d6a4ece828bcbf8a1d0cb5cd47b03047.ppt

- Количество слайдов: 34

Odor Barrier Characterization of Polymer Materials MOCON 2008 Internet Seminar Series June 11, 2008

Background Information n A company needs to contain the odor generated from a waste process.

Background Information n The company has oxygen transmission rate equipment “in house”. n They want to know if this equipment can be used to screen potential barrier materials for their odor barrier properties.

Background Information The Goal: Compare odor barrier with oxygen barrier to determine if oxygen barrier property can be used for odor barrier prediction.

What’s Smelly? n n Chemical and chemical reactions are responsible for odors. Which chemicals does one choose to represent a particular odor? Sensory testing – can help choose a consensus of the odor (i. e. good vs. bad) and descriptors. GC testing can quantify the chemicals comprising the odor.

What’s Smelly? Microanalytics performed an odor characterization study of the “Smelly” material. They utilized a Multidimensional Gas Chromatograph with FID / PID / Olfactory / MS Detectors

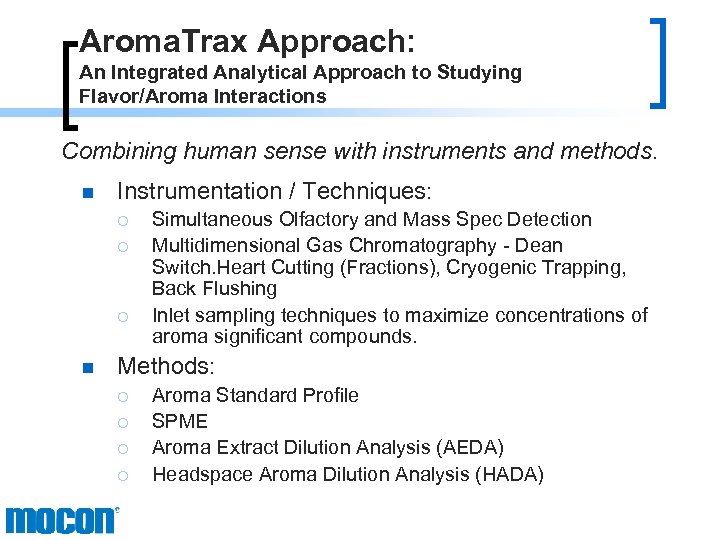

Aroma. Trax Approach: An Integrated Analytical Approach to Studying Flavor/Aroma Interactions Combining human sense with instruments and methods. n Instrumentation / Techniques: ¡ ¡ ¡ n Simultaneous Olfactory and Mass Spec Detection Multidimensional Gas Chromatography - Dean Switch. Heart Cutting (Fractions), Cryogenic Trapping, Back Flushing Inlet sampling techniques to maximize concentrations of aroma significant compounds. Methods: ¡ ¡ Aroma Standard Profile SPME Aroma Extract Dilution Analysis (AEDA) Headspace Aroma Dilution Analysis (HADA)

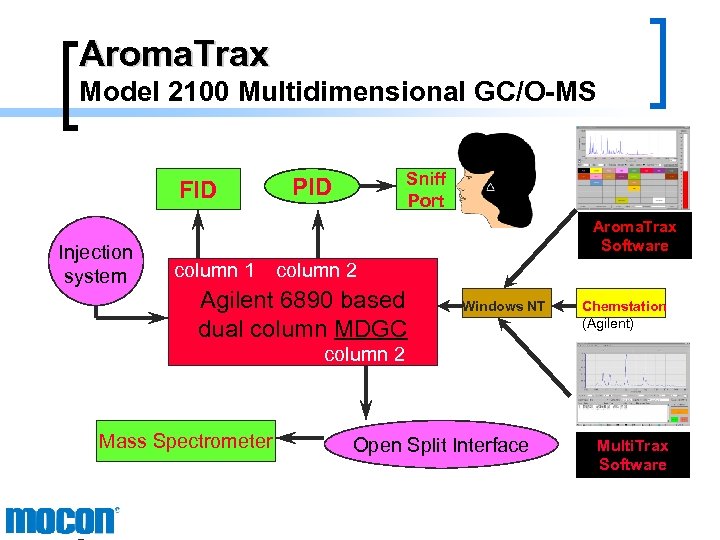

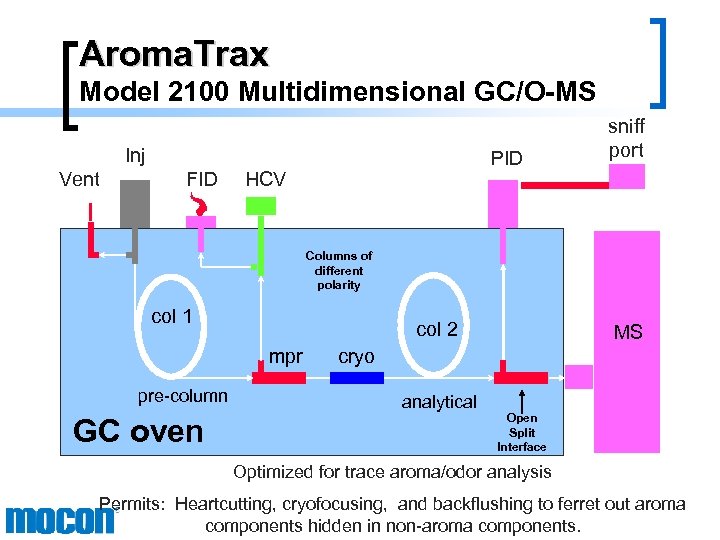

Aroma. Trax Model 2100 Multidimensional GC/O-MS FID Injection system Sniff Port PID Aroma. Trax Software column 1 column 2 Agilent 6890 based dual column MDGC Windows NT Chemstation (Agilent) column 2 Mass Spectrometer Open Split Interface Multi. Trax Software

Aroma. Trax Model 2100 Multidimensional GC/O-MS Inj Vent FID PID HCV sniff port Columns of different polarity col 1 col 2 mpr pre-column GC oven MS cryo analytical Open Split Interface Optimized for trace aroma/odor analysis Permits: Heartcutting, cryofocusing, and backflushing to ferret out aroma components hidden in non-aroma components.

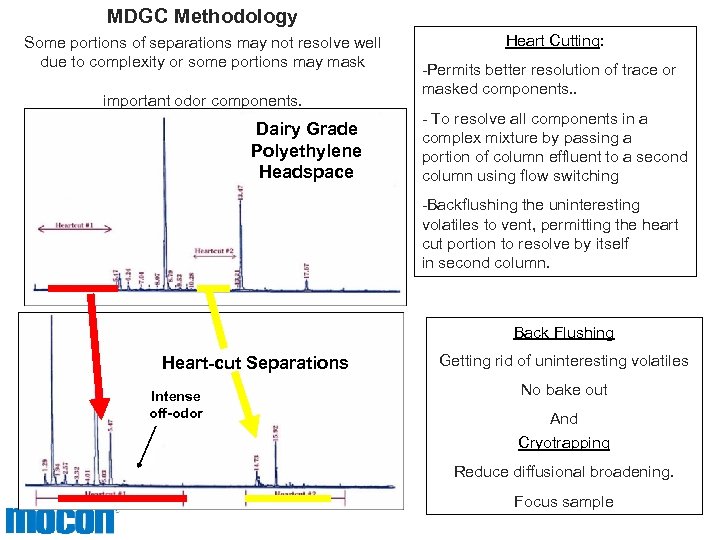

MDGC Methodology Some portions of separations may not resolve well due to complexity or some portions may mask important odor components. Dairy Grade Polyethylene Headspace Heart Cutting: -Permits better resolution of trace or masked components. . - To resolve all components in a complex mixture by passing a portion of column effluent to a second column using flow switching -Backflushing the uninteresting volatiles to vent, permitting the heart cut portion to resolve by itself in second column. Back Flushing Heart-cut Separations Intense off-odor Getting rid of uninteresting volatiles No bake out And Cryotrapping Reduce diffusional broadening. Focus sample

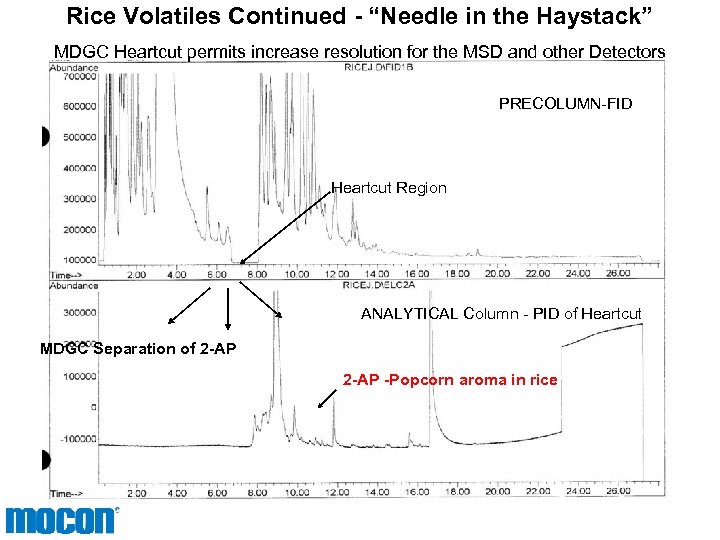

Rice Volatiles Continued - “Needle in the Haystack” MDGC Heartcut permits increase resolution for the MSD and other Detectors PRECOLUMN-FID Heartcut Region ANALYTICAL Column - PID of Heartcut MDGC Separation of 2 -AP -Popcorn aroma in rice

What’s Smelly? Over 100 different aroma chemicals were identified from the samples. n d- limonene (terpene / essential oil family) was a prominent chemical in all of the tested samples. n Toluene (aromatic hydrocarbon) was also found in the aroma profile.

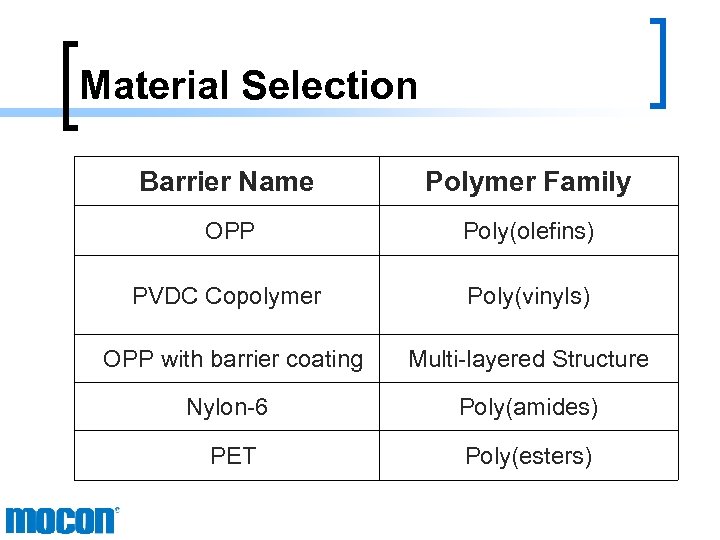

Material Selection Barrier Name Polymer Family OPP Poly(olefins) PVDC Copolymer Poly(vinyls) OPP with barrier coating Multi-layered Structure Nylon-6 Poly(amides) PET Poly(esters)

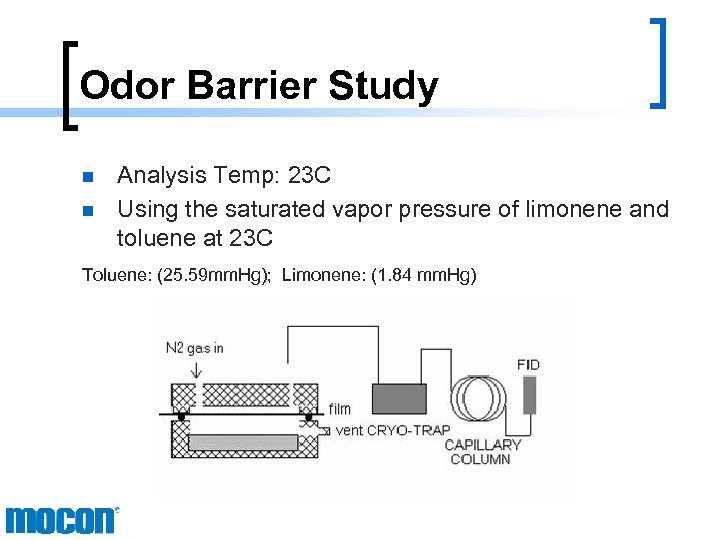

Odor Barrier Study n n Analysis Temp: 23 C Using the saturated vapor pressure of limonene and toluene at 23 C Toluene: (25. 59 mm. Hg); Limonene: (1. 84 mm. Hg)

Odor Barrier Study

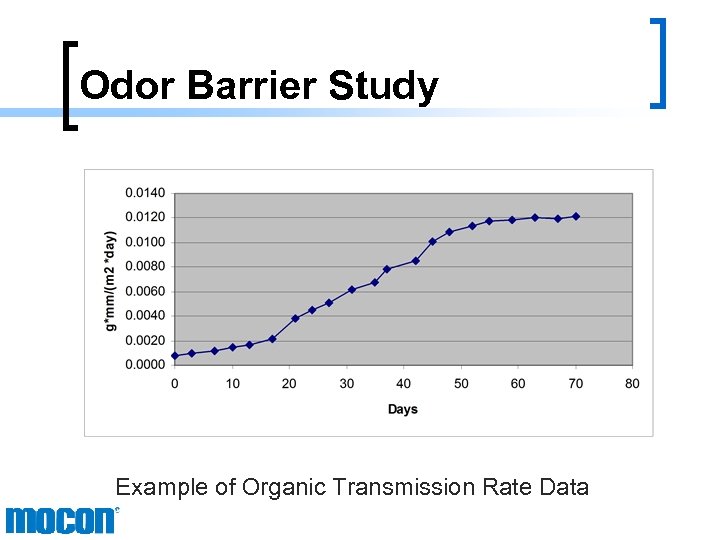

Odor Barrier Study Example of Organic Transmission Rate Data

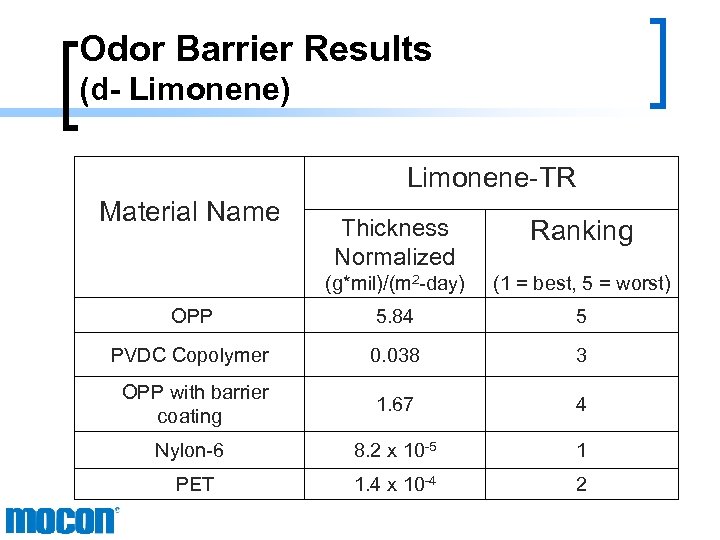

Odor Barrier Results (d- Limonene) Limonene-TR Material Name Thickness Normalized Ranking (g*mil)/(m 2 -day) (1 = best, 5 = worst) OPP 5. 84 5 PVDC Copolymer 0. 038 3 OPP with barrier coating 1. 67 4 Nylon-6 8. 2 x 10 -5 1 PET 1. 4 x 10 -4 2

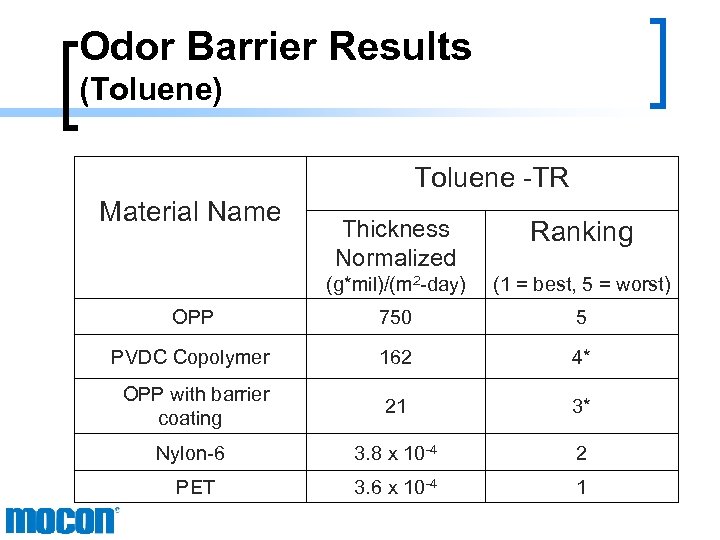

Odor Barrier Results (Toluene) Toluene -TR Material Name Thickness Normalized Ranking (g*mil)/(m 2 -day) (1 = best, 5 = worst) OPP 750 5 PVDC Copolymer 162 4* OPP with barrier coating 21 3* Nylon-6 3. 8 x 10 -4 2 PET 3. 6 x 10 -4 1

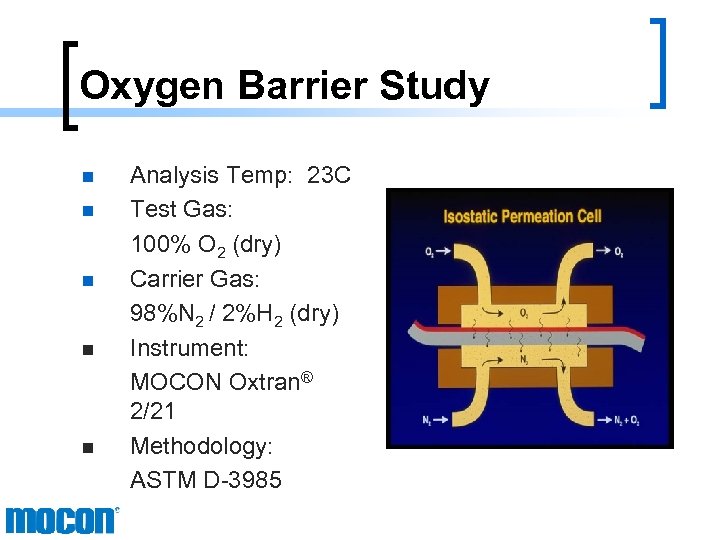

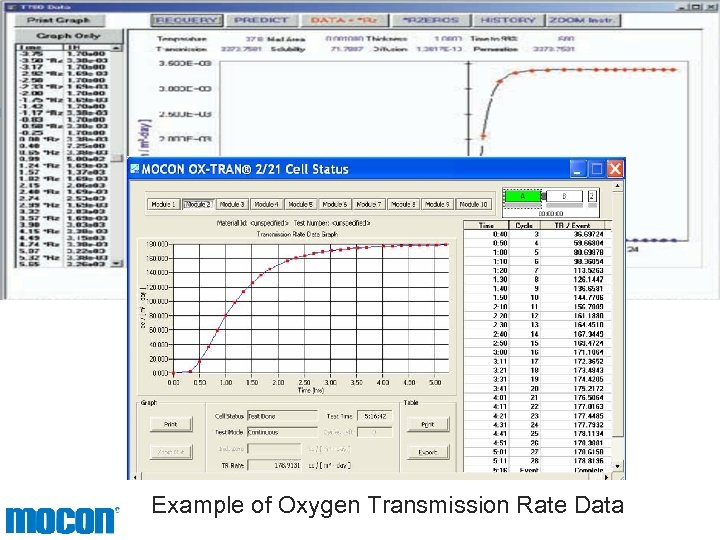

Oxygen Barrier Study n n n Analysis Temp: 23 C Test Gas: 100% O 2 (dry) Carrier Gas: 98%N 2 / 2%H 2 (dry) Instrument: MOCON Oxtran® 2/21 Methodology: ASTM D-3985

Oxygen Barrier Study

Oxygen Barrier Study Example of Oxygen Transmission Rate Data

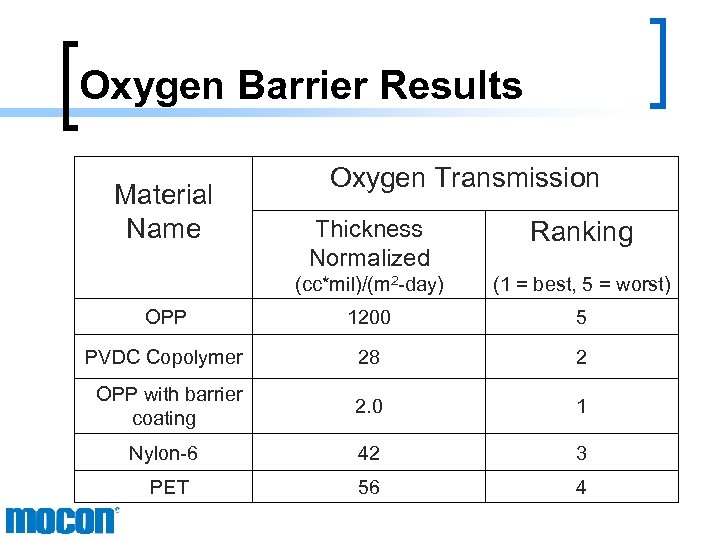

Oxygen Barrier Results Material Name Oxygen Transmission Thickness Normalized Ranking (cc*mil)/(m 2 -day) (1 = best, 5 = worst) OPP 1200 5 PVDC Copolymer 28 2 OPP with barrier coating 2. 0 1 Nylon-6 42 3 PET 56 4

Odor Barrier / Oxygen Barrier Comparison So, how do they compare?

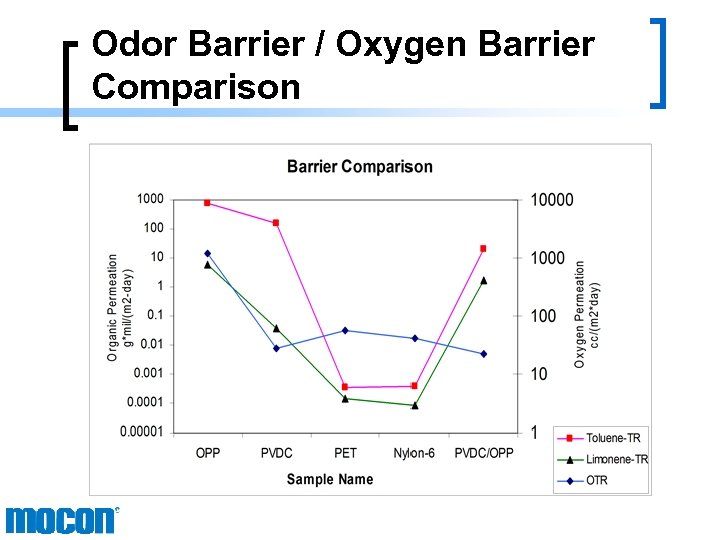

Odor Barrier / Oxygen Barrier Comparison

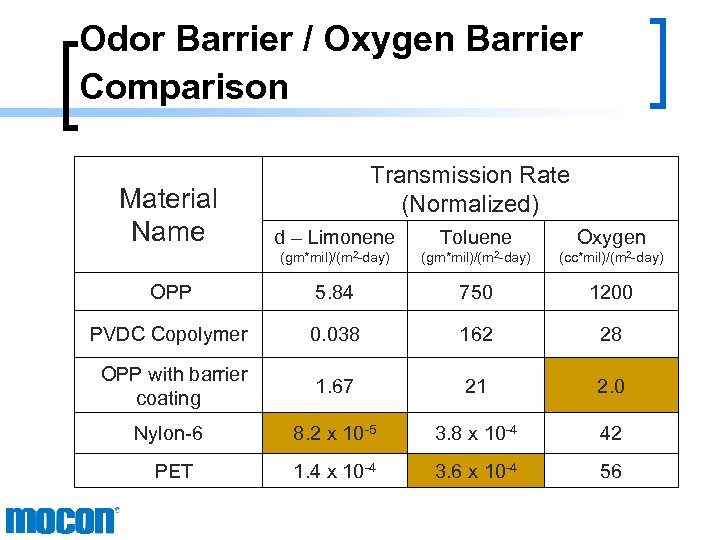

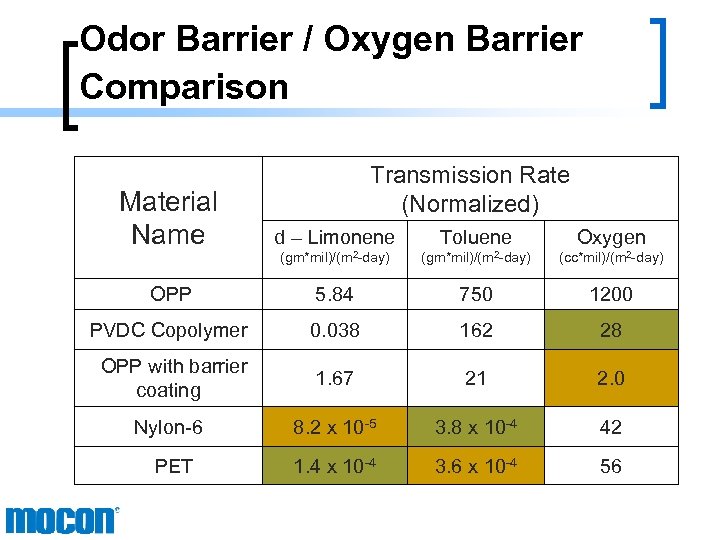

Odor Barrier / Oxygen Barrier Comparison Material Name Transmission Rate (Normalized) d – Limonene Toluene Oxygen (gm*mil)/(m 2 -day) (cc*mil)/(m 2 -day) OPP 5. 84 750 1200 PVDC Copolymer 0. 038 162 28 OPP with barrier coating 1. 67 21 2. 0 Nylon-6 8. 2 x 10 -5 3. 8 x 10 -4 42 PET 1. 4 x 10 -4 3. 6 x 10 -4 56

Odor Barrier / Oxygen Barrier Comparison Transmission Rate (Normalized) Material Name d – Limonene Toluene Oxygen (gm*mil)/(m 2 -day) (cc*mil)/(m 2 -day) OPP 5. 84 750 1200 PVDC Copolymer 0. 038 162 28 OPP with barrier coating 1. 67 21 2. 0 Nylon-6 8. 2 x 10 -5 3. 8 x 10 -4 42 PET 1. 4 x 10 -4 3. 6 x 10 -4 56

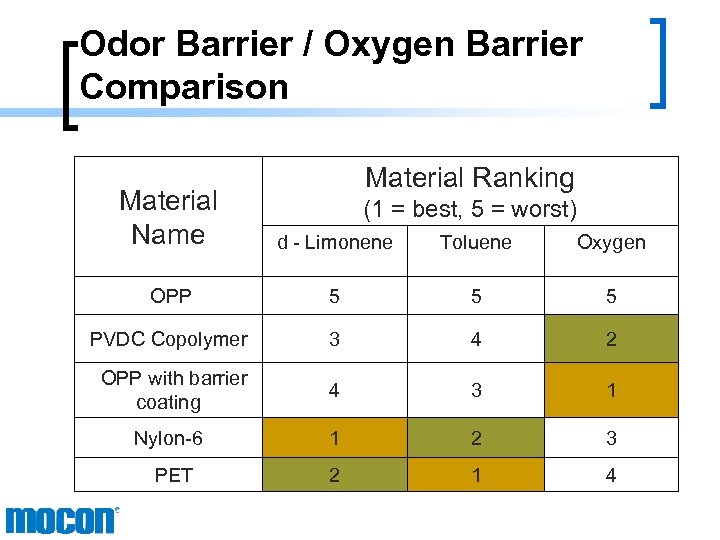

Odor Barrier / Oxygen Barrier Comparison Material Ranking Material Name d - Limonene Toluene Oxygen OPP 5 5 5 PVDC Copolymer 3 4 2 OPP with barrier coating 4 3 1 Nylon-6 1 2 3 PET 2 1 4 (1 = best, 5 = worst)

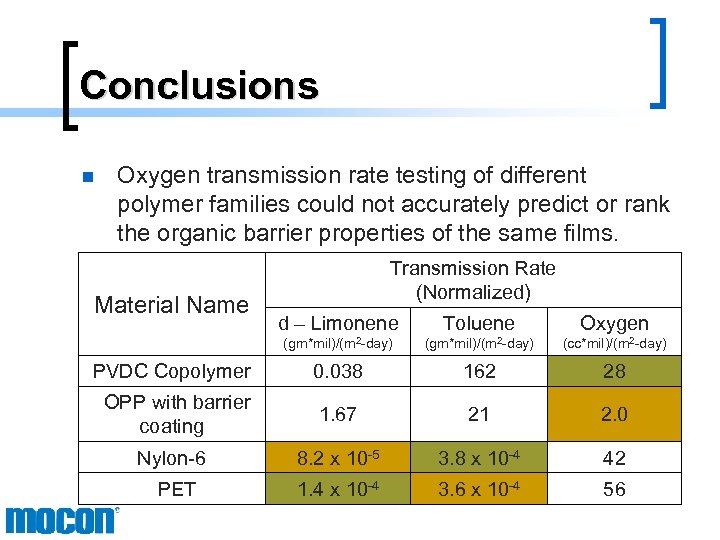

Conclusions n Oxygen transmission rate testing of different polymer families could not accurately predict or rank the organic barrier properties of the same films. Material Name Transmission Rate (Normalized) d – Limonene Toluene Oxygen (gm*mil)/(m 2 -day) (cc*mil)/(m 2 -day) PVDC Copolymer 0. 038 162 28 OPP with barrier coating 1. 67 21 2. 0 Nylon-6 8. 2 x 10 -5 3. 8 x 10 -4 42 PET 1. 4 x 10 -4 3. 6 x 10 -4 56

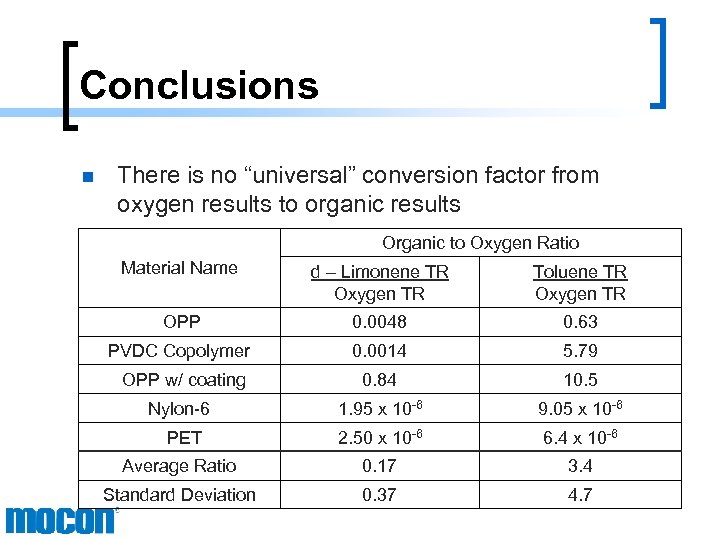

Conclusions n There is no “universal” conversion factor from oxygen results to organic results Organic to Oxygen Ratio Material Name d – Limonene TR Oxygen TR Toluene TR Oxygen TR OPP 0. 0048 0. 63 PVDC Copolymer 0. 0014 5. 79 OPP w/ coating 0. 84 10. 5 Nylon-6 1. 95 x 10 -6 9. 05 x 10 -6 PET 2. 50 x 10 -6 6. 4 x 10 -6 Average Ratio 0. 17 3. 4 Standard Deviation 0. 37 4. 7

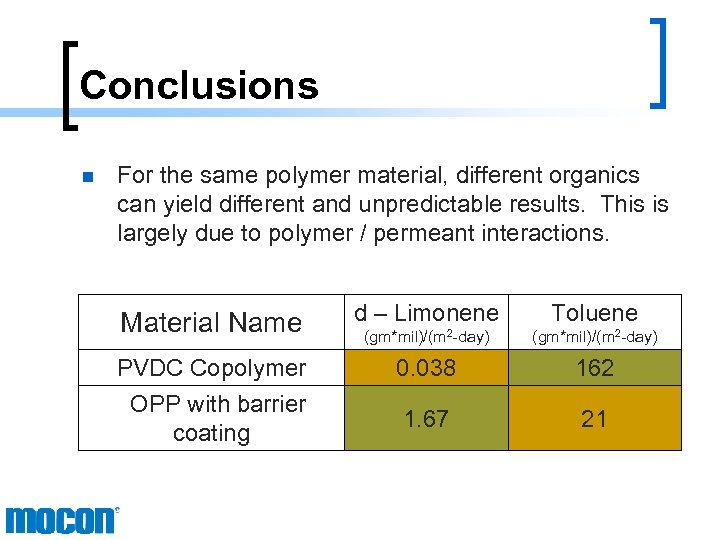

Conclusions n For the same polymer material, different organics can yield different and unpredictable results. This is largely due to polymer / permeant interactions. Material Name d – Limonene Toluene (gm*mil)/(m 2 -day) PVDC Copolymer OPP with barrier coating 0. 038 162 1. 67 21

Conclusions n In most cases, the best way to determine whether a material is a good organic (aroma or odor) barrier, is to: First : Determine which organics are the key players. Second: Test the material with the proper permeant.

Recommendation for a Future Study n Even though oxygen transmission testing was a poor tool for ranking the overall organic barrier for differing materials, it may prove meaningful to use an oxygen / aroma correlation when comparing barrier properties of like polymers of different thickness, grades or added coatings.

Thank you! Questions, please!

Please join us next month… Introduction to Scientific Instrument IQ/OQ/PQ Validations: Wednesday, July 9, 2008 10 am Central

d6a4ece828bcbf8a1d0cb5cd47b03047.ppt