ca1063b3b986503dbdc07a19ed0de1ce.ppt

- Количество слайдов: 17

“Now That I Have the Data How Can I Best Use and Maintain It" Presented By: Greg Anderson (Mc. Kim & Creed) and John Sorrell (CORPUD)

“Now That I Have the Data How Can I Best Use and Maintain It" Presented By: Greg Anderson (Mc. Kim & Creed) and John Sorrell (CORPUD)

ABSTRACT As the City of Raleigh Public Utilities Department, CORPUD, began its first water distribution & wastewater collection system asset management initiative two major service areas within the City were identified and individual consultants were selected to complete each project. As no previous protocols for collecting the necessary hydraulic and condition assessment data was currently in place CORPUD relied on the consultants to provide recommendations on different processes for collecting the data. While the scope of the flow monitoring and I/I evaluation efforts were very similar in nature the approach to collect manhole and gravity piping condition assessment information was very different. This paper discusses one of the selected methods chosen and the processes which were undertaken to collect the data and merge it into CORPUD’s Cityworks asset management system.

ABSTRACT As the City of Raleigh Public Utilities Department, CORPUD, began its first water distribution & wastewater collection system asset management initiative two major service areas within the City were identified and individual consultants were selected to complete each project. As no previous protocols for collecting the necessary hydraulic and condition assessment data was currently in place CORPUD relied on the consultants to provide recommendations on different processes for collecting the data. While the scope of the flow monitoring and I/I evaluation efforts were very similar in nature the approach to collect manhole and gravity piping condition assessment information was very different. This paper discusses one of the selected methods chosen and the processes which were undertaken to collect the data and merge it into CORPUD’s Cityworks asset management system.

PROJECT SUMMARY Scope – Complete an Evaluation of the Wastewater Collection System in the Upper Pigeon House Drainage Area Tasks: 1. Inventory of Collection System Infrastructure (1, 100 MH) 2. Open Channel Flow Monitoring/Rainfall Gauging (11 Sites) 3. Smoke/Dye Testing in Areas Prone to Excessive Storm Water Inflow (150, 000 LF & 30 Dye Water Floods) 4. Inspection of Deficient Collection System Manholes (468 MH) 5. Inspection of Gravity Piping in Areas Scheduled for Pavement Overlay and Piping in High Traffic Areas (70, 000 LF) 6. Prepare R&R Recommendations and Provide Construction Cost Opinions

PROJECT SUMMARY Scope – Complete an Evaluation of the Wastewater Collection System in the Upper Pigeon House Drainage Area Tasks: 1. Inventory of Collection System Infrastructure (1, 100 MH) 2. Open Channel Flow Monitoring/Rainfall Gauging (11 Sites) 3. Smoke/Dye Testing in Areas Prone to Excessive Storm Water Inflow (150, 000 LF & 30 Dye Water Floods) 4. Inspection of Deficient Collection System Manholes (468 MH) 5. Inspection of Gravity Piping in Areas Scheduled for Pavement Overlay and Piping in High Traffic Areas (70, 000 LF) 6. Prepare R&R Recommendations and Provide Construction Cost Opinions

INVENTORY OF COLLECTION SYSTEM Scope – Validate GIS Information Through Conduction of a Level One (MACP) Manhole Inspection Effort 1. 2. 3. 4. 5. Validate Structure Location (GPS Sub-Meter Accuracy) Confirm Piping to Structure Connectivity Verify Pipe Sizes and Construction Materials Document Significant Manhole O&M, or Structural Defects Identify Connecting Pipe Defects w/Zoom Pole Cameras

INVENTORY OF COLLECTION SYSTEM Scope – Validate GIS Information Through Conduction of a Level One (MACP) Manhole Inspection Effort 1. 2. 3. 4. 5. Validate Structure Location (GPS Sub-Meter Accuracy) Confirm Piping to Structure Connectivity Verify Pipe Sizes and Construction Materials Document Significant Manhole O&M, or Structural Defects Identify Connecting Pipe Defects w/Zoom Pole Cameras

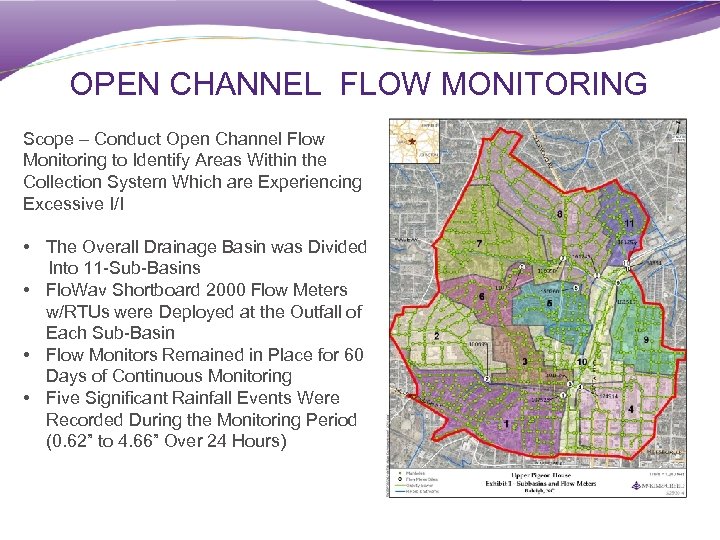

OPEN CHANNEL FLOW MONITORING Scope – Conduct Open Channel Flow Monitoring to Identify Areas Within the Collection System Which are Experiencing Excessive I/I • The Overall Drainage Basin was Divided Into 11 -Sub-Basins • Flo. Wav Shortboard 2000 Flow Meters w/RTUs were Deployed at the Outfall of Each Sub-Basin • Flow Monitors Remained in Place for 60 Days of Continuous Monitoring • Five Significant Rainfall Events Were Recorded During the Monitoring Period (0. 62” to 4. 66” Over 24 Hours)

OPEN CHANNEL FLOW MONITORING Scope – Conduct Open Channel Flow Monitoring to Identify Areas Within the Collection System Which are Experiencing Excessive I/I • The Overall Drainage Basin was Divided Into 11 -Sub-Basins • Flo. Wav Shortboard 2000 Flow Meters w/RTUs were Deployed at the Outfall of Each Sub-Basin • Flow Monitors Remained in Place for 60 Days of Continuous Monitoring • Five Significant Rainfall Events Were Recorded During the Monitoring Period (0. 62” to 4. 66” Over 24 Hours)

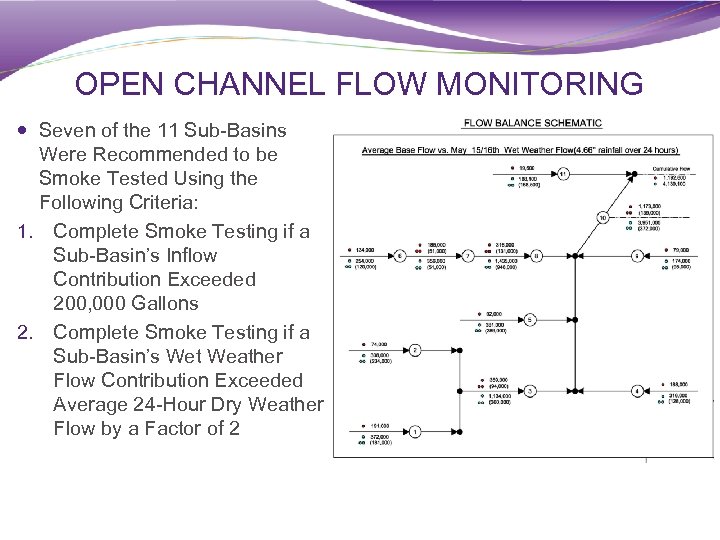

OPEN CHANNEL FLOW MONITORING Seven of the 11 Sub-Basins Were Recommended to be Smoke Tested Using the Following Criteria: 1. Complete Smoke Testing if a Sub-Basin’s Inflow Contribution Exceeded 200, 000 Gallons 2. Complete Smoke Testing if a Sub-Basin’s Wet Weather Flow Contribution Exceeded Average 24 -Hour Dry Weather Flow by a Factor of 2

OPEN CHANNEL FLOW MONITORING Seven of the 11 Sub-Basins Were Recommended to be Smoke Tested Using the Following Criteria: 1. Complete Smoke Testing if a Sub-Basin’s Inflow Contribution Exceeded 200, 000 Gallons 2. Complete Smoke Testing if a Sub-Basin’s Wet Weather Flow Contribution Exceeded Average 24 -Hour Dry Weather Flow by a Factor of 2

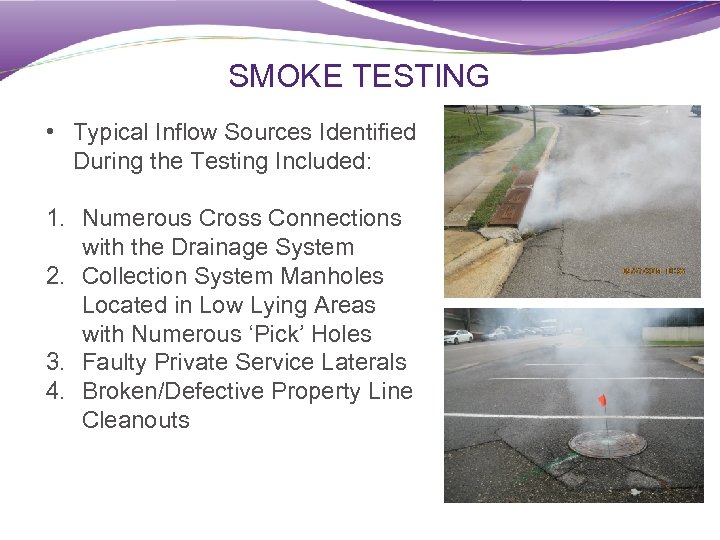

SMOKE TESTING • Typical Inflow Sources Identified During the Testing Included: 1. Numerous Cross Connections with the Drainage System 2. Collection System Manholes Located in Low Lying Areas with Numerous ‘Pick’ Holes 3. Faulty Private Service Laterals 4. Broken/Defective Property Line Cleanouts

SMOKE TESTING • Typical Inflow Sources Identified During the Testing Included: 1. Numerous Cross Connections with the Drainage System 2. Collection System Manholes Located in Low Lying Areas with Numerous ‘Pick’ Holes 3. Faulty Private Service Laterals 4. Broken/Defective Property Line Cleanouts

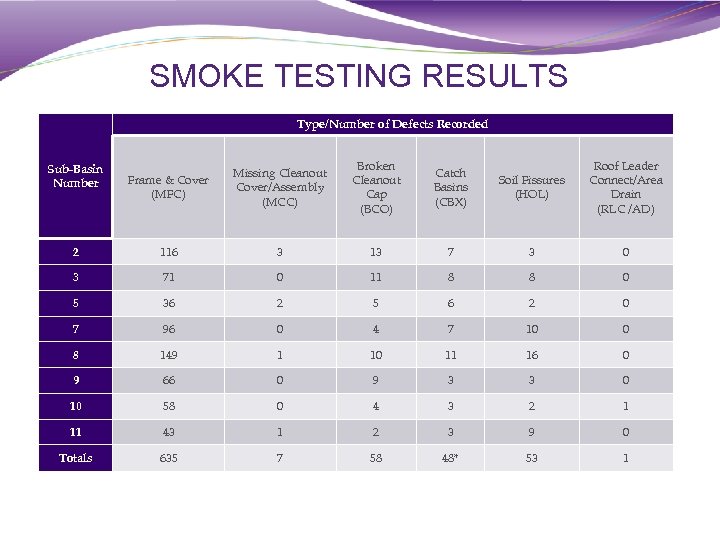

SMOKE TESTING RESULTS Type/Number of Defects Recorded Frame & Cover (MFC) Missing Cleanout Cover/Assembly (MCC) Broken Cleanout Cap (BCO) Catch Basins (CBX) Soil Fissures (HOL) Roof Leader Connect/Area Drain (RLC /AD) 2 116 3 13 7 3 0 3 71 0 11 8 8 0 5 36 2 5 6 2 0 7 96 0 4 7 10 0 8 149 1 10 11 16 0 9 66 0 9 3 3 0 10 58 0 4 3 2 1 11 43 1 2 3 9 0 Totals 635 7 58 48* 53 1 Sub-Basin Number

SMOKE TESTING RESULTS Type/Number of Defects Recorded Frame & Cover (MFC) Missing Cleanout Cover/Assembly (MCC) Broken Cleanout Cap (BCO) Catch Basins (CBX) Soil Fissures (HOL) Roof Leader Connect/Area Drain (RLC /AD) 2 116 3 13 7 3 0 3 71 0 11 8 8 0 5 36 2 5 6 2 0 7 96 0 4 7 10 0 8 149 1 10 11 16 0 9 66 0 9 3 3 0 10 58 0 4 3 2 1 11 43 1 2 3 9 0 Totals 635 7 58 48* 53 1 Sub-Basin Number

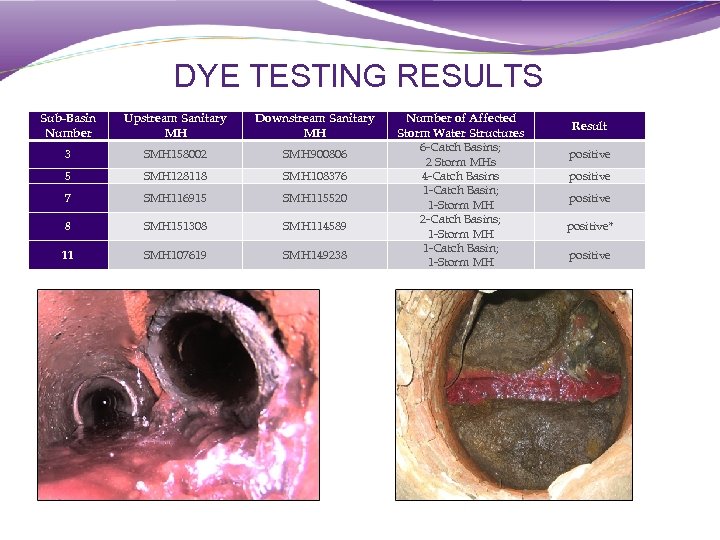

DYE TESTING RESULTS Sub-Basin Number Upstream Sanitary MH Downstream Sanitary MH 3 SMH 158002 SMH 900806 5 SMH 128118 SMH 108376 7 SMH 116915 SMH 115520 8 SMH 151308 SMH 114589 11 SMH 107619 SMH 149238 Number of Affected Storm Water Structures 6 -Catch Basins; 2 Storm MHs 4 -Catch Basins 1 -Catch Basin; 1 -Storm MH 2 -Catch Basins; 1 -Storm MH 1 -Catch Basin; 1 -Storm MH Result positive* positive

DYE TESTING RESULTS Sub-Basin Number Upstream Sanitary MH Downstream Sanitary MH 3 SMH 158002 SMH 900806 5 SMH 128118 SMH 108376 7 SMH 116915 SMH 115520 8 SMH 151308 SMH 114589 11 SMH 107619 SMH 149238 Number of Affected Storm Water Structures 6 -Catch Basins; 2 Storm MHs 4 -Catch Basins 1 -Catch Basin; 1 -Storm MH 2 -Catch Basins; 1 -Storm MH 1 -Catch Basin; 1 -Storm MH Result positive* positive

MANHOLE INSPECTIONS Scope – Document Structural and O&M Conditions for all Manholes Which Were Identified With Defects Rated 3 and Above Using Digital Side Scanning Equipment

MANHOLE INSPECTIONS Scope – Document Structural and O&M Conditions for all Manholes Which Were Identified With Defects Rated 3 and Above Using Digital Side Scanning Equipment

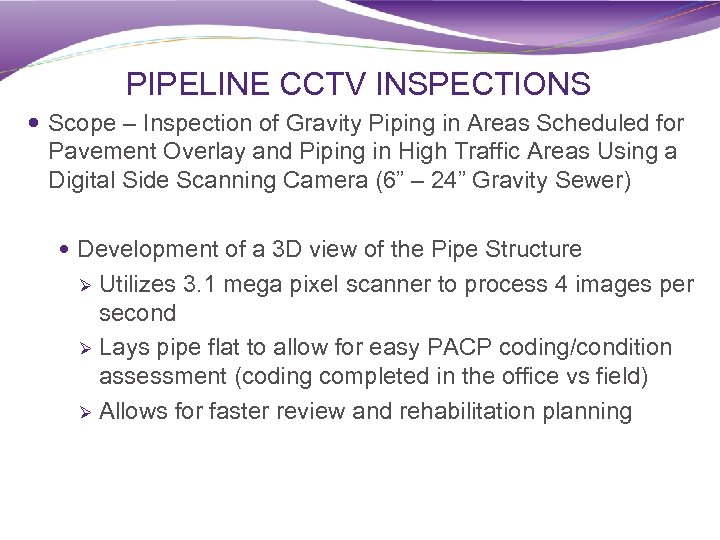

PIPELINE CCTV INSPECTIONS Scope – Inspection of Gravity Piping in Areas Scheduled for Pavement Overlay and Piping in High Traffic Areas Using a Digital Side Scanning Camera (6” – 24” Gravity Sewer) Development of a 3 D view of the Pipe Structure Utilizes 3. 1 mega pixel scanner to process 4 images per second Ø Lays pipe flat to allow for easy PACP coding/condition assessment (coding completed in the office vs field) Ø Allows for faster review and rehabilitation planning Ø

PIPELINE CCTV INSPECTIONS Scope – Inspection of Gravity Piping in Areas Scheduled for Pavement Overlay and Piping in High Traffic Areas Using a Digital Side Scanning Camera (6” – 24” Gravity Sewer) Development of a 3 D view of the Pipe Structure Utilizes 3. 1 mega pixel scanner to process 4 images per second Ø Lays pipe flat to allow for easy PACP coding/condition assessment (coding completed in the office vs field) Ø Allows for faster review and rehabilitation planning Ø

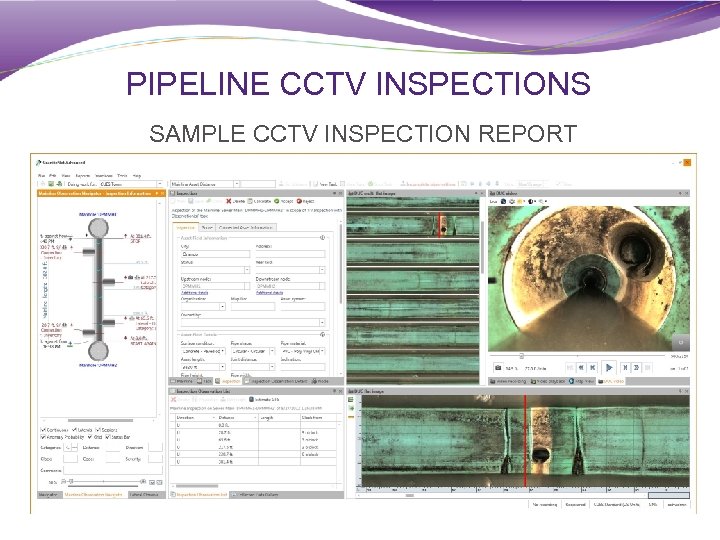

PIPELINE CCTV INSPECTIONS SAMPLE CCTV INSPECTION REPORT

PIPELINE CCTV INSPECTIONS SAMPLE CCTV INSPECTION REPORT

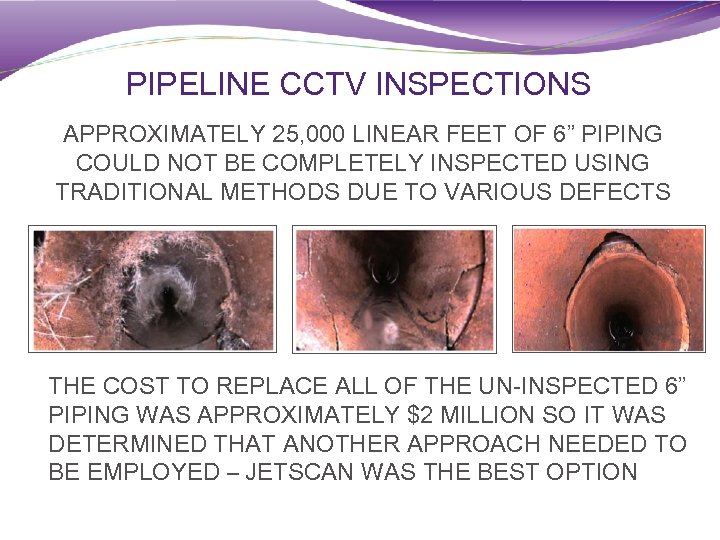

PIPELINE CCTV INSPECTIONS APPROXIMATELY 25, 000 LINEAR FEET OF 6” PIPING COULD NOT BE COMPLETELY INSPECTED USING TRADITIONAL METHODS DUE TO VARIOUS DEFECTS THE COST TO REPLACE ALL OF THE UN-INSPECTED 6” PIPING WAS APPROXIMATELY $2 MILLION SO IT WAS DETERMINED THAT ANOTHER APPROACH NEEDED TO BE EMPLOYED – JETSCAN WAS THE BEST OPTION

PIPELINE CCTV INSPECTIONS APPROXIMATELY 25, 000 LINEAR FEET OF 6” PIPING COULD NOT BE COMPLETELY INSPECTED USING TRADITIONAL METHODS DUE TO VARIOUS DEFECTS THE COST TO REPLACE ALL OF THE UN-INSPECTED 6” PIPING WAS APPROXIMATELY $2 MILLION SO IT WAS DETERMINED THAT ANOTHER APPROACH NEEDED TO BE EMPLOYED – JETSCAN WAS THE BEST OPTION

PIPELINE CCTV INSPECTIONS INSPECTION OF 6” PIPING WHICH COULD NOT BE COMPLETED USING TRADITIONAL INSPECTION APPROACH

PIPELINE CCTV INSPECTIONS INSPECTION OF 6” PIPING WHICH COULD NOT BE COMPLETED USING TRADITIONAL INSPECTION APPROACH

PIPELINE CCTV INSPECTIONS INSPECTION OF 6” PIPING WHICH COULD NOT BE COMPLETED USING TRADITIONAL INSPECTION APPROACH

PIPELINE CCTV INSPECTIONS INSPECTION OF 6” PIPING WHICH COULD NOT BE COMPLETED USING TRADITIONAL INSPECTION APPROACH

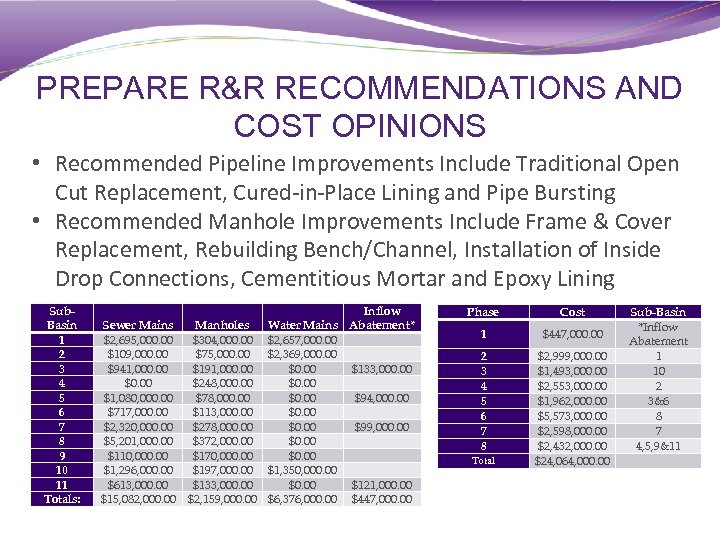

PREPARE R&R RECOMMENDATIONS AND COST OPINIONS • Recommended Pipeline Improvements Include Traditional Open Cut Replacement, Cured-in-Place Lining and Pipe Bursting • Recommended Manhole Improvements Include Frame & Cover Replacement, Rebuilding Bench/Channel, Installation of Inside Drop Connections, Cementitious Mortar and Epoxy Lining Sub. Basin 1 2 3 4 5 6 7 8 9 10 11 Totals: Sewer Mains $2, 695, 000. 00 $109, 000. 00 $941, 000. 00 $1, 080, 000. 00 $717, 000. 00 $2, 320, 000. 00 $5, 201, 000. 00 $110, 000. 00 $1, 296, 000. 00 $613, 000. 00 $15, 082, 000. 00 Inflow Manholes Water Mains Abatement* $304, 000. 00 $2, 657, 000. 00 $75, 000. 00 $2, 369, 000. 00 $191, 000. 00 $133, 000. 00 $248, 000. 00 $78, 000. 00 $94, 000. 00 $113, 000. 00 $278, 000. 00 $99, 000. 00 $372, 000. 00 $170, 000. 00 $197, 000. 00 $1, 350, 000. 00 $133, 000. 00 $121, 000. 00 $2, 159, 000. 00 $6, 376, 000. 00 $447, 000. 00 Phase Cost 1 $447, 000. 00 2 3 4 5 6 7 8 $2, 999, 000. 00 $1, 493, 000. 00 $2, 553, 000. 00 $1, 962, 000. 00 $5, 573, 000. 00 $2, 598, 000. 00 $2, 432, 000. 00 $24, 064, 000. 00 Total Sub-Basin *Inflow Abatement 1 10 2 3&6 8 7 4, 5, 9&11

PREPARE R&R RECOMMENDATIONS AND COST OPINIONS • Recommended Pipeline Improvements Include Traditional Open Cut Replacement, Cured-in-Place Lining and Pipe Bursting • Recommended Manhole Improvements Include Frame & Cover Replacement, Rebuilding Bench/Channel, Installation of Inside Drop Connections, Cementitious Mortar and Epoxy Lining Sub. Basin 1 2 3 4 5 6 7 8 9 10 11 Totals: Sewer Mains $2, 695, 000. 00 $109, 000. 00 $941, 000. 00 $1, 080, 000. 00 $717, 000. 00 $2, 320, 000. 00 $5, 201, 000. 00 $110, 000. 00 $1, 296, 000. 00 $613, 000. 00 $15, 082, 000. 00 Inflow Manholes Water Mains Abatement* $304, 000. 00 $2, 657, 000. 00 $75, 000. 00 $2, 369, 000. 00 $191, 000. 00 $133, 000. 00 $248, 000. 00 $78, 000. 00 $94, 000. 00 $113, 000. 00 $278, 000. 00 $99, 000. 00 $372, 000. 00 $170, 000. 00 $197, 000. 00 $1, 350, 000. 00 $133, 000. 00 $121, 000. 00 $2, 159, 000. 00 $6, 376, 000. 00 $447, 000. 00 Phase Cost 1 $447, 000. 00 2 3 4 5 6 7 8 $2, 999, 000. 00 $1, 493, 000. 00 $2, 553, 000. 00 $1, 962, 000. 00 $5, 573, 000. 00 $2, 598, 000. 00 $2, 432, 000. 00 $24, 064, 000. 00 Total Sub-Basin *Inflow Abatement 1 10 2 3&6 8 7 4, 5, 9&11

Contact Information: Greg Anderson, PE ganderson@mckimcreed. com 757. 435. 7363

Contact Information: Greg Anderson, PE ganderson@mckimcreed. com 757. 435. 7363