167878dc33ee66dc2e01a9d990d60915.ppt

- Количество слайдов: 17

NEW EXCELLENT TECHNOLOGY Moving Disk Type Thickening & Dewatering Equipment 2010. 02. ISO 9001 17 -4, Cheonan 4 th local industrial complex, Mosi-ri Jiksan-eup Cheonan-si Chungcheongnam-do, Korea, 331 -814 TEL : 82 -41 -587 -0111 FAX : 82 -41 -587 -0555 1

NEW EXCELLENT TECHNOLOGY Moving Disk Type Thickening & Dewatering Equipment 2010. 02. ISO 9001 17 -4, Cheonan 4 th local industrial complex, Mosi-ri Jiksan-eup Cheonan-si Chungcheongnam-do, Korea, 331 -814 TEL : 82 -41 -587 -0111 FAX : 82 -41 -587 -0555 1

1. INTRODUCTION OF COMPANY Name : O H K Co. , Ltd Establishment : 1999. Jan. 14 Address : Siwha industrial complex 3 Ra 805 Ho Jungwang-dong, Siheung City, Kyunggi-province, Korea C. E. O : Yang Won, Nam Product 1) Thickening & Dewatering Equipment 2) Thickening Equipment 3) ACS Wastewater Treatment System 4) Ultrasonic Density Meter 5) Autoleveler Homepage : //www. ohk. co. kr 2

1. INTRODUCTION OF COMPANY Name : O H K Co. , Ltd Establishment : 1999. Jan. 14 Address : Siwha industrial complex 3 Ra 805 Ho Jungwang-dong, Siheung City, Kyunggi-province, Korea C. E. O : Yang Won, Nam Product 1) Thickening & Dewatering Equipment 2) Thickening Equipment 3) ACS Wastewater Treatment System 4) Ultrasonic Density Meter 5) Autoleveler Homepage : //www. ohk. co. kr 2

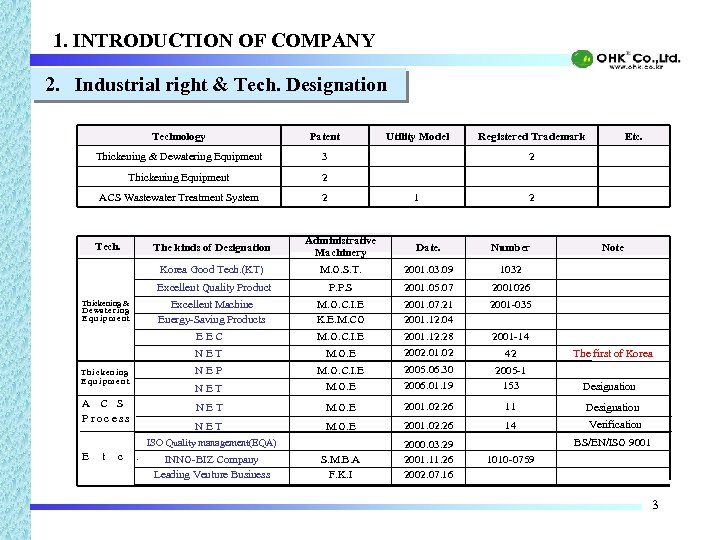

1. INTRODUCTION OF COMPANY 2. Industrial right & Tech. Designation Technology Patent Thickening & Dewatering Equipment 3 Thickening Equipment 2 ACS Wastewater Treatment System 2 Utility Model Registered Trademark Etc. 2 1 2 The kinds of Designation M. O. S. T. 2001. 03. 09 1032 P. P. S M. O. C. I. E K. E. M. CO 2001. 05. 07 2001. 07. 21 2001. 12. 04 2001026 2001 -035 M. O. C. I. E M. O. E 2001. 12. 28 2002. 01. 02 2001 -14 NET NEP NET M. O. C. I. E M. O. E 2005. 06. 30 2006. 01. 19 2005 -1 153 NET M. O. E 2001. 02. 26 11 Designation NET A C S Process Number EEC Thickening Equipment Date. Excellent Quality Product Excellent Machine Energy-Saving Products Thickening & Dewatering Equipment Administrative Machinery Korea Good Tech. (KT) Tech. M. O. E 2001. 02. 26 14 Verification S. M. B. A F. K. I 2000. 03. 29 2001. 11. 26 2002. 07. 16 ISO Quality management(EQA) E t c . INNO-BIZ Company Leading Venture Business 42 Note The first of Korea Designation BS/EN/ISO 9001 1010 -0759 3

1. INTRODUCTION OF COMPANY 2. Industrial right & Tech. Designation Technology Patent Thickening & Dewatering Equipment 3 Thickening Equipment 2 ACS Wastewater Treatment System 2 Utility Model Registered Trademark Etc. 2 1 2 The kinds of Designation M. O. S. T. 2001. 03. 09 1032 P. P. S M. O. C. I. E K. E. M. CO 2001. 05. 07 2001. 07. 21 2001. 12. 04 2001026 2001 -035 M. O. C. I. E M. O. E 2001. 12. 28 2002. 01. 02 2001 -14 NET NEP NET M. O. C. I. E M. O. E 2005. 06. 30 2006. 01. 19 2005 -1 153 NET M. O. E 2001. 02. 26 11 Designation NET A C S Process Number EEC Thickening Equipment Date. Excellent Quality Product Excellent Machine Energy-Saving Products Thickening & Dewatering Equipment Administrative Machinery Korea Good Tech. (KT) Tech. M. O. E 2001. 02. 26 14 Verification S. M. B. A F. K. I 2000. 03. 29 2001. 11. 26 2002. 07. 16 ISO Quality management(EQA) E t c . INNO-BIZ Company Leading Venture Business 42 Note The first of Korea Designation BS/EN/ISO 9001 1010 -0759 3

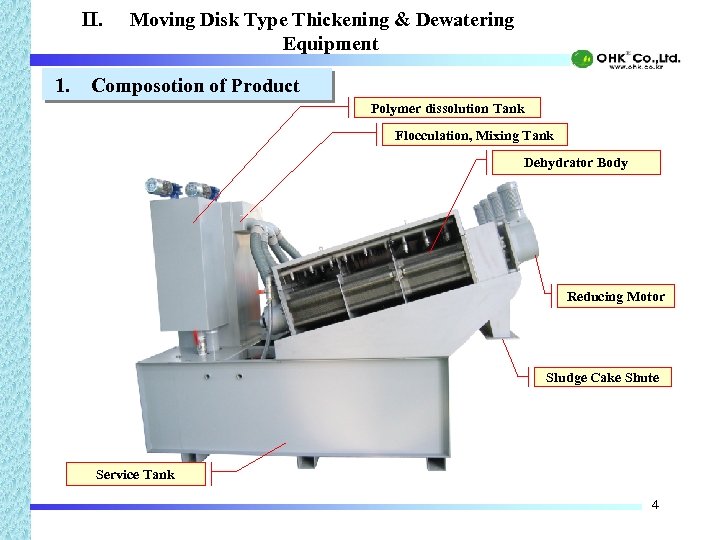

II. 1. Moving Disk Type Thickening & Dewatering Equipment Composotion of Product Polymer dissolution Tank Flocculation, Mixing Tank Dehydrator Body Reducing Motor Sludge Cake Shute Service Tank 4

II. 1. Moving Disk Type Thickening & Dewatering Equipment Composotion of Product Polymer dissolution Tank Flocculation, Mixing Tank Dehydrator Body Reducing Motor Sludge Cake Shute Service Tank 4

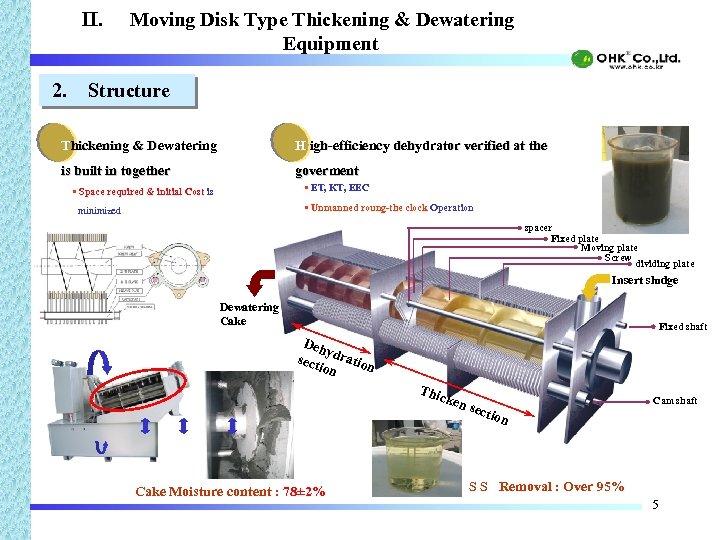

II. 2. Moving Disk Type Thickening & Dewatering Equipment Structure Thickening & Dewatering H igh-efficiency dehydrator verified at the is built in together goverment • ET, KT, EEC • Space required & initial Cost is • Unmanned roung-the clock Operation minimized spacer Fixed plate Moving plate Screw dividing plate Insert sludge Dewatering Cake Fixed shaft Deh y sect dratio n ion Thi cken Cake Moisture content : 78± 2% Cam shaft sect ion S S Removal : Over 95% 5

II. 2. Moving Disk Type Thickening & Dewatering Equipment Structure Thickening & Dewatering H igh-efficiency dehydrator verified at the is built in together goverment • ET, KT, EEC • Space required & initial Cost is • Unmanned roung-the clock Operation minimized spacer Fixed plate Moving plate Screw dividing plate Insert sludge Dewatering Cake Fixed shaft Deh y sect dratio n ion Thi cken Cake Moisture content : 78± 2% Cam shaft sect ion S S Removal : Over 95% 5

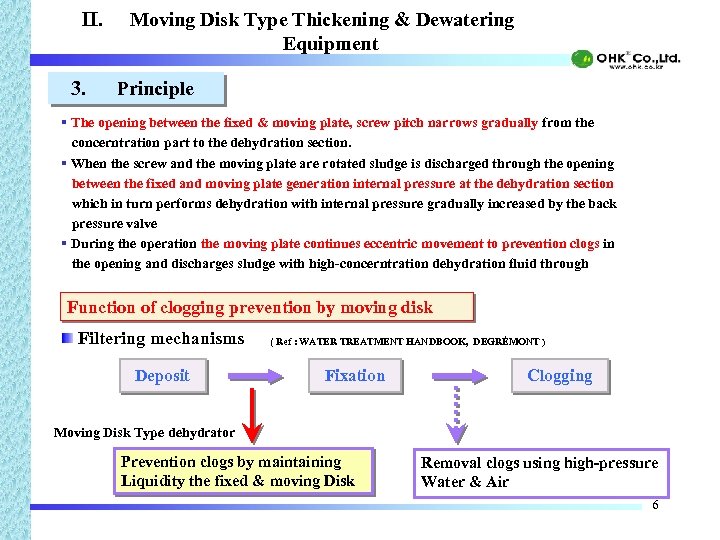

II. 3. Moving Disk Type Thickening & Dewatering Equipment Principle § The opening between the fixed & moving plate, screw pitch narrows gradually from the concerntration part to the dehydration section. § When the screw and the moving plate are rotated sludge is discharged through the opening between the fixed and moving plate generation internal pressure at the dehydration section which in turn performs dehydration with internal pressure gradually increased by the back pressure valve § During the operation the moving plate continues eccentric movement to prevention clogs in the opening and discharges sludge with high-concerntration dehydration fluid through Function of clogging prevention by moving disk Filtering mechanisms Deposit ( Ref : WATER TREATMENT HANDBOOK, DEGRÉMONT ) Fixation Clogging Moving Disk Type dehydrator Prevention clogs by maintaining Liquidity the fixed & moving Disk Removal clogs using high-pressure Water & Air 6

II. 3. Moving Disk Type Thickening & Dewatering Equipment Principle § The opening between the fixed & moving plate, screw pitch narrows gradually from the concerntration part to the dehydration section. § When the screw and the moving plate are rotated sludge is discharged through the opening between the fixed and moving plate generation internal pressure at the dehydration section which in turn performs dehydration with internal pressure gradually increased by the back pressure valve § During the operation the moving plate continues eccentric movement to prevention clogs in the opening and discharges sludge with high-concerntration dehydration fluid through Function of clogging prevention by moving disk Filtering mechanisms Deposit ( Ref : WATER TREATMENT HANDBOOK, DEGRÉMONT ) Fixation Clogging Moving Disk Type dehydrator Prevention clogs by maintaining Liquidity the fixed & moving Disk Removal clogs using high-pressure Water & Air 6

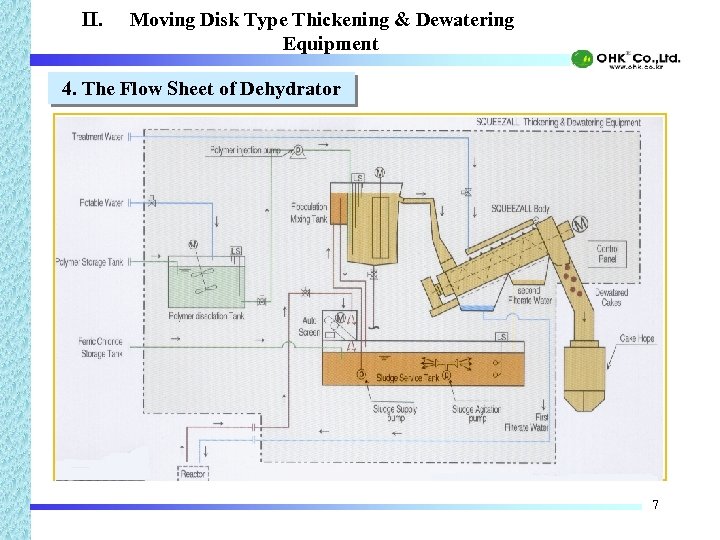

II. Moving Disk Type Thickening & Dewatering Equipment 4. The Flow Sheet of Dehydrator 7

II. Moving Disk Type Thickening & Dewatering Equipment 4. The Flow Sheet of Dehydrator 7

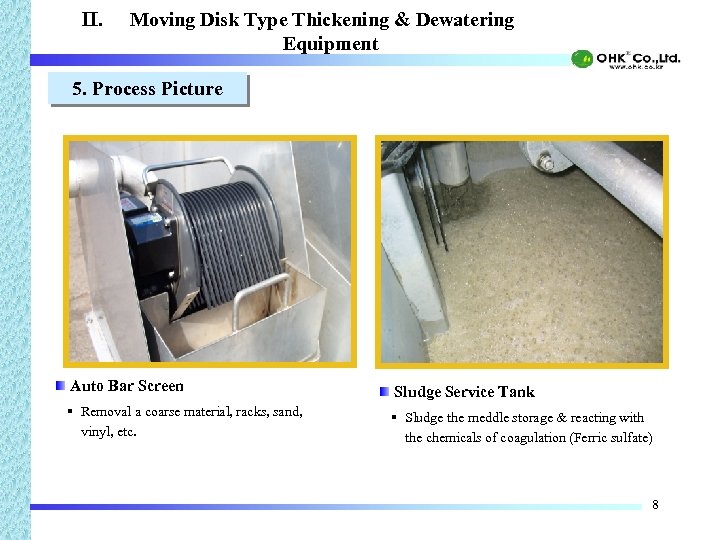

II. Moving Disk Type Thickening & Dewatering Equipment 5. Process Picture Auto Bar Screen Sludge Service Tank § Removal a coarse material, racks, sand, vinyl, etc. § Sludge the meddle storage & reacting with the chemicals of coagulation (Ferric sulfate) 8

II. Moving Disk Type Thickening & Dewatering Equipment 5. Process Picture Auto Bar Screen Sludge Service Tank § Removal a coarse material, racks, sand, vinyl, etc. § Sludge the meddle storage & reacting with the chemicals of coagulation (Ferric sulfate) 8

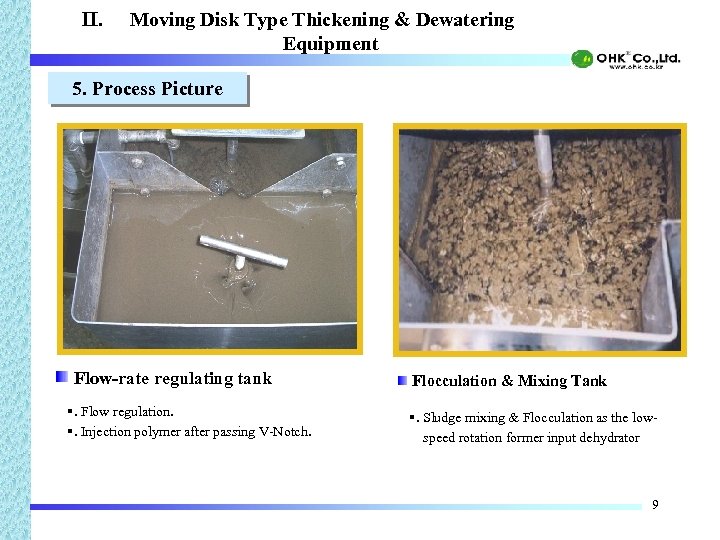

II. Moving Disk Type Thickening & Dewatering Equipment 5. Process Picture Flow-rate regulating tank §. Flow regulation. §. Injection polymer after passing V-Notch. Flocculation & Mixing Tank §. Sludge mixing & Flocculation as the lowspeed rotation former input dehydrator 9

II. Moving Disk Type Thickening & Dewatering Equipment 5. Process Picture Flow-rate regulating tank §. Flow regulation. §. Injection polymer after passing V-Notch. Flocculation & Mixing Tank §. Sludge mixing & Flocculation as the lowspeed rotation former input dehydrator 9

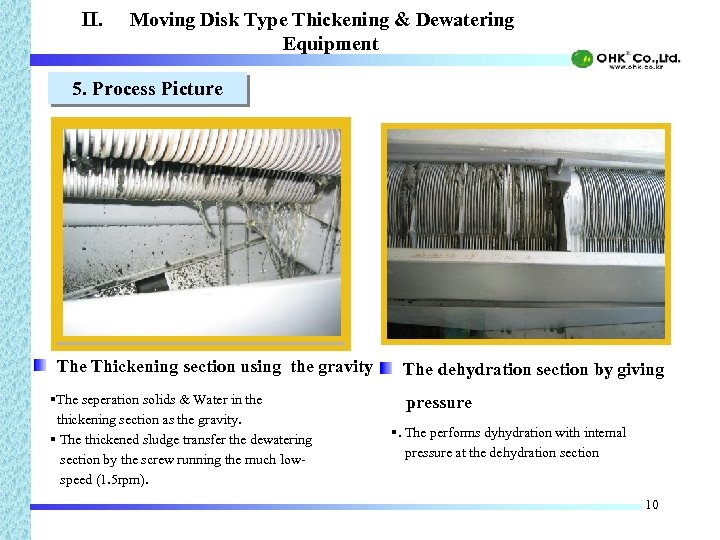

II. Moving Disk Type Thickening & Dewatering Equipment 5. Process Picture Thickening section using the gravity §The seperation solids & Water in the thickening section as the gravity. § The thickened sludge transfer the dewatering section by the screw running the much lowspeed (1. 5 rpm). The dehydration section by giving pressure §. The performs dyhydration with internal pressure at the dehydration section 10

II. Moving Disk Type Thickening & Dewatering Equipment 5. Process Picture Thickening section using the gravity §The seperation solids & Water in the thickening section as the gravity. § The thickened sludge transfer the dewatering section by the screw running the much lowspeed (1. 5 rpm). The dehydration section by giving pressure §. The performs dyhydration with internal pressure at the dehydration section 10

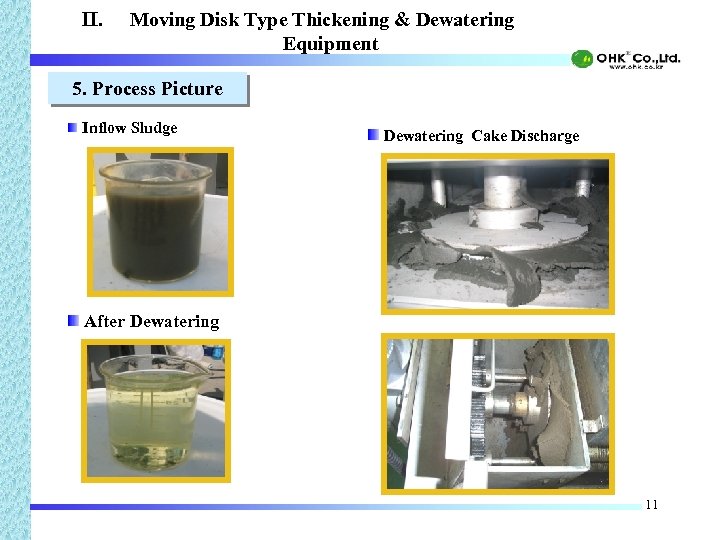

II. Moving Disk Type Thickening & Dewatering Equipment 5. Process Picture Inflow Sludge Dewatering Cake Discharge After Dewatering 11

II. Moving Disk Type Thickening & Dewatering Equipment 5. Process Picture Inflow Sludge Dewatering Cake Discharge After Dewatering 11

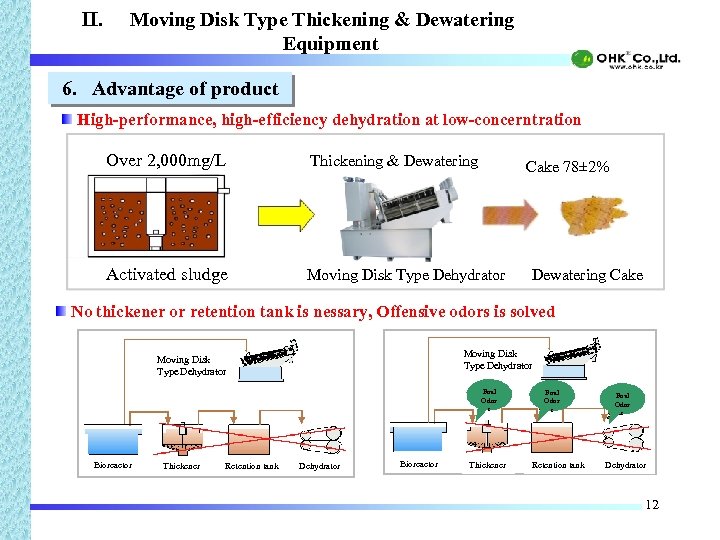

II. Moving Disk Type Thickening & Dewatering Equipment 6. Advantage of product High-performance, high-efficiency dehydration at low-concerntration Over 2, 000 mg/L Thickening & Dewatering Activated sludge Moving Disk Type Dehydrator Cake 78± 2% Dewatering Cake No thickener or retention tank is nessary, Offensive odors is solved Moving Disk Type Dehydrator Foul Odor s Bioreactor Thickener Retention tank Dehydrator Bioreactor Thickener Foul Odor s Retention tank Foul Odor s Dehydrator 12

II. Moving Disk Type Thickening & Dewatering Equipment 6. Advantage of product High-performance, high-efficiency dehydration at low-concerntration Over 2, 000 mg/L Thickening & Dewatering Activated sludge Moving Disk Type Dehydrator Cake 78± 2% Dewatering Cake No thickener or retention tank is nessary, Offensive odors is solved Moving Disk Type Dehydrator Foul Odor s Bioreactor Thickener Retention tank Dehydrator Bioreactor Thickener Foul Odor s Retention tank Foul Odor s Dehydrator 12

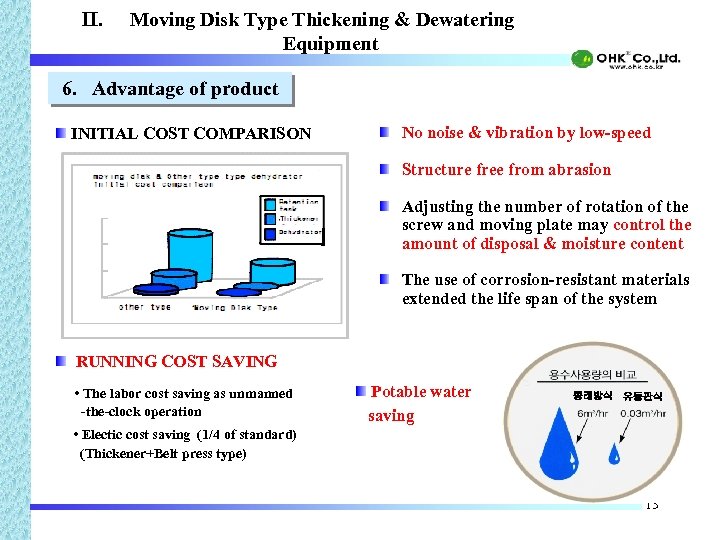

II. Moving Disk Type Thickening & Dewatering Equipment 6. Advantage of product INITIAL COST COMPARISON No noise & vibration by low-speed Structure free from abrasion Adjusting the number of rotation of the screw and moving plate may control the amount of disposal & moisture content The use of corrosion-resistant materials extended the life span of the system RUNNING COST SAVING • The labor cost saving as unmanned -the-clock operation Potable water saving 종래방식 유동판식 • Electic cost saving (1/4 of standard) (Thickener+Belt press type) 13

II. Moving Disk Type Thickening & Dewatering Equipment 6. Advantage of product INITIAL COST COMPARISON No noise & vibration by low-speed Structure free from abrasion Adjusting the number of rotation of the screw and moving plate may control the amount of disposal & moisture content The use of corrosion-resistant materials extended the life span of the system RUNNING COST SAVING • The labor cost saving as unmanned -the-clock operation Potable water saving 종래방식 유동판식 • Electic cost saving (1/4 of standard) (Thickener+Belt press type) 13

II. Moving Disk Type Thickening & Dewatering Equipment 7. SUPPLIES • Sewage & Wastewater Excess Sludge Thickening & Dewatering • Pre-treatment in the stocks raising & Excretions wastewater Treatment • Sludge Dewatering after aerobic/anaerobic digestion • Dehydration of directly low-concerntration activated sludge in the reactor • Dehydrator applied for the small, medium scale sewage treatment. 14

II. Moving Disk Type Thickening & Dewatering Equipment 7. SUPPLIES • Sewage & Wastewater Excess Sludge Thickening & Dewatering • Pre-treatment in the stocks raising & Excretions wastewater Treatment • Sludge Dewatering after aerobic/anaerobic digestion • Dehydration of directly low-concerntration activated sludge in the reactor • Dehydrator applied for the small, medium scale sewage treatment. 14

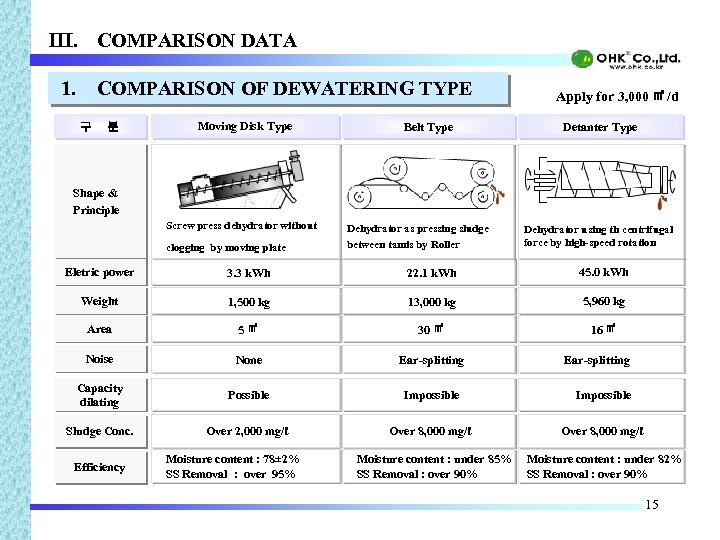

III. COMPARISON DATA 1. COMPARISON OF DEWATERING TYPE 구 분 Moving Disk Type Belt Type Apply for 3, 000 ㎥/d Detanter Type Shape & Principle Screw press dehydrator without clogging by moving plate Dehydrator as pressing sludge between tamis by Roller Dehydrator using th centrifugal force by high-speed rotation Eletric power 3. 3 k. Wh 22. 1 k. Wh 45. 0 k. Wh Weight 1, 500 kg 13, 000 kg 5, 960 kg Area 5㎡ 30 ㎡ 16 ㎡ Noise None Ear-splitting Capacity dilating Possible Impossible Sludge Conc. Over 2, 000 mg/ℓ Over 8, 000 mg/ℓ Efficiency Moisture content : 78± 2% SS Removal : over 95% Moisture content : under 85% SS Removal : over 90% Ear-splitting Moisture content : under 82% SS Removal : over 90% 15

III. COMPARISON DATA 1. COMPARISON OF DEWATERING TYPE 구 분 Moving Disk Type Belt Type Apply for 3, 000 ㎥/d Detanter Type Shape & Principle Screw press dehydrator without clogging by moving plate Dehydrator as pressing sludge between tamis by Roller Dehydrator using th centrifugal force by high-speed rotation Eletric power 3. 3 k. Wh 22. 1 k. Wh 45. 0 k. Wh Weight 1, 500 kg 13, 000 kg 5, 960 kg Area 5㎡ 30 ㎡ 16 ㎡ Noise None Ear-splitting Capacity dilating Possible Impossible Sludge Conc. Over 2, 000 mg/ℓ Over 8, 000 mg/ℓ Efficiency Moisture content : 78± 2% SS Removal : over 95% Moisture content : under 85% SS Removal : over 90% Ear-splitting Moisture content : under 82% SS Removal : over 90% 15

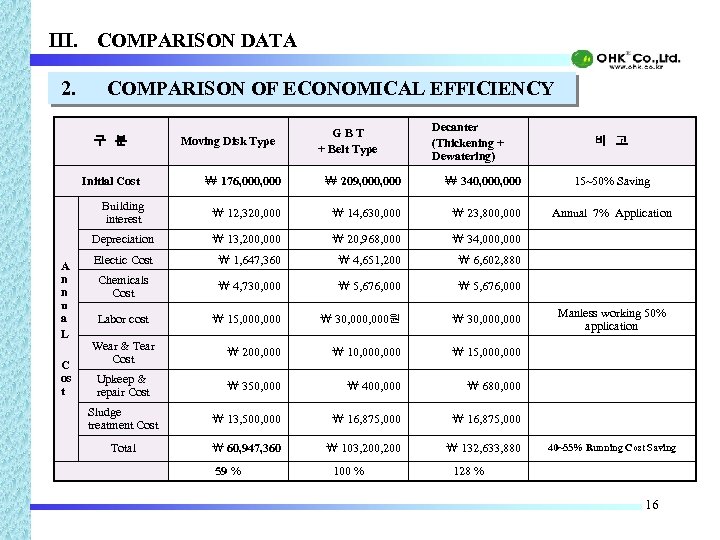

III. COMPARISON DATA 2. COMPARISON OF ECONOMICAL EFFICIENCY 구 분 Moving Disk Type GBT + Belt Type Decanter (Thickening + Dewatering) ₩ 176, 000 ₩ 209, 000 ₩ 340, 000 Building interest ₩ 12, 320, 000 ₩ 14, 630, 000 ₩ 23, 800, 000 Depreciation ₩ 13, 200, 000 ₩ 20, 968, 000 ₩ 34, 000 Electic Cost ₩ 1, 647, 360 ₩ 4, 651, 200 ₩ 6, 602, 880 Chemicals Cost ₩ 4, 730, 000 ₩ 5, 676, 000 Labor cost ₩ 15, 000 ₩ 30, 000원 ₩ 30, 000 Wear & Tear Cost ₩ 200, 000 ₩ 10, 000 ₩ 15, 000 Upkeep & repair Cost ₩ 350, 000 ₩ 400, 000 ₩ 680, 000 Sludge treatment Cost ₩ 13, 500, 000 ₩ 16, 875, 000 Total ₩ 60, 947, 360 ₩ 103, 200 ₩ 132, 633, 880 Initial Cost A n n u a L C os t 비 고 59 % 100 % 15~50% Saving Annual 7% Application Manless working 50% application 40~55% Running Cost Saving 128 % 16

III. COMPARISON DATA 2. COMPARISON OF ECONOMICAL EFFICIENCY 구 분 Moving Disk Type GBT + Belt Type Decanter (Thickening + Dewatering) ₩ 176, 000 ₩ 209, 000 ₩ 340, 000 Building interest ₩ 12, 320, 000 ₩ 14, 630, 000 ₩ 23, 800, 000 Depreciation ₩ 13, 200, 000 ₩ 20, 968, 000 ₩ 34, 000 Electic Cost ₩ 1, 647, 360 ₩ 4, 651, 200 ₩ 6, 602, 880 Chemicals Cost ₩ 4, 730, 000 ₩ 5, 676, 000 Labor cost ₩ 15, 000 ₩ 30, 000원 ₩ 30, 000 Wear & Tear Cost ₩ 200, 000 ₩ 10, 000 ₩ 15, 000 Upkeep & repair Cost ₩ 350, 000 ₩ 400, 000 ₩ 680, 000 Sludge treatment Cost ₩ 13, 500, 000 ₩ 16, 875, 000 Total ₩ 60, 947, 360 ₩ 103, 200 ₩ 132, 633, 880 Initial Cost A n n u a L C os t 비 고 59 % 100 % 15~50% Saving Annual 7% Application Manless working 50% application 40~55% Running Cost Saving 128 % 16

IV. Verbalism § M. O. S. T § P. P. S : Ministry Of Science & Technology : Public Procurement Service § M. O. C. I. E : Ministry Of Commence, Industry and Energy § K. E. M. Co : Korea Energy Management Corporation § M. O. E : Ministry of Environmental Republic of Korea § S. M. B. A : Small and Medium Business, Adminstration § F. K. I : The Federation of Korean Industries § EEC : Environmental Equipment Certification § NEP : New Excellent Production 17

IV. Verbalism § M. O. S. T § P. P. S : Ministry Of Science & Technology : Public Procurement Service § M. O. C. I. E : Ministry Of Commence, Industry and Energy § K. E. M. Co : Korea Energy Management Corporation § M. O. E : Ministry of Environmental Republic of Korea § S. M. B. A : Small and Medium Business, Adminstration § F. K. I : The Federation of Korean Industries § EEC : Environmental Equipment Certification § NEP : New Excellent Production 17