71025a034aa613e54ee0e1fcf508570d.ppt

- Количество слайдов: 12

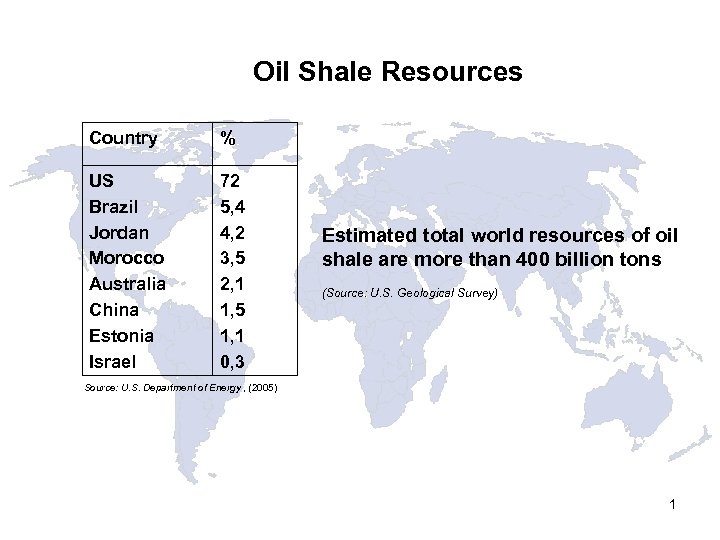

Oil Shale Resources Country % US Brazil Jordan Morocco Australia China Estonia Israel 72 5, 4 4, 2 3, 5 2, 1 1, 5 1, 1 0, 3 Estimated total world resources of oil shale are more than 400 billion tons (Source: U. S. Geological Survey) Source: U. S. Department of Energy , (2005) 1

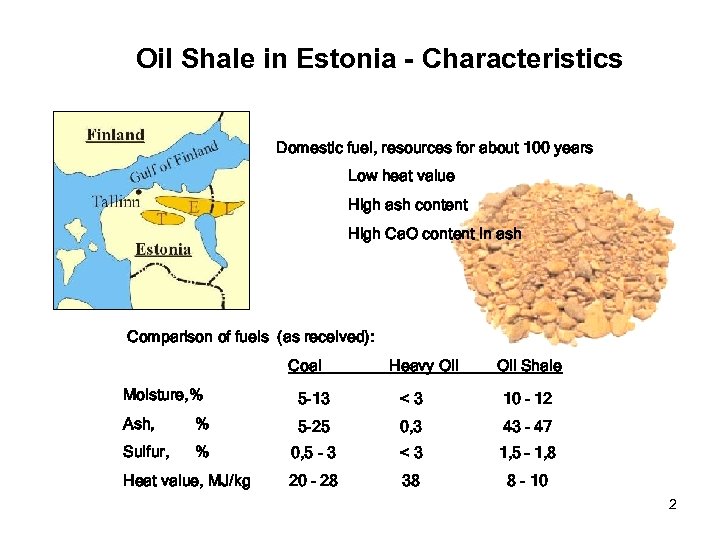

Oil Shale in Estonia - Characteristics Domestic fuel, resources for about 100 years Low heat value High ash content High Ca. O content in ash Comparison of fuels (as received): Coal Heavy Oil Shale Moisture, % 5 -13 <3 10 - 12 Ash, % 5 -25 0, 3 43 - 47 Sulfur, % 0, 5 - 3 <3 1, 5 – 1, 8 20 - 28 38 8 - 10 Heat value, MJ/kg 2

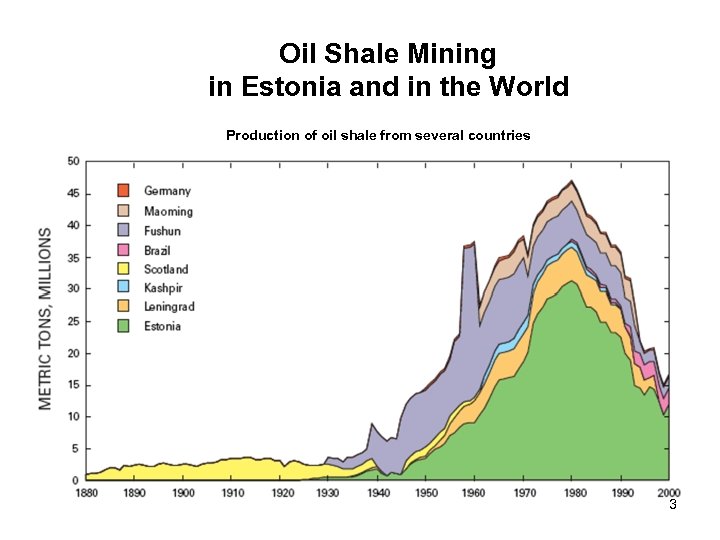

Oil Shale Mining in Estonia and in the World Production of oil shale from several countries 3

MAP OF ESTONIA AS Narva Elektrijaamad 4

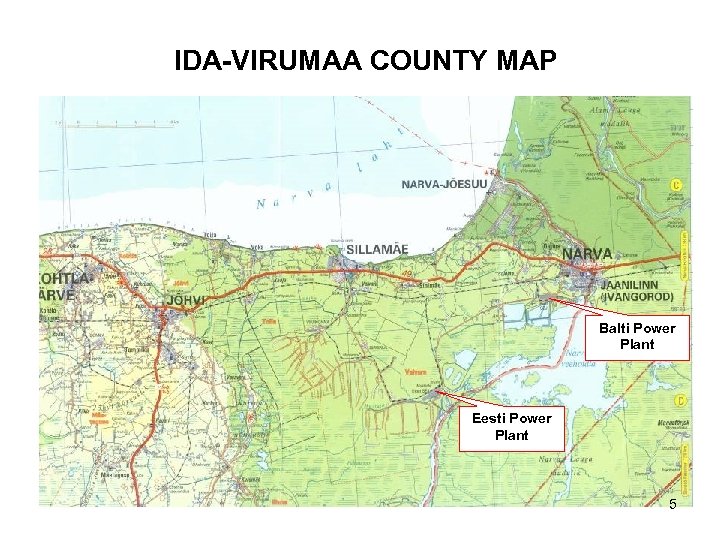

IDA-VIRUMAA COUNTY MAP Balti Power Plant Eesti Power Plant 5

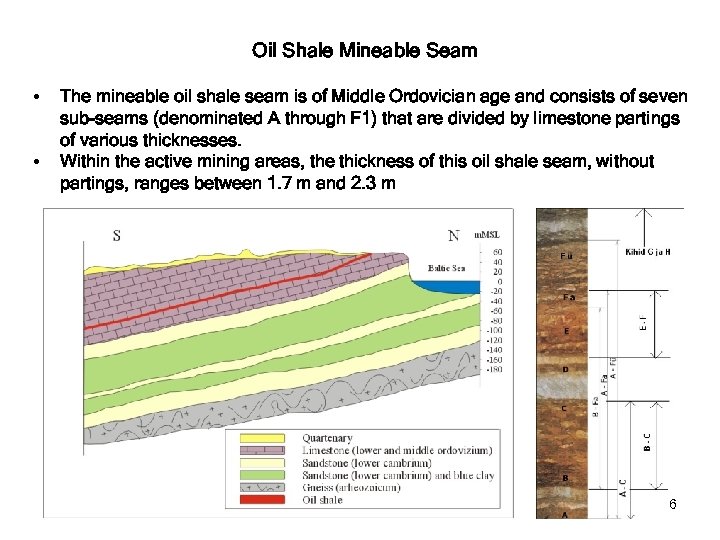

Oil Shale Mineable Seam • • The mineable oil shale seam is of Middle Ordovician age and consists of seven sub-seams (denominated A through F 1) that are divided by limestone partings of various thicknesses. Within the active mining areas, the thickness of this oil shale seam, without partings, ranges between 1. 7 m and 2. 3 m 6

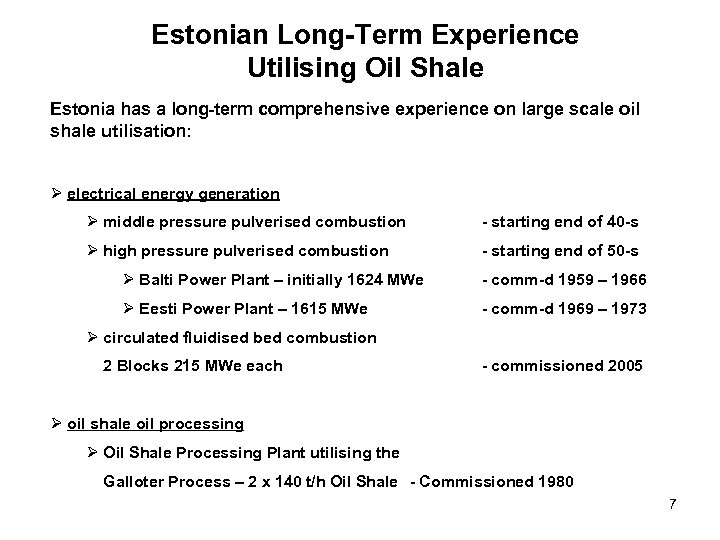

Estonian Long-Term Experience Utilising Oil Shale Estonia has a long-term comprehensive experience on large scale oil shale utilisation: Ø electrical energy generation Ø middle pressure pulverised combustion - starting end of 40 -s Ø high pressure pulverised combustion - starting end of 50 -s Ø Balti Power Plant – initially 1624 MWe - comm-d 1959 – 1966 Ø Eesti Power Plant – 1615 MWe - comm-d 1969 – 1973 Ø circulated fluidised bed combustion 2 Blocks 215 MWe each - commissioned 2005 Ø oil shale oil processing Ø Oil Shale Processing Plant utilising the Galloter Process – 2 x 140 t/h Oil Shale - Commissioned 1980 7

AS Narva Elektrijaamad part in Estonian electricity production in 2005 94% Narva Power Plants Eesti Power Plant 1615 MW Balti Power Plant 765 MW Oil Factory Balti PP 20% Iru PP Kohtla-Järve PP Eesti PP 74% Other 6% Ahtme PP Industry’s PP Renewable 8

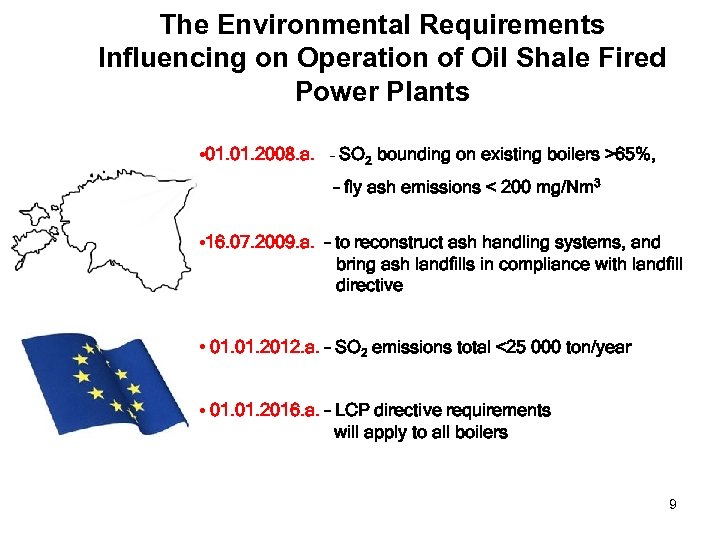

The Environmental Requirements Influencing on Operation of Oil Shale Fired Power Plants • 01. 2008. a. – SO 2 bounding on existing boilers >65%, – fly ash emissions < 200 mg/Nm 3 • 16. 07. 2009. a. – to reconstruct ash handling systems, and bring ash landfills in compliance with landfill directive • 01. 2012. a. – SO 2 emissions total <25 000 ton/year • 01. 2016. a. – LCP directive requirements will apply to all boilers 9

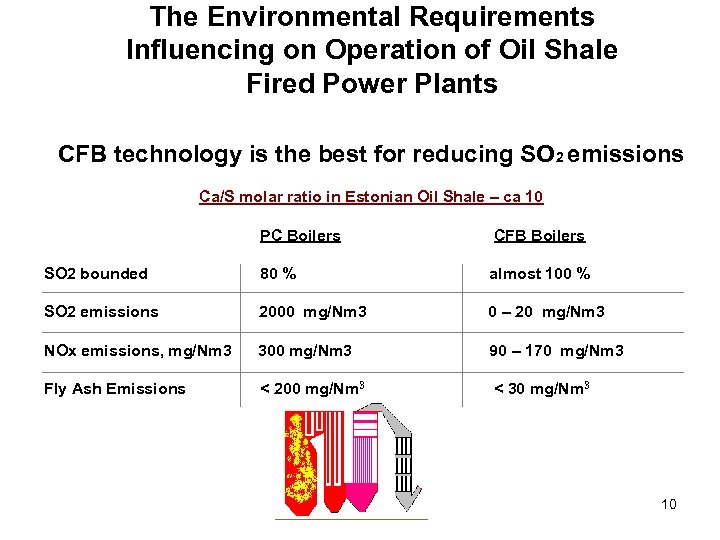

The Environmental Requirements Influencing on Operation of Oil Shale Fired Power Plants CFB technology is the best for reducing SO 2 emissions Ca/S molar ratio in Estonian Oil Shale – ca 10 PC Boilers CFB Boilers SO 2 bounded 80 % almost 100 % SO 2 emissions 2000 mg/Nm 3 0 – 20 mg/Nm 3 NOx emissions, mg/Nm 3 300 mg/Nm 3 90 – 170 mg/Nm 3 Fly Ash Emissions < 200 mg/Nm 3 < 30 mg/Nm 3 10

FWE CFB-Combustion System for Oil Shale Net Heat to Steam With oil shale 247 MWth With shale oil 112, 5 MWth Main Steam 90 kg/s l 535’C l 12. 7 MPa Hot Reheat 77 kg/s l 535’C l 2. 4 MPa Steam Drum 13. 3 MPa NET EFFICIENCY ~37% 11

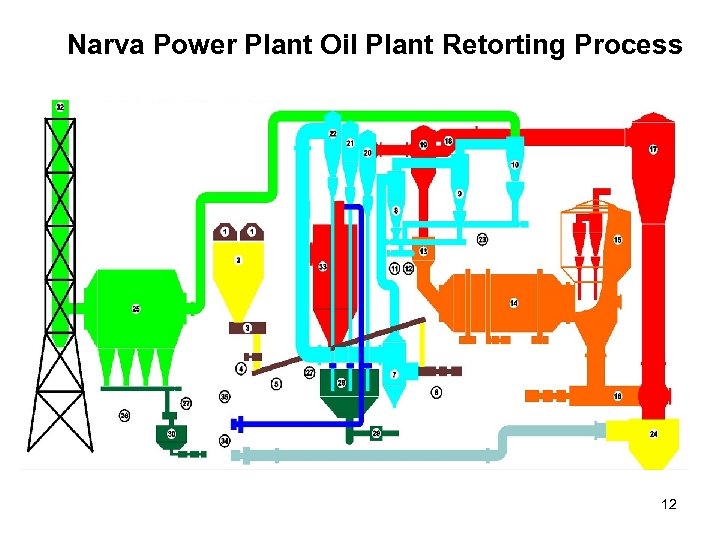

Narva Power Plant Oil Plant Retorting Process 12

71025a034aa613e54ee0e1fcf508570d.ppt