04e703870b59b279bfb5d0a32e792f32.ppt

- Количество слайдов: 38

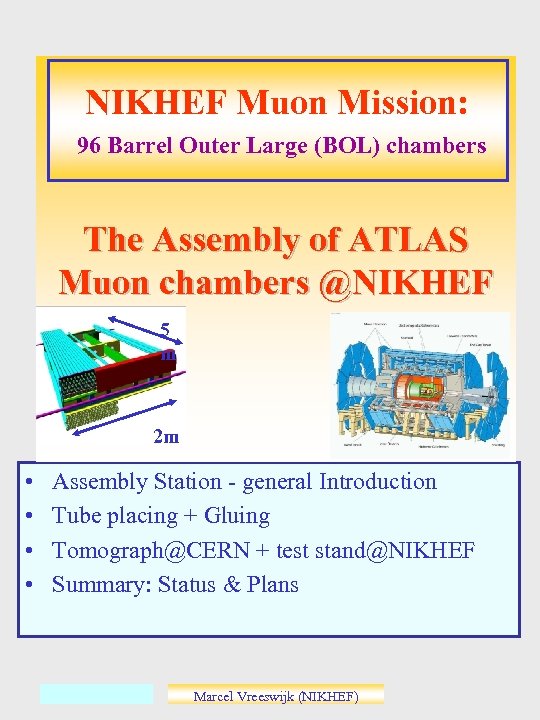

NIKHEF Muon Mission: 96 Barrel Outer Large (BOL) chambers The Assembly of ATLAS Muon chambers @NIKHEF 5 m 2 m • • Assembly Station - general Introduction Tube placing + Gluing Tomograph@CERN + test stand@NIKHEF Summary: Status & Plans Marcel Vreeswijk (NIKHEF)

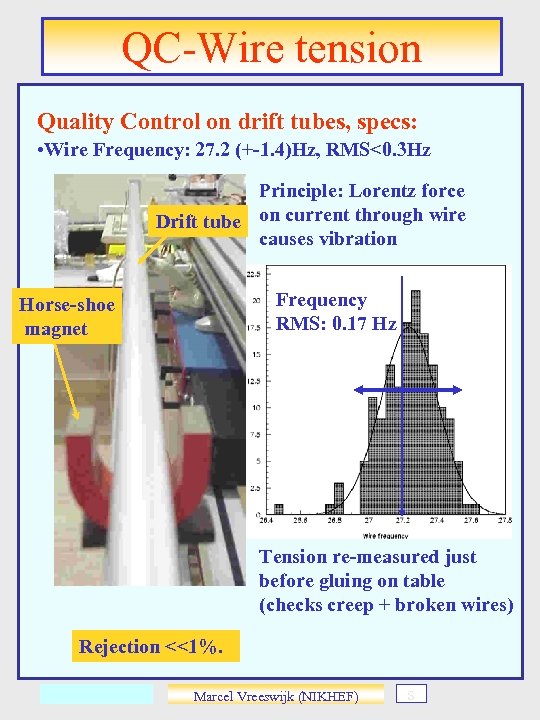

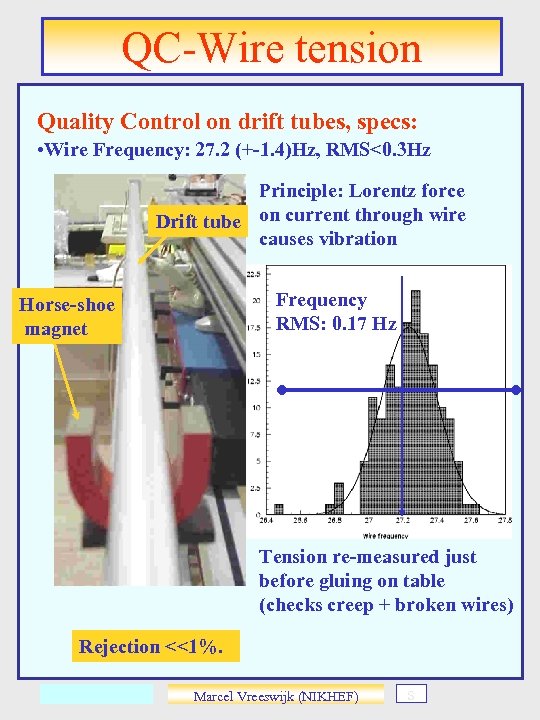

QC-Wire tension Quality Control on drift tubes, specs: • Wire Frequency: 27. 2 (+-1. 4)Hz, RMS<0. 3 Hz Principle: Lorentz force Drift tube on current through wire causes vibration Frequency RMS: 0. 17 Hz Horse-shoe magnet Tension re-measured just before gluing on table (checks creep + broken wires) Rejection <<1%. Marcel Vreeswijk (NIKHEF) s

Tube wiring + QC • Drift tubes: • Extruded aluminum drift tubes (3 cm) • Wire (50 mm gold-plated tungsten) positioned by two end-plugs Endplug QC on drift tubes, specs: • Wire position: |Z, Y|<25 mm • Wire tension=> frequency 27. 2+-1. 4 Hz, RMS<0. 3 Hz • Leak rate: <2. 5 10 -8 bl/s • HV check: <20 n. A @3500 V Marcel Vreeswijk (NIKHEF)

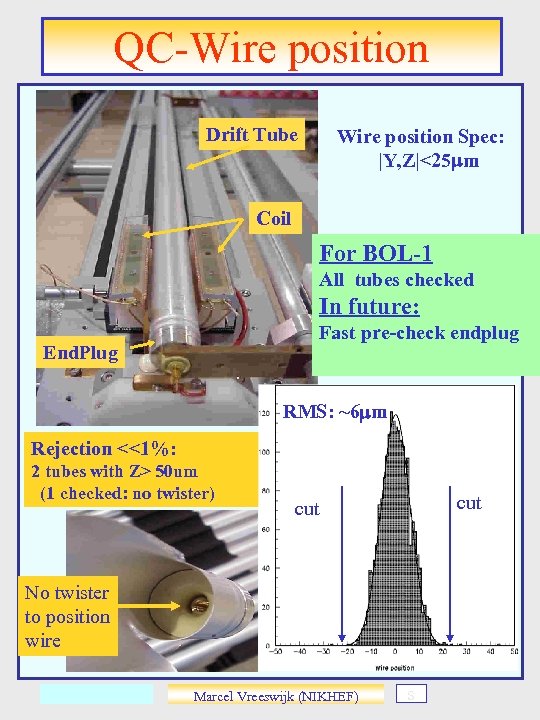

QC-Wire position Drift Tube Wire position Spec: |Y, Z|<25 mm Coil For BOL-1 All tubes checked In future: Fast pre-check endplug End. Plug RMS: ~6 mm Rejection <<1%: 2 tubes with Z> 50 um (1 checked: no twister) cut No twister to position wire Marcel Vreeswijk (NIKHEF) s

QC-Wire tension Quality Control on drift tubes, specs: • Wire Frequency: 27. 2 (+-1. 4)Hz, RMS<0. 3 Hz Principle: Lorentz force Drift tube on current through wire causes vibration Frequency RMS: 0. 17 Hz Horse-shoe magnet Tension re-measured just before gluing on table (checks creep + broken wires) Rejection <<1%. Marcel Vreeswijk (NIKHEF) s

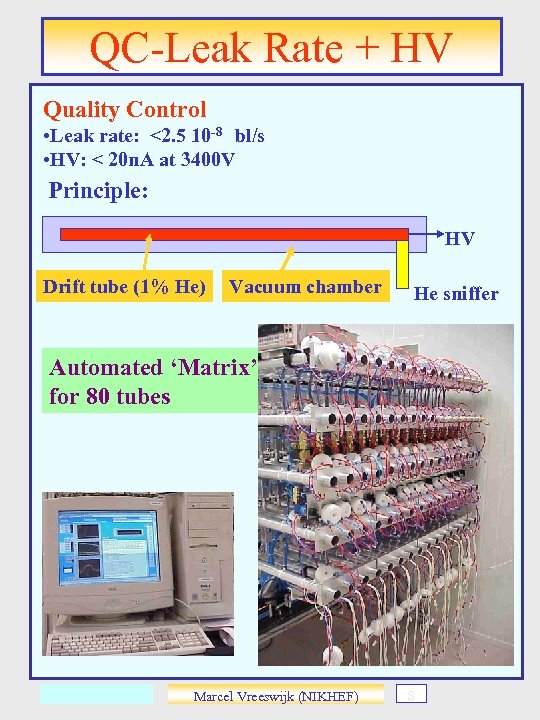

QC-Leak Rate + HV Quality Control • Leak rate: <2. 5 10 -8 bl/s • HV: < 20 n. A at 3400 V Principle: HV Drift tube (1% He) Vacuum chamber He sniffer Automated ‘Matrix’ for 80 tubes Marcel Vreeswijk (NIKHEF) s

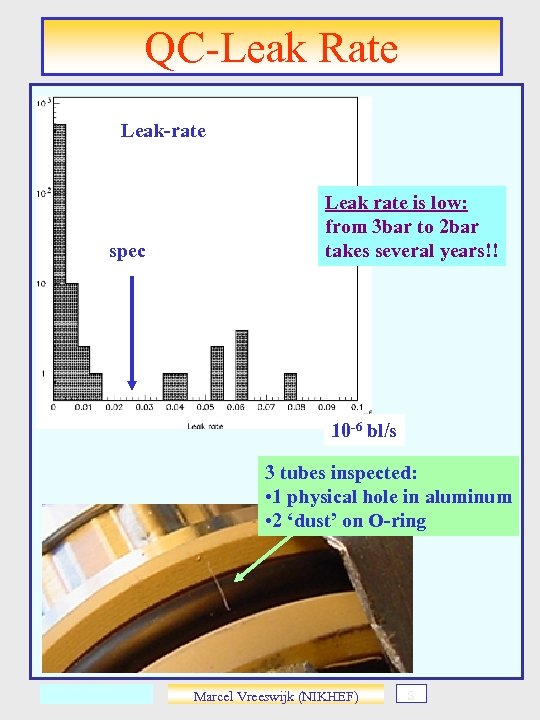

QC-Leak Rate Leak-rate spec Leak rate is low: from 3 bar to 2 bar takes several years!! Rejection 1% (!) 10 -6 bl/s 3 tubes inspected: • 1 physical hole in aluminum • 2 ‘dust’ on O-ring Marcel Vreeswijk (NIKHEF) s

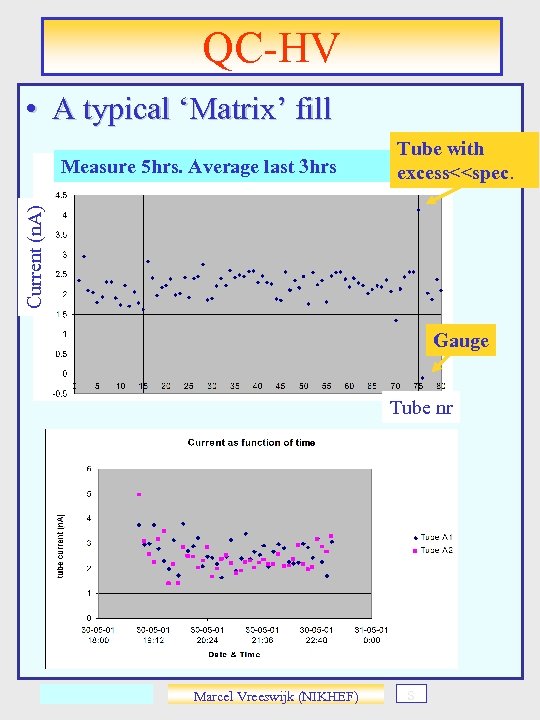

QC-HV • A typical ‘Matrix’ fill Current (n. A) Measure 5 hrs. Average last 3 hrs Tube with excess<<spec. Gauge Tube nr Marcel Vreeswijk (NIKHEF) s

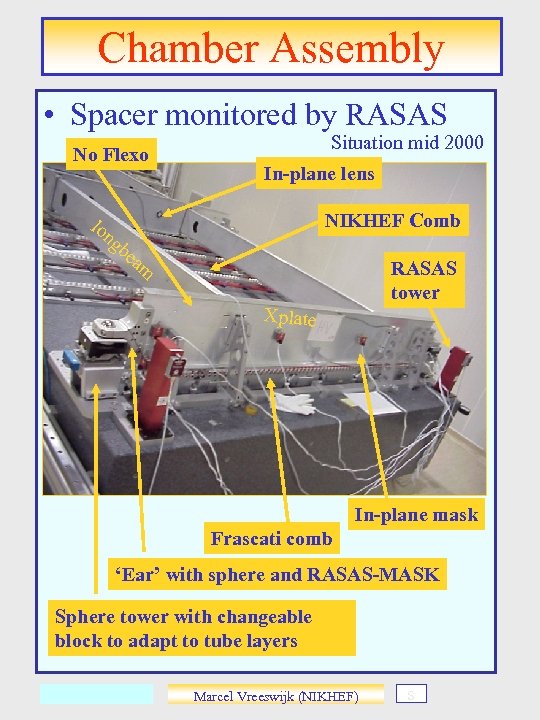

Chamber Assembly • Spacer monitored by RASAS No Flexo lo ng Situation mid 2000 In-plane lens NIKHEF Comb be am RASAS tower Xplate In-plane mask Frascati comb ‘Ear’ with sphere and RASAS-MASK Sphere tower with changeable block to adapt expansion length o 0. 1 m in Xras West side has to tube layers Marcel Vreeswijk (NIKHEF) s

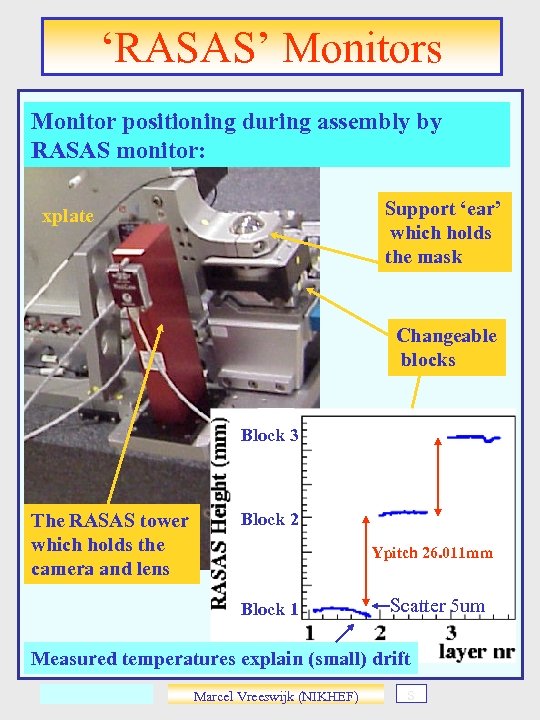

‘RASAS’ Monitors Monitor positioning during assembly by RASAS monitor: Support ‘ear’ which holds the mask xplate Changeable blocks Block 3 The RASAS tower which holds the camera and lens Block 2 Ypitch 26. 011 mm Block 1 Scatter 5 um Measured temperatures explain (small) drift Marcel Vreeswijk (NIKHEF) s

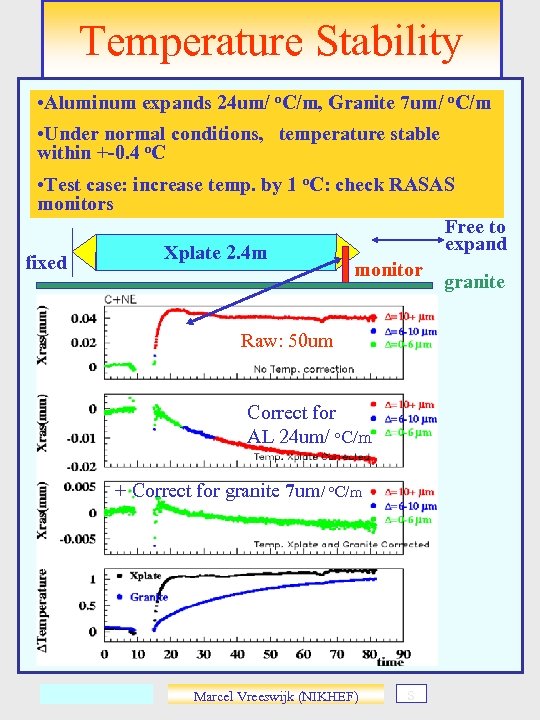

Temperature Stability • Aluminum expands 24 um/ o. C/m, Granite 7 um/ o. C/m • Under normal conditions, temperature stable within +-0. 4 o. C • Test case: increase temp. by 1 o. C: check RASAS monitors Free to expand Xplate 2. 4 m fixed monitor granite Raw: 50 um Correct for AL 24 um/ o. C/m + Correct for granite 7 um/ o. C/m Marcel Vreeswijk (NIKHEF) s

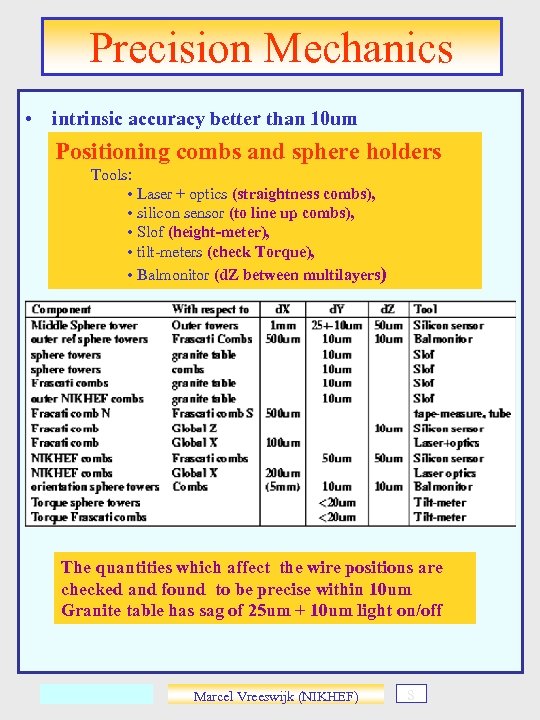

Precision Mechanics • intrinsic accuracy better than 10 um Positioning combs and sphere holders Tools: • Laser + optics (straightness combs), • silicon sensor (to line up combs), • Slof (height-meter), • tilt-meters (check Torque), • Balmonitor (d. Z between multilayers) The quantities which affect the wire positions are checked and found to be precise within 10 um Granite table has sag of 25 um + 10 um light on/off West side has expansion length o 0. 1 m in Xras Marcel Vreeswijk (NIKHEF) s

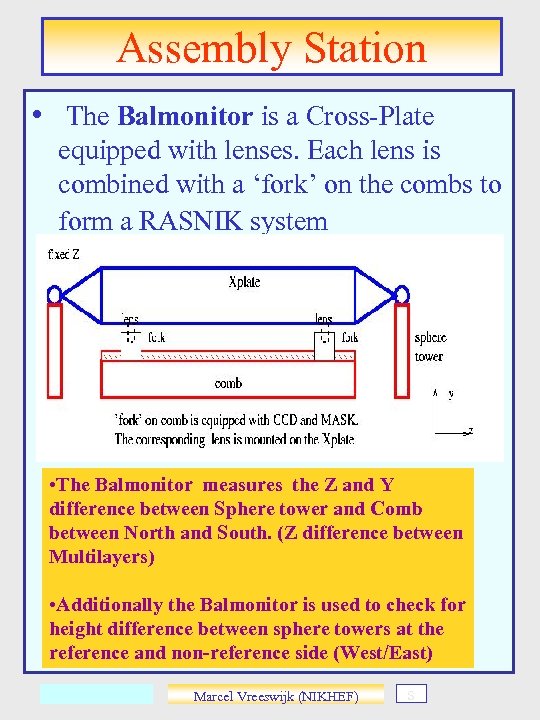

Assembly Station • The Balmonitor is a Cross-Plate equipped with lenses. Each lens is combined with a ‘fork’ on the combs to form a RASNIK system • The Balmonitor measures the Z and Y difference between Sphere tower and Comb between North and South. (Z difference between Multilayers) • Additionally the Balmonitor is used to check for height difference between sphere towers at the West side has expansion length o 0. 1 m in Xras reference and non-reference side (West/East) Marcel Vreeswijk (NIKHEF) s

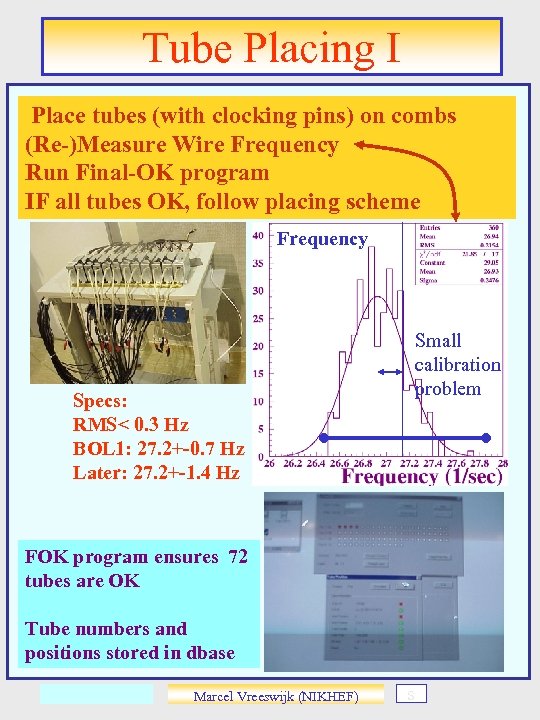

Tube Placing I Place tubes (with clocking pins) on combs (Re-)Measure Wire Frequency Run Final-OK program IF all tubes OK, follow placing scheme Frequency Small calibration problem Specs: RMS< 0. 3 Hz BOL 1: 27. 2+-0. 7 Hz Later: 27. 2+-1. 4 Hz FOK program ensures 72 tubes are OK Tube numbers and positions stored in dbase Marcel Vreeswijk (NIKHEF) s

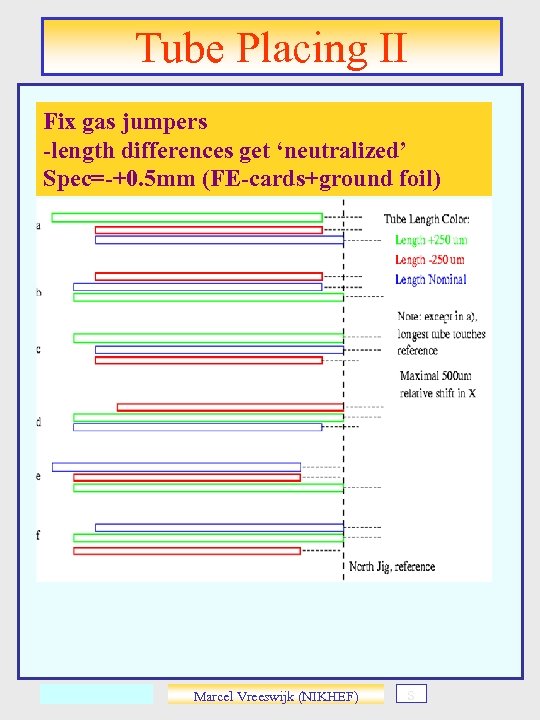

Tube Placing II Fix gas jumpers -length differences get ‘neutralized’ Spec=-+0. 5 mm (FE-cards+ground foil) Marcel Vreeswijk (NIKHEF) s

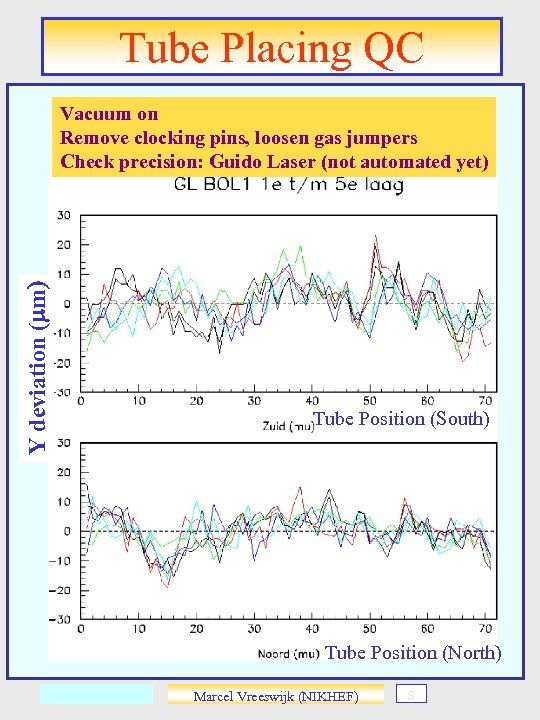

Tube Placing QC Y deviation (mm) Vacuum on Remove clocking pins, loosen gas jumpers Check precision: Guido Laser (not automated yet) Tube Position (South) Tube Position (North) Marcel Vreeswijk (NIKHEF) s

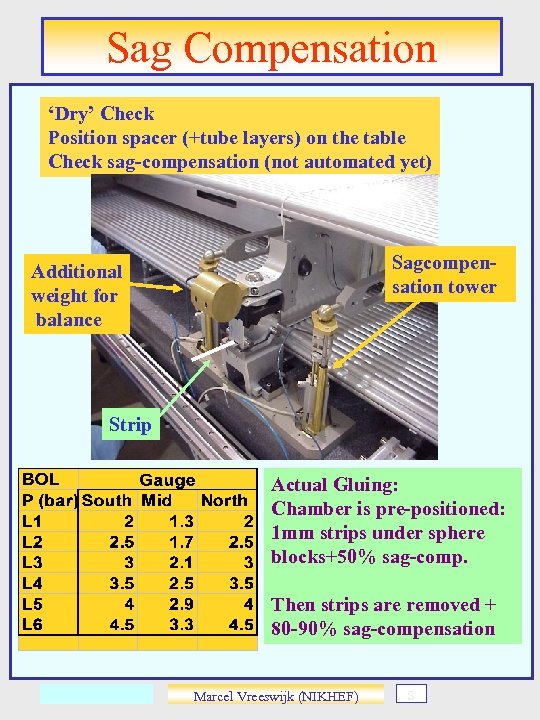

Sag Compensation ‘Dry’ Check Position spacer (+tube layers) on the table Check sag-compensation (not automated yet) Sagcompensation tower Additional weight for balance Strip Actual Gluing: Chamber is pre-positioned: 1 mm strips under sphere blocks+50% sag-comp. Then strips are removed + 80 -90% sag-compensation Marcel Vreeswijk (NIKHEF) s

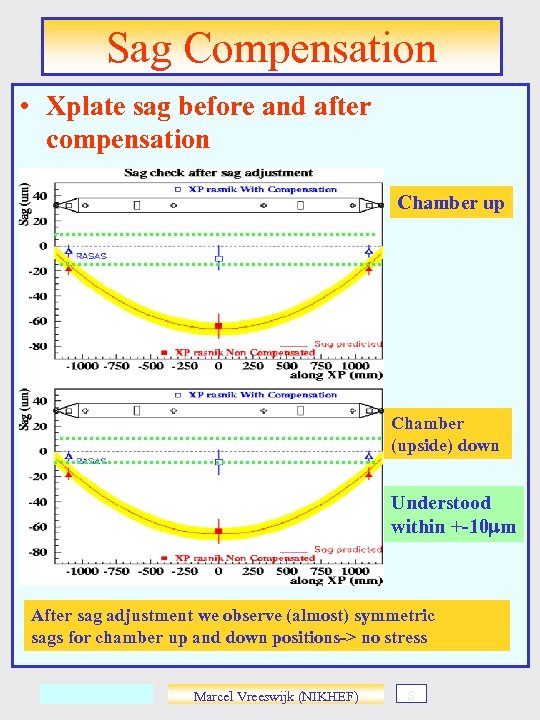

Sag Compensation • Xplate sag before and after compensation Chamber up Chamber (upside) down Understood within +-10 mm After sag adjustment we observe (almost) symmetric sags for chamber up and down positions-> no stress Marcel Vreeswijk (NIKHEF) s

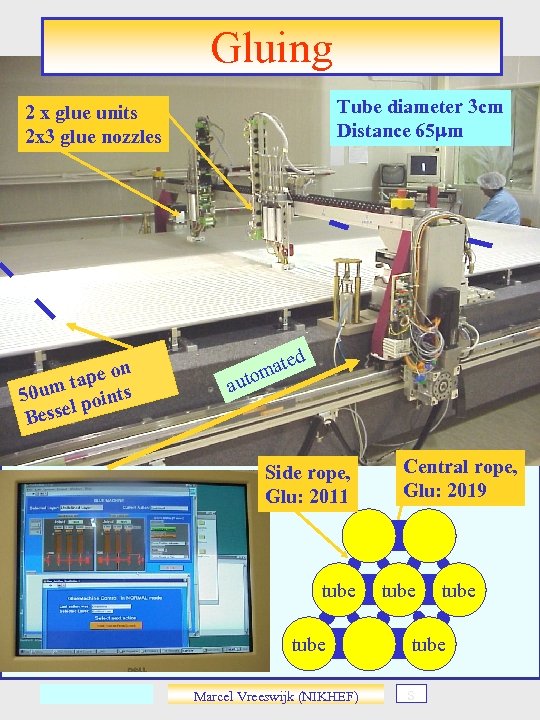

Gluing Tube diameter 3 cm Distance 65 mm 2 x glue units 2 x 3 glue nozzles n ape o t 50 um points l Besse ated om aut Side rope, Glu: 2011 tube Marcel Vreeswijk (NIKHEF) Central rope, Glu: 2019 tube s

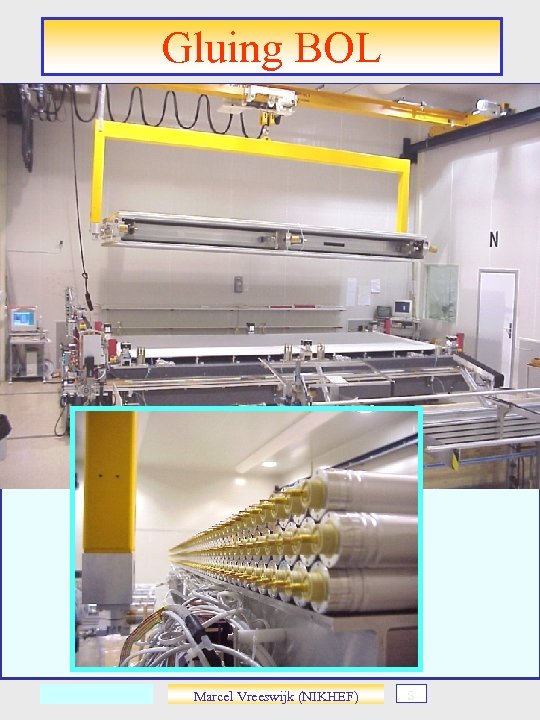

Gluing BOL Marcel Vreeswijk (NIKHEF) s

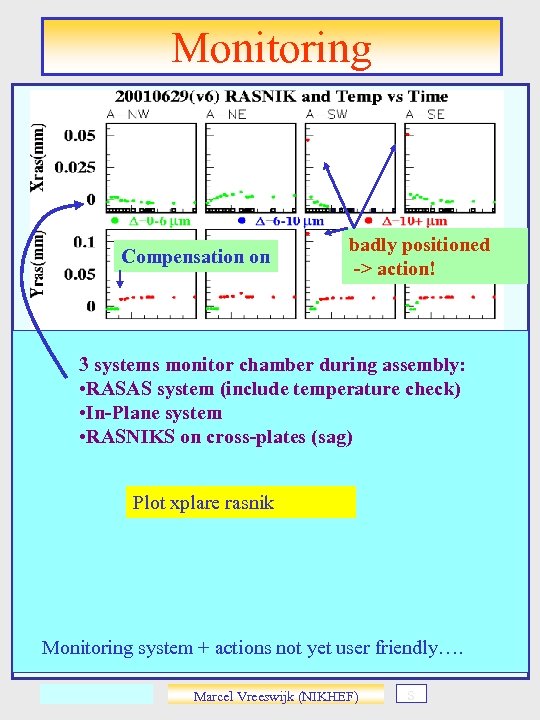

Monitoring Compensation on badly positioned -> action! 3 systems monitor chamber during assembly: • RASAS system (include temperature check) • In-Plane system • RASNIKS on cross-plates (sag) Plot xplare rasnik Monitoring system + actions not yet user friendly…. Marcel Vreeswijk (NIKHEF) s

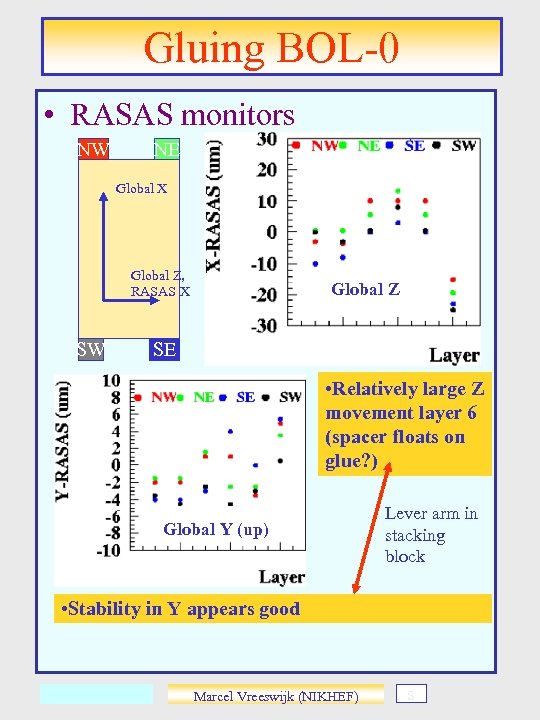

Gluing BOL-0 • RASAS monitors NW NE Global X Global Z, RASAS X SW Global Z SE • Relatively large Z movement layer 6 (spacer floats on glue? ) Global Y (up) Lever arm in stacking block • Stability in Y appears good Marcel Vreeswijk (NIKHEF) s

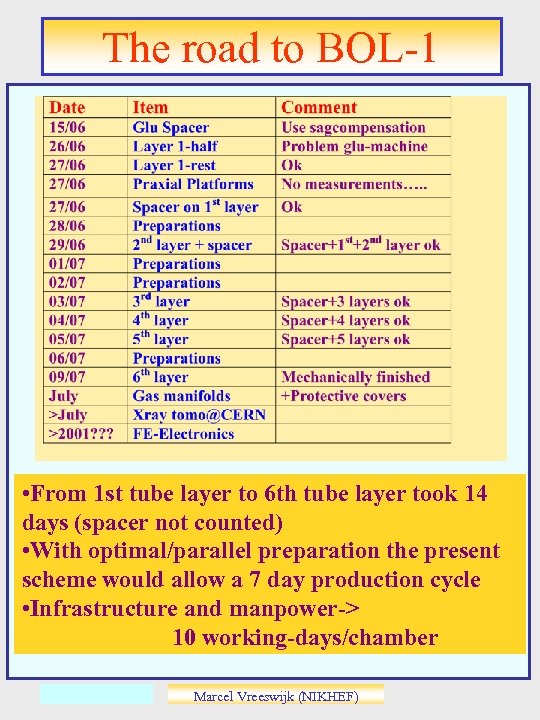

The road to BOL-1 • From 1 st tube layer to 6 th tube layer took 14 days (spacer not counted) • With optimal/parallel preparation the present scheme would allow a 7 day production cycle • Infrastructure and manpower-> 10 working-days/chamber Marcel Vreeswijk (NIKHEF)

Power Outage- BOL 1 Power outage Amsterdam, during curing of layer 5 Chamber immediately covered with foil (sag compensation remained on + vacuum probably ok No indications for damage Marcel Vreeswijk (NIKHEF) s

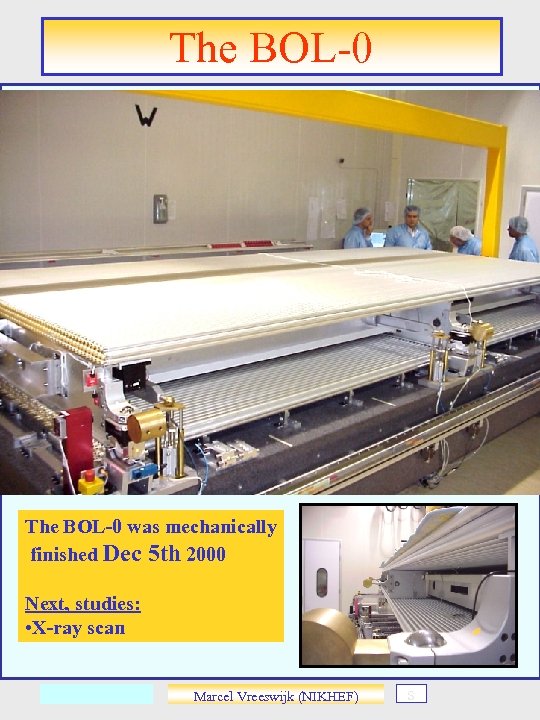

The BOL-0 was mechanically finished Dec 5 th 2000 Next, studies: • X-ray scan Marcel Vreeswijk (NIKHEF) s

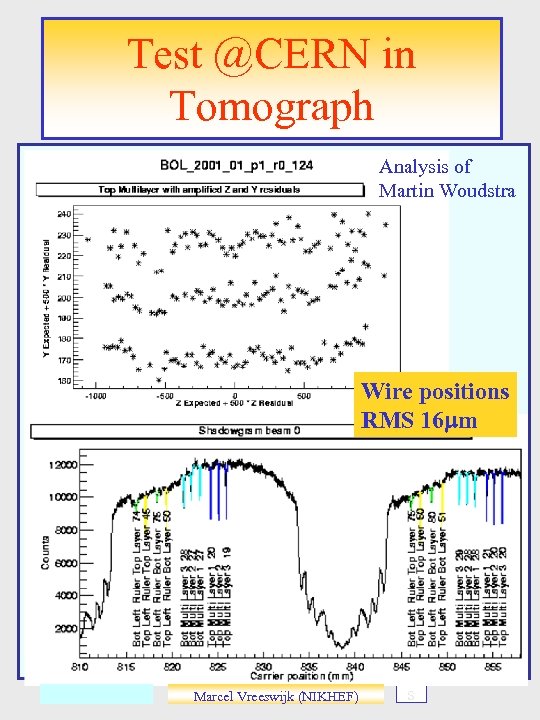

Test @CERN in Tomograph Analysis of Martin Woudstra Wire positions RMS 16 mm Marcel Vreeswijk (NIKHEF) s

Parameters Zpitch wires: 30. 0354 mm (30. 0353 expected) Ypitch wire-planes: 26. 026 mm (26. 011 expected). Especially between two inner layers we have a larger pitch. Inelastic deformation during gluing? d. Y multilayers ~75 mm. Hard to understand. ALL chamber scanned at CERN have deviations in this parameter? ! d. Z multilayers ~12 mm. We expected deviations of this order, based on Balmonitor measurements • Relevant Parameters (goal 20 mm): RO side s=15. 8 mm HV side s=16. 1 mm Marcel Vreeswijk (NIKHEF) s

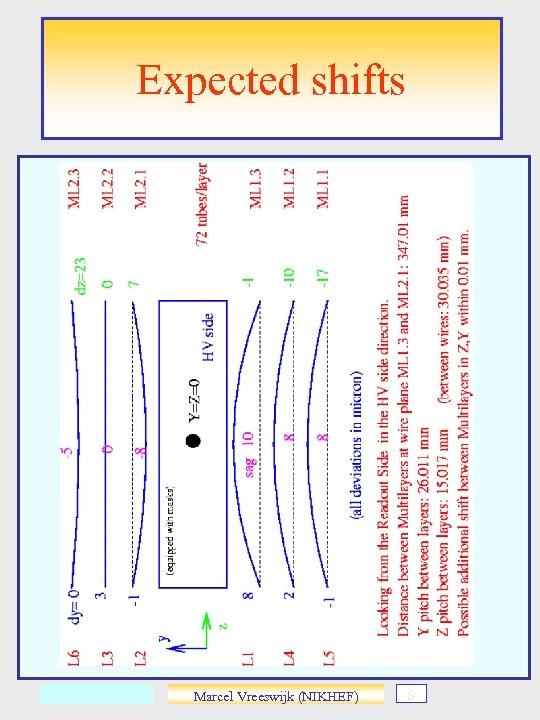

Expected shifts Marcel Vreeswijk (NIKHEF) s

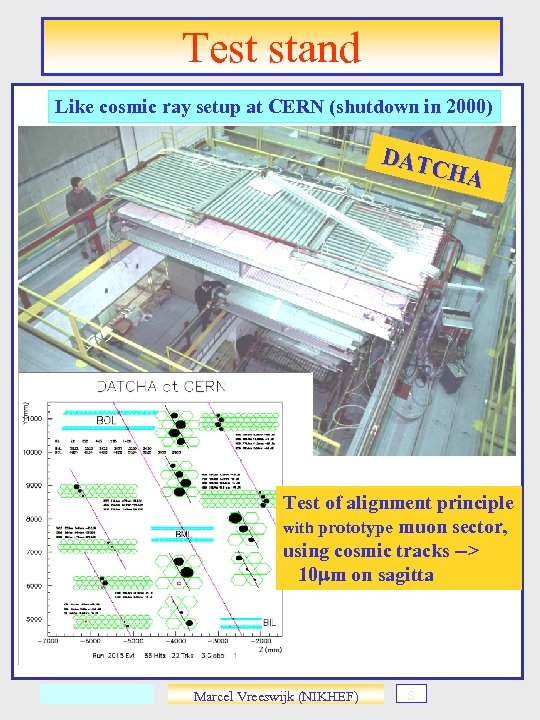

Test stand Like cosmic ray setup at CERN (shutdown in 2000) DAT CHA Test of alignment principle with prototype muon sector, using cosmic tracks --> 10 mm on sagitta Marcel Vreeswijk (NIKHEF) s

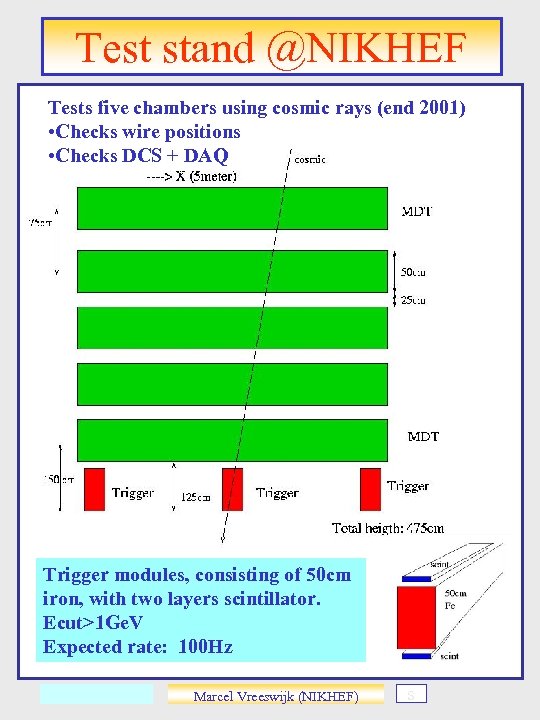

Test stand @NIKHEF Tests five chambers using cosmic rays (end 2001) • Checks wire positions • Checks DCS + DAQ Trigger modules, consisting of 50 cm iron, with two layers scintillator. Ecut>1 Ge. V Expected rate: 100 Hz Marcel Vreeswijk (NIKHEF) s

Status & Plans • Finished BOL-0 at NIKHEF (dec. 5 th 2000) with high mechanical precision (16 mm RMS) • Quality Control Tube Assembly automated • Production of tubes started May 2001 • First chamber, BOL 1, produced! • Automate steps+QC chamber assembly • Cosmic ray setup end 2001…. Marcel Vreeswijk (NIKHEF)

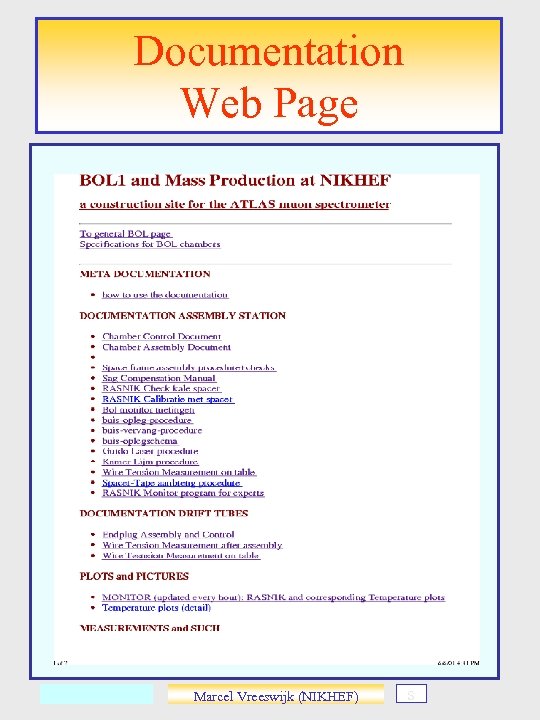

Documentation Web Page Marcel Vreeswijk (NIKHEF) s

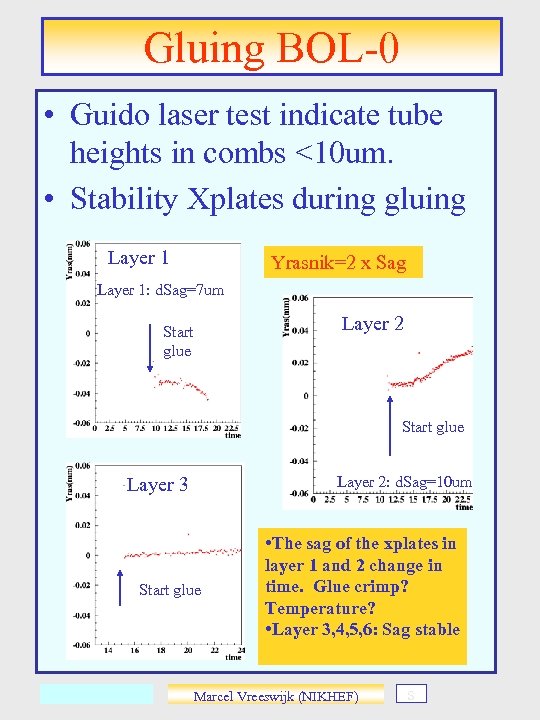

Gluing BOL-0 • Guido laser test indicate tube heights in combs <10 um. • Stability Xplates during gluing Layer 1 Yrasnik=2 x Sag Layer 1: d. Sag=7 um Layer 2 Start glue Layer 2: d. Sag=10 um Layer 3 Start glue • The sag of the xplates in layer 1 and 2 change in time. Glue crimp? Temperature? • Layer 3, 4, 5, 6: Sag stable Marcel Vreeswijk (NIKHEF) s

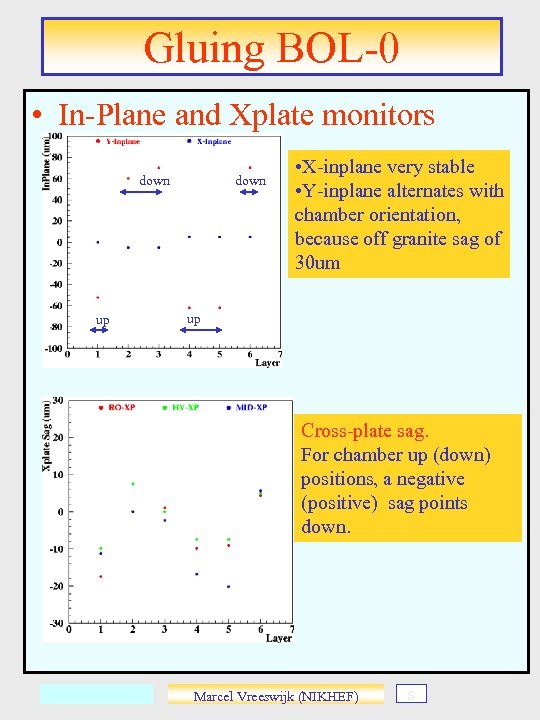

Gluing BOL-0 • In-Plane and Xplate monitors down up down • X-inplane very stable • Y-inplane alternates with chamber orientation, because off granite sag of 30 um up Cross-plate sag. For chamber up (down) positions, a negative (positive) sag points down. Marcel Vreeswijk (NIKHEF) s

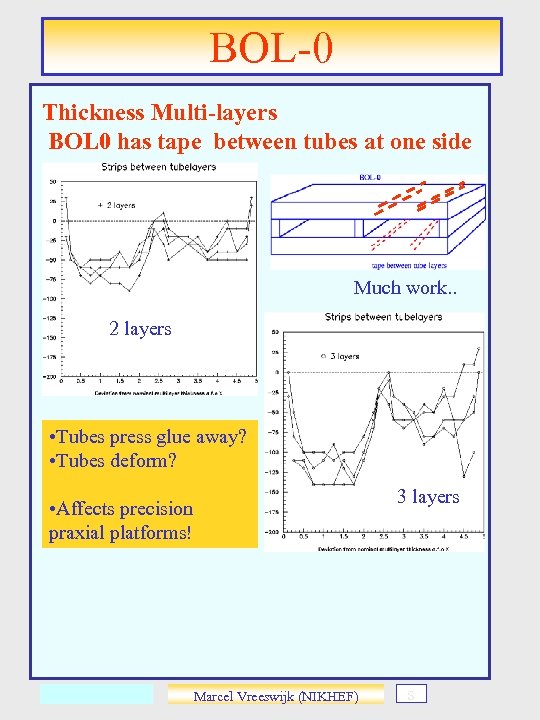

BOL-0 Thickness Multi-layers BOL 0 has tape between tubes at one side Much work. . 2 layers • Tubes press glue away? • Tubes deform? 3 layers • Affects precision praxial platforms! Marcel Vreeswijk (NIKHEF) s

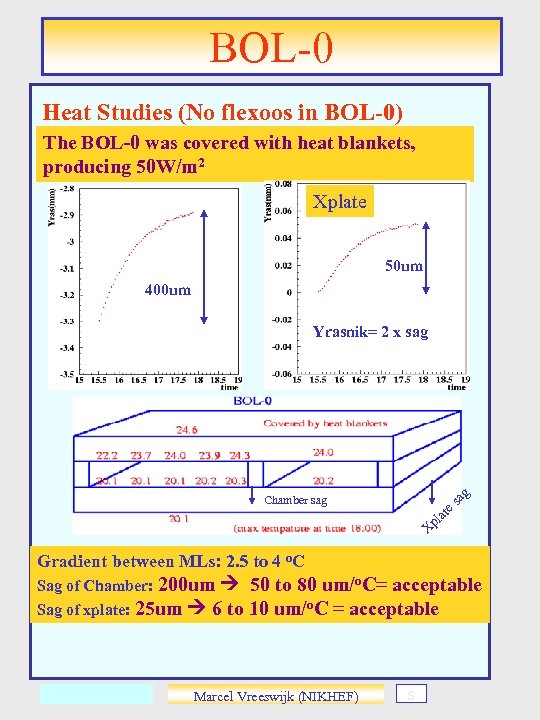

BOL-0 Heat Studies (No flexoos in BOL-0) The BOL-0 was covered with heat blankets, producing 50 W/m 2 Xplate Inplane 50 um 400 um Yrasnik= 2 x sag g Chamber sag at pl X a es Gradient between MLs: 2. 5 to 4 o. C Sag of Chamber: 200 um Sag of xplate: 25 um 6 to 50 to 80 um/o. C= acceptable 10 um/o. C = acceptable Marcel Vreeswijk (NIKHEF) s

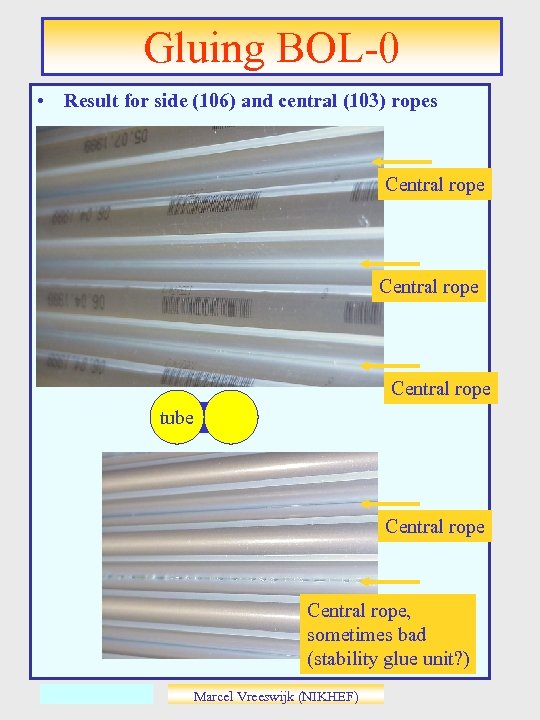

Gluing BOL-0 • Result for side (106) and central (103) ropes Central rope tube Central rope, sometimes bad (stability glue unit? ) Marcel Vreeswijk (NIKHEF)

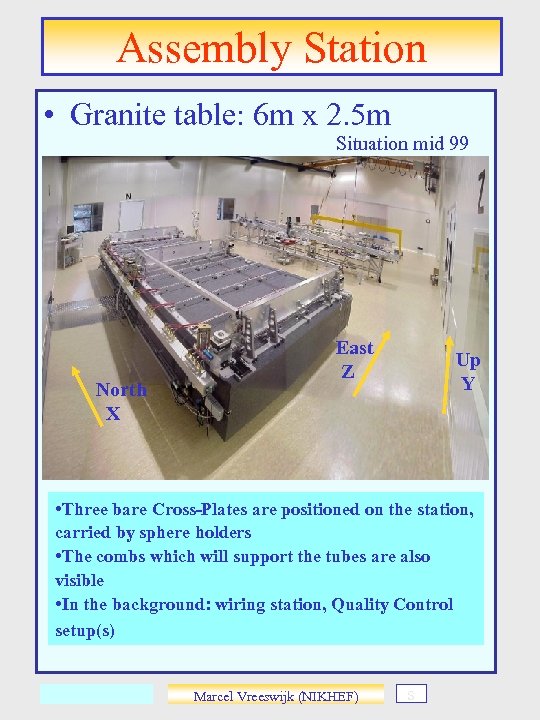

Assembly Station • Granite table: 6 m x 2. 5 m Situation mid 99 North X East Z Up Y • Three bare Cross-Plates are positioned on the station, carried by sphere holders • The combs which will support the tubes are also visible • In the background: wiring station, Quality Control setup(s) West side has expansion length o 0. 1 m in Xras Marcel Vreeswijk (NIKHEF) s

04e703870b59b279bfb5d0a32e792f32.ppt