82ae4f099de444a7625df15de47f3dc5.ppt

- Количество слайдов: 58

Note: This program was produced by Covalence Stretch Films. As of April, 2007, Covalence Stretch Films is now Berry Plastics. Mike Barry's new e-mail address is mikebarry@berryplastics. com • university Of stretch

stretch film university table of contents • Industry Overview • Manufacturing • Applications • Covalence Products • Competitive Films • Film Testing • Glossary

stretch film industry Overview

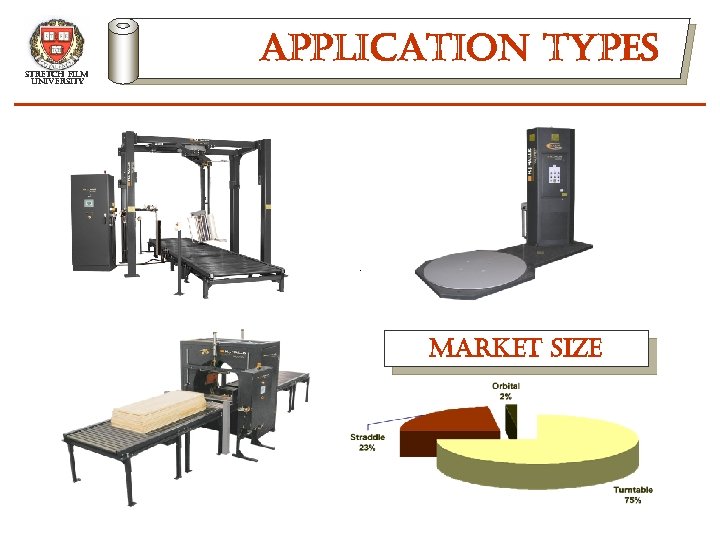

stretch film university application types mar. Ket si. Ze

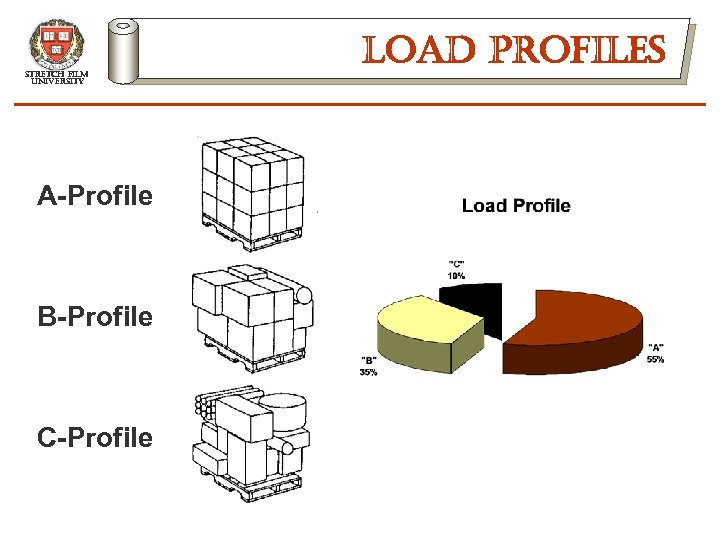

stretch film university A-Profile B-Profile C-Profile load profiles

stretch film university stretch mar. Ket • Stretch Film is a fully mature market, with most prospective customers already using either hand and/or machine film • Most commonly, the opportunities to add value for the customer are to: üLower overall cost per load üImprove load integrity / reduce shipping damage üReduce the number of film “breaks” during application üShorten wrapping cycle time üUpgrade from hand-wrap to machine film

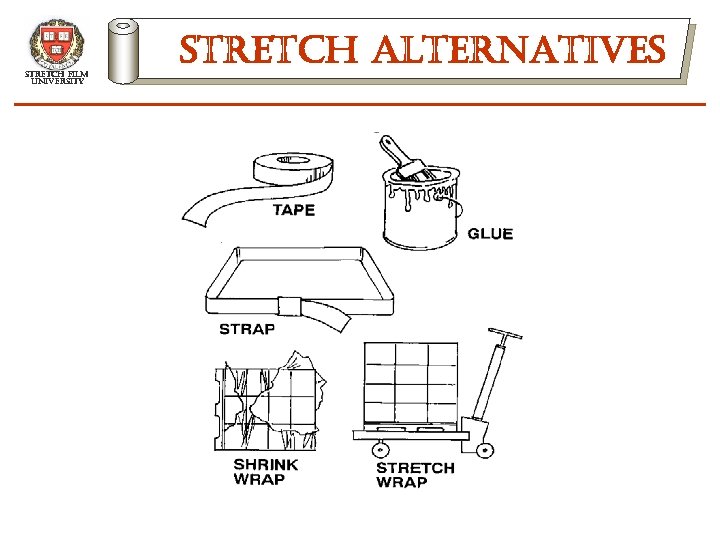

stretch film university stretch alternatives

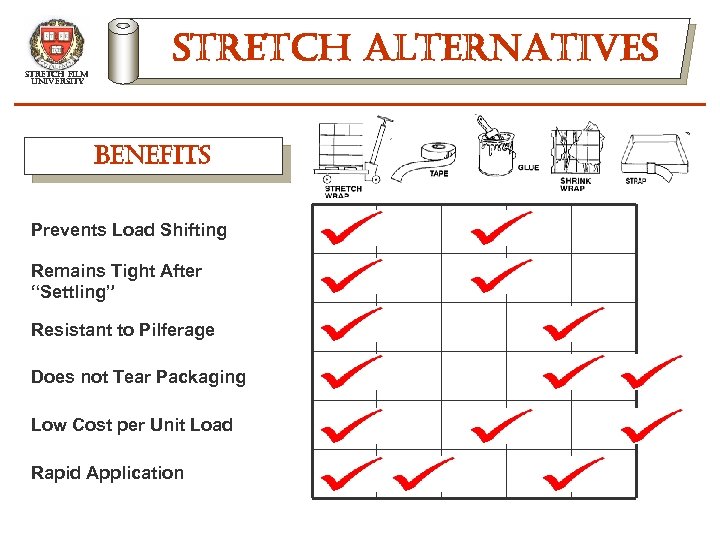

stretch film university stretch alternatives benefits Prevents Load Shifting Remains Tight After “Settling” Resistant to Pilferage Does not Tear Packaging Low Cost per Unit Load Rapid Application

stretch film manufacturing

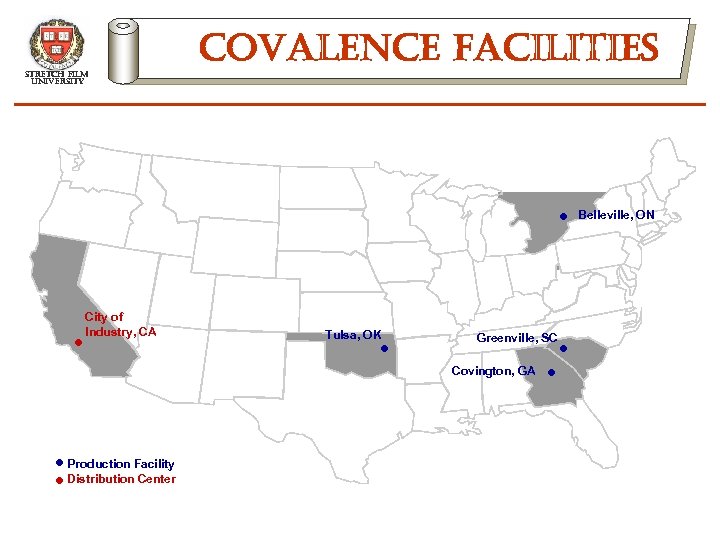

stretch film university covalence facilities • Belleville, ON • City of Industry, CA Tulsa, OK • Greenville, SC Covington, GA • Production Facility • Distribution Center • •

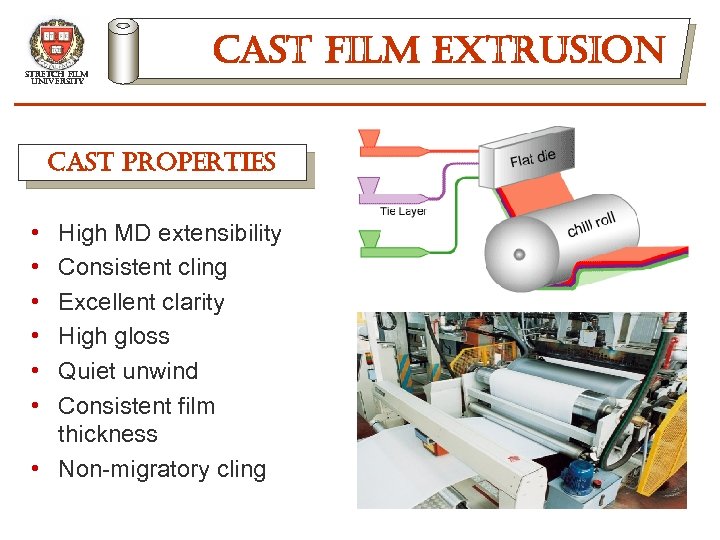

stretch film university cast film extrusion cast properties • • • High MD extensibility Consistent cling Excellent clarity High gloss Quiet unwind Consistent film thickness • Non-migratory cling

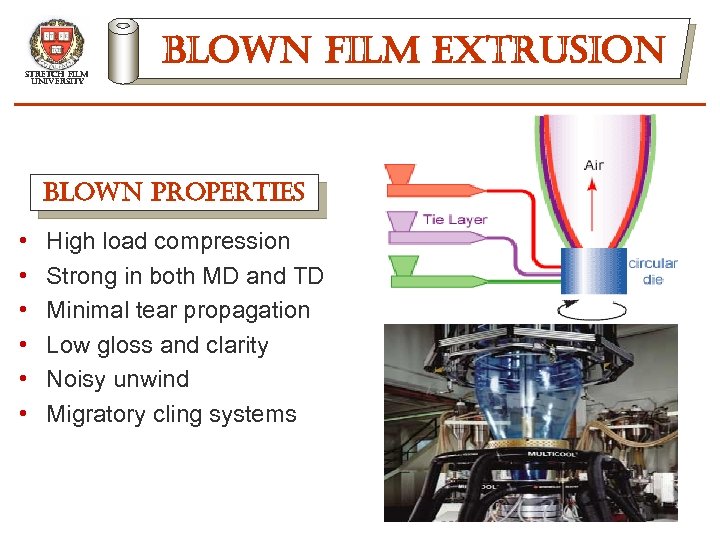

stretch film university blown film extrusion blown properties • • • High load compression Strong in both MD and TD Minimal tear propagation Low gloss and clarity Noisy unwind Migratory cling systems

stretch film university what is metallocene? • • m. LLDPE Increases load force Improves clarity Provides puncture resistance consistent with blown film Not All Metallocene Films Are Created Equal

stretch film selecti. On

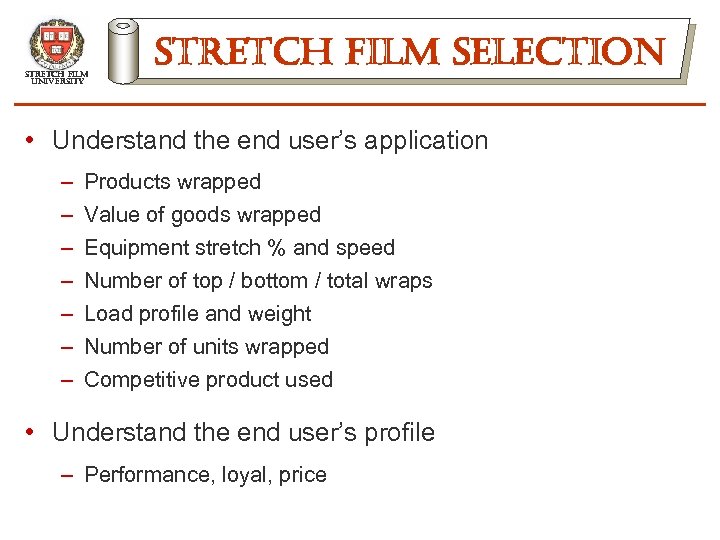

stretch film university stretch film selection • Understand the end user’s application – – – – Products wrapped Value of goods wrapped Equipment stretch % and speed Number of top / bottom / total wraps Load profile and weight Number of units wrapped Competitive product used • Understand the end user’s profile – Performance, loyal, price

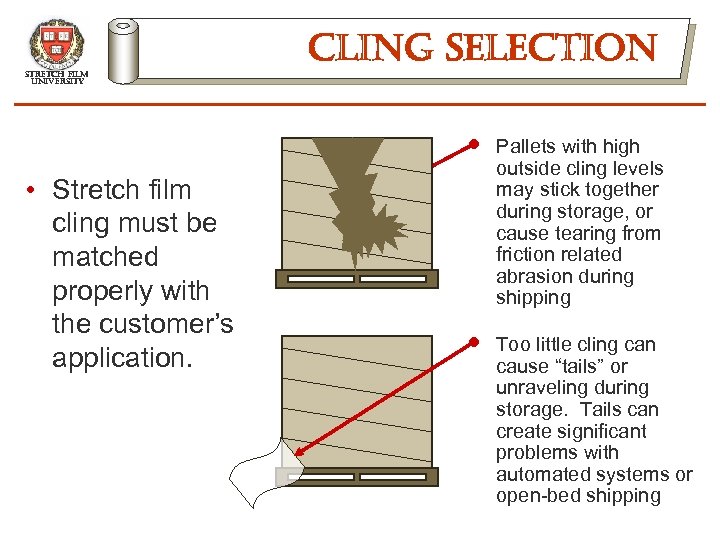

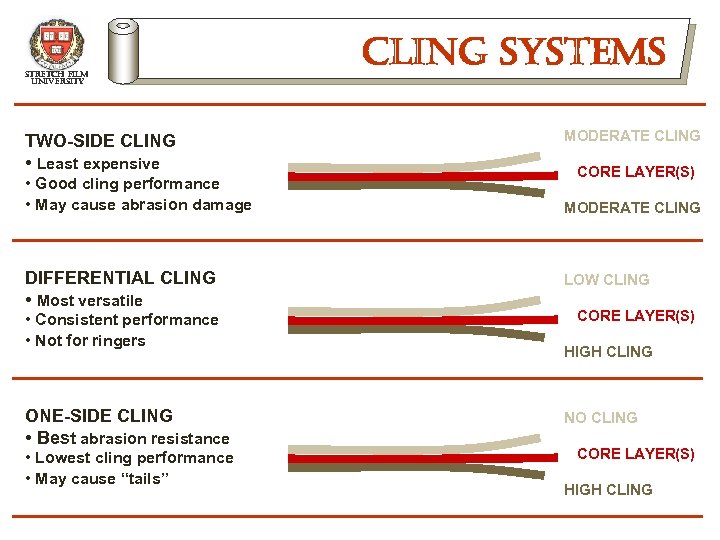

stretch film university • Stretch film cling must be matched properly with the customer’s application. cling selection • Pallets with high outside cling levels may stick together during storage, or cause tearing from friction related abrasion during shipping • Too little cling can cause “tails” or unraveling during storage. Tails can create significant problems with automated systems or open-bed shipping

stretch film university TWO-SIDE CLING • Least expensive • Good cling performance • May cause abrasion damage DIFFERENTIAL CLING • Most versatile • Consistent performance • Not for ringers ONE-SIDE CLING • Best abrasion resistance • Lowest cling performance • May cause “tails” cling systems MODERATE CLING CORE LAYER(S) MODERATE CLING LOW CLING CORE LAYER(S) HIGH CLING NO CLING CORE LAYER(S) HIGH CLING

stretch film university bottom line: • What is working for the customer? • What is the customer comfortable with? • What motivates the customer?

c. Ovalence Pr. Oducts

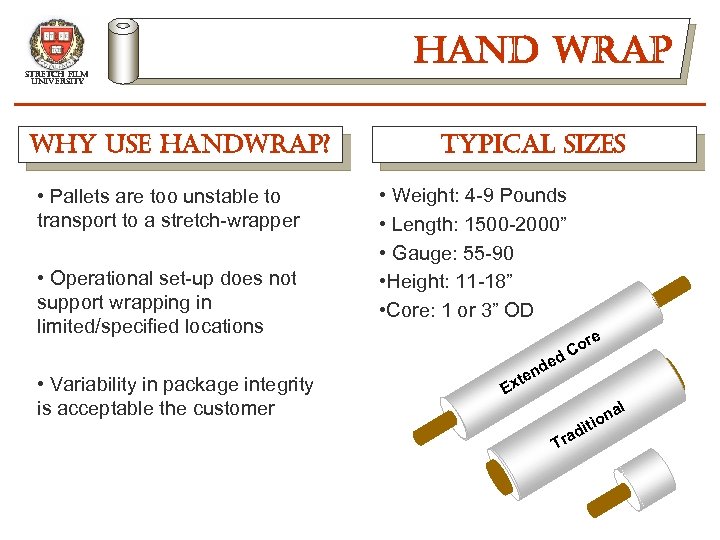

stretch film university why use handwrap? • Pallets are too unstable to transport to a stretch-wrapper • Operational set-up does not support wrapping in limited/specified locations • Variability in package integrity is acceptable the customer hand wrap typical si. Zes • Weight: 4 -9 Pounds • Length: 1500 -2000” • Gauge: 55 -90 • Height: 11 -18” • Core: 1 or 3” OD ore d C de n xte E l d Tra it a ion

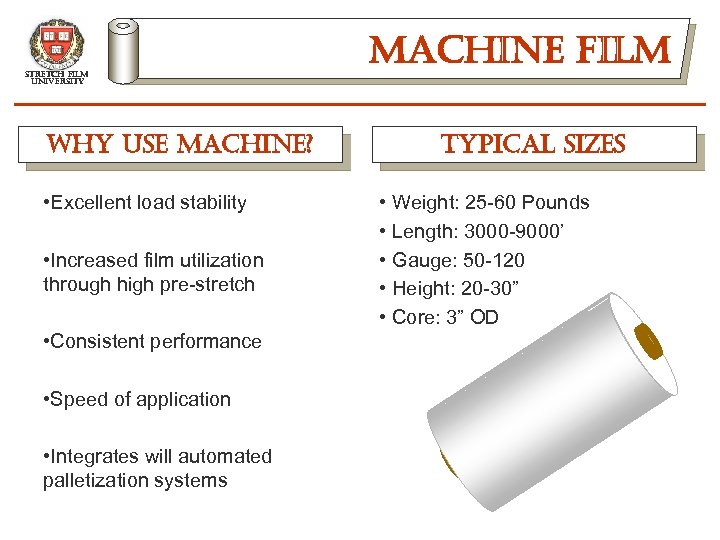

stretch film university why use machine? • Excellent load stability • Increased film utilization through high pre-stretch • Consistent performance • Speed of application • Integrates will automated palletization systems machine film typical si. Zes • Weight: 25 -60 Pounds • Length: 3000 -9000’ • Gauge: 50 -120 • Height: 20 -30” • Core: 3” OD

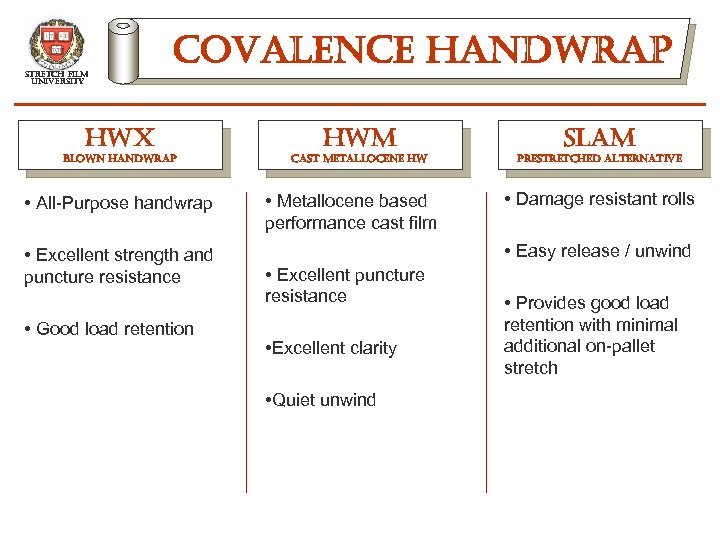

stretch film university covalence handwrap hwx blown handwrap • All-Purpose handwrap • Excellent strength and puncture resistance • Good load retention hwm cast metallocene hw • Metallocene based performance cast film slam prestretched alternative • Damage resistant rolls • Easy release / unwind • Excellent puncture resistance • Excellent clarity • Quiet unwind • Provides good load retention with minimal additional on-pallet stretch

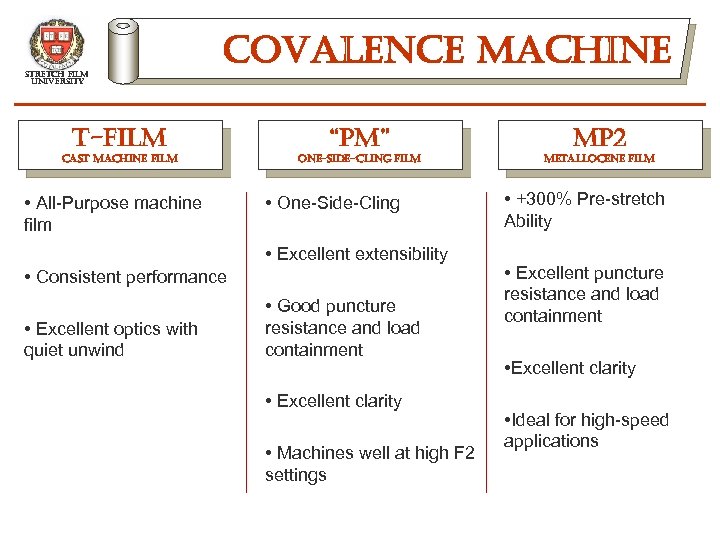

stretch film university covalence machine t-film cast machine film • All-Purpose machine film “pm” one-side-cling film • One-Side-Cling • Excellent extensibility • Consistent performance • Excellent optics with quiet unwind • Good puncture resistance and load containment • Excellent clarity • Machines well at high F 2 settings mp 2 metallocene film • +300% Pre-stretch Ability • Excellent puncture resistance and load containment • Excellent clarity • Ideal for high-speed applications

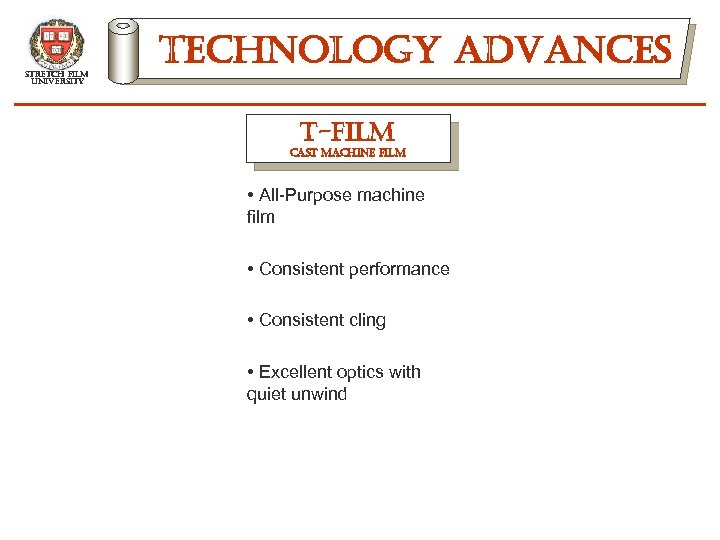

stretch film university technology advances t-film cast machine film • All-Purpose machine film • Consistent performance • Consistent cling • Excellent optics with quiet unwind

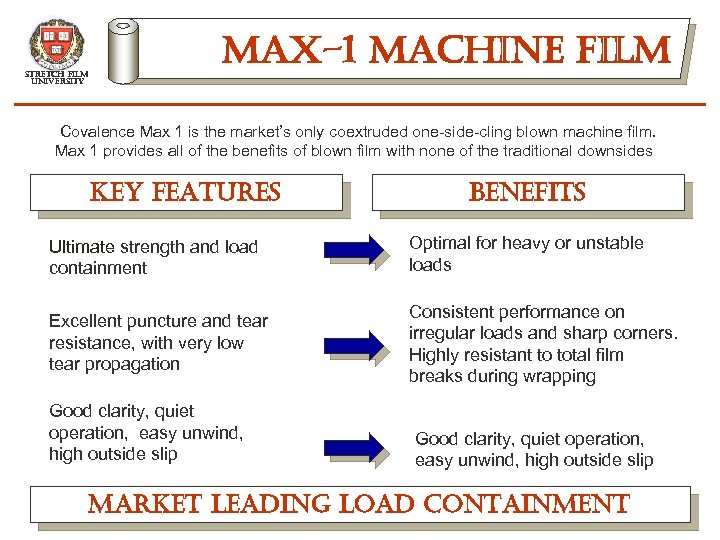

stretch film university max-1 machine film Covalence Max 1 is the market’s only coextruded one-side-cling blown machine film. Max 1 provides all of the benefits of blown film with none of the traditional downsides Key features benefits Ultimate strength and load containment Optimal for heavy or unstable loads Excellent puncture and tear resistance, with very low tear propagation Consistent performance on irregular loads and sharp corners. Highly resistant to total film breaks during wrapping Good clarity, quiet operation, easy unwind, high outside slip mar. Ket leading load containment

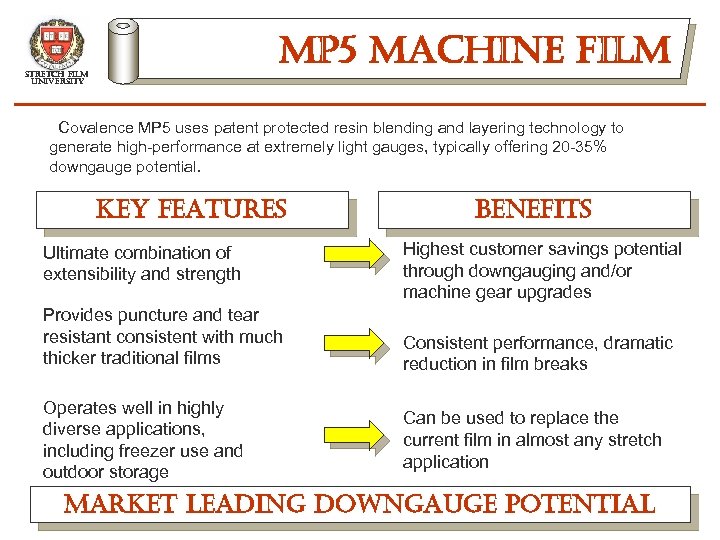

mp 5 machine film stretch film university Covalence MP 5 uses patent protected resin blending and layering technology to generate high-performance at extremely light gauges, typically offering 20 -35% downgauge potential. Key features Ultimate combination of extensibility and strength Provides puncture and tear resistant consistent with much thicker traditional films Operates well in highly diverse applications, including freezer use and outdoor storage benefits Highest customer savings potential through downgauging and/or machine gear upgrades Consistent performance, dramatic reduction in film breaks Can be used to replace the current film in almost any stretch application mar. Ket leading downgauge potential

stretch film university convenience film Convenience Films • Masterwrap – 2”, 3”, 5” width –. 67, . 90, 1. 20 mil • Handwrap II – – Cast film 20” width. 60, . 80 mil Flexible hand brakes or gloves • Loadwrapper – 5” - 20” widths – Medium and heavy gauges – Disposable handwrap system and gloves

stretch film testing

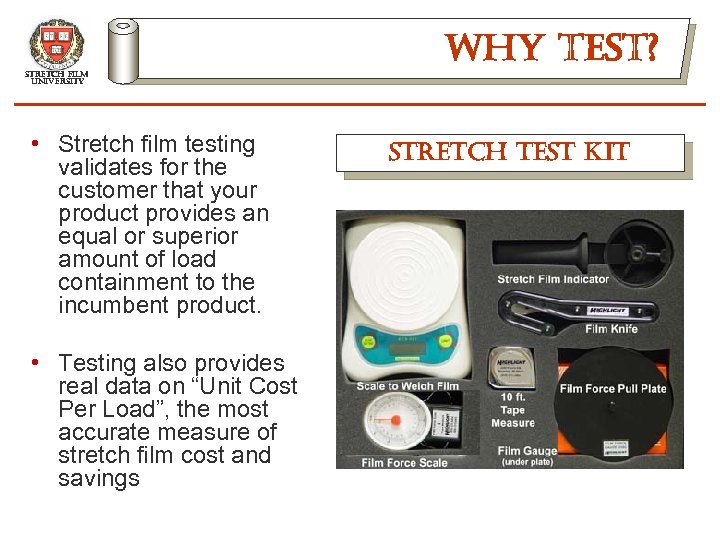

stretch film university • Stretch film testing validates for the customer that your product provides an equal or superior amount of load containment to the incumbent product. • Testing also provides real data on “Unit Cost Per Load”, the most accurate measure of stretch film cost and savings why test? stretch test Kit

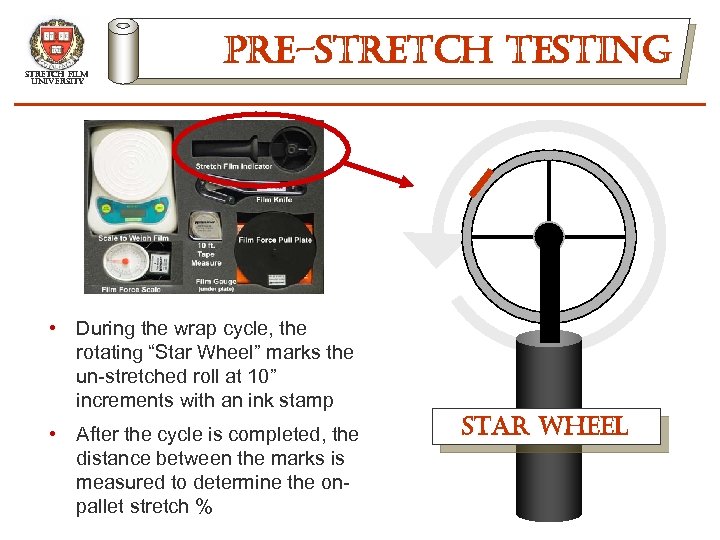

stretch film university pre-stretch testing • During the wrap cycle, the rotating “Star Wheel” marks the un-stretched roll at 10” increments with an ink stamp • After the cycle is completed, the distance between the marks is measured to determine the onpallet stretch % star wheel

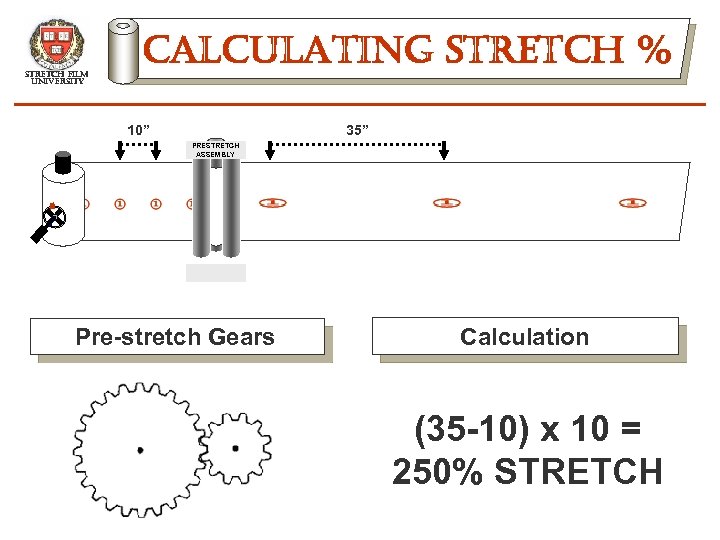

stretch film university calculating stretch % 10” 35” PRESTRETCH ASSEMBLY Pre-stretch Gears Calculation (35 -10) x 10 = 250% STRETCH

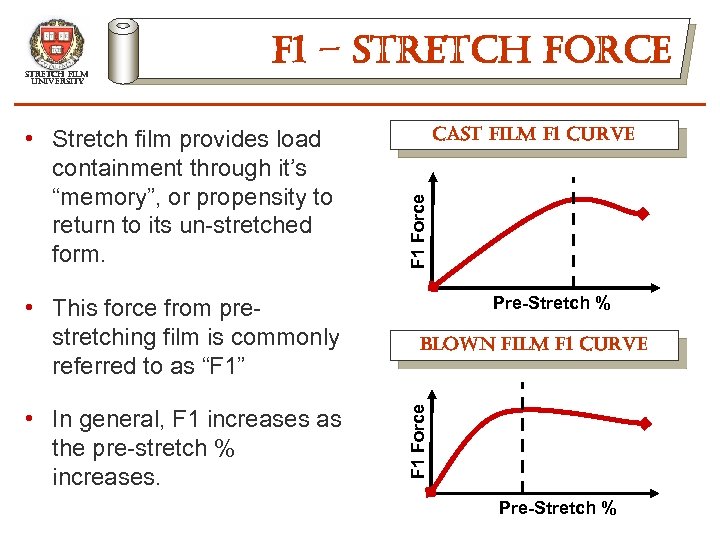

• This force from prestretching film is commonly referred to as “F 1” • In general, F 1 increases as the pre-stretch % increases. cast film f 1 curve F 1 Force • Stretch film provides load containment through it’s “memory”, or propensity to return to its un-stretched form. Pre-Stretch % blown film f 1 curve F 1 Force stretch film university f 1 – stretch force Pre-Stretch %

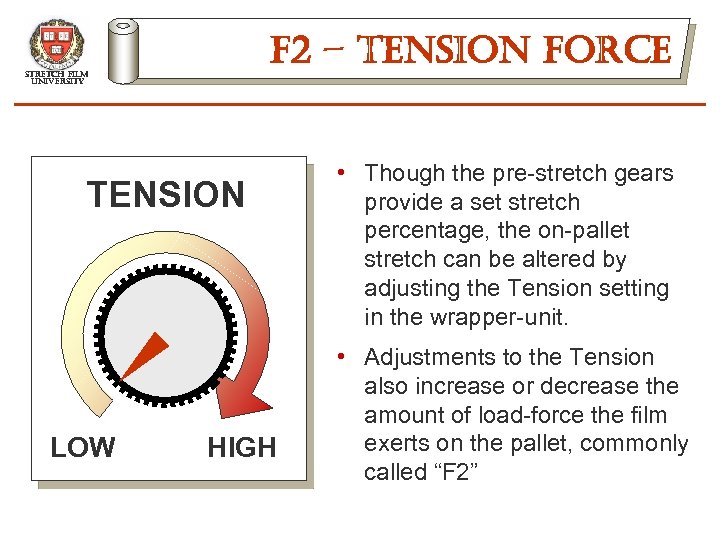

f 2 – tension force stretch film university TENSION LOW HIGH • Though the pre-stretch gears provide a set stretch percentage, the on-pallet stretch can be altered by adjusting the Tension setting in the wrapper-unit. • Adjustments to the Tension also increase or decrease the amount of load-force the film exerts on the pallet, commonly called “F 2”

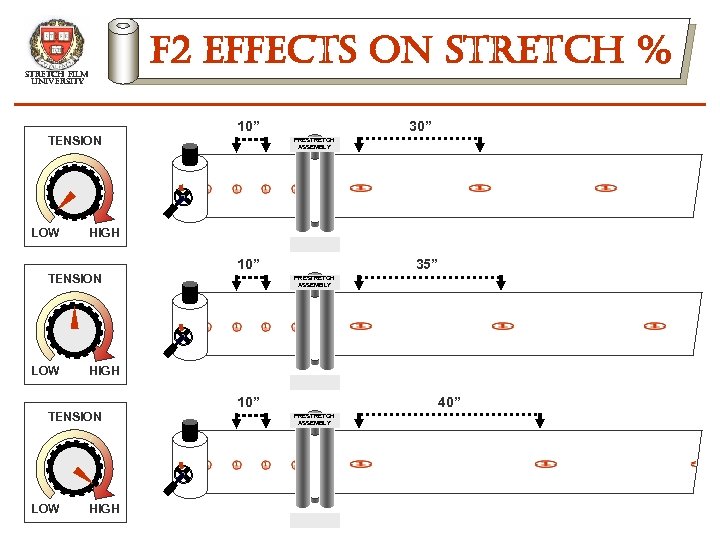

f 2 effects on stretch % stretch film university 10” TENSION LOW 30” PRESTRETCH ASSEMBLY HIGH 10” TENSION LOW 35” PRESTRETCH ASSEMBLY HIGH 10” TENSION LOW HIGH 40” PRESTRETCH ASSEMBLY

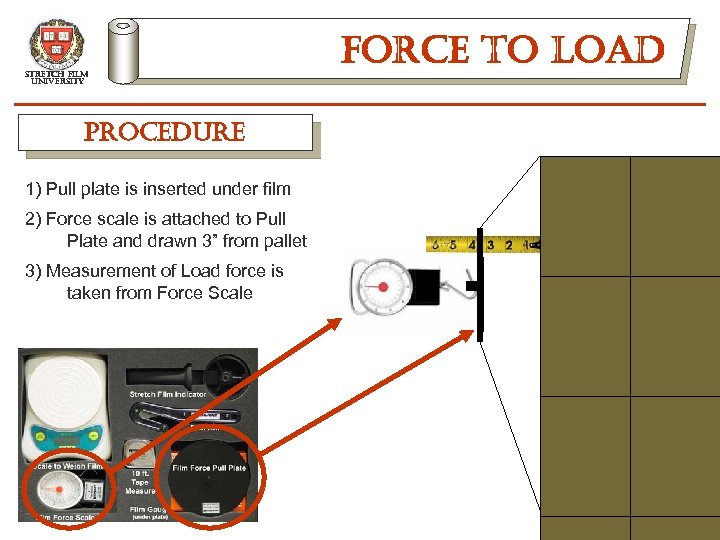

stretch film university procedure 1) Pull plate is inserted under film 2) Force scale is attached to Pull Plate and drawn 3” from pallet 3) Measurement of Load force is taken from Force Scale force to load

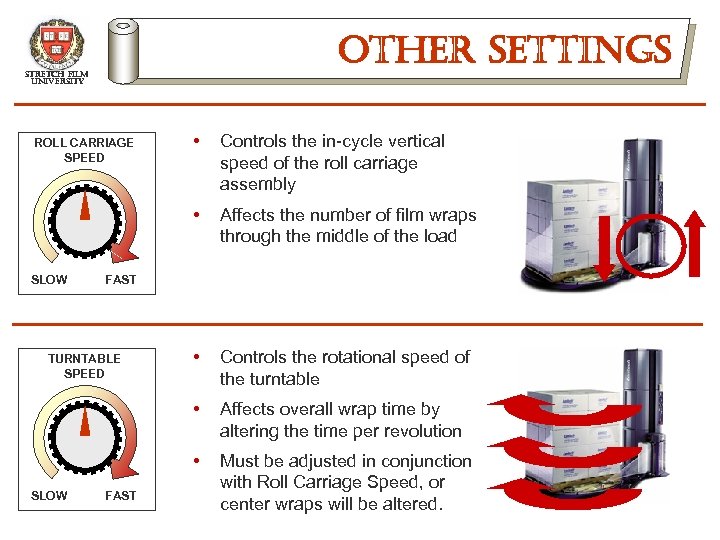

other settings stretch film university Affects the number of film wraps through the middle of the load • Controls the rotational speed of the turntable Affects overall wrap time by altering the time per revolution • Must be adjusted in conjunction with Roll Carriage Speed, or center wraps will be altered. FAST TURNTABLE SPEED SLOW Controls the in-cycle vertical speed of the roll carriage assembly • SLOW • • ROLL CARRIAGE SPEED FAST

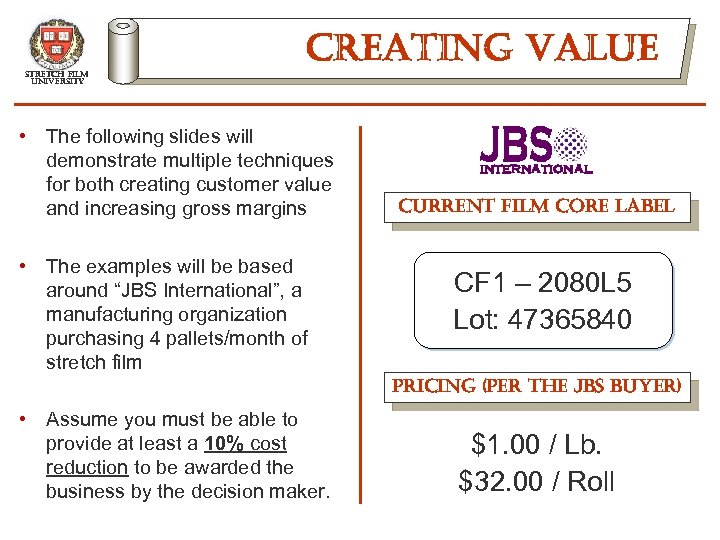

stretch film university creating value • The following slides will demonstrate multiple techniques for both creating customer value and increasing gross margins • The examples will be based around “JBS International”, a manufacturing organization purchasing 4 pallets/month of stretch film INTERNATIONAL current film core label CF 1 – 2080 L 5 Lot: 47365840 pricing (per the Jbs buyer) • Assume you must be able to provide at least a 10% cost reduction to be awarded the business by the decision maker. $1. 00 / Lb. $32. 00 / Roll

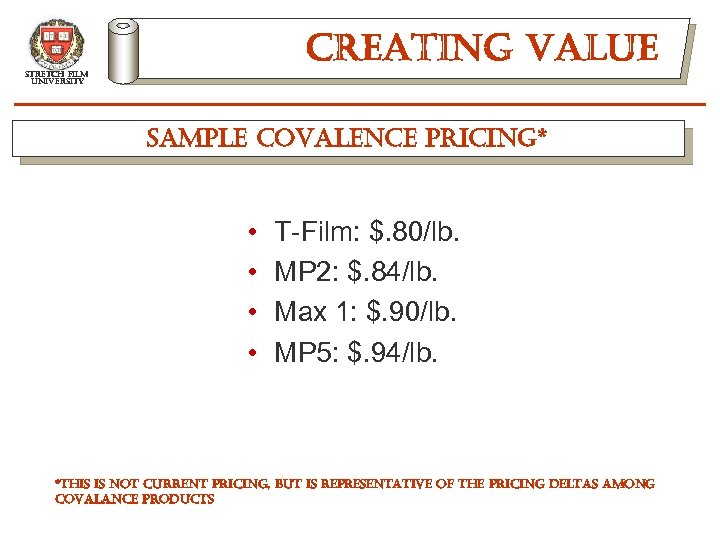

creating value stretch film university sample covalence pricing* • • T-Film: $. 80/lb. MP 2: $. 84/lb. Max 1: $. 90/lb. MP 5: $. 94/lb. *this is not current pricing, but is representative of the pricing deltas among covalance products

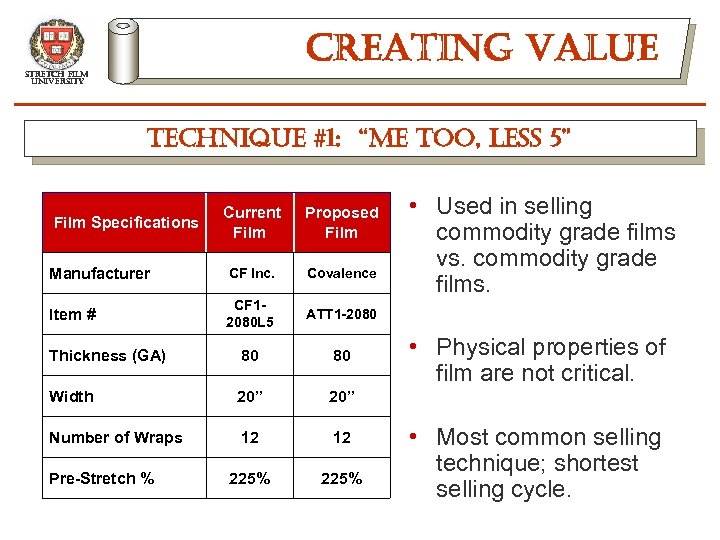

creating value stretch film university technique #1: “me too, less 5” Current Film Specifications Film Proposed Film Manufacturer CF Inc. Covalence Item # CF 12080 L 5 ATT 1 -2080 Thickness (GA) 80 80 Width 20” Number of Wraps 12 12 225% • Used in selling commodity grade films vs. commodity grade films. Pre-Stretch % • Physical properties of film are not critical. • Most common selling technique; shortest selling cycle.

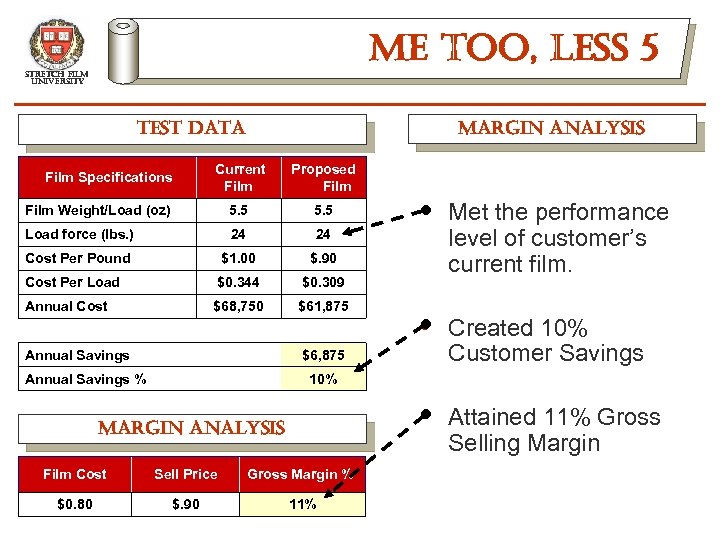

me too, less 5 stretch film university margin analysis test data Current Film Proposed Film Weight/Load (oz) 5. 5 Load force (lbs. ) 24 24 Cost Per Pound $1. 00 $. 90 Cost Per Load $0. 344 $0. 309 Annual Cost $68, 750 $61, 875 Film Specifications Annual Savings $6, 875 Annual Savings % • Met the performance level of customer’s current film. • Created 10% Customer Savings 10% • Attained 11% Gross Selling Margin margin analysis Film Cost Sell Price Gross Margin % $0. 80 $. 90 11%

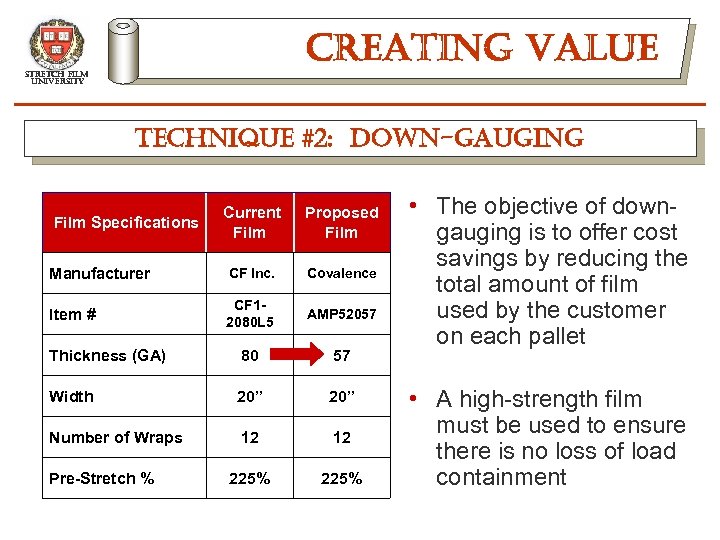

creating value stretch film university technique #2: down-gauging Current Film Specifications Film Proposed Film Manufacturer CF Inc. Covalence Item # CF 12080 L 5 AMP 52057 Thickness (GA) 80 57 Width 20” Number of Wraps 12 12 225% Pre-Stretch % • The objective of downgauging is to offer cost savings by reducing the total amount of film used by the customer on each pallet • A high-strength film must be used to ensure there is no loss of load containment

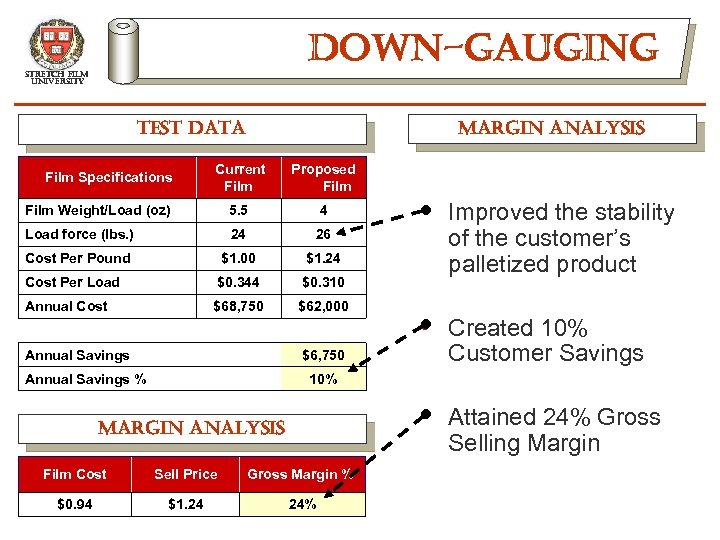

down-gauging stretch film university margin analysis test data Current Film Proposed Film Weight/Load (oz) 5. 5 4 Load force (lbs. ) 24 26 Cost Per Pound $1. 00 $1. 24 Cost Per Load $0. 344 $0. 310 Annual Cost $68, 750 $62, 000 Film Specifications Annual Savings $6, 750 Annual Savings % • Improved the stability of the customer’s palletized product • Created 10% Customer Savings 10% • Attained 24% Gross Selling Margin margin analysis Film Cost Sell Price Gross Margin % $0. 94 $1. 24 24%

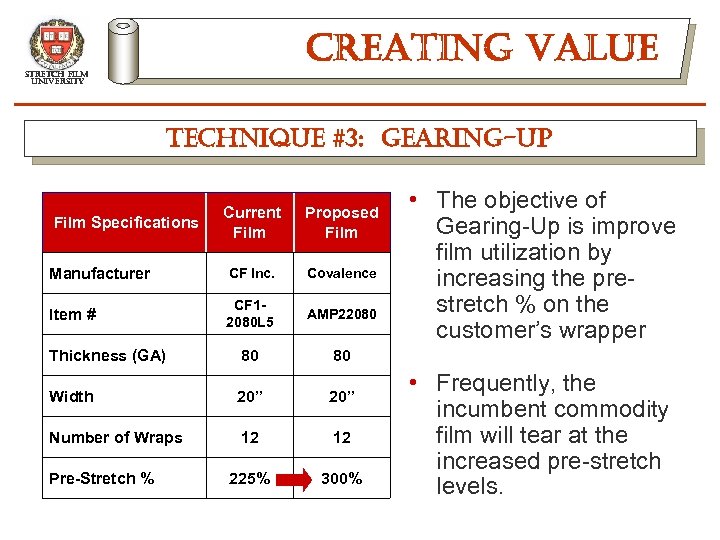

creating value stretch film university technique #3: gearing-up Current Film Specifications Film Proposed Film Manufacturer CF Inc. Covalence Item # CF 12080 L 5 AMP 22080 Thickness (GA) 80 80 Width 20” Number of Wraps 12 12 225% 300% • The objective of Gearing-Up is improve film utilization by increasing the prestretch % on the customer’s wrapper Pre-Stretch % • Frequently, the incumbent commodity film will tear at the increased pre-stretch levels.

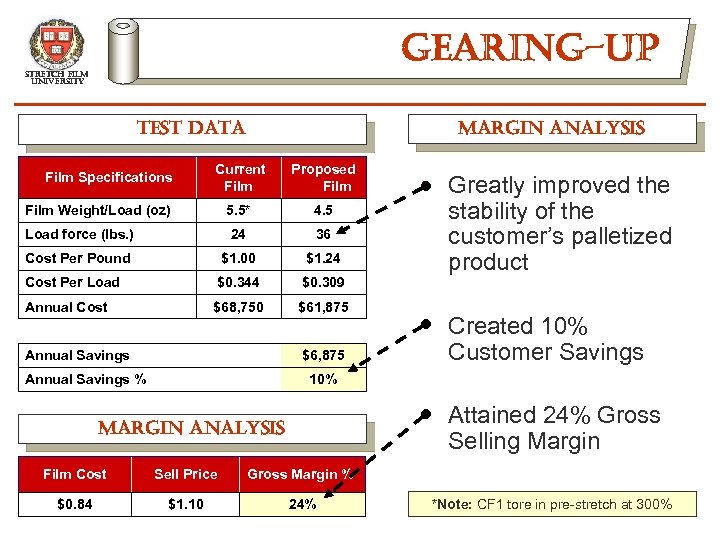

gearing-up stretch film university margin analysis test data Current Film Proposed Film 5. 5* 4. 5 Load force (lbs. ) 24 36 Cost Per Pound $1. 00 $1. 24 Cost Per Load $0. 344 $0. 309 Annual Cost $68, 750 $61, 875 Film Specifications Film Weight/Load (oz) Annual Savings $6, 875 Annual Savings % • Greatly improved the stability of the customer’s palletized product • Created 10% Customer Savings 10% • Attained 24% Gross Selling Margin margin analysis Film Cost Sell Price Gross Margin % $0. 84 $1. 10 24% *Note: CF 1 tore in pre-stretch at 300%

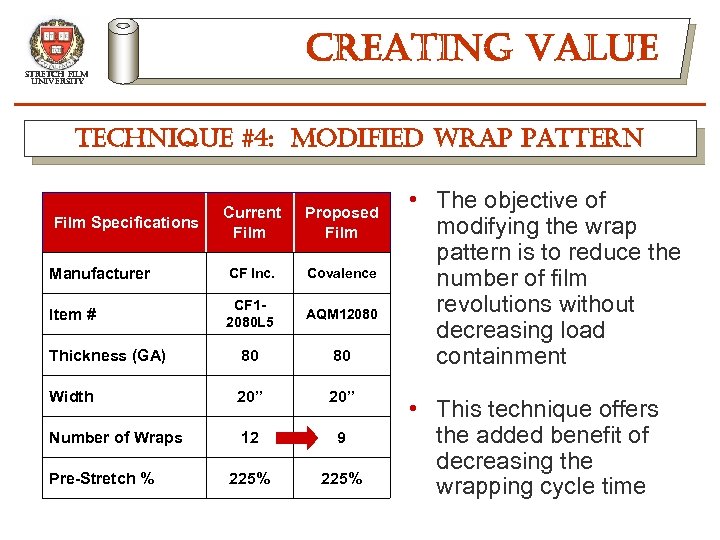

creating value stretch film university technique #4: modified wrap pattern Current Film Specifications Film Proposed Film Manufacturer CF Inc. Covalence Item # CF 12080 L 5 AQM 12080 Thickness (GA) 80 80 Width 20” Number of Wraps 12 9 225% Pre-Stretch % • The objective of modifying the wrap pattern is to reduce the number of film revolutions without decreasing load containment • This technique offers the added benefit of decreasing the wrapping cycle time

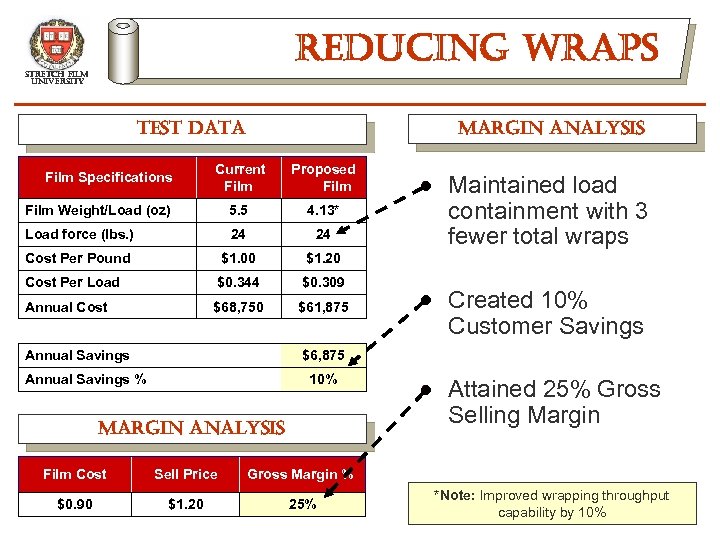

reducing wraps stretch film university margin analysis test data Current Film Proposed Film Weight/Load (oz) 5. 5 4. 13* Load force (lbs. ) 24 24 Cost Per Pound $1. 00 $1. 20 Cost Per Load $0. 344 $0. 309 Annual Cost $68, 750 $61, 875 Film Specifications Annual Savings • Maintained load containment with 3 fewer total wraps • Created 10% Customer Savings $6, 875 Annual Savings % 10% margin analysis Film Cost Sell Price Gross Margin % $0. 90 $1. 20 25% • Attained 25% Gross Selling Margin *Note: Improved wrapping throughput capability by 10%

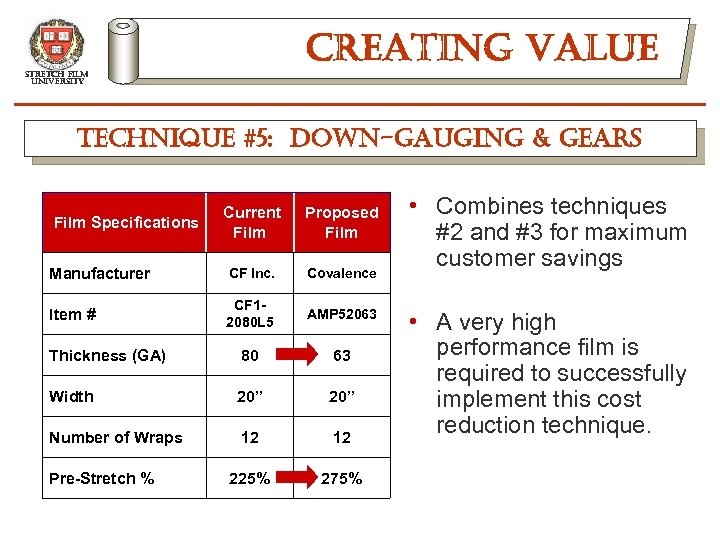

creating value stretch film university technique #5: down-gauging & gears Current Film Specifications Film Proposed Film Manufacturer CF Inc. Covalence Item # CF 12080 L 5 AMP 52063 Thickness (GA) 80 63 Width 20” Number of Wraps 12 12 225% 275% Pre-Stretch % • Combines techniques #2 and #3 for maximum customer savings • A very high performance film is required to successfully implement this cost reduction technique.

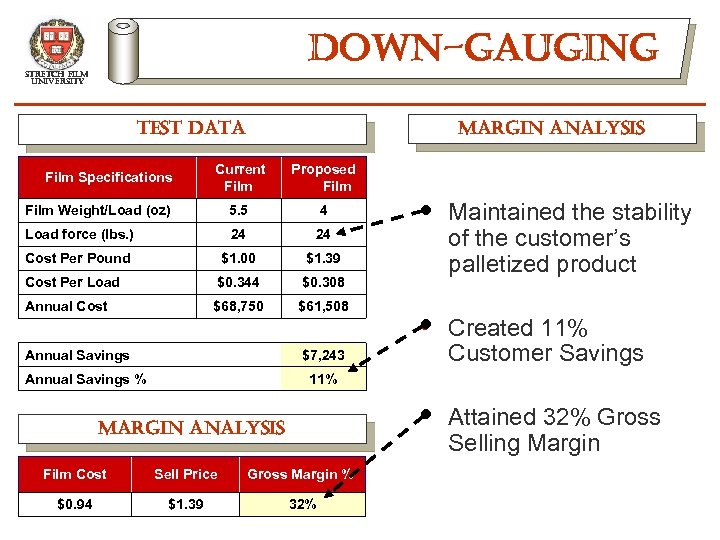

down-gauging stretch film university margin analysis test data Current Film Proposed Film Weight/Load (oz) 5. 5 4 Load force (lbs. ) 24 24 Cost Per Pound $1. 00 $1. 39 Cost Per Load $0. 344 $0. 308 Annual Cost $68, 750 $61, 508 Film Specifications Annual Savings $7, 243 Annual Savings % • Maintained the stability of the customer’s palletized product • Created 11% Customer Savings 11% • Attained 32% Gross Selling Margin margin analysis Film Cost Sell Price Gross Margin % $0. 94 $1. 39 32%

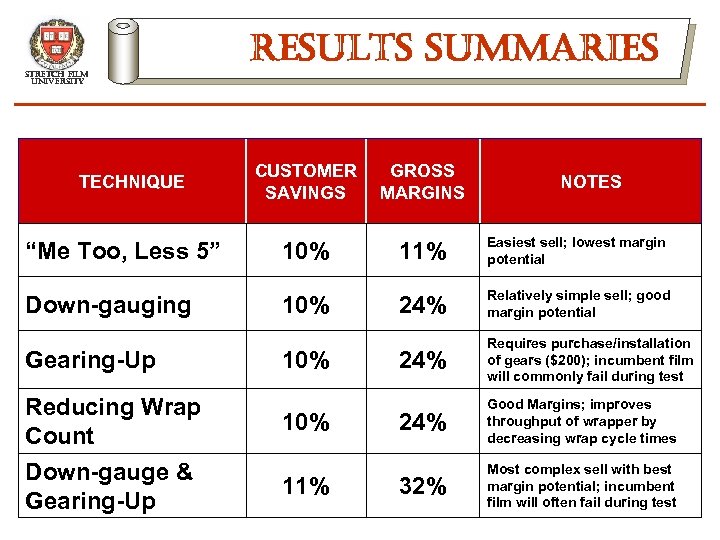

stretch film university results summaries CUSTOMER SAVINGS GROSS MARGINS “Me Too, Less 5” 10% 11% Easiest sell; lowest margin potential Down-gauging 10% 24% Relatively simple sell; good margin potential 24% Requires purchase/installation of gears ($200); incumbent film will commonly fail during test 24% Good Margins; improves throughput of wrapper by decreasing wrap cycle times 32% Most complex sell with best margin potential; incumbent film will often fail during test TECHNIQUE Gearing-Up Reducing Wrap Count Down-gauge & Gearing-Up 10% 11% NOTES

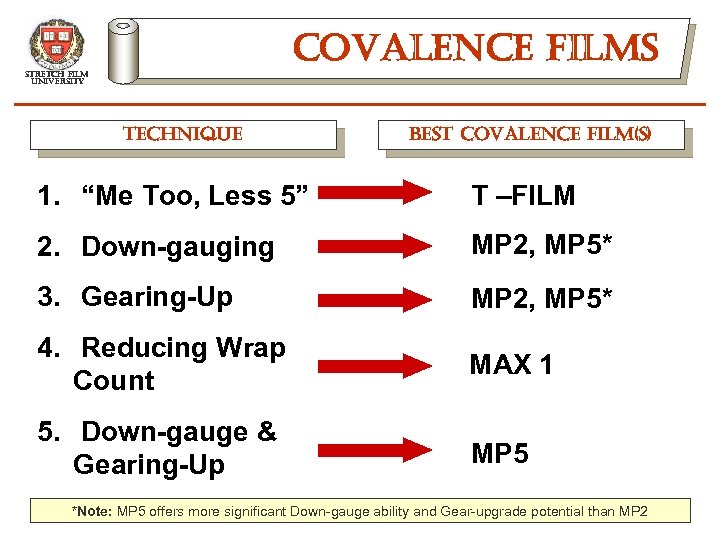

covalence films stretch film university technique best covalence film(s) 1. “Me Too, Less 5” T –FILM 2. Down-gauging MP 2, MP 5* 3. Gearing-Up MP 2, MP 5* 4. Reducing Wrap Count MAX 1 5. Down-gauge & Gearing-Up MP 5 *Note: MP 5 offers more significant Down-gauge ability and Gear-upgrade potential than MP 2

stretch film university glossary Blocking Film layers bonded together. Blown Film that is fabricated by continuously pumping the polymer through a circular orifice (die). Once through the die, this polymer is then drawn upward and filled with air, creating a tube. Caliper The thickness of a film or bag, normally expressed in mils or as “gauge” (. 9 mil = 90 gauge =. 0009 inches). Cast Film Indicates fabrication of film by continuously pumping the polymer through a straight slot orifice (die), then chilling this hot sheet of plastic immediately after the die by contact with a cooled roll. Film width is determined by the length of the slot. Clarity Ability to view through film. Cling The characteristics of stretch film which make it stick to itself. Coefficient of Friction The ease with which two objects or services will slide against each other. Low numbers slide easily. Total range due to the test definition is 0 to 1.

stretch film university glossary Co-extrusion Fabrication of a multi-layer film by pumping the various materials through separate extruders and then merging the extrudates into a common die assembly. Dart Drop A method of measuring a film’s impact strength or dynamic toughness. A hemispherical shaped, weighted “dart” is dropped onto a film sample. Die A device used in extrusion processes to shape the extrudate. We use circular dies for blown products and slot dies for cast products. Elastic Recovery The ability of a material to return to its original shapes or sizes after having been deformed or subjected to strain. Extrusion The process of feeding, melting, and pumping a material such that a desired shape or configuration can be created. It is a continuous process and utilizes a device similar to a meat grinder. Gauge Used as a synonym for film thickness or film caliper. Sometimes expressed as 80 gauge or 100 gauge.

stretch film university glossary Gauge Band A conformation irregularity found in rolls of material. A thick area in a film will produce a raised or elevated ring in a finished roll of product. Conversely, a thin area will result in a soft ring in a finished roll. Gloss The shine or “sparkle” of a surface. In LDPE film, it is described as the amount of light reflected from the surface. Hand Film Stretch film designed for hand application. LDPE Low Density Polyethylene LLDPE Linear Low Density Polyethylene Machine Direction Perpendicular to film web width Machine Films Stretch film designed for stretch film equipment. Metallocene Newly developed polyethylene resins produced using “Metallocene” catalyst. It allows the resin manufacturer to custom tailor properties. Compared to other linear low density resins, Metallocene resin stretch film can achieve greater puncture resistance and greater clarity.

stretch film university glossary Micron A unit of length equal to one millionth of a meter (micron = mil x 25. 4) Reactor The equipment used to transform ethylene gas to polyethylene. Roping A method of bunching stretch film. Stretchability A combination of factors related to the ability of a material to be stretched or elongated (i. e. how easily does a film stretch, how much will it stretch, does it return to its original length? ) Tackifiers Chemical substances added to increase the “tack” of the parent or base material. Tear Resistance The resistance of the film to be torn. This is quantified by Elmendorf Tear testing, and is measured as the force required to propagate an initiated tear in the MD or TD direction. Transverse Direction across the stretch film web. Zippering Lack of resistance to tear propagation or an initiated TD cut or tear. Once the film has been torn or cut, the resulting slip rapidly opens and completes a full web break.

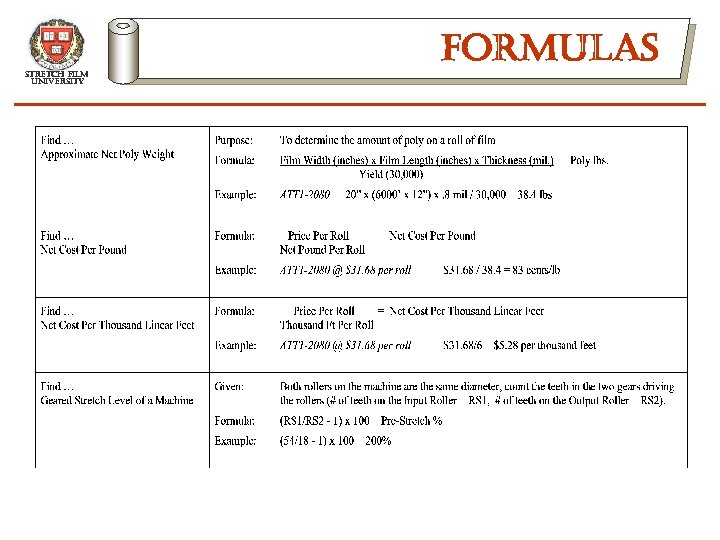

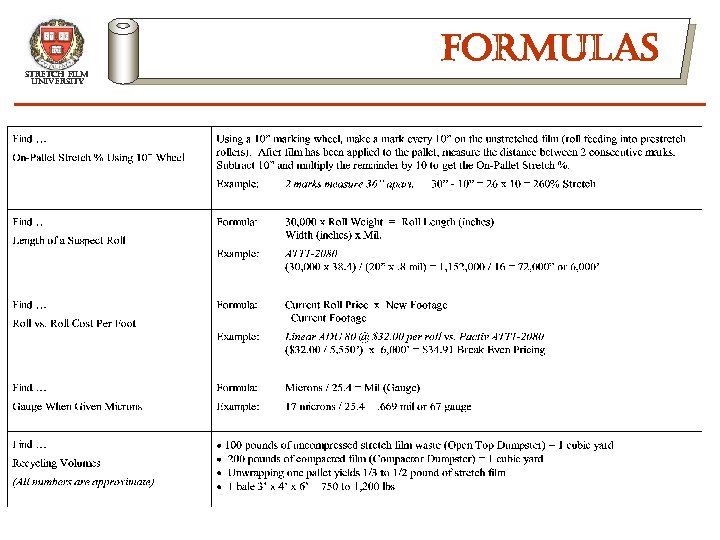

stretch film university formulas

stretch film university formulas

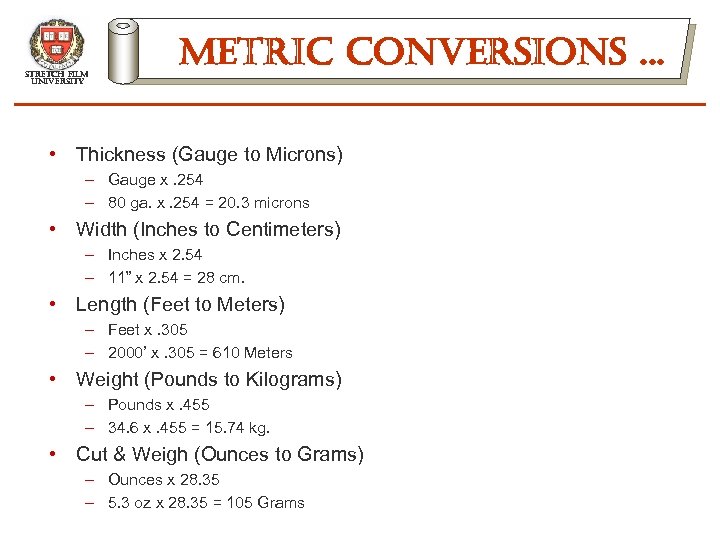

stretch film university metric conversions. . . • Thickness (Gauge to Microns) – Gauge x. 254 – 80 ga. x. 254 = 20. 3 microns • Width (Inches to Centimeters) – Inches x 2. 54 – 11” x 2. 54 = 28 cm. • Length (Feet to Meters) – Feet x. 305 – 2000’ x. 305 = 610 Meters • Weight (Pounds to Kilograms) – Pounds x. 455 – 34. 6 x. 455 = 15. 74 kg. • Cut & Weigh (Ounces to Grams) – Ounces x 28. 35 – 5. 3 oz x 28. 35 = 105 Grams

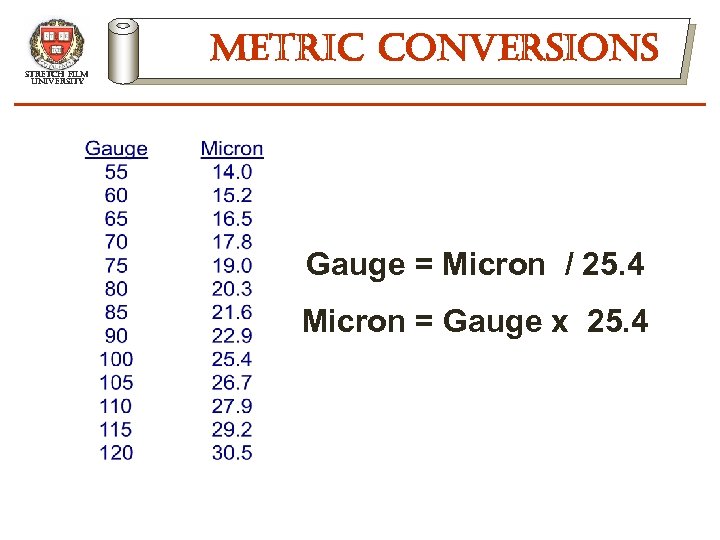

stretch film university metric conversions Gauge = Micron / 25. 4 Micron = Gauge x 25. 4

82ae4f099de444a7625df15de47f3dc5.ppt