b5d80a5da26eb63da59e14395bc926dc.ppt

- Количество слайдов: 14

New Components Introduction (NCI) and Suppliers Selection. General Awareness Presentation Valentina Shirina GE Transportation June 22, 2011 Eskisehir

New Components Introduction (NCI) and Suppliers Selection. General Awareness Presentation Valentina Shirina GE Transportation June 22, 2011 Eskisehir

WHAT is NCI process and WHY GE follows it? NCI (New Component Introduction) – is a GE process to establish and statistically prove conformity of a component to a certain set of requirements (typically: specification and drawing), in other words, process designed to approve component for use in manufacturing of GE products. NCI Goals: – Components Quality …. Smooth operations – Cost out… avoidance of costs related to incoming inspection, deliveries shortages due to defects, inventory optimization – Mitigation of product/brand reputation risks…supplier accountability 2 GE Transportation/Dimitry Sevostyanov 3/19/2018

WHAT is NCI process and WHY GE follows it? NCI (New Component Introduction) – is a GE process to establish and statistically prove conformity of a component to a certain set of requirements (typically: specification and drawing), in other words, process designed to approve component for use in manufacturing of GE products. NCI Goals: – Components Quality …. Smooth operations – Cost out… avoidance of costs related to incoming inspection, deliveries shortages due to defects, inventory optimization – Mitigation of product/brand reputation risks…supplier accountability 2 GE Transportation/Dimitry Sevostyanov 3/19/2018

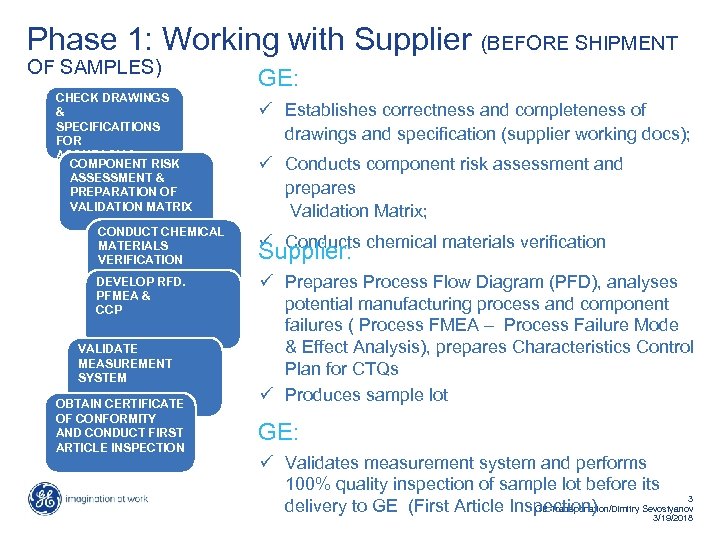

Phase 1: Working with Supplier (BEFORE SHIPMENT OF SAMPLES) CHECK DRAWINGS & SPECIFICAITIONS FOR ACCURACY & COMPONENT RISK COMPLETENESS ASSESSMENT & PREPARATION OF VALIDATION MATRIX CONDUCT CHEMICAL MATERIALS VERIFICATION DEVELOP RFD. PFMEA & CCP VALIDATE MEASUREMENT SYSTEM OBTAIN CERTIFICATE OF CONFORMITY AND CONDUCT FIRST ARTICLE INSPECTION GE: ü Establishes correctness and completeness of drawings and specification (supplier working docs); ü Conducts component risk assessment and prepares Validation Matrix; ü Conducts chemical materials verification Supplier: ü Prepares Process Flow Diagram (PFD), analyses potential manufacturing process and component failures ( Process FMEA – Process Failure Mode & Effect Analysis), prepares Characteristics Control Plan for CTQs ü Produces sample lot GE: ü Validates measurement system and performs 100% quality inspection of sample lot before its 3 GE Transportation/Dimitry Sevostyanov delivery to GE (First Article Inspection) 3/19/2018

Phase 1: Working with Supplier (BEFORE SHIPMENT OF SAMPLES) CHECK DRAWINGS & SPECIFICAITIONS FOR ACCURACY & COMPONENT RISK COMPLETENESS ASSESSMENT & PREPARATION OF VALIDATION MATRIX CONDUCT CHEMICAL MATERIALS VERIFICATION DEVELOP RFD. PFMEA & CCP VALIDATE MEASUREMENT SYSTEM OBTAIN CERTIFICATE OF CONFORMITY AND CONDUCT FIRST ARTICLE INSPECTION GE: ü Establishes correctness and completeness of drawings and specification (supplier working docs); ü Conducts component risk assessment and prepares Validation Matrix; ü Conducts chemical materials verification Supplier: ü Prepares Process Flow Diagram (PFD), analyses potential manufacturing process and component failures ( Process FMEA – Process Failure Mode & Effect Analysis), prepares Characteristics Control Plan for CTQs ü Produces sample lot GE: ü Validates measurement system and performs 100% quality inspection of sample lot before its 3 GE Transportation/Dimitry Sevostyanov delivery to GE (First Article Inspection) 3/19/2018

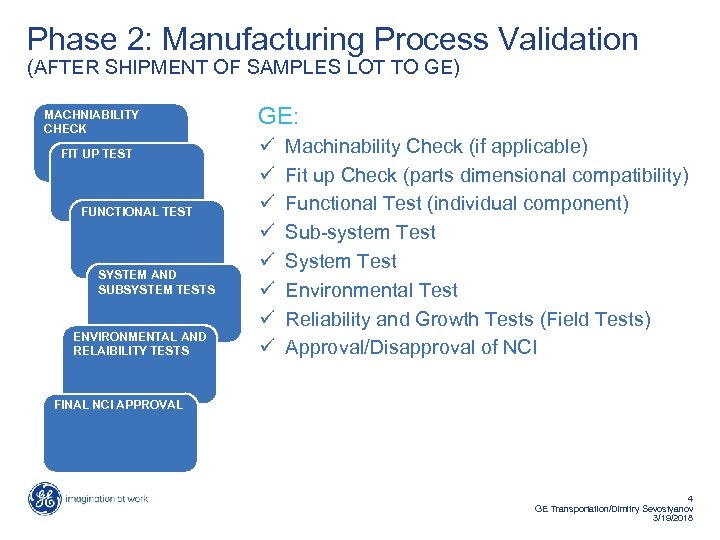

Phase 2: Manufacturing Process Validation (AFTER SHIPMENT OF SAMPLES LOT TO GE) MACHNIABILITY CHECK FIT UP TEST FUNCTIONAL TEST SYSTEM AND SUBSYSTEM TESTS ENVIRONMENTAL AND RELAIBILITY TESTS GE: ü ü ü ü Machinability Check (if applicable) Fit up Check (parts dimensional compatibility) Functional Test (individual component) Sub-system Test System Test Environmental Test Reliability and Growth Tests (Field Tests) Approval/Disapproval of NCI FINAL NCI APPROVAL 4 GE Transportation/Dimitry Sevostyanov 3/19/2018

Phase 2: Manufacturing Process Validation (AFTER SHIPMENT OF SAMPLES LOT TO GE) MACHNIABILITY CHECK FIT UP TEST FUNCTIONAL TEST SYSTEM AND SUBSYSTEM TESTS ENVIRONMENTAL AND RELAIBILITY TESTS GE: ü ü ü ü Machinability Check (if applicable) Fit up Check (parts dimensional compatibility) Functional Test (individual component) Sub-system Test System Test Environmental Test Reliability and Growth Tests (Field Tests) Approval/Disapproval of NCI FINAL NCI APPROVAL 4 GE Transportation/Dimitry Sevostyanov 3/19/2018

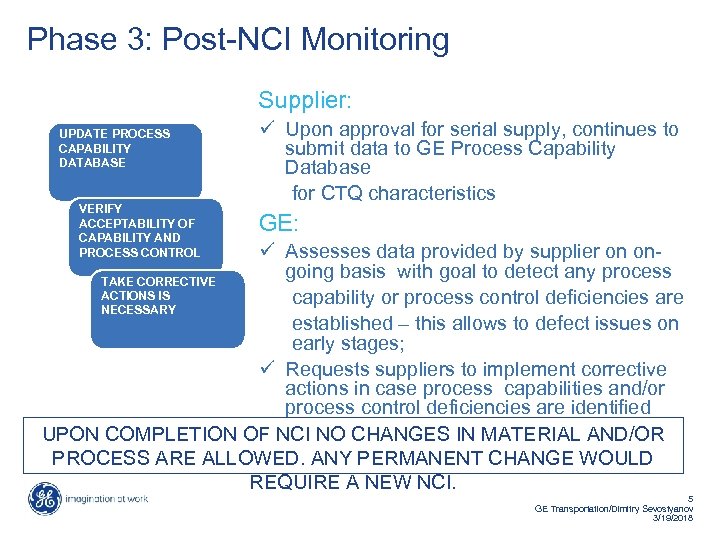

Phase 3: Post-NCI Monitoring Supplier: UPDATE PROCESS CAPABILITY DATABASE VERIFY ACCEPTABILITY OF CAPABILITY AND PROCESS CONTROL ü Upon approval for serial supply, continues to submit data to GE Process Capability Database for CTQ characteristics GE: ü Assesses data provided by supplier on ongoing basis with goal to detect any process TAKE CORRECTIVE ACTIONS IS capability or process control deficiencies are NECESSARY established – this allows to defect issues on early stages; ü Requests suppliers to implement corrective actions in case process capabilities and/or process control deficiencies are identified UPON COMPLETION OF NCI NO CHANGES IN MATERIAL AND/OR PROCESS ARE ALLOWED. ANY PERMANENT CHANGE WOULD REQUIRE A NEW NCI. 5 GE Transportation/Dimitry Sevostyanov 3/19/2018

Phase 3: Post-NCI Monitoring Supplier: UPDATE PROCESS CAPABILITY DATABASE VERIFY ACCEPTABILITY OF CAPABILITY AND PROCESS CONTROL ü Upon approval for serial supply, continues to submit data to GE Process Capability Database for CTQ characteristics GE: ü Assesses data provided by supplier on ongoing basis with goal to detect any process TAKE CORRECTIVE ACTIONS IS capability or process control deficiencies are NECESSARY established – this allows to defect issues on early stages; ü Requests suppliers to implement corrective actions in case process capabilities and/or process control deficiencies are identified UPON COMPLETION OF NCI NO CHANGES IN MATERIAL AND/OR PROCESS ARE ALLOWED. ANY PERMANENT CHANGE WOULD REQUIRE A NEW NCI. 5 GE Transportation/Dimitry Sevostyanov 3/19/2018

Supplier Selection

Supplier Selection

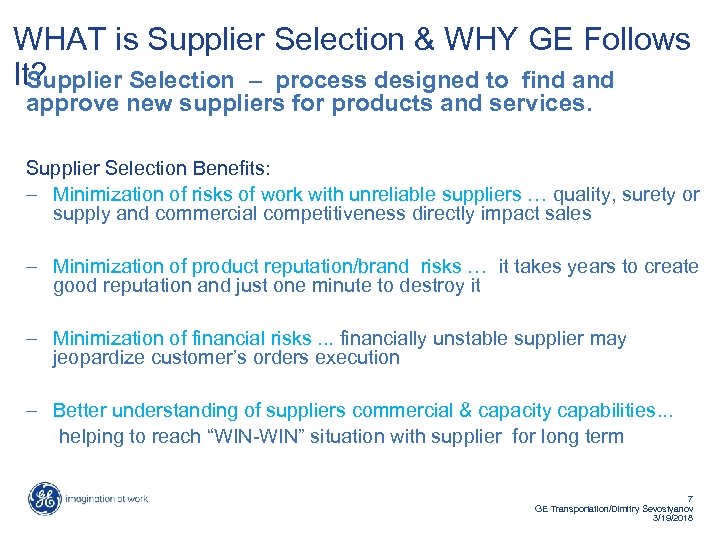

WHAT is Supplier Selection & WHY GE Follows It? Supplier Selection – process designed to find approve new suppliers for products and services. Supplier Selection Benefits: – Minimization of risks of work with unreliable suppliers … quality, surety or supply and commercial competitiveness directly impact sales – Minimization of product reputation/brand risks … it takes years to create good reputation and just one minute to destroy it – Minimization of financial risks. . . financially unstable supplier may jeopardize customer’s orders execution – Better understanding of suppliers commercial & capacity capabilities. . . helping to reach “WIN-WIN” situation with supplier for long term 7 GE Transportation/Dimitry Sevostyanov 3/19/2018

WHAT is Supplier Selection & WHY GE Follows It? Supplier Selection – process designed to find approve new suppliers for products and services. Supplier Selection Benefits: – Minimization of risks of work with unreliable suppliers … quality, surety or supply and commercial competitiveness directly impact sales – Minimization of product reputation/brand risks … it takes years to create good reputation and just one minute to destroy it – Minimization of financial risks. . . financially unstable supplier may jeopardize customer’s orders execution – Better understanding of suppliers commercial & capacity capabilities. . . helping to reach “WIN-WIN” situation with supplier for long term 7 GE Transportation/Dimitry Sevostyanov 3/19/2018

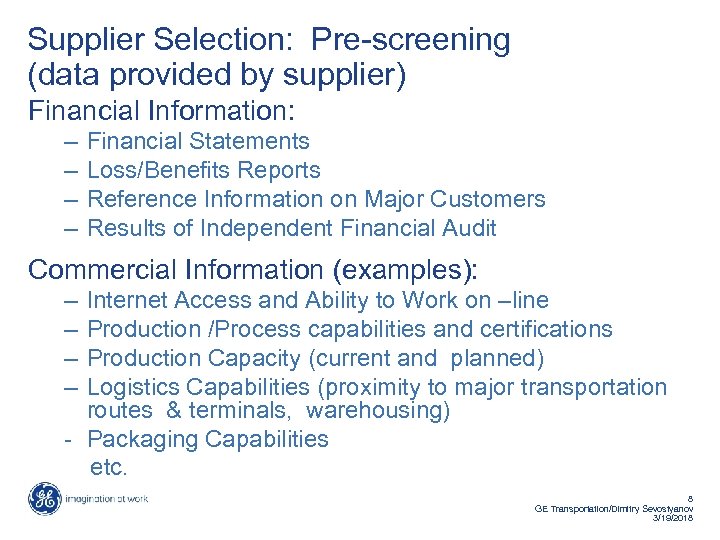

Supplier Selection: Pre-screening (data provided by supplier) Financial Information: – – Financial Statements Loss/Benefits Reports Reference Information on Major Customers Results of Independent Financial Audit Commercial Information (examples): – – Internet Access and Ability to Work on –line Production /Process capabilities and certifications Production Capacity (current and planned) Logistics Capabilities (proximity to major transportation routes & terminals, warehousing) - Packaging Capabilities etc. 8 GE Transportation/Dimitry Sevostyanov 3/19/2018

Supplier Selection: Pre-screening (data provided by supplier) Financial Information: – – Financial Statements Loss/Benefits Reports Reference Information on Major Customers Results of Independent Financial Audit Commercial Information (examples): – – Internet Access and Ability to Work on –line Production /Process capabilities and certifications Production Capacity (current and planned) Logistics Capabilities (proximity to major transportation routes & terminals, warehousing) - Packaging Capabilities etc. 8 GE Transportation/Dimitry Sevostyanov 3/19/2018

Supplier Selection: On-Site Audit Compliance (examples): – EHS – IP protection – Compliance: to local & international law; readiness to adhere to GE Supplier Commitment – Management Integrity etc. General Assessment: - Operational Management - Quality Management System – Manufacturing and Engineering Technology, R&D Capability – Special Processes KNOW YOUR SUPPLIERS ! 9 GE Transportation/Dimitry Sevostyanov 3/19/2018

Supplier Selection: On-Site Audit Compliance (examples): – EHS – IP protection – Compliance: to local & international law; readiness to adhere to GE Supplier Commitment – Management Integrity etc. General Assessment: - Operational Management - Quality Management System – Manufacturing and Engineering Technology, R&D Capability – Special Processes KNOW YOUR SUPPLIERS ! 9 GE Transportation/Dimitry Sevostyanov 3/19/2018

Supplier Selection and NCI… One Process 10 GE Transportation/Dimitry Sevostyanov 3/19/2018

Supplier Selection and NCI… One Process 10 GE Transportation/Dimitry Sevostyanov 3/19/2018

GE Transportation Global Sourcing • Matrix Organization: Commodities X Poles • >3, 500 Global Suppliers • ~ $1. 5 B Spend Globally Europe: • Over 110 Qualified Suppliers (85 Active) • 15 countries • Supplier of Critical Parts and Assemblies to the business 11 GE Transportation/Dimitry Sevostyanov 3/19/2018

GE Transportation Global Sourcing • Matrix Organization: Commodities X Poles • >3, 500 Global Suppliers • ~ $1. 5 B Spend Globally Europe: • Over 110 Qualified Suppliers (85 Active) • 15 countries • Supplier of Critical Parts and Assemblies to the business 11 GE Transportation/Dimitry Sevostyanov 3/19/2018

Europe: Key Commodities & Established Supply: Suppliers pumps, brake systems, heat exchangers , valves, Engineered Systems: Vibration dampers Bearings: ball & roller (in tamper) bearings Castings: large & mid size (1, 000 -8, 000 mt) steel & ductile iron; Al castings Forgings: large, mid, small size forgings (incl forged rings) Machined Parts: rough and fully machined castings and forgings New Opportunities: Fabrications, Electrical Parts, C-class (catalog parts Looking Forward to Find New Suppliers! 12 GE Transportation/Dimitry Sevostyanov 3/19/2018

Europe: Key Commodities & Established Supply: Suppliers pumps, brake systems, heat exchangers , valves, Engineered Systems: Vibration dampers Bearings: ball & roller (in tamper) bearings Castings: large & mid size (1, 000 -8, 000 mt) steel & ductile iron; Al castings Forgings: large, mid, small size forgings (incl forged rings) Machined Parts: rough and fully machined castings and forgings New Opportunities: Fabrications, Electrical Parts, C-class (catalog parts Looking Forward to Find New Suppliers! 12 GE Transportation/Dimitry Sevostyanov 3/19/2018

Questions?

Questions?

THANK YOU ! 14 GE Transportation/Dimitry Sevostyanov 3/19/2018

THANK YOU ! 14 GE Transportation/Dimitry Sevostyanov 3/19/2018