787491e46f804b011dc19eb878ddbc57.ppt

- Количество слайдов: 34

NODDEX: Nitric Oxide and Dust Detector EXperiment Preliminary Design Review Virginia Tech/Baylor University Presented by Stephen Noel December 7, 2011 2012 PDR 1

NODDEX: Nitric Oxide and Dust Detector EXperiment Preliminary Design Review Virginia Tech/Baylor University Presented by Stephen Noel December 7, 2011 2012 PDR 1

PDR Presentation Content • Section 1: Mission Overview – – – Mission Overview Organizational Chart Theory and Concepts Concept of Operations Expected Results – – – Subsystem Definitions Critical Interfaces System Level Block Diagram System/Project Level Requirement Verification Plan User Guide Compliance Sharing Logistics with UW • Section 2: System Overview 2012 PDR 2

PDR Presentation Content • Section 1: Mission Overview – – – Mission Overview Organizational Chart Theory and Concepts Concept of Operations Expected Results – – – Subsystem Definitions Critical Interfaces System Level Block Diagram System/Project Level Requirement Verification Plan User Guide Compliance Sharing Logistics with UW • Section 2: System Overview 2012 PDR 2

PDR Presentation Contents • Section 3: Subsystem Design – Data Logger Trade Study – NO Sensor • NO Block Diagram • PDD Risk Matrix/Mitigation – PDD • PDD Block Diagram • PDD Risk Matrix/Mitigation – IMU • IMU Block Diagram • IMU Risk Matrix/Mitigation 2012 PDR 3

PDR Presentation Contents • Section 3: Subsystem Design – Data Logger Trade Study – NO Sensor • NO Block Diagram • PDD Risk Matrix/Mitigation – PDD • PDD Block Diagram • PDD Risk Matrix/Mitigation – IMU • IMU Block Diagram • IMU Risk Matrix/Mitigation 2012 PDR 3

PDR Presentation Contents • Section 4: Prototyping Plan – NO Prototyping (or reuse) – PDD Prototyping and Testing • Section 5: Project Management Plan – Schedule – Budget – Work Breakdown Structure 2012 PDR 4

PDR Presentation Contents • Section 4: Prototyping Plan – NO Prototyping (or reuse) – PDD Prototyping and Testing • Section 5: Project Management Plan – Schedule – Budget – Work Breakdown Structure 2012 PDR 4

Mission Overview Stephen Noel 2012 PDR 5

Mission Overview Stephen Noel 2012 PDR 5

Mission Overview • Nitric Oxide (NO) sensor implementation – Measure concentration of NO as a function of altitude – Flight heritage in Rock. Sat-C (NOIME) • Piezo Dust Detector (PDD) – Collect measurements of velocity and energy from incoming dust particles – Existing flight heritage on UT satellite 2012 PDR 6

Mission Overview • Nitric Oxide (NO) sensor implementation – Measure concentration of NO as a function of altitude – Flight heritage in Rock. Sat-C (NOIME) • Piezo Dust Detector (PDD) – Collect measurements of velocity and energy from incoming dust particles – Existing flight heritage on UT satellite 2012 PDR 6

Mission Overview • Utilize Nitric Oxide sensor for NO concentration data collection in high altitudes – – IMU data to accompany NO data Optimal senor orientation Successful data transmission and storage Mechanical and thermal securing for reentry • Successful implementation of Piezo Dust Detector and collection of space dust impact energy readings for Baylor University – Successful data transmission and storage – Mechanical and thermal securing for reentry 2012 PDR 7

Mission Overview • Utilize Nitric Oxide sensor for NO concentration data collection in high altitudes – – IMU data to accompany NO data Optimal senor orientation Successful data transmission and storage Mechanical and thermal securing for reentry • Successful implementation of Piezo Dust Detector and collection of space dust impact energy readings for Baylor University – Successful data transmission and storage – Mechanical and thermal securing for reentry 2012 PDR 7

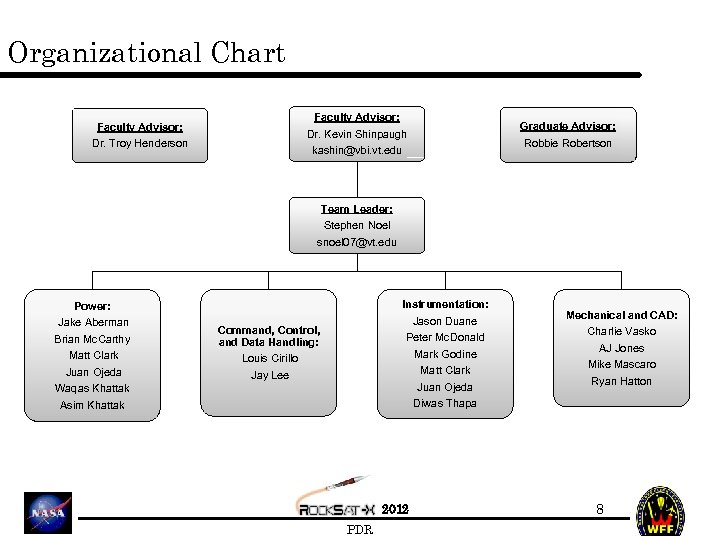

Organizational Chart Faculty Advisor: Dr. Troy Henderson Faculty Advisor: Dr. Kevin Shinpaugh kashin@vbi. vt. edu Graduate Advisor: Robbie Robertson Team Leader: Stephen Noel snoel 07@vt. edu Power: Jake Aberman Brian Mc. Carthy Matt Clark Juan Ojeda Waqas Khattak Asim Khattak Instrumentation: Jason Duane Command, Control, and Data Handling: Louis Cirillo Jay Lee Peter Mc. Donald Mark Godine Matt Clark Juan Ojeda Diwas Thapa 2012 PDR Mechanical and CAD: Charlie Vasko AJ Jones Mike Mascaro Ryan Hatton 8

Organizational Chart Faculty Advisor: Dr. Troy Henderson Faculty Advisor: Dr. Kevin Shinpaugh kashin@vbi. vt. edu Graduate Advisor: Robbie Robertson Team Leader: Stephen Noel snoel 07@vt. edu Power: Jake Aberman Brian Mc. Carthy Matt Clark Juan Ojeda Waqas Khattak Asim Khattak Instrumentation: Jason Duane Command, Control, and Data Handling: Louis Cirillo Jay Lee Peter Mc. Donald Mark Godine Matt Clark Juan Ojeda Diwas Thapa 2012 PDR Mechanical and CAD: Charlie Vasko AJ Jones Mike Mascaro Ryan Hatton 8

Theory and Concepts • Utilizing NO sensor and IMU from NOIME (Rock. Sat-C flight heritage) – NO sensor collects wavelength data around 220 nm – NO sensor oriented at 45 degrees to catch light off of upper atmosphere – Stepped conical shape on the inside to allow only direct rays – IMU collects acceleration, angular rate, and magnetic field data 2012 PDR 9

Theory and Concepts • Utilizing NO sensor and IMU from NOIME (Rock. Sat-C flight heritage) – NO sensor collects wavelength data around 220 nm – NO sensor oriented at 45 degrees to catch light off of upper atmosphere – Stepped conical shape on the inside to allow only direct rays – IMU collects acceleration, angular rate, and magnetic field data 2012 PDR 9

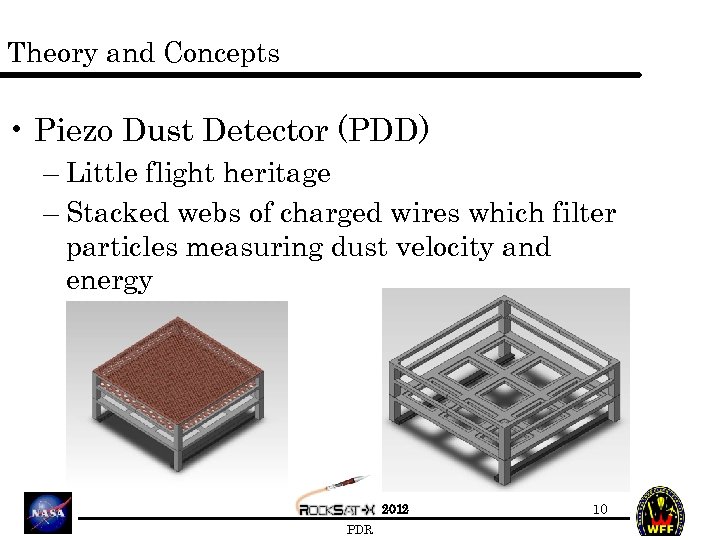

Theory and Concepts • Piezo Dust Detector (PDD) – Little flight heritage – Stacked webs of charged wires which filter particles measuring dust velocity and energy 2012 PDR 10

Theory and Concepts • Piezo Dust Detector (PDD) – Little flight heritage – Stacked webs of charged wires which filter particles measuring dust velocity and energy 2012 PDR 10

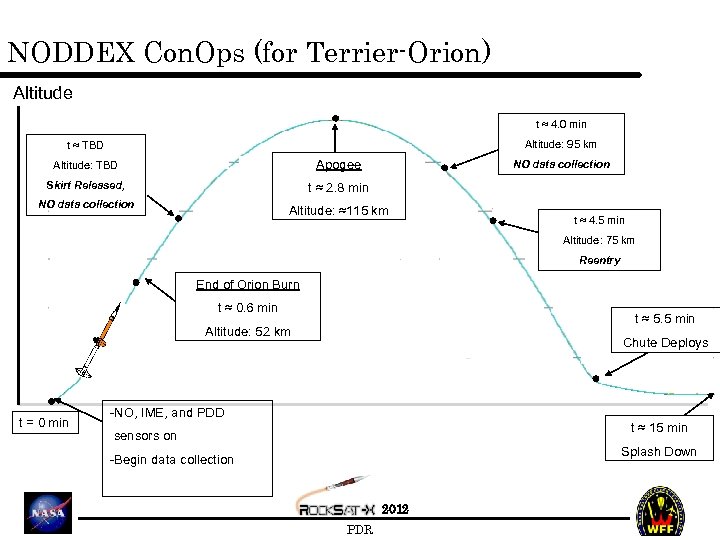

NODDEX Con. Ops (for Terrier-Orion) Altitude t ≈ 4. 0 min Altitude: 95 km t ≈ TBD Altitude: TBD Apogee Skirt Released, t ≈ 2. 8 min NO data collection Altitude: ≈115 km NO data collection t ≈ 4. 5 min Altitude: 75 km Reentry End of Orion Burn t ≈ 0. 6 min t ≈ 5. 5 min Altitude: 52 km t = 0 min Chute Deploys -NO, IME, and PDD t ≈ 15 min sensors on Splash Down -Begin data collection 2012 PDR

NODDEX Con. Ops (for Terrier-Orion) Altitude t ≈ 4. 0 min Altitude: 95 km t ≈ TBD Altitude: TBD Apogee Skirt Released, t ≈ 2. 8 min NO data collection Altitude: ≈115 km NO data collection t ≈ 4. 5 min Altitude: 75 km Reentry End of Orion Burn t ≈ 0. 6 min t ≈ 5. 5 min Altitude: 52 km t = 0 min Chute Deploys -NO, IME, and PDD t ≈ 15 min sensors on Splash Down -Begin data collection 2012 PDR

Expected Results • Utilizing NO sensor and IMU from NOIME (Rock. Sat-C flight heritage) – NO sensor collects wavelength data around 220 nm – Compare data to current atmospheric models • Still need expected PDD results data from Baylor University 2012 PDR 12

Expected Results • Utilizing NO sensor and IMU from NOIME (Rock. Sat-C flight heritage) – NO sensor collects wavelength data around 220 nm – Compare data to current atmospheric models • Still need expected PDD results data from Baylor University 2012 PDR 12

System Overview Stephen Noel 2012 PDR 13

System Overview Stephen Noel 2012 PDR 13

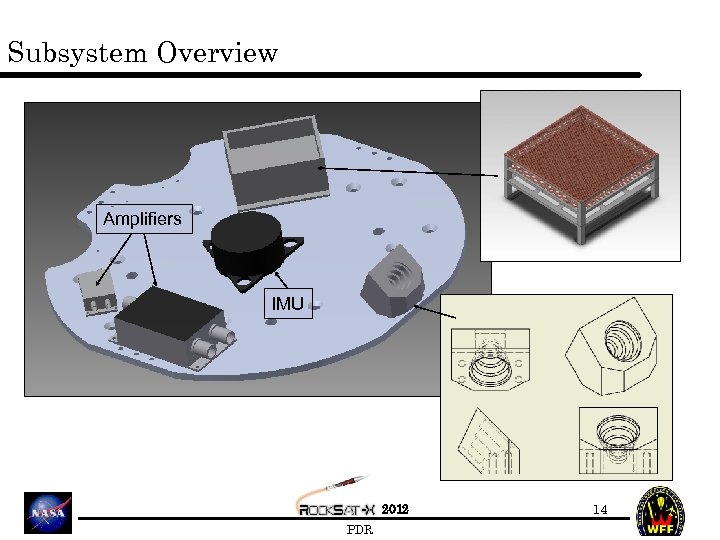

Subsystem Overview Amplifiers IMU 2012 PDR 14

Subsystem Overview Amplifiers IMU 2012 PDR 14

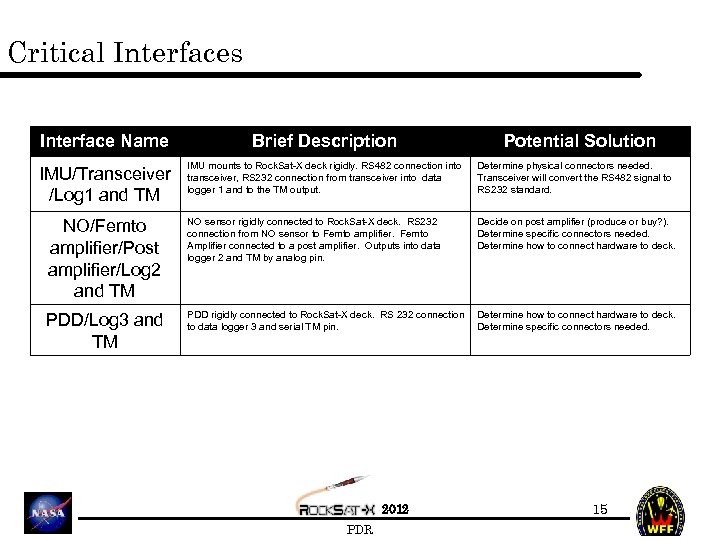

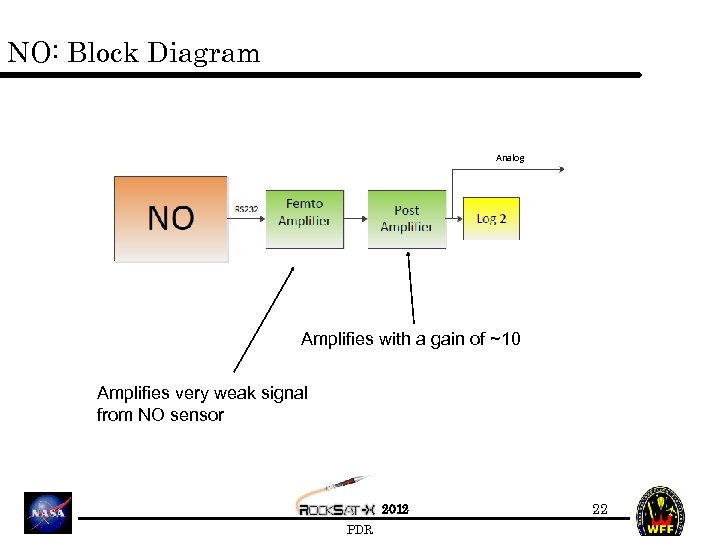

Critical Interfaces Interface Name Brief Description IMU/Transceiver /Log 1 and TM IMU mounts to Rock. Sat-X deck rigidly. RS 482 connection into transceiver, RS 232 connection from transceiver into data logger 1 and to the TM output. Determine physical connectors needed. Transceiver will convert the RS 482 signal to RS 232 standard. NO/Femto amplifier/Post amplifier/Log 2 and TM NO sensor rigidly connected to Rock. Sat-X deck. RS 232 connection from NO sensor to Femto amplifier. Femto Amplifier connected to a post amplifier. Outputs into data logger 2 and TM by analog pin. Decide on post amplifier (produce or buy? ). Determine specific connectors needed. Determine how to connect hardware to deck. PDD/Log 3 and TM PDD rigidly connected to Rock. Sat-X deck. RS 232 connection to data logger 3 and serial TM pin. Determine how to connect hardware to deck. Determine specific connectors needed. 2012 PDR Potential Solution 15

Critical Interfaces Interface Name Brief Description IMU/Transceiver /Log 1 and TM IMU mounts to Rock. Sat-X deck rigidly. RS 482 connection into transceiver, RS 232 connection from transceiver into data logger 1 and to the TM output. Determine physical connectors needed. Transceiver will convert the RS 482 signal to RS 232 standard. NO/Femto amplifier/Post amplifier/Log 2 and TM NO sensor rigidly connected to Rock. Sat-X deck. RS 232 connection from NO sensor to Femto amplifier. Femto Amplifier connected to a post amplifier. Outputs into data logger 2 and TM by analog pin. Decide on post amplifier (produce or buy? ). Determine specific connectors needed. Determine how to connect hardware to deck. PDD/Log 3 and TM PDD rigidly connected to Rock. Sat-X deck. RS 232 connection to data logger 3 and serial TM pin. Determine how to connect hardware to deck. Determine specific connectors needed. 2012 PDR Potential Solution 15

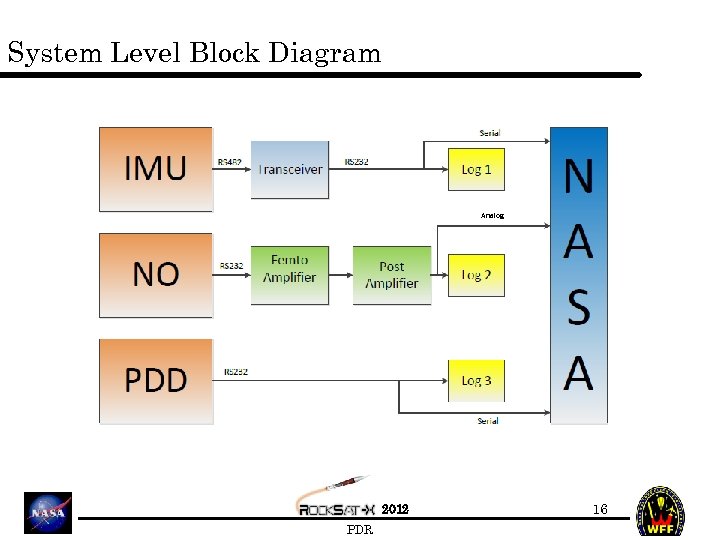

System Level Block Diagram Analog 2012 PDR 16

System Level Block Diagram Analog 2012 PDR 16

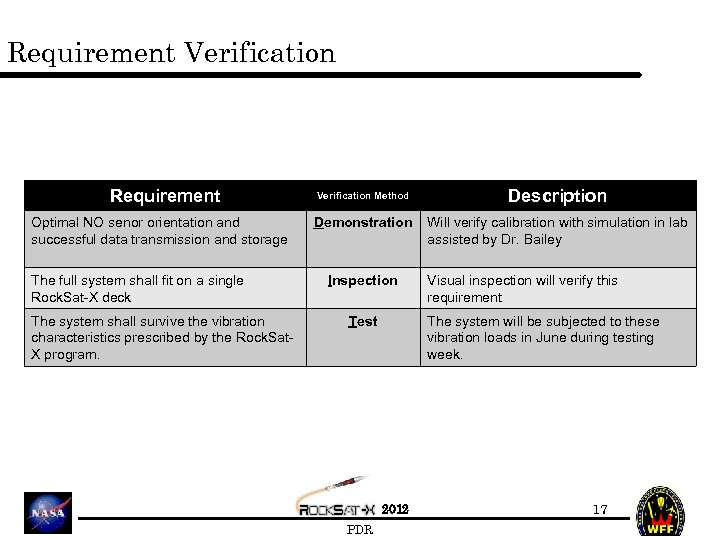

Requirement Verification Requirement Optimal NO senor orientation and successful data transmission and storage The full system shall fit on a single Rock. Sat-X deck The system shall survive the vibration characteristics prescribed by the Rock. Sat. X program. Verification Method Description Demonstration Will verify calibration with simulation in lab assisted by Dr. Bailey Inspection Test The system will be subjected to these vibration loads in June during testing week. 2012 PDR Visual inspection will verify this requirement 17

Requirement Verification Requirement Optimal NO senor orientation and successful data transmission and storage The full system shall fit on a single Rock. Sat-X deck The system shall survive the vibration characteristics prescribed by the Rock. Sat. X program. Verification Method Description Demonstration Will verify calibration with simulation in lab assisted by Dr. Bailey Inspection Test The system will be subjected to these vibration loads in June during testing week. 2012 PDR Visual inspection will verify this requirement 17

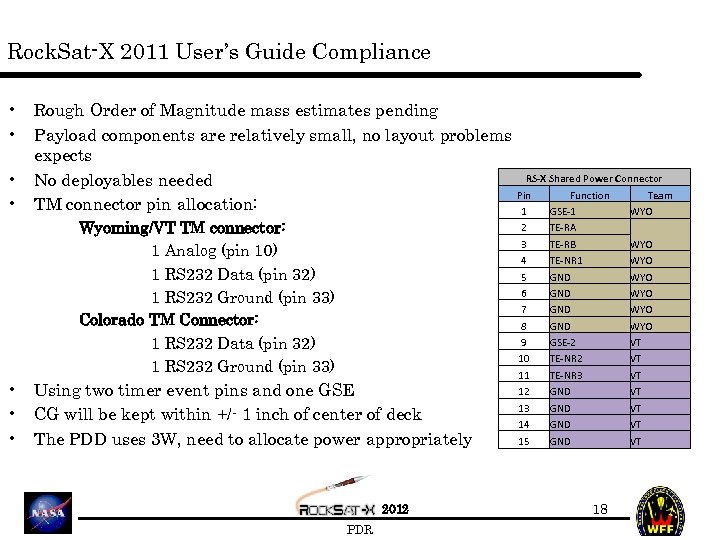

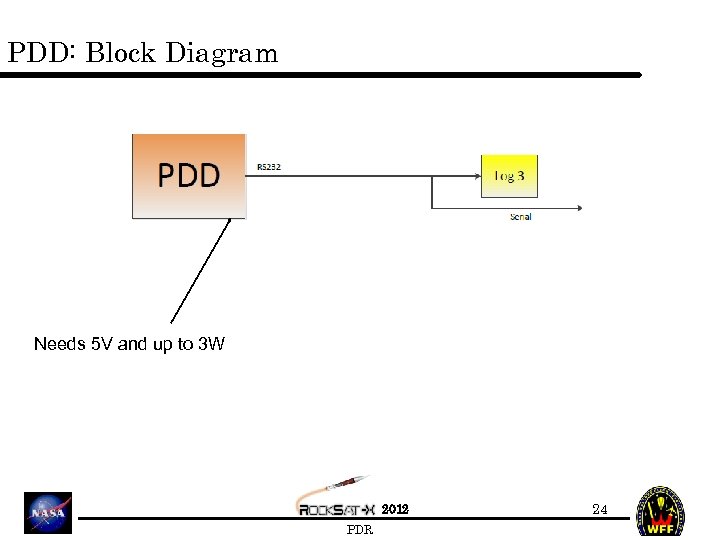

Rock. Sat-X 2011 User’s Guide Compliance • Rough Order of Magnitude mass estimates pending • Payload components are relatively small, no layout problems expects RS-X Shared Power Connector • No deployables needed Pin Function Team • TM connector pin allocation: 1 GSE-1 WYO Wyoming/VT TM connector: 1 Analog (pin 10) 1 RS 232 Data (pin 32) 1 RS 232 Ground (pin 33) Colorado TM Connector: 1 RS 232 Data (pin 32) 1 RS 232 Ground (pin 33) • Using two timer event pins and one GSE • CG will be kept within +/- 1 inch of center of deck • The PDD uses 3 W, need to allocate power appropriately 2012 PDR 2 3 4 5 6 7 8 9 10 11 12 13 14 TE-RA TE-RB TE-NR 1 GND GND GSE-2 TE-NR 3 GND GND WYO WYO WYO VT VT VT 15 GND VT 18

Rock. Sat-X 2011 User’s Guide Compliance • Rough Order of Magnitude mass estimates pending • Payload components are relatively small, no layout problems expects RS-X Shared Power Connector • No deployables needed Pin Function Team • TM connector pin allocation: 1 GSE-1 WYO Wyoming/VT TM connector: 1 Analog (pin 10) 1 RS 232 Data (pin 32) 1 RS 232 Ground (pin 33) Colorado TM Connector: 1 RS 232 Data (pin 32) 1 RS 232 Ground (pin 33) • Using two timer event pins and one GSE • CG will be kept within +/- 1 inch of center of deck • The PDD uses 3 W, need to allocate power appropriately 2012 PDR 2 3 4 5 6 7 8 9 10 11 12 13 14 TE-RA TE-RB TE-NR 1 GND GND GSE-2 TE-NR 3 GND GND WYO WYO WYO VT VT VT 15 GND VT 18

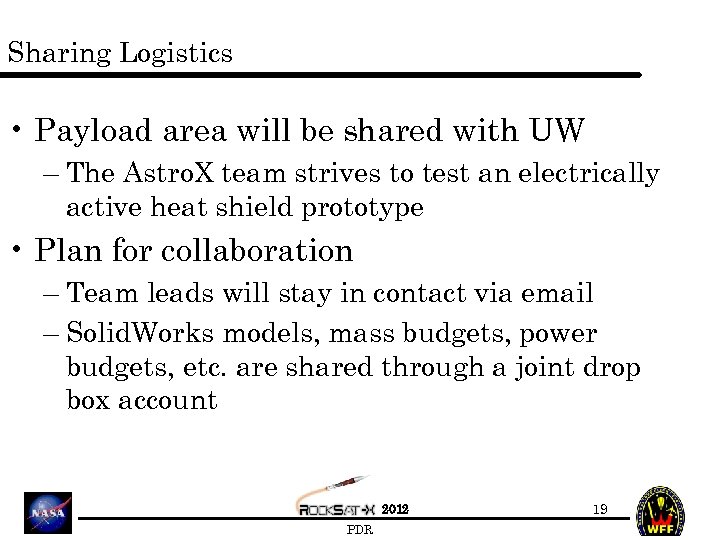

Sharing Logistics • Payload area will be shared with UW – The Astro. X team strives to test an electrically active heat shield prototype • Plan for collaboration – Team leads will stay in contact via email – Solid. Works models, mass budgets, power budgets, etc. are shared through a joint drop box account 2012 PDR 19

Sharing Logistics • Payload area will be shared with UW – The Astro. X team strives to test an electrically active heat shield prototype • Plan for collaboration – Team leads will stay in contact via email – Solid. Works models, mass budgets, power budgets, etc. are shared through a joint drop box account 2012 PDR 19

Subsystem Design Stephen Noel 2012 PDR 20

Subsystem Design Stephen Noel 2012 PDR 20

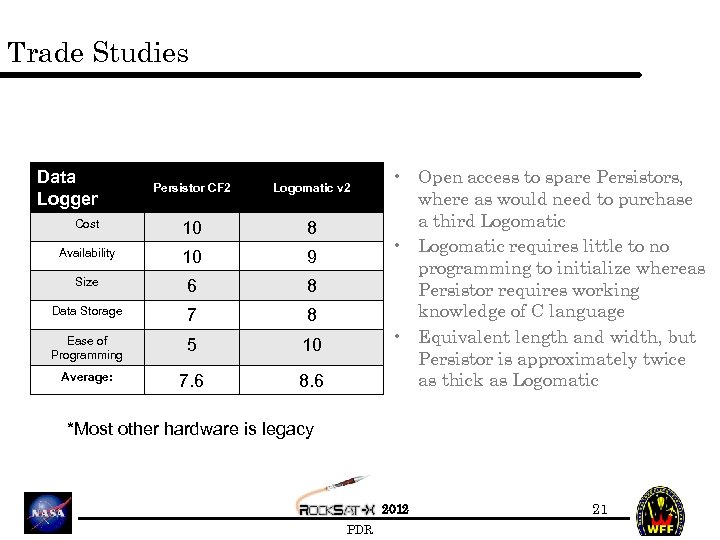

Trade Studies Data Logger Persistor CF 2 Logomatic v 2 Cost 10 8 Availability 10 9 Size 6 8 Data Storage 7 8 Ease of Programming 5 10 Average: 7. 6 8. 6 • Open access to spare Persistors, where as would need to purchase a third Logomatic • Logomatic requires little to no programming to initialize whereas Persistor requires working knowledge of C language • Equivalent length and width, but Persistor is approximately twice as thick as Logomatic *Most other hardware is legacy 2012 PDR 21

Trade Studies Data Logger Persistor CF 2 Logomatic v 2 Cost 10 8 Availability 10 9 Size 6 8 Data Storage 7 8 Ease of Programming 5 10 Average: 7. 6 8. 6 • Open access to spare Persistors, where as would need to purchase a third Logomatic • Logomatic requires little to no programming to initialize whereas Persistor requires working knowledge of C language • Equivalent length and width, but Persistor is approximately twice as thick as Logomatic *Most other hardware is legacy 2012 PDR 21

NO: Block Diagram Analog Amplifies with a gain of ~10 Amplifies very weak signal from NO sensor 2012 PDR 22

NO: Block Diagram Analog Amplifies with a gain of ~10 Amplifies very weak signal from NO sensor 2012 PDR 22

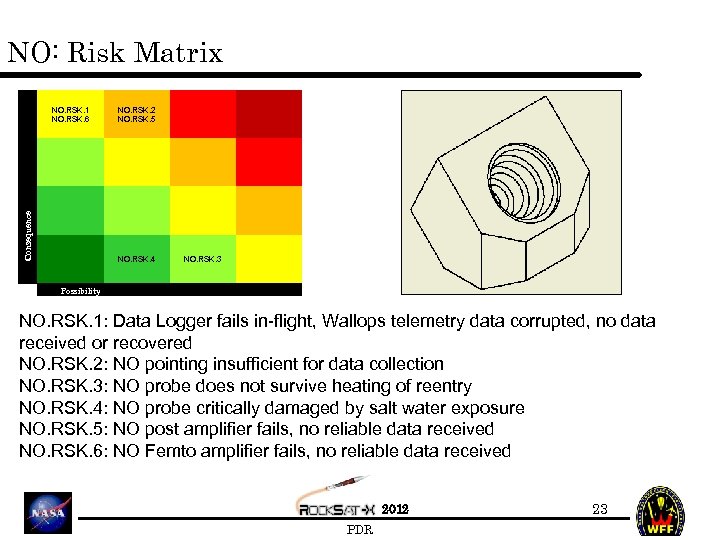

NO: Risk Matrix Consequence NO. RSK. 1 NO. RSK. 6 NO. RSK. 2 NO. RSK. 5 NO. RSK. 4 NO. RSK. 3 Possibility NO. RSK. 1: Data Logger fails in-flight, Wallops telemetry data corrupted, no data received or recovered NO. RSK. 2: NO pointing insufficient for data collection NO. RSK. 3: NO probe does not survive heating of reentry NO. RSK. 4: NO probe critically damaged by salt water exposure NO. RSK. 5: NO post amplifier fails, no reliable data received NO. RSK. 6: NO Femto amplifier fails, no reliable data received 2012 PDR 23

NO: Risk Matrix Consequence NO. RSK. 1 NO. RSK. 6 NO. RSK. 2 NO. RSK. 5 NO. RSK. 4 NO. RSK. 3 Possibility NO. RSK. 1: Data Logger fails in-flight, Wallops telemetry data corrupted, no data received or recovered NO. RSK. 2: NO pointing insufficient for data collection NO. RSK. 3: NO probe does not survive heating of reentry NO. RSK. 4: NO probe critically damaged by salt water exposure NO. RSK. 5: NO post amplifier fails, no reliable data received NO. RSK. 6: NO Femto amplifier fails, no reliable data received 2012 PDR 23

PDD: Block Diagram Needs 5 V and up to 3 W 2012 PDR 24

PDD: Block Diagram Needs 5 V and up to 3 W 2012 PDR 24

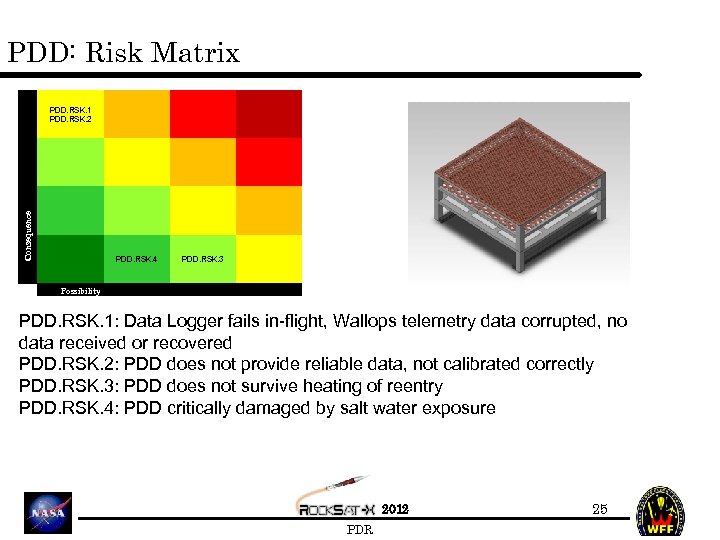

PDD: Risk Matrix Consequence PDD. RSK. 1 PDD. RSK. 2 PDD. RSK. 4 PDD. RSK. 3 Possibility PDD. RSK. 1: Data Logger fails in-flight, Wallops telemetry data corrupted, no data received or recovered PDD. RSK. 2: PDD does not provide reliable data, not calibrated correctly PDD. RSK. 3: PDD does not survive heating of reentry PDD. RSK. 4: PDD critically damaged by salt water exposure 2012 PDR 25

PDD: Risk Matrix Consequence PDD. RSK. 1 PDD. RSK. 2 PDD. RSK. 4 PDD. RSK. 3 Possibility PDD. RSK. 1: Data Logger fails in-flight, Wallops telemetry data corrupted, no data received or recovered PDD. RSK. 2: PDD does not provide reliable data, not calibrated correctly PDD. RSK. 3: PDD does not survive heating of reentry PDD. RSK. 4: PDD critically damaged by salt water exposure 2012 PDR 25

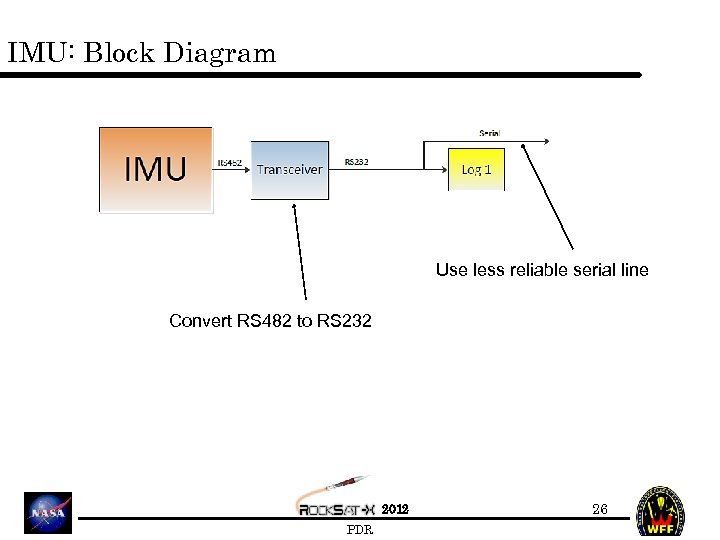

IMU: Block Diagram Use less reliable serial line Convert RS 482 to RS 232 2012 PDR 26

IMU: Block Diagram Use less reliable serial line Convert RS 482 to RS 232 2012 PDR 26

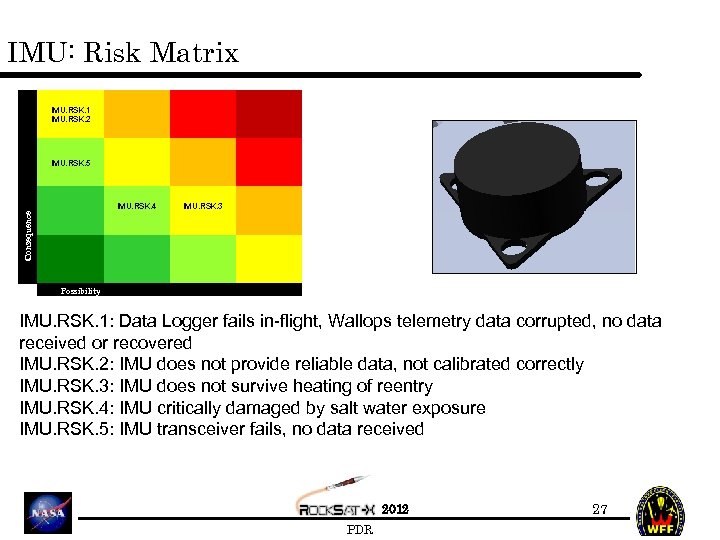

IMU: Risk Matrix IMU. RSK. 1 IMU. RSK. 2 IMU. RSK. 5 Consequence IMU. RSK. 4 IMU. RSK. 3 Possibility IMU. RSK. 1: Data Logger fails in-flight, Wallops telemetry data corrupted, no data received or recovered IMU. RSK. 2: IMU does not provide reliable data, not calibrated correctly IMU. RSK. 3: IMU does not survive heating of reentry IMU. RSK. 4: IMU critically damaged by salt water exposure IMU. RSK. 5: IMU transceiver fails, no data received 2012 PDR 27

IMU: Risk Matrix IMU. RSK. 1 IMU. RSK. 2 IMU. RSK. 5 Consequence IMU. RSK. 4 IMU. RSK. 3 Possibility IMU. RSK. 1: Data Logger fails in-flight, Wallops telemetry data corrupted, no data received or recovered IMU. RSK. 2: IMU does not provide reliable data, not calibrated correctly IMU. RSK. 3: IMU does not survive heating of reentry IMU. RSK. 4: IMU critically damaged by salt water exposure IMU. RSK. 5: IMU transceiver fails, no data received 2012 PDR 27

Prototyping Plan Stephen Noel 2012 PDR 28

Prototyping Plan Stephen Noel 2012 PDR 28

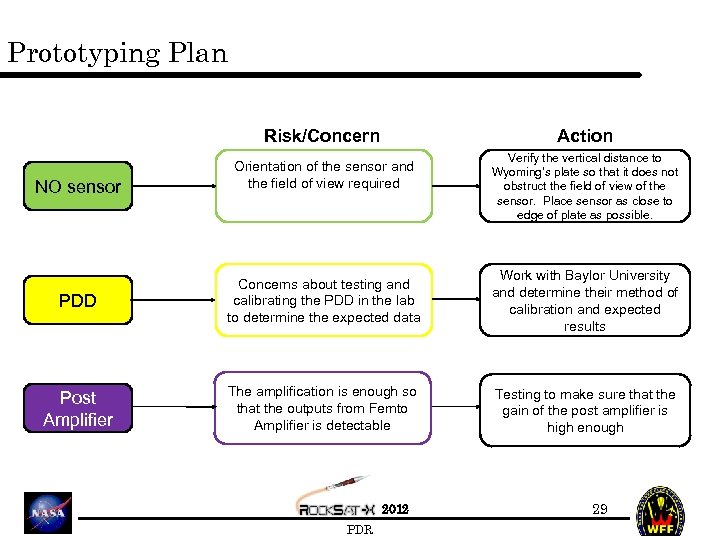

Prototyping Plan Risk/Concern NO sensor Action Orientation of the sensor and the field of view required Verify the vertical distance to Wyoming’s plate so that it does not obstruct the field of view of the sensor. Place sensor as close to edge of plate as possible. PDD Concerns about testing and calibrating the PDD in the lab to determine the expected data Work with Baylor University and determine their method of calibration and expected results Post Amplifier The amplification is enough so that the outputs from Femto Amplifier is detectable Testing to make sure that the gain of the post amplifier is high enough 2012 PDR 29

Prototyping Plan Risk/Concern NO sensor Action Orientation of the sensor and the field of view required Verify the vertical distance to Wyoming’s plate so that it does not obstruct the field of view of the sensor. Place sensor as close to edge of plate as possible. PDD Concerns about testing and calibrating the PDD in the lab to determine the expected data Work with Baylor University and determine their method of calibration and expected results Post Amplifier The amplification is enough so that the outputs from Femto Amplifier is detectable Testing to make sure that the gain of the post amplifier is high enough 2012 PDR 29

Project Management Plan Stephen Noel 2012 PDR 30

Project Management Plan Stephen Noel 2012 PDR 30

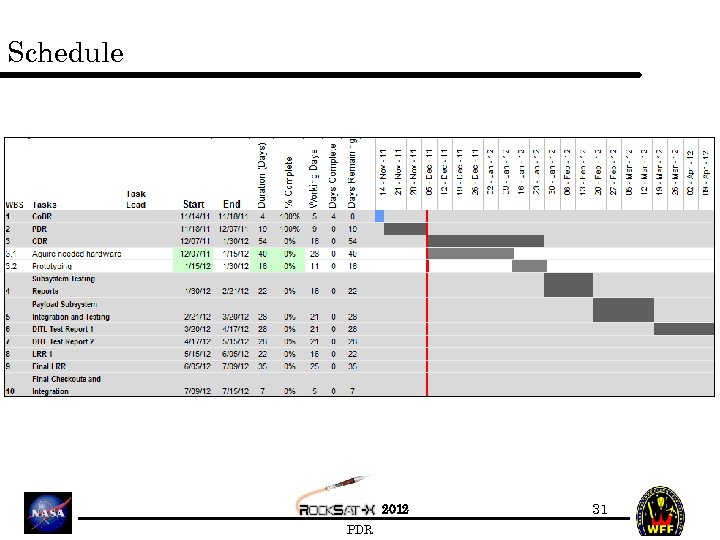

Schedule 2012 PDR 31

Schedule 2012 PDR 31

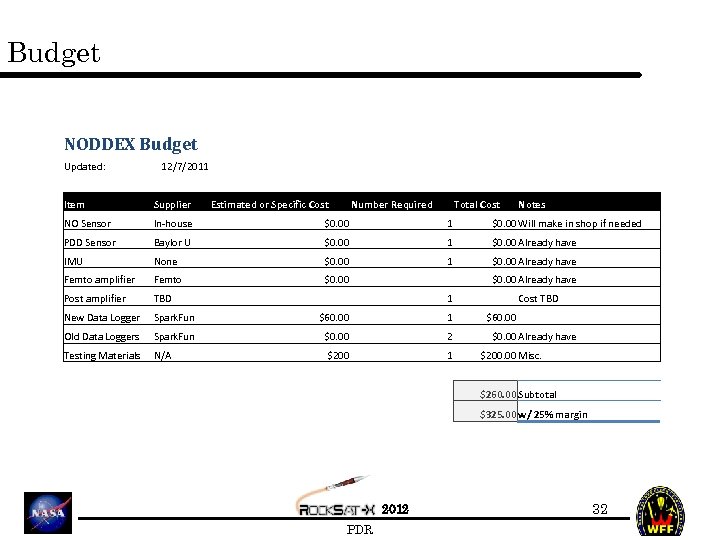

Budget NODDEX Budget Updated: 12/7/2011 Item Supplier Estimated or Specific Cost Number Required Total Cost Notes NO Sensor In-house $0. 00 1 $0. 00 Will make in shop if needed PDD Sensor Baylor U $0. 00 1 $0. 00 Already have IMU None $0. 00 1 $0. 00 Already have Femto amplifier Femto $0. 00 Post amplifier TBD New Data Logger Spark. Fun $60. 00 1 Old Data Loggers Spark. Fun $0. 00 2 Testing Materials N/A $200 1 $0. 00 Already have 1 Cost TBD $60. 00 $0. 00 Already have $200. 00 Misc. $260. 00 Subtotal $325. 00 w/ 25% margin 2012 PDR 32

Budget NODDEX Budget Updated: 12/7/2011 Item Supplier Estimated or Specific Cost Number Required Total Cost Notes NO Sensor In-house $0. 00 1 $0. 00 Will make in shop if needed PDD Sensor Baylor U $0. 00 1 $0. 00 Already have IMU None $0. 00 1 $0. 00 Already have Femto amplifier Femto $0. 00 Post amplifier TBD New Data Logger Spark. Fun $60. 00 1 Old Data Loggers Spark. Fun $0. 00 2 Testing Materials N/A $200 1 $0. 00 Already have 1 Cost TBD $60. 00 $0. 00 Already have $200. 00 Misc. $260. 00 Subtotal $325. 00 w/ 25% margin 2012 PDR 32

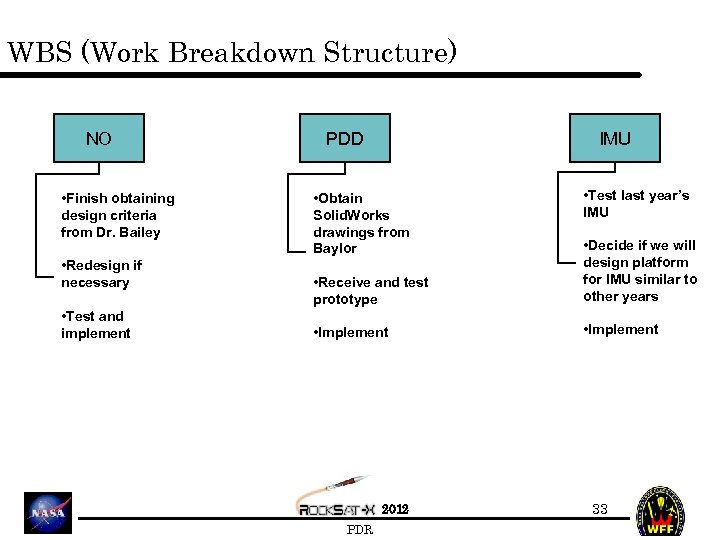

WBS (Work Breakdown Structure) NO • Finish obtaining design criteria from Dr. Bailey • Redesign if necessary • Test and implement PDD IMU • Obtain Solid. Works drawings from Baylor • Test last year’s IMU • Receive and test prototype • Decide if we will design platform for IMU similar to other years • Implement 2012 PDR 33

WBS (Work Breakdown Structure) NO • Finish obtaining design criteria from Dr. Bailey • Redesign if necessary • Test and implement PDD IMU • Obtain Solid. Works drawings from Baylor • Test last year’s IMU • Receive and test prototype • Decide if we will design platform for IMU similar to other years • Implement 2012 PDR 33

Conclusion Questions? 2012 PDR 34

Conclusion Questions? 2012 PDR 34