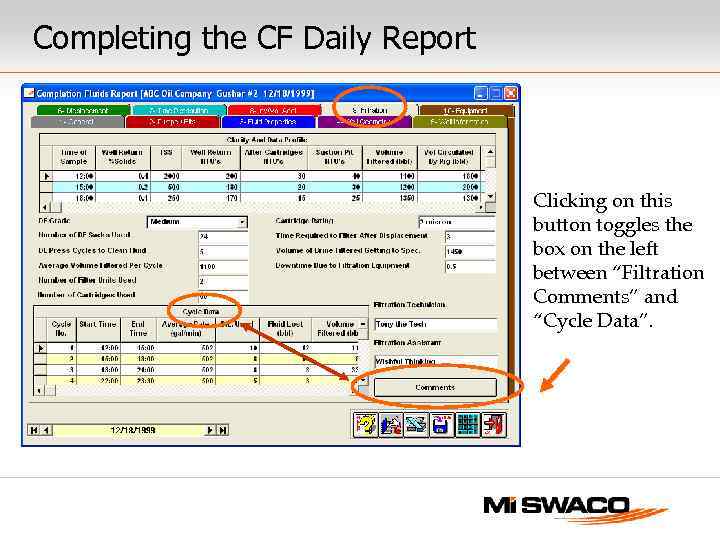

Completing the CF Daily Report Clicking on this button toggles the box on the left between “Filtration Comments” and “Cycle Data”.

Completing the CF Daily Report Clicking on this button toggles the box on the left between “Filtration Comments” and “Cycle Data”.

Completing the CF Daily Report Clicking on this button toggles the box on the left between “Filtration Comments” and “Cycle Data”.

Completing the CF Daily Report Clicking on this button toggles the box on the left between “Filtration Comments” and “Cycle Data”.

Completing the CF Daily Report Some of the information in this section is responsible for populating a graph in the Filtration Daily Report.

Completing the CF Daily Report Some of the information in this section is responsible for populating a graph in the Filtration Daily Report.

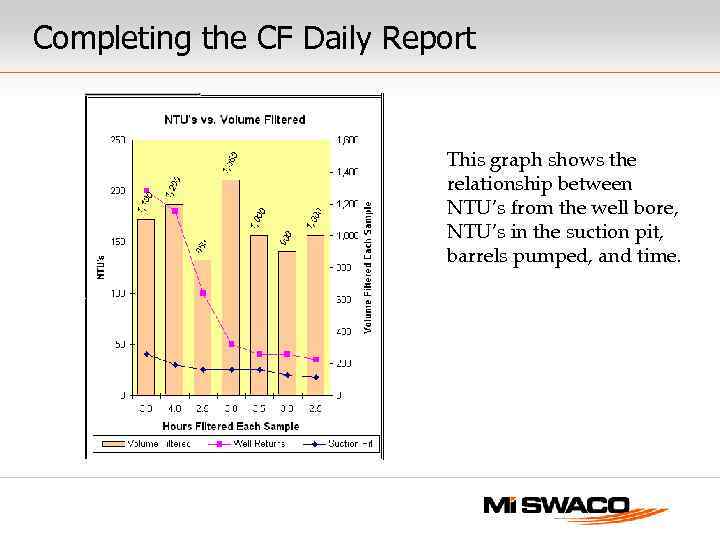

Completing the CF Daily Report This graph shows the relationship between NTU’s from the well bore, NTU’s in the suction pit, barrels pumped, and time.

Completing the CF Daily Report This graph shows the relationship between NTU’s from the well bore, NTU’s in the suction pit, barrels pumped, and time.

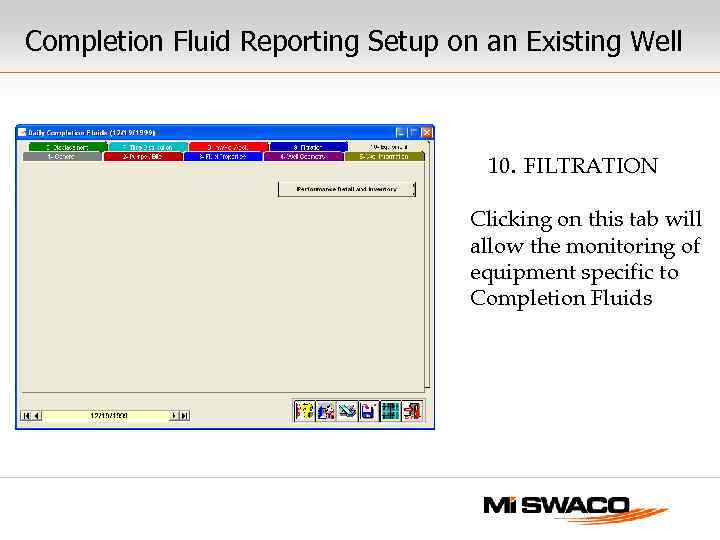

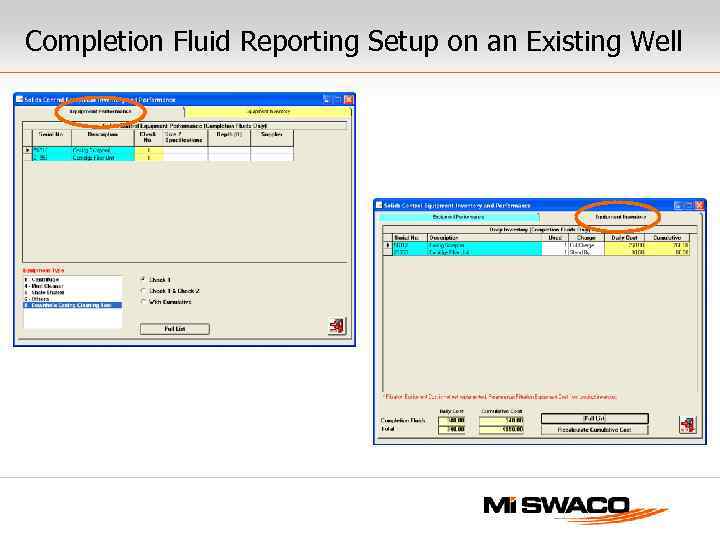

Completion Fluid Reporting Setup on an Existing Well 10. FILTRATION Clicking on this tab will allow the monitoring of equipment specific to Completion Fluids

Completion Fluid Reporting Setup on an Existing Well 10. FILTRATION Clicking on this tab will allow the monitoring of equipment specific to Completion Fluids

Completion Fluid Reporting Setup on an Existing Well

Completion Fluid Reporting Setup on an Existing Well

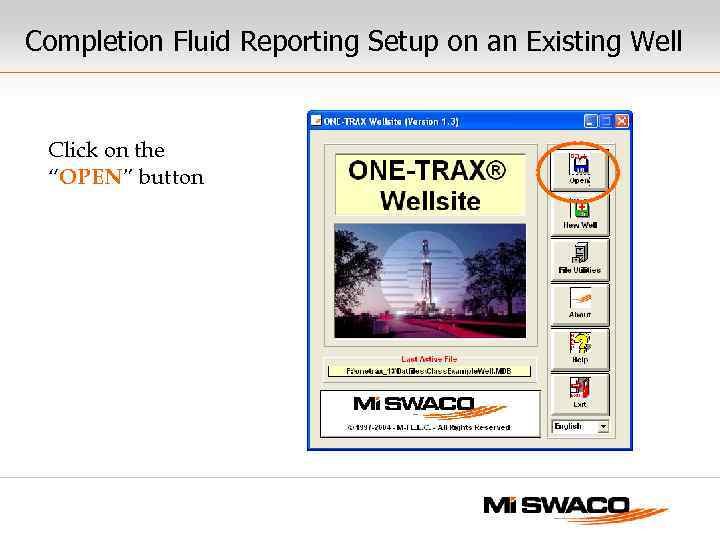

Completion Fluid Reporting Setup on an Existing Well Click on the “OPEN” button

Completion Fluid Reporting Setup on an Existing Well Click on the “OPEN” button

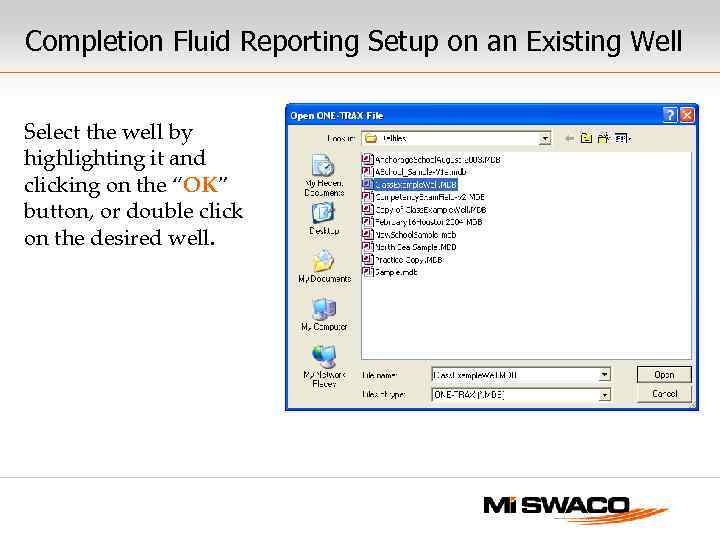

Completion Fluid Reporting Setup on an Existing Well Select the well by highlighting it and clicking on the “OK” button, or double click on the desired well.

Completion Fluid Reporting Setup on an Existing Well Select the well by highlighting it and clicking on the “OK” button, or double click on the desired well.

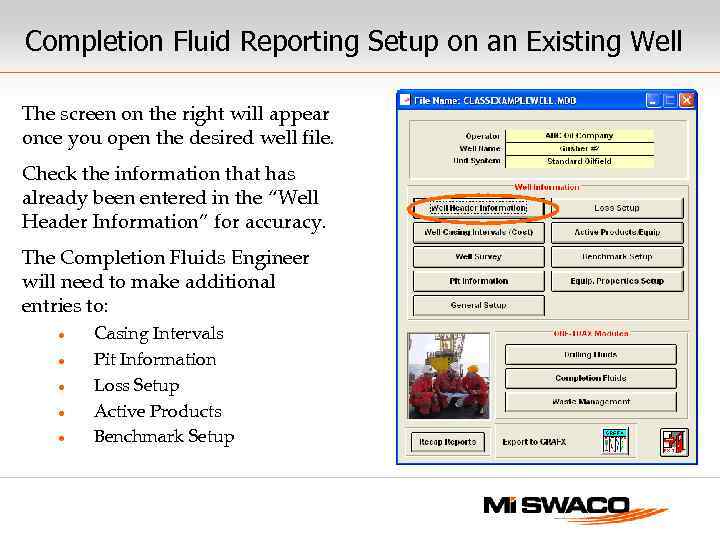

Completion Fluid Reporting Setup on an Existing Well The screen on the right will appear once you open the desired well file. Check the information that has already been entered in the “Well Header Information” for accuracy. The Completion Fluids Engineer will need to make additional entries to: l l l Casing Intervals Pit Information Loss Setup Active Products Benchmark Setup

Completion Fluid Reporting Setup on an Existing Well The screen on the right will appear once you open the desired well file. Check the information that has already been entered in the “Well Header Information” for accuracy. The Completion Fluids Engineer will need to make additional entries to: l l l Casing Intervals Pit Information Loss Setup Active Products Benchmark Setup

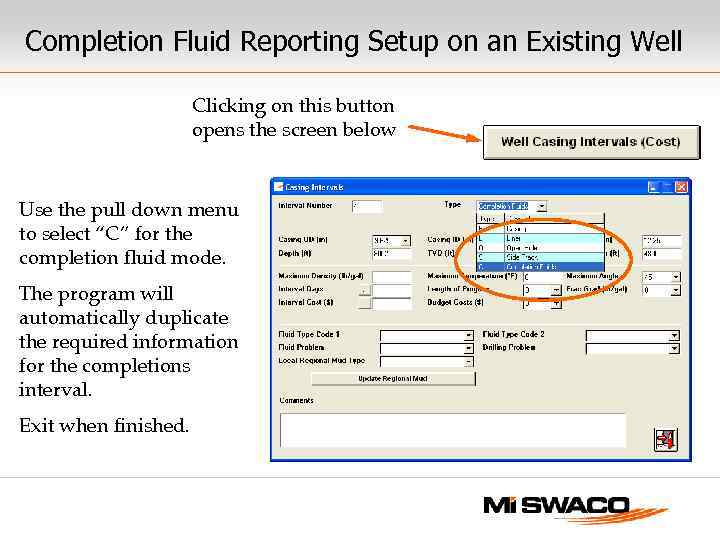

Completion Fluid Reporting Setup on an Existing Well Clicking on this button opens the screen below Use the pull down menu to select “C” for the completion fluid mode. The program will automatically duplicate the required information for the completions interval. Exit when finished.

Completion Fluid Reporting Setup on an Existing Well Clicking on this button opens the screen below Use the pull down menu to select “C” for the completion fluid mode. The program will automatically duplicate the required information for the completions interval. Exit when finished.

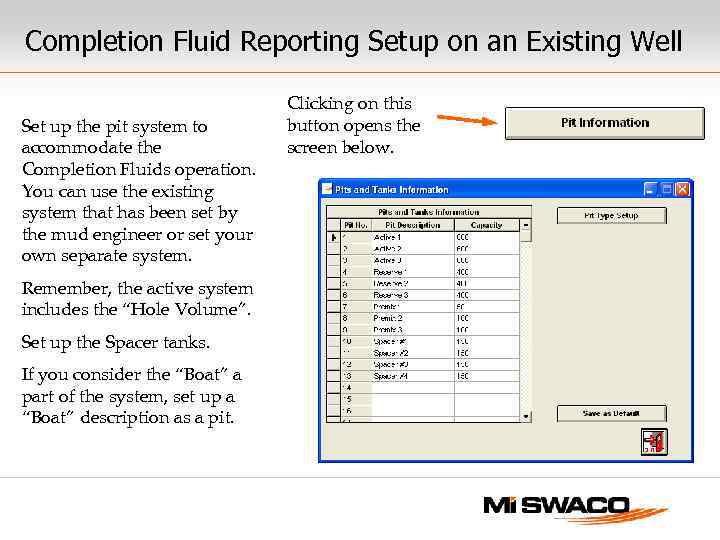

Completion Fluid Reporting Setup on an Existing Well Set up the pit system to accommodate the Completion Fluids operation. You can use the existing system that has been set by the mud engineer or set your own separate system. Remember, the active system includes the “Hole Volume”. Set up the Spacer tanks. If you consider the “Boat” a part of the system, set up a “Boat” description as a pit. Clicking on this button opens the screen below.

Completion Fluid Reporting Setup on an Existing Well Set up the pit system to accommodate the Completion Fluids operation. You can use the existing system that has been set by the mud engineer or set your own separate system. Remember, the active system includes the “Hole Volume”. Set up the Spacer tanks. If you consider the “Boat” a part of the system, set up a “Boat” description as a pit. Clicking on this button opens the screen below.

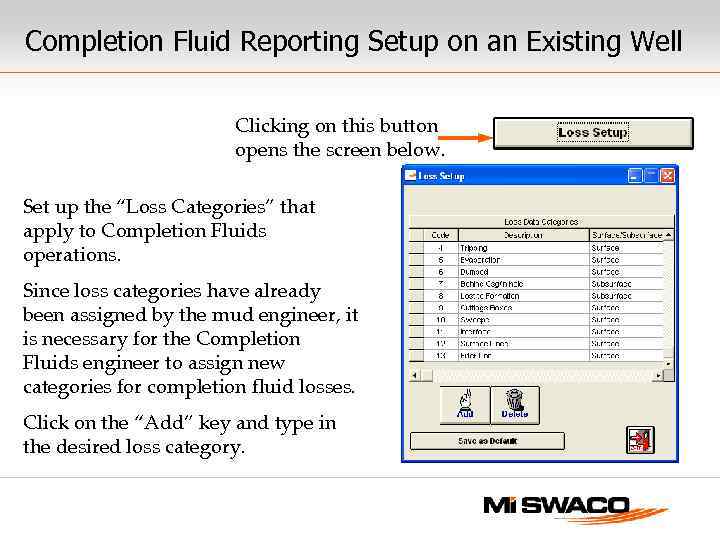

Completion Fluid Reporting Setup on an Existing Well Clicking on this button opens the screen below. Set up the “Loss Categories” that apply to Completion Fluids operations. Since loss categories have already been assigned by the mud engineer, it is necessary for the Completion Fluids engineer to assign new categories for completion fluid losses. Click on the “Add” key and type in the desired loss category.

Completion Fluid Reporting Setup on an Existing Well Clicking on this button opens the screen below. Set up the “Loss Categories” that apply to Completion Fluids operations. Since loss categories have already been assigned by the mud engineer, it is necessary for the Completion Fluids engineer to assign new categories for completion fluid losses. Click on the “Add” key and type in the desired loss category.

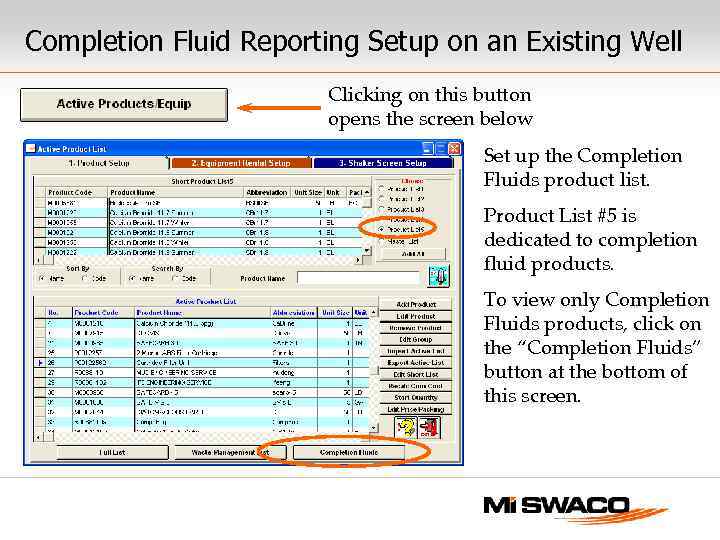

Completion Fluid Reporting Setup on an Existing Well Clicking on this button opens the screen below Set up the Completion Fluids product list. Product List #5 is dedicated to completion fluid products. To view only Completion Fluids products, click on the “Completion Fluids” button at the bottom of this screen.

Completion Fluid Reporting Setup on an Existing Well Clicking on this button opens the screen below Set up the Completion Fluids product list. Product List #5 is dedicated to completion fluid products. To view only Completion Fluids products, click on the “Completion Fluids” button at the bottom of this screen.

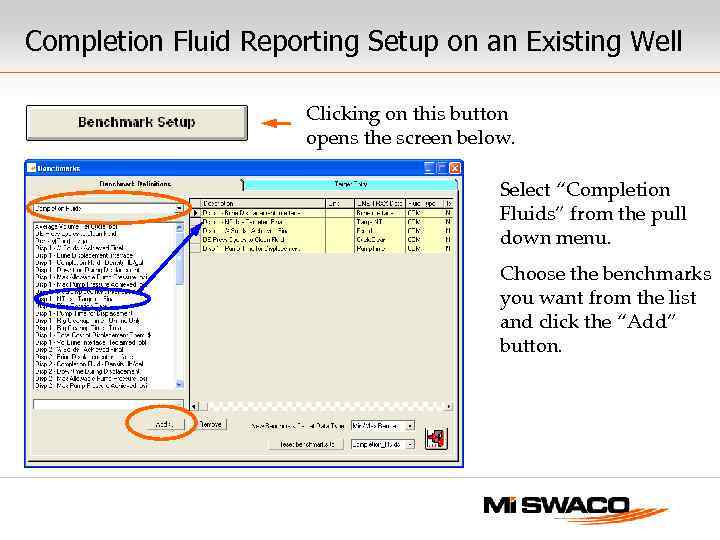

Completion Fluid Reporting Setup on an Existing Well Clicking on this button opens the screen below. Select “Completion Fluids” from the pull down menu. Choose the benchmarks you want from the list and click the “Add” button.

Completion Fluid Reporting Setup on an Existing Well Clicking on this button opens the screen below. Select “Completion Fluids” from the pull down menu. Choose the benchmarks you want from the list and click the “Add” button.

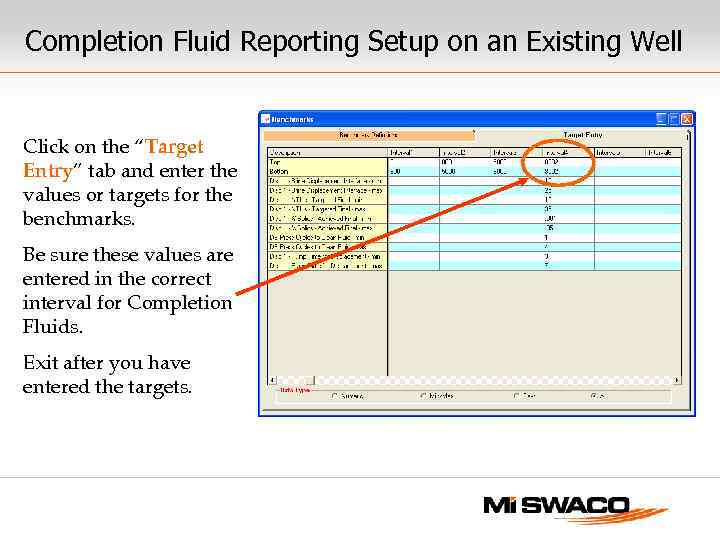

Completion Fluid Reporting Setup on an Existing Well Click on the “Target Entry” tab and enter the values or targets for the benchmarks. Be sure these values are entered in the correct interval for Completion Fluids. Exit after you have entered the targets.

Completion Fluid Reporting Setup on an Existing Well Click on the “Target Entry” tab and enter the values or targets for the benchmarks. Be sure these values are entered in the correct interval for Completion Fluids. Exit after you have entered the targets.

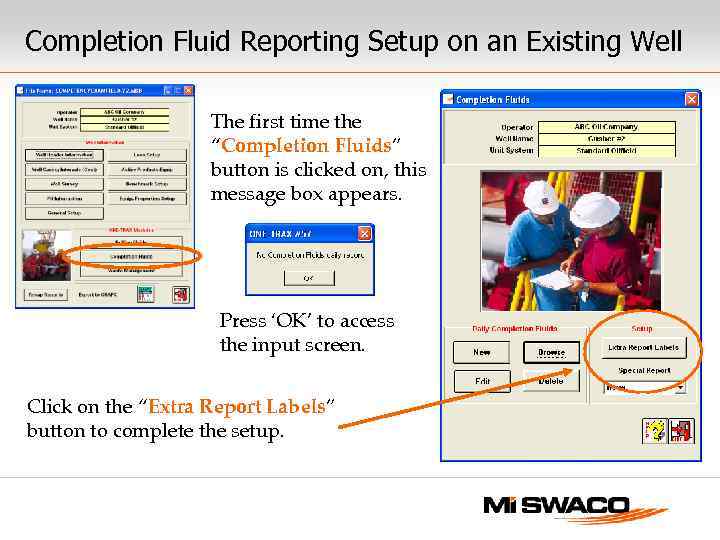

Completion Fluid Reporting Setup on an Existing Well The first time the “Completion Fluids” button is clicked on, this message box appears. Press ‘OK’ to access the input screen. Click on the “Extra Report Labels” button to complete the setup.

Completion Fluid Reporting Setup on an Existing Well The first time the “Completion Fluids” button is clicked on, this message box appears. Press ‘OK’ to access the input screen. Click on the “Extra Report Labels” button to complete the setup.

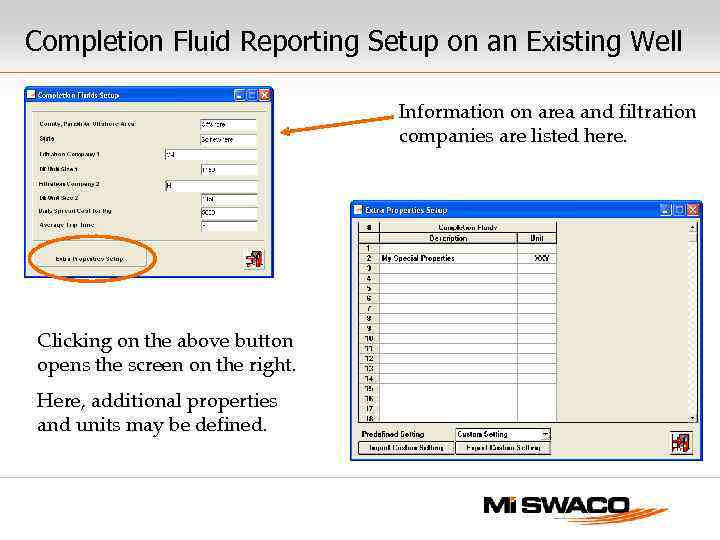

Completion Fluid Reporting Setup on an Existing Well Information on area and filtration companies are listed here. Clicking on the above button opens the screen on the right. Here, additional properties and units may be defined.

Completion Fluid Reporting Setup on an Existing Well Information on area and filtration companies are listed here. Clicking on the above button opens the screen on the right. Here, additional properties and units may be defined.

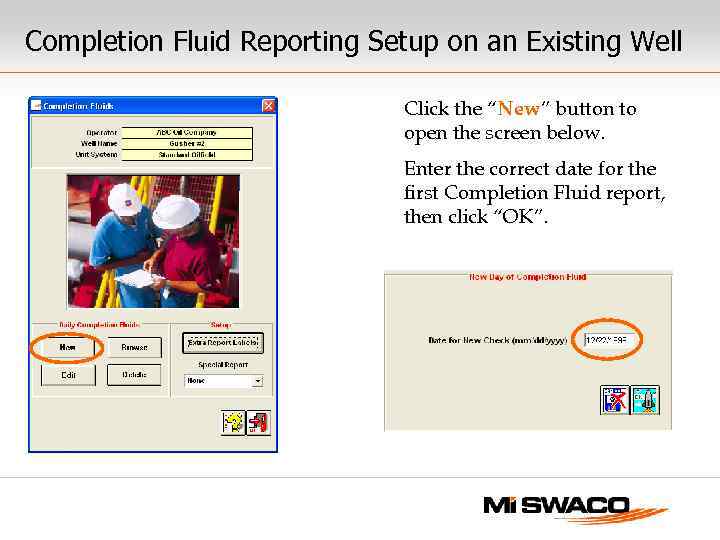

Completion Fluid Reporting Setup on an Existing Well Click the “New” button to open the screen below. Enter the correct date for the first Completion Fluid report, then click “OK”.

Completion Fluid Reporting Setup on an Existing Well Click the “New” button to open the screen below. Enter the correct date for the first Completion Fluid report, then click “OK”.

Completion Fluid Reporting Setup on an Existing Well When you click “OK”, the screen on the left will appear. For the first Completion Fluid report, you may select “No” to enter data. Or, you can select “Yes” and change the existing data as needed. Once you have the correct information entered for the Completion Fluids operation, you may choose “Yes” when prompted and the information will carry over from the previous report.

Completion Fluid Reporting Setup on an Existing Well When you click “OK”, the screen on the left will appear. For the first Completion Fluid report, you may select “No” to enter data. Or, you can select “Yes” and change the existing data as needed. Once you have the correct information entered for the Completion Fluids operation, you may choose “Yes” when prompted and the information will carry over from the previous report.

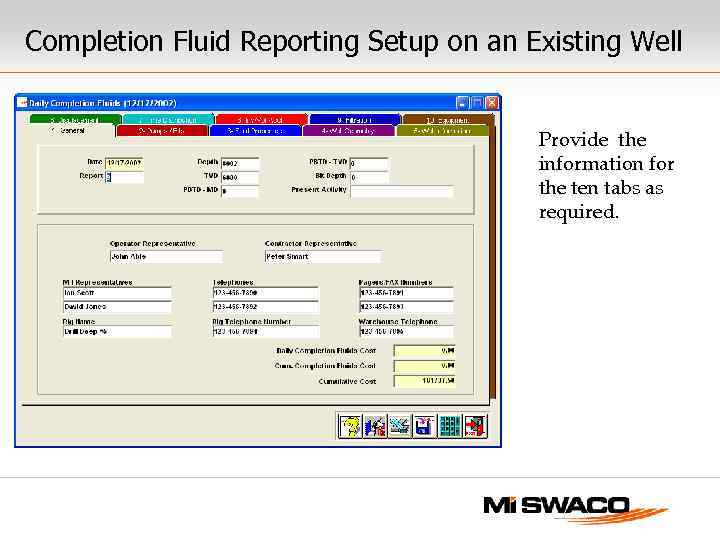

Completion Fluid Reporting Setup on an Existing Well Provide the information for the ten tabs as required.

Completion Fluid Reporting Setup on an Existing Well Provide the information for the ten tabs as required.