1e85303898f2dca2453dc3c753f0a4b9.ppt

- Количество слайдов: 28

NOR Shipping ISM the Tanker Owners Perspective Howard Snaith Marine & Chemical Director INTERTANKO

NOR Shipping ISM the Tanker Owners Perspective Howard Snaith Marine & Chemical Director INTERTANKO

Views from the INTERTANKO Vetting Committee

Views from the INTERTANKO Vetting Committee

What is ISM?

What is ISM?

Does ISM Really Work Today? Are We Doing It Right?

Does ISM Really Work Today? Are We Doing It Right?

For the quality owner/manager - “YES” is the answer. Because they were doing it right before ISM has simply formalised their operating procedures

For the quality owner/manager - “YES” is the answer. Because they were doing it right before ISM has simply formalised their operating procedures

But what about the sub-standard operator? Raises the question is ISM correctly implemented across the whole industry?

But what about the sub-standard operator? Raises the question is ISM correctly implemented across the whole industry?

One of our membership criteria requires the owner to not only have an ISM system but an IMPLEMENTED ISM system

One of our membership criteria requires the owner to not only have an ISM system but an IMPLEMENTED ISM system

The Paris Mo. U & Tokyo Mo. U have just published reports recently The Media may be surprised at the results!

The Paris Mo. U & Tokyo Mo. U have just published reports recently The Media may be surprised at the results!

• BUT we are not. Because what we have known all along is; The Tanker Owner is shown as the best operator from all ship types

• BUT we are not. Because what we have known all along is; The Tanker Owner is shown as the best operator from all ship types

A total of 3191 ships of all ship types were detained during 2002 (By the Tokyo Mo. U, Paris Mo. U & USCG) However, only 9. 5% were Tankers

A total of 3191 ships of all ship types were detained during 2002 (By the Tokyo Mo. U, Paris Mo. U & USCG) However, only 9. 5% were Tankers

We believe it noteworthy that ONLY 1. 9% were INTERTANKO members' tankers ISM was quoted as the reason for the detention in only 0. 18% of INTERTANKO detentions

We believe it noteworthy that ONLY 1. 9% were INTERTANKO members' tankers ISM was quoted as the reason for the detention in only 0. 18% of INTERTANKO detentions

Conclusion ISM works in the INTERTANKO fleet

Conclusion ISM works in the INTERTANKO fleet

Can we improve more? We can always improve and this is in the sprit of the ISM code Auditing could be made more stringent to weed out the substandard operator. ISM is made by humans and its implementation is done by them The system draws to our attention its failures, not its successes. These failures are brought to the attention of others via casualty reports, Non Conformities and Near Misses, the system is then improved and safety enhanced It is therefore the failures in the system that strengthen it and makes it work. The key element that keeps ISM up to date and alive is the continual improvement

Can we improve more? We can always improve and this is in the sprit of the ISM code Auditing could be made more stringent to weed out the substandard operator. ISM is made by humans and its implementation is done by them The system draws to our attention its failures, not its successes. These failures are brought to the attention of others via casualty reports, Non Conformities and Near Misses, the system is then improved and safety enhanced It is therefore the failures in the system that strengthen it and makes it work. The key element that keeps ISM up to date and alive is the continual improvement

Has it improved and raised standards in the tanker industry? Judging by some press reports regarding various measures being adopted worldwide, to try and rid the world of substandard tankers - one would think not. However, PSC and ship vetting have probably done more to raise standards than ISM.

Has it improved and raised standards in the tanker industry? Judging by some press reports regarding various measures being adopted worldwide, to try and rid the world of substandard tankers - one would think not. However, PSC and ship vetting have probably done more to raise standards than ISM.

Do we pay lip service to ISM or does it fulfil its intentions? The Quality owner/manager uses ISM as a tool to improve safety of operations as the system was intended to do. But there remain those on the fringe who do pay lip service to ISM PSC has a positive effect and is the final safety net. However, this is not how it should be. Flag and Class need to do more to ensure correct implementation across the world fleet

Do we pay lip service to ISM or does it fulfil its intentions? The Quality owner/manager uses ISM as a tool to improve safety of operations as the system was intended to do. But there remain those on the fringe who do pay lip service to ISM PSC has a positive effect and is the final safety net. However, this is not how it should be. Flag and Class need to do more to ensure correct implementation across the world fleet

What does ISM mean to a tanker operator today? It is the new minimum standard. Everybody has it - good and sub standard.

What does ISM mean to a tanker operator today? It is the new minimum standard. Everybody has it - good and sub standard.

If the quality operator is to differentiate himself from the rest of the pack then he must do more than ISM. Unfortunately the market does not always want to pay more for that higher standard.

If the quality operator is to differentiate himself from the rest of the pack then he must do more than ISM. Unfortunately the market does not always want to pay more for that higher standard.

Text for slides Slide 1 Good morning Ladies & Gentlemen, thank you for the opportunity to be able to come here today and speak on this very interesting topic. I have been involved with ISM for some years now and also directly involved with its implementation onboard when it was in its early days. I therefore came to know very quickly the difficulties that needed to be overcome when ISM was first introduced at sea. Slide 2 However one of the roles that I have at INTERTANKO is to act as secretary to the INTERTANKO Vetting Committee, a body of about 20 INTERTANKO members that work closely with the many aspects of ship inspections including, Port State Control, Commercial vetting inspections, EQUASIS, the CDI/SIRE systems, Detentions, Appeal procedures and ISM issues. Therefore when I was preparing this paper I thought what better than to seek the views of our Vetting committee members when compiling the “The Tanker Owners Perspective” I have therefore collated the views from this committee which are the views or senior people working closely with ISM on tankers on a daily basis.

Text for slides Slide 1 Good morning Ladies & Gentlemen, thank you for the opportunity to be able to come here today and speak on this very interesting topic. I have been involved with ISM for some years now and also directly involved with its implementation onboard when it was in its early days. I therefore came to know very quickly the difficulties that needed to be overcome when ISM was first introduced at sea. Slide 2 However one of the roles that I have at INTERTANKO is to act as secretary to the INTERTANKO Vetting Committee, a body of about 20 INTERTANKO members that work closely with the many aspects of ship inspections including, Port State Control, Commercial vetting inspections, EQUASIS, the CDI/SIRE systems, Detentions, Appeal procedures and ISM issues. Therefore when I was preparing this paper I thought what better than to seek the views of our Vetting committee members when compiling the “The Tanker Owners Perspective” I have therefore collated the views from this committee which are the views or senior people working closely with ISM on tankers on a daily basis.

Text for slides Slide 3 But what is ISM? It is stated that the ISM code is to improve safety at sea, prevent human injury or loss of life, and avoid damage to the marine environment and property. But the fear is that the full implementation of a living breathing working safety management system has only partially been achieved and if the ship owner does NOT make it work as intended then governments will introduce another layer of inspections and stricter regimes. The Code requires a safety management system (SMS) to be established by "the Company", which is defined as the shipowner or any person who has assumed responsibility for operating the ship. The SMS sets out the procedures by which the safety and pollution prevention aspects of a ship are managed, both ashore and on board. The Company should be able to follow the set procedures to check that it complies, and continues to comply, with the various rules and regulation, e. g. the Load Line Regulations, MARPOL, STCW, other chapters of SOLAS, etc. The Company is required to provide the necessary resources and shore-based support to implement the SMS. The Company is also expected to designate a person or persons ashore (DPA) having direct access to the highest level of management to ensure the safe operation of each ship and to provide a link between the Company and those on board. The Administration (the State whose flag the ship is entitled to fly) or the organisation(s) recognised by the Administration is responsible for verifying compliance with the requirements of the ISM Code and for issuing the appropriate certificates.

Text for slides Slide 3 But what is ISM? It is stated that the ISM code is to improve safety at sea, prevent human injury or loss of life, and avoid damage to the marine environment and property. But the fear is that the full implementation of a living breathing working safety management system has only partially been achieved and if the ship owner does NOT make it work as intended then governments will introduce another layer of inspections and stricter regimes. The Code requires a safety management system (SMS) to be established by "the Company", which is defined as the shipowner or any person who has assumed responsibility for operating the ship. The SMS sets out the procedures by which the safety and pollution prevention aspects of a ship are managed, both ashore and on board. The Company should be able to follow the set procedures to check that it complies, and continues to comply, with the various rules and regulation, e. g. the Load Line Regulations, MARPOL, STCW, other chapters of SOLAS, etc. The Company is required to provide the necessary resources and shore-based support to implement the SMS. The Company is also expected to designate a person or persons ashore (DPA) having direct access to the highest level of management to ensure the safe operation of each ship and to provide a link between the Company and those on board. The Administration (the State whose flag the ship is entitled to fly) or the organisation(s) recognised by the Administration is responsible for verifying compliance with the requirements of the ISM Code and for issuing the appropriate certificates.

Text for slides Slide 3 cont… A Document of Compliance (DOC) will be issued by the Administration or recognised organisation(s) after having verified that the Company has properly developed and implemented a SMS which complies with the ISM Code. The Company must produce objective evidence to show that the SMS has been in operation for at least three months on board at least one ship of each type operated by the Company. A Safety Management Certificate (SMC) will be issued by the Administration or recognised organisation(s) to each ship operated by the Company after an initial verification of compliance by way of an external audit on board the particular ship. The DOC has a validity of five years, subject to annual verification to check that the SMS is still functioning properly. The SMC also has a validity of five years but, unlike the DOC, requires at least one intermediate verification within the validity period Slide 4 So the big question remains, - Does ISM really work today? And are we doing it right?

Text for slides Slide 3 cont… A Document of Compliance (DOC) will be issued by the Administration or recognised organisation(s) after having verified that the Company has properly developed and implemented a SMS which complies with the ISM Code. The Company must produce objective evidence to show that the SMS has been in operation for at least three months on board at least one ship of each type operated by the Company. A Safety Management Certificate (SMC) will be issued by the Administration or recognised organisation(s) to each ship operated by the Company after an initial verification of compliance by way of an external audit on board the particular ship. The DOC has a validity of five years, subject to annual verification to check that the SMS is still functioning properly. The SMC also has a validity of five years but, unlike the DOC, requires at least one intermediate verification within the validity period Slide 4 So the big question remains, - Does ISM really work today? And are we doing it right?

Text for slides Slide 5 If we look at the Quality Owner/Manager then the answer is “yes” they are doing it right and ”Yes” it does work. Why is that? – because these guys were doing it right before ISM was implemented. The introduction of ISM to them has simply formalised what they did anyway. Slide 6 So we don’t need to worry about the quality owner, but what about the sub-standard operator? Is he doing it right? Does it work for him? Before ISM became mandatory for tankers several fears were raised that not all tanker operators would have the ISM code implemented in time. However, as far as we are aware all met the deadlines. Sub-standard operators do exist, so the question is – is ISM correctly implemented across the while industry, are all of the existing certified ISM systems living, breathing working systems, i. e fully implemented? It is of course questionable if this is the case. Slide 7 INTERTANKO has several membership criteria, one of these was that all our members should have an ISM system. In the days before this was mandatory in the tanker industry this was a very strong statement indeed, however now ISM is a mandatory requirement we decided to re-assess this. Therefore, with regards to this particular criterion what we now say is that not only will all our members have an ISM system but that they will have an IMPLEMENTED ISM system.

Text for slides Slide 5 If we look at the Quality Owner/Manager then the answer is “yes” they are doing it right and ”Yes” it does work. Why is that? – because these guys were doing it right before ISM was implemented. The introduction of ISM to them has simply formalised what they did anyway. Slide 6 So we don’t need to worry about the quality owner, but what about the sub-standard operator? Is he doing it right? Does it work for him? Before ISM became mandatory for tankers several fears were raised that not all tanker operators would have the ISM code implemented in time. However, as far as we are aware all met the deadlines. Sub-standard operators do exist, so the question is – is ISM correctly implemented across the while industry, are all of the existing certified ISM systems living, breathing working systems, i. e fully implemented? It is of course questionable if this is the case. Slide 7 INTERTANKO has several membership criteria, one of these was that all our members should have an ISM system. In the days before this was mandatory in the tanker industry this was a very strong statement indeed, however now ISM is a mandatory requirement we decided to re-assess this. Therefore, with regards to this particular criterion what we now say is that not only will all our members have an ISM system but that they will have an IMPLEMENTED ISM system.

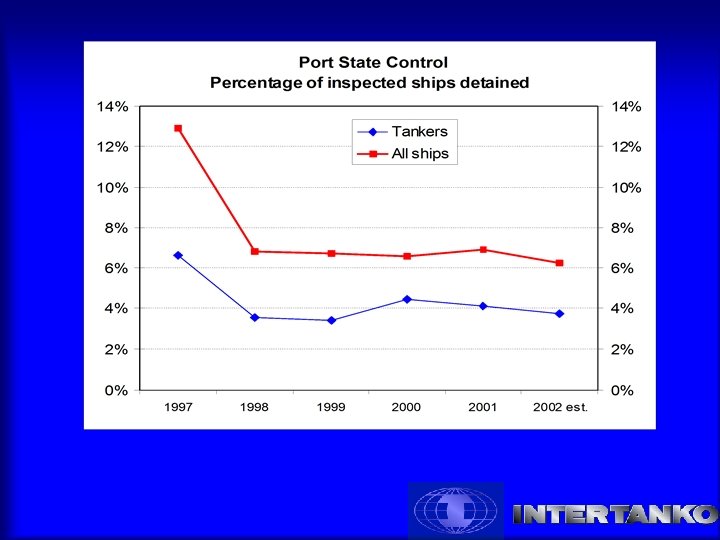

Text for slides Slide 8 One other area where we have monitored our members for some time now is by reviewing and assessing detentions. The Paris Mo. U and Tokyo Mo. U have recently published their reports. As always, these are very interesting, but they are also very useful as a tool for assessment and problem identification. We think the media may be surprised by some of the data that can be drawn from these reports, Slide 9 However, INTERTANKO is NOT surprised because this is what we have known all along, “THE TANKER OWNER IS SHOWN AS THE BEST OPERATOR FROM ALL SHIP TYPES”. Slide 10 We can see that although the percentage of inspected ships that have been detained have reduced since 1997 the percentage of inspected tankers that have been detained has always been considerably less

Text for slides Slide 8 One other area where we have monitored our members for some time now is by reviewing and assessing detentions. The Paris Mo. U and Tokyo Mo. U have recently published their reports. As always, these are very interesting, but they are also very useful as a tool for assessment and problem identification. We think the media may be surprised by some of the data that can be drawn from these reports, Slide 9 However, INTERTANKO is NOT surprised because this is what we have known all along, “THE TANKER OWNER IS SHOWN AS THE BEST OPERATOR FROM ALL SHIP TYPES”. Slide 10 We can see that although the percentage of inspected ships that have been detained have reduced since 1997 the percentage of inspected tankers that have been detained has always been considerably less

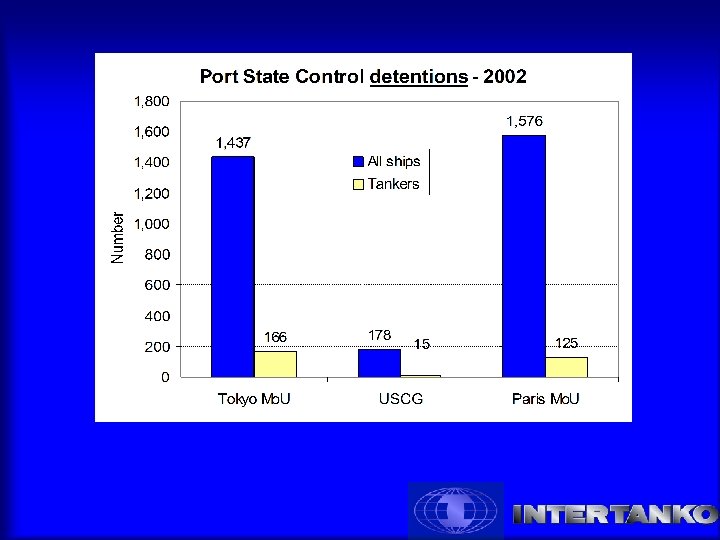

Text for slides Slide 11 This slide breaks down the detentions in to Mo. U regions, for example we can see that the Tokyo Mo. U detained 1437 ships in 2002 but only 166 tankers. The United States Coastguard detained 178 ships but only 15 tankers, and The Paris Mo. U detained 1576 ships but only 125 tankers. Slide 12 A total of 3191 ships of all types were detained during 2002 by the Tokyo Mo. U, Paris Mo. U and USCG. But of all these ships only 9. 5% were tankers! Slide 13 But we what we believe is very noteworthy from this is when we look at the INTERTANKO membership is the fact that of these 3191 detained ships ONLY 1. 9% were INTERTANKO tankers Slide 14 Now if we look at the reasons given for these detentions what is also we can see that ISM was the given reason for the detention in only 0. 18% of the cases within INTERTANKO. So what can we conclude by this?

Text for slides Slide 11 This slide breaks down the detentions in to Mo. U regions, for example we can see that the Tokyo Mo. U detained 1437 ships in 2002 but only 166 tankers. The United States Coastguard detained 178 ships but only 15 tankers, and The Paris Mo. U detained 1576 ships but only 125 tankers. Slide 12 A total of 3191 ships of all types were detained during 2002 by the Tokyo Mo. U, Paris Mo. U and USCG. But of all these ships only 9. 5% were tankers! Slide 13 But we what we believe is very noteworthy from this is when we look at the INTERTANKO membership is the fact that of these 3191 detained ships ONLY 1. 9% were INTERTANKO tankers Slide 14 Now if we look at the reasons given for these detentions what is also we can see that ISM was the given reason for the detention in only 0. 18% of the cases within INTERTANKO. So what can we conclude by this?

Text for slides Slide 15 The Conclusion is that ISM works in the INTERTANKO Fleet Slide 16 We may still ask the question though, can we improve, and of course we can always improve, this is embedded into the ISM code, auditing could be made more stringent to weed out the substandard operator, but it must be remembered that ISM is made by humans and it is implemented by humans, the system is designed such that it draws our attention to its failures rather than its successes. These failures are then brought to the attention of others via casualty reports, Non conformities and near miss reports. By virtue of this the system is improved and safety enhanced. It is therefore the failures in the system that strengthens it and makes it work. The key element that makes ISM a working living breathing form is continual improvement. Slide 17 But has ISM improved and raised standards in the tanker industry? If we look at some of the press reports regarding various measures being adopted worldwide to try and rid the world of the substandard tankers one would think not. But in essence it is probably PSC and Tanker vetting that have done more to raise standards more than ISM

Text for slides Slide 15 The Conclusion is that ISM works in the INTERTANKO Fleet Slide 16 We may still ask the question though, can we improve, and of course we can always improve, this is embedded into the ISM code, auditing could be made more stringent to weed out the substandard operator, but it must be remembered that ISM is made by humans and it is implemented by humans, the system is designed such that it draws our attention to its failures rather than its successes. These failures are then brought to the attention of others via casualty reports, Non conformities and near miss reports. By virtue of this the system is improved and safety enhanced. It is therefore the failures in the system that strengthens it and makes it work. The key element that makes ISM a working living breathing form is continual improvement. Slide 17 But has ISM improved and raised standards in the tanker industry? If we look at some of the press reports regarding various measures being adopted worldwide to try and rid the world of the substandard tankers one would think not. But in essence it is probably PSC and Tanker vetting that have done more to raise standards more than ISM

Text for slides Slide 18 But the quality owner/manager will use and does use ISM as a tool to improve the safety of operations as intended by the system. But there remain some who operate on the fringe and only pay lip service to ISM. Port State Control does has a positive effect and is the ultimate final safety net, but should it really be necessary for PSC to have to do this? Flag and Class need to do more to ensure the correct implementation of ISM across the worlds fleet Slide 19 So exactly what does ISM mean to the tanker operator today? It is the new minimum standard, every body has it the quality operator and the sub-standard vessel Slide 20 So if the quality operator is to differentiate himself from the rest of the pack then he needs to do more than ISM - unfortunately the market is not always prepared to pay for that higher standard. Slide 21 Thank you very much

Text for slides Slide 18 But the quality owner/manager will use and does use ISM as a tool to improve the safety of operations as intended by the system. But there remain some who operate on the fringe and only pay lip service to ISM. Port State Control does has a positive effect and is the ultimate final safety net, but should it really be necessary for PSC to have to do this? Flag and Class need to do more to ensure the correct implementation of ISM across the worlds fleet Slide 19 So exactly what does ISM mean to the tanker operator today? It is the new minimum standard, every body has it the quality operator and the sub-standard vessel Slide 20 So if the quality operator is to differentiate himself from the rest of the pack then he needs to do more than ISM - unfortunately the market is not always prepared to pay for that higher standard. Slide 21 Thank you very much