a140ddc235e16c81f30126853708b2bc.ppt

- Количество слайдов: 72

Norm Workshop (Pdo - Oman) 21 - 24 February 2005 TIM ELEY - SCOTOIL GROUP plc, ABERDEEN MARK RITCHIE - OES, CAIRO, EGYPT

Norm Workshop (Pdo - Oman) 21 - 24 February 2005 TIM ELEY - SCOTOIL GROUP plc, ABERDEEN MARK RITCHIE - OES, CAIRO, EGYPT

AGENDA • Introduction to Scotoil Group & Scotoil Services • Equipment subject to NORM - ‘Rogue’s Gallery’ • Equipment Decontamination Procedure Step by Step, Aberdeen • Disposal Route - Compliance with Regulations • Scotoil - Oilfield Environmental Services Equipment Decontamination Procedure Step by Step, Cairo QUESTIONS ?

AGENDA • Introduction to Scotoil Group & Scotoil Services • Equipment subject to NORM - ‘Rogue’s Gallery’ • Equipment Decontamination Procedure Step by Step, Aberdeen • Disposal Route - Compliance with Regulations • Scotoil - Oilfield Environmental Services Equipment Decontamination Procedure Step by Step, Cairo QUESTIONS ?

INTERNATIONAL EUROPE Scotoil Group plc headquarters in Aberdeen, Scotland MIDDLE EAST Alliance between Scotoil Services (Middle East) Ltd and Gulf Environmental Company LLC (GENCO), based in Abu Dhabi, UAE NORTH AFRICA Oilfield Environmental Services (OES) - JV company based in Cairo, Egypt

INTERNATIONAL EUROPE Scotoil Group plc headquarters in Aberdeen, Scotland MIDDLE EAST Alliance between Scotoil Services (Middle East) Ltd and Gulf Environmental Company LLC (GENCO), based in Abu Dhabi, UAE NORTH AFRICA Oilfield Environmental Services (OES) - JV company based in Cairo, Egypt

OUR CREDENTIALS • More than 20 years’ experience • SCOAA Environment award recognising “world class standards” • Operations meet exacting standards of regulatory and assessment bodies • ISO 9001: 2000, ISO 14001 • FPAL • Scotland’s Health at Work Gold Award

OUR CREDENTIALS • More than 20 years’ experience • SCOAA Environment award recognising “world class standards” • Operations meet exacting standards of regulatory and assessment bodies • ISO 9001: 2000, ISO 14001 • FPAL • Scotland’s Health at Work Gold Award

OUR CLIENTS

OUR CLIENTS

OUR SERVICES • Equipment decontamination • Removal and disposal of NORM • Instrumentation • Onshore and offshore RPS • Emerging technologies in water purification and land remediation

OUR SERVICES • Equipment decontamination • Removal and disposal of NORM • Instrumentation • Onshore and offshore RPS • Emerging technologies in water purification and land remediation

EQUIPMENT DECONTAMINATION • High Pressure Generally for component parts and tubulars • Ultra High Pressure - Trials More efficient tubular cleaning Increased throughput More effective cleaning of lead contaminated tubulars

EQUIPMENT DECONTAMINATION • High Pressure Generally for component parts and tubulars • Ultra High Pressure - Trials More efficient tubular cleaning Increased throughput More effective cleaning of lead contaminated tubulars

REMOVAL AND DISPOSAL OF NORM • UK’s first authorised NORM removal and disposal facility • Disposal facility regulated by SEPA • Environment controls through independent impact assessments and monitoring • Accountability - operational controls and licensed disposal route

REMOVAL AND DISPOSAL OF NORM • UK’s first authorised NORM removal and disposal facility • Disposal facility regulated by SEPA • Environment controls through independent impact assessments and monitoring • Accountability - operational controls and licensed disposal route

INSTRUMENTATION SERVICES • Scotoil Services offers a complete radiological instrumentation package: § Equipment training § Sales § Rental § Repair § Calibration § Certification MINI 900 SERIES MONITOR ELECTRA CONTAMINATION METER

INSTRUMENTATION SERVICES • Scotoil Services offers a complete radiological instrumentation package: § Equipment training § Sales § Rental § Repair § Calibration § Certification MINI 900 SERIES MONITOR ELECTRA CONTAMINATION METER

RPS SERVICES • • • Radiological surveys RPS control during workovers etc. Induction training Personnel monitoring Documentation Supply of appropriate PPE

RPS SERVICES • • • Radiological surveys RPS control during workovers etc. Induction training Personnel monitoring Documentation Supply of appropriate PPE

WHAT IS NORM SCALE? • Formation water contains naturally-occurring mineral salts • These salts can come out of solution in contact with injected water • Radium may be present in minute concentrations • Naturally radioactive, radium may mean the scale is classified as radioactive

WHAT IS NORM SCALE? • Formation water contains naturally-occurring mineral salts • These salts can come out of solution in contact with injected water • Radium may be present in minute concentrations • Naturally radioactive, radium may mean the scale is classified as radioactive

UNITS OF MEASUREMENT • Specific Activity § Activity per gram i. e. Bq/gram • Surface Contamination § Activity per cm squared i. e. Bq/cm 2 § A contamination monitor can measure surface activity

UNITS OF MEASUREMENT • Specific Activity § Activity per gram i. e. Bq/gram • Surface Contamination § Activity per cm squared i. e. Bq/cm 2 § A contamination monitor can measure surface activity

DOSE RATES • Measured in sieverts { large unit} usually prefix sub multiplier e. g. 1 µSv {micro sievert} • Dose rates greater than 2. 5 µSv/hr mark supervised areas • Dose rates greater than 7. 5 µSv/hr mark controlled areas

DOSE RATES • Measured in sieverts { large unit} usually prefix sub multiplier e. g. 1 µSv {micro sievert} • Dose rates greater than 2. 5 µSv/hr mark supervised areas • Dose rates greater than 7. 5 µSv/hr mark controlled areas

WHAT IT MEANS FOR THE INDUSTRY • Naturally occurring radioactive material is a major issue for § field operation § decommissioning • NORM scale build up can render equipment inoperable • Classed as radioactive, its removal and disposal must be carefully controlled

WHAT IT MEANS FOR THE INDUSTRY • Naturally occurring radioactive material is a major issue for § field operation § decommissioning • NORM scale build up can render equipment inoperable • Classed as radioactive, its removal and disposal must be carefully controlled

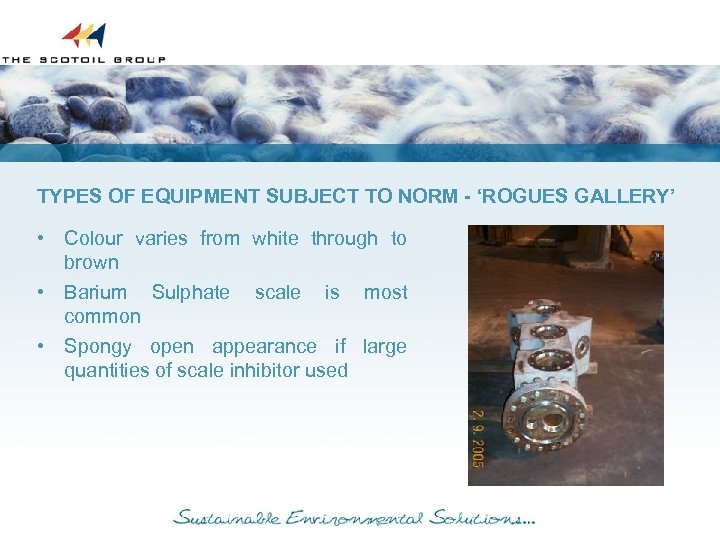

TYPES OF EQUIPMENT SUBJECT TO NORM - ‘ROGUES GALLERY’ • Colour varies from white through to brown • Barium Sulphate scale is most common • Spongy open appearance if large quantities of scale inhibitor used

TYPES OF EQUIPMENT SUBJECT TO NORM - ‘ROGUES GALLERY’ • Colour varies from white through to brown • Barium Sulphate scale is most common • Spongy open appearance if large quantities of scale inhibitor used

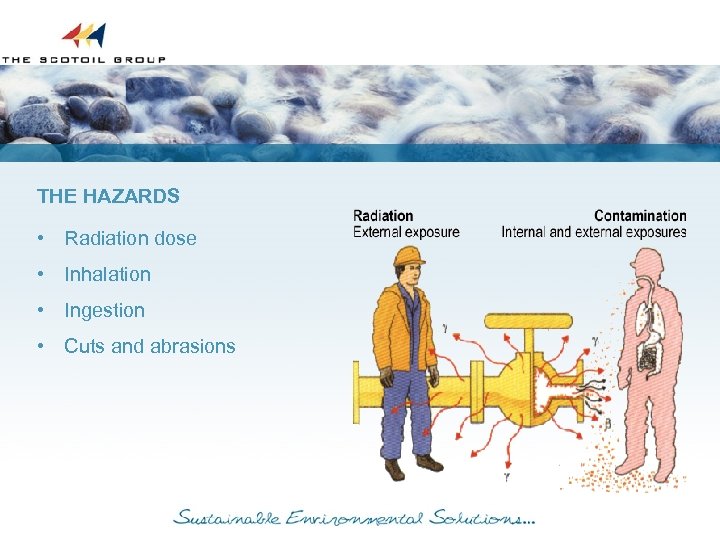

THE HAZARDS • Radiation dose • Inhalation • Ingestion • Cuts and abrasions

THE HAZARDS • Radiation dose • Inhalation • Ingestion • Cuts and abrasions

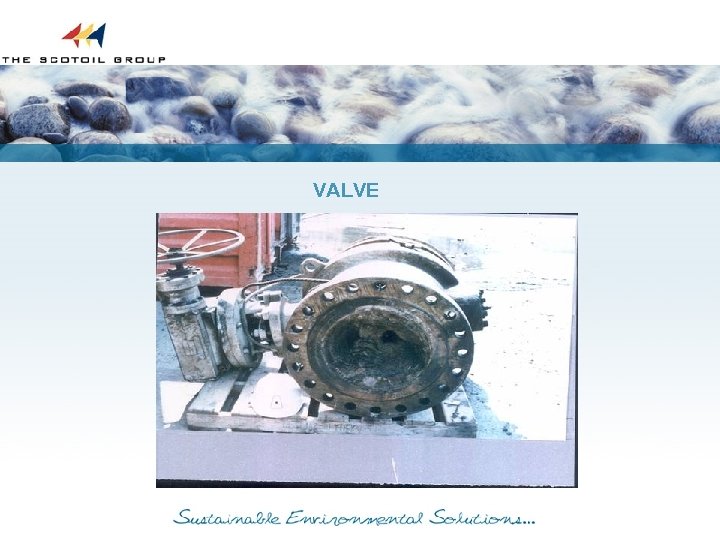

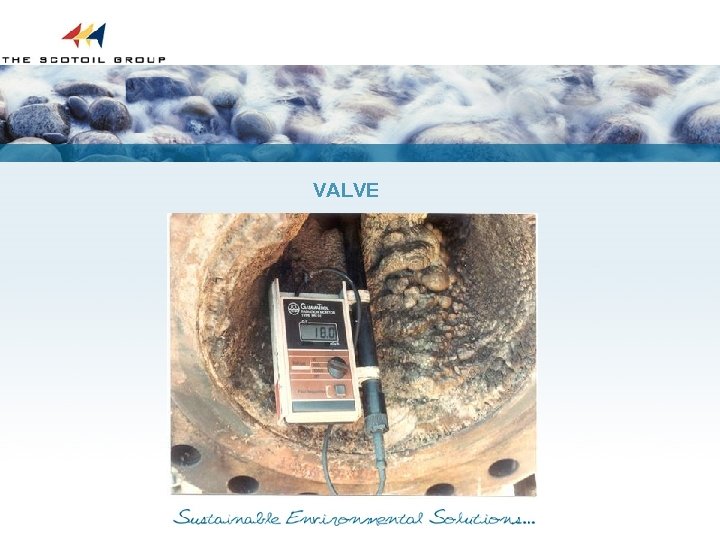

VALVE

VALVE

VALVE

VALVE

MISCELLANEOUS VALVES

MISCELLANEOUS VALVES

VALVES & ACTUATORS

VALVES & ACTUATORS

PIPEWORK

PIPEWORK

HEAT EXCHANGER

HEAT EXCHANGER

HEAT EXCHANGER CLEANED & DE-SCALED

HEAT EXCHANGER CLEANED & DE-SCALED

OIL COOLER PLATES

OIL COOLER PLATES

LOOSE SCALE

LOOSE SCALE

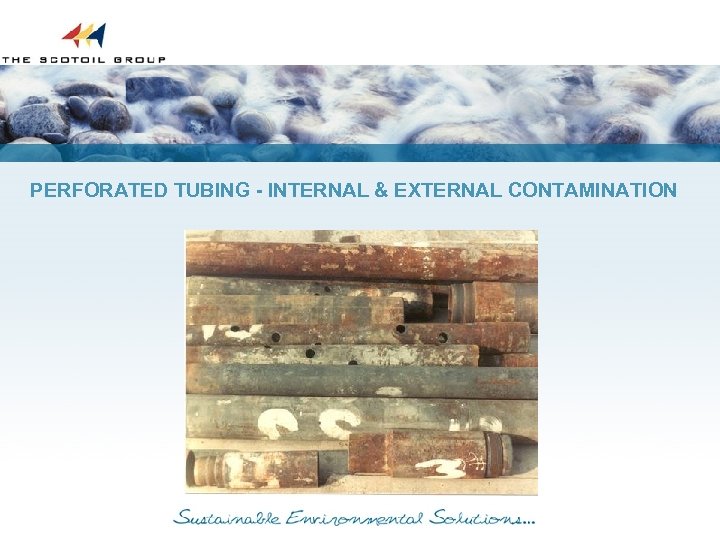

PERFORATED TUBING - INTERNAL & EXTERNAL CONTAMINATION

PERFORATED TUBING - INTERNAL & EXTERNAL CONTAMINATION

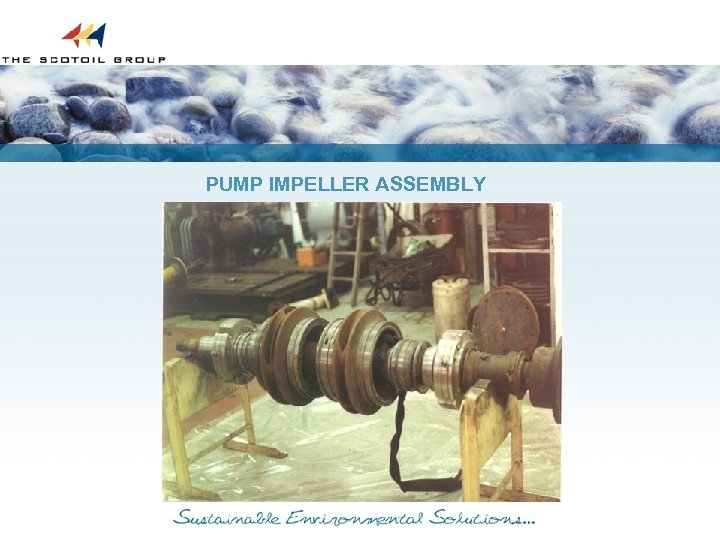

PUMP IMPELLER ASSEMBLY

PUMP IMPELLER ASSEMBLY

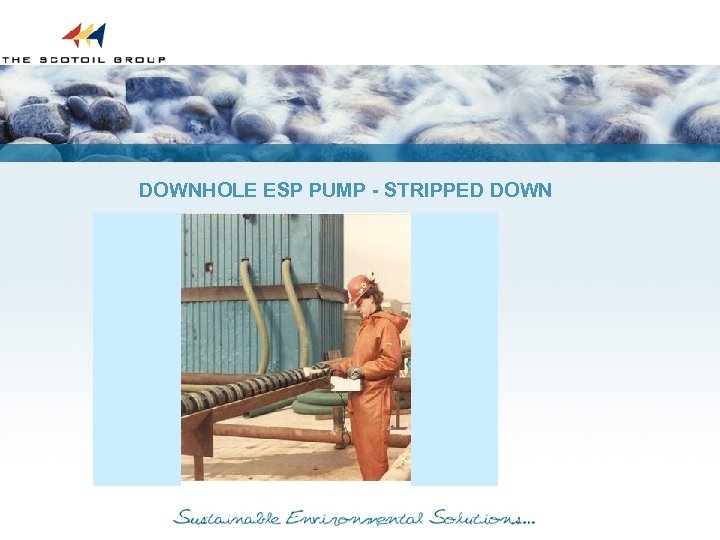

DOWNHOLE ESP PUMP - STRIPPED DOWN

DOWNHOLE ESP PUMP - STRIPPED DOWN

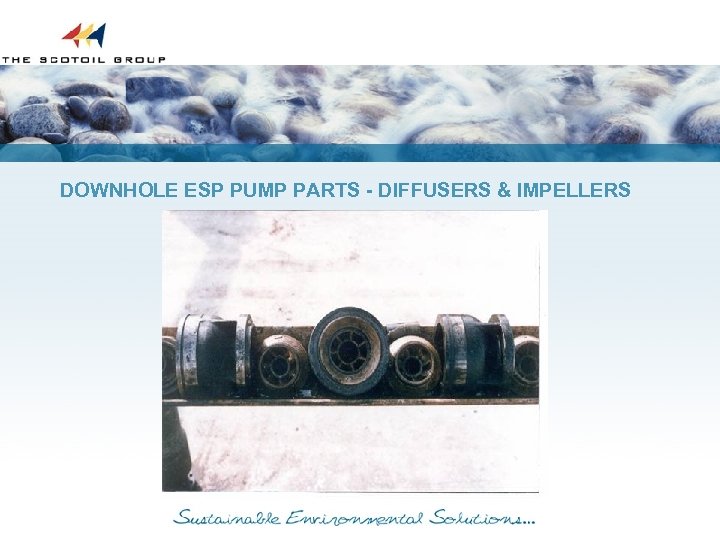

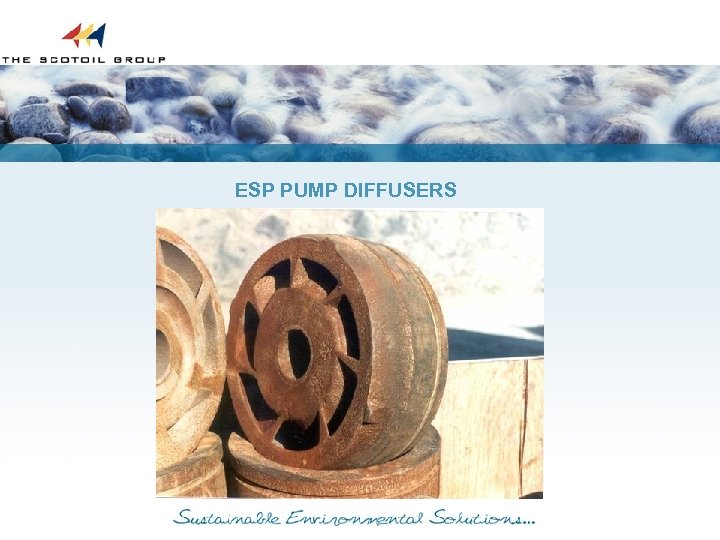

DOWNHOLE ESP PUMP PARTS - DIFFUSERS & IMPELLERS

DOWNHOLE ESP PUMP PARTS - DIFFUSERS & IMPELLERS

ESP PUMP DIFFUSERS

ESP PUMP DIFFUSERS

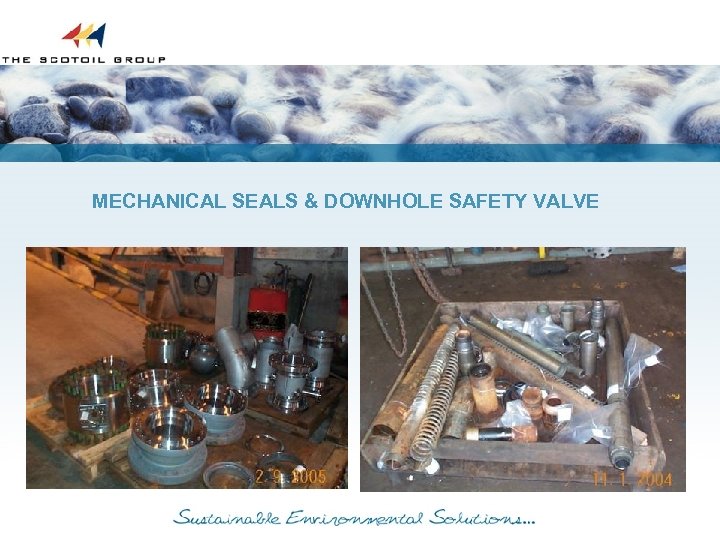

MECHANICAL SEALS & DOWNHOLE SAFETY VALVE

MECHANICAL SEALS & DOWNHOLE SAFETY VALVE

XMAS TREES

XMAS TREES

CASING

CASING

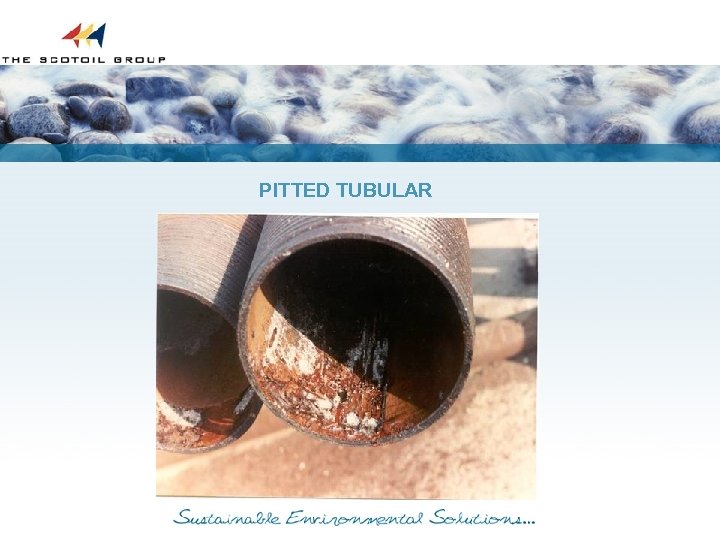

PITTED TUBULAR

PITTED TUBULAR

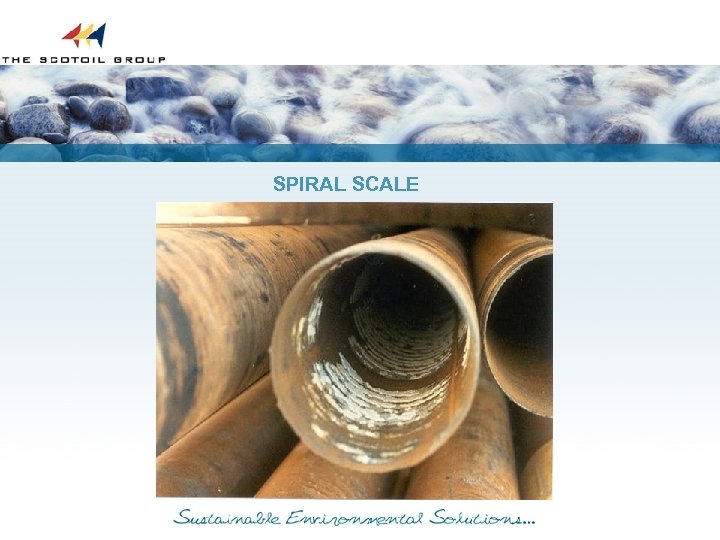

SPIRAL SCALE

SPIRAL SCALE

EQUIPMENT DECONTAMINATION PROCEDURE Step by Step

EQUIPMENT DECONTAMINATION PROCEDURE Step by Step

EQUIPMENT DECONTAMINATION • Written notification from the Operator of NORM consignment • Identified offshore by platform/rig RPS • Scotoil authorised to accept contaminated equipment • Contamination levels monitored on arrival

EQUIPMENT DECONTAMINATION • Written notification from the Operator of NORM consignment • Identified offshore by platform/rig RPS • Scotoil authorised to accept contaminated equipment • Contamination levels monitored on arrival

• Unload equipment into Controlled Area • Enter job details on computerised Job Register

• Unload equipment into Controlled Area • Enter job details on computerised Job Register

• Scale sample passed to Laboratory • Radiological analysis, total activity, type of scale

• Scale sample passed to Laboratory • Radiological analysis, total activity, type of scale

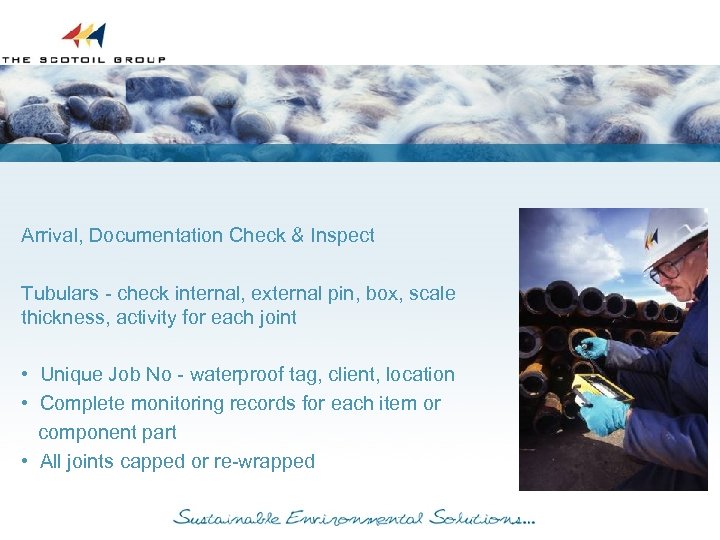

Arrival, Documentation Check & Inspect Tubulars - check internal, external pin, box, scale thickness, activity for each joint • Unique Job No - waterproof tag, client, location • Complete monitoring records for each item or component part • All joints capped or re-wrapped

Arrival, Documentation Check & Inspect Tubulars - check internal, external pin, box, scale thickness, activity for each joint • Unique Job No - waterproof tag, client, location • Complete monitoring records for each item or component part • All joints capped or re-wrapped

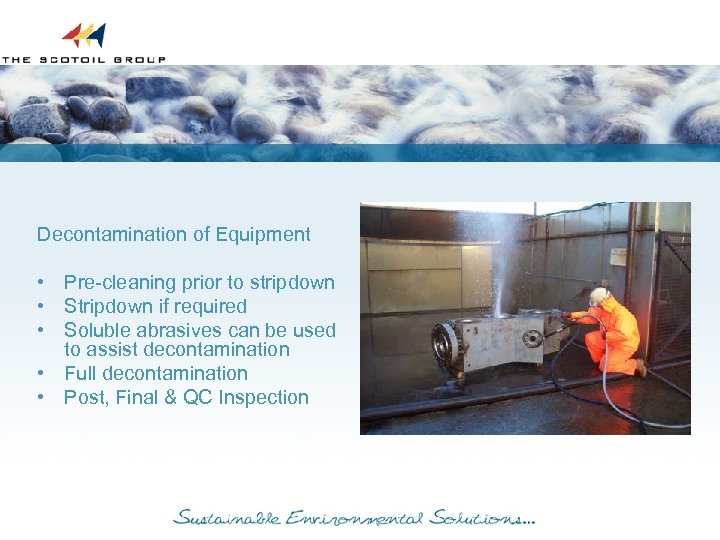

Decontamination of Equipment • Pre-cleaning prior to stripdown • Stripdown if required • Soluble abrasives can be used to assist decontamination • Full decontamination • Post, Final & QC Inspection

Decontamination of Equipment • Pre-cleaning prior to stripdown • Stripdown if required • Soluble abrasives can be used to assist decontamination • Full decontamination • Post, Final & QC Inspection

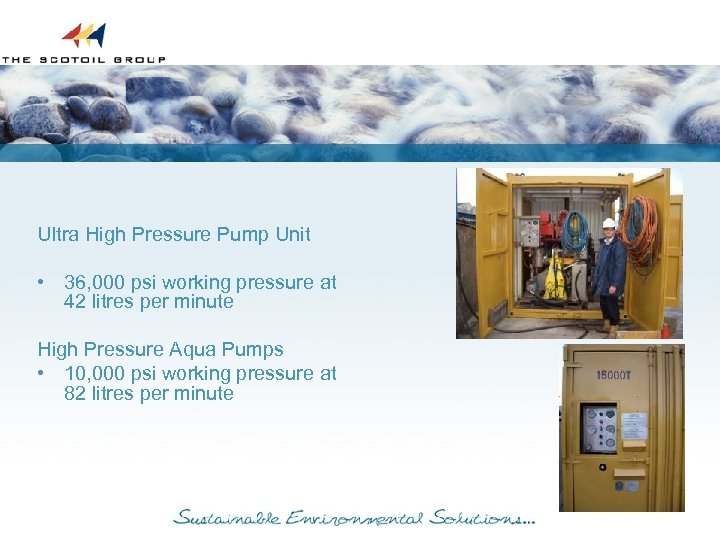

Ultra High Pressure Pump Unit • 36, 000 psi working pressure at 42 litres per minute High Pressure Aqua Pumps • 10, 000 psi working pressure at 82 litres per minute

Ultra High Pressure Pump Unit • 36, 000 psi working pressure at 42 litres per minute High Pressure Aqua Pumps • 10, 000 psi working pressure at 82 litres per minute

Tubular Decontamination System • High Pressure jetting combined with lance mounted cutter ‘Rattler head’

Tubular Decontamination System • High Pressure jetting combined with lance mounted cutter ‘Rattler head’

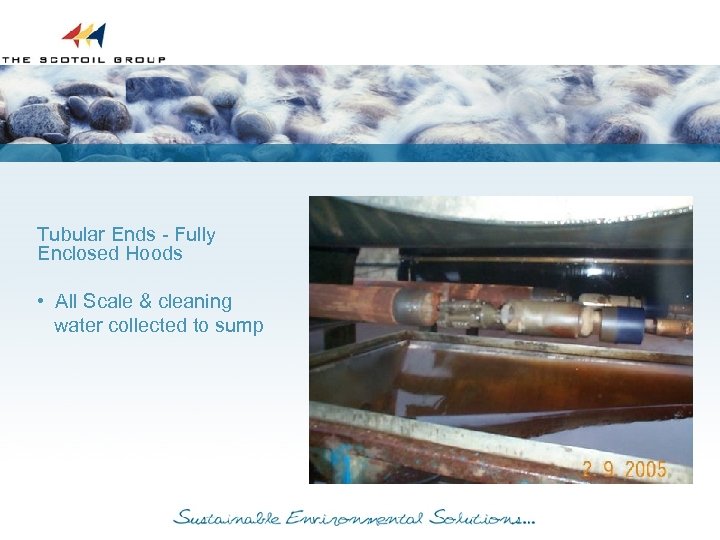

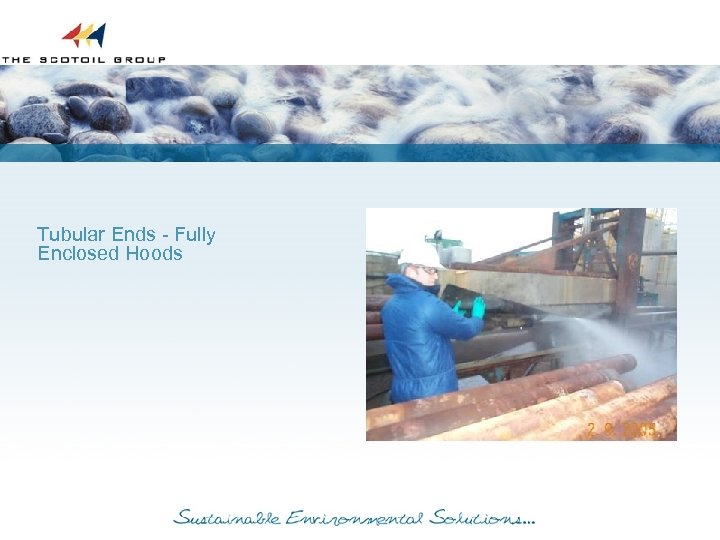

Tubular Ends - Fully Enclosed Hoods • All Scale & cleaning water collected to sump

Tubular Ends - Fully Enclosed Hoods • All Scale & cleaning water collected to sump

Tubular Ends - Fully Enclosed Hoods

Tubular Ends - Fully Enclosed Hoods

Lance Mounted Cutter Head ‘Rattler’ • Machine with hardened cutting surfaces

Lance Mounted Cutter Head ‘Rattler’ • Machine with hardened cutting surfaces

All Scale ground down to less than <250 microns • All Scale passed through screens • Oil Separator - two stage • Controlled discharged to sea regulated by SEPA • Post Cleaning Monitor Record • Final Check Monitor Record

All Scale ground down to less than <250 microns • All Scale passed through screens • Oil Separator - two stage • Controlled discharged to sea regulated by SEPA • Post Cleaning Monitor Record • Final Check Monitor Record

SCALE DISPOSAL • Results of radiochemical analysis on computerised Job Register • Certificate of Scale Disposal - master job file • Quarterly Scale Disposal computerised records • Quarterly Sea Survey - results, particle size analysis to radiation specialists at SEPA (Scottish Environment Protection Agency)

SCALE DISPOSAL • Results of radiochemical analysis on computerised Job Register • Certificate of Scale Disposal - master job file • Quarterly Scale Disposal computerised records • Quarterly Sea Survey - results, particle size analysis to radiation specialists at SEPA (Scottish Environment Protection Agency)

Compliance with HSE Regulations • • • Ionising Radiation Regulations 1999 Control of Pollution Act 1974* Radiation Substances Act 1993 Environmental Pollution Act 1990 Registered under the pipeline Act 1962 Authorisation for the Accumulation and Disposal of Radioactive Waste* * Regulated by SEPA (Scottish Environment Protection Agency)

Compliance with HSE Regulations • • • Ionising Radiation Regulations 1999 Control of Pollution Act 1974* Radiation Substances Act 1993 Environmental Pollution Act 1990 Registered under the pipeline Act 1962 Authorisation for the Accumulation and Disposal of Radioactive Waste* * Regulated by SEPA (Scottish Environment Protection Agency)

DECONTAMINATION PROCESS FOR NORM CONTAMINATED OILFIELD EQUIPMENT 6 th OCTOBER CITY - EGYPT Davidson House, Miller Street, Aberdeen, AB 11 5 AN, Scotland, UK Telephone +44 (0) 1224 571491 Fax +44 (0) 1224 580861 enquiries@scotoil. co. uk www. scotoil. co. uk

DECONTAMINATION PROCESS FOR NORM CONTAMINATED OILFIELD EQUIPMENT 6 th OCTOBER CITY - EGYPT Davidson House, Miller Street, Aberdeen, AB 11 5 AN, Scotland, UK Telephone +44 (0) 1224 571491 Fax +44 (0) 1224 580861 enquiries@scotoil. co. uk www. scotoil. co. uk

Oilfield Environmental Services is a joint Venture company between Scotoil (UK) and Minaoil (Egypt). Scotoil, bringing 20 years of North Sea NORM decontamination experience and Minaoil, bringing 20 years of Egyptian oil and gas industry expertise joined forces in 2001 to combat the NORM problem in Egypt. Oilfield Environmental Services was formed and is now operational and fully licensed by the Egyptian Authorities including EGPC, AEA, MOE and GAFI.

Oilfield Environmental Services is a joint Venture company between Scotoil (UK) and Minaoil (Egypt). Scotoil, bringing 20 years of North Sea NORM decontamination experience and Minaoil, bringing 20 years of Egyptian oil and gas industry expertise joined forces in 2001 to combat the NORM problem in Egypt. Oilfield Environmental Services was formed and is now operational and fully licensed by the Egyptian Authorities including EGPC, AEA, MOE and GAFI.

The following presentation, details the basic decontamination process of NORM contaminated equipment at Oilfield Environmental Services decontamination facility, situated in 6 th October City, Egypt. For the purpose of this presentation we will follow a contaminated ESP and resulting waste from arrival at OES until the equipment is despatched to the client in a safe, certified and contamination free state.

The following presentation, details the basic decontamination process of NORM contaminated equipment at Oilfield Environmental Services decontamination facility, situated in 6 th October City, Egypt. For the purpose of this presentation we will follow a contaminated ESP and resulting waste from arrival at OES until the equipment is despatched to the client in a safe, certified and contamination free state.

ON ARRIVAL, THE CONTAMINATED ITEM IS OFFLOADED AND DIRECTED TO OES RADIATION CONTROLLED AREA.

ON ARRIVAL, THE CONTAMINATED ITEM IS OFFLOADED AND DIRECTED TO OES RADIATION CONTROLLED AREA.

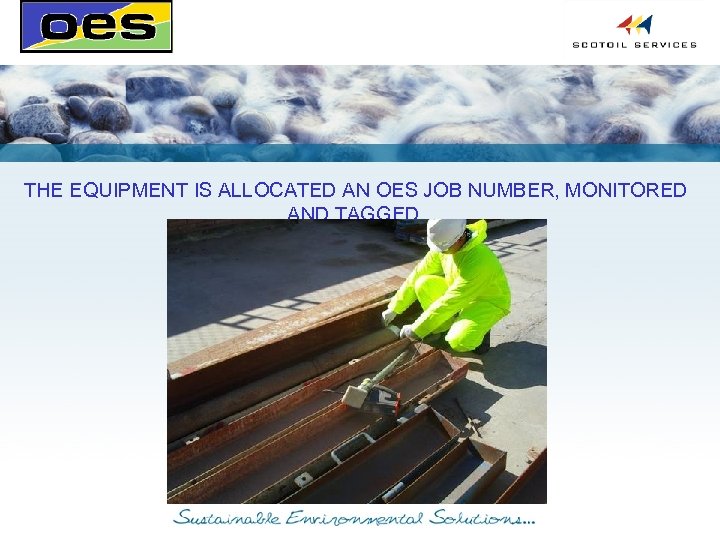

THE EQUIPMENT IS ALLOCATED AN OES JOB NUMBER, MONITORED AND TAGGED.

THE EQUIPMENT IS ALLOCATED AN OES JOB NUMBER, MONITORED AND TAGGED.

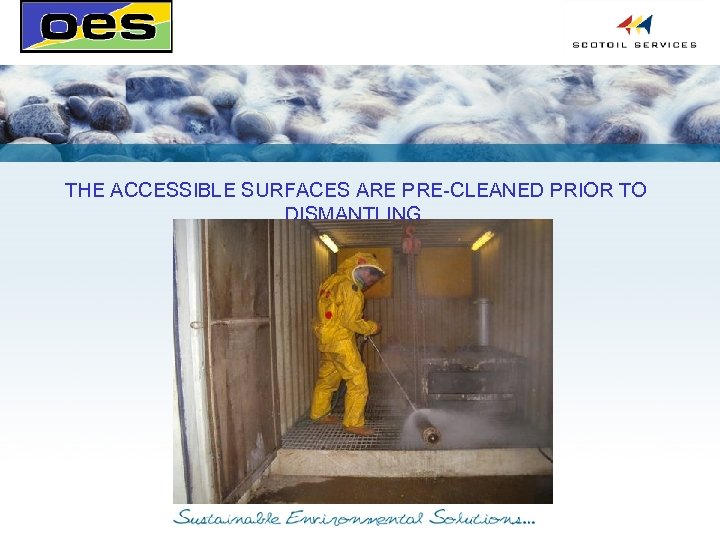

THE ACCESSIBLE SURFACES ARE PRE-CLEANED PRIOR TO DISMANTLING.

THE ACCESSIBLE SURFACES ARE PRE-CLEANED PRIOR TO DISMANTLING.

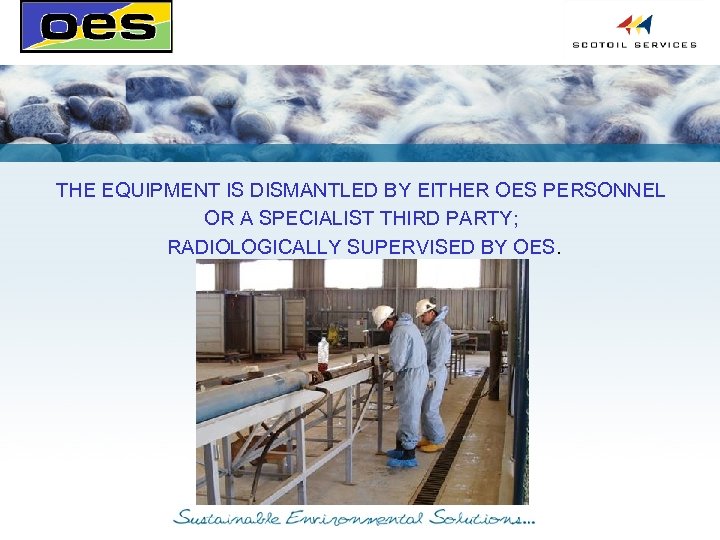

THE EQUIPMENT IS DISMANTLED BY EITHER OES PERSONNEL OR A SPECIALIST THIRD PARTY; RADIOLOGICALLY SUPERVISED BY OES.

THE EQUIPMENT IS DISMANTLED BY EITHER OES PERSONNEL OR A SPECIALIST THIRD PARTY; RADIOLOGICALLY SUPERVISED BY OES.

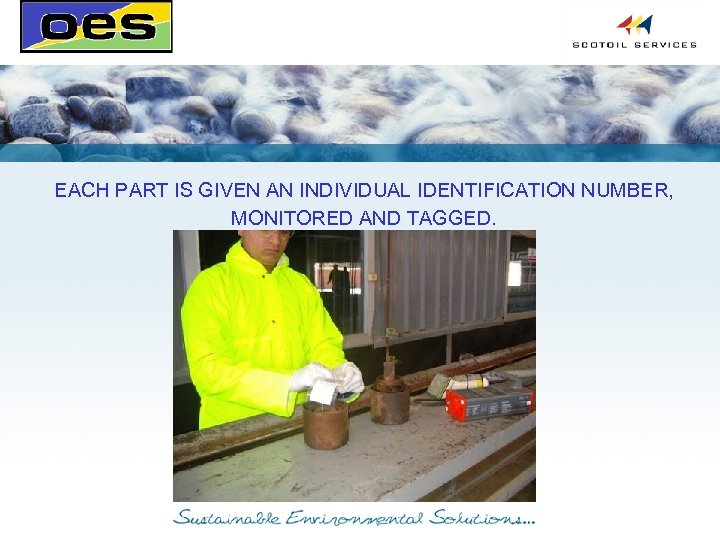

EACH PART IS GIVEN AN INDIVIDUAL IDENTIFICATION NUMBER, MONITORED AND TAGGED.

EACH PART IS GIVEN AN INDIVIDUAL IDENTIFICATION NUMBER, MONITORED AND TAGGED.

THE BREAKDOWN AREA IS DECONTAMINATED, FLUSHING ALL CONTAMINENTS INTO THE CLOSED LOOP DRAINAGE AND FILTRATION SYSTEM.

THE BREAKDOWN AREA IS DECONTAMINATED, FLUSHING ALL CONTAMINENTS INTO THE CLOSED LOOP DRAINAGE AND FILTRATION SYSTEM.

EACH PART IS INDIVIDUALLY DECONTAMINATED BY MEANS OF…. .

EACH PART IS INDIVIDUALLY DECONTAMINATED BY MEANS OF…. .

STATE OF THE ART UHP WATER JETTING EQUIPMENT.

STATE OF THE ART UHP WATER JETTING EQUIPMENT.

RESULTING RADIOACTIVE WASTE IS COLLECTED IN A CLOSED LOOP SIX STAGE FILTRATION AND WATER RECYCLING SYSTEM.

RESULTING RADIOACTIVE WASTE IS COLLECTED IN A CLOSED LOOP SIX STAGE FILTRATION AND WATER RECYCLING SYSTEM.

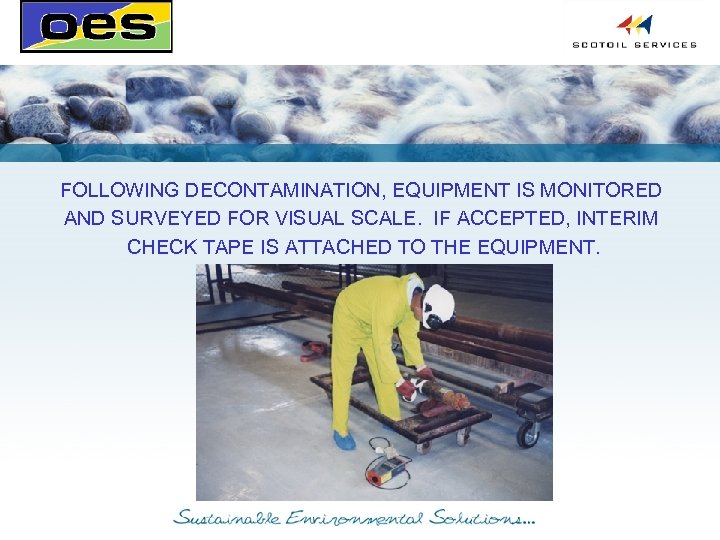

FOLLOWING DECONTAMINATION, EQUIPMENT IS MONITORED AND SURVEYED FOR VISUAL SCALE. IF ACCEPTED, INTERIM CHECK TAPE IS ATTACHED TO THE EQUIPMENT.

FOLLOWING DECONTAMINATION, EQUIPMENT IS MONITORED AND SURVEYED FOR VISUAL SCALE. IF ACCEPTED, INTERIM CHECK TAPE IS ATTACHED TO THE EQUIPMENT.

EQUIPMENT IS NOW MONITORED BY A HEALTH PHYSICIST AT THE QUALITY CONTROL STAGE.

EQUIPMENT IS NOW MONITORED BY A HEALTH PHYSICIST AT THE QUALITY CONTROL STAGE.

FOLLOWING ACCEPTANCE BY THE QC DEPARTMENT AND CLIENT, THE EQUIPMENT IS SUITABLY WRAPPED AND EITHER BOXED, PALLETISED OR RETURNED TO ITS ORIGINAL CONTAINER.

FOLLOWING ACCEPTANCE BY THE QC DEPARTMENT AND CLIENT, THE EQUIPMENT IS SUITABLY WRAPPED AND EITHER BOXED, PALLETISED OR RETURNED TO ITS ORIGINAL CONTAINER.

THE EQUIPMENT IS CLEAN, SAFE, CERTIFIED AND READY FOR CUSTOMER UPLIFT.

THE EQUIPMENT IS CLEAN, SAFE, CERTIFIED AND READY FOR CUSTOMER UPLIFT.

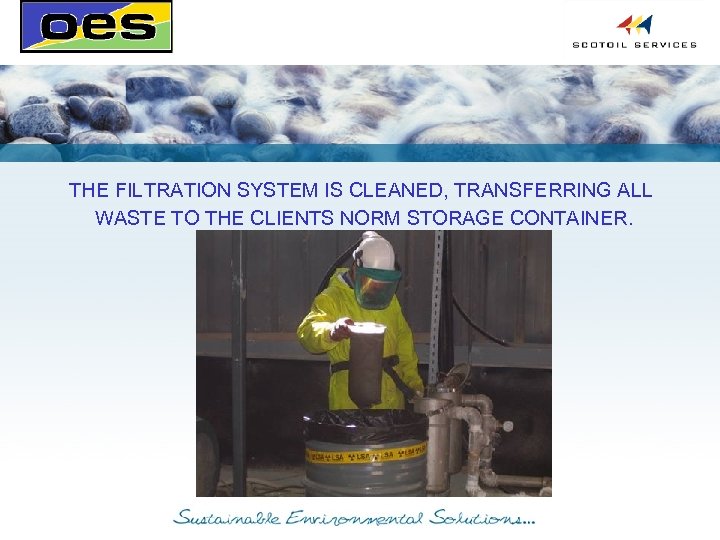

THE FILTRATION SYSTEM IS CLEANED, TRANSFERRING ALL WASTE TO THE CLIENTS NORM STORAGE CONTAINER.

THE FILTRATION SYSTEM IS CLEANED, TRANSFERRING ALL WASTE TO THE CLIENTS NORM STORAGE CONTAINER.

THE ENTIRE CONTROLLED AREA IS SURVEYED BY A QUALIFIED HEALTH PHYSICIST TO ENSURE THAT IT IS FREE OF CONTAMINATION.

THE ENTIRE CONTROLLED AREA IS SURVEYED BY A QUALIFIED HEALTH PHYSICIST TO ENSURE THAT IT IS FREE OF CONTAMINATION.

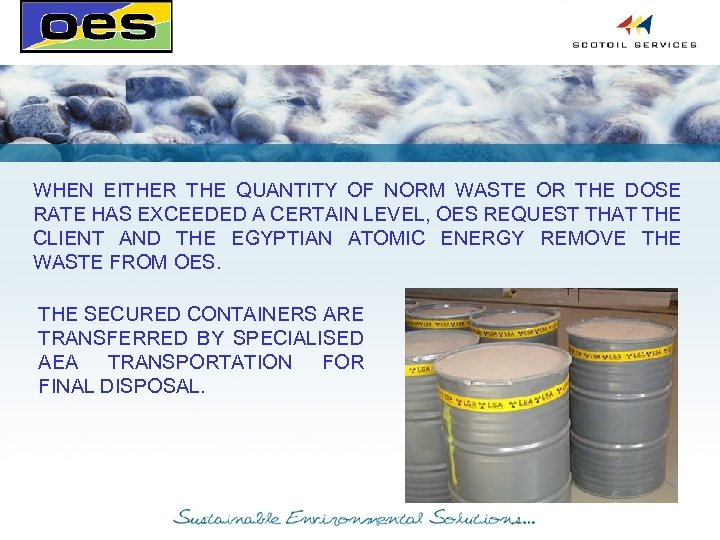

WHEN EITHER THE QUANTITY OF NORM WASTE OR THE DOSE RATE HAS EXCEEDED A CERTAIN LEVEL, OES REQUEST THAT THE CLIENT AND THE EGYPTIAN ATOMIC ENERGY REMOVE THE WASTE FROM OES. THE SECURED CONTAINERS ARE TRANSFERRED BY SPECIALISED AEA TRANSPORTATION FOR FINAL DISPOSAL.

WHEN EITHER THE QUANTITY OF NORM WASTE OR THE DOSE RATE HAS EXCEEDED A CERTAIN LEVEL, OES REQUEST THAT THE CLIENT AND THE EGYPTIAN ATOMIC ENERGY REMOVE THE WASTE FROM OES. THE SECURED CONTAINERS ARE TRANSFERRED BY SPECIALISED AEA TRANSPORTATION FOR FINAL DISPOSAL.

AT THE TIME OF EQUIPMENT DESPATCH, A FULL REPORT IS SUBMITTED TO THE CLIENT WITH ALL RELEVANT DOCUMENTATION. THIS TYPICALLY INCLUDES : - EQUIPMENT / PART RECORDS WORK SUMMARY DISMANTLING DETAILS RADIATION ANALYSIS RESULTS FROM EACH STAGE IN THE PROCESS RADIATION SUMMARY QC DOCUMENTATION NORM WASTE DATA DECONTAMINATION CERTIFICATE

AT THE TIME OF EQUIPMENT DESPATCH, A FULL REPORT IS SUBMITTED TO THE CLIENT WITH ALL RELEVANT DOCUMENTATION. THIS TYPICALLY INCLUDES : - EQUIPMENT / PART RECORDS WORK SUMMARY DISMANTLING DETAILS RADIATION ANALYSIS RESULTS FROM EACH STAGE IN THE PROCESS RADIATION SUMMARY QC DOCUMENTATION NORM WASTE DATA DECONTAMINATION CERTIFICATE

QUESTIONS?

QUESTIONS?