2578111f070e7687f31255c500b56519.ppt

- Количество слайдов: 16

New ISO standards Christfried Pumm Wenzel Präzision ia. cmm International Conference Sinsheim (Germany), April 28 th, 2005 21/04/2005 Christfried Pumm, Wenzel Präzision

New ISO standards Christfried Pumm Wenzel Präzision ia. cmm International Conference Sinsheim (Germany), April 28 th, 2005 21/04/2005 Christfried Pumm, Wenzel Präzision

“Specifications” WG n The working group “Specifications” is one of several sub-groups of ia. cmm. The performance specifications for CMMs are defined by the ISO 10360 series. Based on ISO 10360 -1, the “Specifications” WG e. g. created a structure for a common data sheet within all associated companies. This was completed succesfully during the last two years. Future work will concentrate on informing ia. cmm-members and customers on new standards and revisions related to CMMtechnologies. Actually this task refers to: u u u 21/04/2005 ISO 10360 -2 CMMs used for measuring linear dimensions ISO 10360 -5 CMM probing performance with contacting probing systems ISO/TS 23165 Guide to evaluation of CMM test uncertainty Christfried Pumm, Wenzel Präzision 2

“Specifications” WG n The working group “Specifications” is one of several sub-groups of ia. cmm. The performance specifications for CMMs are defined by the ISO 10360 series. Based on ISO 10360 -1, the “Specifications” WG e. g. created a structure for a common data sheet within all associated companies. This was completed succesfully during the last two years. Future work will concentrate on informing ia. cmm-members and customers on new standards and revisions related to CMMtechnologies. Actually this task refers to: u u u 21/04/2005 ISO 10360 -2 CMMs used for measuring linear dimensions ISO 10360 -5 CMM probing performance with contacting probing systems ISO/TS 23165 Guide to evaluation of CMM test uncertainty Christfried Pumm, Wenzel Präzision 2

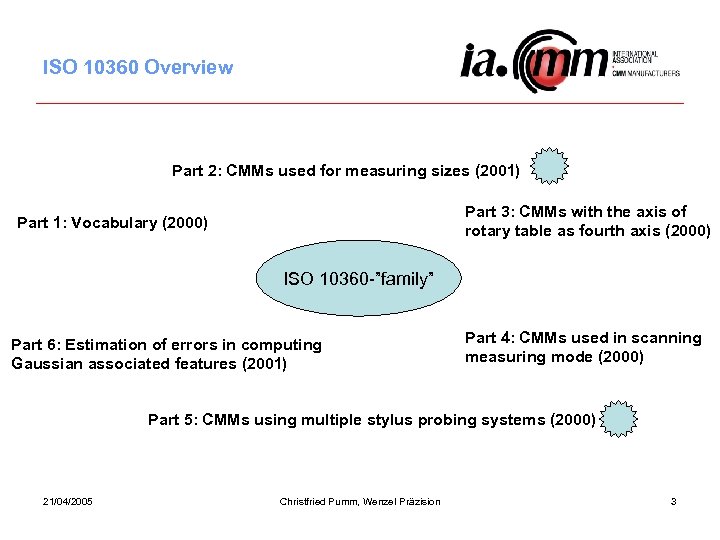

ISO 10360 Overview Part 2: CMMs used for measuring sizes (2001) Part 3: CMMs with the axis of rotary table as fourth axis (2000) Part 1: Vocabulary (2000) ISO 10360 -”family” Part 6: Estimation of errors in computing Gaussian associated features (2001) Part 4: CMMs used in scanning measuring mode (2000) Part 5: CMMs using multiple stylus probing systems (2000) 21/04/2005 Christfried Pumm, Wenzel Präzision 3

ISO 10360 Overview Part 2: CMMs used for measuring sizes (2001) Part 3: CMMs with the axis of rotary table as fourth axis (2000) Part 1: Vocabulary (2000) ISO 10360 -”family” Part 6: Estimation of errors in computing Gaussian associated features (2001) Part 4: CMMs used in scanning measuring mode (2000) Part 5: CMMs using multiple stylus probing systems (2000) 21/04/2005 Christfried Pumm, Wenzel Präzision 3

New ISO 10360 -2 n Technologies applicable to coordinate measurement in field have been rapidly evolved during the last years requiring better clarified CMM specifications as well as enhancements of the proven standards. Main topics discussed by ISO/TC 213/WG 10 during the last meeting in New Orleans are: u Enhanced and clarified test procedures Ø Ø u Thermal properties of test length Ø Ø 21/04/2005 Test to verify probing error was moved from ISO 10360 -2 to ISO 10360 -5 Test to verify MPEE is now called “E 0 -test” instead of “E-test” Thermal performance of artefacts used for CMM-tests is specified; CTE as well as the uncertainty of CTE is now to be declared. Standard tests must use test lengths with a CTE between 8 x 10 -6/K and 13 x 10 -6/K as default! Specification statements based on test lengths with non-corresponding CTE’s must be indicated (MPE*E 0) and an additional E 0 -test must be done on a “normal” test length! Christfried Pumm, Wenzel Präzision 4

New ISO 10360 -2 n Technologies applicable to coordinate measurement in field have been rapidly evolved during the last years requiring better clarified CMM specifications as well as enhancements of the proven standards. Main topics discussed by ISO/TC 213/WG 10 during the last meeting in New Orleans are: u Enhanced and clarified test procedures Ø Ø u Thermal properties of test length Ø Ø 21/04/2005 Test to verify probing error was moved from ISO 10360 -2 to ISO 10360 -5 Test to verify MPEE is now called “E 0 -test” instead of “E-test” Thermal performance of artefacts used for CMM-tests is specified; CTE as well as the uncertainty of CTE is now to be declared. Standard tests must use test lengths with a CTE between 8 x 10 -6/K and 13 x 10 -6/K as default! Specification statements based on test lengths with non-corresponding CTE’s must be indicated (MPE*E 0) and an additional E 0 -test must be done on a “normal” test length! Christfried Pumm, Wenzel Präzision 4

New ISO 10360 -2 u Improving test sensitivity to ram axis roll Ø u Repeatability test Ø 21/04/2005 A new EL-test has been introduced with test sensitivity to ram axis roll proportional to the offset distance between the centerline of the ram axis and the center of the stylus tip. Two EL-tests are performed with a 150 mm offset distance in the default case. The user can choose the position and orientation for the test from eight possibilities along plane diagonals on planes parallel to the ram axis movement. Repeatability R 0 is calculated and tested using the results from an E 0 -test comprising three repetitive measurements performed on the CMM. Conformance or non-conformance to the specification is verified. Christfried Pumm, Wenzel Präzision 5

New ISO 10360 -2 u Improving test sensitivity to ram axis roll Ø u Repeatability test Ø 21/04/2005 A new EL-test has been introduced with test sensitivity to ram axis roll proportional to the offset distance between the centerline of the ram axis and the center of the stylus tip. Two EL-tests are performed with a 150 mm offset distance in the default case. The user can choose the position and orientation for the test from eight possibilities along plane diagonals on planes parallel to the ram axis movement. Repeatability R 0 is calculated and tested using the results from an E 0 -test comprising three repetitive measurements performed on the CMM. Conformance or non-conformance to the specification is verified. Christfried Pumm, Wenzel Präzision 5

New ISO 10360 -2 u Various artefacts that represent a calibrated test length Ø 21/04/2005 Within the last few years a lot of new artefacts like lasertrackers, ball bars, ball plates etc. have been developed allowing to perform adequate and comparable test even on large CMM’s, e. g. used in automotive and aerospace applications. Most of these artefacts allow only unidirectional tests; combining a series of unidirectional measurements with at least one size measurement on a short gauge block make these tests directly comparable to standard bidirectional test procedures. Christfried Pumm, Wenzel Präzision 6

New ISO 10360 -2 u Various artefacts that represent a calibrated test length Ø 21/04/2005 Within the last few years a lot of new artefacts like lasertrackers, ball bars, ball plates etc. have been developed allowing to perform adequate and comparable test even on large CMM’s, e. g. used in automotive and aerospace applications. Most of these artefacts allow only unidirectional tests; combining a series of unidirectional measurements with at least one size measurement on a short gauge block make these tests directly comparable to standard bidirectional test procedures. Christfried Pumm, Wenzel Präzision 6

New ISO 10360 -2 u Application possibilities for CMM’s with particular functionalities Ø Ø 21/04/2005 Non-cartesian CMM’s as well as optical systems gain more and more importance in applications formerly covered by “standard” CMM’s with orthogonal axes. New ISO 10360 definitely allows to transfer test procedures to these kinds of machines based on an agreement between supplier and CMM user. Very important: test procedures for dual arm CMM’s working in a common coordinate system are now specified! Christfried Pumm, Wenzel Präzision 7

New ISO 10360 -2 u Application possibilities for CMM’s with particular functionalities Ø Ø 21/04/2005 Non-cartesian CMM’s as well as optical systems gain more and more importance in applications formerly covered by “standard” CMM’s with orthogonal axes. New ISO 10360 definitely allows to transfer test procedures to these kinds of machines based on an agreement between supplier and CMM user. Very important: test procedures for dual arm CMM’s working in a common coordinate system are now specified! Christfried Pumm, Wenzel Präzision 7

New ISO 10360 -5 n New title: ISO 10360 -5: CMM Probing Performance with Contacting Probing System u u 21/04/2005 The scope of ISO 10360 -5 will be limited to contacting probing systems only. Additional new parts of ISO 10360 to be released later will cover the performance tests for further probing systems. ISO 10360 -7 for CMMs equipped with video probing systems is already under preparation. As already mentioned, the test of probing error P will be taken out of part 2 and will be integrated in part 5 as “single stylus probing system test”. All tests related to a contacting probing system will be in part 5. Part 2 contains the basic background description and will focus on size tests only. Double measurements are eliminated! Christfried Pumm, Wenzel Präzision 8

New ISO 10360 -5 n New title: ISO 10360 -5: CMM Probing Performance with Contacting Probing System u u 21/04/2005 The scope of ISO 10360 -5 will be limited to contacting probing systems only. Additional new parts of ISO 10360 to be released later will cover the performance tests for further probing systems. ISO 10360 -7 for CMMs equipped with video probing systems is already under preparation. As already mentioned, the test of probing error P will be taken out of part 2 and will be integrated in part 5 as “single stylus probing system test”. All tests related to a contacting probing system will be in part 5. Part 2 contains the basic background description and will focus on size tests only. Double measurements are eliminated! Christfried Pumm, Wenzel Präzision 8

New ISO 10360 -5 u u It is very important to understand that probing system performance is directly influenced by CMM performance! Probe system performance as “standalone specification” cannot be isolated and tested! Tests specified in ISO 10360 -5 are sensitive to many errors produced by the complex system “CMM”. Expanded scope The definition of specific parameters for additional types of contacting probing systems will allow the application of ISO 10360 -5 for Ø Ø Ø 21/04/2005 multiple styli connected to the CMM probe (e. g. a star), installations using an articulating probing system (motorized or manual) that can be pre-qualified in empirical mode at each angular position used (e. g. PH 10, RDS) or at a few angular positions in inferred mode with interpolation for any angular positions (e. g. DSE, PHS 1) installations using a repeatable probe-changing system, installations using a repeatable stylus-changing system multiple-probe installations. Christfried Pumm, Wenzel Präzision 9

New ISO 10360 -5 u u It is very important to understand that probing system performance is directly influenced by CMM performance! Probe system performance as “standalone specification” cannot be isolated and tested! Tests specified in ISO 10360 -5 are sensitive to many errors produced by the complex system “CMM”. Expanded scope The definition of specific parameters for additional types of contacting probing systems will allow the application of ISO 10360 -5 for Ø Ø Ø 21/04/2005 multiple styli connected to the CMM probe (e. g. a star), installations using an articulating probing system (motorized or manual) that can be pre-qualified in empirical mode at each angular position used (e. g. PH 10, RDS) or at a few angular positions in inferred mode with interpolation for any angular positions (e. g. DSE, PHS 1) installations using a repeatable probe-changing system, installations using a repeatable stylus-changing system multiple-probe installations. Christfried Pumm, Wenzel Präzision 9

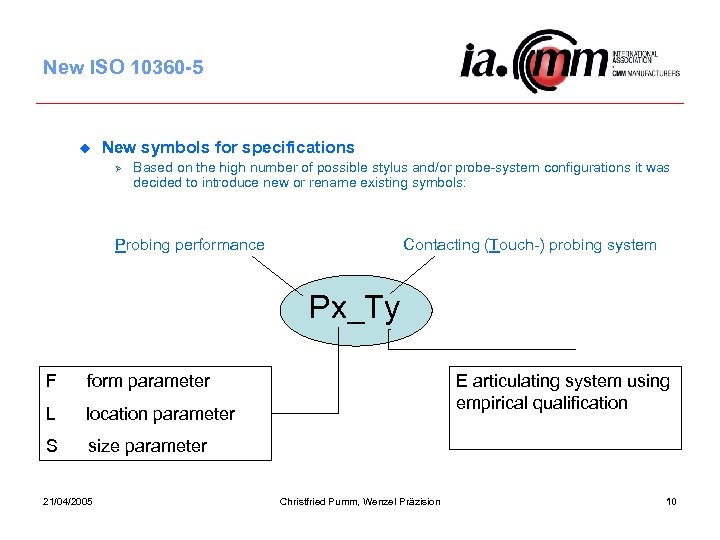

New ISO 10360 -5 u New symbols for specifications Ø Based on the high number of possible stylus and/or probe-system configurations it was decided to introduce new or rename existing symbols: Probing performance Contacting (Touch-) probing system Px_Ty F form parameter L location parameter S size parameter 21/04/2005 E articulating system using empirical qualification Christfried Pumm, Wenzel Präzision 10

New ISO 10360 -5 u New symbols for specifications Ø Based on the high number of possible stylus and/or probe-system configurations it was decided to introduce new or rename existing symbols: Probing performance Contacting (Touch-) probing system Px_Ty F form parameter L location parameter S size parameter 21/04/2005 E articulating system using empirical qualification Christfried Pumm, Wenzel Präzision 10

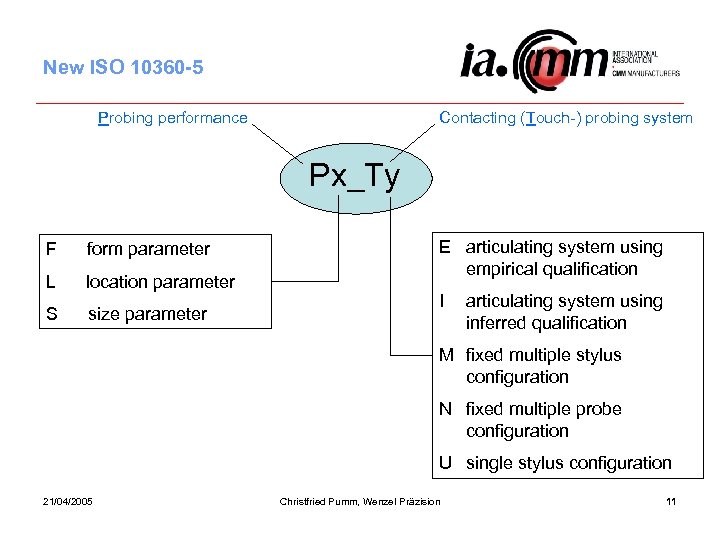

New ISO 10360 -5 Probing performance Contacting (Touch-) probing system Px_Ty F form parameter L location parameter S size parameter E articulating system using empirical qualification I articulating system using inferred qualification M fixed multiple stylus configuration N fixed multiple probe configuration U single stylus configuration 21/04/2005 Christfried Pumm, Wenzel Präzision 11

New ISO 10360 -5 Probing performance Contacting (Touch-) probing system Px_Ty F form parameter L location parameter S size parameter E articulating system using empirical qualification I articulating system using inferred qualification M fixed multiple stylus configuration N fixed multiple probe configuration U single stylus configuration 21/04/2005 Christfried Pumm, Wenzel Präzision 11

New ISO 10360 -5 u Clarified test procedures Ø Specification and test is necessary for one extension length only Ø Different styli diameters can be used Ø Test sphere must be calibrated form and size Ø Ø 21/04/2005 Form error of styli and test sphere must not exceed 20% of the specified MPE and can not be subtracted from the test result If not specified otherwise, the location of the test sphere can be chosen anywhere inside the measuring volume Christfried Pumm, Wenzel Präzision 12

New ISO 10360 -5 u Clarified test procedures Ø Specification and test is necessary for one extension length only Ø Different styli diameters can be used Ø Test sphere must be calibrated form and size Ø Ø 21/04/2005 Form error of styli and test sphere must not exceed 20% of the specified MPE and can not be subtracted from the test result If not specified otherwise, the location of the test sphere can be chosen anywhere inside the measuring volume Christfried Pumm, Wenzel Präzision 12

ISO/TS 23165 n ISO/TS 23165: Guide to evaluation of CMM test uncertainty u u u 21/04/2005 It has the status of a technical specification, is officially released but still doesn’t have the status of an international standard Since all ISO 10360 chapters require that uncertainty of measurements must be taken into account (specified by ISO 14253 -1), ISO/TS 23165 describes the main influencing factors; up to now this was not clearly fixed. Important: ISO/TS 23165 can only be applied to CMM-verification, not to general measurements performed by an CMM; these issues are covered by ISO 15530 series! Christfried Pumm, Wenzel Präzision 13

ISO/TS 23165 n ISO/TS 23165: Guide to evaluation of CMM test uncertainty u u u 21/04/2005 It has the status of a technical specification, is officially released but still doesn’t have the status of an international standard Since all ISO 10360 chapters require that uncertainty of measurements must be taken into account (specified by ISO 14253 -1), ISO/TS 23165 describes the main influencing factors; up to now this was not clearly fixed. Important: ISO/TS 23165 can only be applied to CMM-verification, not to general measurements performed by an CMM; these issues are covered by ISO 15530 series! Christfried Pumm, Wenzel Präzision 13

ISO/TS 23165 n Test uncertainty contributors u Test of probing errors Ø Ø u Test of size errors Ø Ø Ø 21/04/2005 Form error F of the test sphere as stated in the calibration certificate Standard uncertainty u(F) as reported in the calibration certificate Uncertainty of calibration for the standard of size used Uncertainty due to the CTE of the standard of size used; valid only if the CMM expects the tester to input a CTE-value. On non-compensated CMM’s (for temperature influence), related inaccuracies are part of the MPE specification. Uncertainty due to the “real” temperature of the material standard of size used Christfried Pumm, Wenzel Präzision 14

ISO/TS 23165 n Test uncertainty contributors u Test of probing errors Ø Ø u Test of size errors Ø Ø Ø 21/04/2005 Form error F of the test sphere as stated in the calibration certificate Standard uncertainty u(F) as reported in the calibration certificate Uncertainty of calibration for the standard of size used Uncertainty due to the CTE of the standard of size used; valid only if the CMM expects the tester to input a CTE-value. On non-compensated CMM’s (for temperature influence), related inaccuracies are part of the MPE specification. Uncertainty due to the “real” temperature of the material standard of size used Christfried Pumm, Wenzel Präzision 14

ISO/TS 23165 Ø Ø 21/04/2005 Uncertainty due to a misalignment of material standard of size used. This normally has negligible influence on CNC-machines; on manual machines misalignment is very important. Uncertainty of fixturing the artefact; on properly designed fixtures this should not be relevant. Looking at big artefacts like ball-bars which are shipped and reassembled on side statistical analysis and expert judgement must be used to determine this factor. Christfried Pumm, Wenzel Präzision 15

ISO/TS 23165 Ø Ø 21/04/2005 Uncertainty due to a misalignment of material standard of size used. This normally has negligible influence on CNC-machines; on manual machines misalignment is very important. Uncertainty of fixturing the artefact; on properly designed fixtures this should not be relevant. Looking at big artefacts like ball-bars which are shipped and reassembled on side statistical analysis and expert judgement must be used to determine this factor. Christfried Pumm, Wenzel Präzision 15

Thanks to: Mr. Abbe from Mitutoyo Japan, Mr. Verdi from Hexagon DEA, Mr. Wanner from Carl Zeiss. Based on their activities as members of ISO/TC/WG 10 they wrote an article „Revision of CMM performance specifications“ , published on ia. cmm homepage. This article and their reports to ia. cmm WG „Specifications“ created a solid base for this presentation! 21/04/2005 Christfried Pumm, Wenzel Präzision 16

Thanks to: Mr. Abbe from Mitutoyo Japan, Mr. Verdi from Hexagon DEA, Mr. Wanner from Carl Zeiss. Based on their activities as members of ISO/TC/WG 10 they wrote an article „Revision of CMM performance specifications“ , published on ia. cmm homepage. This article and their reports to ia. cmm WG „Specifications“ created a solid base for this presentation! 21/04/2005 Christfried Pumm, Wenzel Präzision 16