05a179fa7758b49cb4ff0e57f481cd57.ppt

- Количество слайдов: 118

Objectives At the end of this module you should be able to: 1) Identify “Hazardous Zones” on board a tanker or similar vessel. 2) Predict the possible “Electrical Sources of Ignition” considered to be “Hazardous”. 3) Identify Explosion Protected Equipment 4) State the significance of equipment with various “Ex” markings 5) Describe essential items to be checked on “Ex-Protected” Equipment. 6) Demonstrate the precautionary measures in the maintenance of explosive proof lights.

STATUTORY WARNING: SMOKING COULD TAKE YOUR LIFE … … AND THE LIVES OF OTHERS The most prominent sign in sight …

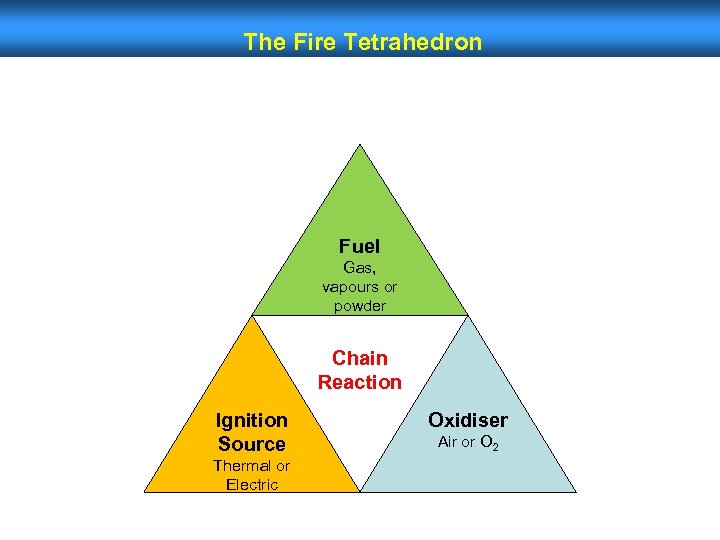

The Fire Tetrahedron Fuel Gas, vapours or powder Chain Reaction Ignition Source Thermal or Electric Oxidiser Air or O 2

The Dust Explosion Pentagon Read Details

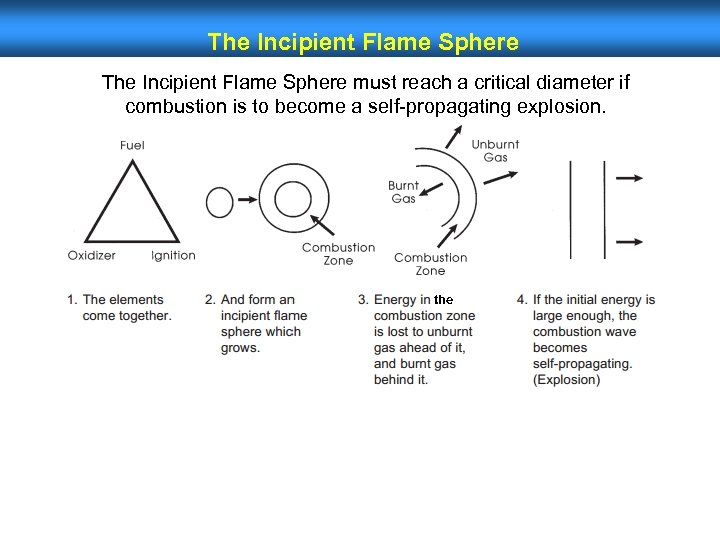

The Incipient Flame Sphere must reach a critical diameter if combustion is to become a self-propagating explosion. the

The Incipient Flame Sphere If the initial spark is not large enough, (i. e. does not possess enough energy), the combustion zone will not have enough energy to self propagate. It will just collapse upon itself, and fizzle out. This means a small spark can occur in a potentially explosive air/gas mixture, with no danger of an explosion. The maximum amount of energy of this “safe” spark varies with the specific air/gas mixture present.

Extract from ABS Rules for Building and Classing Steel Vessels - 2005 Part 4 Vessel Systems and Machinery Chapter 1 General Section 1 Classification of Machinery Quote 1. 9. 4 Hazardous Area 4 -1 -1/1. 9. 4 Areas where flammable or explosive gases, vapors, or dust are normally present or likely to be present are known as hazardous areas. Hazardous areas are however more specifically defined for certain machinery installations, storage spaces and cargo spaces that present such hazard, e. g. : helicopter refueling facilities, see 4 -8 -4/27. 3. 3; paint stores, see 4 -8 -4/27. 3. 3; cargo oil tanks and other spaces of oil carriers; see 5 -1 -7/31. 5; ro-ro cargo spaces; see 5 -10 -4/3. 9. 2. Unquote

Classification of Hazardous Materials (The American System) Class 1 : Flammable gases or vapours Class 2 : Combustible dusts Class 3 : Fibres or flyings (particles normally suspended in air) Class 1: The following groups are listed in the most dangerous to the least dangerous ones: Group A : Acetylenes Group B : Hydrogen, Hydrogen mixtures Group C : Ethylene, Ethers, Some Aldehydes Group D: Alkanes (Butane, Ethane, Methane, Octane, Propane), Hydrocarbon mixtures (Diesel oil, Kerosene, Petroleum mixtures, Gasoline), Alcohol, Ketones, Esters, Amines, Alkenes, Benzoids Class 2 (Combustible Dusts): Group E : Metallic Dusts (resistivity < 100 kΩ/cm) Group F, Group G : Non-conductive dusts (agri, plastic, chemical and textile dusts – resistivity > 100 kΩ/cm).

if Hazardous Areas Onboard Ships When a ship is involved in its normal operational functions there will be some areas and zones where flammable gases can accumulate in the atmosphere and present a hazard to the ship, its crew and other personnel who may be onboard. Such areas are defined as hazardous and classified in terms of the risks involved. For example, IEC Publication 79 -10 defines three such categories: Zone 0: The flammable mixture is continuously present or present for long periods. Zone 1: The during normal operations. present, not butnormally Zone flammable be mixture 2: would The be present for a short period only. (Note: Zones 0 and 1 is also known as Division 1 while Zone 2 is known as Division 2) Continued…

Hazardous Areas Onboard Ships The terms ‘gas-dangerous area’ or ‘gas-safe area’ may also be mentioned on ships. The general ship’s operation manual, or other similar documents, must be referred to in order to determine the number and extent of the hazardous areas for any given ship. Hydrocarbon gases or vapours from crude oil form highly flammable mixtures with air when they are present in the proportion between 1% and 10% hydrocarbon with 99% down to 90% normal air. Below the lower explosive limit (LEL) the mixture is too lean to burn rapidly, although a lean mixture will burn slowly in the presence of a naked flame or a spark, as is proved by the operation of explosimeters in this range. Over-rich mixtures exist when the level of the hydrocarbon exceeds 10%. Read Details

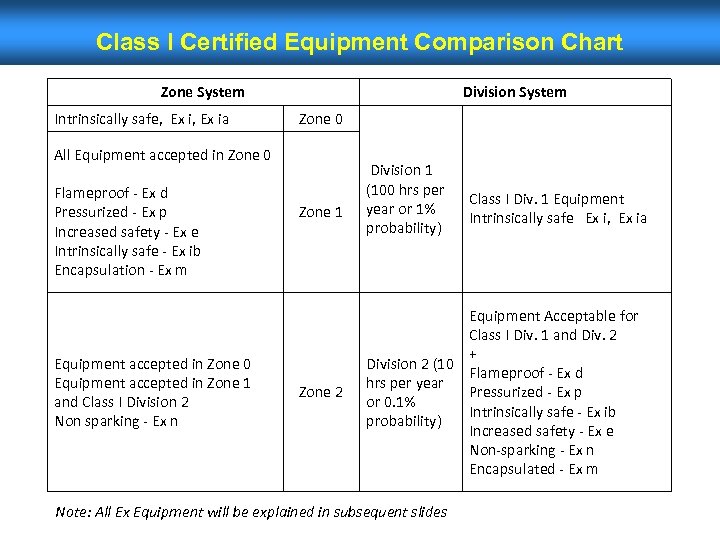

Class I Certified Equipment Comparison Chart Zone System Intrinsically safe, Ex i, Ex ia Division System Zone 0 All Equipment accepted in Zone 0 Flameproof - Ex d Pressurized - Ex p Increased safety - Ex e Intrinsically safe - Ex ib Encapsulation - Ex m Equipment accepted in Zone 0 Equipment accepted in Zone 1 and Class I Division 2 Non sparking - Ex n Zone 1 Zone 2 Division 1 (100 hrs per year or 1% probability) Class I Div. 1 Equipment Intrinsically safe Ex i, Ex ia Equipment Acceptable for Class I Div. 1 and Div. 2 + Division 2 (10 Flameproof - Ex d hrs per year Pressurized - Ex p or 0. 1% Intrinsically safe - Ex ib probability) Increased safety - Ex e Non-sparking - Ex n Encapsulated - Ex m Note: All Ex Equipment will be explained in subsequent slides

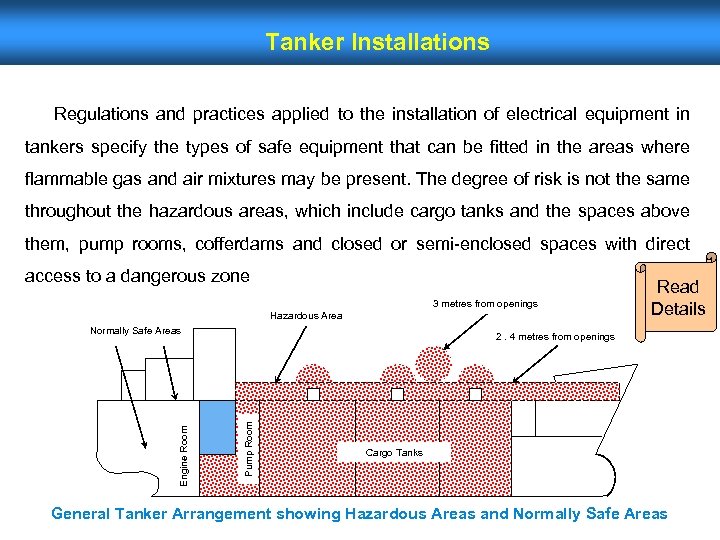

Tanker Installations Regulations and practices applied to the installation of electrical equipment in tankers specify the types of safe equipment that can be fitted in the areas where flammable gas and air mixtures may be present. The degree of risk is not the same throughout the hazardous areas, which include cargo tanks and the spaces above them, pump rooms, cofferdams and closed or semi-enclosed spaces with direct access to a dangerous zone 3 metres from openings Hazardous Area 2. 4 metres from openings Pump Room Engine Room Normally Safe Areas Read Details Cargo Tanks General Tanker Arrangement showing Hazardous Areas and Normally Safe Areas

Potential Sources of Ignition Should there be a flammable gas, vapour or dust in the atmosphere, the following are considered to be potential sources of ignition: ~ Sockets And Plugs, ~ Open Fuses, ~ Light Switches, ~ Relays, ~ Push Button Contacts, ~ Torches, ~ Starters, ~ Circuit Breakers, ~ Electric Bells, ~ Components like Capacitors, Inductors and Resistors

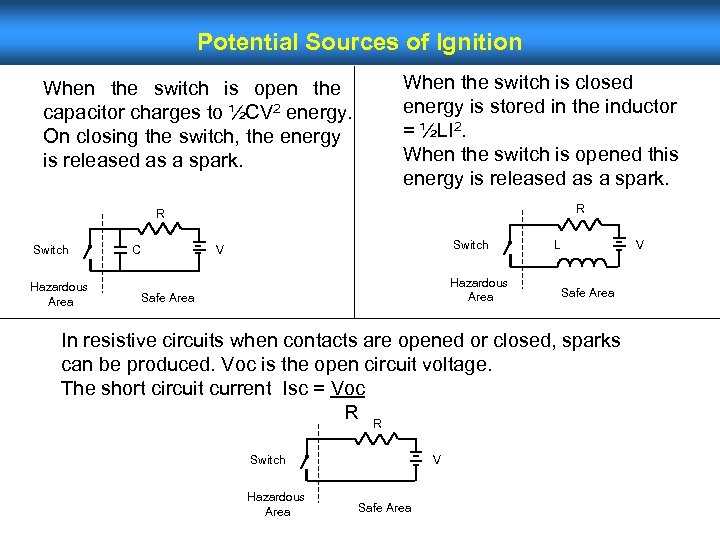

Potential Sources of Ignition When the switch is open the capacitor charges to ½CV 2 energy. On closing the switch, the energy is released as a spark. When the switch is closed energy is stored in the inductor = ½LI 2. When the switch is opened this energy is released as a spark. R R Switch Hazardous Area C Switch V Hazardous Area Safe Area L V Safe Area In resistive circuits when contacts are opened or closed, sparks can be produced. Voc is the open circuit voltage. The short circuit current Isc = Voc R R Switch Hazardous Area V Safe Area

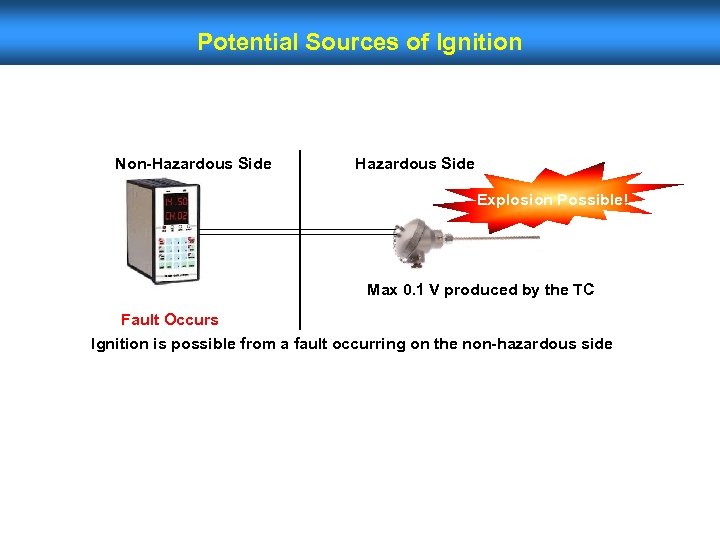

Potential Sources of Ignition Non-Hazardous Side Explosion Possible! Max 0. 1 V produced by the TC Fault Occurs Ignition is possible from a fault occurring on the non-hazardous side

Potential Sources of Ignition There are no special measures taken in ordinary electrical equipment to encapsulate contacts, which arc as they close or open. Thus the following are more apparent as sources of ignition: ~ The danger from arcing contacts in a starter box or switch is not obvious because the arc is hidden. ~ Sparks from an electric motor, particularly of the commutator-type, ~ The momentary glow of a broken light bulb filament, ~ Arcing from a broken or damaged power cable Conventional equipment and cables are suitable for areas that are considered safe. Continued…

Potential Sources of Ignition Static electricity is generated within tanks in several ways. Flammable gas remains in a tank even after it is discharged. This presents a hazard – particularly during washing – unless appropriate steps are taken. Here, the product or water mist or steam becomes charged with electricity. This can occur… ~ When filling with clean oil products ~ When washing with water jets ~ When steaming a tank ~ A static charge and spark may also be caused by carbon dioxide or steam being discharged at a high rate from a nozzle. ! Keep tank openings closed as much as possible. ! Do not disconnect tank cleaning hoses from their hydrants until they have been removed from the tank. Continued…

Potential Sources of Ignition There are several ways in which this sufficient charge becomes a hot spark – capable of igniting a flammable mixture. This might involve the introduction of metal objects into a tank. Objects which may have caused a spark include: ~ Hand-held metal ullage tapes ~ Metal sample cans ~ Metal sounding rods ~ Ungrounded portable washing machines ! Do not introduce metal objects into the tank, other than a grounded washing machine. Click on the icons to see more details on Static Electricity Each file is unique

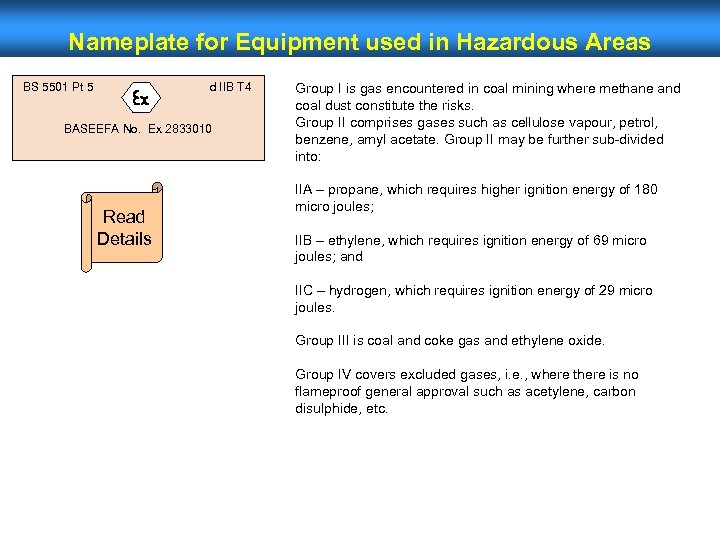

Nameplate for Equipment used in Hazardous Areas BS 5501 Pt 5 d IIB T 4 BASEEFA No. Ex 2833010 Read Details Group I is gas encountered in coal mining where methane and coal dust constitute the risks. Group II comprises gases such as cellulose vapour, petrol, benzene, amyl acetate. Group II may be further sub-divided into: IIA – propane, which requires higher ignition energy of 180 micro joules; IIB – ethylene, which requires ignition energy of 69 micro joules; and IIC – hydrogen, which requires ignition energy of 29 micro joules. Group III is coal and coke gas and ethylene oxide. Group IV covers excluded gases, i. e. , where there is no flameproof general approval such as acetylene, carbon disulphide, etc.

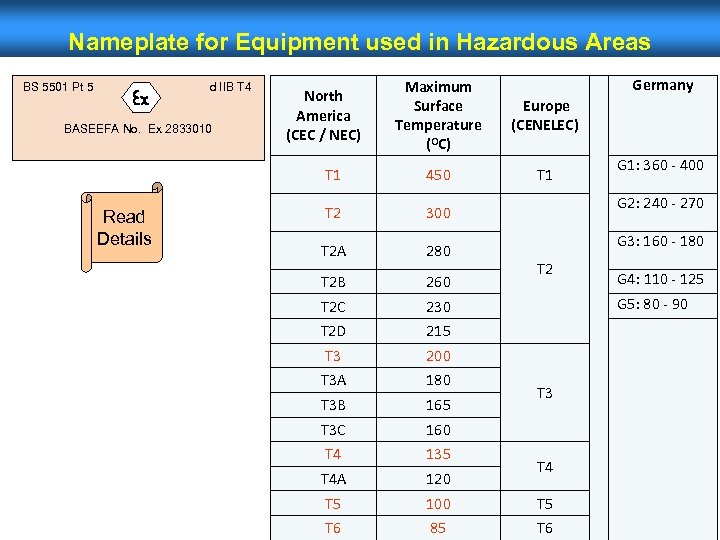

Nameplate for Equipment used in Hazardous Areas d IIB T 4 BASEEFA No. Ex 2833010 Read Details Maximum Surface Temperature (OC) 450 T 1 T 2 300 T 2 A 280 T 2 B 260 T 2 C 230 T 2 D 215 T 3 200 T 3 A 180 T 3 B 165 T 3 C 160 T 4 135 T 4 A 120 T 5 100 T 5 T 6 85 T 6 Germany Europe (CENELEC) T 1 BS 5501 Pt 5 North America (CEC / NEC) G 1: 360 - 400 G 2: 240 - 270 G 3: 160 - 180 T 2 G 4: 110 - 125 G 5: 80 - 90 T 3 T 4

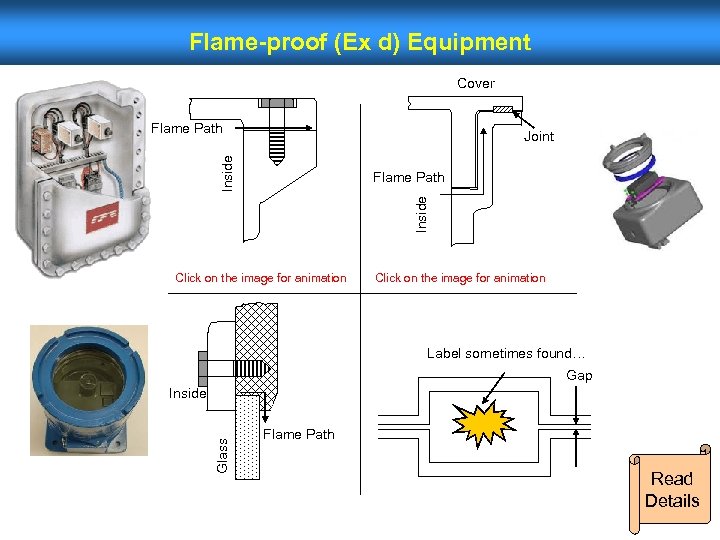

Flame-proof (Ex d) Equipment Cover Flame Path Inside Joint Inside Flame Path Click on the image for animation Label sometimes found… Gap Glass Inside Flame Path Read Details

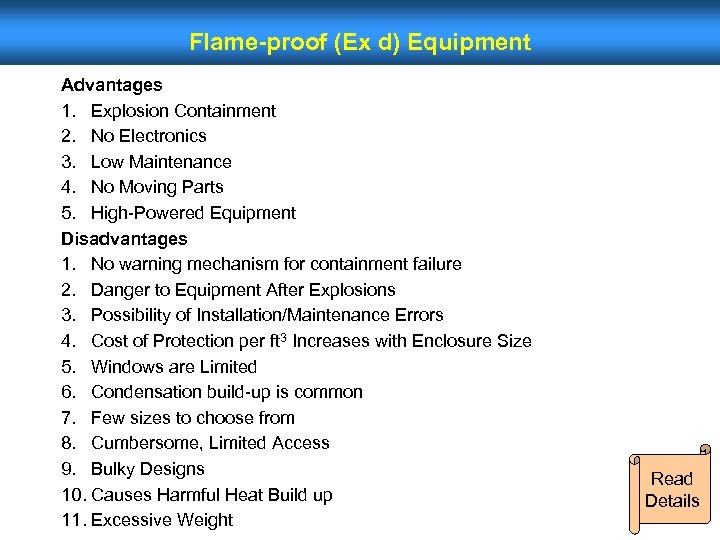

Flame-proof (Ex d) Equipment Advantages 1. Explosion Containment 2. No Electronics 3. Low Maintenance 4. No Moving Parts 5. High-Powered Equipment Disadvantages 1. No warning mechanism for containment failure 2. Danger to Equipment After Explosions 3. Possibility of Installation/Maintenance Errors 4. Cost of Protection per ft 3 Increases with Enclosure Size 5. Windows are Limited 6. Condensation build-up is common 7. Few sizes to choose from 8. Cumbersome, Limited Access 9. Bulky Designs 10. Causes Harmful Heat Build up 11. Excessive Weight Read Details

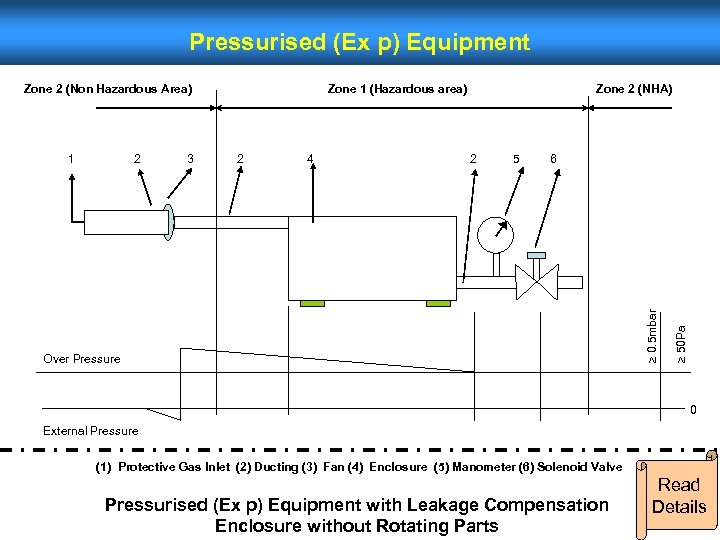

Pressurised (Ex p) Equipment 2 3 2 4 Zone 2 (NHA) 2 5 6 Over Pressure 50 Pa 1 Zone 1 (Hazardous area) 0. 5 mbar Zone 2 (Non Hazardous Area) 0 External Pressure (1) Protective Gas Inlet (2) Ducting (3) Fan (4) Enclosure (5) Manometer (6) Solenoid Valve Pressurised (Ex p) Equipment with Leakage Compensation Enclosure without Rotating Parts Read Details

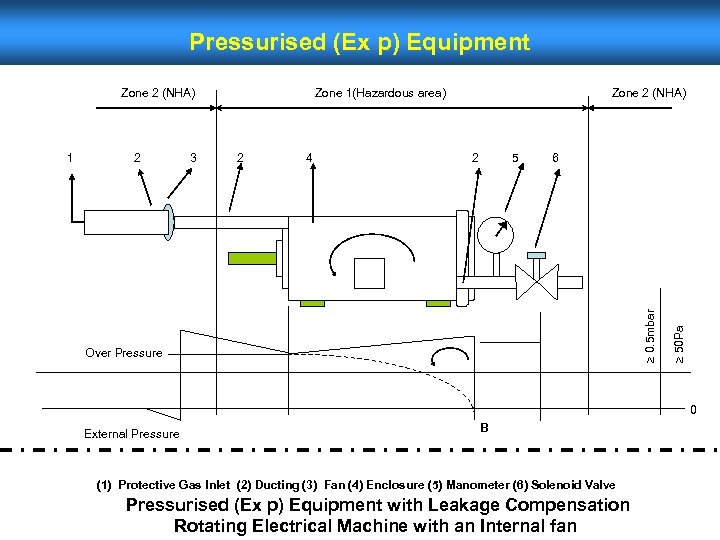

Pressurised (Ex p) Equipment 2 3 2 4 Zone 2 (NHA) 2 5 6 Over Pressure 50 Pa 1 Zone 1(Hazardous area) 0. 5 mbar Zone 2 (NHA) 0 External Pressure B (1) Protective Gas Inlet (2) Ducting (3) Fan (4) Enclosure (5) Manometer (6) Solenoid Valve Pressurised (Ex p) Equipment with Leakage Compensation Rotating Electrical Machine with an Internal fan

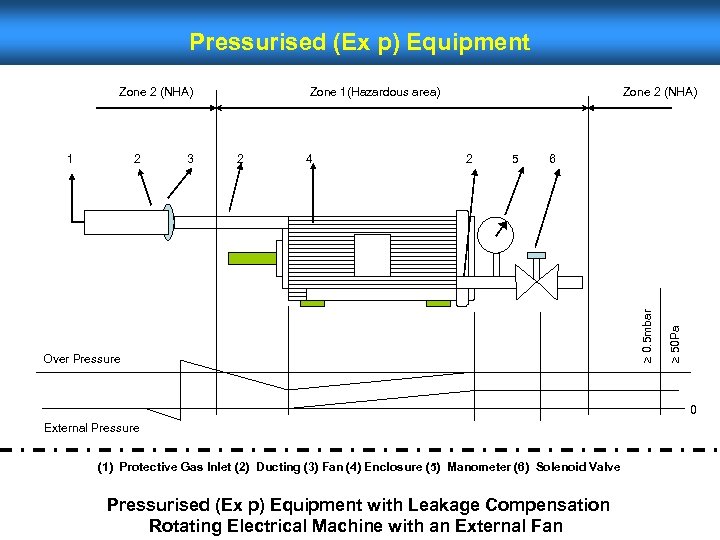

Pressurised (Ex p) Equipment 2 3 2 4 Zone 2 (NHA) 2 5 6 Over Pressure 50 Pa 1 Zone 1(Hazardous area) 0. 5 mbar Zone 2 (NHA) 0 External Pressure (1) Protective Gas Inlet (2) Ducting (3) Fan (4) Enclosure (5) Manometer (6) Solenoid Valve Pressurised (Ex p) Equipment with Leakage Compensation Rotating Electrical Machine with an External Fan

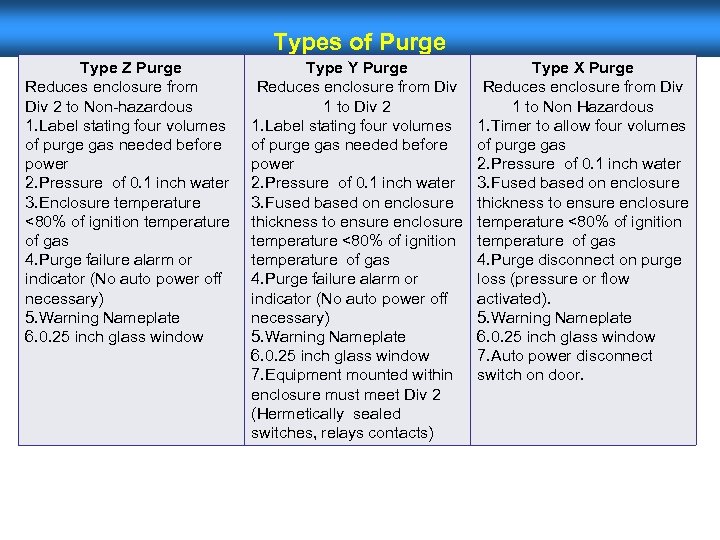

Types of Purge Type Z Purge Reduces enclosure from Div 2 to Non-hazardous 1. Label stating four volumes of purge gas needed before power 2. Pressure of 0. 1 inch water 3. Enclosure temperature <80% of ignition temperature of gas 4. Purge failure alarm or indicator (No auto power off necessary) 5. Warning Nameplate 6. 0. 25 inch glass window Type Y Purge Reduces enclosure from Div 1 to Div 2 1. Label stating four volumes of purge gas needed before power 2. Pressure of 0. 1 inch water 3. Fused based on enclosure thickness to ensure enclosure temperature <80% of ignition temperature of gas 4. Purge failure alarm or indicator (No auto power off necessary) 5. Warning Nameplate 6. 0. 25 inch glass window 7. Equipment mounted within enclosure must meet Div 2 (Hermetically sealed switches, relays contacts) Type X Purge Reduces enclosure from Div 1 to Non Hazardous 1. Timer to allow four volumes of purge gas 2. Pressure of 0. 1 inch water 3. Fused based on enclosure thickness to ensure enclosure temperature <80% of ignition temperature of gas 4. Purge disconnect on purge loss (pressure or flow activated). 5. Warning Nameplate 6. 0. 25 inch glass window 7. Auto power disconnect switch on door.

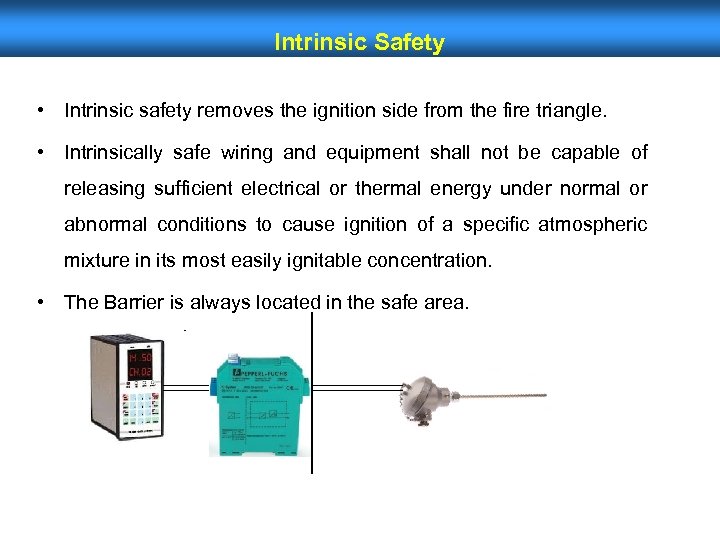

Intrinsic Safety • Intrinsic safety removes the ignition side from the fire triangle. • Intrinsically safe wiring and equipment shall not be capable of releasing sufficient electrical or thermal energy under normal or abnormal conditions to cause ignition of a specific atmospheric mixture in its most easily ignitable concentration. • The Barrier is always located in the safe area.

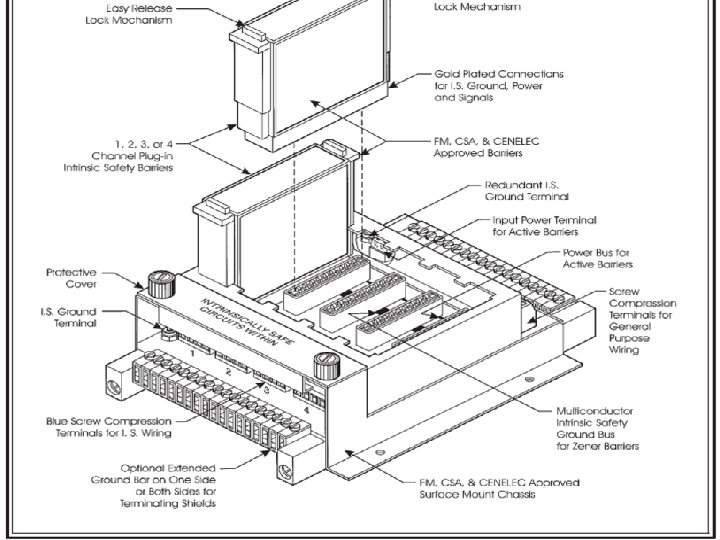

Requirements for Intrinsically Safe Systems 1. Ensure that there is positive separation between intrinsically and non intrinsically safe circuits; this prevents the ignition energy from entering the intrinsically safe circuit. 2. Separate trays, conduits be used for intrinsically safe wiring and be properly tagged / identified. 3. IS wiring is not to be mixed with other wiring. 4. If conduit is used it must be effectively sealed to prevent gases fro the hazardous area to reach safe area. 5. ensure that the entity parameters upon which the system is designed match correctly.

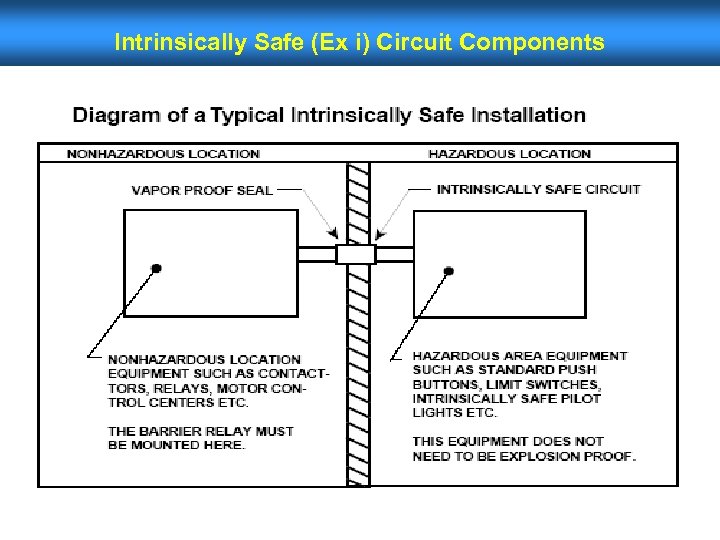

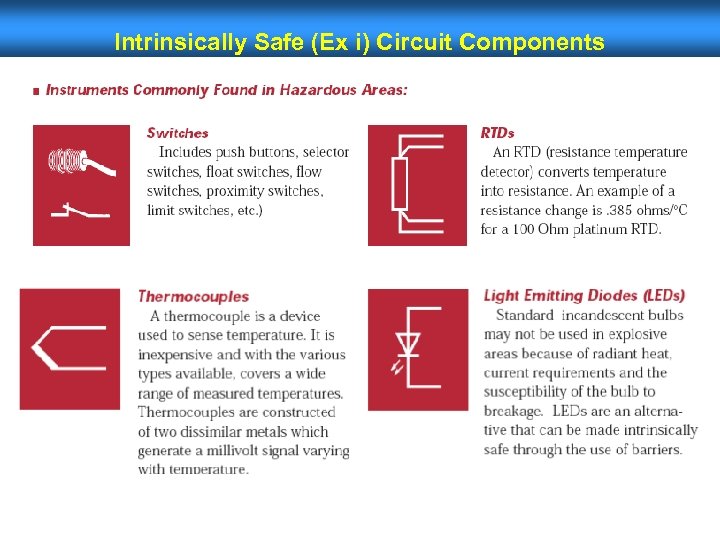

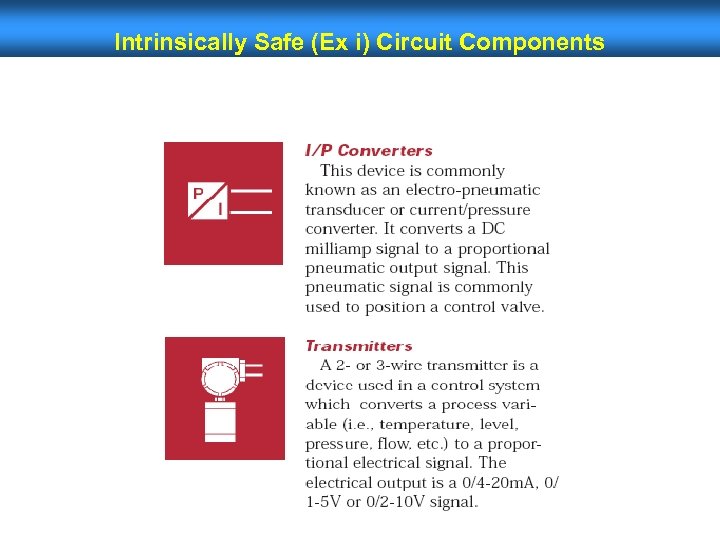

Intrinsically Safe (Ex i) Circuit Components

Intrinsically Safe (Ex i) Circuit Components What is a simple apparatus? A simple apparatus does not generate or store more than the following: - 1. 2 V - 100 m. A - 20 micro J - 25 m. W This type of device does not require certification from a third party but still requires an intrinsically safe barrier. Examples: 1. Switches – limit, pressure, temperature, float, flow. 2. Push buttons 3. Analogue sensors : Thermocouple, RTD 4. LEDs

Intrinsically Safe (Ex i) Circuit Components

Intrinsically Safe (Ex i) Circuit Components

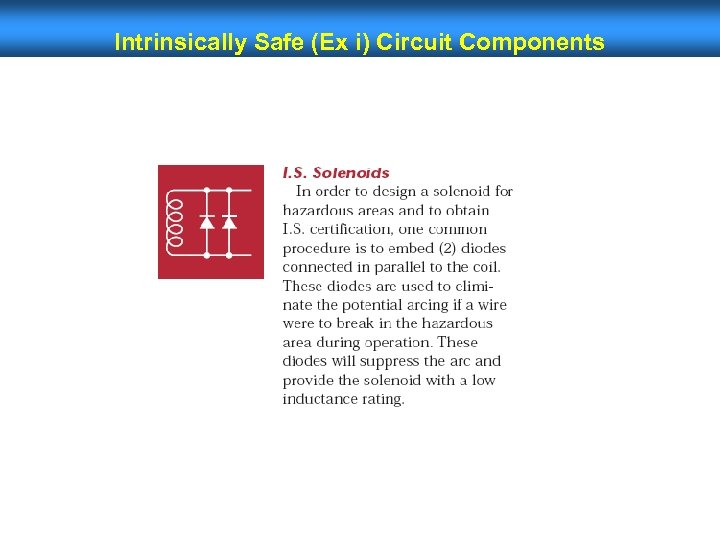

Intrinsically Safe (Ex i) Circuit Components

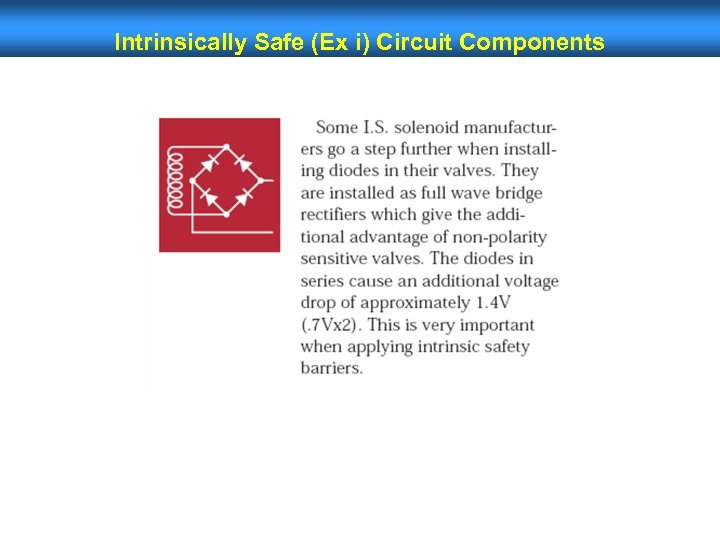

Intrinsically Safe (Ex i) Circuit Components

Intrinsically Safe (Ex i) Circuit Components

Intrinsically Safe (Ex i) Circuit Components

Intrinsically Safe (Ex i) Circuit Components

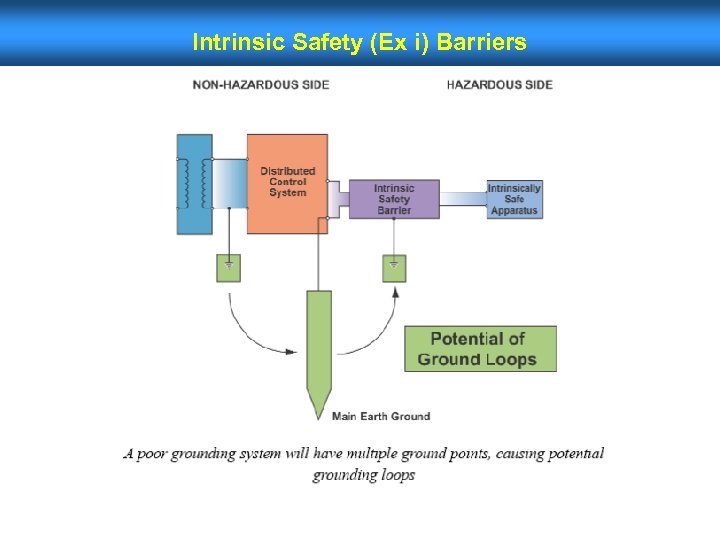

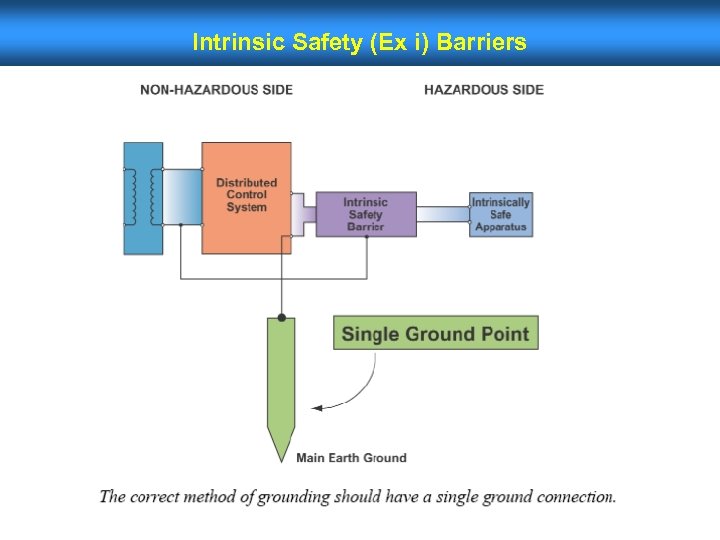

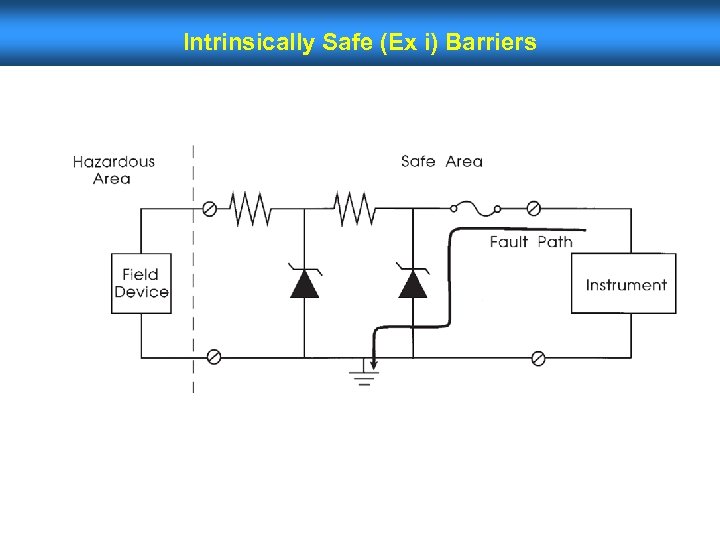

Intrinsic Safety (Ex i) Barriers 1. The intrinsic safety barrier is inserted in the safe area between the field device and the safe area instrument. 2. The barrier blocks dangerous energy that can be released due to a fault in the safe area from being transmitted to the hazardous area. This energy may be from the power supply or stored in a capacitor, inductor, etc. 3. The dangerous energy is diverted to the ground. Therefore it is important to ensure a high quality of intrinsic safe ground. As this grounding is so critical, two separate ground connections from each barrier are recommended, each with a resistance < 1. 0 ohm.

Intrinsic Safety (Ex i) Barriers

Intrinsic Safety (Ex i) Barriers

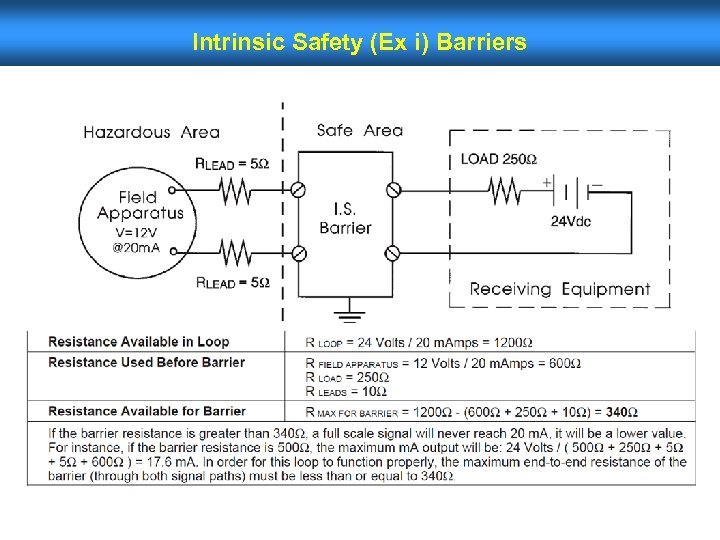

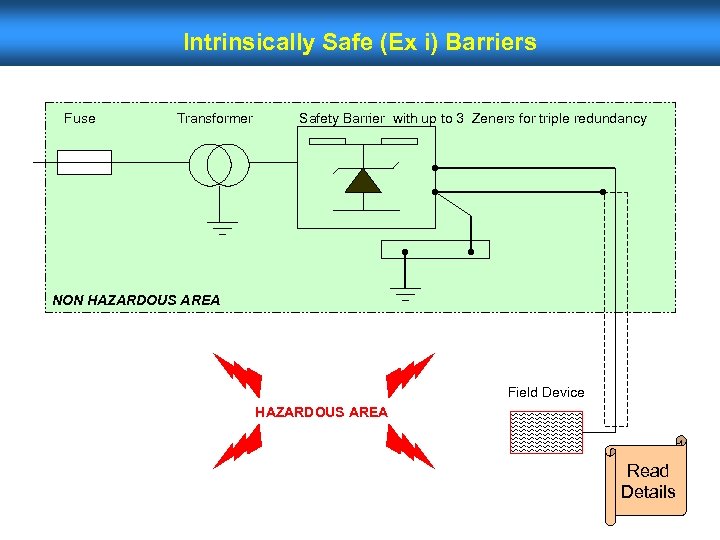

Intrinsic Safety (Ex i) Barriers There are two types of intrinsic safety barriers : 1) Zener barrier (2) Active barrier. 1) Zener barrier: This works on the principle of diverting hazardous energy to the ground safely before it can reach the hazardous area. Zener diodes limit the fault voltage to the hazardous area. There are two such diodes for redundancy. The series resistor limits the current to the hazardous area. The zener barrier is a loop which can restrict the current by the resistor. At the same time it must allow the loop to function normally by allowing the required values of current to flow in normal operation to enable the instrument in the safe area to operate to full range.

Intrinsic Safety (Ex i) Barriers There are two types of intrinsic safety barriers : 1) Zener barrier (2) Active barrier. 1) Zener barrier: The series resistor limits the current to the hazardous area. The zener barrier is a loop which can restrict the current by the resistor. At the same time it must allow the loop to function normally by allowing the required values of current to flow in normal operation to enable the instrument in the safe area to operate to full range.

Intrinsically Safe (Ex i) Barriers

Intrinsic Safety (Ex i) Barriers

Intrinsically Safe (Ex i) Barriers Fuse Transformer Safety Barrier with up to 3 Zeners for triple redundancy NON HAZARDOUS AREA Field Device HAZARDOUS AREA Read Details

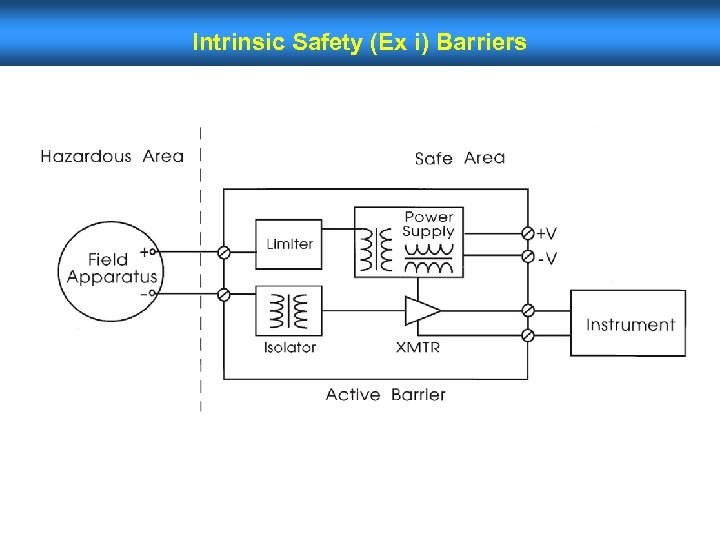

Intrinsic Safety (Ex i) Barriers 2) Active Barrier: The active barrier uses transformers, opto isolators and relays to provide the isolation between the safe and unsafe areas. It does not require an intrinsically safe ground connection. This is the safest barrier to use if a high quality intrinsically safe ground connection is not available. The active barrier can drive a higher power load as compared to a zener barrier.

Intrinsic Safety (Ex i) Barriers

Intrinsically Safe (Ex i) Barriers Advantages: 1. A Transformer Isolation Barrier (TIB) contains current limiting circuitry that limits the short circuit current and the fuse does not blow unlike the zener barrier. 2. TIBs can be connected in parallel so that one power supply can feed multiple TIBs. 3. It is designed for specific applications (transmitters, solenoids, switching inputs, thermocouples), allowing easy system design 4. It does not require an IS ground as the transformer isolates hazardous area connection from non hazardous area; However for enhanced safety reasons, grounding is done. 5. Regulated power supply is not required. 6. Any process control signal to remains floating unlike for a zener barrier where one side is grounded. 7. It can be repaired.

Intrinsically Safe (Ex i) Barriers TIBs are used when: 1. Installation of a high integrity IS grounding is not available. 2. Regulated power supply is available. 3. The potential of signal noise due to ground loop is un desirable. 4. The cost of replacing the Zener barrier exceeds the cost of TIB. 5. The total loop resistance exceeds the specification.

Intrinsic Safety Barrier and Components’ Certification 1. Any device which does not fall into the category of a simple apparatus must be certified. This includes transmitters, solenoids, etc which store energy. 2. A barrier cannot be used to make an uncertified device in the hazardous area safe. If the field device is uncertified it can have energy storing components. In the event of a fault this energy can be released to ignite the flammable gases. 3. The barrier only protects the hazardous area from the energy released from the safe area’s uncertified devices. 4. An intrinsic safety barrier thus enables a non certified device in the safe area to be connected to a simple device or a certified device in the hazardous area and is an energy limiting device.

Certification 1. Why doesn’t a customer just buy a safety product from a vendor, connect them up and pronounce them as safe? 2. Why does he need an approval agency? The approval agency does all the safety analysis for the end user. The user does not have the responsibility to decide whether the products are safe or not. The user does not have the extensive ignition testing facility used by the certifying agency. The customer may have queries wrt to the intrinsically safe devices, field devices or combined devices and he can ask the vendor bout such information. The vendor has to provide certification papers, drawings etc as required by the customer. The vendor has to answer the customers queries wrt use of his equipment.

Certifying Agencies 1. USA : NEC (National electric code), FMRC (Factory mutual research corporation) 2. Canada : CSA (Canadian safety association) 3. UK : BASEEFA (British Approvals Service for Electrical Equipment in Flammable Atmospheres) 4. Other countries have their own agencies as approved by their government.

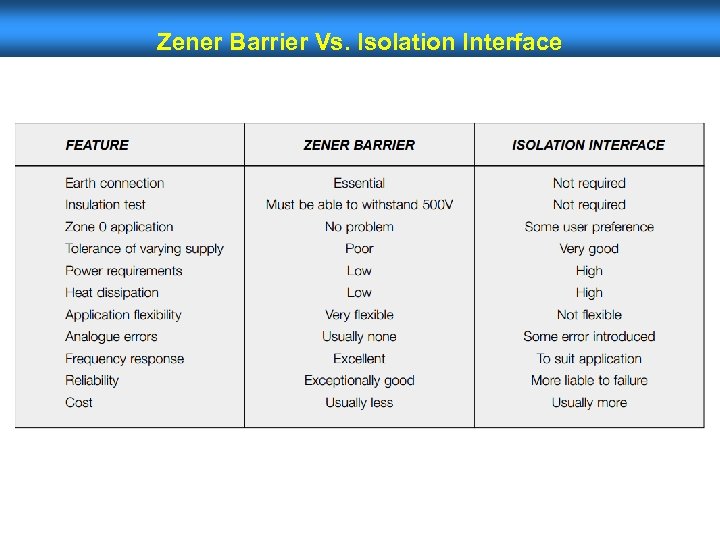

Zener Barrier Vs. Isolation Interface

Intrinsically Safe (Ex i) Barriers

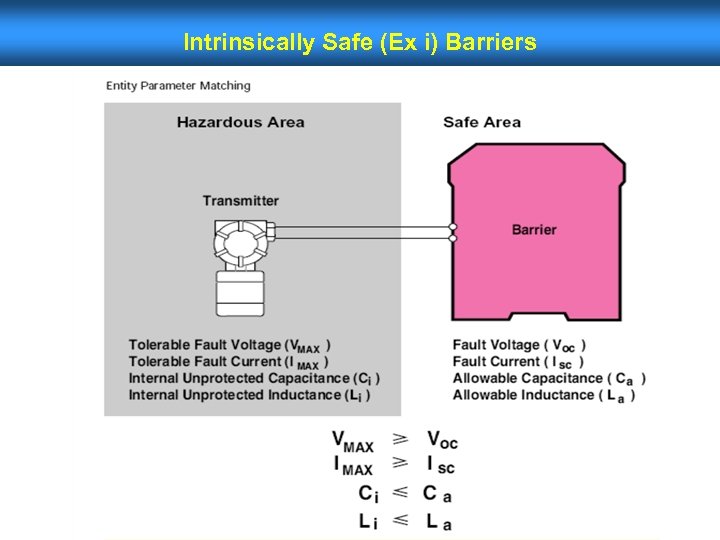

The Entity Concept for EXi Equipment 1. The Entity concept specifies the maximum amount of energy an intrinsic barrier can ever deliver and also the maximum amount of energy the field device can safely receive. 2. The Entity concept allows interconnection of IS barriers to IS field devices not specifically tested for such combination. 3. It also allows mixing up of equipment from different manufacturers without additional approvals.

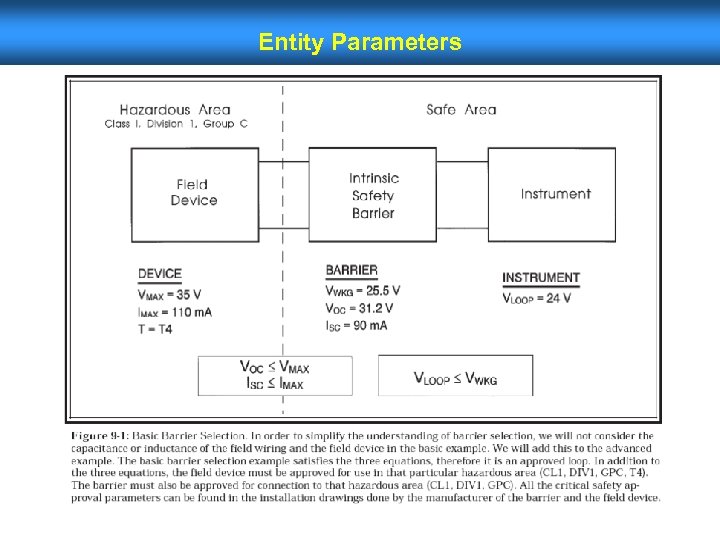

Entity Equations for Current and Voltage Entity equations for current and voltage: 1. An IS barrier can safely be used with a field device if it has a maximum current and voltage less than or equal to that which the field can safely receive. 2. All these parameters are defined by the approval agency. 3. Entity equations for current and voltage : I total (barrier) <= I max (field device) V total (barrier) <= V max (field device)

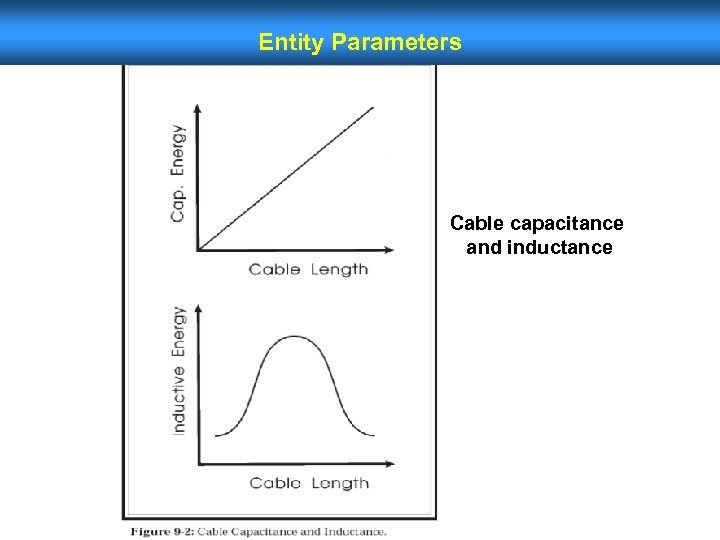

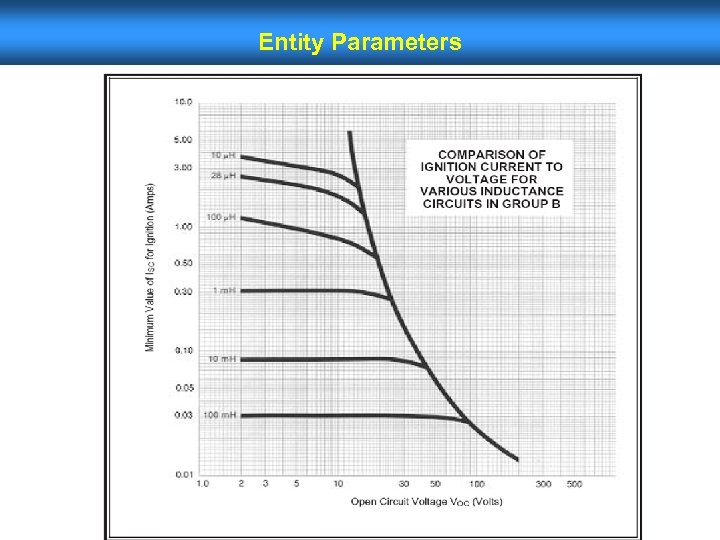

Entity Parameters • • • In addition to voltage and current the entity parameters also include two more terms to ensure that the energy storing devices in the field do not store up dangerous amounts of energy. These terms deal with the capacitance and inductance of the system. A barrier has parameters which state the maximum capacitance and inductance that can be safely be connected to it. The field device has parameters which state the equivalent capacitance and inductance of the field device. Since the wiring has capacitance and inductance this also has to be considered. The total capacitance and inductance must not exceed that permitted by the barrier

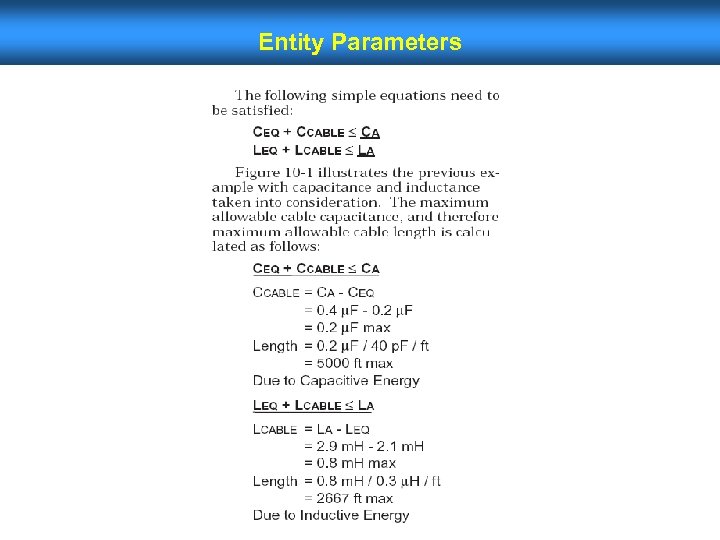

Entity Parameters Entity equations for capacitance and inductance Capacitance (field device) + Capacitance (field wiring) <= Capacitance (I. S. Barrier Max) Inductance (field device) + Inductance (field device) <= Inductance (I. S. Barrier Max)

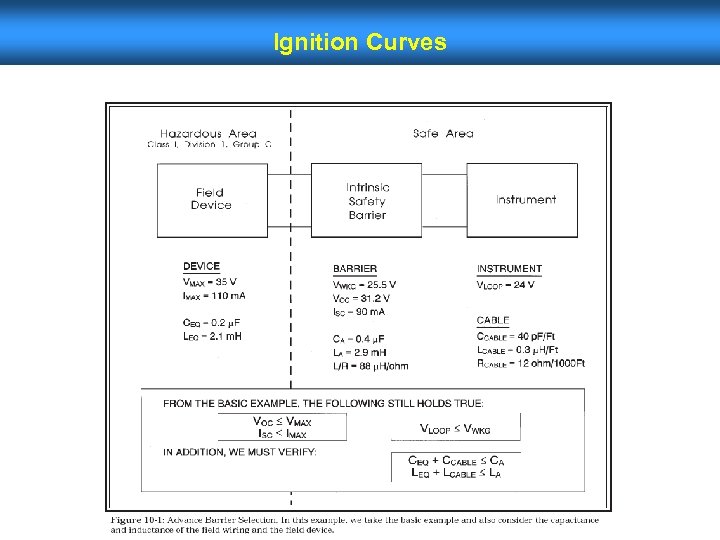

Entity Parameters 1. 2. 3. 4. The field device is approved for the hazardous area if it never receives more than 35 V. The barrier ensures this. the barrier can never deliver more than 90 m. A to the hazardous area under fault condition. The field device is safe as long as it never receives more than 110 m. A. The barrier ensures this as well. Therefore because the voltage and current entity parameters match up correctly, this circuit is intrinsically safe.

Entity Parameters 1. 2. 3. 4. 5. The next figure shows a barrier connected between a safe area terminal and a hazardous area field device. this barrier can be safely used and also has approval. The instrument loop operates with normal 24 VDC. The zener diodes do not conduct until their voltage reaches 25. 5 VDC. During a fault the maximum voltage the barrier can deliver to the hazardous area is 31. 2 V.

Entity Parameters

Entity Parameters Capacitance and inductance as entity parameters 1. 2. 3. 4. For this circuit which we considered we did not consider the capacitance and inductance parameters. All the parameters viz, voltage, current, capacitance, inductance must match up correctly. The entity parameters are given by the approval agency and obtained through the manufacturer. These are shown in the installation drawing.

Entity Parameters Cable capacitance and inductance 1. 2. 3. 4. A cable is an energy storing device. Cable can store capacitance and inductive energy. From an intrinsic safety point of view, this cabling has to be considered. The attached diagrams show the capacitance and inductance of cabling as function of length.

Entity Parameters Choice of cable length 1. 2. 3. 4. Considering capacitance 5000 ft is the largest possible length allowed. Considering inductance maximum cable length permitted is 2667 ft. Thus having known the cable length, the designer can ascertain other required parameters. The values use viz 40 pf/ft and 0. 3 micro H/ft are high values chosen and are normally not exceeded.

Entity Parameters

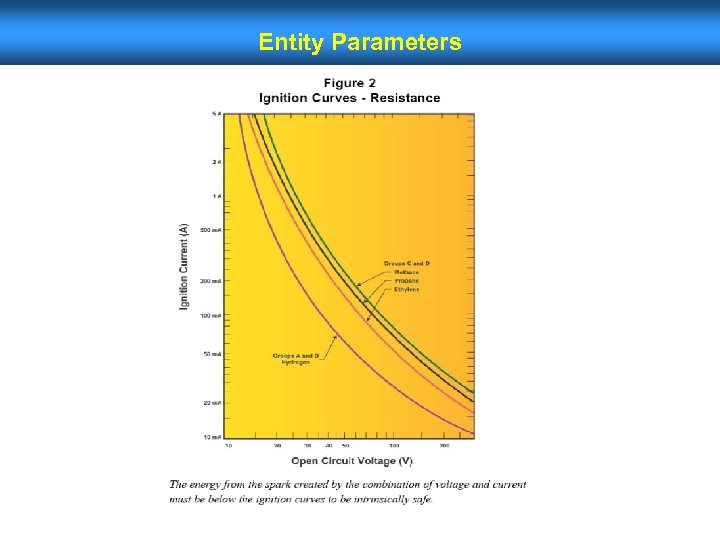

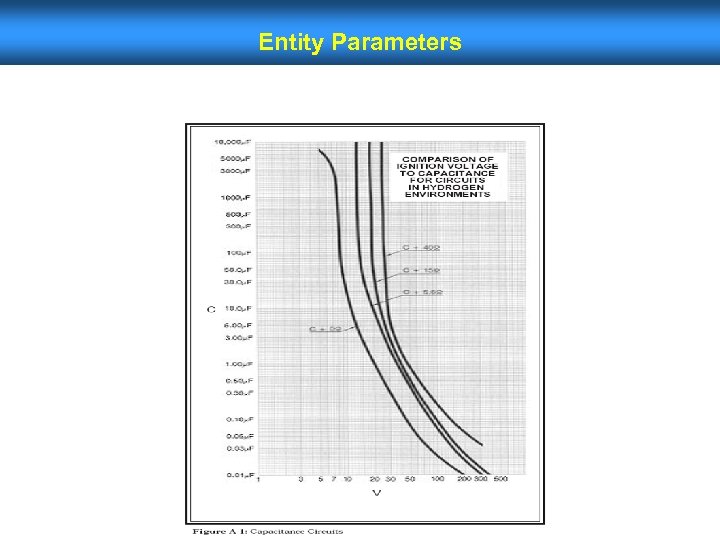

Ignition Curves

Entity Parameters Cable capacitance and inductance

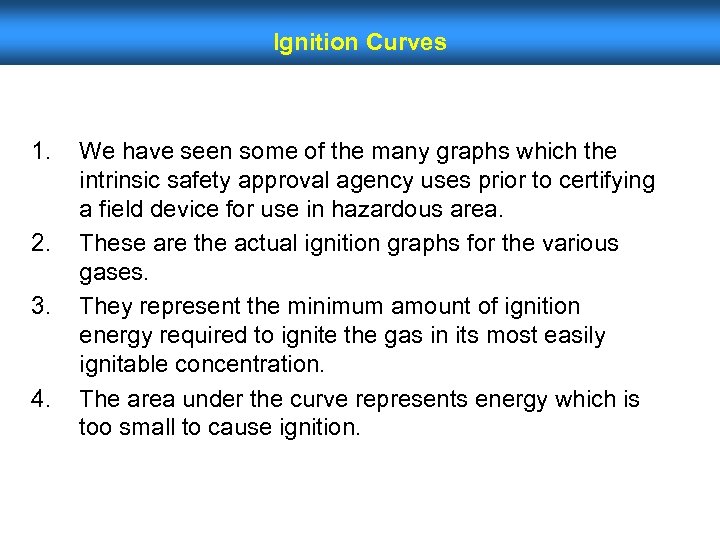

Ignition Curves 1. 2. 3. The following graphs are actual ignition curves for various gases. They represent the minimum amount of ignition energy required to ignite the gas in its most easily ignitable concentration. The area under the curve represents energy which is too small to cause ignition.

Entity Parameters

Entity Parameters

Entity Parameters

Ignition Curves 1. 2. 3. 4. We have seen some of the many graphs which the intrinsic safety approval agency uses prior to certifying a field device for use in hazardous area. These are the actual ignition graphs for the various gases. They represent the minimum amount of ignition energy required to ignite the gas in its most easily ignitable concentration. The area under the curve represents energy which is too small to cause ignition.

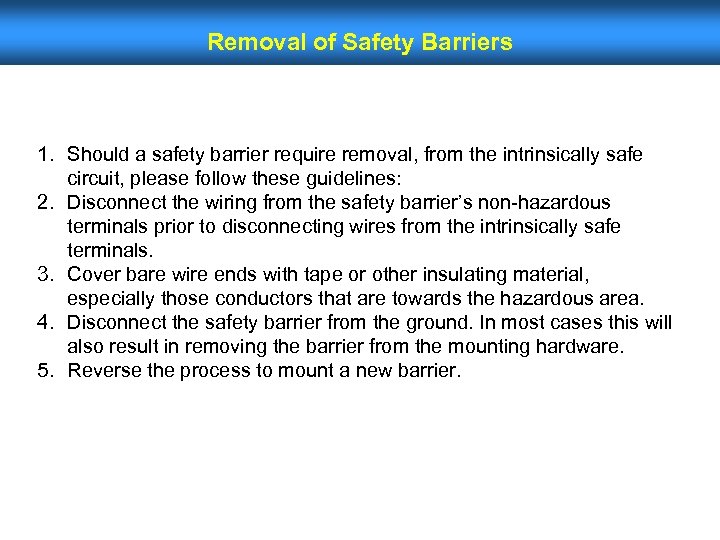

Removal of Safety Barriers 1. Should a safety barrier require removal, from the intrinsically safe circuit, please follow these guidelines: 2. Disconnect the wiring from the safety barrier’s non-hazardous terminals prior to disconnecting wires from the intrinsically safe terminals. 3. Cover bare wire ends with tape or other insulating material, especially those conductors that are towards the hazardous area. 4. Disconnect the safety barrier from the ground. In most cases this will also result in removing the barrier from the mounting hardware. 5. Reverse the process to mount a new barrier.

Intrinsically Safe Relays DA 149 Series Intrinsically Safe Relay • Used for isolated signal transfer between safe and hazardous area. • Inputs / outputs are galvanically isolated; no earth is required. • Certified equivalent to ‘simple apparatus’ no system certificate is required. • Extremely low power, avoids affecting operation of connected equipment. • Relay coil; AC or DC energised over a wide voltage range. • Can be supplied in safe or hazardous mounting versions. • DIN rail mounting slim case.

Intrinsically Safe Relays DA 149 Series Intrinsically Safe Relay • Used for isolated signal transfer between safe and hazardous area. • Inputs / outputs are galvanically isolated; no earth is required. • Certified equivalent to ‘simple apparatus’ no system certificate is required. • Extremely low power, avoids affecting operation of connected equipment. • Relay coil; AC or DC energised over a wide voltage range. • Can be supplied in safe or hazardous mounting versions. • DIN rail mounting slim case.

Intrinsically Safe Relays DA 149 Series Intrinsically Safe Relay By using DA 149 intrinsically safe isolating relays, control signals and other data can be exchanged between items of equipment in hazardous area and between hazardous and safe area equipment. Since the relays require very little power they do not affect the operation of other equipment connected.

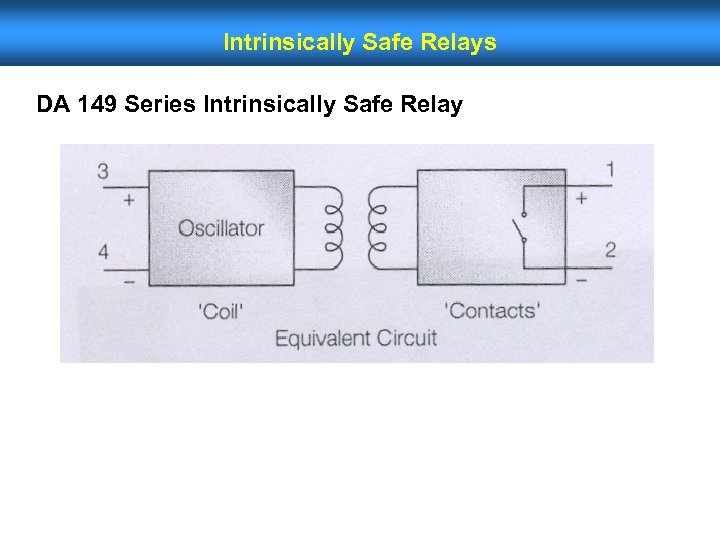

Intrinsically Safe Relays DA 149 Series Intrinsically Safe Relay

Intrinsically Safe Relays DA 149 Series Intrinsically Safe Relay • Each relay is a solid state device consisting of an oscillator and an intrinsically safe transformer to provide the necessary isolated coupling to a MOSFET switch. • For all practical purposes each can be regarded as a coil and a normally open contact. • Diodes are connected in series with the hazardous area input / and or output terminals to make them electrically equivalent to ‘simple apparatus’, ie, they can be included in any IS lop without any IS certification.

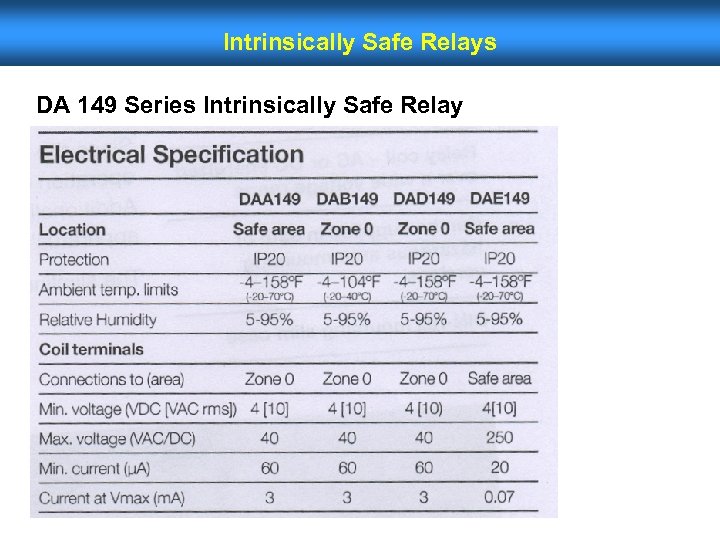

Intrinsically Safe Relays DA 149 Series Intrinsically Safe Relay Inputs and outputs are galvanically isolated so they do not require any IS grounding. The only power required is less than 60 µA at 4. 0 V to energize the coil by comparison with certified opto isolators or relays which need at least 10 m. A to function, so the relays can be used in virtually in any loop powered system without affecting the operation. These relays can be mounted either in the safe area OR in the hazardous area as required for specific use. . DAA 149 IS relay, Zone 0 to Safe area. DAB 149 IS relay, Zone 0 to Zone 0; 100 m. A fuse. DAD 149 IS relay, Zone 0 to Zone 0; 50 m. A fuse. DAE 149 IS relay, Safe area to Zone 0; 250 m. A fuse.

Intrinsically Safe Relays DA 149 Series Intrinsically Safe Relay

Intrinsically Safe Relays Series RLSH Relays Interface from a Safe Area to a Hazardous Area

Intrinsically Safe Relays Series RLSH Relays Interface from a Safe Area to a Hazardous Area • These relays present volt free contacts to the Safe area in response to the Hazardous area coils. • The certified parameters of the Hazardous area coil terminals are such that they may be used in any IS field loop without further certification.

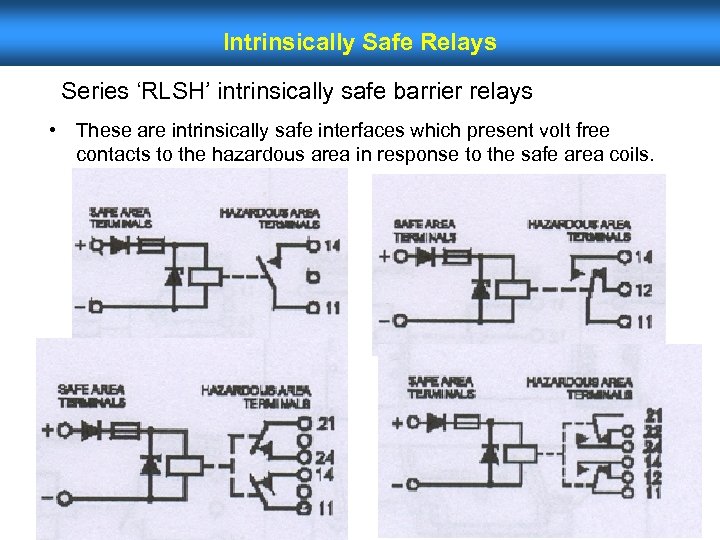

Intrinsically Safe Relays Series ‘RLSH’ intrinsically safe barrier relays • These are intrinsically safe interfaces which present volt free contacts to the hazardous area in response to the safe area coils.

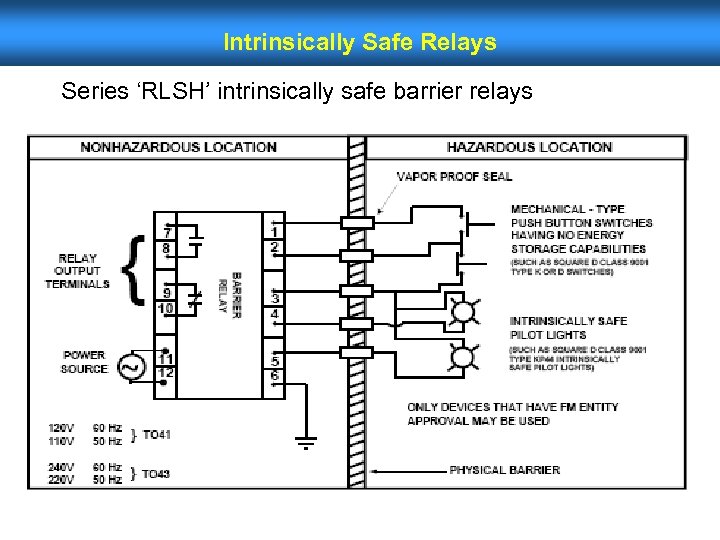

Intrinsically Safe Relays Series ‘RLSH’ intrinsically safe barrier relays

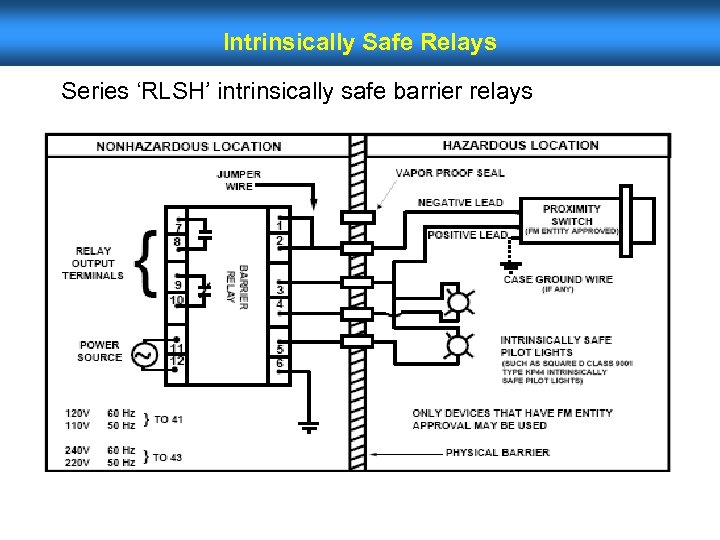

Intrinsically Safe Relays Series ‘RLSH’ intrinsically safe barrier relays

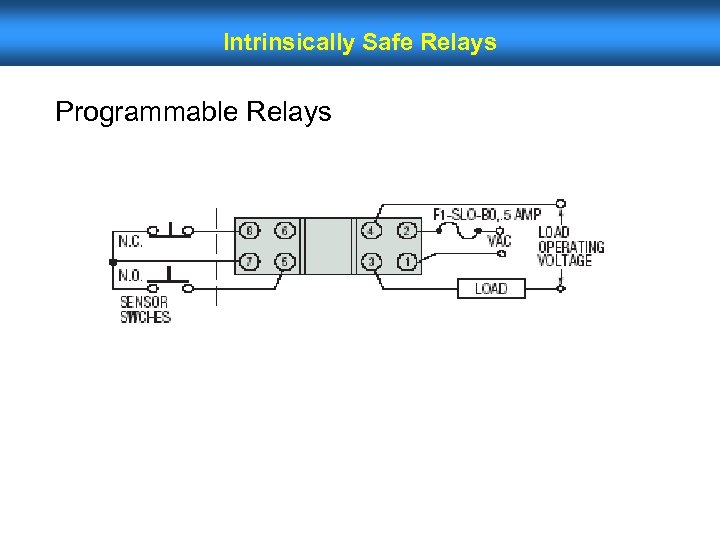

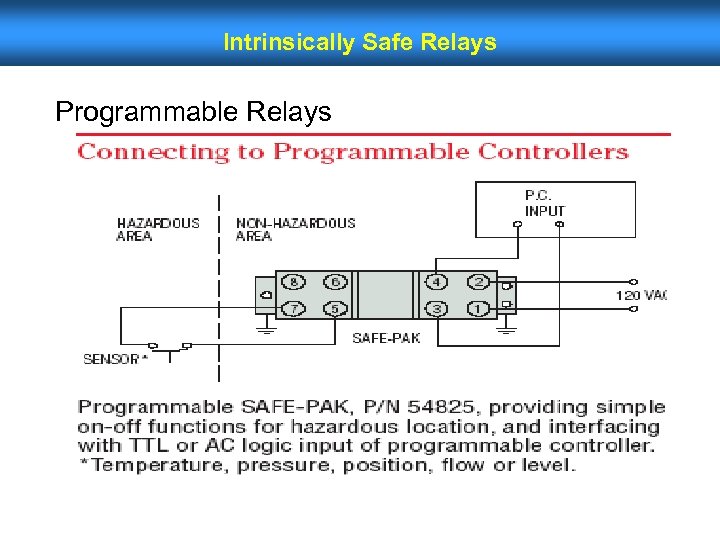

Intrinsically Safe Relays Programmable Relays

Intrinsically Safe Relays Programmable Relays

Intrinsically Safe Relays Programmable Relays

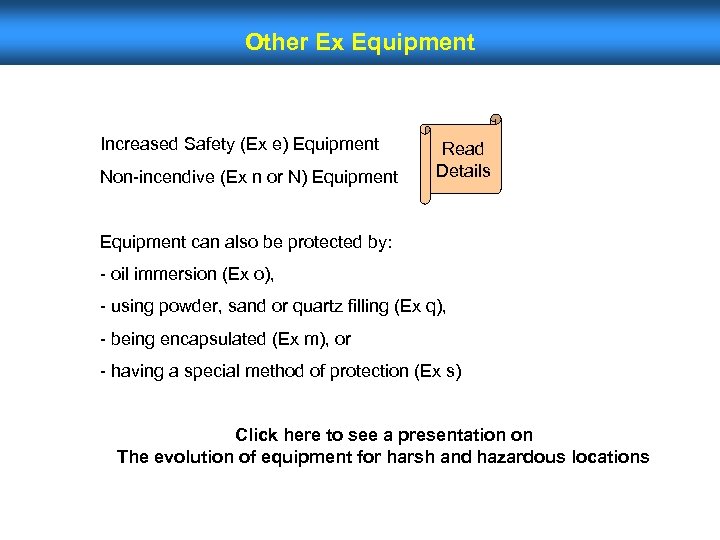

Other Ex Equipment Increased Safety (Ex e) Equipment Non-incendive (Ex n or N) Equipment Read Details Equipment can also be protected by: - oil immersion (Ex o), - using powder, sand or quartz filling (Ex q), - being encapsulated (Ex m), or - having a special method of protection (Ex s) Click here to see a presentation on The evolution of equipment for harsh and hazardous locations

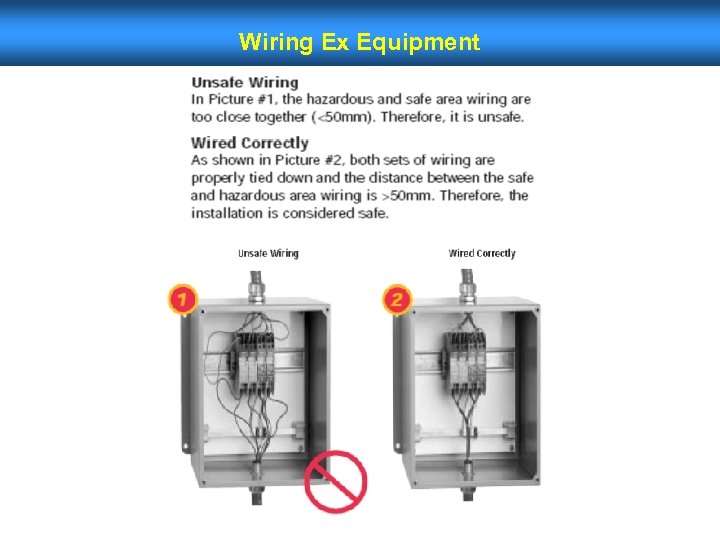

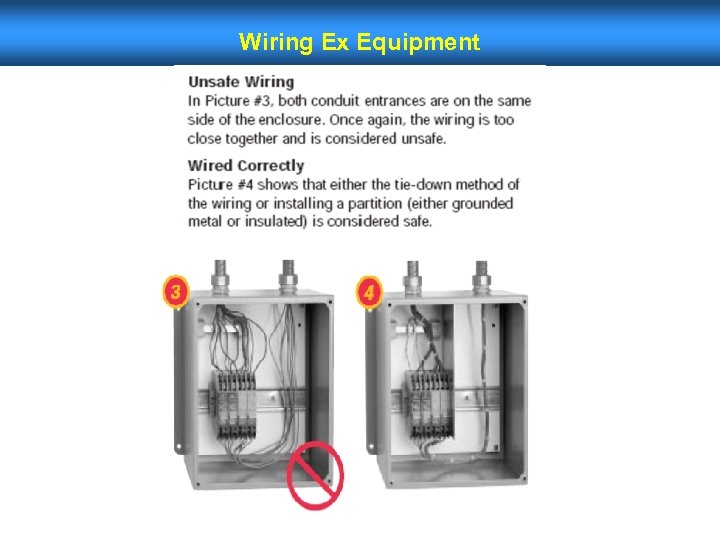

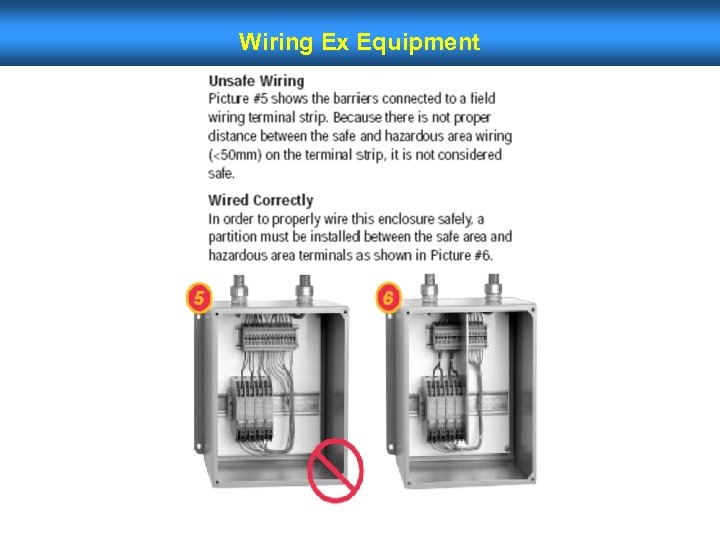

Wiring Ex Equipment

Wiring Ex Equipment

Wiring Ex Equipment

Maintenance of Ex Equipment This section contains the following: Maintenance of Ex Equipment Read Details Read Periodic and Continuous Inspection of Ex Equipment Details A movie on maintaining Ex Equipment like lights and motors The following slides depict methods to maintain a Saab Tank Radar… ü These slides contain movie files that start automatically; ü Click the left button of your mouse to stop a movie; ü Click the left button of your mouse on this to proceed to the next slide

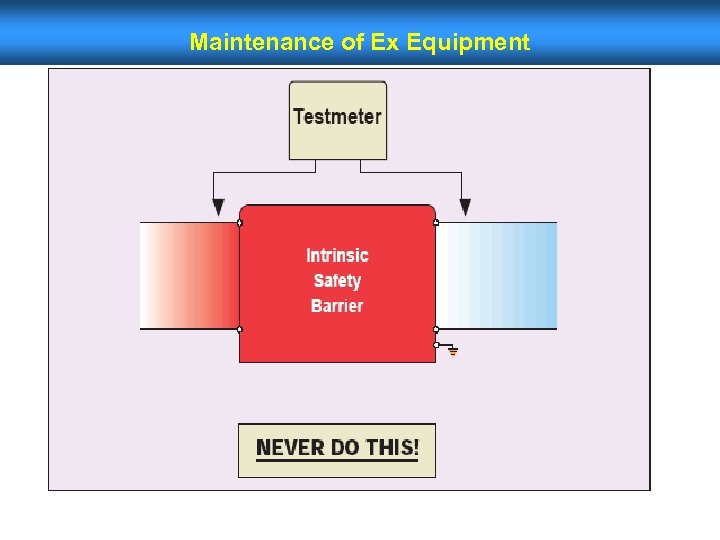

Maintenance of Ex Equipment

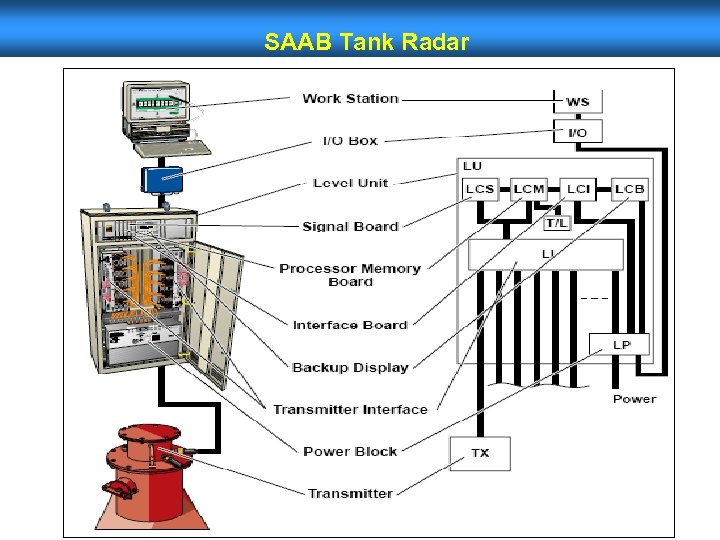

SAAB Tank Radar

Cleaning The Parabolic Antenna Courtesy: SAAB Marine Electronics As the IG Pressure Sensor is in the same housing, it will be shown automatically after this video clip Back to Diagram Skip this video clip

Cleaning an IG Pressure Sensor Courtesy: SAAB Marine Electronics As the IG Pressure Sensor is in the same housing, it will be shown automatically after this video clip Back to Diagram Skip this video clip

Replacing an Inert Gas Pressure Sensor Courtesy: SAAB Marine Electronics Back to Diagram Skip this video clip

Cleaning the cone antenna transmitter Courtesy: SAAB Marine Electronics Back to Diagram Skip this video clip

Replacing a Board in the I / O Box Courtesy: SAAB Marine Electronics Back to Diagram Skip this video clip

Replacing the LCI (Interface) Board Courtesy: SAAB Marine Electronics Back to Diagram Skip this video clip

Replacing the LCM (Processor Memory) Board Courtesy: SAAB Marine Electronics Back to Diagram Skip this video clip

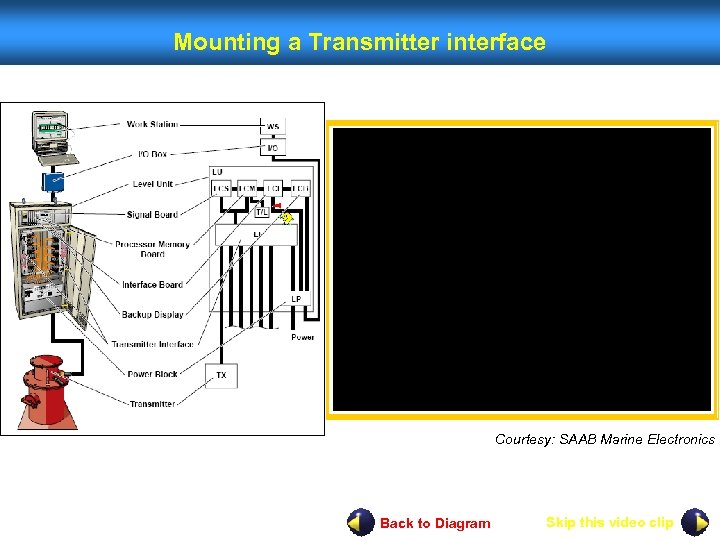

Mounting a Transmitter interface Courtesy: SAAB Marine Electronics Back to Diagram Skip this video clip

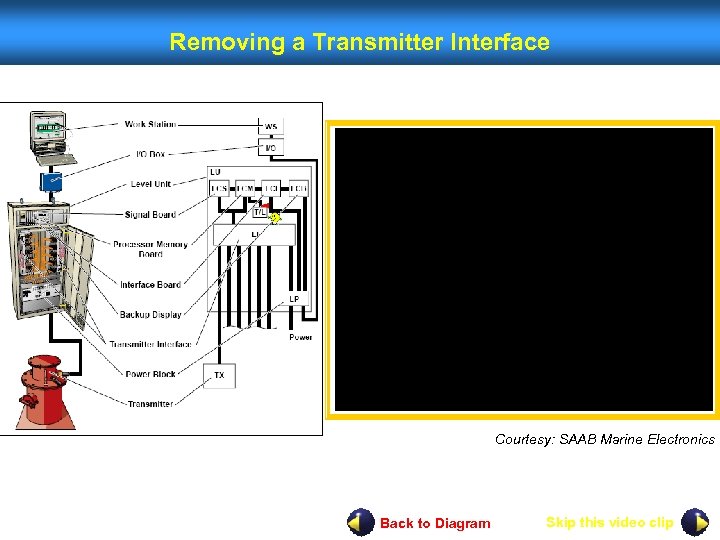

Removing a Transmitter Interface Courtesy: SAAB Marine Electronics Back to Diagram Skip this video clip

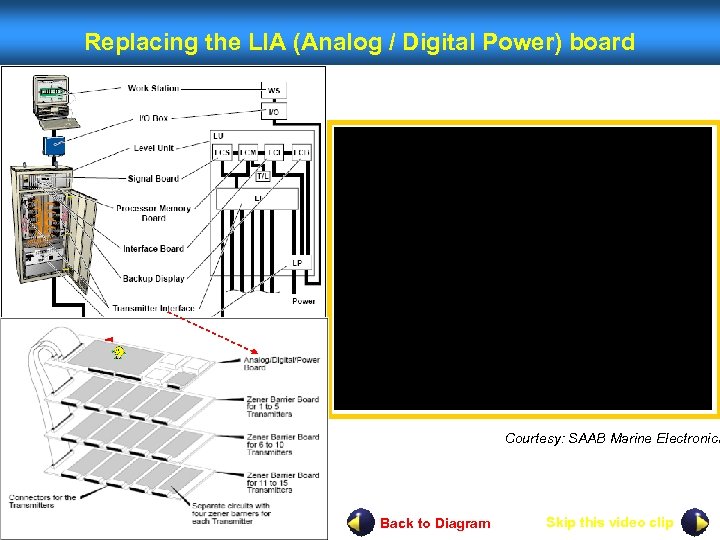

Replacing the LIA (Analog / Digital Power) board Courtesy: SAAB Marine Electronics Back to Diagram Skip this video clip

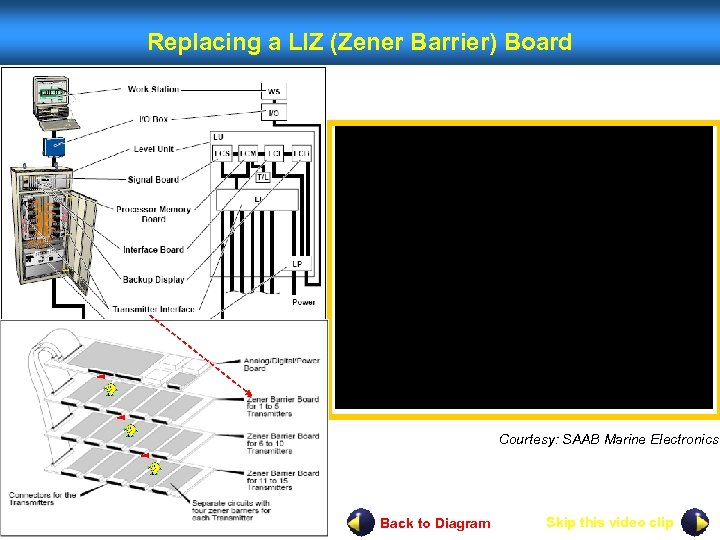

Replacing a LIZ (Zener Barrier) Board Courtesy: SAAB Marine Electronics Back to Diagram Skip this video clip

Replacing a card in the Work Station Courtesy: SAAB Marine Electronics As the Hard Disk is in the same housing, it will be shown automatically after this video clip Back to Diagram Skip this video clip

Replacing a hard disk in the Work Station Courtesy: SAAB Marine Electronics This ends the maintenance of essential components of the SAAB Tank Radar Back to Diagram Skip this video clip

Probable Questions by Examiners 1) Show “Hazardous Zones” are classified on board a tanker. 2) Predict the possible “Electrical Sources of Ignition” that can be considered to be “Hazardous”. 3) Identify the “Explosion Protected Equipment” in terms of “Symbol” and “Type of Protection”. 4) State the significance of equipment marked: Exd; Exe; Exp; Exi; and Exn. 5) Demonstrate the precautionary measures in the maintenance of explosive proof lights. 6) Describe / demonstrate essential items to be checked on “Ex-Protected” Apparatus.

May you have a safe voyage Suggestions to upgrade / correct this module are welcome Please email any queries or advice to elstan. a. fernandez@gmail. com

05a179fa7758b49cb4ff0e57f481cd57.ppt