ca6dab57f022a8c612d51daec1ebb3c9.ppt

- Количество слайдов: 20

Off-Grid Power Using Enphase Micro-Inverters • Off-grid inverter systems, using batteries, can be used to provide AC power when the grid is down. It is possible to use Enphase Micro-Inverters to charge batteries for an off-grid inverter system using a process called AC coupling

Off-Grid Power Using Enphase Micro-Inverters • Off-grid inverter systems, using batteries, can be used to provide AC power when the grid is down. It is possible to use Enphase Micro-Inverters to charge batteries for an off-grid inverter system using a process called AC coupling

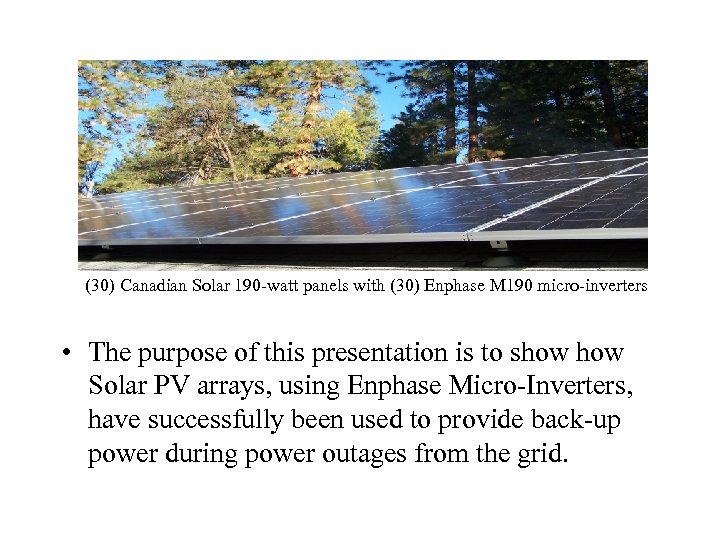

(30) Canadian Solar 190 -watt panels with (30) Enphase M 190 micro-inverters • The purpose of this presentation is to show Solar PV arrays, using Enphase Micro-Inverters, have successfully been used to provide back-up power during power outages from the grid.

(30) Canadian Solar 190 -watt panels with (30) Enphase M 190 micro-inverters • The purpose of this presentation is to show Solar PV arrays, using Enphase Micro-Inverters, have successfully been used to provide back-up power during power outages from the grid.

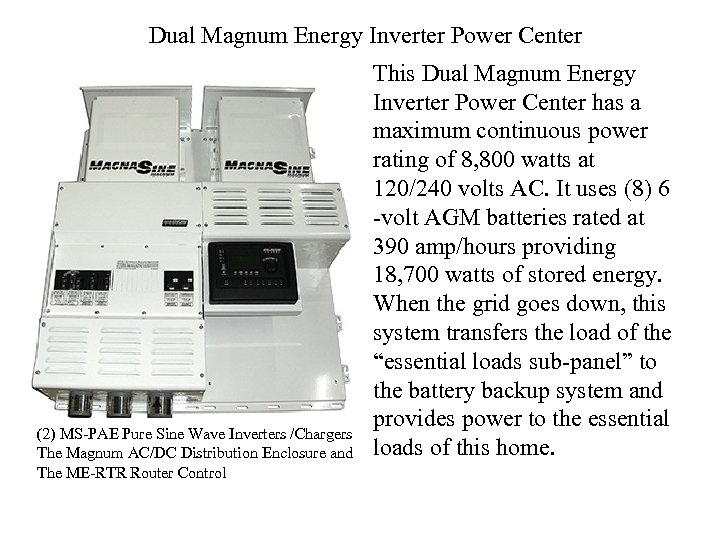

Dual Magnum Energy Inverter Power Center (2) MS-PAE Pure Sine Wave Inverters /Chargers The Magnum AC/DC Distribution Enclosure and The ME-RTR Router Control This Dual Magnum Energy Inverter Power Center has a maximum continuous power rating of 8, 800 watts at 120/240 volts AC. It uses (8) 6 -volt AGM batteries rated at 390 amp/hours providing 18, 700 watts of stored energy. When the grid goes down, this system transfers the load of the “essential loads sub-panel” to the battery backup system and provides power to the essential loads of this home.

Dual Magnum Energy Inverter Power Center (2) MS-PAE Pure Sine Wave Inverters /Chargers The Magnum AC/DC Distribution Enclosure and The ME-RTR Router Control This Dual Magnum Energy Inverter Power Center has a maximum continuous power rating of 8, 800 watts at 120/240 volts AC. It uses (8) 6 -volt AGM batteries rated at 390 amp/hours providing 18, 700 watts of stored energy. When the grid goes down, this system transfers the load of the “essential loads sub-panel” to the battery backup system and provides power to the essential loads of this home.

Magnum Energy Off-Grid System Advantage There are four major manufacturers of off-grid systems that can also be used with grid-tied systems. 1) 2) 3) 4) SMA – Sunny Boy Outback Power Xantrex/Schneider Electric Magnum Energy Only Magnum Energy does not manufacture “proprietary” grid-tied inverters to be used with their systems. Enphase grid-tied microinverters have a unique advantage over other grid-tied systems, when using off-grid inverters (see next page). Magnum Energy battery backed-up systems, are designed so that they can be used with Enphase micro-inverters.

Magnum Energy Off-Grid System Advantage There are four major manufacturers of off-grid systems that can also be used with grid-tied systems. 1) 2) 3) 4) SMA – Sunny Boy Outback Power Xantrex/Schneider Electric Magnum Energy Only Magnum Energy does not manufacture “proprietary” grid-tied inverters to be used with their systems. Enphase grid-tied microinverters have a unique advantage over other grid-tied systems, when using off-grid inverters (see next page). Magnum Energy battery backed-up systems, are designed so that they can be used with Enphase micro-inverters.

Enphase/Magnum Advantage Grid-tied systems are designed to always have the grid present to use any excess power that is generated by the array. If excess power is being generated, it must be used. With grid-tied, battery backed systems, the power generated from the array can only be used to charge batteries or operate loads in the house. With Enphase micro-inverter systems it is possible to vary the power production of the grid-tied systems by shutting off some of the inverters, as house loads and charging loads in the system change. With string inverters, there is full power or no power. With Enphase micro-inverters, it is possible to vary the power from the array to meet the ever changing needs of the battery based backup system (the details of this topic will be addressed later).

Enphase/Magnum Advantage Grid-tied systems are designed to always have the grid present to use any excess power that is generated by the array. If excess power is being generated, it must be used. With grid-tied, battery backed systems, the power generated from the array can only be used to charge batteries or operate loads in the house. With Enphase micro-inverter systems it is possible to vary the power production of the grid-tied systems by shutting off some of the inverters, as house loads and charging loads in the system change. With string inverters, there is full power or no power. With Enphase micro-inverters, it is possible to vary the power from the array to meet the ever changing needs of the battery based backup system (the details of this topic will be addressed later).

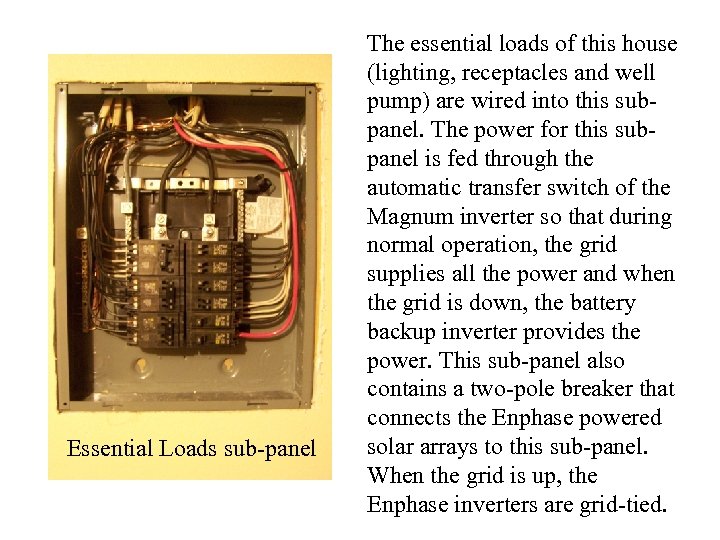

Essential Loads sub-panel The essential loads of this house (lighting, receptacles and well pump) are wired into this subpanel. The power for this subpanel is fed through the automatic transfer switch of the Magnum inverter so that during normal operation, the grid supplies all the power and when the grid is down, the battery backup inverter provides the power. This sub-panel also contains a two-pole breaker that connects the Enphase powered solar arrays to this sub-panel. When the grid is up, the Enphase inverters are grid-tied.

Essential Loads sub-panel The essential loads of this house (lighting, receptacles and well pump) are wired into this subpanel. The power for this subpanel is fed through the automatic transfer switch of the Magnum inverter so that during normal operation, the grid supplies all the power and when the grid is down, the battery backup inverter provides the power. This sub-panel also contains a two-pole breaker that connects the Enphase powered solar arrays to this sub-panel. When the grid is up, the Enphase inverters are grid-tied.

Local Mini-Grid When the grid is down, the Magnum Power System provides a “local mini-grid” that enables the Enphase inverters to continue to produce power from the solar arrays. This Enphase 120/240 VAC power can be used by any of the circuits in the essential loads sub-panel. Excess power from the Enphase system is fed back into the Magnum Power System and charges the batteries using a process called AC-coupling. The challenge with this kind of system, is regulating how much power the Enphase system provides so that the batteries are not over charged.

Local Mini-Grid When the grid is down, the Magnum Power System provides a “local mini-grid” that enables the Enphase inverters to continue to produce power from the solar arrays. This Enphase 120/240 VAC power can be used by any of the circuits in the essential loads sub-panel. Excess power from the Enphase system is fed back into the Magnum Power System and charges the batteries using a process called AC-coupling. The challenge with this kind of system, is regulating how much power the Enphase system provides so that the batteries are not over charged.

Frequency Shift The Magnum Power Center has a built in feature, to help protect the batteries from overcharging, when using AC-coupling. When the battery voltage rises too high, the frequency of the AC power is shifted from 60 Hz to 60. 6 Hz. Enphase inverters are programmed to shut down if the frequency rises above 60. 5 Hz. The problem with this feature is that the Enphase inverters are either all “on” or all “off”. There is no way to balance the output of the power from the Enphase inverters with the load of the “essential loads panel” and/or the need to recharge the batteries. I believe this feature, the frequency shift, works best as a “last resort” safety feature to help protect the batteries.

Frequency Shift The Magnum Power Center has a built in feature, to help protect the batteries from overcharging, when using AC-coupling. When the battery voltage rises too high, the frequency of the AC power is shifted from 60 Hz to 60. 6 Hz. Enphase inverters are programmed to shut down if the frequency rises above 60. 5 Hz. The problem with this feature is that the Enphase inverters are either all “on” or all “off”. There is no way to balance the output of the power from the Enphase inverters with the load of the “essential loads panel” and/or the need to recharge the batteries. I believe this feature, the frequency shift, works best as a “last resort” safety feature to help protect the batteries.

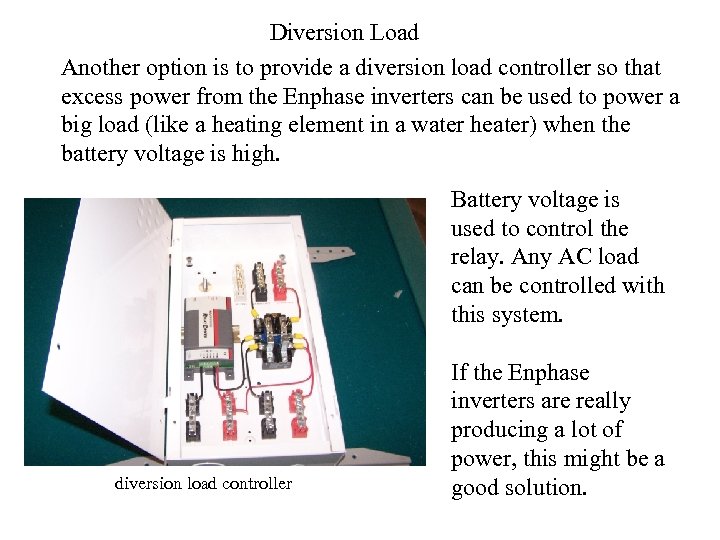

Diversion Load Another option is to provide a diversion load controller so that excess power from the Enphase inverters can be used to power a big load (like a heating element in a water heater) when the battery voltage is high. Battery voltage is used to control the relay. Any AC load can be controlled with this system. diversion load controller If the Enphase inverters are really producing a lot of power, this might be a good solution.

Diversion Load Another option is to provide a diversion load controller so that excess power from the Enphase inverters can be used to power a big load (like a heating element in a water heater) when the battery voltage is high. Battery voltage is used to control the relay. Any AC load can be controlled with this system. diversion load controller If the Enphase inverters are really producing a lot of power, this might be a good solution.

The Challenge: 1) DC voltage of the batteries varies depending on the power usage of the Magnum Power Center and the state of charge of the batteries. 1) AC power from the Enphase Inverters varies depending on the time of day, the time of the year, the weather, etc. 1) AC coupled power to each of the Magnum inverters should not exceed 3, 000 watts. Conclusion: The power output of the Enphase inverters needs to be regulated to match the needs of the battery system, using battery voltage to control the output of the Enphase inverters.

The Challenge: 1) DC voltage of the batteries varies depending on the power usage of the Magnum Power Center and the state of charge of the batteries. 1) AC power from the Enphase Inverters varies depending on the time of day, the time of the year, the weather, etc. 1) AC coupled power to each of the Magnum inverters should not exceed 3, 000 watts. Conclusion: The power output of the Enphase inverters needs to be regulated to match the needs of the battery system, using battery voltage to control the output of the Enphase inverters.

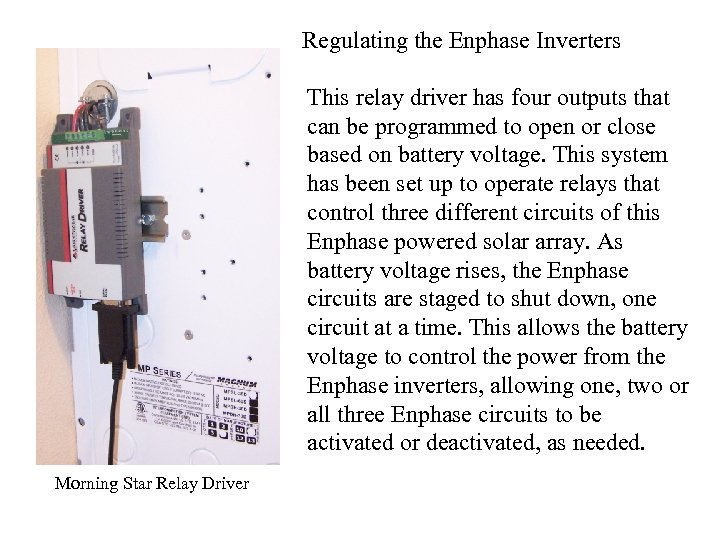

Regulating the Enphase Inverters This relay driver has four outputs that can be programmed to open or close based on battery voltage. This system has been set up to operate relays that control three different circuits of this Enphase powered solar array. As battery voltage rises, the Enphase circuits are staged to shut down, one circuit at a time. This allows the battery voltage to control the power from the Enphase inverters, allowing one, two or all three Enphase circuits to be activated or deactivated, as needed. Morning Star Relay Driver

Regulating the Enphase Inverters This relay driver has four outputs that can be programmed to open or close based on battery voltage. This system has been set up to operate relays that control three different circuits of this Enphase powered solar array. As battery voltage rises, the Enphase circuits are staged to shut down, one circuit at a time. This allows the battery voltage to control the power from the Enphase inverters, allowing one, two or all three Enphase circuits to be activated or deactivated, as needed. Morning Star Relay Driver

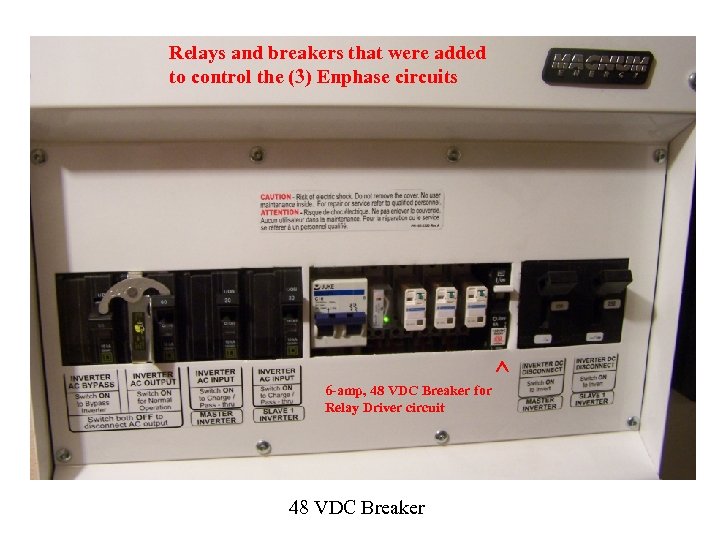

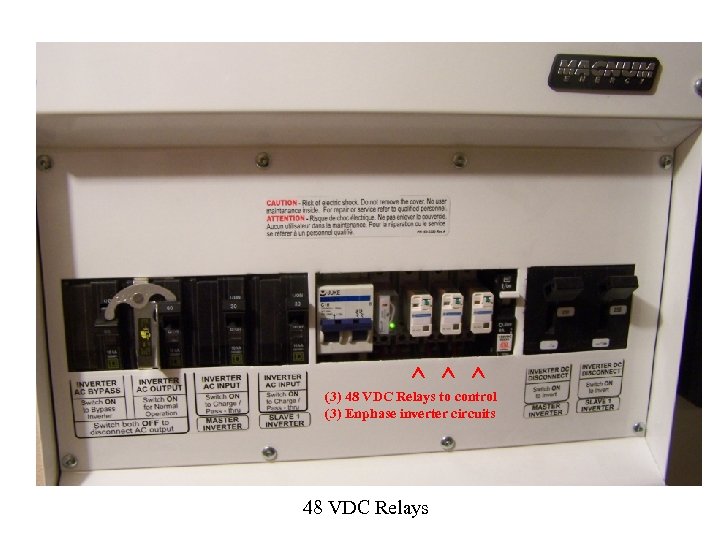

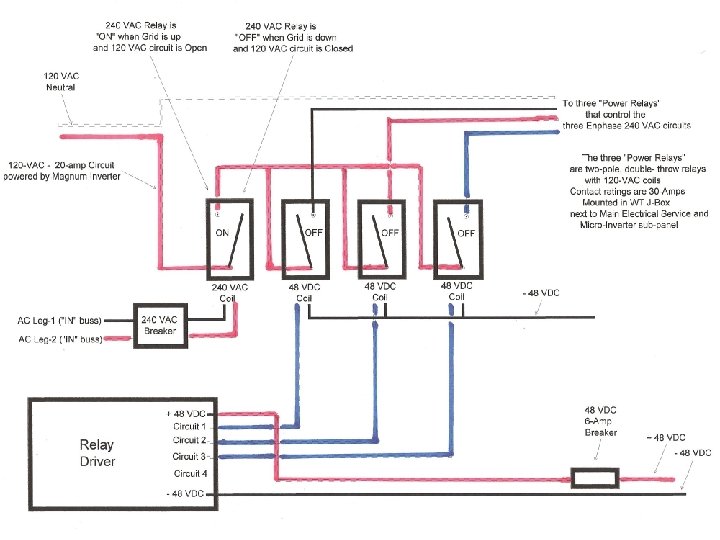

Relays and breakers that were added to control the (3) Enphase circuits 6 -amp, 48 VDC Breaker for Relay Driver circuit 48 VDC Breaker ^

Relays and breakers that were added to control the (3) Enphase circuits 6 -amp, 48 VDC Breaker for Relay Driver circuit 48 VDC Breaker ^

^^^ (3) 48 VDC Relays to control (3) Enphase inverter circuits 48 VDC Relays

^^^ (3) 48 VDC Relays to control (3) Enphase inverter circuits 48 VDC Relays

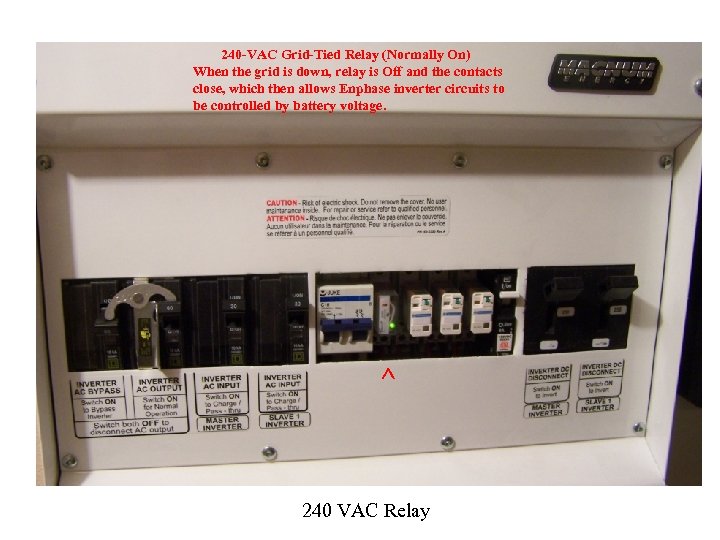

240 -VAC Grid-Tied Relay (Normally On) When the grid is down, relay is Off and the contacts close, which then allows Enphase inverter circuits to be controlled by battery voltage. ^ 240 VAC Relay

240 -VAC Grid-Tied Relay (Normally On) When the grid is down, relay is Off and the contacts close, which then allows Enphase inverter circuits to be controlled by battery voltage. ^ 240 VAC Relay

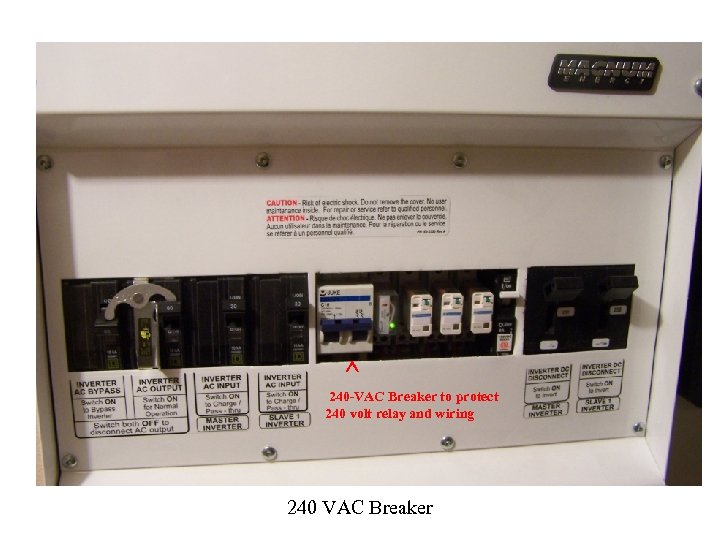

^ 240 -VAC Breaker to protect 240 volt relay and wiring 240 VAC Breaker

^ 240 -VAC Breaker to protect 240 volt relay and wiring 240 VAC Breaker

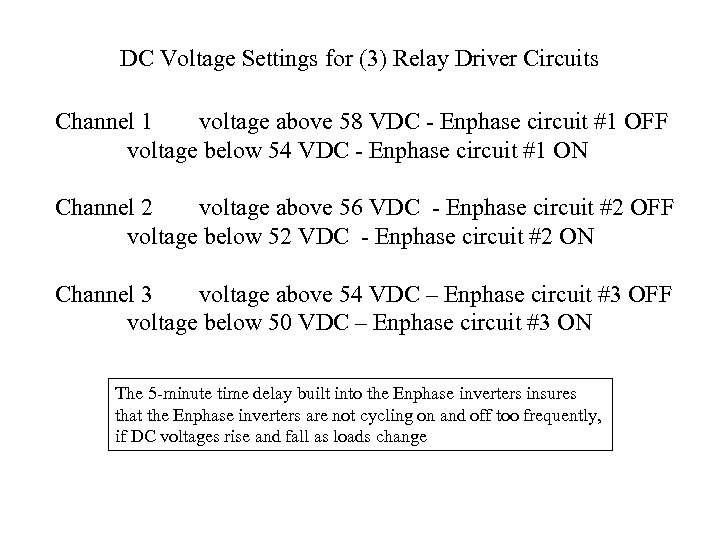

DC Voltage Settings for (3) Relay Driver Circuits Channel 1 voltage above 58 VDC - Enphase circuit #1 OFF voltage below 54 VDC - Enphase circuit #1 ON Channel 2 voltage above 56 VDC - Enphase circuit #2 OFF voltage below 52 VDC - Enphase circuit #2 ON Channel 3 voltage above 54 VDC – Enphase circuit #3 OFF voltage below 50 VDC – Enphase circuit #3 ON The 5 -minute time delay built into the Enphase inverters insures that the Enphase inverters are not cycling on and off too frequently, if DC voltages rise and fall as loads change

DC Voltage Settings for (3) Relay Driver Circuits Channel 1 voltage above 58 VDC - Enphase circuit #1 OFF voltage below 54 VDC - Enphase circuit #1 ON Channel 2 voltage above 56 VDC - Enphase circuit #2 OFF voltage below 52 VDC - Enphase circuit #2 ON Channel 3 voltage above 54 VDC – Enphase circuit #3 OFF voltage below 50 VDC – Enphase circuit #3 ON The 5 -minute time delay built into the Enphase inverters insures that the Enphase inverters are not cycling on and off too frequently, if DC voltages rise and fall as loads change

Balance of AC and DC Power If the DC voltage in the batteries is low, all three of the Enphase circuits will be activated to help handle the load of the “essential loads sub-panel” and/or to recharge the batteries. If the power from the Enphase inverters exceeds the demand from the batteries, the battery voltage will rise and start reducing the number of Enphase circuits that are needed to keep the batteries charged. If the power from the solar arrays begins to fall, battery voltage will drop and allow more Enphase circuits to be activated. This system allows the solar arrays to provide the maximum power that the battery based system can safely handle by adjusting power production of the solar arrays as the battery voltage dictates.

Balance of AC and DC Power If the DC voltage in the batteries is low, all three of the Enphase circuits will be activated to help handle the load of the “essential loads sub-panel” and/or to recharge the batteries. If the power from the Enphase inverters exceeds the demand from the batteries, the battery voltage will rise and start reducing the number of Enphase circuits that are needed to keep the batteries charged. If the power from the solar arrays begins to fall, battery voltage will drop and allow more Enphase circuits to be activated. This system allows the solar arrays to provide the maximum power that the battery based system can safely handle by adjusting power production of the solar arrays as the battery voltage dictates.

Schematic

Schematic

240 VAC Relay This installation is wired so that the relay driver is always powered by 48 VDC. The three din-rail mounted 48 VDC relays that are controlled by the relay driver are always working, controlled by the battery voltage. The 240 VAC relay controls a 120 VAC circuit that is powered by the Magnum inverter. This 120 VAC circuit is wired to the "normally open" contacts (when the grid is up) of the 240 -VAC relay. When the grid goes down, the 240 VAC relay NO-contacts closes and the 120 VAC circuit is fed to the three din-rail mounted, 48 VDC relays. This 120 VAC circuit is used to control three remote "power relays" that control three Enphase. inverter circuits. The "power relay" circuits are normally "off". The power from the Enphase inverter circuits are fed through "normally closed" contacts of these three relays. .

240 VAC Relay This installation is wired so that the relay driver is always powered by 48 VDC. The three din-rail mounted 48 VDC relays that are controlled by the relay driver are always working, controlled by the battery voltage. The 240 VAC relay controls a 120 VAC circuit that is powered by the Magnum inverter. This 120 VAC circuit is wired to the "normally open" contacts (when the grid is up) of the 240 -VAC relay. When the grid goes down, the 240 VAC relay NO-contacts closes and the 120 VAC circuit is fed to the three din-rail mounted, 48 VDC relays. This 120 VAC circuit is used to control three remote "power relays" that control three Enphase. inverter circuits. The "power relay" circuits are normally "off". The power from the Enphase inverter circuits are fed through "normally closed" contacts of these three relays. .

Power Relays These three "power relays" are double-pole, double throw relays with a 120 VAC coil. When 120 VAC is fed to the "power relays", they open the Enphase circuit that they are controlling. These three "power relays" are mounted outside, in a weather tight J-box, under the sub-panel that controls the three Enphase circuits. I designed it this way so that the 48 VDC circuit would only be in the Magnum inverter and the relay driver. I also did not want to bring the three 240 VAC, Enphase circuits into the Magnum inverter. The way this system is wired I can see that the relay driver is turning the three 48 VDC-relays on an off, based on the battery voltage, but the "power relays" are not controlled, unless the grid is off.

Power Relays These three "power relays" are double-pole, double throw relays with a 120 VAC coil. When 120 VAC is fed to the "power relays", they open the Enphase circuit that they are controlling. These three "power relays" are mounted outside, in a weather tight J-box, under the sub-panel that controls the three Enphase circuits. I designed it this way so that the 48 VDC circuit would only be in the Magnum inverter and the relay driver. I also did not want to bring the three 240 VAC, Enphase circuits into the Magnum inverter. The way this system is wired I can see that the relay driver is turning the three 48 VDC-relays on an off, based on the battery voltage, but the "power relays" are not controlled, unless the grid is off.