07395a8eec1ccc16a931cb852da59a7f.ppt

- Количество слайдов: 35

o Electro chlorination is the name given to process whereby an electrical current is used to convert sodium chloride solution to sodium hypochlorite or chlorine. o In practice a number of electrodes are normally connected together to form an electrolyser assembly. o Brine solution passes through the Oxi. Max electrolyser cells where it is electrochemically transformed into sodium hypochlorite (Na. OCl). o The overall reaction, sustained by electrical energy, is as follows: o 2 Na. Cl (salt) + H 2 O (water) + Energy = Na. OCl (hypo) + Na. Cl ( salt ) + H 2 ( hydrogen )

o Electro chlorination is the name given to process whereby an electrical current is used to convert sodium chloride solution to sodium hypochlorite or chlorine. o In practice a number of electrodes are normally connected together to form an electrolyser assembly. o Brine solution passes through the Oxi. Max electrolyser cells where it is electrochemically transformed into sodium hypochlorite (Na. OCl). o The overall reaction, sustained by electrical energy, is as follows: o 2 Na. Cl (salt) + H 2 O (water) + Energy = Na. OCl (hypo) + Na. Cl ( salt ) + H 2 ( hydrogen )

Electrochlorination The fundamental laws of electrolysis were developed by English scientist, Michael Faraday in 1833. In simple terms they relate to the process of passing an electric current through an aqueous salt solution. In modern terms the laws can be stated as follows: The mass of an element discharged at an electrode m is directly proportional to the amount of electrical charge Q passed through the electrode. If the same amount of electrical charge Q is passed through several electrodes, the mass m of an element discharged at each electrode will be directly proportional to both (a) the atomic mass of the element, and (b) the number of moles of electrons required to discharge one mole of the element from whatever material is being discharged at the electrode ( the charge number z). Not only did Faraday explain what was happening during the process of electrolysis, he also introduced the terminology - electrolysis, electrolyte, electrode that we still use today. HYPOCHLORITE

Electrochlorination The fundamental laws of electrolysis were developed by English scientist, Michael Faraday in 1833. In simple terms they relate to the process of passing an electric current through an aqueous salt solution. In modern terms the laws can be stated as follows: The mass of an element discharged at an electrode m is directly proportional to the amount of electrical charge Q passed through the electrode. If the same amount of electrical charge Q is passed through several electrodes, the mass m of an element discharged at each electrode will be directly proportional to both (a) the atomic mass of the element, and (b) the number of moles of electrons required to discharge one mole of the element from whatever material is being discharged at the electrode ( the charge number z). Not only did Faraday explain what was happening during the process of electrolysis, he also introduced the terminology - electrolysis, electrolyte, electrode that we still use today. HYPOCHLORITE

HOW IT WORKS

HOW IT WORKS

o Safe – No Hazardous Chemicals to handle, transport or store. o Reliable – hundreds of systems operating over many years. o Efficient – high efficiency electrodes, leading edge design. o Low Operating Cost - low salt and power requirements = < ½ Chlorine gas or Bulk Hypochlorite.

o Safe – No Hazardous Chemicals to handle, transport or store. o Reliable – hundreds of systems operating over many years. o Efficient – high efficiency electrodes, leading edge design. o Low Operating Cost - low salt and power requirements = < ½ Chlorine gas or Bulk Hypochlorite.

o International Experience – Water Engineers have installed hundreds of Electrochlorination systems throughout the world and we have been manufacturing equipment for over 17 years. We are ISO 9001 – 2000 Certified and we have many long term customers. International Consulting. o Technology – Water Engineers leads the world in many of our current designs. Key features being High Visibility Cells, high performance long life electrodes, modular Cell systems and leading edge control and power systems. We hold a number of patents for our equipment. o Electrodes – Water Engineers designs and manufactures all electrodes, rather than using third party suppliers. We offer full guarantees on all of our electrodes and equipment. o Focus – The total business of Water Engineers is Electrochlorination, our team is made up of more than 25 specialists including Chemical, Mechanical, Civil, Electrical and Electronic Engineers and our services range from electrode supply to complete turn key installations. We take great pride in our work and offer full recoating and rebuilding work as required.

o International Experience – Water Engineers have installed hundreds of Electrochlorination systems throughout the world and we have been manufacturing equipment for over 17 years. We are ISO 9001 – 2000 Certified and we have many long term customers. International Consulting. o Technology – Water Engineers leads the world in many of our current designs. Key features being High Visibility Cells, high performance long life electrodes, modular Cell systems and leading edge control and power systems. We hold a number of patents for our equipment. o Electrodes – Water Engineers designs and manufactures all electrodes, rather than using third party suppliers. We offer full guarantees on all of our electrodes and equipment. o Focus – The total business of Water Engineers is Electrochlorination, our team is made up of more than 25 specialists including Chemical, Mechanical, Civil, Electrical and Electronic Engineers and our services range from electrode supply to complete turn key installations. We take great pride in our work and offer full recoating and rebuilding work as required.

Advanced Features: □ Built with engineering plastics □ Controlled by microprocessor based pre-programmed logic control system □ Oxi. Max incorporates sensor system to automatically sense operations through out the process to minimize operator intervention □ Only electro chlorinator manufactured in India incorporating reference cell technology for accurate salinity check before hypo generation □ Only system manufactured in India with a see-through process □ Integrated brine storage and hypo storage tank MODEL Capacity of active chlorine generation per hour Capacity active chlorine generation 24 Hours Quantity of water that can be treated with 24 hour generation @ 1 PPM MMi 15 15 Grams 360 Grams 3, 60, 000 Litres MMi 25 25 Grams 600 Grams 6, 000 Litres MMi 50 50 Grams 1200 Grams 12, 000 Litres

Advanced Features: □ Built with engineering plastics □ Controlled by microprocessor based pre-programmed logic control system □ Oxi. Max incorporates sensor system to automatically sense operations through out the process to minimize operator intervention □ Only electro chlorinator manufactured in India incorporating reference cell technology for accurate salinity check before hypo generation □ Only system manufactured in India with a see-through process □ Integrated brine storage and hypo storage tank MODEL Capacity of active chlorine generation per hour Capacity active chlorine generation 24 Hours Quantity of water that can be treated with 24 hour generation @ 1 PPM MMi 15 15 Grams 360 Grams 3, 60, 000 Litres MMi 25 25 Grams 600 Grams 6, 000 Litres MMi 50 50 Grams 1200 Grams 12, 000 Litres

Model capacity active chlorine generation per hour Capacity active chlorine generation per day Quantity of water that can be treated in one day @1 PPM MM 100 Grams 2. 4 – 3 kg 25, 000 Ltr MM 150 Grams 3. 6 - 4. 0 kg 36, 000 Ltr MM 250 Grams 6. 0 – 6. 5 Kg 60, 000 Ltr MM 350 Grams 8. 4 -9. 0 kg 84, 000 Ltr MM 500 Grams 12. 0 -12. 5 kg 120, 000 Ltr MM 750 Grams 18. 0 -18. 5 kg 180, 000 Ltr MM 1000 Grams 24. 0 -24. 5 kg 240, 000 Ltr MM 1500 Grams 36. 0 -36. 5 kg 360, 000 Ltr MM 2000 Grams 48. 0 -48. 5 kg 480, 000 Ltrs MM 3000 Grams 72. 0 -73. 0 kg 720, 000 Ltrs

Model capacity active chlorine generation per hour Capacity active chlorine generation per day Quantity of water that can be treated in one day @1 PPM MM 100 Grams 2. 4 – 3 kg 25, 000 Ltr MM 150 Grams 3. 6 - 4. 0 kg 36, 000 Ltr MM 250 Grams 6. 0 – 6. 5 Kg 60, 000 Ltr MM 350 Grams 8. 4 -9. 0 kg 84, 000 Ltr MM 500 Grams 12. 0 -12. 5 kg 120, 000 Ltr MM 750 Grams 18. 0 -18. 5 kg 180, 000 Ltr MM 1000 Grams 24. 0 -24. 5 kg 240, 000 Ltr MM 1500 Grams 36. 0 -36. 5 kg 360, 000 Ltr MM 2000 Grams 48. 0 -48. 5 kg 480, 000 Ltrs MM 3000 Grams 72. 0 -73. 0 kg 720, 000 Ltrs

MODEL Capacity active chlorine generation per 8 hours Capacity active chlorine generation 24 hours Quantity of water that can be treated with 24 hours generation @ 1 PPM MMb 15 120 Grams 360 Grams 3, 60, 000 Ltr MMb 25 200 Grams 6, 000 Ltr MMb 50 400 Grams 12, 000 Ltr MMb 100 800 Grams 24, 000 Ltr MMb 150 1200 Grams 36, 000 Ltr MMb 250 2000 Grams 60, 000 Ltr

MODEL Capacity active chlorine generation per 8 hours Capacity active chlorine generation 24 hours Quantity of water that can be treated with 24 hours generation @ 1 PPM MMb 15 120 Grams 360 Grams 3, 60, 000 Ltr MMb 25 200 Grams 6, 000 Ltr MMb 50 400 Grams 12, 000 Ltr MMb 100 800 Grams 24, 000 Ltr MMb 150 1200 Grams 36, 000 Ltr MMb 250 2000 Grams 60, 000 Ltr

The MT Series is a new range of electro chlorination equipment designed for a variety of on-line water treatment/disinfection applications, including Swimming pools and water parks. Water with natural salinity requires no raw material. Natural salts in water are converted to chlorine.

The MT Series is a new range of electro chlorination equipment designed for a variety of on-line water treatment/disinfection applications, including Swimming pools and water parks. Water with natural salinity requires no raw material. Natural salts in water are converted to chlorine.

Oxi. Max electro chlorination equipment comes in various capacities starting from 15 grams per hour to 40 kg of active chlorine generation. Oxi. Max has advanced instrumentation and process can be explained as under: Stage – 1: Operator has to fill the Salt saturation tank with salt upto 2/3 rd level. This salt is sufficient for 4 -8 days of salt requirement Stage – 2: Switch on the power Stage-3: Job of operator ends and system takes over. Water starts pouring into the brine tank as well as generation tank and will stop automatically once a pre-determined level is reached. Immediately thereafter, saturated brine shall start moving to generation chamber and will stop once it satisfies the salinity check system requirement System is fitted with a unique reference cell to check accurate salinity required to generate desired hypo. Only after checking accuracy, it shall trigger main cell for hypo generation. Hypo ready transfer to storage tank

Oxi. Max electro chlorination equipment comes in various capacities starting from 15 grams per hour to 40 kg of active chlorine generation. Oxi. Max has advanced instrumentation and process can be explained as under: Stage – 1: Operator has to fill the Salt saturation tank with salt upto 2/3 rd level. This salt is sufficient for 4 -8 days of salt requirement Stage – 2: Switch on the power Stage-3: Job of operator ends and system takes over. Water starts pouring into the brine tank as well as generation tank and will stop automatically once a pre-determined level is reached. Immediately thereafter, saturated brine shall start moving to generation chamber and will stop once it satisfies the salinity check system requirement System is fitted with a unique reference cell to check accurate salinity required to generate desired hypo. Only after checking accuracy, it shall trigger main cell for hypo generation. Hypo ready transfer to storage tank

Factor Chlorine Gas Commercial Hypochlorite Bleaching Powder Oxi. Max generated onsite hypochlorite SAFETY Chlorine is a dangerous gas Is a hazardous chemical Concentration less than 1% and completely safe to handle CORROSIVE NATURE Highly corrosive Highly Corrosive Not corrosive due to low concentration TRANSPORTATION Difficult to transport due to hazardous nature Difficult to reach remote locations Generated onsite. No transportation required STABILITY Stable but wastage can not be avoided Highly unstable Stable DOSING ACCURACY Possible Not possible due to unstable nature Can dose accurately COST Considering the cost of safety equipment and arrangements required along with gas chlorination, cost works out extremely high Very high. Per kg of free chlorine works out to more than 100/- Very high. Per kg of chlorine works out to approximately 70/- Per kg of chlorine will cost only about 15/- USER FRIENDLY No. Operators scared to use. Requires plethora of safety equipments. No. Chemical requires safe handling No. Requires safe handling Yes. No safety requirements. Concentration below hazard limit

Factor Chlorine Gas Commercial Hypochlorite Bleaching Powder Oxi. Max generated onsite hypochlorite SAFETY Chlorine is a dangerous gas Is a hazardous chemical Concentration less than 1% and completely safe to handle CORROSIVE NATURE Highly corrosive Highly Corrosive Not corrosive due to low concentration TRANSPORTATION Difficult to transport due to hazardous nature Difficult to reach remote locations Generated onsite. No transportation required STABILITY Stable but wastage can not be avoided Highly unstable Stable DOSING ACCURACY Possible Not possible due to unstable nature Can dose accurately COST Considering the cost of safety equipment and arrangements required along with gas chlorination, cost works out extremely high Very high. Per kg of free chlorine works out to more than 100/- Very high. Per kg of chlorine works out to approximately 70/- Per kg of chlorine will cost only about 15/- USER FRIENDLY No. Operators scared to use. Requires plethora of safety equipments. No. Chemical requires safe handling No. Requires safe handling Yes. No safety requirements. Concentration below hazard limit

Oxi. Max compared with other techniques Factor OZONE CHLORINE DIOXIDE CHLORAMI NES OXIMAX What is this? Oxygen containing feed gas in an electrical discharge, which is passed between electrodes, charged at 20, 000 volts. A pale blue gas with a distinct pungent odour. Mix of potassium chlorate and hydrochloric acid. Initially called Euchlorine Formed by combining chlorine and ammonia. Onsite generation of hypochlorite by electrolysis of salt.

Oxi. Max compared with other techniques Factor OZONE CHLORINE DIOXIDE CHLORAMI NES OXIMAX What is this? Oxygen containing feed gas in an electrical discharge, which is passed between electrodes, charged at 20, 000 volts. A pale blue gas with a distinct pungent odour. Mix of potassium chlorate and hydrochloric acid. Initially called Euchlorine Formed by combining chlorine and ammonia. Onsite generation of hypochlorite by electrolysis of salt.

Oxi. Max compared with other techniques Factor SAFETY OZONE CHLORINE DIOXIDE CHLORAMI NES OXIMAX Ozone gas is extremely toxic. Unstable gas or liquid- can explode with changes in the environment such as temprature rising, exposure to light and contact with some organic substance. Required to be mixed onsite – is hazardous as contact is extremely dangerous. Handling of chemicals such as chlorine and ammonia. Raw material is only common salt. No handling of chemicals.

Oxi. Max compared with other techniques Factor SAFETY OZONE CHLORINE DIOXIDE CHLORAMI NES OXIMAX Ozone gas is extremely toxic. Unstable gas or liquid- can explode with changes in the environment such as temprature rising, exposure to light and contact with some organic substance. Required to be mixed onsite – is hazardous as contact is extremely dangerous. Handling of chemicals such as chlorine and ammonia. Raw material is only common salt. No handling of chemicals.

Oxi. Max compared with other techniques Factor Advantages OZONE CHLORINE DIOXIDE CHLORAMI NES Powerful disinfectant. More effective than chlorine dioxide. Very Forms more effective stable disinfectant. residual than chlorine. OXIMAX Very effective disinfectant.

Oxi. Max compared with other techniques Factor Advantages OZONE CHLORINE DIOXIDE CHLORAMI NES Powerful disinfectant. More effective than chlorine dioxide. Very Forms more effective stable disinfectant. residual than chlorine. OXIMAX Very effective disinfectant.

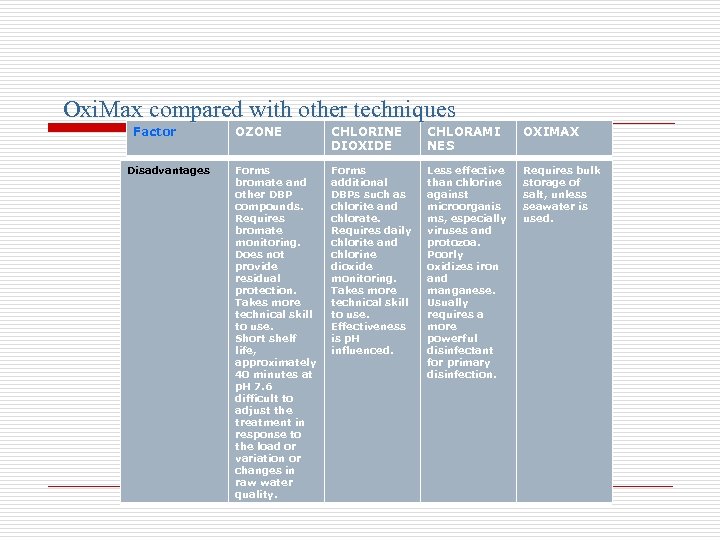

Oxi. Max compared with other techniques Factor Disadvantages OZONE CHLORINE DIOXIDE CHLORAMI NES OXIMAX Forms bromate and other DBP compounds. Requires bromate monitoring. Does not provide residual protection. Takes more technical skill to use. Short shelf life, approximately 40 minutes at p. H 7. 6 difficult to adjust the treatment in response to the load or variation or changes in raw water quality. Forms additional DBPs such as chlorite and chlorate. Requires daily chlorite and chlorine dioxide monitoring. Takes more technical skill to use. Effectiveness is p. H influenced. Less effective than chlorine against microorganis ms, especially viruses and protozoa. Poorly oxidizes iron and manganese. Usually requires a more powerful disinfectant for primary disinfection. Requires bulk storage of salt, unless seawater is used.

Oxi. Max compared with other techniques Factor Disadvantages OZONE CHLORINE DIOXIDE CHLORAMI NES OXIMAX Forms bromate and other DBP compounds. Requires bromate monitoring. Does not provide residual protection. Takes more technical skill to use. Short shelf life, approximately 40 minutes at p. H 7. 6 difficult to adjust the treatment in response to the load or variation or changes in raw water quality. Forms additional DBPs such as chlorite and chlorate. Requires daily chlorite and chlorine dioxide monitoring. Takes more technical skill to use. Effectiveness is p. H influenced. Less effective than chlorine against microorganis ms, especially viruses and protozoa. Poorly oxidizes iron and manganese. Usually requires a more powerful disinfectant for primary disinfection. Requires bulk storage of salt, unless seawater is used.

Oxi. Max compared with other techniques Factor COST USER FRIENDLY OZONE CHLORINE DIOXIDE CHLORAMI NES OXIMAX Equipment and operating costs are significantly higher. High cost Very low operational cost. NO NO NO YES

Oxi. Max compared with other techniques Factor COST USER FRIENDLY OZONE CHLORINE DIOXIDE CHLORAMI NES OXIMAX Equipment and operating costs are significantly higher. High cost Very low operational cost. NO NO NO YES

Sr no. Other electro Chlorinators in India market Oxi. Max Electro Chlorinators 1 All other brands work on 8 to 24 hours batch basis, thus highly susceptible to power failures Oxi. Max is the only brand that generates chlrine on continuous basis from hour to hour. 2 No other electro chlorinator in India has auto sensing system for checking salinity and storage levels Oxi. Max is the only brand having state of art auto sensing system. 3 No other Electro Chlorinator in India has micro processor based pre programmed logic control system All functions in Oxi. Max are auto tuned by a microprocessor based logic control system. 4 No other Electro Chlorinator in India provides for a salt saturation tank of more than one day or even one batch requirement Oxi. Max has the flexibility of pouring salt for 4 -8 days at one go. Who says only bike manufacturers can claim “ fill it – shut it – forget it” 5. No other Electro Chlorinator has the function of “Accurate salinity check” in hypo generation tank. , a very vital function to ensure proper strength of hypo chlorite solution Only Oxi. Max has an inbuilt feature of Salinity check, without which the electrolyzer will not start. 6. All or most other brands have hidden, inaccessible electrolyser In Oxi. Max, the electrolyser is mounted in an acrylic / pvc shell and process of generation can actually be seen. 7. Most other electro chlorinators require 4. 5 to 5 kg salt for generating 1 kg of active chlorine. Oxi. Max requires only 3. 5 to 4 kg salt for generating 1 kg active chlorine Oxi. Max MM Series Electro Chlorinator – a Mind Machine

Sr no. Other electro Chlorinators in India market Oxi. Max Electro Chlorinators 1 All other brands work on 8 to 24 hours batch basis, thus highly susceptible to power failures Oxi. Max is the only brand that generates chlrine on continuous basis from hour to hour. 2 No other electro chlorinator in India has auto sensing system for checking salinity and storage levels Oxi. Max is the only brand having state of art auto sensing system. 3 No other Electro Chlorinator in India has micro processor based pre programmed logic control system All functions in Oxi. Max are auto tuned by a microprocessor based logic control system. 4 No other Electro Chlorinator in India provides for a salt saturation tank of more than one day or even one batch requirement Oxi. Max has the flexibility of pouring salt for 4 -8 days at one go. Who says only bike manufacturers can claim “ fill it – shut it – forget it” 5. No other Electro Chlorinator has the function of “Accurate salinity check” in hypo generation tank. , a very vital function to ensure proper strength of hypo chlorite solution Only Oxi. Max has an inbuilt feature of Salinity check, without which the electrolyzer will not start. 6. All or most other brands have hidden, inaccessible electrolyser In Oxi. Max, the electrolyser is mounted in an acrylic / pvc shell and process of generation can actually be seen. 7. Most other electro chlorinators require 4. 5 to 5 kg salt for generating 1 kg of active chlorine. Oxi. Max requires only 3. 5 to 4 kg salt for generating 1 kg active chlorine Oxi. Max MM Series Electro Chlorinator – a Mind Machine

Oxi. Max can be used for various disinfection and sanitization applications. These include but not limited to:

Oxi. Max can be used for various disinfection and sanitization applications. These include but not limited to:

Chlorine in drinking water Chlorine is a disinfectant added to drinking water to reduce or eliminate microorganisms, such as bacteria and viruses, which can be present in water supplies. The addition of chlorine to our drinking water has greatly reduced the risk of waterborne diseases. Background For many years, the safety of drinking water supplies has been greatly improved by the addition of chlorine. Disinfecting our drinking water ensures it is free of the microorganisms that can cause serious and life-threatening diseases, such as cholera and typhoid fever. To this day, chlorine remains the most commonly used drinking water disinfectant, and the disinfectant for which we have the most scientific information. Chlorine is added as part of the drinking water treatment process. However, chlorine also reacts with the organic matter, naturally present in water, such as decaying leaves. This chemical reaction forms a group of chemicals known as disinfection by-products. The most common of these by-products are trihalomethanes (THMs), which include chloroform. The amount of THMs found in drinking water depends on a number of things, including the season and the source of the water. For example, THM levels are generally lower in winter than in summer, because the amount of natural organic matter is lower and less chlorine is needed to disinfect at colder temperatures. THM levels are also low when wells or large lakes are the drinking water source, and higher when rivers or other surface waters are the source, because they generally contain more organic matter The Benefits of Chlorine Current scientific data shows that the benefits of chlorinating our drinking water (less disease) are much greater than any health risks from THMs and other by-products. Although other disinfectants are available, chlorine remains the choice of water treatment experts. When used with modern water filtration methods, chlorine is effective against virtually all microorganisms. Chlorine is easy to apply and small amounts of the chemical remain in the water as it travels in the distribution system from the treatment plant to the consumer's tap, This level of effectiveness ensures that microorganisms cannot recontaminate the water after it leaves the treatment plant. Alternatives to Chlorination A number of cities use ozone to disinfect their water, because ozonation does not produce THMs. Although ozone is a very effective disinfectant, it breaks down quickly and cannot be used to maintain disinfection in the distribution system. Small amounts of chlorine or other disinfectants still must be added. Renovating water treatment plants so they can use ozone can be expensive. Examples of other disinfectants include chloramines and chlorine dioxide. Chloramines are weaker disinfectants than chlorine, but are very effective in the distribution system. Chlorine dioxide can be used in the treatment plant, but it is not very effective in the distribution system.

Chlorine in drinking water Chlorine is a disinfectant added to drinking water to reduce or eliminate microorganisms, such as bacteria and viruses, which can be present in water supplies. The addition of chlorine to our drinking water has greatly reduced the risk of waterborne diseases. Background For many years, the safety of drinking water supplies has been greatly improved by the addition of chlorine. Disinfecting our drinking water ensures it is free of the microorganisms that can cause serious and life-threatening diseases, such as cholera and typhoid fever. To this day, chlorine remains the most commonly used drinking water disinfectant, and the disinfectant for which we have the most scientific information. Chlorine is added as part of the drinking water treatment process. However, chlorine also reacts with the organic matter, naturally present in water, such as decaying leaves. This chemical reaction forms a group of chemicals known as disinfection by-products. The most common of these by-products are trihalomethanes (THMs), which include chloroform. The amount of THMs found in drinking water depends on a number of things, including the season and the source of the water. For example, THM levels are generally lower in winter than in summer, because the amount of natural organic matter is lower and less chlorine is needed to disinfect at colder temperatures. THM levels are also low when wells or large lakes are the drinking water source, and higher when rivers or other surface waters are the source, because they generally contain more organic matter The Benefits of Chlorine Current scientific data shows that the benefits of chlorinating our drinking water (less disease) are much greater than any health risks from THMs and other by-products. Although other disinfectants are available, chlorine remains the choice of water treatment experts. When used with modern water filtration methods, chlorine is effective against virtually all microorganisms. Chlorine is easy to apply and small amounts of the chemical remain in the water as it travels in the distribution system from the treatment plant to the consumer's tap, This level of effectiveness ensures that microorganisms cannot recontaminate the water after it leaves the treatment plant. Alternatives to Chlorination A number of cities use ozone to disinfect their water, because ozonation does not produce THMs. Although ozone is a very effective disinfectant, it breaks down quickly and cannot be used to maintain disinfection in the distribution system. Small amounts of chlorine or other disinfectants still must be added. Renovating water treatment plants so they can use ozone can be expensive. Examples of other disinfectants include chloramines and chlorine dioxide. Chloramines are weaker disinfectants than chlorine, but are very effective in the distribution system. Chlorine dioxide can be used in the treatment plant, but it is not very effective in the distribution system.

The perpetual growth of marine life within a cooling system can cost a significant annual charge. This cost can prove very expensive. Mollusks, algae, slime and weed not only constrict the flow of cooling water to the heat exchanger surfaces, they also hasten localised corrossion by restricting oxygen diffusion, and cause destructive turbulence at inlets which can severly shorten the life of equipment. In addition, this shall also lead to stop of other activities, thus causing severe financial cost, directly and indirectly. Chlorination is an obvious answer to this problem. oxi. Max technology, the most advanced electrochlorination system – provides the answer; it produces in-situ a dilute solution of sodium hypochlorite as and when required. , for direct injection into the water circuit. With Oxi. Max, you can avoid using hazardous gas or storing chemicals with concentration beyond safety parameters.

The perpetual growth of marine life within a cooling system can cost a significant annual charge. This cost can prove very expensive. Mollusks, algae, slime and weed not only constrict the flow of cooling water to the heat exchanger surfaces, they also hasten localised corrossion by restricting oxygen diffusion, and cause destructive turbulence at inlets which can severly shorten the life of equipment. In addition, this shall also lead to stop of other activities, thus causing severe financial cost, directly and indirectly. Chlorination is an obvious answer to this problem. oxi. Max technology, the most advanced electrochlorination system – provides the answer; it produces in-situ a dilute solution of sodium hypochlorite as and when required. , for direct injection into the water circuit. With Oxi. Max, you can avoid using hazardous gas or storing chemicals with concentration beyond safety parameters.

Power Plants, Cooling Towers and Oxi. Max: Preventing Bio-fouling Cooling water towers, especially during higher temperatures, are susceptible to the growth of algae and slime. For cooling water, there are three possible application points for chlorination – intake water, circulating water and service water. All cooling water applications require control of bacteria, algae and slime, microbiological influenced corrosion (MIC), bio-fouling, and fouled heat-exchange surfaces. In salt or brackish water systems, particularly marine environments, it’s wise to chlorinate ahead of the cooling water intake screens to help control mollusks, barnacles and sponges. Freshwater cooling circuits can take advantage of short contact times; and the point of application can be close to the condenser water tubes. In order for the heat transfer process to operate at maximum efficiency, heat exchange surfaces must be free of algae and slime. Otherwise, the efficiency of the cooling system will be severely impaired

Power Plants, Cooling Towers and Oxi. Max: Preventing Bio-fouling Cooling water towers, especially during higher temperatures, are susceptible to the growth of algae and slime. For cooling water, there are three possible application points for chlorination – intake water, circulating water and service water. All cooling water applications require control of bacteria, algae and slime, microbiological influenced corrosion (MIC), bio-fouling, and fouled heat-exchange surfaces. In salt or brackish water systems, particularly marine environments, it’s wise to chlorinate ahead of the cooling water intake screens to help control mollusks, barnacles and sponges. Freshwater cooling circuits can take advantage of short contact times; and the point of application can be close to the condenser water tubes. In order for the heat transfer process to operate at maximum efficiency, heat exchange surfaces must be free of algae and slime. Otherwise, the efficiency of the cooling system will be severely impaired

The Oxi. Max system is a superior alternative to traditional chlorine water treatment. When it comes to swimming Pool, the Oxi. Max system is one of the most efficient system available in market. Oxi. Max electro chlorinator generates its own chlorine for swimming pools by converting mild saline pool water or by addition of salt, into chlorine. The process of electrolysis splits the salt molecule (Sodium chloride) into sodium and chlorine. At the same time hydrogen is freed up from the water molecule. This produces sodium hypochlorite ( liquid chlorine) for your swimming pool. Sodium hypochlorite is a chlorine in usable form, which purifies and sterilizes pool water. The Oxi. Max electro chlorination system will drastically reduce purchasing or adding sanitizing chemicals such as liquid or granular chlorine. It will also minimize the hazards of handling and storing of chlorine chemicals or gas. Not only will you have peace of mind that the Oxi. Max system is keeping your pool clean, clear, sparkling and sterile, but you will also enjoy other benefits of swimming in mild salt water, such as no sore, stinging red eyes and no smelly or itchy skin.

The Oxi. Max system is a superior alternative to traditional chlorine water treatment. When it comes to swimming Pool, the Oxi. Max system is one of the most efficient system available in market. Oxi. Max electro chlorinator generates its own chlorine for swimming pools by converting mild saline pool water or by addition of salt, into chlorine. The process of electrolysis splits the salt molecule (Sodium chloride) into sodium and chlorine. At the same time hydrogen is freed up from the water molecule. This produces sodium hypochlorite ( liquid chlorine) for your swimming pool. Sodium hypochlorite is a chlorine in usable form, which purifies and sterilizes pool water. The Oxi. Max electro chlorination system will drastically reduce purchasing or adding sanitizing chemicals such as liquid or granular chlorine. It will also minimize the hazards of handling and storing of chlorine chemicals or gas. Not only will you have peace of mind that the Oxi. Max system is keeping your pool clean, clear, sparkling and sterile, but you will also enjoy other benefits of swimming in mild salt water, such as no sore, stinging red eyes and no smelly or itchy skin.

Oxi. Max generated hypo chlorite solution, when injected into the sewage or waste stream shall be as effective as chlorine gas or commercial hypochlorite, though without all the disadvantages associated with such chemicals or gas. Oxidant generated by Oxi. Max will react with both inorganic and organic matter, as well as bacteria, to provide effective disinfection. Oxi. Max systems are being used worldwide in power stations, refineries, industrial plants, marine and municipal applications. With Central and State Governments increasingly regulating the use of chlorine gas and also considering the safety hazards, Oxi. Max is an ideal solution.

Oxi. Max generated hypo chlorite solution, when injected into the sewage or waste stream shall be as effective as chlorine gas or commercial hypochlorite, though without all the disadvantages associated with such chemicals or gas. Oxidant generated by Oxi. Max will react with both inorganic and organic matter, as well as bacteria, to provide effective disinfection. Oxi. Max systems are being used worldwide in power stations, refineries, industrial plants, marine and municipal applications. With Central and State Governments increasingly regulating the use of chlorine gas and also considering the safety hazards, Oxi. Max is an ideal solution.

To control bacterial and microorganisms growth, use of chlorine is a necessity in food processing plants such as Mushrooms, Bee Cells, Harvested fruits, Harvested Vegetables, Tea Estates, Fruit Juice, Fish and meat processing etc. For example, to control bacterial blotch, apply a 100 to 200 ppm solution prior to watering mushroom production surfaces. Sodium hypochlorite may be applied directly to pins to control small infection foci. Similarly, sodium hypochlorite solution will control the growth of bacteria and microorganisms which occur in fish processing plants. It will also provide odour control. Sodium hypochlorite solution provides an effective, economical method of sanitizing processing equipment and problem areas in dairy industry. To prevent contamination of the product, apply sodium hypochlorite to every surface it will touch.

To control bacterial and microorganisms growth, use of chlorine is a necessity in food processing plants such as Mushrooms, Bee Cells, Harvested fruits, Harvested Vegetables, Tea Estates, Fruit Juice, Fish and meat processing etc. For example, to control bacterial blotch, apply a 100 to 200 ppm solution prior to watering mushroom production surfaces. Sodium hypochlorite may be applied directly to pins to control small infection foci. Similarly, sodium hypochlorite solution will control the growth of bacteria and microorganisms which occur in fish processing plants. It will also provide odour control. Sodium hypochlorite solution provides an effective, economical method of sanitizing processing equipment and problem areas in dairy industry. To prevent contamination of the product, apply sodium hypochlorite to every surface it will touch.

Oxi. Max finds endless uses in hotels and hospitals such as: • • • Sanitization of hotel and medical equipments and operation theatres. Laundry sanitization. Disinfection of drinking water Disinfection of pools. Sanitization of floors.

Oxi. Max finds endless uses in hotels and hospitals such as: • • • Sanitization of hotel and medical equipments and operation theatres. Laundry sanitization. Disinfection of drinking water Disinfection of pools. Sanitization of floors.

Oxi. Max: Total peace of mind

Oxi. Max: Total peace of mind