50cda739d5c891b7d65a21a6816f1433.ppt

- Количество слайдов: 71

NESHAP info sources • http//ttnwww. rtpnc. epa. gov • ward. ingred@epamail. epa. gov – (919)541 -0300 • USEPA Region IX, San Francisco – (415) 744 -1143

NESHAP info sources • http//ttnwww. rtpnc. epa. gov • ward. ingred@epamail. epa. gov – (919)541 -0300 • USEPA Region IX, San Francisco – (415) 744 -1143

http: //www. epa. gov/ttn/atw/gp/gppg. html Rule and Implementation Information for Part 63 General Provisions (Subpart A) http: //www. epa. gov/ttn/atw/aerosp/aeropg. html Rule and Implementation Information for the Aerospace Industry http: //www. epa. gov/ttn/atw/aerosp/filter. pdf List of a dozen Manufacturers of Paint Arrestors Certified by Method 319 http: //www. epa. gov/ttn/atw/aerosp/fr 398 f. txt Aerospace Manufacture & Rework Facilities; NESHAP and Control Techniques Guideline; Final and Proposed Rules

http: //www. epa. gov/ttn/atw/gp/gppg. html Rule and Implementation Information for Part 63 General Provisions (Subpart A) http: //www. epa. gov/ttn/atw/aerosp/aeropg. html Rule and Implementation Information for the Aerospace Industry http: //www. epa. gov/ttn/atw/aerosp/filter. pdf List of a dozen Manufacturers of Paint Arrestors Certified by Method 319 http: //www. epa. gov/ttn/atw/aerosp/fr 398 f. txt Aerospace Manufacture & Rework Facilities; NESHAP and Control Techniques Guideline; Final and Proposed Rules

EPA’s Hazardous Air Pollutants Program Clean Air Act § 112 • • • (b) list of 188 HAP (c) list of sources emitting these HAP (d) performance standard shall be the Maximum Achievable Control Technology (MACT) (twelfth percentile of existing installations) • (f) residual risk

EPA’s Hazardous Air Pollutants Program Clean Air Act § 112 • • • (b) list of 188 HAP (c) list of sources emitting these HAP (d) performance standard shall be the Maximum Achievable Control Technology (MACT) (twelfth percentile of existing installations) • (f) residual risk

EPA’s Hazardous Air Pollutants Program Aerospace NESHAP • General Provisions 40 CFR 63, subpart A, 1994 • List of sources emitting 40 CFR 61 • MACT standard for Aerospace Coating Operations 40 CFR 63 Subpart GG • Residual risk - not yet drafted

EPA’s Hazardous Air Pollutants Program Aerospace NESHAP • General Provisions 40 CFR 63, subpart A, 1994 • List of sources emitting 40 CFR 61 • MACT standard for Aerospace Coating Operations 40 CFR 63 Subpart GG • Residual risk - not yet drafted

General NESHAP Final Compliance Date September 1, 1998

General NESHAP Final Compliance Date September 1, 1998

NESHAP vs District Rules The NESHAP provides additional HAP reductions and enhanced compliance by self reporting

NESHAP vs District Rules The NESHAP provides additional HAP reductions and enhanced compliance by self reporting

NESHAP vs District Rules The following substances are listed as federal HAP but are exempt from existing district VOC rules • 1, 1, 1 - Trichloroethane • Perchloroethylene • Methylene Chloride

NESHAP vs District Rules The following substances are listed as federal HAP but are exempt from existing district VOC rules • 1, 1, 1 - Trichloroethane • Perchloroethylene • Methylene Chloride

NESHAP vs District Rules Both the district breakdown rule and the NESHAP malfunction provision allow the source to continue operating while affecting repairs. EPA has traditionally opposed variances. Will the variance application and report delineating emission minimization during breakdown satisfy EPA’s malfunction plan requirements?

NESHAP vs District Rules Both the district breakdown rule and the NESHAP malfunction provision allow the source to continue operating while affecting repairs. EPA has traditionally opposed variances. Will the variance application and report delineating emission minimization during breakdown satisfy EPA’s malfunction plan requirements?

NESHAP vs District Rules District rules require new and existing sources meet the same limits. The NESHAP has stricter limits for reconstructions with a capital cost in excess of 50% of the cost of the facility. • District rules will likely be changed.

NESHAP vs District Rules District rules require new and existing sources meet the same limits. The NESHAP has stricter limits for reconstructions with a capital cost in excess of 50% of the cost of the facility. • District rules will likely be changed.

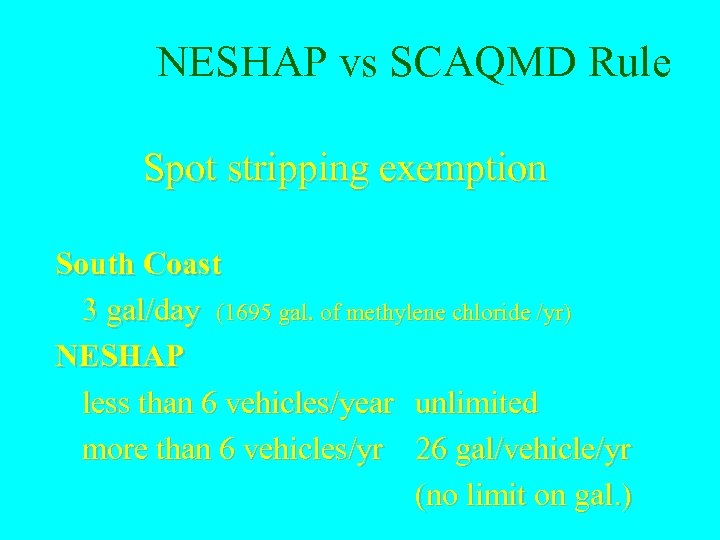

NESHAP vs SCAQMD Rule Spot stripping exemption South Coast 3 gal/day (1695 gal. of methylene chloride /yr) NESHAP less than 6 vehicles/year unlimited more than 6 vehicles/yr 26 gal/vehicle/yr (no limit on gal. )

NESHAP vs SCAQMD Rule Spot stripping exemption South Coast 3 gal/day (1695 gal. of methylene chloride /yr) NESHAP less than 6 vehicles/year unlimited more than 6 vehicles/yr 26 gal/vehicle/yr (no limit on gal. )

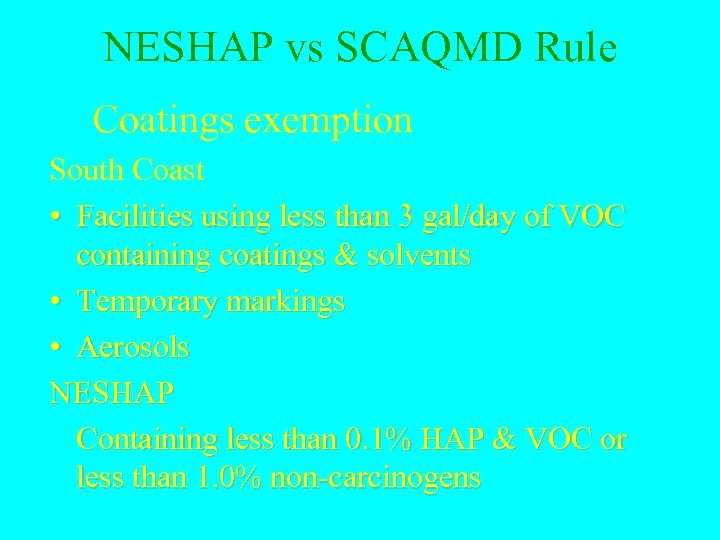

NESHAP vs SCAQMD Rule Coatings exemption South Coast • Facilities using less than 3 gal/day of VOC containing coatings & solvents • Temporary markings • Aerosols NESHAP Containing less than 0. 1% HAP & VOC or less than 1. 0% non-carcinogens

NESHAP vs SCAQMD Rule Coatings exemption South Coast • Facilities using less than 3 gal/day of VOC containing coatings & solvents • Temporary markings • Aerosols NESHAP Containing less than 0. 1% HAP & VOC or less than 1. 0% non-carcinogens

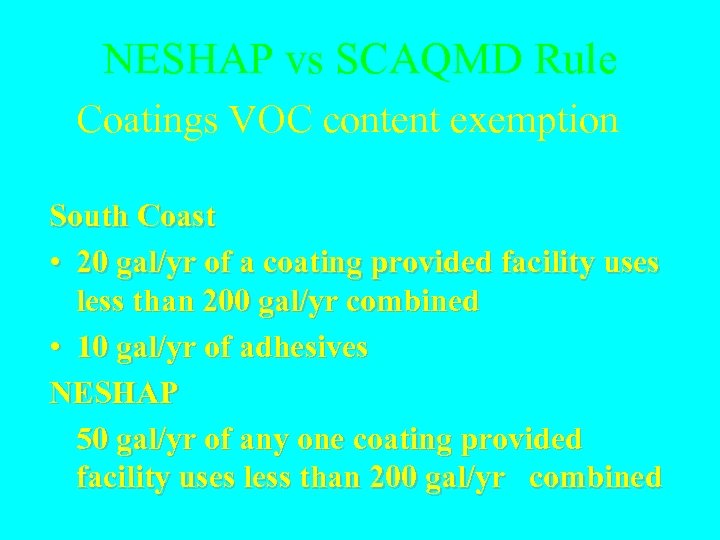

NESHAP vs SCAQMD Rule Coatings VOC content exemption South Coast • 20 gal/yr of a coating provided facility uses less than 200 gal/yr combined • 10 gal/yr of adhesives NESHAP 50 gal/yr of any one coating provided facility uses less than 200 gal/yr combined

NESHAP vs SCAQMD Rule Coatings VOC content exemption South Coast • 20 gal/yr of a coating provided facility uses less than 200 gal/yr combined • 10 gal/yr of adhesives NESHAP 50 gal/yr of any one coating provided facility uses less than 200 gal/yr combined

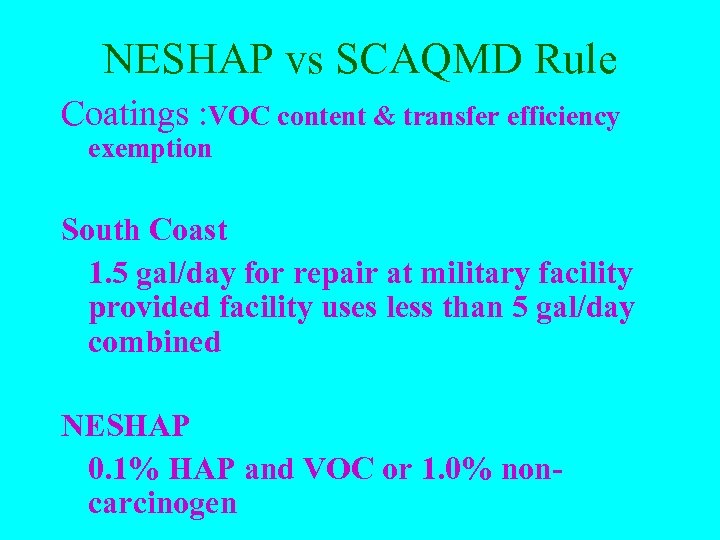

NESHAP vs SCAQMD Rule Coatings : VOC content & transfer efficiency exemption South Coast 1. 5 gal/day for repair at military facility provided facility uses less than 5 gal/day combined NESHAP 0. 1% HAP and VOC or 1. 0% noncarcinogen

NESHAP vs SCAQMD Rule Coatings : VOC content & transfer efficiency exemption South Coast 1. 5 gal/day for repair at military facility provided facility uses less than 5 gal/day combined NESHAP 0. 1% HAP and VOC or 1. 0% noncarcinogen

NESHAP vs SCAQMD Rule Controled Coatings South Coast • 86% Control (90% capture x 95% control) or • 50 ppm at exhaust NESHAP 81% Control

NESHAP vs SCAQMD Rule Controled Coatings South Coast • 86% Control (90% capture x 95% control) or • 50 ppm at exhaust NESHAP 81% Control

NESHAP vs District Rules No specific “minimize spills” provision in district rule. For handwipe cleaning district has “ 200 gms VOC” vs. compositional compliance or 60% volume reduction in NESHAP. No HAP limit in district VOC rules Districts will need to incorporate HAP limits for coatings and cleaning solvents. Likely handwipe limit will be less than 0. 1% carcinogen & less than 1. 0% non-carcinogenic HAP to qualify for exemption.

NESHAP vs District Rules No specific “minimize spills” provision in district rule. For handwipe cleaning district has “ 200 gms VOC” vs. compositional compliance or 60% volume reduction in NESHAP. No HAP limit in district VOC rules Districts will need to incorporate HAP limits for coatings and cleaning solvents. Likely handwipe limit will be less than 0. 1% carcinogen & less than 1. 0% non-carcinogenic HAP to qualify for exemption.

NESHAP vs District Rules For chemical milling maskants there is No commonality between rules. SCoast Chemical Milling & Chemical Processing 250 g/l NESHAP Type I 622 g/l Type II 160 g/l

NESHAP vs District Rules For chemical milling maskants there is No commonality between rules. SCoast Chemical Milling & Chemical Processing 250 g/l NESHAP Type I 622 g/l Type II 160 g/l

NESHAP vs District Rules For “any alternative approved by the director” EPA has 180 days to decide. Districts suggest authority reverts to local district after 15 days.

NESHAP vs District Rules For “any alternative approved by the director” EPA has 180 days to decide. Districts suggest authority reverts to local district after 15 days.

Aerospace NESHAP Matrix • Applicability Organic Depainting • Exemptions Inorganic Depainting Gun Cleaning • Standards Surf. Cleaning • Tests, Recordkeeping & Reporting Painting

Aerospace NESHAP Matrix • Applicability Organic Depainting • Exemptions Inorganic Depainting Gun Cleaning • Standards Surf. Cleaning • Tests, Recordkeeping & Reporting Painting

Aerospace Coating MACT • Applicability • Exemptions • Standards • Tests, Recordkeeping & Reporting

Aerospace Coating MACT • Applicability • Exemptions • Standards • Tests, Recordkeeping & Reporting

Aerospace NESHAP Applicability • A major HAP source making or reworking commercial, civil or military vehicles or components and • Applying primer, topcoat or chemical milling maskant, cleaning with solvent or stripping paint

Aerospace NESHAP Applicability • A major HAP source making or reworking commercial, civil or military vehicles or components and • Applying primer, topcoat or chemical milling maskant, cleaning with solvent or stripping paint

NESHAP-General Provisions Applicability • Major sources - those facilities with the potential to emit 10 tpy of any listed HAP or 25 tpy of any combination of listed HAP

NESHAP-General Provisions Applicability • Major sources - those facilities with the potential to emit 10 tpy of any listed HAP or 25 tpy of any combination of listed HAP

Aerospace NESHAP Applicability • All hand wipe and flush cleaning operations • Each spray gun cleaner, chemical milling maskant application operation, waste storage and handling operation • Each primer, topcoat and depainting operation that emits organic HAP or VOC • Each spray booth or hangar that contains a primer, topcoat or depainting operation emitting inorganic HAP

Aerospace NESHAP Applicability • All hand wipe and flush cleaning operations • Each spray gun cleaner, chemical milling maskant application operation, waste storage and handling operation • Each primer, topcoat and depainting operation that emits organic HAP or VOC • Each spray booth or hangar that contains a primer, topcoat or depainting operation emitting inorganic HAP

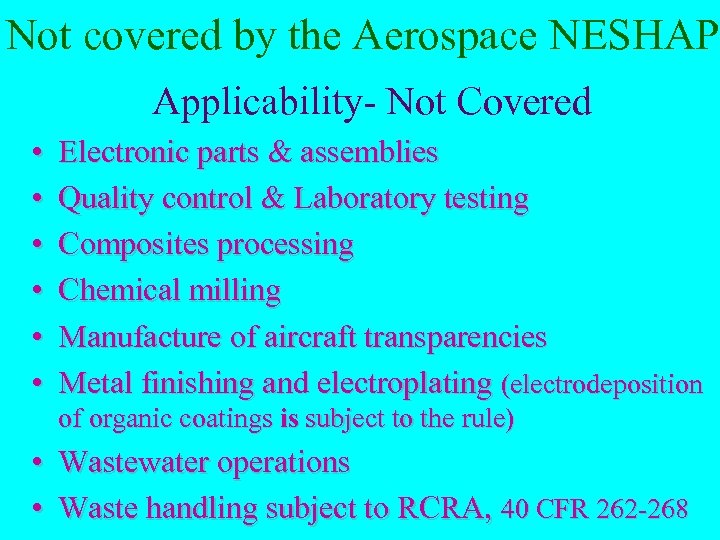

Not covered by the Aerospace NESHAP Applicability- Not Covered • • • Electronic parts & assemblies Quality control & Laboratory testing Composites processing Chemical milling Manufacture of aircraft transparencies Metal finishing and electroplating (electrodeposition of organic coatings is subject to the rule) • Wastewater operations • Waste handling subject to RCRA, 40 CFR 262 -268

Not covered by the Aerospace NESHAP Applicability- Not Covered • • • Electronic parts & assemblies Quality control & Laboratory testing Composites processing Chemical milling Manufacture of aircraft transparencies Metal finishing and electroplating (electrodeposition of organic coatings is subject to the rule) • Wastewater operations • Waste handling subject to RCRA, 40 CFR 262 -268

Aerospace NESHAP Exemptions 63. 741 Specialty coatings (listed in Appendix A) Sealants and adhesives Adhesive bonding primers Any coating, stripper or solvent containing less than 0. 1% carcinogen or less than 1. 0% non-carcinogen Facilities that use less than 50 gal/yr of each coating or maskant and less than 200 gal/yr for all coatings & maskants Parts and assemblies not critical to vehicle’s structural integrity or flight performance Activities associated with space vehicles (except for depainting) Rework of antique aerospace vehicles or components

Aerospace NESHAP Exemptions 63. 741 Specialty coatings (listed in Appendix A) Sealants and adhesives Adhesive bonding primers Any coating, stripper or solvent containing less than 0. 1% carcinogen or less than 1. 0% non-carcinogen Facilities that use less than 50 gal/yr of each coating or maskant and less than 200 gal/yr for all coatings & maskants Parts and assemblies not critical to vehicle’s structural integrity or flight performance Activities associated with space vehicles (except for depainting) Rework of antique aerospace vehicles or components

NESHAP- General Provisions 63. 9 Tests, Recordkeeping & Reporting • Notifications to be sent to Regional Federal authority and Local (State) authority • Initial aerospace notification (A/C or permit app) due 1 Sept 1998 • followed by: Performance test, Continuous Monitoring System, Compliance status

NESHAP- General Provisions 63. 9 Tests, Recordkeeping & Reporting • Notifications to be sent to Regional Federal authority and Local (State) authority • Initial aerospace notification (A/C or permit app) due 1 Sept 1998 • followed by: Performance test, Continuous Monitoring System, Compliance status

Aerospace Cleaning MACT 63. 744 • Applicability • Exemptions • Standards • Tests, Recordkeeping & Reporting

Aerospace Cleaning MACT 63. 744 • Applicability • Exemptions • Standards • Tests, Recordkeeping & Reporting

NESHAP- Cleaning Operations 63. 744(a) Applicability • A major HAP source making or reworking commercial, civil or military vehicles or components and • Hand-wipe clean : remove contaminants from an aerospace vehicle or component by rubbing with material moistened with a cleaning solvent • Flush clean: passing solvent over, into or through the component

NESHAP- Cleaning Operations 63. 744(a) Applicability • A major HAP source making or reworking commercial, civil or military vehicles or components and • Hand-wipe clean : remove contaminants from an aerospace vehicle or component by rubbing with material moistened with a cleaning solvent • Flush clean: passing solvent over, into or through the component

NESHAP- Cleaning Operations 63. 744(a) Standards - Hand wipe compliance alternatives (a)* and (a)** • use aqueous solvent (>80% H 2 O) or hydrocarbon solvent with a maximum vapor pressure of 7 mm Hg at 20 o C and contains no HAP • solvents containing HAP or VOC at concentrations less than 0. 1% for carcinogens and 1. 0% for noncarcinogens (63. 741(f)) no other requirements need be met (*) is an imaginary number not appearing in the federal document

NESHAP- Cleaning Operations 63. 744(a) Standards - Hand wipe compliance alternatives (a)* and (a)** • use aqueous solvent (>80% H 2 O) or hydrocarbon solvent with a maximum vapor pressure of 7 mm Hg at 20 o C and contains no HAP • solvents containing HAP or VOC at concentrations less than 0. 1% for carcinogens and 1. 0% for noncarcinogens (63. 741(f)) no other requirements need be met (*) is an imaginary number not appearing in the federal document

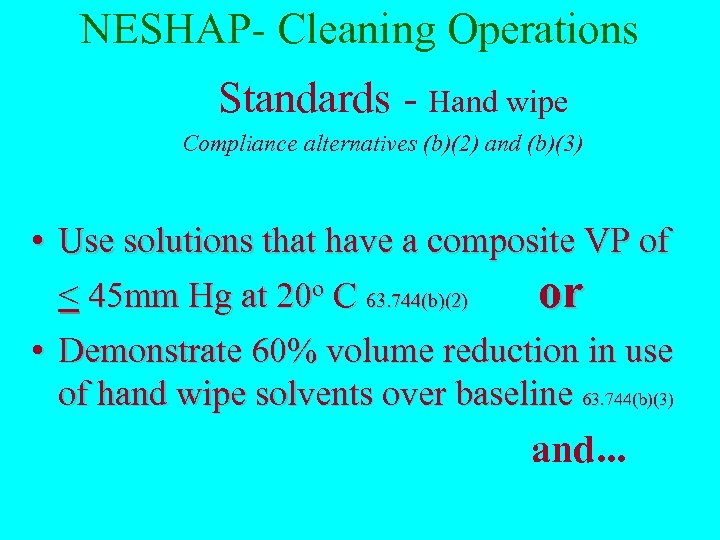

NESHAP- Cleaning Operations Standards - Hand wipe Compliance alternatives (b)(2) and (b)(3) • Use solutions that have a composite VP of < 45 mm Hg at 20 o C 63. 744(b)(2) or • Demonstrate 60% volume reduction in use of hand wipe solvents over baseline 63. 744(b)(3) and. . .

NESHAP- Cleaning Operations Standards - Hand wipe Compliance alternatives (b)(2) and (b)(3) • Use solutions that have a composite VP of < 45 mm Hg at 20 o C 63. 744(b)(2) or • Demonstrate 60% volume reduction in use of hand wipe solvents over baseline 63. 744(b)(3) and. . .

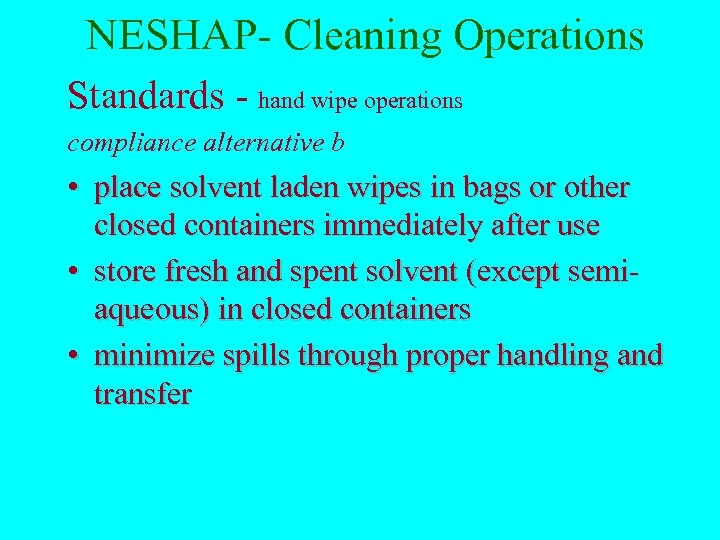

NESHAP- Cleaning Operations Standards - hand wipe operations compliance alternative b • place solvent laden wipes in bags or other closed containers immediately after use • store fresh and spent solvent (except semiaqueous) in closed containers • minimize spills through proper handling and transfer

NESHAP- Cleaning Operations Standards - hand wipe operations compliance alternative b • place solvent laden wipes in bags or other closed containers immediately after use • store fresh and spent solvent (except semiaqueous) in closed containers • minimize spills through proper handling and transfer

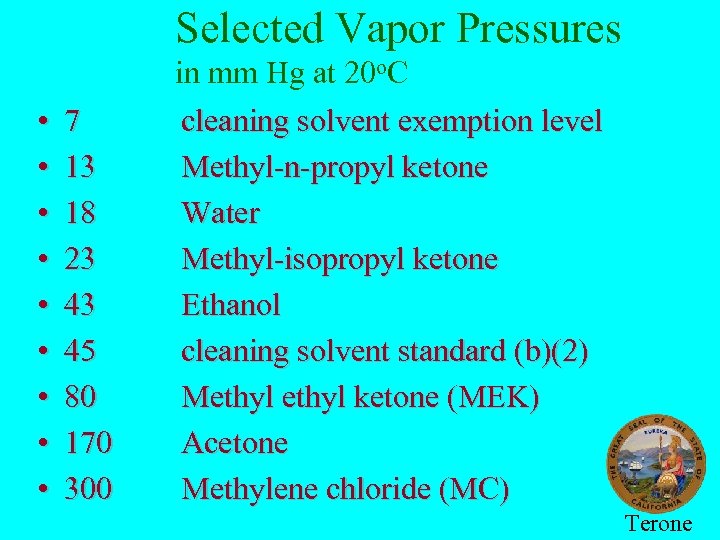

Selected Vapor Pressures • • • 7 13 18 23 43 45 80 170 300 in mm Hg at 20 o. C cleaning solvent exemption level Methyl-n-propyl ketone Water Methyl-isopropyl ketone Ethanol cleaning solvent standard (b)(2) Methyl ketone (MEK) Acetone Methylene chloride (MC) Terone

Selected Vapor Pressures • • • 7 13 18 23 43 45 80 170 300 in mm Hg at 20 o. C cleaning solvent exemption level Methyl-n-propyl ketone Water Methyl-isopropyl ketone Ethanol cleaning solvent standard (b)(2) Methyl ketone (MEK) Acetone Methylene chloride (MC) Terone

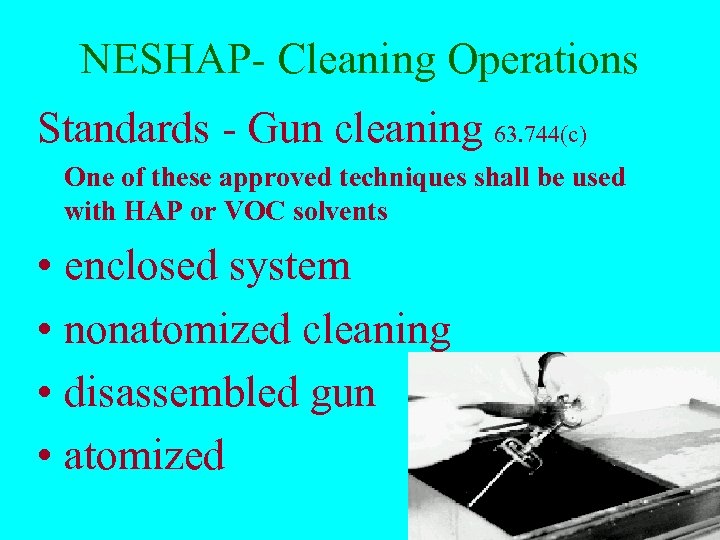

NESHAP- Cleaning Operations Standards - Gun cleaning 63. 744(c) One of these approved techniques shall be used with HAP or VOC solvents • enclosed system • nonatomized cleaning • disassembled gun • atomized

NESHAP- Cleaning Operations Standards - Gun cleaning 63. 744(c) One of these approved techniques shall be used with HAP or VOC solvents • enclosed system • nonatomized cleaning • disassembled gun • atomized

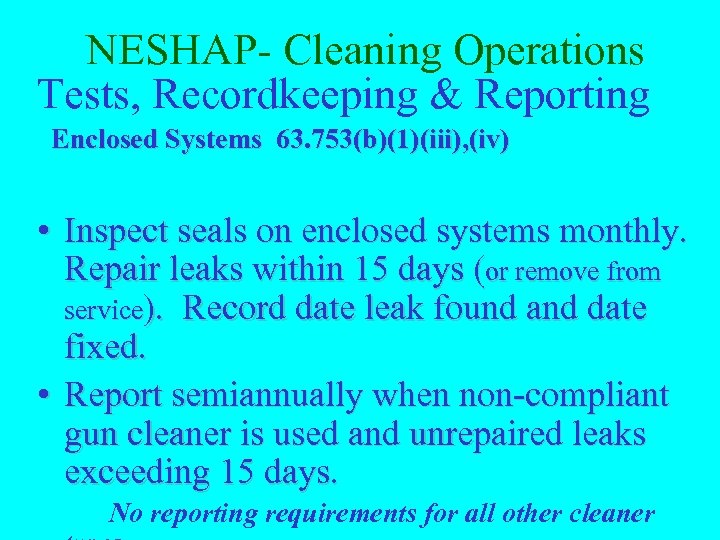

NESHAP- Cleaning Operations Tests, Recordkeeping & Reporting Enclosed Systems 63. 753(b)(1)(iii), (iv) • Inspect seals on enclosed systems monthly. Repair leaks within 15 days (or remove from service). Record date leak found and date fixed. • Report semiannually when non-compliant gun cleaner is used and unrepaired leaks exceeding 15 days. No reporting requirements for all other cleaner

NESHAP- Cleaning Operations Tests, Recordkeeping & Reporting Enclosed Systems 63. 753(b)(1)(iii), (iv) • Inspect seals on enclosed systems monthly. Repair leaks within 15 days (or remove from service). Record date leak found and date fixed. • Report semiannually when non-compliant gun cleaner is used and unrepaired leaks exceeding 15 days. No reporting requirements for all other cleaner

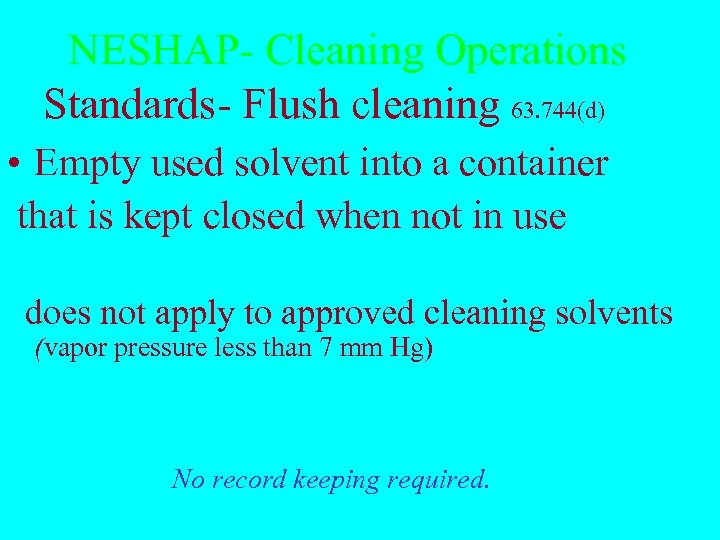

NESHAP- Cleaning Operations Standards- Flush cleaning 63. 744(d) • Empty used solvent into a container that is kept closed when not in use does not apply to approved cleaning solvents (vapor pressure less than 7 mm Hg) No record keeping required.

NESHAP- Cleaning Operations Standards- Flush cleaning 63. 744(d) • Empty used solvent into a container that is kept closed when not in use does not apply to approved cleaning solvents (vapor pressure less than 7 mm Hg) No record keeping required.

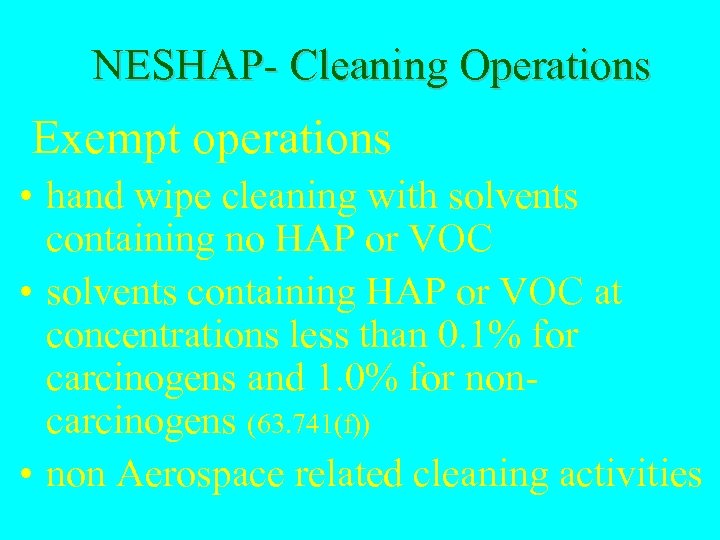

NESHAP- Cleaning Operations Exempt operations • hand wipe cleaning with solvents containing no HAP or VOC • solvents containing HAP or VOC at concentrations less than 0. 1% for carcinogens and 1. 0% for noncarcinogens (63. 741(f)) • non Aerospace related cleaning activities

NESHAP- Cleaning Operations Exempt operations • hand wipe cleaning with solvents containing no HAP or VOC • solvents containing HAP or VOC at concentrations less than 0. 1% for carcinogens and 1. 0% for noncarcinogens (63. 741(f)) • non Aerospace related cleaning activities

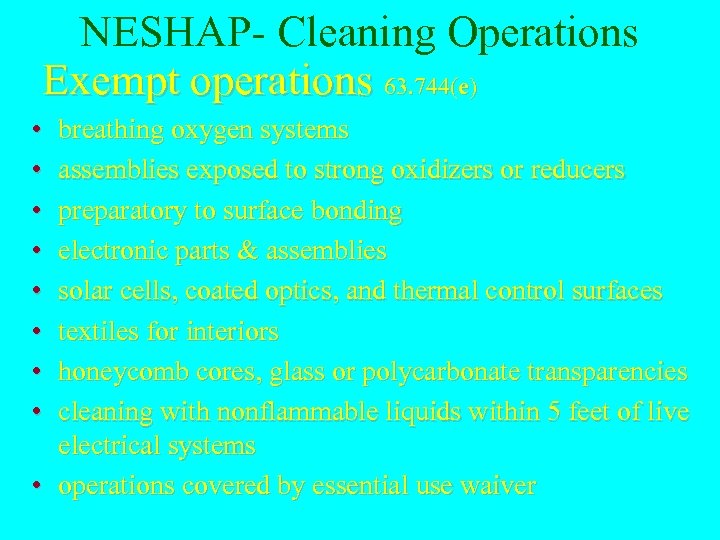

NESHAP- Cleaning Operations Exempt operations 63. 744(e) • • breathing oxygen systems assemblies exposed to strong oxidizers or reducers preparatory to surface bonding electronic parts & assemblies solar cells, coated optics, and thermal control surfaces textiles for interiors honeycomb cores, glass or polycarbonate transparencies cleaning with nonflammable liquids within 5 feet of live electrical systems • operations covered by essential use waiver

NESHAP- Cleaning Operations Exempt operations 63. 744(e) • • breathing oxygen systems assemblies exposed to strong oxidizers or reducers preparatory to surface bonding electronic parts & assemblies solar cells, coated optics, and thermal control surfaces textiles for interiors honeycomb cores, glass or polycarbonate transparencies cleaning with nonflammable liquids within 5 feet of live electrical systems • operations covered by essential use waiver

NESHAP- Cleaning Operations Tests, Recordkeeping & Reporting Vapor Pressure Determination single component solvents see MSDS, product data sheet or other reference blended solvents - calculate composite vp using manufacturer’s data and partial pressures per equation in 63. 750(b)(2)

NESHAP- Cleaning Operations Tests, Recordkeeping & Reporting Vapor Pressure Determination single component solvents see MSDS, product data sheet or other reference blended solvents - calculate composite vp using manufacturer’s data and partial pressures per equation in 63. 750(b)(2)

NESHAP- Cleaning Operations Tests, Recordkeeping & Reporting Name, Vapor Pressure, & organic HAP content of each solvent used For composition compliance , (a)* and (a)**, record calculations and annual consumption For vp compliance , (b)(2), record vp, calculations, test results, & monthly consumption at each operation For 60% reduction compliance, (b)(3), copy of approved alternative plan and all supporting documentation For exempt operations using non-complying solvents record monthly volumes by operation and keep a list of processes using exemption 63. 752(b)(4) Maintain purchase records and MSDS for exempt coatings

NESHAP- Cleaning Operations Tests, Recordkeeping & Reporting Name, Vapor Pressure, & organic HAP content of each solvent used For composition compliance , (a)* and (a)**, record calculations and annual consumption For vp compliance , (b)(2), record vp, calculations, test results, & monthly consumption at each operation For 60% reduction compliance, (b)(3), copy of approved alternative plan and all supporting documentation For exempt operations using non-complying solvents record monthly volumes by operation and keep a list of processes using exemption 63. 752(b)(4) Maintain purchase records and MSDS for exempt coatings

NESHAP- Cleaning Operations Tests, Recordkeeping & Reporting Semi-annual For control options (a)*, (a)** and (b)(2) • Compliant and Non-compliant cleaning solvent usage • New cleaning solvents and vapor pressure or composition • Compliance certification statement For option (b)(3) • Demonstrate that the 60% reduction is equivalent to options (a) or (b)(2)

NESHAP- Cleaning Operations Tests, Recordkeeping & Reporting Semi-annual For control options (a)*, (a)** and (b)(2) • Compliant and Non-compliant cleaning solvent usage • New cleaning solvents and vapor pressure or composition • Compliance certification statement For option (b)(3) • Demonstrate that the 60% reduction is equivalent to options (a) or (b)(2)

NESHAP- Coating Operations Exempt coatings a) any coating, stripper or solvent containing less a) than 0. 1% carcinogen or less than 1. 0% noncarcinogen b) specialty coatings listed in Appendix A b) c) facilities that use less than 50 gal/yr of each c) coating or maskant and than less 200 gal/yr for all exempt coatings & maskants

NESHAP- Coating Operations Exempt coatings a) any coating, stripper or solvent containing less a) than 0. 1% carcinogen or less than 1. 0% noncarcinogen b) specialty coatings listed in Appendix A b) c) facilities that use less than 50 gal/yr of each c) coating or maskant and than less 200 gal/yr for all exempt coatings & maskants

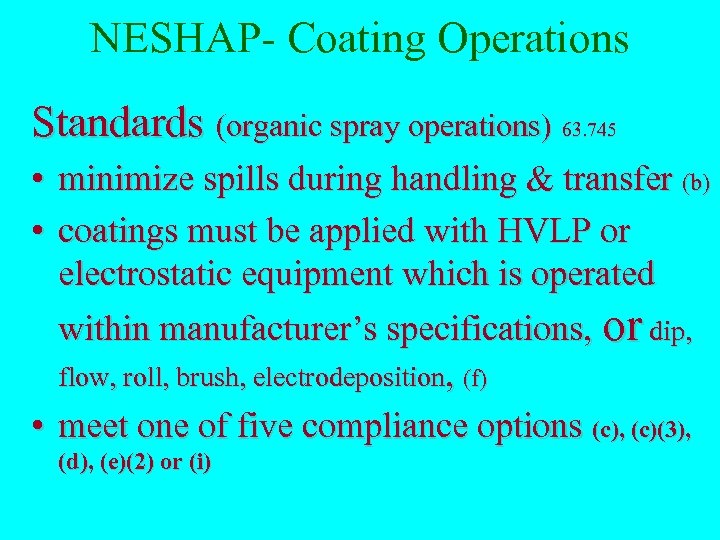

NESHAP- Coating Operations Standards (organic spray operations) 63. 745 • minimize spills during handling & transfer (b) • coatings must be applied with HVLP or electrostatic equipment which is operated within manufacturer’s specifications, or dip, flow, roll, brush, electrodeposition, (f) • meet one of five compliance options (c), (c)(3), (d), (e)(2) or (i)

NESHAP- Coating Operations Standards (organic spray operations) 63. 745 • minimize spills during handling & transfer (b) • coatings must be applied with HVLP or electrostatic equipment which is operated within manufacturer’s specifications, or dip, flow, roll, brush, electrodeposition, (f) • meet one of five compliance options (c), (c)(3), (d), (e)(2) or (i)

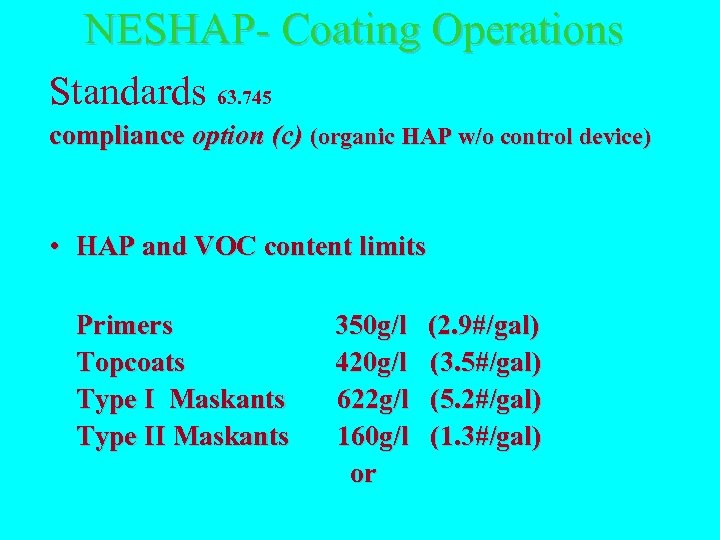

NESHAP- Coating Operations Standards 63. 745 compliance option (c) (organic HAP w/o control device) • HAP and VOC content limits Primers 350 g/l (2. 9#/gal) Topcoats 420 g/l (3. 5#/gal) Type I Maskants 622 g/l (5. 2#/gal) Type II Maskants 160 g/l (1. 3#/gal) or

NESHAP- Coating Operations Standards 63. 745 compliance option (c) (organic HAP w/o control device) • HAP and VOC content limits Primers 350 g/l (2. 9#/gal) Topcoats 420 g/l (3. 5#/gal) Type I Maskants 622 g/l (5. 2#/gal) Type II Maskants 160 g/l (1. 3#/gal) or

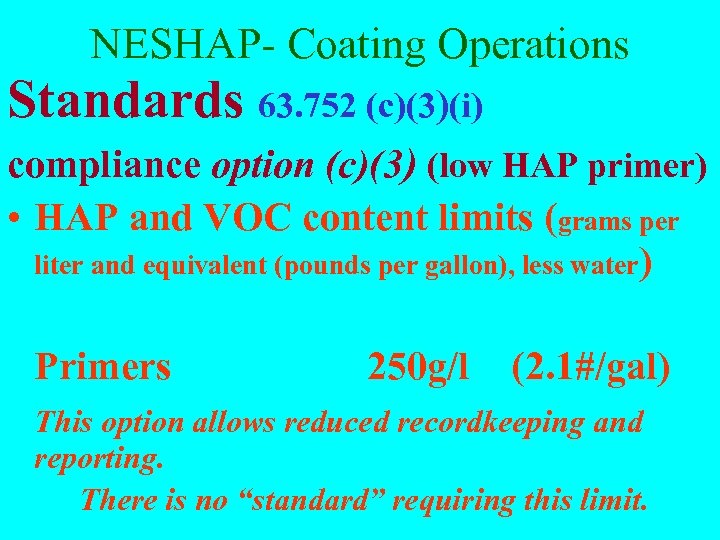

NESHAP- Coating Operations Standards 63. 752 (c)(3)(i) compliance option (c)(3) (low HAP primer) • HAP and VOC content limits (grams per liter and equivalent (pounds per gallon), less water) Primers 250 g/l (2. 1#/gal) This option allows reduced recordkeeping and reporting. There is no “standard” requiring this limit.

NESHAP- Coating Operations Standards 63. 752 (c)(3)(i) compliance option (c)(3) (low HAP primer) • HAP and VOC content limits (grams per liter and equivalent (pounds per gallon), less water) Primers 250 g/l (2. 1#/gal) This option allows reduced recordkeeping and reporting. There is no “standard” requiring this limit.

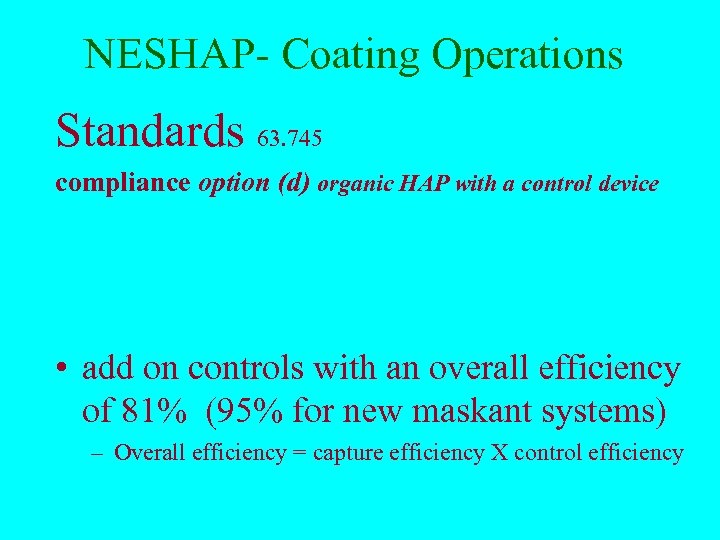

NESHAP- Coating Operations Standards 63. 745 compliance option (d) organic HAP with a control device • add on controls with an overall efficiency of 81% (95% for new maskant systems) – Overall efficiency = capture efficiency X control efficiency

NESHAP- Coating Operations Standards 63. 745 compliance option (d) organic HAP with a control device • add on controls with an overall efficiency of 81% (95% for new maskant systems) – Overall efficiency = capture efficiency X control efficiency

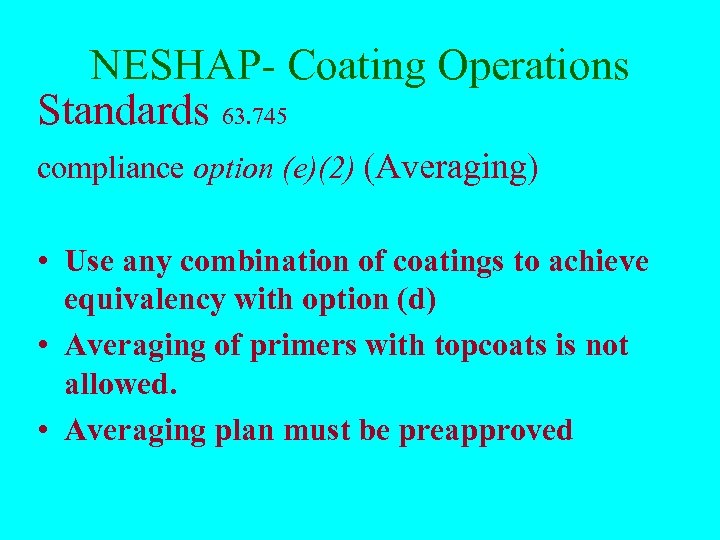

NESHAP- Coating Operations Standards 63. 745 compliance option (e)(2) (Averaging) • Use any combination of coatings to achieve equivalency with option (d) • Averaging of primers with topcoats is not allowed. • Averaging plan must be preapproved

NESHAP- Coating Operations Standards 63. 745 compliance option (e)(2) (Averaging) • Use any combination of coatings to achieve equivalency with option (d) • Averaging of primers with topcoats is not allowed. • Averaging plan must be preapproved

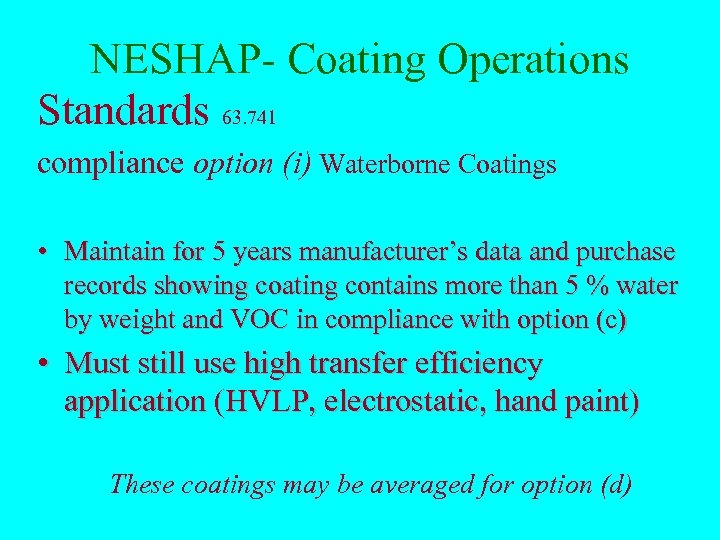

NESHAP- Coating Operations Standards 63. 741 compliance option (i) Waterborne Coatings • Maintain for 5 years manufacturer’s data and purchase records showing coating contains more than 5 % water by weight and VOC in compliance with option (c) • Must still use high transfer efficiency application (HVLP, electrostatic, hand paint) These coatings may be averaged for option (d)

NESHAP- Coating Operations Standards 63. 741 compliance option (i) Waterborne Coatings • Maintain for 5 years manufacturer’s data and purchase records showing coating contains more than 5 % water by weight and VOC in compliance with option (c) • Must still use high transfer efficiency application (HVLP, electrostatic, hand paint) These coatings may be averaged for option (d)

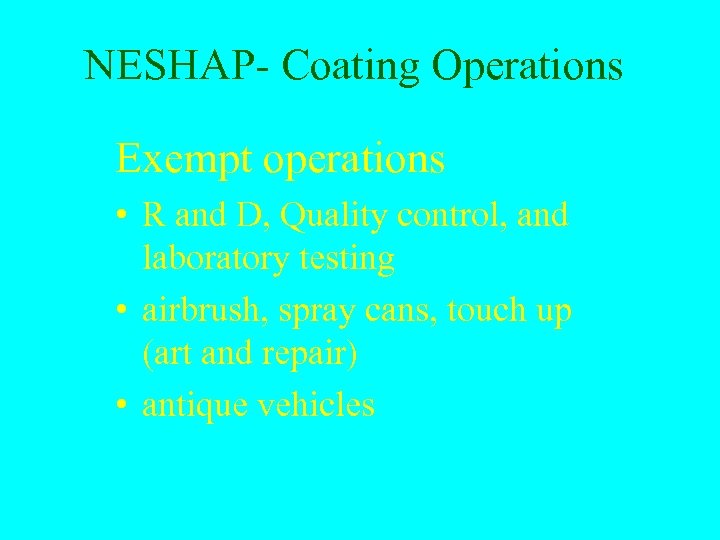

NESHAP- Coating Operations Exempt operations • R and D, Quality control, and laboratory testing • airbrush, spray cans, touch up (art and repair) • antique vehicles

NESHAP- Coating Operations Exempt operations • R and D, Quality control, and laboratory testing • airbrush, spray cans, touch up (art and repair) • antique vehicles

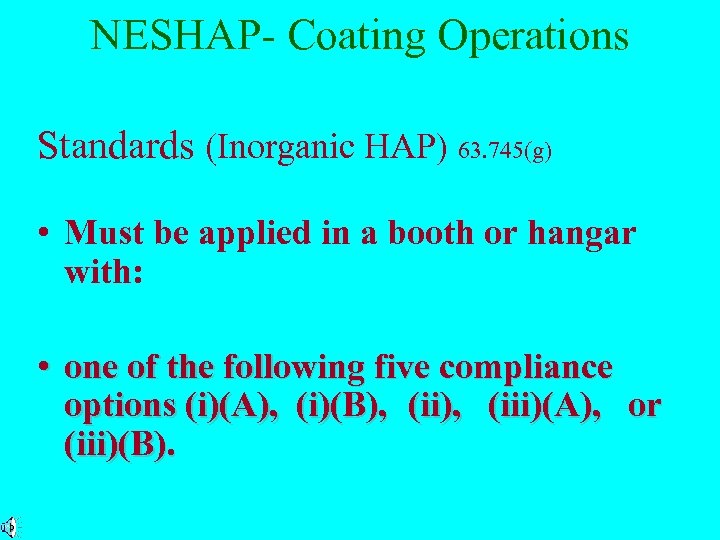

NESHAP- Coating Operations Standards (Inorganic HAP) 63. 745(g) • Must be applied in a booth or hangar with: • one of the following five compliance options (i)(A), (i)(B), (iii)(A), or (iii)(B).

NESHAP- Coating Operations Standards (Inorganic HAP) 63. 745(g) • Must be applied in a booth or hangar with: • one of the following five compliance options (i)(A), (i)(B), (iii)(A), or (iii)(B).

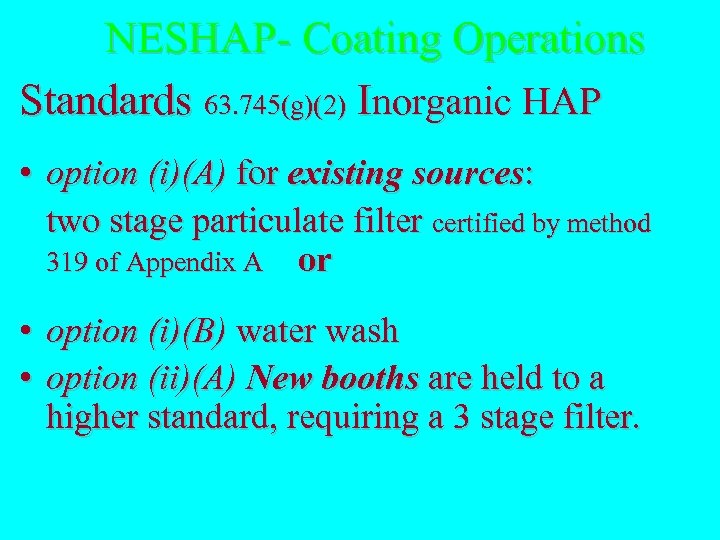

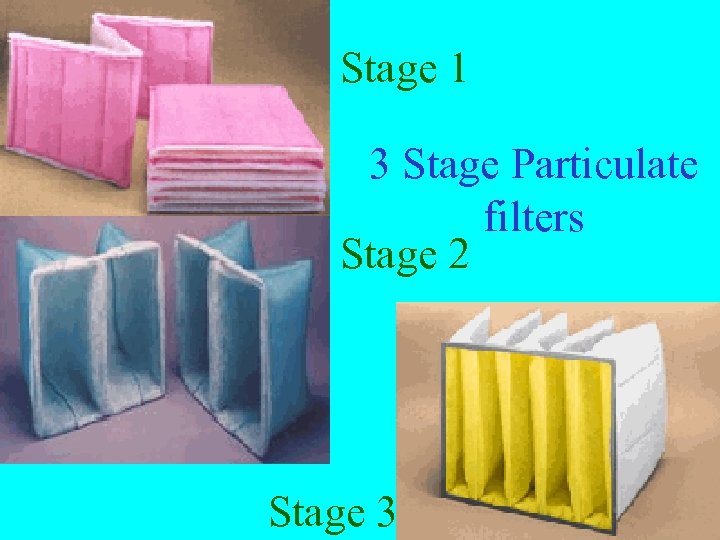

NESHAP- Coating Operations NESHAP- Coating Standards 63. 745(g)(2) Inorganic HAP • option (i)(A) for existing sources: two stage particulate filter certified by method 319 of Appendix A or • option (i)(B) water wash • option (ii)(A) New booths are held to a higher standard, requiring a 3 stage filter.

NESHAP- Coating Operations NESHAP- Coating Standards 63. 745(g)(2) Inorganic HAP • option (i)(A) for existing sources: two stage particulate filter certified by method 319 of Appendix A or • option (i)(B) water wash • option (ii)(A) New booths are held to a higher standard, requiring a 3 stage filter.

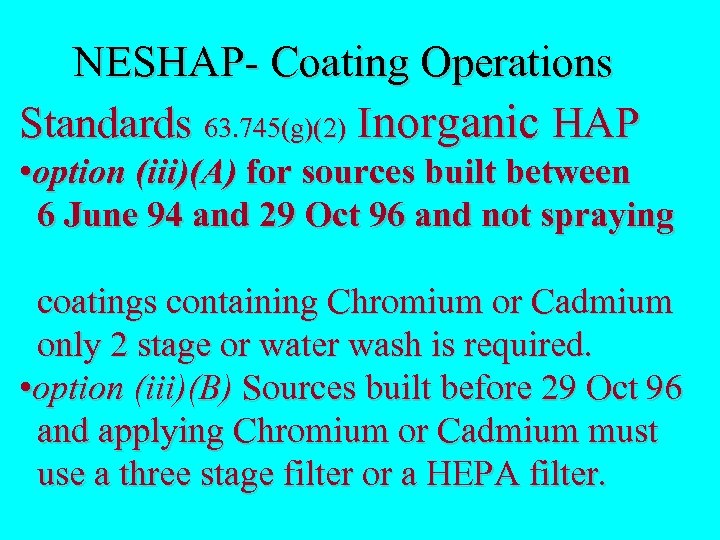

NESHAP- Coating Operations Standards 63. 745(g)(2) Inorganic HAP • option (iii)(A) for sources built between 6 June 94 and 29 Oct 96 and not spraying coatings containing Chromium or Cadmium only 2 stage or water wash is required. • option (iii)(B) Sources built before 29 Oct 96 and applying Chromium or Cadmium must use a three stage filter or a HEPA filter.

NESHAP- Coating Operations Standards 63. 745(g)(2) Inorganic HAP • option (iii)(A) for sources built between 6 June 94 and 29 Oct 96 and not spraying coatings containing Chromium or Cadmium only 2 stage or water wash is required. • option (iii)(B) Sources built before 29 Oct 96 and applying Chromium or Cadmium must use a three stage filter or a HEPA filter.

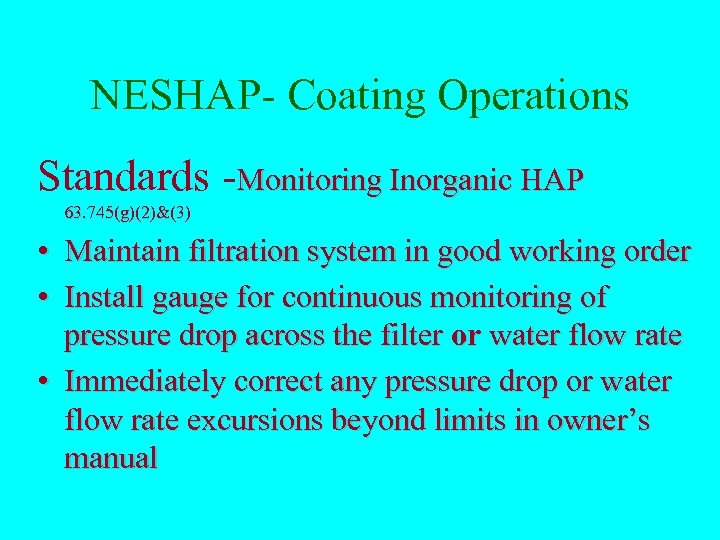

NESHAP- Coating Operations Standards -Monitoring Inorganic HAP 63. 745(g)(2)&(3) • Maintain filtration system in good working order • Install gauge for continuous monitoring of pressure drop across the filter or water flow rate • Immediately correct any pressure drop or water flow rate excursions beyond limits in owner’s manual

NESHAP- Coating Operations Standards -Monitoring Inorganic HAP 63. 745(g)(2)&(3) • Maintain filtration system in good working order • Install gauge for continuous monitoring of pressure drop across the filter or water flow rate • Immediately correct any pressure drop or water flow rate excursions beyond limits in owner’s manual

NESHAP- Coating Operations Tests, Recordkeeping & Reporting 63. 10(b)(1) • Records will be retained for five years, (two years on site).

NESHAP- Coating Operations Tests, Recordkeeping & Reporting 63. 10(b)(1) • Records will be retained for five years, (two years on site).

NESHAP- Coating Operations Tests, Recordkeeping & Reporting • option (d) – start up control efficiency test – carbon adsorber start up test to establish rolling material balance period – control other than carbon will be tested in 3 one hour runs

NESHAP- Coating Operations Tests, Recordkeeping & Reporting • option (d) – start up control efficiency test – carbon adsorber start up test to establish rolling material balance period – control other than carbon will be tested in 3 one hour runs

NESHAP- Coating Operations Tests, Recordkeeping & Reporting • • • control option (d) Filter systems must have pressure gauges. Pressure drop is to be monitored continuously and recorded once per shift. Waterwash systems must monitor water flow continuously and record once per shift when used. Incinerators must have temperature sensors with continuous recorders.

NESHAP- Coating Operations Tests, Recordkeeping & Reporting • • • control option (d) Filter systems must have pressure gauges. Pressure drop is to be monitored continuously and recorded once per shift. Waterwash systems must monitor water flow continuously and record once per shift when used. Incinerators must have temperature sensors with continuous recorders.

NESHAP- Coating Operations Tests, Recordkeeping & Reporting • VOC content & monthly volume of use of coatings option (d) • booth pressure drop across filter or water flow rate as recorded once per shift • incinerator efficiency & temperature • carbon bed efficiency, rolling period & calculations • Start up, shutdown, malfunction plan option (i) Manufacturer’s data on water content and annual purchase records

NESHAP- Coating Operations Tests, Recordkeeping & Reporting • VOC content & monthly volume of use of coatings option (d) • booth pressure drop across filter or water flow rate as recorded once per shift • incinerator efficiency & temperature • carbon bed efficiency, rolling period & calculations • Start up, shutdown, malfunction plan option (i) Manufacturer’s data on water content and annual purchase records

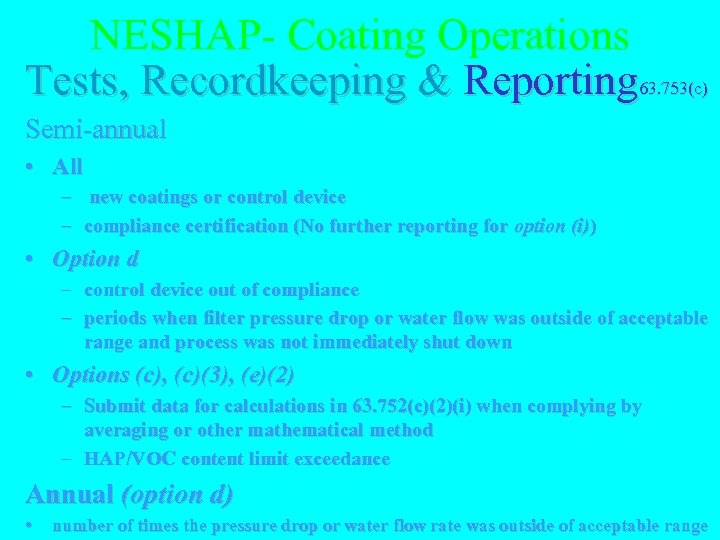

NESHAP- Coating Operations Tests, Recordkeeping & Reporting 63. 753(c) Semi-annual • All – new coatings or control device – compliance certification (No further reporting for option (i)) • Option d – control device out of compliance – periods when filter pressure drop or water flow was outside of acceptable range and process was not immediately shut down • Options (c), (c)(3), (e)(2) – Submit data for calculations in 63. 752(c)(2)(i) when complying by averaging or other mathematical method – HAP/VOC content limit exceedance Annual (option d) • number of times the pressure drop or water flow rate was outside of acceptable range

NESHAP- Coating Operations Tests, Recordkeeping & Reporting 63. 753(c) Semi-annual • All – new coatings or control device – compliance certification (No further reporting for option (i)) • Option d – control device out of compliance – periods when filter pressure drop or water flow was outside of acceptable range and process was not immediately shut down • Options (c), (c)(3), (e)(2) – Submit data for calculations in 63. 752(c)(2)(i) when complying by averaging or other mathematical method – HAP/VOC content limit exceedance Annual (option d) • number of times the pressure drop or water flow rate was outside of acceptable range

Aerospace Depainting MACT 63. 746 • Applicability • Exemptions • Standards • Tests, Recordkeeping & Reporting

Aerospace Depainting MACT 63. 746 • Applicability • Exemptions • Standards • Tests, Recordkeeping & Reporting

NESHAP- Depainting Operations Applicability • A major HAP source making or reworking commercial, civil or military vehicles or components • Outer surface of aerospace vehicles • fuselage, wings and stabilizers are always covered

NESHAP- Depainting Operations Applicability • A major HAP source making or reworking commercial, civil or military vehicles or components • Outer surface of aerospace vehicles • fuselage, wings and stabilizers are always covered

NESHAP- Depainting Operations Exempt operations • facilities that depaint 6 or fewer vehicles per year • radomes • parts and units normally removed • mechanical and hand sanding exempt from requirements of “enclosed area” and control system [746 (b)(1)]

NESHAP- Depainting Operations Exempt operations • facilities that depaint 6 or fewer vehicles per year • radomes • parts and units normally removed • mechanical and hand sanding exempt from requirements of “enclosed area” and control system [746 (b)(1)]

NESHAP- Depainting Operations Standards Option (b) (1) (Organic HAP) no organic HAP shall be emitted for chemical stripping formulations or chemical paint softeners 63. 746(b)(1)

NESHAP- Depainting Operations Standards Option (b) (1) (Organic HAP) no organic HAP shall be emitted for chemical stripping formulations or chemical paint softeners 63. 746(b)(1)

NESHAP- Depainting Operations Standards Option (b)(2) (inorganic HAP) • When dry media blasting (not including hand sanding and mechanical sanding) generates airborne inorganic HAP, the user shall: – blast in an enclosed area – use dry filter or waterwash control system as appropriate for existing sources. – For new source control requirements see “primer & topcoat operations” [745(g)(2)(ii)].

NESHAP- Depainting Operations Standards Option (b)(2) (inorganic HAP) • When dry media blasting (not including hand sanding and mechanical sanding) generates airborne inorganic HAP, the user shall: – blast in an enclosed area – use dry filter or waterwash control system as appropriate for existing sources. – For new source control requirements see “primer & topcoat operations” [745(g)(2)(ii)].

Stage 1 3 Stage Particulate filters Stage 2 Stage 3

Stage 1 3 Stage Particulate filters Stage 2 Stage 3

NESHAP- Depainting Operations Standards Option (c) organic HAP • When using organic HAP strippers – existing sources shall achieve 81% – New sources shall achieve 95% control, either by control device alone or through a combination of control device and reduced stripper usage below baseline (baseline is `96 -`97 usage per aircraft or per sq ft)

NESHAP- Depainting Operations Standards Option (c) organic HAP • When using organic HAP strippers – existing sources shall achieve 81% – New sources shall achieve 95% control, either by control device alone or through a combination of control device and reduced stripper usage below baseline (baseline is `96 -`97 usage per aircraft or per sq ft)

NESHAP- Depainting Operations Standards (organic HAP) In addition to limits for Options (b)1, (b)2 and (c) • Use of organic HAP materials for spot stripping or decal removal is limited to : – 190 lbs (26 gal. ) per aircraft per year for commercial aircraft – 365 lbs. (50 gal. ) per aircraft per year for military aircraft

NESHAP- Depainting Operations Standards (organic HAP) In addition to limits for Options (b)1, (b)2 and (c) • Use of organic HAP materials for spot stripping or decal removal is limited to : – 190 lbs (26 gal. ) per aircraft per year for commercial aircraft – 365 lbs. (50 gal. ) per aircraft per year for military aircraft

NESHAP- Depainting Operations Exempt operations • During periods of malfunction, source may substitute materials chosen to minimize HAP emissions - The HAP containing substitute may not be used for more than 15 days per year.

NESHAP- Depainting Operations Exempt operations • During periods of malfunction, source may substitute materials chosen to minimize HAP emissions - The HAP containing substitute may not be used for more than 15 days per year.

NESHAP- Depainting Operations Tests, Recordkeeping & Reporting • Initial performance test required for control devices to verify compliance with efficiency requirements • For spot stripping and decal removal, calculate organic HAP use once per calendar year

NESHAP- Depainting Operations Tests, Recordkeeping & Reporting • Initial performance test required for control devices to verify compliance with efficiency requirements • For spot stripping and decal removal, calculate organic HAP use once per calendar year

NESHAP- Depainting Operations Tests, Recordkeeping & Reporting • Filter system pressure drop to be read and recorded once per shift • For waterwash systems, record water flow rate once per shift

NESHAP- Depainting Operations Tests, Recordkeeping & Reporting • Filter system pressure drop to be read and recorded once per shift • For waterwash systems, record water flow rate once per shift

NESHAP- Depainting Operations Tests, Recordkeeping & Reporting • Name & monthly usage of organic HAP used in chemical • Efficiency, rolling period (for carbon adsorbers) & supporting calculations/documentation control device • List of parts/units normally removed for depaint • For non-chemical stripping record malfunctions and date, cause and alternative used • Pressure drop or water flow once per shift • For spot stripping, annual quantity & mass per aircraft

NESHAP- Depainting Operations Tests, Recordkeeping & Reporting • Name & monthly usage of organic HAP used in chemical • Efficiency, rolling period (for carbon adsorbers) & supporting calculations/documentation control device • List of parts/units normally removed for depaint • For non-chemical stripping record malfunctions and date, cause and alternative used • Pressure drop or water flow once per shift • For spot stripping, annual quantity & mass per aircraft

NESHAP- Depainting Operations Tests, Recordkeeping & Reporting Semi-annual • • 24 hour periods when organic HAP emitted in violation New & reformulated chemical strippers with HAP content New non-chemical techniques Upset/Breakdown of non-chemical technique Including date, cause and depaint alternative used, date of correction of malfunction

NESHAP- Depainting Operations Tests, Recordkeeping & Reporting Semi-annual • • 24 hour periods when organic HAP emitted in violation New & reformulated chemical strippers with HAP content New non-chemical techniques Upset/Breakdown of non-chemical technique Including date, cause and depaint alternative used, date of correction of malfunction

NESHAP- Depainting Operations Tests, Recordkeeping & Reporting Semi-annual, (con’t) • • periods when filter pressure drop or water flow was outside of acceptable range and process was not immediately shut down List of new/discontinued aircraft models & parts normally removed for depainting Organic HAP control device exceedance Compliance certification statement

NESHAP- Depainting Operations Tests, Recordkeeping & Reporting Semi-annual, (con’t) • • periods when filter pressure drop or water flow was outside of acceptable range and process was not immediately shut down List of new/discontinued aircraft models & parts normally removed for depainting Organic HAP control device exceedance Compliance certification statement

NESHAP- Depainting Operations Tests, Recordkeeping & Reporting Annual • Exceedance of average annual HAP limits for spot stripping and decal removal • Number of times the pressure drop or water flow rate was outside the acceptable limits

NESHAP- Depainting Operations Tests, Recordkeeping & Reporting Annual • Exceedance of average annual HAP limits for spot stripping and decal removal • Number of times the pressure drop or water flow rate was outside the acceptable limits