6aa684b6141f85529e555f3aedb57439.ppt

- Количество слайдов: 33

One Controller - Any Bus Connecting Programmable Automation Controllers , Measurements, Sensors, Networks and PLCs Ian Bell National Instruments

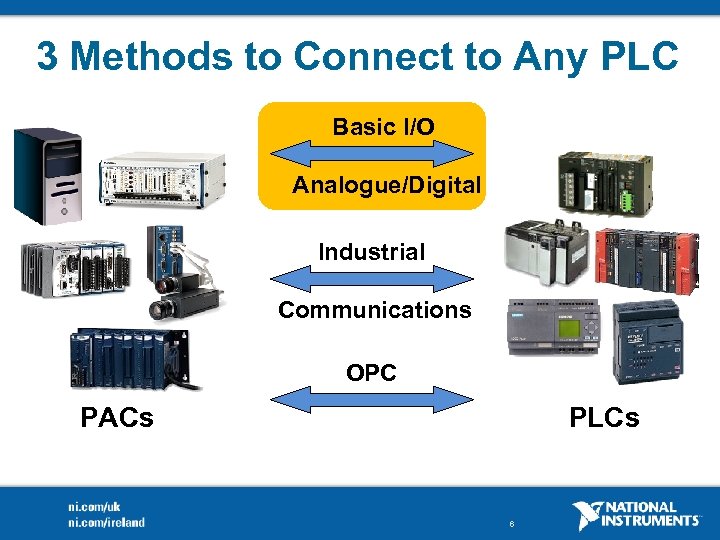

Agenda • Industrial Communications Overview • Why Connect a PAC to Industrial Networks and PLCs? • 3 Methods to Connect to Any PLC or Device Basic Analogue and Digital I/O § Industrial Network Communication § OPC § 2

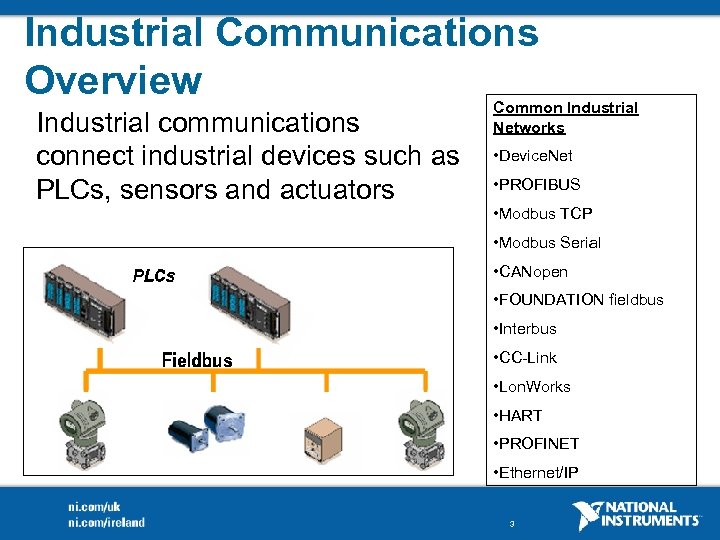

Industrial Communications Overview Industrial communications connect industrial devices such as PLCs, sensors and actuators Common Industrial Networks • Device. Net • PROFIBUS • Modbus TCP • Modbus Serial • CANopen • FOUNDATION fieldbus • Interbus • CC-Link • Lon. Works • HART • PROFINET • Ethernet/IP 3

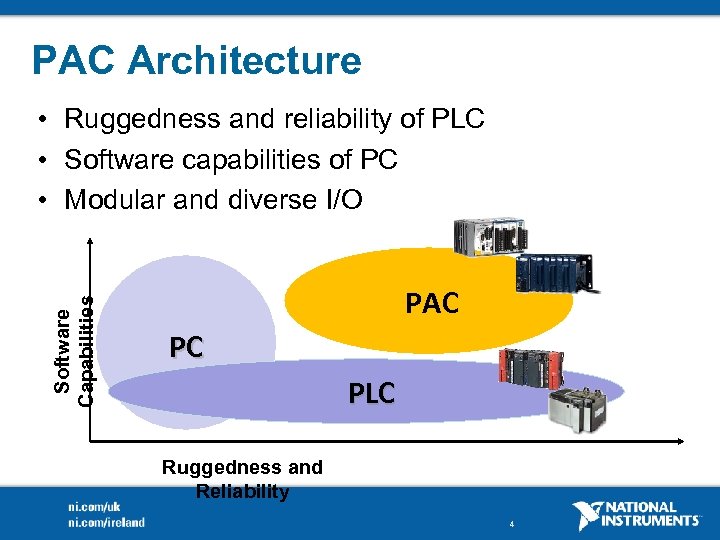

PAC Architecture Software Capabilities • Ruggedness and reliability of PLC • Software capabilities of PC • Modular and diverse I/O PAC PC PL C Ruggedness and Reliability 4

Why Connect PACs to Industrial Networks and PLCs? High-speed analogue measurements § High-resolution analogue measurements § Advanced analysis (digital filtering, frequency analysis) § Custom hardware performance with FPGA technology § • High-speed closed-loop control • FPGA-based processing and analysis § Custom Sensors/Measurements 5

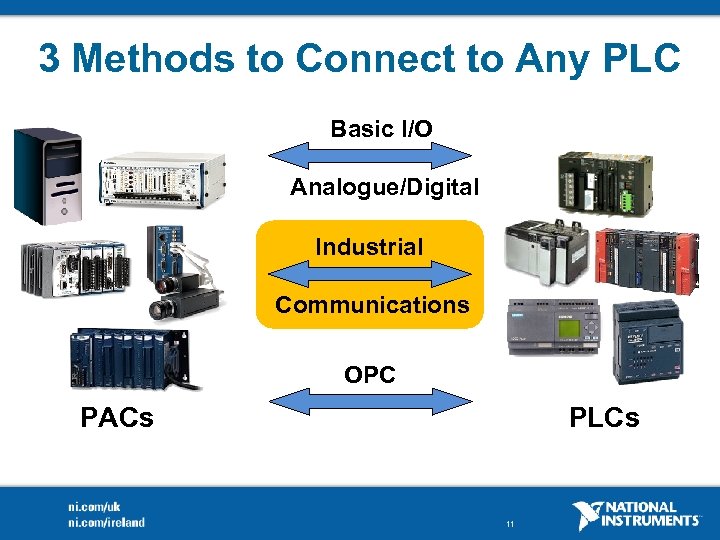

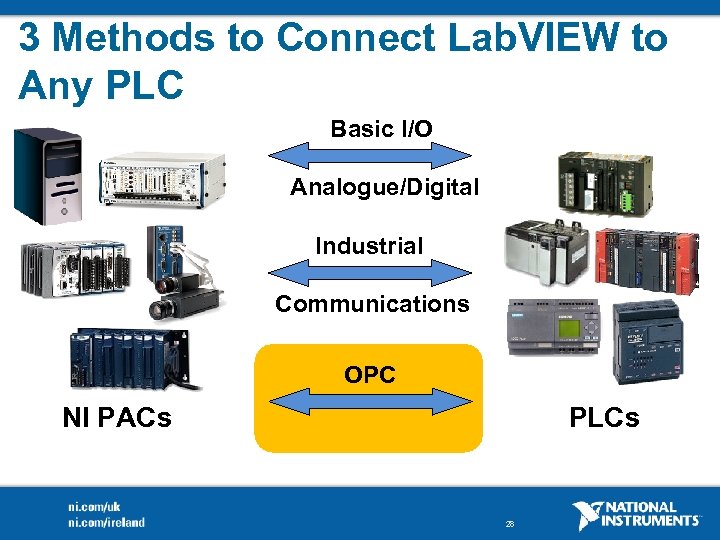

3 Methods to Connect to Any PLC Basic I/O Analogue/Digital Industrial Communications OPC PACs PLCs 6

Basic I/O Cheap, Easy, Fast and Effective • Available on every platform • Analog and digital I/O options • PLC users can easily integrate analogue and digital I/O into their code • Allows PACs to act as intelligent devices 7

Basic I/O • Advantages § Fast, deterministic, little or no software overhead • Considerations Doesn’t scale well § Point-to-point wiring (parallel) § Can’t communicate lots of data § 8

Example Automated Filling of Aerosol Cans • Existing PLC system was being used to automate the filling of aerosol cans • PLC did not have the capability to do high-speed analogue for pressure measurements • NI Compact. RIO PAC was used for high-speed pressure measurements on 8 channels (2 k per channel) • Compact. RIO and PLC were integrated using digital I/O 9

10

3 Methods to Connect to Any PLC Basic I/O Analogue/Digital Industrial Communications OPC PACs PLCs 11

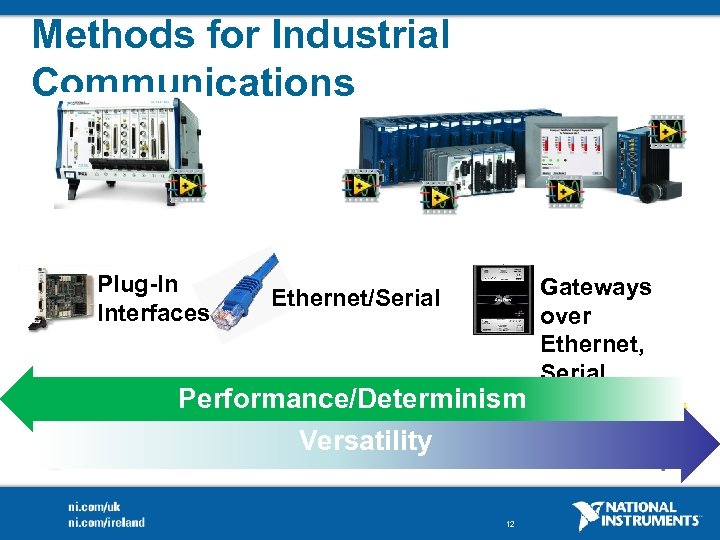

Methods for Industrial Communications Plug-In Interfaces Ethernet/Serial Performance/Determinism Versatility 12 Gateways over Ethernet, Serial

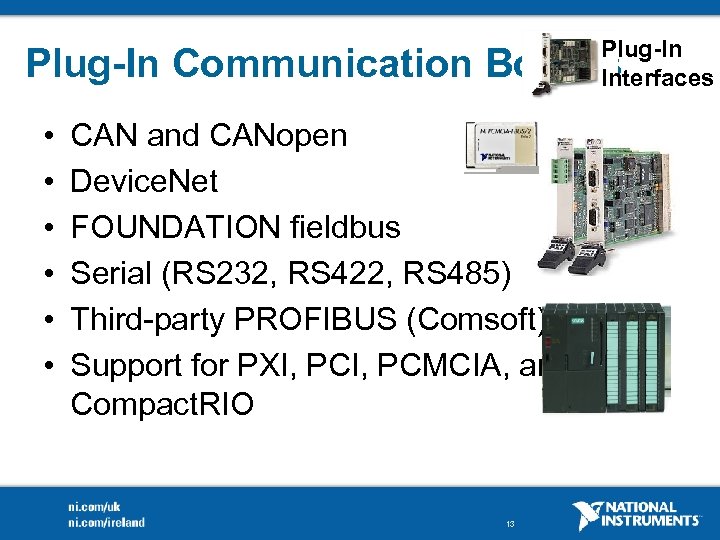

Plug-In Interfaces Plug-In Communication Boards • • • CAN and CANopen Device. Net FOUNDATION fieldbus Serial (RS 232, RS 422, RS 485) Third-party PROFIBUS (Comsoft) Support for PXI, PCMCIA, and Compact. RIO 13

Plug-In Interfaces Plug-In Communication Boards • Advantages Direct, deterministic communication with the processor § Timing and synchronisation with other I/O (DAQ) § High-level API support for Lab. VIEW and other programming languages § • Considerations Many smaller buses and protocols are not supported § Many only available on PC and PXI (real-time supported) § 14

Example : PROFIBUS • PROFIBUS master/slave for PXI and PCI • More than 2 million nodes • Popular in Europe and Asia • Recommended: Comsoft DF PROFI II interfaces 15

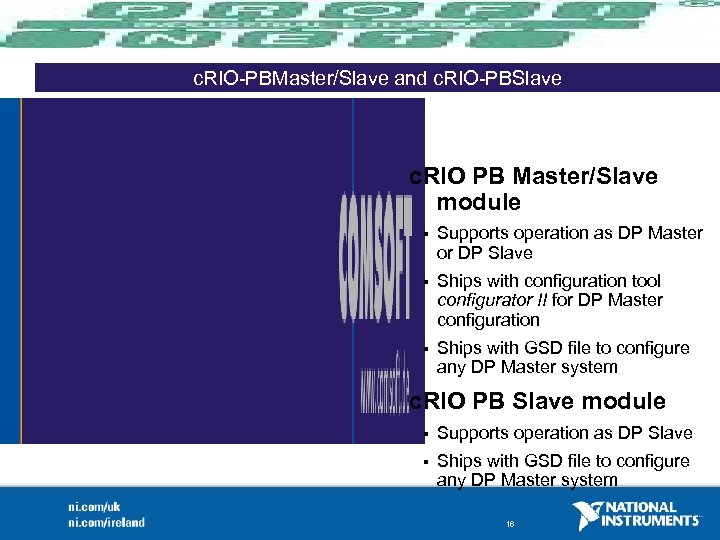

c. RIO-PBMaster/Slave and c. RIO-PBSlave c. RIO PB Master/Slave module § Supports operation as DP Master or DP Slave § Ships with configuration tool configurator II for DP Master configuration § Ships with GSD file to configure any DP Master system c. RIO PB Slave module § Supports operation as DP Slave § Ships with GSD file to configure any DP Master system 16

Ethernet-based Industrial Protocols • • Modbus TCP/IP Ethernet/IP Ether. CAT Profinet 17

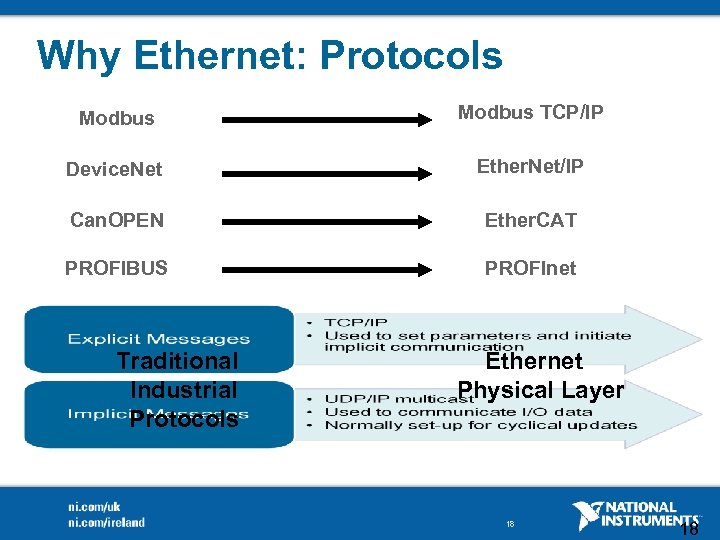

Why Ethernet: Protocols Modbus TCP/IP Device. Net Ether. Net/IP Can. OPEN Ether. CAT PROFIBUS PROFInet Traditional Industrial Protocols Ethernet Physical Layer 18 18

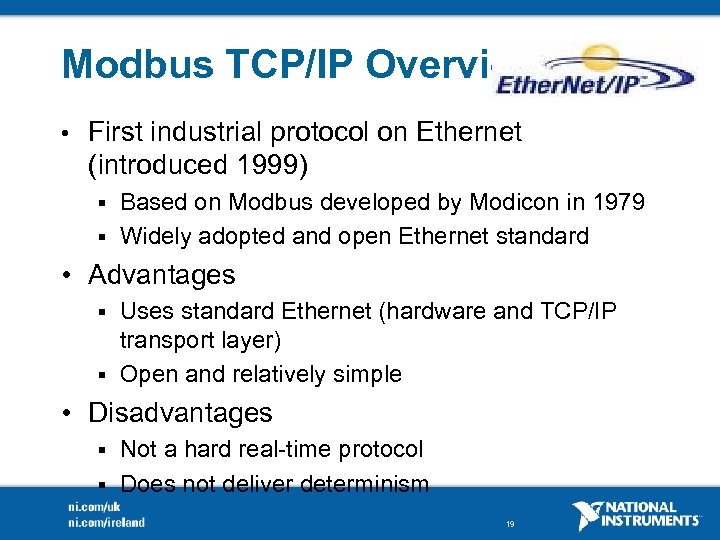

Modbus TCP/IP Overview • First industrial protocol on Ethernet (introduced 1999) Based on Modbus developed by Modicon in 1979 § Widely adopted and open Ethernet standard § • Advantages Uses standard Ethernet (hardware and TCP/IP transport layer) § Open and relatively simple § • Disadvantages Not a hard real-time protocol § Does not deliver determinism § 19

Ethernet-based Industrial Protocols • • Modbus TCP/IP Ethernet/IP Ether. CAT Profinet 20

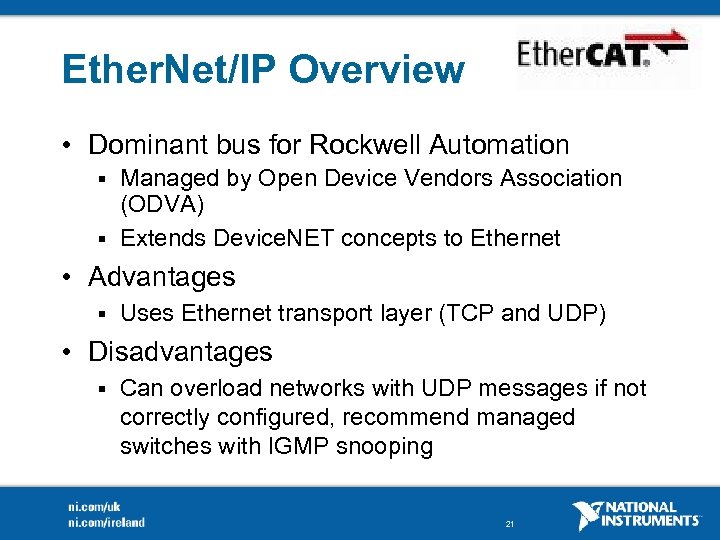

Ether. Net/IP Overview • Dominant bus for Rockwell Automation Managed by Open Device Vendors Association (ODVA) § Extends Device. NET concepts to Ethernet § • Advantages § Uses Ethernet transport layer (TCP and UDP) • Disadvantages § Can overload networks with UDP messages if not correctly configured, recommend managed switches with IGMP snooping 21

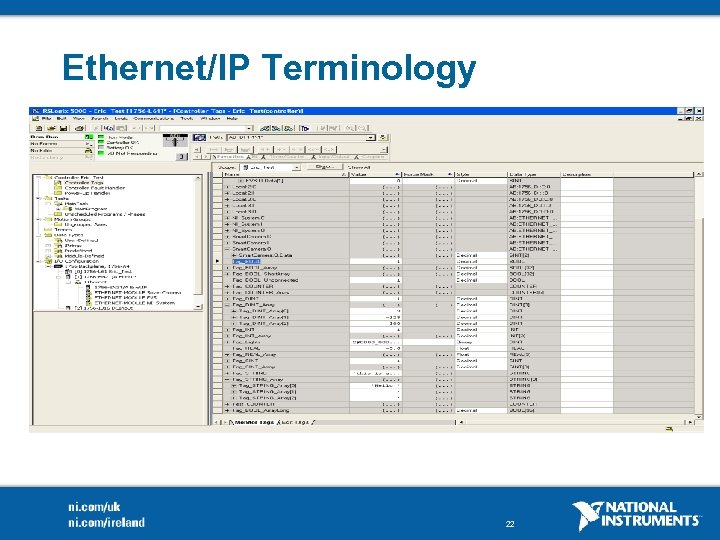

Ethernet/IP Terminology 22

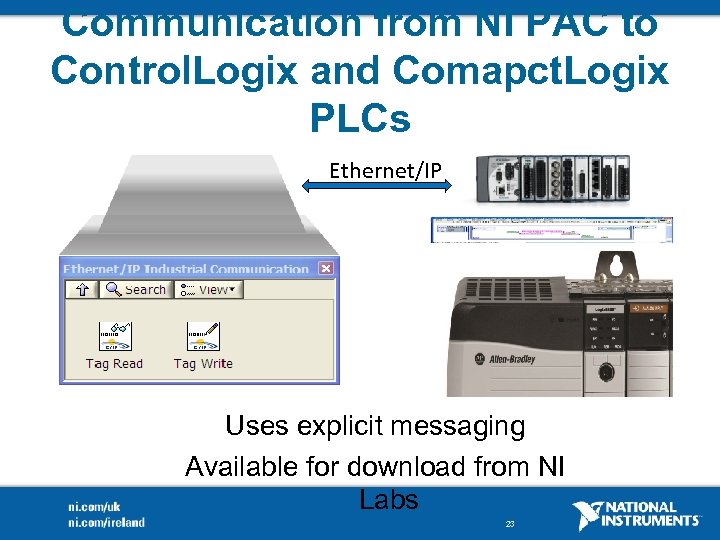

Communication from NI PAC to Control. Logix and Comapct. Logix PLCs Ethernet/IP Uses explicit messaging Available for download from NI Labs 23

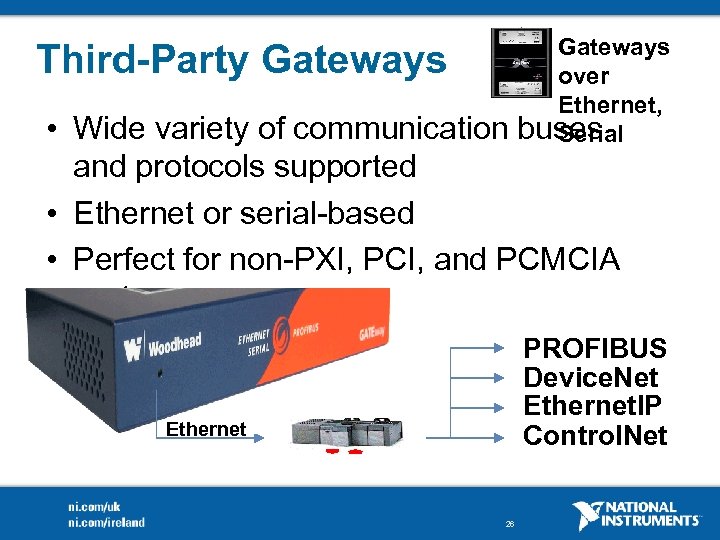

Gateways over Ethernet, buses Serial Third-Party Gateways • Wide variety of communication and protocols supported • Ethernet or serial-based • Perfect for non-PXI, PCI, and PCMCIA systems PROFIBUS Device. Net Ethernet. IP Control. Net Ethernet 26

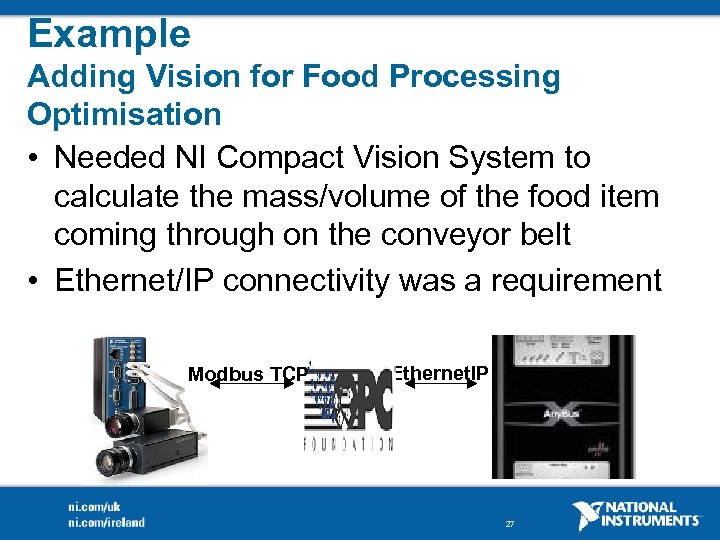

Example Adding Vision for Food Processing Optimisation • Needed NI Compact Vision System to calculate the mass/volume of the food item coming through on the conveyor belt • Ethernet/IP connectivity was a requirement Modbus TCP Ethernet. IP 27

3 Methods to Connect Lab. VIEW to Any PLC Basic I/O Analogue/Digital Industrial Communications OPC NI PACs PLCs 28

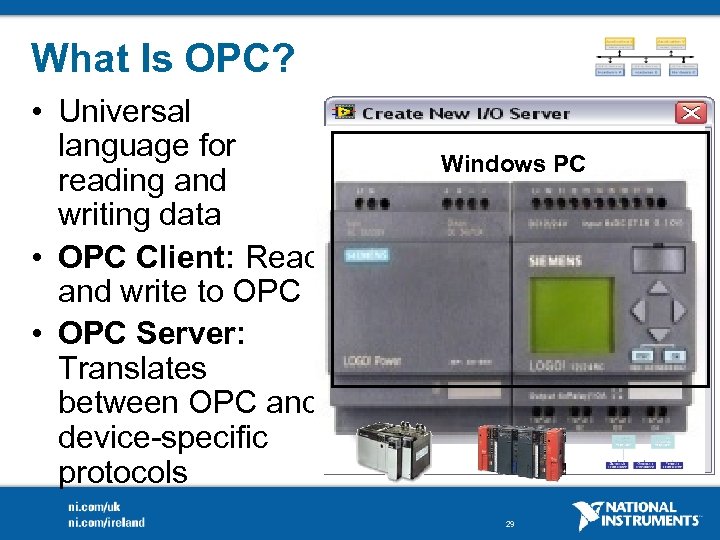

What Is OPC? • Universal language for reading and writing data • OPC Client: Read and write to OPC • OPC Server: Translates between OPC and device-specific protocols Windows PC English 29

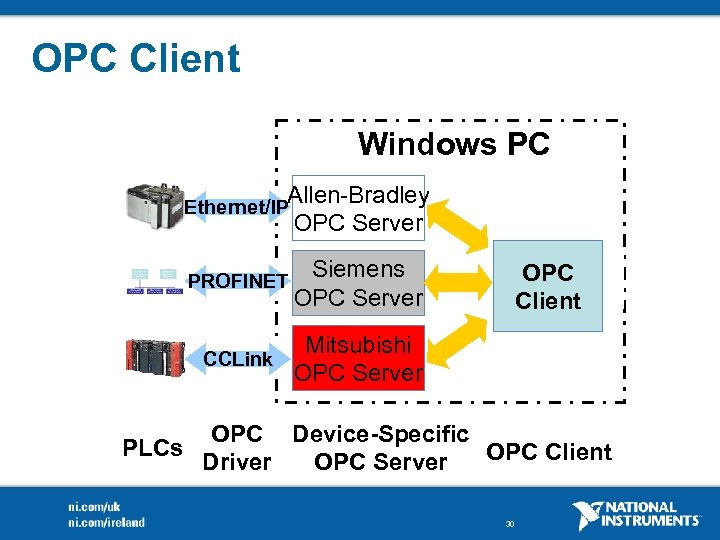

OPC Client Windows PC Allen-Bradley OPC Server Ethernet/IP PROFINET CCLink PLCs Siemens OPC Server Mitsubishi OPC Server OPC Client OPC Device-Specific OPC Client Driver OPC Server 30

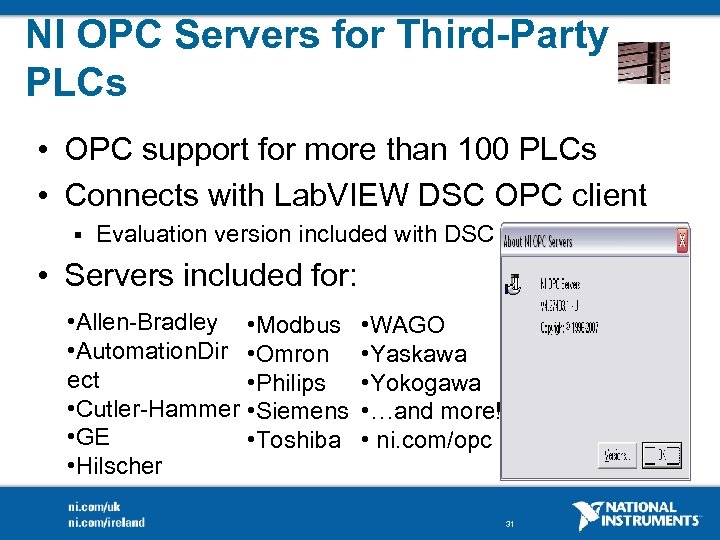

NI OPC Servers for Third-Party PLCs • OPC support for more than 100 PLCs • Connects with Lab. VIEW DSC OPC client § Evaluation version included with DSC • Servers included for: • Allen-Bradley • Automation. Dir ect • Cutler-Hammer • GE • Hilscher • Modbus • Omron • Philips • Siemens • Toshiba • WAGO • Yaskawa • Yokogawa • …and more! • ni. com/opc 31

OPC • Advantages Most universal § Least device-dependent § Ideal for HMI and SCADA applications § • Considerations Slower, not deterministic, single-point only § Can require PC-based OPC servers § Not for safety or critical communications § 32

ABCO Adds Lab. VIEW to PLC System “The ease by which NI can • ABS brake testing system to the Allen-Bradley speak hardware saved me valuable • PXI for high-speed encoder on this delivery-critical job. ” time -Arif Bustani, electrical engineer measurements ABCO • Added to existing Allen. Bradley PLC assembly line • OPC used for communication between PXI and Allen. Bradley PLCs 33

Summary • PACs add flexibility to connect to anything • Use PACs to add any measurements to existing system • 3 Methods to Connect PAC to Any PLC: Basic Analogue and Digital I/O § Native Industrial Communications § OPC § 34

Online Resources ni. com/comm ni. com/pac ni. com/labs www. modbus. org – Modbus TCP/IP www. odva. org – Ethernet/IP www. ethercat. org – Ether. CAT www. profibus. com/pn - PROFINET 35

6aa684b6141f85529e555f3aedb57439.ppt