2e7ba5d212b627cd0deb6c2d88f761dd.ppt

- Количество слайдов: 41

NUMALIGARH REFINERY LIMITED Emergency Response & Disaster Management Plan and Best Practices at NRL

NUMALIGARH REFINERY LIMITED Emergency Response & Disaster Management Plan and Best Practices at NRL

THE GENESIS 1. Proposal for Refinery included in “Assam Accord” : August 15, 1985 2. “Numaligarh Refinery Limited” incorporated : April 22, 1993 3. Commercial Production commenced : Oct. 1, 2000 4. NRL became subsidiary of BPCL : March 31, 2001 2

THE GENESIS 1. Proposal for Refinery included in “Assam Accord” : August 15, 1985 2. “Numaligarh Refinery Limited” incorporated : April 22, 1993 3. Commercial Production commenced : Oct. 1, 2000 4. NRL became subsidiary of BPCL : March 31, 2001 2

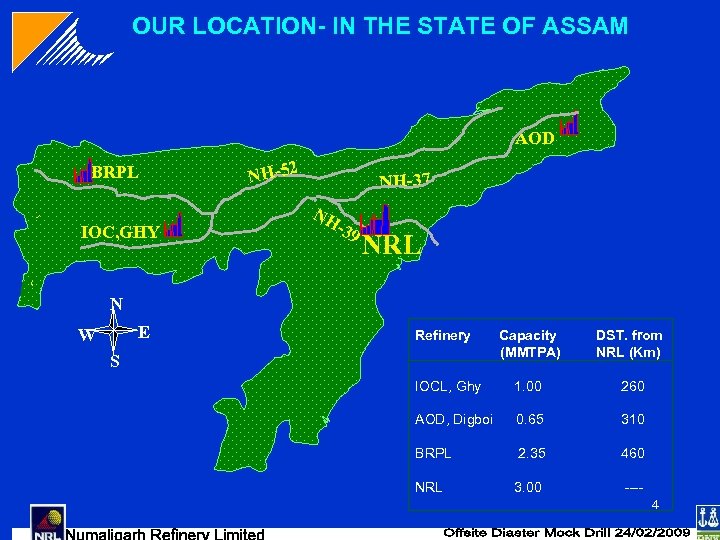

OUR LOCATION- IN THE STATE OF ASSAM AOD BRPL IOC, GHY 2 NH-5 NH-37 NH -39 NRL N E W Refinery Capacity (MMTPA) DST. from NRL (Km) IOCL, Ghy 1. 00 260 AOD, Digboi 0. 65 310 BRPL 2. 35 460 NRL 3. 00 ---- S 4

OUR LOCATION- IN THE STATE OF ASSAM AOD BRPL IOC, GHY 2 NH-5 NH-37 NH -39 NRL N E W Refinery Capacity (MMTPA) DST. from NRL (Km) IOCL, Ghy 1. 00 260 AOD, Digboi 0. 65 310 BRPL 2. 35 460 NRL 3. 00 ---- S 4

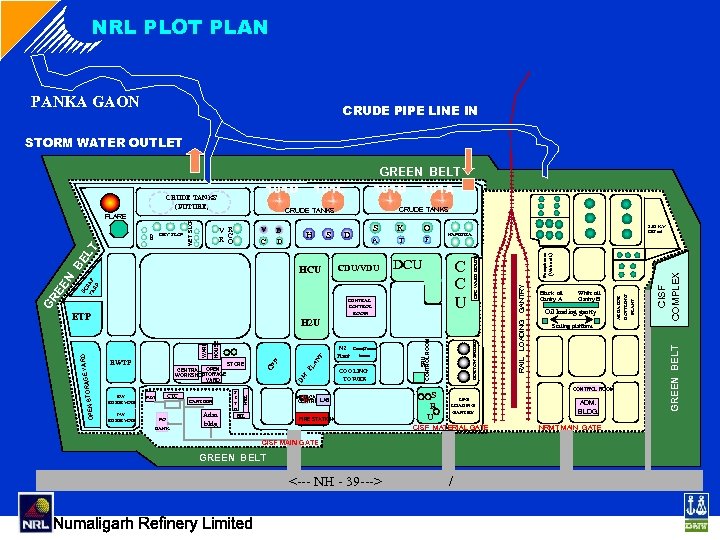

NRL PLOT PLAN PANKA GAON CRUDE PIPE LINE IN STORM WATER OUTLET CRUDE TANKS D S K O A T F BE CDU/VDU DCU C C U SC R YA AP RD GR CENTRAL CONTROL ROOM RW RESERVOIR FW RESERVOIR CTC P&T PO BANK CANTEEN Adm bldg S I T E N 2 Compressor Plant house COOLING TOWER MEDICAL CENTRE LAB EIL FIRE STATION S R U HORTON SPHERE NT STORE PL A CENTRAL OPEN STORAGE WORKSHOP YARD DM RWTP CP P HOUSE WARE H 2 U NRL E YA TORAG OPEN S RD ETP SRU CONTROL ROOM EE N HCU 250 KV DG set NAPHTHA White oil Gantry B Oil loading gantry Scaling platform CONTROL ROOM LPG LOADING GANTRY CISF MATERIAL GATE CISF MAIN GATE GREEN BELT <--- NH - 39 ---> Black oil Gantry A / CISF COMPLEX C H ADM. BLDG. NRMT MAIN GATE GREEN BELT D AREA FOR BOTTLING PLANT V Pump house (White oil. ) V R C R O RAi. L LOADING GANTRY CRUDE TANKS LT FO DRY SLOP WET SLOP FLARE 101 C CPC WARE HOUSE 101 D CRUDE TANKS (FUTURE) GREEN BELT 101 B 101 A

NRL PLOT PLAN PANKA GAON CRUDE PIPE LINE IN STORM WATER OUTLET CRUDE TANKS D S K O A T F BE CDU/VDU DCU C C U SC R YA AP RD GR CENTRAL CONTROL ROOM RW RESERVOIR FW RESERVOIR CTC P&T PO BANK CANTEEN Adm bldg S I T E N 2 Compressor Plant house COOLING TOWER MEDICAL CENTRE LAB EIL FIRE STATION S R U HORTON SPHERE NT STORE PL A CENTRAL OPEN STORAGE WORKSHOP YARD DM RWTP CP P HOUSE WARE H 2 U NRL E YA TORAG OPEN S RD ETP SRU CONTROL ROOM EE N HCU 250 KV DG set NAPHTHA White oil Gantry B Oil loading gantry Scaling platform CONTROL ROOM LPG LOADING GANTRY CISF MATERIAL GATE CISF MAIN GATE GREEN BELT <--- NH - 39 ---> Black oil Gantry A / CISF COMPLEX C H ADM. BLDG. NRMT MAIN GATE GREEN BELT D AREA FOR BOTTLING PLANT V Pump house (White oil. ) V R C R O RAi. L LOADING GANTRY CRUDE TANKS LT FO DRY SLOP WET SLOP FLARE 101 C CPC WARE HOUSE 101 D CRUDE TANKS (FUTURE) GREEN BELT 101 B 101 A

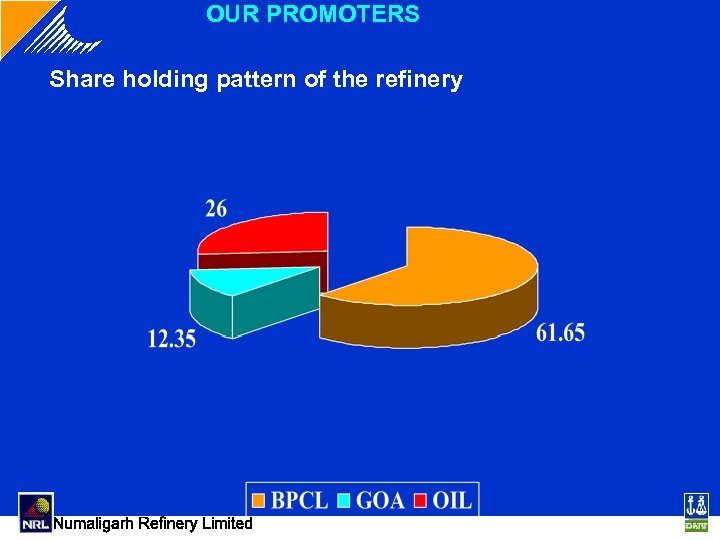

OUR PROMOTERS Share holding pattern of the refinery

OUR PROMOTERS Share holding pattern of the refinery

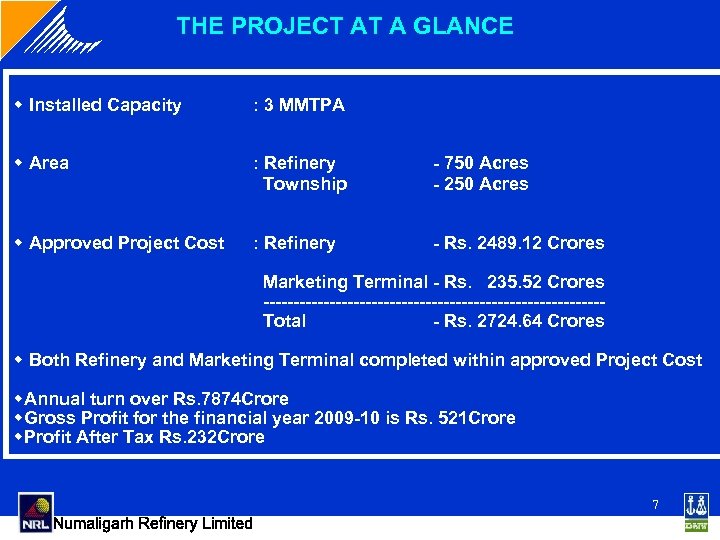

THE PROJECT AT A GLANCE w Installed Capacity : 3 MMTPA w Area : Refinery Township - 750 Acres - 250 Acres w Approved Project Cost : Refinery - Rs. 2489. 12 Crores Marketing Terminal - Rs. 235. 52 Crores ----------------------------Total - Rs. 2724. 64 Crores w Both Refinery and Marketing Terminal completed within approved Project Cost w. Annual turn over Rs. 7874 Crore w. Gross Profit for the financial year 2009 -10 is Rs. 521 Crore w. Profit After Tax Rs. 232 Crore 7

THE PROJECT AT A GLANCE w Installed Capacity : 3 MMTPA w Area : Refinery Township - 750 Acres - 250 Acres w Approved Project Cost : Refinery - Rs. 2489. 12 Crores Marketing Terminal - Rs. 235. 52 Crores ----------------------------Total - Rs. 2724. 64 Crores w Both Refinery and Marketing Terminal completed within approved Project Cost w. Annual turn over Rs. 7874 Crore w. Gross Profit for the financial year 2009 -10 is Rs. 521 Crore w. Profit After Tax Rs. 232 Crore 7

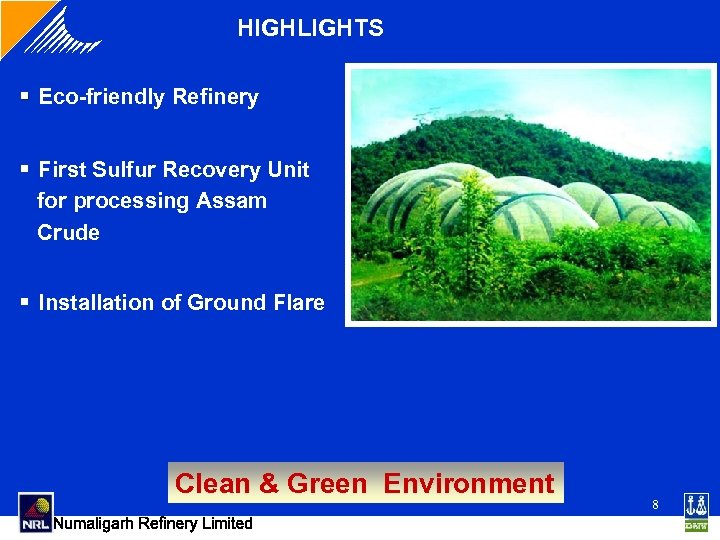

HIGHLIGHTS § Eco-friendly Refinery § First Sulfur Recovery Unit for processing Assam Crude § Installation of Ground Flare Clean & Green Environment 8

HIGHLIGHTS § Eco-friendly Refinery § First Sulfur Recovery Unit for processing Assam Crude § Installation of Ground Flare Clean & Green Environment 8

MILESTONES Management Systems: • IMC Ramakrishna Bajaj National Quality awards for 2009. • Jawaharlal Nehru Centenary Awards for Energy Performance of Refineries for the year 2004 -05 and for 2007 -08. • National Energy Conservation Award consecutively for 2007(2 nd Prize in refinery sector) and 2008 by Bureau of Energy Efficiency. • Oil & Gas Conservation Award in 2008 by Centre of High Technology. • TERI Corporate Environmental excellence Award consecutively for 2007 and 2008. Safety Management: • Oil Industry Safety Awards for the year 2005 -06 and for 2008 by OISD. • National Safety Award in 2008. • Shrestha Suraksha Puraskar consecutively for 2006 and 2007 by National safety council. • Green Tech Safety Gold Award for 2005 -06 by Greentech Foundation, Hyderabad and for 2007 -08 by Greentech Foundation, Delhi. 9

MILESTONES Management Systems: • IMC Ramakrishna Bajaj National Quality awards for 2009. • Jawaharlal Nehru Centenary Awards for Energy Performance of Refineries for the year 2004 -05 and for 2007 -08. • National Energy Conservation Award consecutively for 2007(2 nd Prize in refinery sector) and 2008 by Bureau of Energy Efficiency. • Oil & Gas Conservation Award in 2008 by Centre of High Technology. • TERI Corporate Environmental excellence Award consecutively for 2007 and 2008. Safety Management: • Oil Industry Safety Awards for the year 2005 -06 and for 2008 by OISD. • National Safety Award in 2008. • Shrestha Suraksha Puraskar consecutively for 2006 and 2007 by National safety council. • Green Tech Safety Gold Award for 2005 -06 by Greentech Foundation, Hyderabad and for 2007 -08 by Greentech Foundation, Delhi. 9

MILESTONES (Contd. ) Environment Management: • • Best green Location: Refinery in 2009 by BPC Mumbai Refinery Chairman's award for Excellence in Green (Refinery) in 2007 -08 by Corporate HSE& S award , BPCL Information Technology: • Awarded Best Industry Status in IT Agency National Petroleum Management Programme for year 2001 -02. • Fastest implementation of SAP

MILESTONES (Contd. ) Environment Management: • • Best green Location: Refinery in 2009 by BPC Mumbai Refinery Chairman's award for Excellence in Green (Refinery) in 2007 -08 by Corporate HSE& S award , BPCL Information Technology: • Awarded Best Industry Status in IT Agency National Petroleum Management Programme for year 2001 -02. • Fastest implementation of SAP

HSE – Our Primary Concern v Achieved 15. 96 Million LTA free man-hours (3292 days). v Regular study of water quality of Dhansiri river v Continuous monitoring of the status of ambient air quality. v Waste Management System - Solid Waste Disposal Yard - Secured Land Fill - Melting Pit v Post commissioning Environment Audit by NEERI. v Use of sweet fuel for internal consumption 11

HSE – Our Primary Concern v Achieved 15. 96 Million LTA free man-hours (3292 days). v Regular study of water quality of Dhansiri river v Continuous monitoring of the status of ambient air quality. v Waste Management System - Solid Waste Disposal Yard - Secured Land Fill - Melting Pit v Post commissioning Environment Audit by NEERI. v Use of sweet fuel for internal consumption 11

SAFETY MANAGEMENT SYSTEM OF NRL • NRL is certified by DNV for OHSAS 18001 since 2002 along with ISO 9001 & 14001 for Quality & Environment also. NRL also achieved ISRS level -9 1) Safety points covered under internal and external management system audit. 2) Safety points are discussed everyday in the morning meeting. 3) Quarterly the status of various safety points implementation are reviewed at the level of Director (Technical) in Apex safety Committee Meeting. 4) Every month, in Functional Co ordination meeting, Managing Director takes monthly report on safety performance. 5) Safety Audit by OISD • Status of OISD related points are regularly sent to OISD every three months. • The DGFASLI audit compliance report are also sent to RLI, Kolkata periodically.

SAFETY MANAGEMENT SYSTEM OF NRL • NRL is certified by DNV for OHSAS 18001 since 2002 along with ISO 9001 & 14001 for Quality & Environment also. NRL also achieved ISRS level -9 1) Safety points covered under internal and external management system audit. 2) Safety points are discussed everyday in the morning meeting. 3) Quarterly the status of various safety points implementation are reviewed at the level of Director (Technical) in Apex safety Committee Meeting. 4) Every month, in Functional Co ordination meeting, Managing Director takes monthly report on safety performance. 5) Safety Audit by OISD • Status of OISD related points are regularly sent to OISD every three months. • The DGFASLI audit compliance report are also sent to RLI, Kolkata periodically.

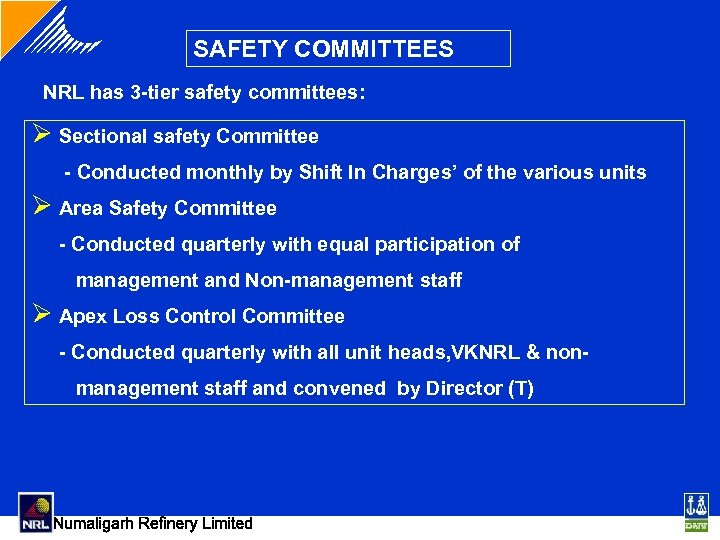

SAFETY COMMITTEES NRL has 3 -tier safety committees: Ø Sectional safety Committee - Conducted monthly by Shift In Charges’ of the various units Ø Area Safety Committee - Conducted quarterly with equal participation of management and Non-management staff Ø Apex Loss Control Committee - Conducted quarterly with all unit heads, VKNRL & nonmanagement staff and convened by Director (T)

SAFETY COMMITTEES NRL has 3 -tier safety committees: Ø Sectional safety Committee - Conducted monthly by Shift In Charges’ of the various units Ø Area Safety Committee - Conducted quarterly with equal participation of management and Non-management staff Ø Apex Loss Control Committee - Conducted quarterly with all unit heads, VKNRL & nonmanagement staff and convened by Director (T)

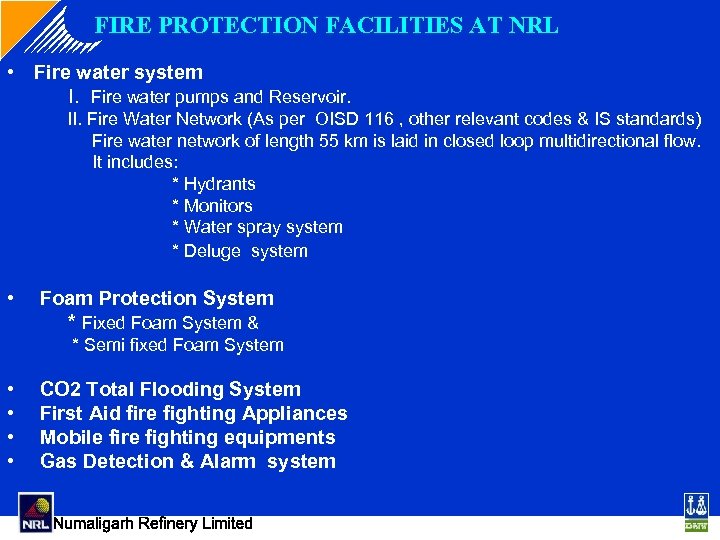

FIRE PROTECTION FACILITIES AT NRL • Fire water system I. Fire water pumps and Reservoir. II. Fire Water Network (As per OISD 116 , other relevant codes & IS standards) Fire water network of length 55 km is laid in closed loop multidirectional flow. It includes: * Hydrants * Monitors * Water spray system * Deluge system • Foam Protection System * Fixed Foam System & * Semi fixed Foam System • • CO 2 Total Flooding System First Aid fire fighting Appliances Mobile fire fighting equipments Gas Detection & Alarm system

FIRE PROTECTION FACILITIES AT NRL • Fire water system I. Fire water pumps and Reservoir. II. Fire Water Network (As per OISD 116 , other relevant codes & IS standards) Fire water network of length 55 km is laid in closed loop multidirectional flow. It includes: * Hydrants * Monitors * Water spray system * Deluge system • Foam Protection System * Fixed Foam System & * Semi fixed Foam System • • CO 2 Total Flooding System First Aid fire fighting Appliances Mobile fire fighting equipments Gas Detection & Alarm system

FIRE PROTECTION FACILITIES I. Fire Water Pumps: • 100% back up with 4 Diesel driven pumps • Second Source of Fire water : Raw water reservoir of capacity (2 x 12000) m 3 PA-101 PA-102 A RE PA-103 SE RV OIR PA-104 -70 00 PA-105 M 3 PA-106 LEGEND CAPACITY Pump Head 3 JOCKEY PUMPS (Electric Driven) 65 M 3/Hr. 11 kg/cm 2 4 MAIN FW PUMPS (Electric Driven) 700 M 3/Hr. 10. 5 kg/cm 2 4 MAIN FW PUMPS (Diesel Driven) 700 M 3/Hr. 10. 5 kg/cm 2 PA-107 RE SE PA-108 RV O IR- 70 PA-109 00 M 3 PA-110

FIRE PROTECTION FACILITIES I. Fire Water Pumps: • 100% back up with 4 Diesel driven pumps • Second Source of Fire water : Raw water reservoir of capacity (2 x 12000) m 3 PA-101 PA-102 A RE PA-103 SE RV OIR PA-104 -70 00 PA-105 M 3 PA-106 LEGEND CAPACITY Pump Head 3 JOCKEY PUMPS (Electric Driven) 65 M 3/Hr. 11 kg/cm 2 4 MAIN FW PUMPS (Electric Driven) 700 M 3/Hr. 10. 5 kg/cm 2 4 MAIN FW PUMPS (Diesel Driven) 700 M 3/Hr. 10. 5 kg/cm 2 PA-107 RE SE PA-108 RV O IR- 70 PA-109 00 M 3 PA-110

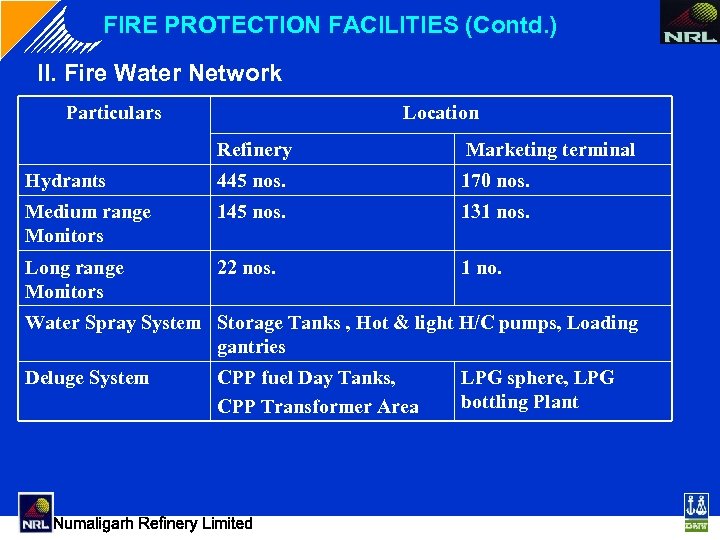

FIRE PROTECTION FACILITIES (Contd. ) II. Fire Water Network Particulars Location Refinery Marketing terminal Hydrants 445 nos. 170 nos. Medium range Monitors 145 nos. 131 nos. Long range Monitors 22 nos. 1 no. Water Spray System Storage Tanks , Hot & light H/C pumps, Loading gantries Deluge System CPP fuel Day Tanks, CPP Transformer Area LPG sphere, LPG bottling Plant

FIRE PROTECTION FACILITIES (Contd. ) II. Fire Water Network Particulars Location Refinery Marketing terminal Hydrants 445 nos. 170 nos. Medium range Monitors 145 nos. 131 nos. Long range Monitors 22 nos. 1 no. Water Spray System Storage Tanks , Hot & light H/C pumps, Loading gantries Deluge System CPP fuel Day Tanks, CPP Transformer Area LPG sphere, LPG bottling Plant

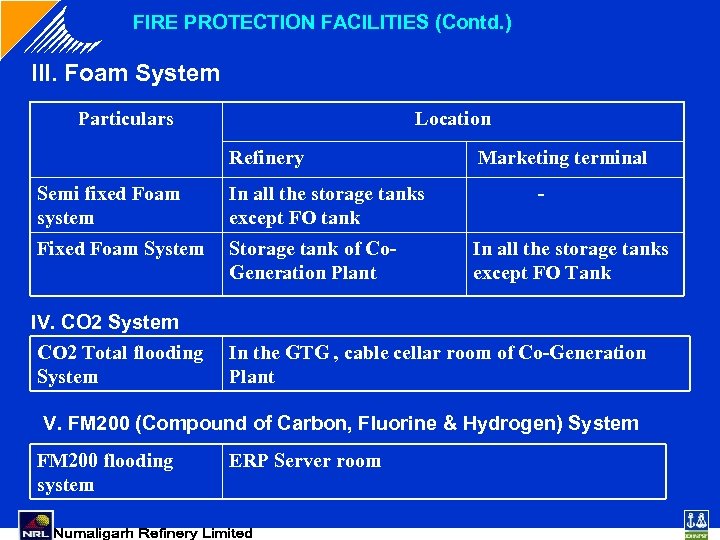

FIRE PROTECTION FACILITIES (Contd. ) III. Foam System Particulars Location Refinery Semi fixed Foam system In all the storage tanks except FO tank Fixed Foam System Storage tank of Co. Generation Plant IV. CO 2 System CO 2 Total flooding System Marketing terminal In all the storage tanks except FO Tank In the GTG , cable cellar room of Co-Generation Plant V. FM 200 (Compound of Carbon, Fluorine & Hydrogen) System FM 200 flooding system ERP Server room

FIRE PROTECTION FACILITIES (Contd. ) III. Foam System Particulars Location Refinery Semi fixed Foam system In all the storage tanks except FO tank Fixed Foam System Storage tank of Co. Generation Plant IV. CO 2 System CO 2 Total flooding System Marketing terminal In all the storage tanks except FO Tank In the GTG , cable cellar room of Co-Generation Plant V. FM 200 (Compound of Carbon, Fluorine & Hydrogen) System FM 200 flooding system ERP Server room

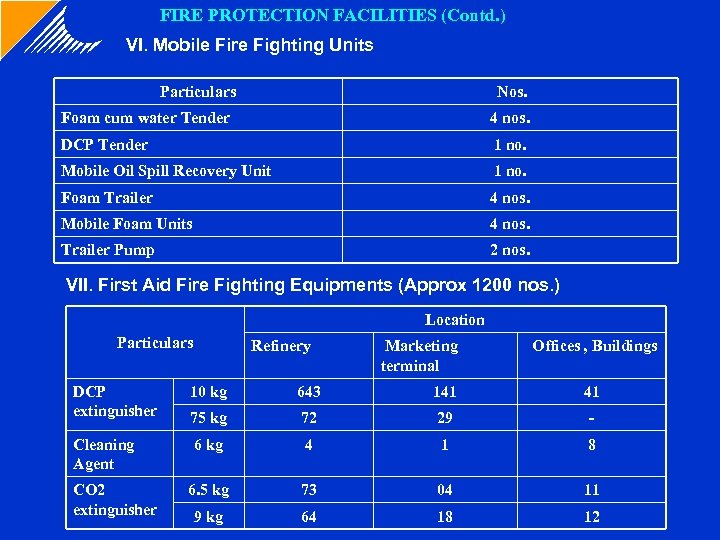

FIRE PROTECTION FACILITIES (Contd. ) VI. Mobile Fire Fighting Units Particulars Nos. Foam cum water Tender 4 nos. DCP Tender 1 no. Mobile Oil Spill Recovery Unit 1 no. Foam Trailer 4 nos. Mobile Foam Units 4 nos. Trailer Pump 2 nos. VII. First Aid Fire Fighting Equipments (Approx 1200 nos. ) Location Particulars Refinery Marketing terminal Offices , Buildings DCP extinguisher 10 kg 643 141 41 75 kg 72 29 - Cleaning Agent 6 kg 4 1 8 6. 5 kg 73 04 11 9 kg 64 18 12 CO 2 extinguisher

FIRE PROTECTION FACILITIES (Contd. ) VI. Mobile Fire Fighting Units Particulars Nos. Foam cum water Tender 4 nos. DCP Tender 1 no. Mobile Oil Spill Recovery Unit 1 no. Foam Trailer 4 nos. Mobile Foam Units 4 nos. Trailer Pump 2 nos. VII. First Aid Fire Fighting Equipments (Approx 1200 nos. ) Location Particulars Refinery Marketing terminal Offices , Buildings DCP extinguisher 10 kg 643 141 41 75 kg 72 29 - Cleaning Agent 6 kg 4 1 8 6. 5 kg 73 04 11 9 kg 64 18 12 CO 2 extinguisher

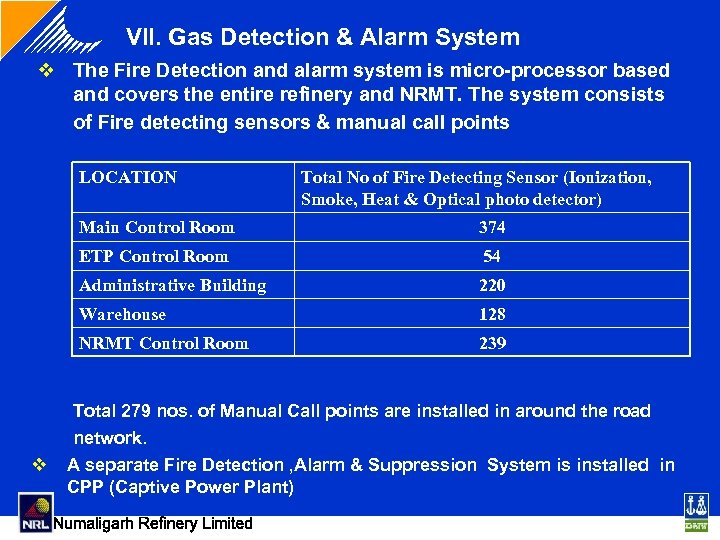

VII. Gas Detection & Alarm System v The Fire Detection and alarm system is micro-processor based and covers the entire refinery and NRMT. The system consists of Fire detecting sensors & manual call points LOCATION Total No of Fire Detecting Sensor (Ionization, Smoke, Heat & Optical photo detector) Main Control Room 374 ETP Control Room 54 Administrative Building 220 Warehouse 128 NRMT Control Room 239 Total 279 nos. of Manual Call points are installed in around the road v network. A separate Fire Detection , Alarm & Suppression System is installed in CPP (Captive Power Plant)

VII. Gas Detection & Alarm System v The Fire Detection and alarm system is micro-processor based and covers the entire refinery and NRMT. The system consists of Fire detecting sensors & manual call points LOCATION Total No of Fire Detecting Sensor (Ionization, Smoke, Heat & Optical photo detector) Main Control Room 374 ETP Control Room 54 Administrative Building 220 Warehouse 128 NRMT Control Room 239 Total 279 nos. of Manual Call points are installed in around the road v network. A separate Fire Detection , Alarm & Suppression System is installed in CPP (Captive Power Plant)

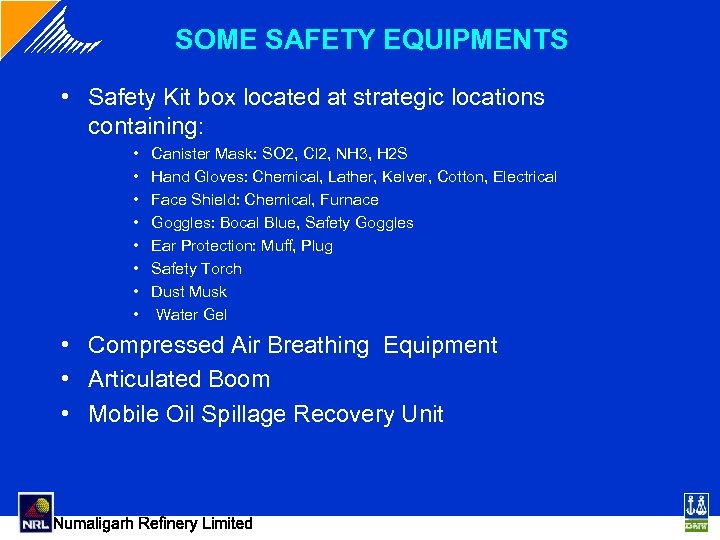

SOME SAFETY EQUIPMENTS • Safety Kit box located at strategic locations containing: • • Canister Mask: SO 2, Cl 2, NH 3, H 2 S Hand Gloves: Chemical, Lather, Kelver, Cotton, Electrical Face Shield: Chemical, Furnace Goggles: Bocal Blue, Safety Goggles Ear Protection: Muff, Plug Safety Torch Dust Musk Water Gel • Compressed Air Breathing Equipment • Articulated Boom • Mobile Oil Spillage Recovery Unit

SOME SAFETY EQUIPMENTS • Safety Kit box located at strategic locations containing: • • Canister Mask: SO 2, Cl 2, NH 3, H 2 S Hand Gloves: Chemical, Lather, Kelver, Cotton, Electrical Face Shield: Chemical, Furnace Goggles: Bocal Blue, Safety Goggles Ear Protection: Muff, Plug Safety Torch Dust Musk Water Gel • Compressed Air Breathing Equipment • Articulated Boom • Mobile Oil Spillage Recovery Unit

Mobile Fire Fighting Units

Mobile Fire Fighting Units

Mobile Fire Fighting Units DCP TENDER

Mobile Fire Fighting Units DCP TENDER

Mobile Fire Fighting Units

Mobile Fire Fighting Units

EQUIPMENTS MOBILE OIL SPILLAGE RECOVERY UNIT ARTICULATOR

EQUIPMENTS MOBILE OIL SPILLAGE RECOVERY UNIT ARTICULATOR

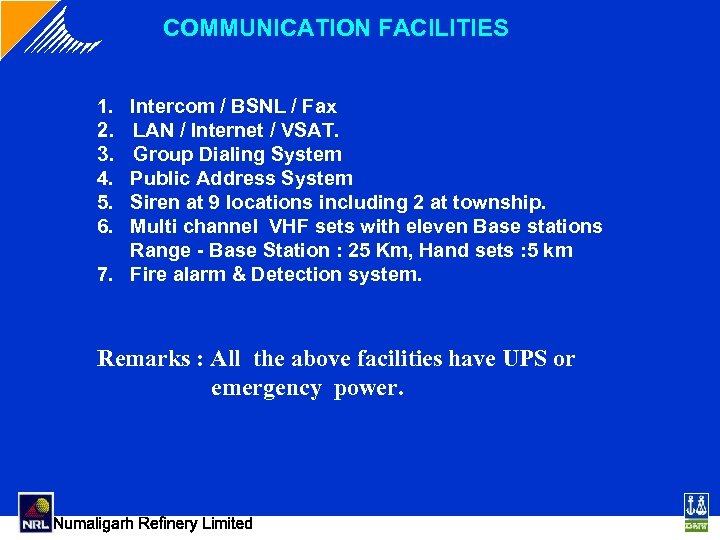

COMMUNICATION FACILITIES 1. 2. 3. 4. 5. 6. Intercom / BSNL / Fax LAN / Internet / VSAT. Group Dialing System Public Address System Siren at 9 locations including 2 at township. Multi channel VHF sets with eleven Base stations Range - Base Station : 25 Km, Hand sets : 5 km 7. Fire alarm & Detection system. Remarks : All the above facilities have UPS or emergency power.

COMMUNICATION FACILITIES 1. 2. 3. 4. 5. 6. Intercom / BSNL / Fax LAN / Internet / VSAT. Group Dialing System Public Address System Siren at 9 locations including 2 at township. Multi channel VHF sets with eleven Base stations Range - Base Station : 25 Km, Hand sets : 5 km 7. Fire alarm & Detection system. Remarks : All the above facilities have UPS or emergency power.

MANUALS & DOCUMENTS • • • CONSTRUCTION SAFETY MANUAL (ENGLISH / ASSAMESE) SAFETY MANUAL FIRE MANUAL ONSITE DISASTER MAMAGEMENT PLAN OFFSITE DISASTER MANAGEMENT PLAN FIRE ORDER MATERIAL SAFETY DATA SHEET CONTRACTOR SAFETY MANUAL FIRE PROTECTION & SAFETY POCKET MANUAL VISITOR’S FAMILIARISATION & SAFETY CARD LEAFLET ON LPG SAFETY

MANUALS & DOCUMENTS • • • CONSTRUCTION SAFETY MANUAL (ENGLISH / ASSAMESE) SAFETY MANUAL FIRE MANUAL ONSITE DISASTER MAMAGEMENT PLAN OFFSITE DISASTER MANAGEMENT PLAN FIRE ORDER MATERIAL SAFETY DATA SHEET CONTRACTOR SAFETY MANUAL FIRE PROTECTION & SAFETY POCKET MANUAL VISITOR’S FAMILIARISATION & SAFETY CARD LEAFLET ON LPG SAFETY

Onsite & Offsite Disaster Management Plan

Onsite & Offsite Disaster Management Plan

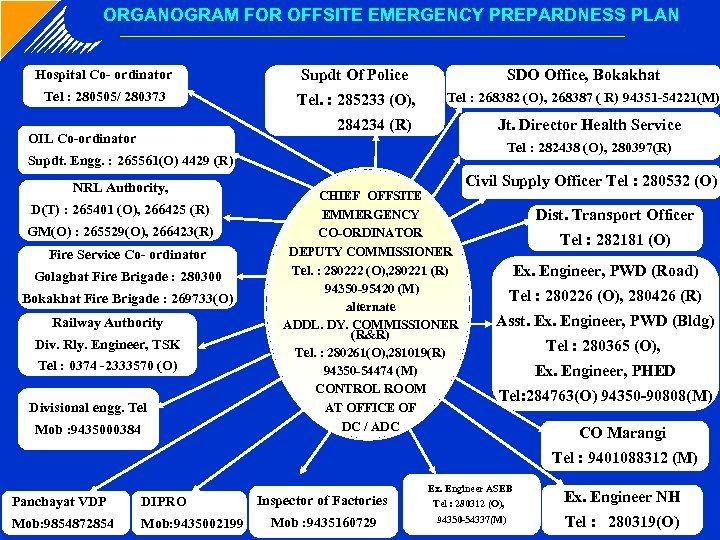

ORGANOGRAM FOR OFFSITE EMERGENCY PREPARDNESS PLAN Hospital Co- ordinator Supdt Of Police SDO Office, Bokakhat Tel : 280505/ 280373 Tel. : 285233 (O), Tel : 268382 (O), 268387 ( R) 94351 -54221(M) Jt. Director Health Service 284234 (R) OIL Co-ordinator Tel : 282438 (O), 280397(R) Supdt. Engg. : 265561(O) 4429 (R) NRL Authority, D(T) : 265401 (O), 266425 (R) GM(O) : 265529(O), 266423(R) Fire Service Co- ordinator Golaghat Fire Brigade : 280300 Bokakhat Fire Brigade : 269733(O) Railway Authority Div. Rly. Engineer, TSK Tel : 0374 -2333570 (O) Divisional engg. Tel Mob : 9435000384 CHIEF OFFSITE EMMERGENCY CO-ORDINATOR DEPUTY COMMISSIONER Tel. : 280222 (O), 280221 (R) 94350 -95420 (M) alternate ADDL. DY. COMMISSIONER (R&R) Tel. : 280261(O), 281019(R) 94350 -54474 (M) CONTROL ROOM AT OFFICE OF DC / ADC Civil Supply Officer Tel : 280532 (O) Dist. Transport Officer Tel : 282181 (O) Ex. Engineer, PWD (Road) Tel : 280226 (O), 280426 (R) Asst. Ex. Engineer, PWD (Bldg) Tel : 280365 (O), Ex. Engineer, PHED Tel: 284763(O) 94350 -90808(M) CO Marangi Tel : 9401088312 (M) Panchayat VDP DIPRO Mob: 9854872854 Mob: 9435002199 Inspector of Factories Mob : 9435160729 Ex. Engineer ASEB Tel : 280312 (O), 94350 -54337(M) Ex. Engineer NH Tel : 280319(O)

ORGANOGRAM FOR OFFSITE EMERGENCY PREPARDNESS PLAN Hospital Co- ordinator Supdt Of Police SDO Office, Bokakhat Tel : 280505/ 280373 Tel. : 285233 (O), Tel : 268382 (O), 268387 ( R) 94351 -54221(M) Jt. Director Health Service 284234 (R) OIL Co-ordinator Tel : 282438 (O), 280397(R) Supdt. Engg. : 265561(O) 4429 (R) NRL Authority, D(T) : 265401 (O), 266425 (R) GM(O) : 265529(O), 266423(R) Fire Service Co- ordinator Golaghat Fire Brigade : 280300 Bokakhat Fire Brigade : 269733(O) Railway Authority Div. Rly. Engineer, TSK Tel : 0374 -2333570 (O) Divisional engg. Tel Mob : 9435000384 CHIEF OFFSITE EMMERGENCY CO-ORDINATOR DEPUTY COMMISSIONER Tel. : 280222 (O), 280221 (R) 94350 -95420 (M) alternate ADDL. DY. COMMISSIONER (R&R) Tel. : 280261(O), 281019(R) 94350 -54474 (M) CONTROL ROOM AT OFFICE OF DC / ADC Civil Supply Officer Tel : 280532 (O) Dist. Transport Officer Tel : 282181 (O) Ex. Engineer, PWD (Road) Tel : 280226 (O), 280426 (R) Asst. Ex. Engineer, PWD (Bldg) Tel : 280365 (O), Ex. Engineer, PHED Tel: 284763(O) 94350 -90808(M) CO Marangi Tel : 9401088312 (M) Panchayat VDP DIPRO Mob: 9854872854 Mob: 9435002199 Inspector of Factories Mob : 9435160729 Ex. Engineer ASEB Tel : 280312 (O), 94350 -54337(M) Ex. Engineer NH Tel : 280319(O)

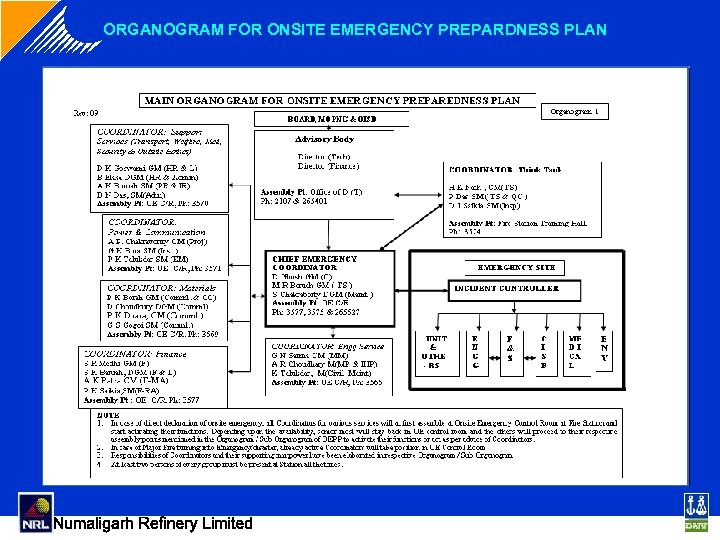

ORGANOGRAM FOR ONSITE EMERGENCY PREPARDNESS PLAN

ORGANOGRAM FOR ONSITE EMERGENCY PREPARDNESS PLAN

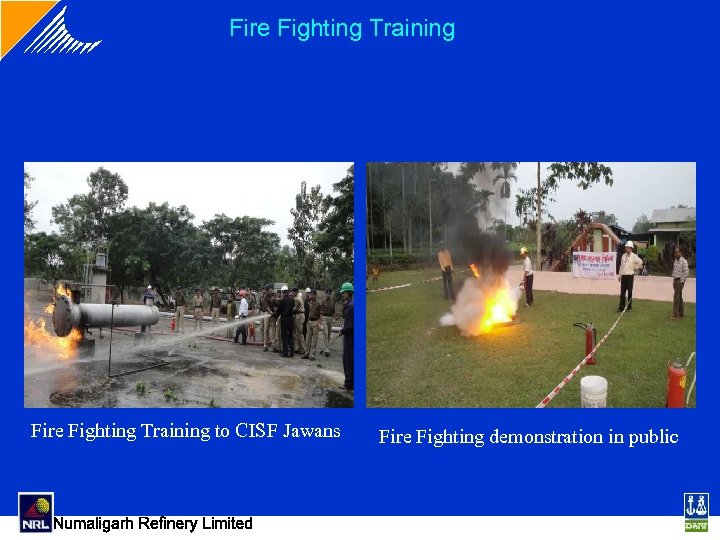

FIRE & SAFETY TRAINING FACILITIES: • TRAINING HALL AT FIRE STATION • FIRE TRAINING GROUND AS PER OISD 116 • TRAINING POLICY AS PER OISD - 154 TYPES OF TRAINING: • FRESHER TRAINING FOR NEW EMPLOYEES • RE-FRESHER TRAINING FOR ALL EMPLOYEES OTHERS • CONTRACTOR’S SUPERVISORS / WORKMEN • CISF & OTHER SECURITY STAFF • POL DRIVERS

FIRE & SAFETY TRAINING FACILITIES: • TRAINING HALL AT FIRE STATION • FIRE TRAINING GROUND AS PER OISD 116 • TRAINING POLICY AS PER OISD - 154 TYPES OF TRAINING: • FRESHER TRAINING FOR NEW EMPLOYEES • RE-FRESHER TRAINING FOR ALL EMPLOYEES OTHERS • CONTRACTOR’S SUPERVISORS / WORKMEN • CISF & OTHER SECURITY STAFF • POL DRIVERS

Fire Fighting Training to CISF Jawans Fire Fighting demonstration in public

Fire Fighting Training to CISF Jawans Fire Fighting demonstration in public

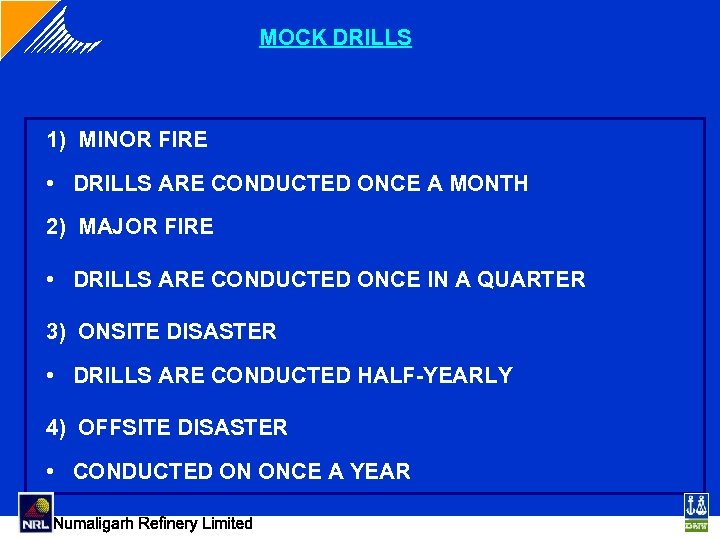

MOCK DRILLS 1) MINOR FIRE • DRILLS ARE CONDUCTED ONCE A MONTH 2) MAJOR FIRE • DRILLS ARE CONDUCTED ONCE IN A QUARTER 3) ONSITE DISASTER • DRILLS ARE CONDUCTED HALF-YEARLY 4) OFFSITE DISASTER • CONDUCTED ON ONCE A YEAR

MOCK DRILLS 1) MINOR FIRE • DRILLS ARE CONDUCTED ONCE A MONTH 2) MAJOR FIRE • DRILLS ARE CONDUCTED ONCE IN A QUARTER 3) ONSITE DISASTER • DRILLS ARE CONDUCTED HALF-YEARLY 4) OFFSITE DISASTER • CONDUCTED ON ONCE A YEAR

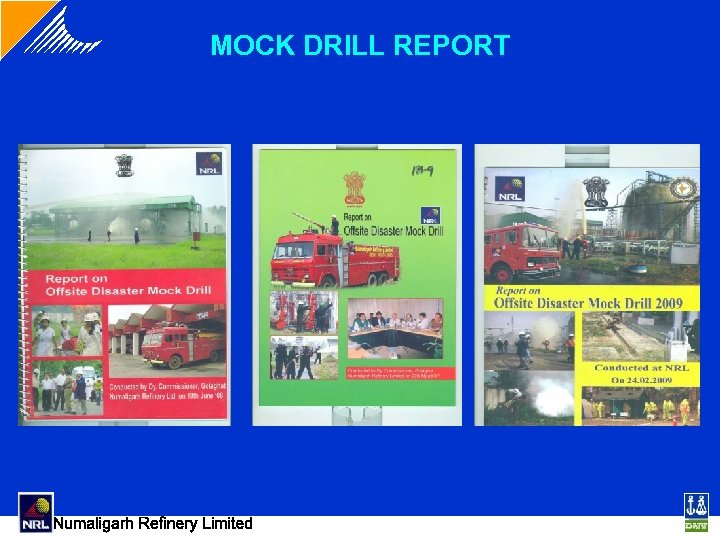

MOCK DRILL REPORT

MOCK DRILL REPORT

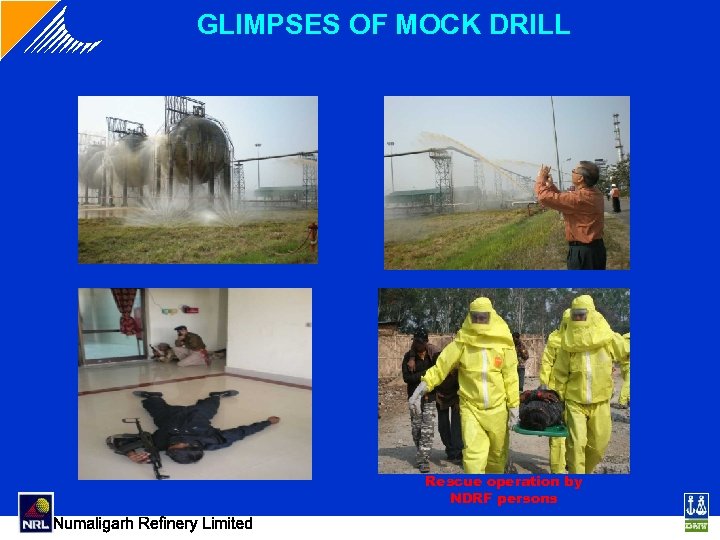

GLIMPSES OF MOCK DRILL Rescue operation by NDRF persons

GLIMPSES OF MOCK DRILL Rescue operation by NDRF persons

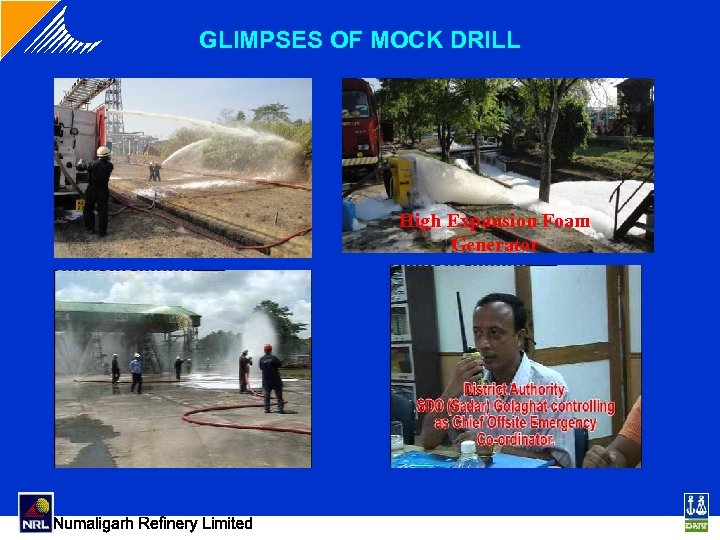

GLIMPSES OF MOCK DRILL High Expansion Foam Generator

GLIMPSES OF MOCK DRILL High Expansion Foam Generator

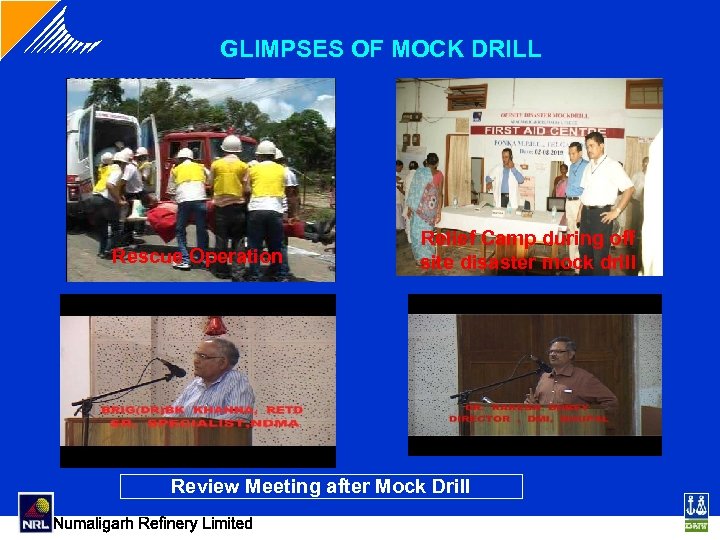

GLIMPSES OF MOCK DRILL Rescue Operation Relief Camp during off site disaster mock drill Review Meeting after Mock Drill

GLIMPSES OF MOCK DRILL Rescue Operation Relief Camp during off site disaster mock drill Review Meeting after Mock Drill

SAFETY INCENTIVE SCHEMES • INCENTIVE LINKED WITH MILLION LTA FREE MAN HRS. • OUTSTANDING SAFETY PERFORMANCE AWARD. • HOUSEKEEPING AWARD (FOR UNITS). • SECTIONAL SAFETY AWARDS. • SAFETY AWARD FOR CONTRACTORS. • TURN AROUND SAFETY AWRAD • BEST SAFETY AWARD FOR NRL EMPLOYEES • BEST SAFETY AWARD FOR CONTRACTS EMPLOYEES (AMC/PROJECT)

SAFETY INCENTIVE SCHEMES • INCENTIVE LINKED WITH MILLION LTA FREE MAN HRS. • OUTSTANDING SAFETY PERFORMANCE AWARD. • HOUSEKEEPING AWARD (FOR UNITS). • SECTIONAL SAFETY AWARDS. • SAFETY AWARD FOR CONTRACTORS. • TURN AROUND SAFETY AWRAD • BEST SAFETY AWARD FOR NRL EMPLOYEES • BEST SAFETY AWARD FOR CONTRACTS EMPLOYEES (AMC/PROJECT)

RECENT PROJECTS COMPLETED PROJECTS • Motor Spirit Unit • Utilization of Natural Gas • Diesel Quality Up gradation Project • 12 MW Steam Turbine Generator • Pipeline Dispatch & Receipt Terminal FUTURE PERSPECTIVE • Naphtha Splitter Project • Wax Project • Production of Needle Coke

RECENT PROJECTS COMPLETED PROJECTS • Motor Spirit Unit • Utilization of Natural Gas • Diesel Quality Up gradation Project • 12 MW Steam Turbine Generator • Pipeline Dispatch & Receipt Terminal FUTURE PERSPECTIVE • Naphtha Splitter Project • Wax Project • Production of Needle Coke

Key Tasks Adopted in NRL for Improvement of Health & Fire 1. 2. 3. 4. 5. Health Hazard Survey for Employees: • As a good corporate citizen among oil industries in India, NRL has under taken the health hazard survey for critical tasks and high hazard areas in plants and other areas On the site Safety training for employees: • A specific training programme adopted for training of employees at the site. Contractor Safety Evaluation for Turn Around Jobs: • NRL was having a full-fledged contractor safety evaluation during turn • The system of evaluation for contractors is very elusive considering all aspects of HSE. Survey of fire fighting and safety equipments: • The fire fighting and safety items in refinery are surveyed by a multidisciplinary team of operation, Maint and F&S to exactly evaluate the correct equipments for fire fighting and safety. All required actions are taken by F&S for the same. Internal Safety Audit by members from group companies: • The system of Internal Safety Audit is being prevailed in NRL as per OISD guidelines.

Key Tasks Adopted in NRL for Improvement of Health & Fire 1. 2. 3. 4. 5. Health Hazard Survey for Employees: • As a good corporate citizen among oil industries in India, NRL has under taken the health hazard survey for critical tasks and high hazard areas in plants and other areas On the site Safety training for employees: • A specific training programme adopted for training of employees at the site. Contractor Safety Evaluation for Turn Around Jobs: • NRL was having a full-fledged contractor safety evaluation during turn • The system of evaluation for contractors is very elusive considering all aspects of HSE. Survey of fire fighting and safety equipments: • The fire fighting and safety items in refinery are surveyed by a multidisciplinary team of operation, Maint and F&S to exactly evaluate the correct equipments for fire fighting and safety. All required actions are taken by F&S for the same. Internal Safety Audit by members from group companies: • The system of Internal Safety Audit is being prevailed in NRL as per OISD guidelines.

EXAMPLES OF POSITIVE ACTION TAKEN • • From last year onwards, NRL’s all meetings starts with a “safety moment” where safety points are discussed. NRL is always meeting MOU target of Training of NRL personnel, workers of contractors, CISF & security guards etc on safety. General Loss Control Rules/Don’ts Hazard Communication: – Contractor must familiarize himself from NRL EICs about all known potential fire, explosion or toxic release hazards related to his contract. He in turn will ensure that same information has been passed to his supervisors and workmen. • • • Contractors Penalty clause – In order to improve and maintain safe working environment we are planning to introduce a special conditions of contracts for HSE (Health Safety and Environment) regulation for contractors. Note: Generally we do counseling to the workers if they are found practicing unsafe acts or work in unsafe condition before imposing the above penalty clauses. PPE: NRL has adopted colour code for PPEs to improve safety culture at NRL with effect from 1 st January, 2011.

EXAMPLES OF POSITIVE ACTION TAKEN • • From last year onwards, NRL’s all meetings starts with a “safety moment” where safety points are discussed. NRL is always meeting MOU target of Training of NRL personnel, workers of contractors, CISF & security guards etc on safety. General Loss Control Rules/Don’ts Hazard Communication: – Contractor must familiarize himself from NRL EICs about all known potential fire, explosion or toxic release hazards related to his contract. He in turn will ensure that same information has been passed to his supervisors and workmen. • • • Contractors Penalty clause – In order to improve and maintain safe working environment we are planning to introduce a special conditions of contracts for HSE (Health Safety and Environment) regulation for contractors. Note: Generally we do counseling to the workers if they are found practicing unsafe acts or work in unsafe condition before imposing the above penalty clauses. PPE: NRL has adopted colour code for PPEs to improve safety culture at NRL with effect from 1 st January, 2011.

Thank You

Thank You