84ad2e92e903498be1ff1263eec7a9de.ppt

- Количество слайдов: 47

NDIA Systems Engineering Division, M&S Committee April 22, 2009 Washington, DC Model-Based SE Using Sys. ML Part 2: Integrating Manufacturing Design and Simulation Leon Mc. Ginnis Georgia Institute of Technology Product & Systems Lifecycle Management Center www. pslm. gatech. edu 1

NDIA Systems Engineering Division, M&S Committee April 22, 2009 Washington, DC Model-Based SE Using Sys. ML Part 2: Integrating Manufacturing Design and Simulation Leon Mc. Ginnis Georgia Institute of Technology Product & Systems Lifecycle Management Center www. pslm. gatech. edu 1

GIT Product & Systems Lifecycle Management Center Leveraging Related Efforts www. pslm. gatech. edu • Sys. ML-related projects: – Deere, Lockheed, Boeing, NASA, NIST, TRW Automotive, . . . • Other efforts based at GIT: – Vendor collaboration (tool licenses, support, . . . ) – Keck Virtual Factory Lab – Sys. ML course development • For Professional Masters in SE program, continuing ed. short course, . . . – ASDL in AE – Tennenbaum Institute for Enterprise Transformation • Consortia & other GIT involvements: – OMG (Sys. ML, . . . ) – PDES Inc. (MBE, APs 210, 233, . . . ) 2

GIT Product & Systems Lifecycle Management Center Leveraging Related Efforts www. pslm. gatech. edu • Sys. ML-related projects: – Deere, Lockheed, Boeing, NASA, NIST, TRW Automotive, . . . • Other efforts based at GIT: – Vendor collaboration (tool licenses, support, . . . ) – Keck Virtual Factory Lab – Sys. ML course development • For Professional Masters in SE program, continuing ed. short course, . . . – ASDL in AE – Tennenbaum Institute for Enterprise Transformation • Consortia & other GIT involvements: – OMG (Sys. ML, . . . ) – PDES Inc. (MBE, APs 210, 233, . . . ) 2

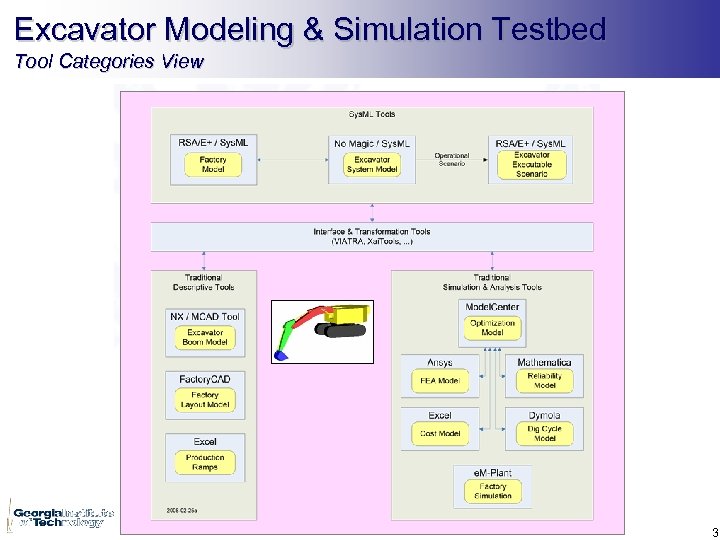

Excavator Modeling & Simulation Testbed Tool Categories View 3

Excavator Modeling & Simulation Testbed Tool Categories View 3

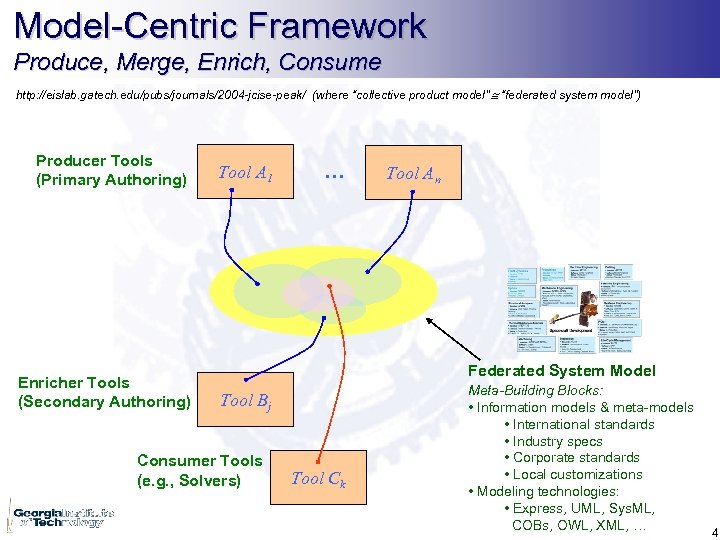

Model-Centric Framework Produce, Merge, Enrich, Consume http: //eislab. gatech. edu/pubs/journals/2004 -jcise-peak/ (where “collective product model” “federated system model”) Producer Tools (Primary Authoring) Enricher Tools (Secondary Authoring) Tool A 1 . . . Federated System Model Meta-Building Blocks: Tool Bj Consumer Tools (e. g. , Solvers) Tool An Tool Ck • Information models & meta-models • International standards • Industry specs • Corporate standards • Local customizations • Modeling technologies: • Express, UML, Sys. ML, COBs, OWL, XML, … 4

Model-Centric Framework Produce, Merge, Enrich, Consume http: //eislab. gatech. edu/pubs/journals/2004 -jcise-peak/ (where “collective product model” “federated system model”) Producer Tools (Primary Authoring) Enricher Tools (Secondary Authoring) Tool A 1 . . . Federated System Model Meta-Building Blocks: Tool Bj Consumer Tools (e. g. , Solvers) Tool An Tool Ck • Information models & meta-models • International standards • Industry specs • Corporate standards • Local customizations • Modeling technologies: • Express, UML, Sys. ML, COBs, OWL, XML, … 4

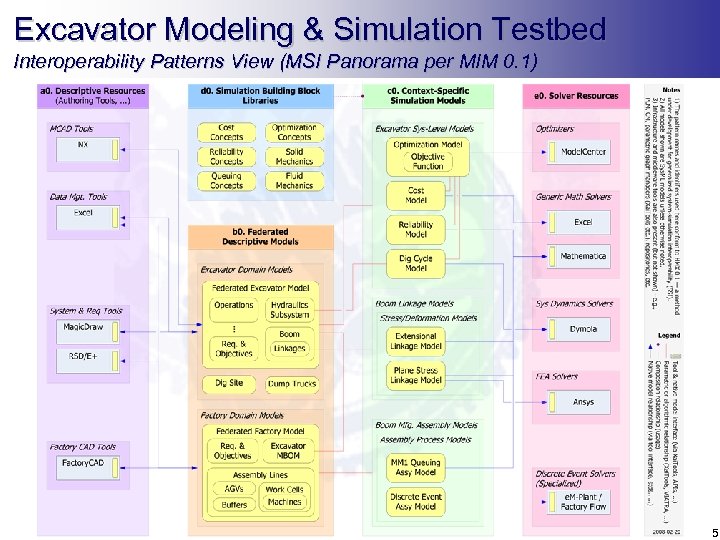

Excavator Modeling & Simulation Testbed Interoperability Patterns View (MSI Panorama per MIM 0. 1) 5

Excavator Modeling & Simulation Testbed Interoperability Patterns View (MSI Panorama per MIM 0. 1) 5

My focus today: • What does it mean “to integrate manufacturing with design? ” • What does it mean “to integrate manufacturing system design with manufacturing system simulation? ” • How can we make these two things happen? 6

My focus today: • What does it mean “to integrate manufacturing with design? ” • What does it mean “to integrate manufacturing system design with manufacturing system simulation? ” • How can we make these two things happen? 6

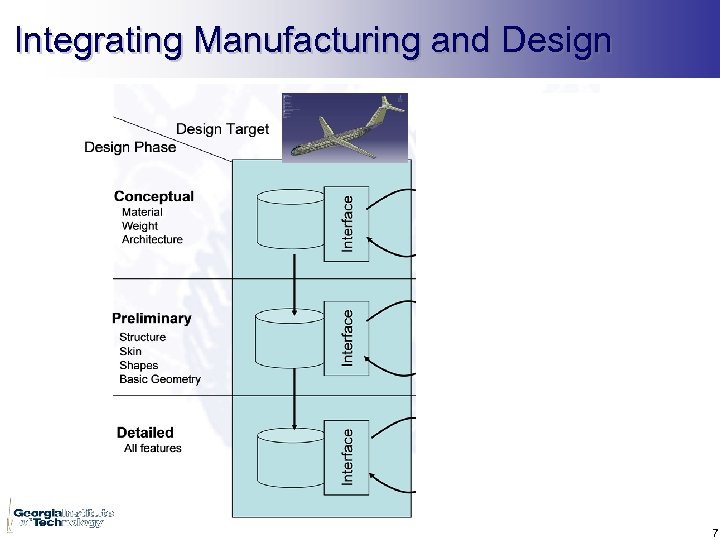

Integrating Manufacturing and Design ? ? ? 7

Integrating Manufacturing and Design ? ? ? 7

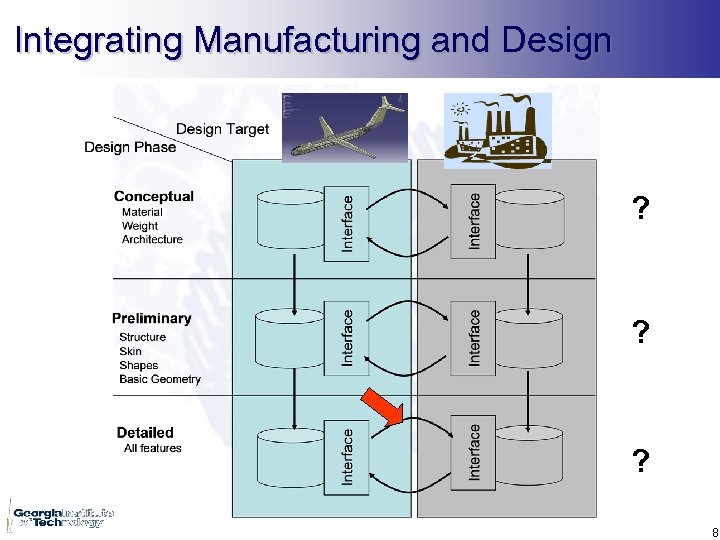

Integrating Manufacturing and Design ? ? ? 8

Integrating Manufacturing and Design ? ? ? 8

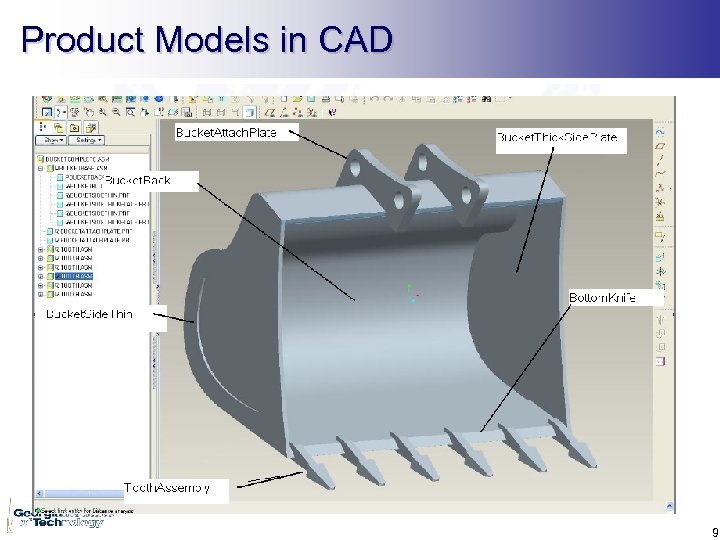

Product Models in CAD 9

Product Models in CAD 9

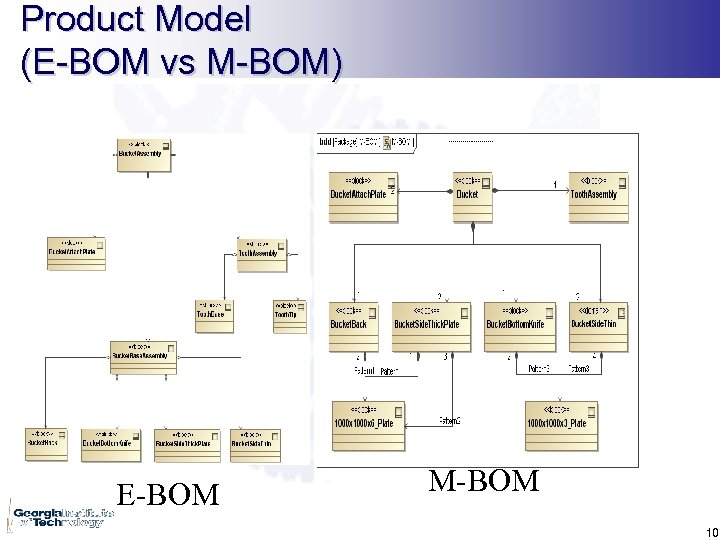

Product Model (E-BOM vs M-BOM) E-BOM M-BOM 10

Product Model (E-BOM vs M-BOM) E-BOM M-BOM 10

Design to Manufacturing Integration • EBOM to MBOM Transformation • Or “EBOM to WBS” • More than “interoperability” or “converting a file format”; “how” based on “what” – Sourcing (=> logistics, cost, schedule …) – Resource organization/assignment (=> mfg cost) – Inventory/WIP positioning (=> cycle time …) 12

Design to Manufacturing Integration • EBOM to MBOM Transformation • Or “EBOM to WBS” • More than “interoperability” or “converting a file format”; “how” based on “what” – Sourcing (=> logistics, cost, schedule …) – Resource organization/assignment (=> mfg cost) – Inventory/WIP positioning (=> cycle time …) 12

R&D Strategy • Conform factory design to product design – Functional design – Detailed design • Recognize process planning as the “design to manufacturing” bridge • Manufacturing as part of a federated “enterprise” model 13

R&D Strategy • Conform factory design to product design – Functional design – Detailed design • Recognize process planning as the “design to manufacturing” bridge • Manufacturing as part of a federated “enterprise” model 13

Factory Design Capabilities 14

Factory Design Capabilities 14

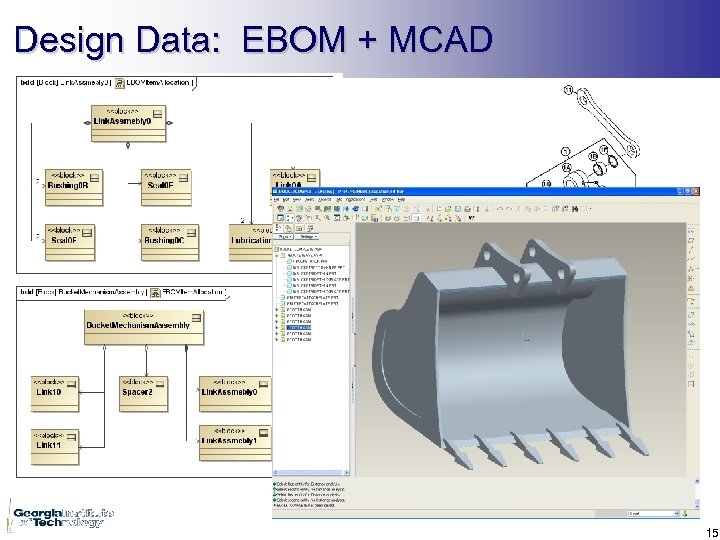

Design Data: EBOM + MCAD 15

Design Data: EBOM + MCAD 15

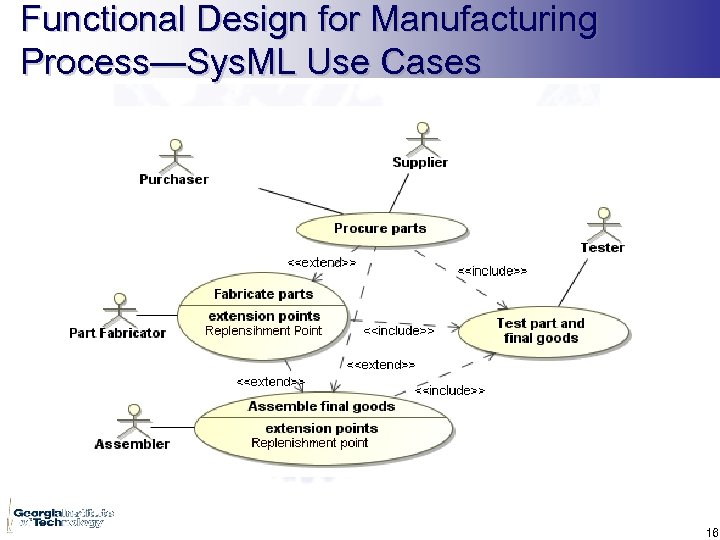

Functional Design for Manufacturing Process—Sys. ML Use Cases 16

Functional Design for Manufacturing Process—Sys. ML Use Cases 16

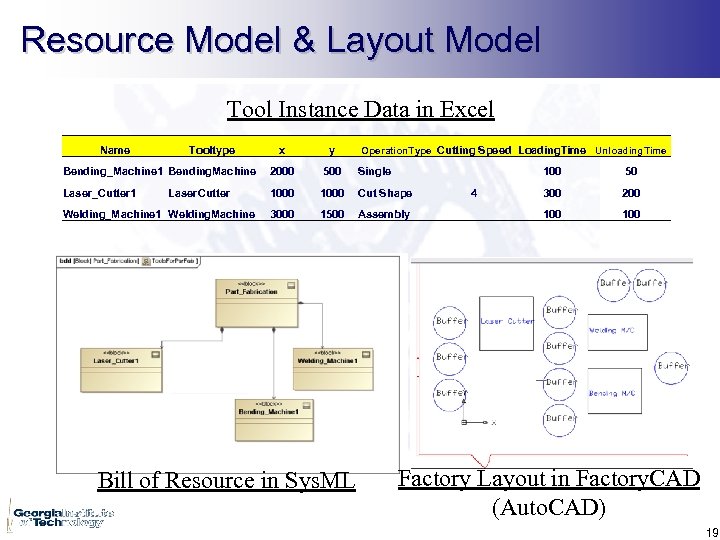

Resource Model & Layout Model Tool Instance Data in Excel Name Tooltype x y Bending_Machine 1 Bending. Machine 2000 500 Single Laser_Cutter 1 1000 Cut Shape 3000 1500 Assembly Laser. Cutter Welding_Machine 1 Welding. Machine Bill of Resource in Sys. ML Operation. Type Cutting Speed Loading. Time Unloading. Time 100 4 50 300 200 100 Factory Layout in Factory. CAD (Auto. CAD) 19

Resource Model & Layout Model Tool Instance Data in Excel Name Tooltype x y Bending_Machine 1 Bending. Machine 2000 500 Single Laser_Cutter 1 1000 Cut Shape 3000 1500 Assembly Laser. Cutter Welding_Machine 1 Welding. Machine Bill of Resource in Sys. ML Operation. Type Cutting Speed Loading. Time Unloading. Time 100 4 50 300 200 100 Factory Layout in Factory. CAD (Auto. CAD) 19

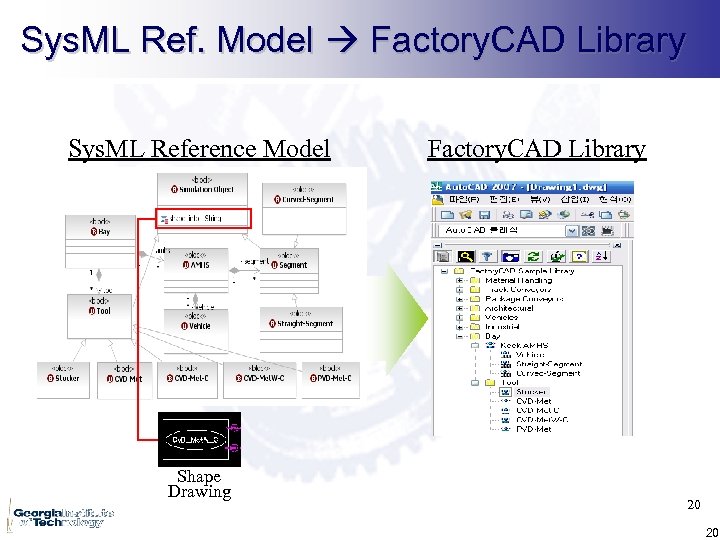

Sys. ML Ref. Model Factory. CAD Library Sys. ML Reference Model Shape Drawing Factory. CAD Library 20 20

Sys. ML Ref. Model Factory. CAD Library Sys. ML Reference Model Shape Drawing Factory. CAD Library 20 20

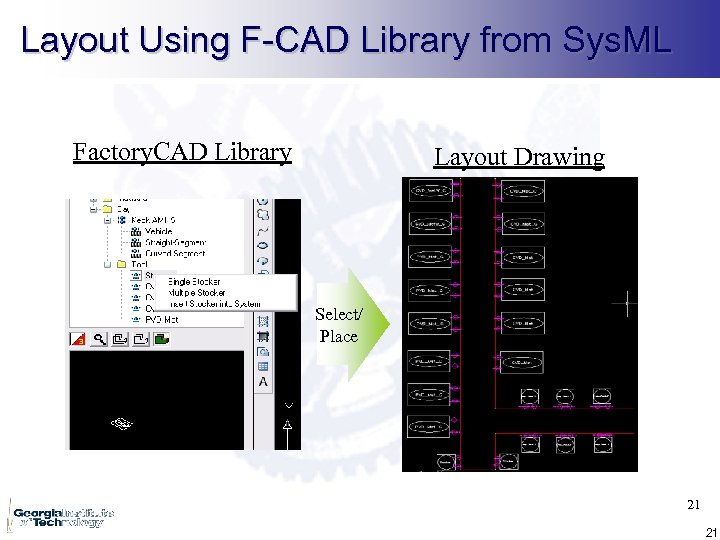

Layout Using F-CAD Library from Sys. ML Factory. CAD Library Layout Drawing Select/ Place 21 21

Layout Using F-CAD Library from Sys. ML Factory. CAD Library Layout Drawing Select/ Place 21 21

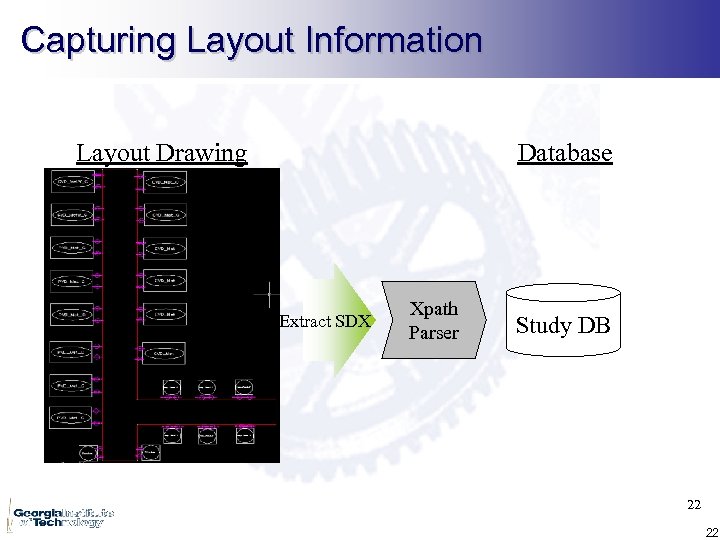

Capturing Layout Information Layout Drawing Database Extract SDX Xpath Parser Study DB 22 22

Capturing Layout Information Layout Drawing Database Extract SDX Xpath Parser Study DB 22 22

Observations • Factory design is driven by: – What – How much – When – Where • So how do we integrate those issues? • Use Sys. ML Activity Diagrams to capture how we intend to use manufacturing resources to create the product 23

Observations • Factory design is driven by: – What – How much – When – Where • So how do we integrate those issues? • Use Sys. ML Activity Diagrams to capture how we intend to use manufacturing resources to create the product 23

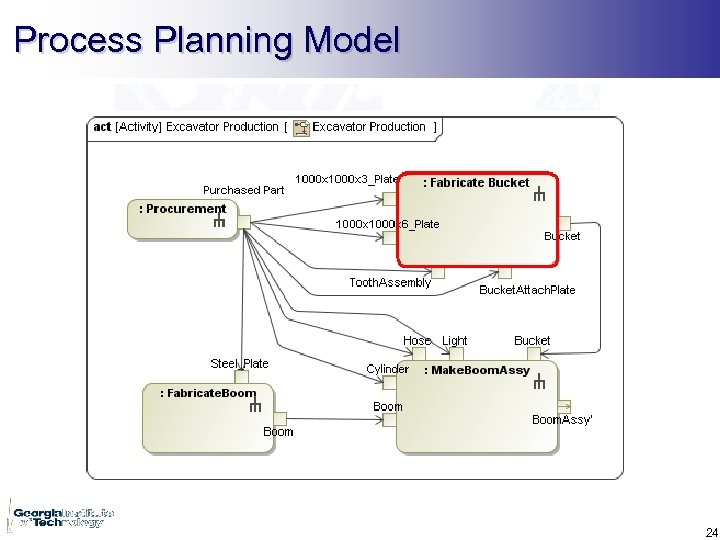

Process Planning Model 24

Process Planning Model 24

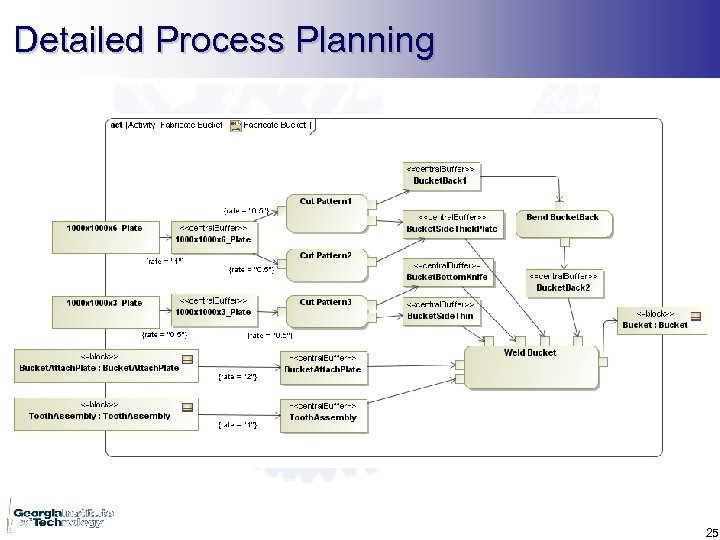

Detailed Process Planning 25

Detailed Process Planning 25

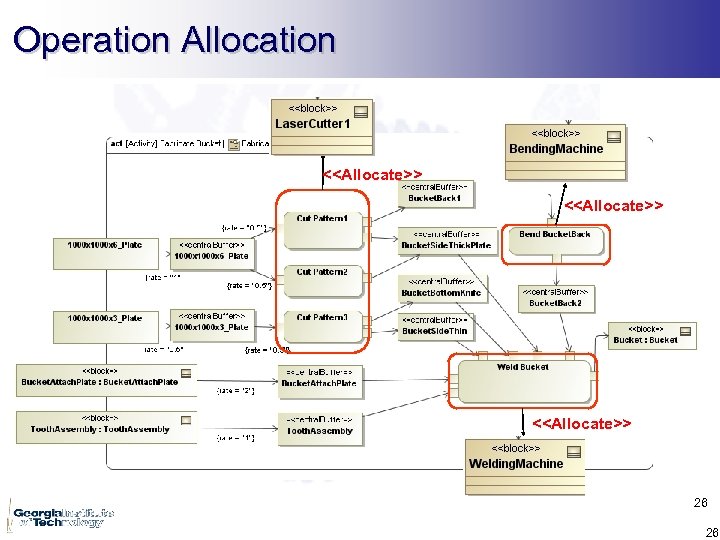

Operation Allocation <

Operation Allocation <

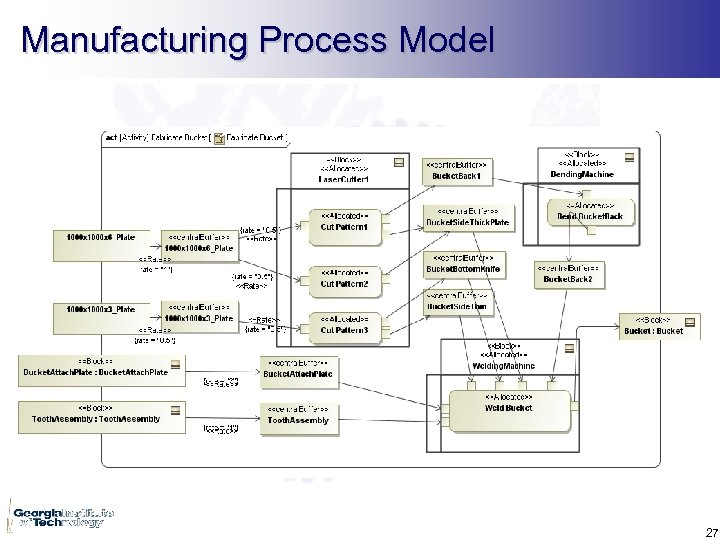

Manufacturing Process Model 27

Manufacturing Process Model 27

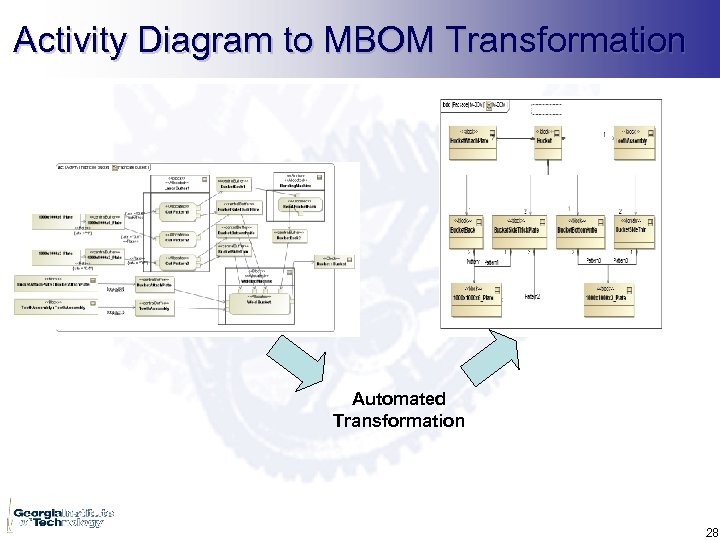

Activity Diagram to MBOM Transformation Automated Transformation 28

Activity Diagram to MBOM Transformation Automated Transformation 28

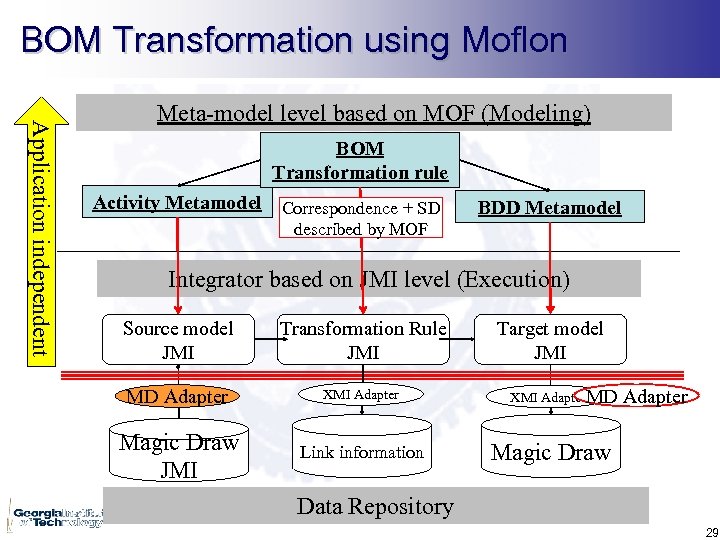

BOM Transformation using Moflon Application independent Meta-model level based on MOF (Modeling) BOM Transformation rule Activity Metamodel Correspondence + SD BDD Metamodel described by MOF Integrator based on JMI level (Execution) Source model JMI Transformation Rule JMI MD Adapter XMI Adapter Magic Draw JMI Link information Target model JMI XMI Adapter. MD Adapter Magic Draw Data Repository 29

BOM Transformation using Moflon Application independent Meta-model level based on MOF (Modeling) BOM Transformation rule Activity Metamodel Correspondence + SD BDD Metamodel described by MOF Integrator based on JMI level (Execution) Source model JMI Transformation Rule JMI MD Adapter XMI Adapter Magic Draw JMI Link information Target model JMI XMI Adapter. MD Adapter Magic Draw Data Repository 29

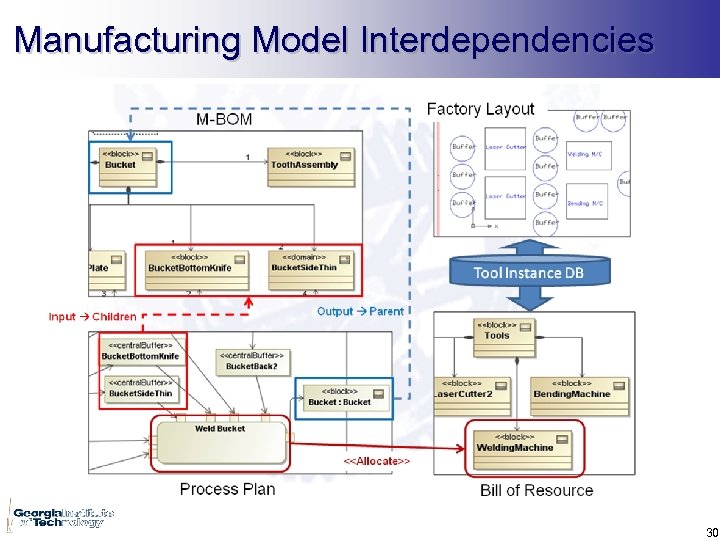

Manufacturing Model Interdependencies 30

Manufacturing Model Interdependencies 30

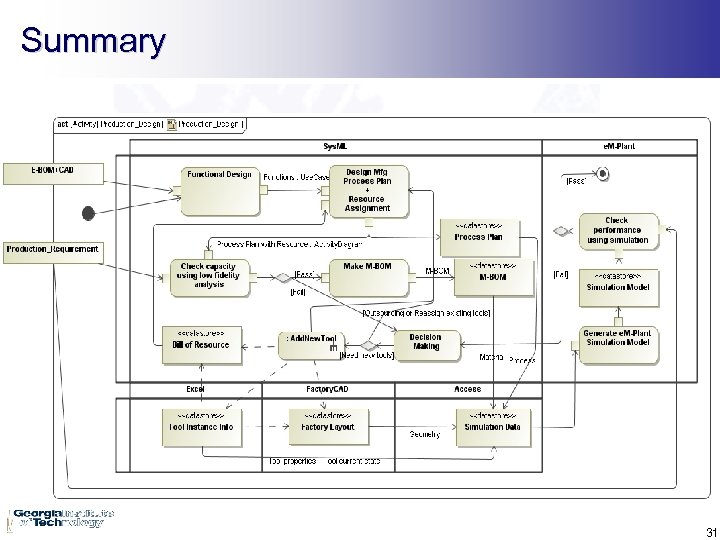

Summary 31

Summary 31

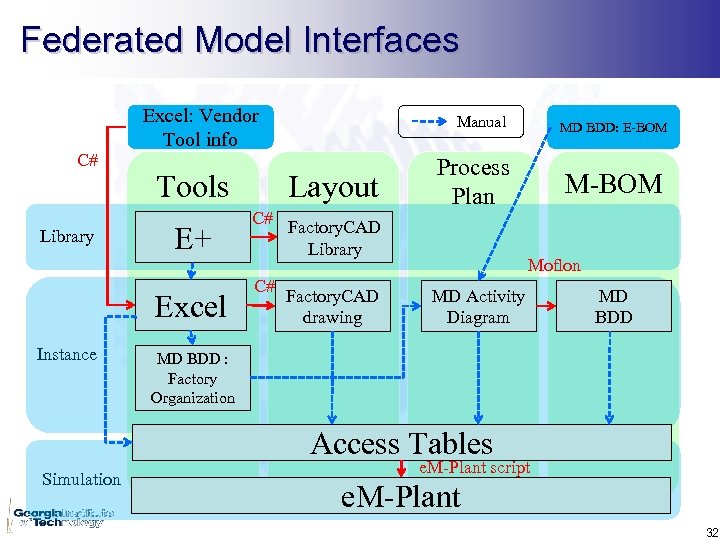

Federated Model Interfaces C# Library Excel: Vendor Tool info Tools E+ Excel Instance Manual Layout C# Factory. CAD Library C# Factory. CAD drawing MD BDD: E-BOM Process Plan M-BOM Moflon MD Activity Diagram MD BDD : Factory Organization Access Tables Simulation e. M-Plant script e. M-Plant 32

Federated Model Interfaces C# Library Excel: Vendor Tool info Tools E+ Excel Instance Manual Layout C# Factory. CAD Library C# Factory. CAD drawing MD BDD: E-BOM Process Plan M-BOM Moflon MD Activity Diagram MD BDD : Factory Organization Access Tables Simulation e. M-Plant script e. M-Plant 32

Conclusion • Sys. ML and formal models enable a formal interoperability between product design models and factory design and process planning models. • Not clear yet how to make the connection the other way…future R&D 33

Conclusion • Sys. ML and formal models enable a formal interoperability between product design models and factory design and process planning models. • Not clear yet how to make the connection the other way…future R&D 33

Simulation Capabilities 34

Simulation Capabilities 34

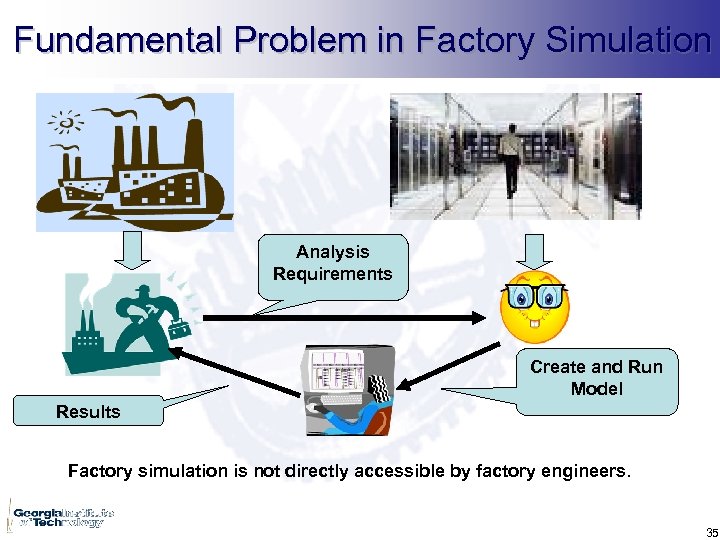

Fundamental Problem in Factory Simulation Analysis Requirements Create and Run Model Results Factory simulation is not directly accessible by factory engineers. 35

Fundamental Problem in Factory Simulation Analysis Requirements Create and Run Model Results Factory simulation is not directly accessible by factory engineers. 35

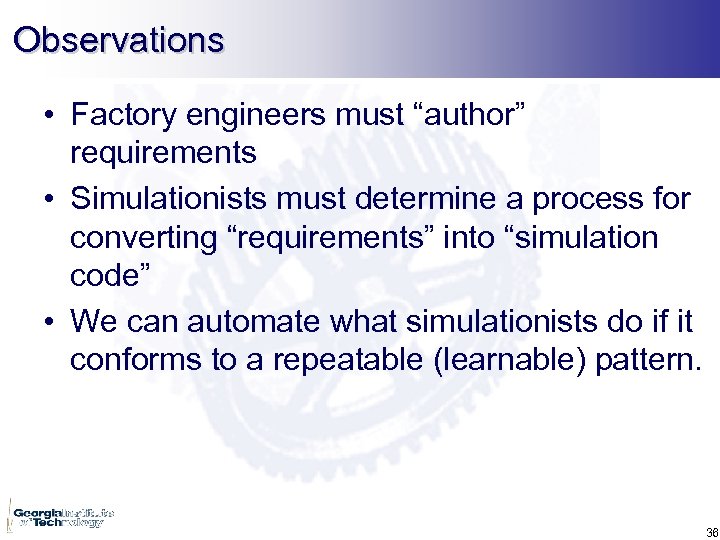

Observations • Factory engineers must “author” requirements • Simulationists must determine a process for converting “requirements” into “simulation code” • We can automate what simulationists do if it conforms to a repeatable (learnable) pattern. 36

Observations • Factory engineers must “author” requirements • Simulationists must determine a process for converting “requirements” into “simulation code” • We can automate what simulationists do if it conforms to a repeatable (learnable) pattern. 36

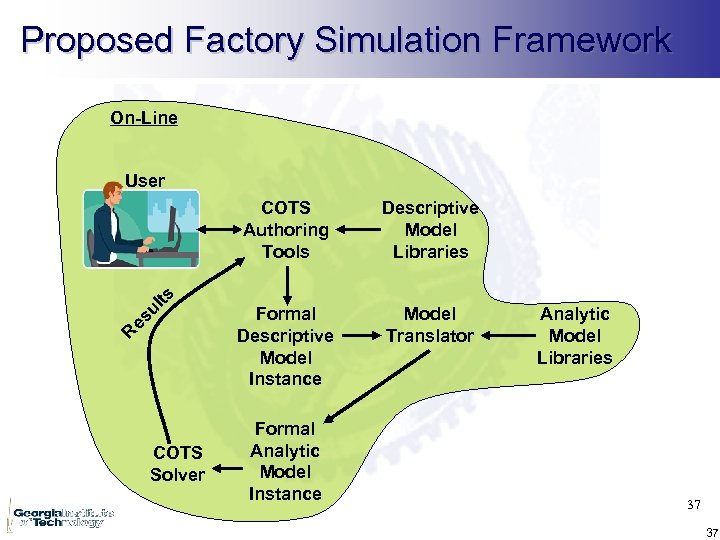

Proposed Factory Simulation Framework On-Line User R es ul ts COTS Authoring Tools COTS Solver Descriptive Model Libraries Formal Descriptive Model Instance Model Translator Formal Analytic Model Instance Analytic Model Libraries 37 37

Proposed Factory Simulation Framework On-Line User R es ul ts COTS Authoring Tools COTS Solver Descriptive Model Libraries Formal Descriptive Model Instance Model Translator Formal Analytic Model Instance Analytic Model Libraries 37 37

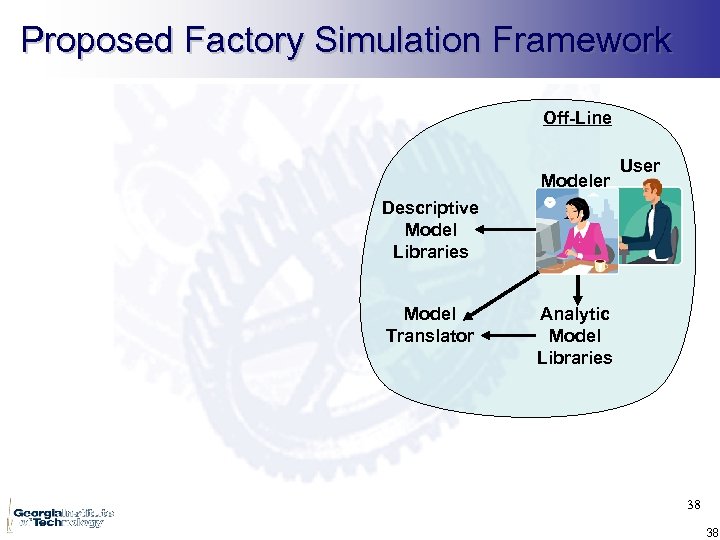

Proposed Factory Simulation Framework Off-Line Modeler User Descriptive Model Libraries Model Translator Analytic Model Libraries 38 38

Proposed Factory Simulation Framework Off-Line Modeler User Descriptive Model Libraries Model Translator Analytic Model Libraries 38 38

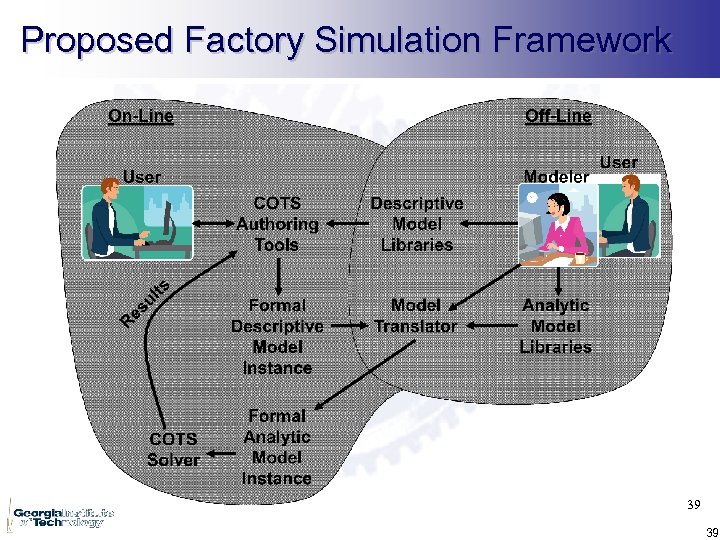

Proposed Factory Simulation Framework 39 39

Proposed Factory Simulation Framework 39 39

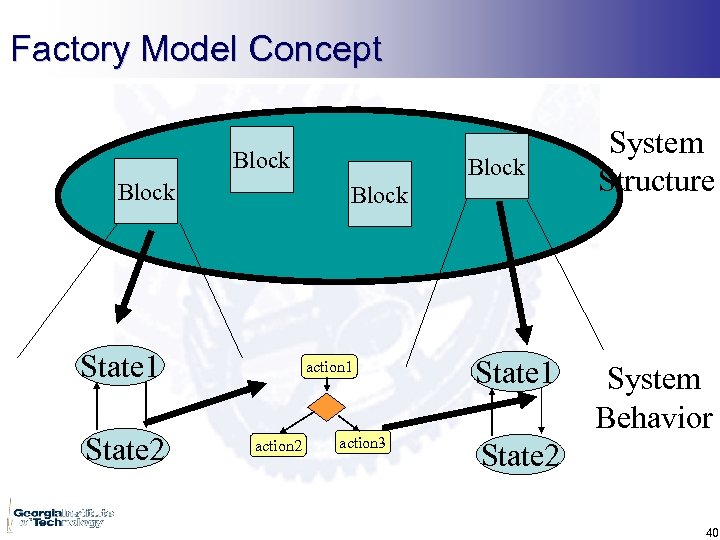

Factory Model Concept Block State 1 State 2 Block action 1 action 2 action 3 State 1 System Structure System Behavior State 2 40

Factory Model Concept Block State 1 State 2 Block action 1 action 2 action 3 State 1 System Structure System Behavior State 2 40

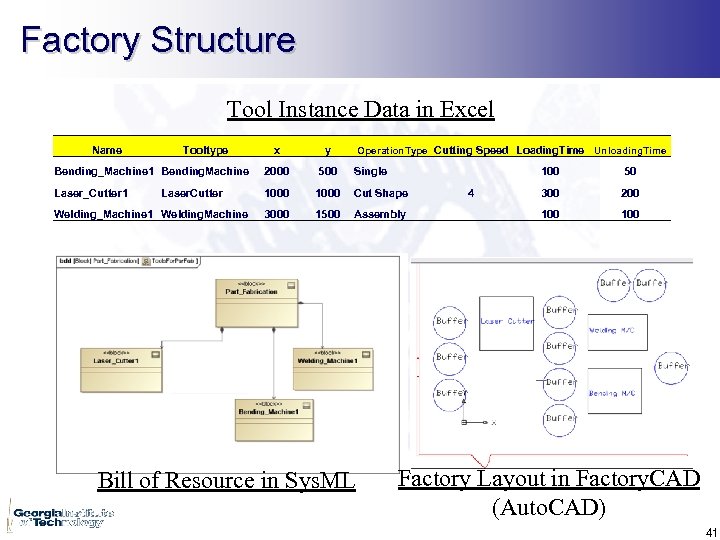

Factory Structure Tool Instance Data in Excel Name Tooltype x y Bending_Machine 1 Bending. Machine 2000 500 Single Laser_Cutter 1 1000 Cut Shape 3000 1500 Assembly Laser. Cutter Welding_Machine 1 Welding. Machine Operation. Type Cutting Speed Loading. Time Unloading. Time Bill of Resource in Sys. ML 100 4 50 300 200 100 Factory Layout in Factory. CAD (Auto. CAD) 41

Factory Structure Tool Instance Data in Excel Name Tooltype x y Bending_Machine 1 Bending. Machine 2000 500 Single Laser_Cutter 1 1000 Cut Shape 3000 1500 Assembly Laser. Cutter Welding_Machine 1 Welding. Machine Operation. Type Cutting Speed Loading. Time Unloading. Time Bill of Resource in Sys. ML 100 4 50 300 200 100 Factory Layout in Factory. CAD (Auto. CAD) 41

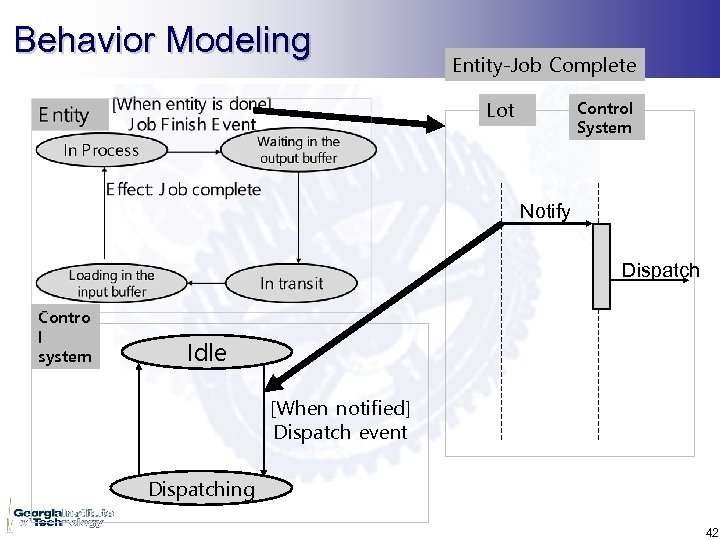

Behavior Modeling Entity-Job Complete Lot Control System Notify Dispatch Contro l system Idle [When notified] Dispatch event Dispatching 42

Behavior Modeling Entity-Job Complete Lot Control System Notify Dispatch Contro l system Idle [When notified] Dispatch event Dispatching 42

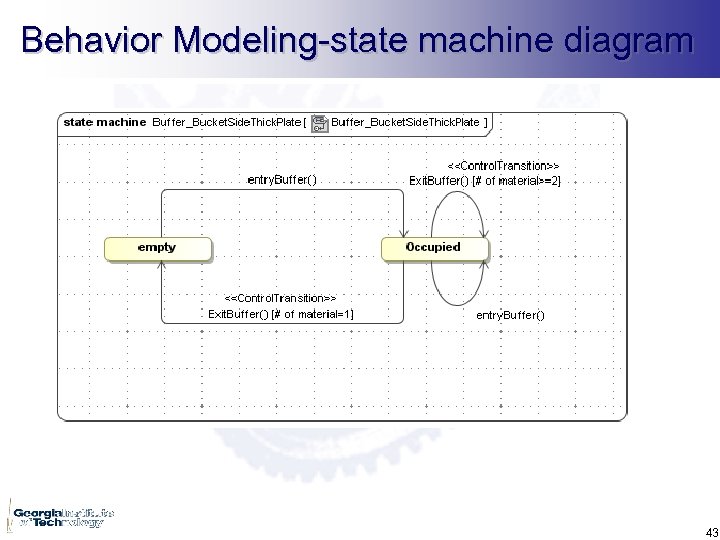

Behavior Modeling-state machine diagram 43

Behavior Modeling-state machine diagram 43

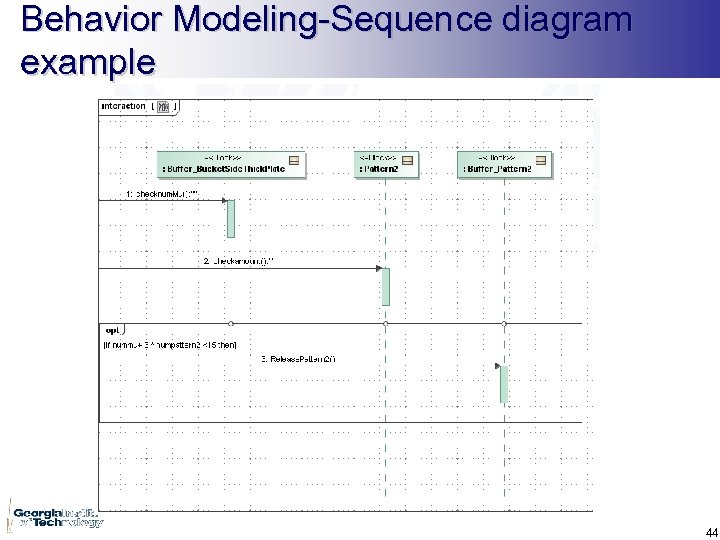

Behavior Modeling-Sequence diagram example 44

Behavior Modeling-Sequence diagram example 44

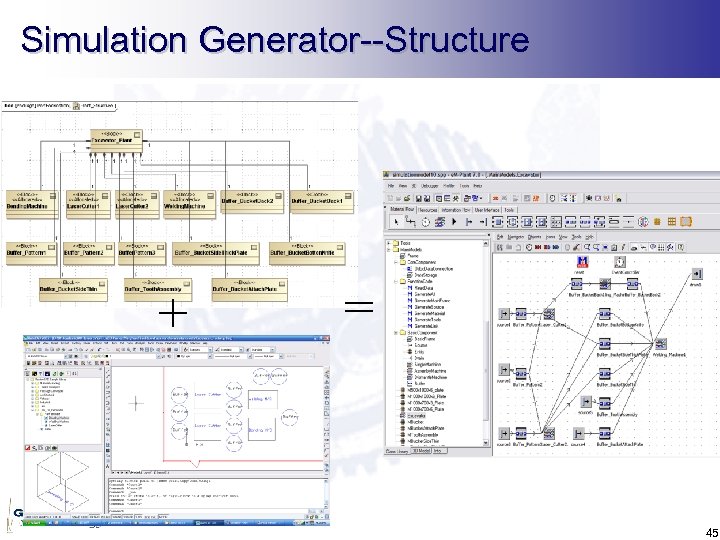

Simulation Generator--Structure + = 45

Simulation Generator--Structure + = 45

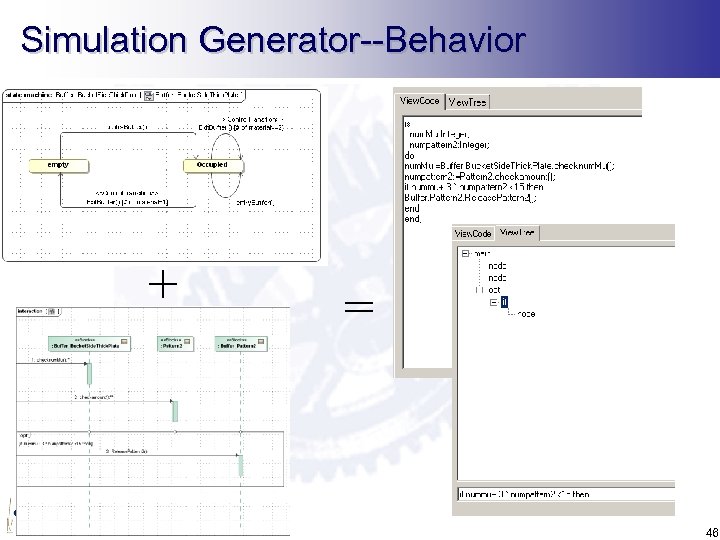

Simulation Generator--Behavior + = 46

Simulation Generator--Behavior + = 46

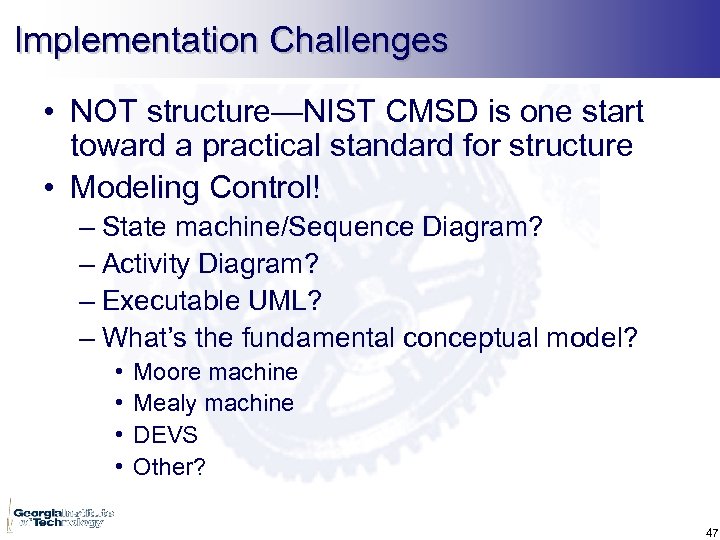

Implementation Challenges • NOT structure—NIST CMSD is one start toward a practical standard for structure • Modeling Control! – State machine/Sequence Diagram? – Activity Diagram? – Executable UML? – What’s the fundamental conceptual model? • • Moore machine Mealy machine DEVS Other? 47

Implementation Challenges • NOT structure—NIST CMSD is one start toward a practical standard for structure • Modeling Control! – State machine/Sequence Diagram? – Activity Diagram? – Executable UML? – What’s the fundamental conceptual model? • • Moore machine Mealy machine DEVS Other? 47

If you want to play this game • Formal languages – Sys. ML is our bet • Model transformation – MOFLON? QVT? We’re not completely sold… • Implicit/Explicit paradox • Domain specific languages – Profiles of Sys. ML 48

If you want to play this game • Formal languages – Sys. ML is our bet • Model transformation – MOFLON? QVT? We’re not completely sold… • Implicit/Explicit paradox • Domain specific languages – Profiles of Sys. ML 48

Conclusion • Sys. ML and formal models (potentially) enable an unprecedented integration of manufacturing system “description” and manufacturing system simulation (like the MCAD and ECAD domains now enjoy) • Rationalization of factory control remains the fundamental challenge—how can we reconcile the complexity of real factory control with the need to create (in finite time and finite cost) useful factory simulations? 49

Conclusion • Sys. ML and formal models (potentially) enable an unprecedented integration of manufacturing system “description” and manufacturing system simulation (like the MCAD and ECAD domains now enjoy) • Rationalization of factory control remains the fundamental challenge—how can we reconcile the complexity of real factory control with the need to create (in finite time and finite cost) useful factory simulations? 49

Main Questions Addressed by Project • Process: How do we include engineering analysis tools in the MBSE process? • Representation: How do we represent engineering analysis models in Sys. ML? • Execution: How do we integrate engineering analysis tools & models with Sys. ML tools & models? 50

Main Questions Addressed by Project • Process: How do we include engineering analysis tools in the MBSE process? • Representation: How do we represent engineering analysis models in Sys. ML? • Execution: How do we integrate engineering analysis tools & models with Sys. ML tools & models? 50