NCDA: Pickle Sorter Project Proposal Project 98. 09 Sponsored by Ed Kee of Keeman Produce, Lincoln, DE

NCDA: Pickle Sorter Project Proposal Project 98. 09 Sponsored by Ed Kee of Keeman Produce, Lincoln, DE

2 Overview • Introduction – Description of Problem • Method – Wants Metrics Concepts – System and Functional Benchmarking • Schedule – Division of labor – Budget

2 Overview • Introduction – Description of Problem • Method – Wants Metrics Concepts – System and Functional Benchmarking • Schedule – Division of labor – Budget

3 Project Background • Title: Pickle Sorter • Sponsor: Ed Kee of Keeman Produce • Problem: The pickling cucumber industry currently separates undesirable cucumbers from desirable ones manually. Mr. Kee would like a device to efficiently and reliably separate the usable cucumbers from the unusable ones.

3 Project Background • Title: Pickle Sorter • Sponsor: Ed Kee of Keeman Produce • Problem: The pickling cucumber industry currently separates undesirable cucumbers from desirable ones manually. Mr. Kee would like a device to efficiently and reliably separate the usable cucumbers from the unusable ones.

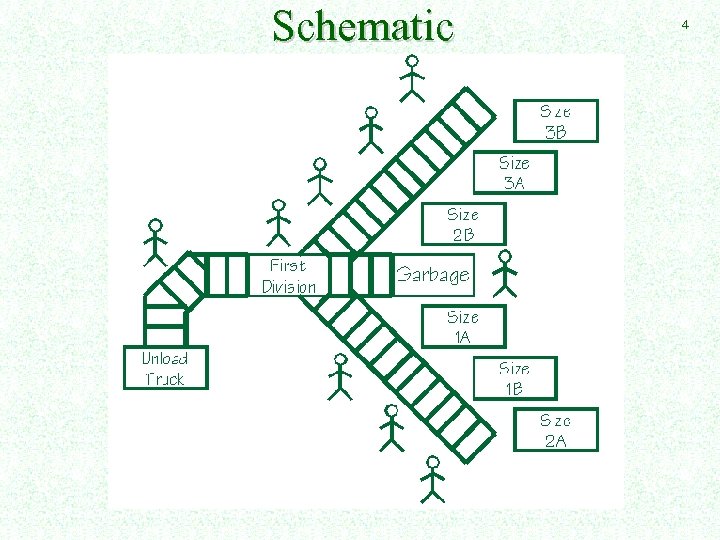

Schematic 4

Schematic 4

5 Strategy • Mission: To provide an integrated, automated system to sort out undesirable pickles on the processing line. • Approach: Collect customer wants and develop them into metrics which can be used to evaluate benchmarks and concepts for a design solution.

5 Strategy • Mission: To provide an integrated, automated system to sort out undesirable pickles on the processing line. • Approach: Collect customer wants and develop them into metrics which can be used to evaluate benchmarks and concepts for a design solution.

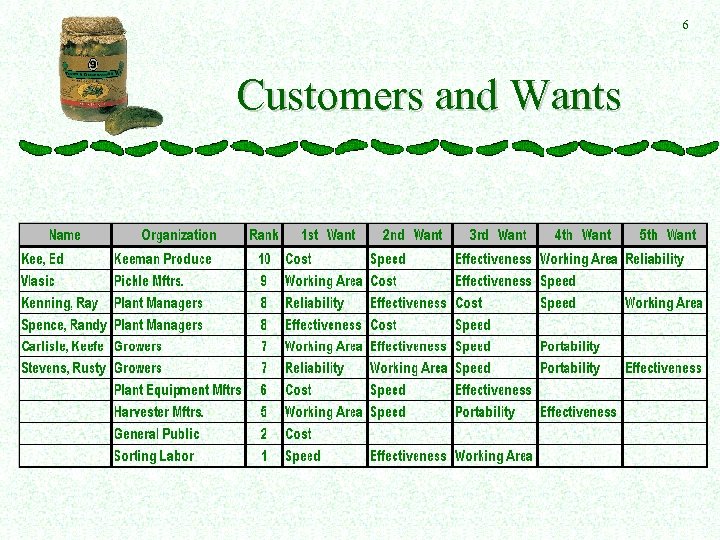

6 Customers and Wants

6 Customers and Wants

7 Benchmarking • Current Method: – Manual selection and removal - No integrated, efficient, inexpensive system currently in use. • System: – Several integrated solutions exist, each having its own set of problems. • Functional: – Many of our concepts include functions that have been independently developed for other.

7 Benchmarking • Current Method: – Manual selection and removal - No integrated, efficient, inexpensive system currently in use. • System: – Several integrated solutions exist, each having its own set of problems. • Functional: – Many of our concepts include functions that have been independently developed for other.

8 Wants Metrics • Cost – Price • Effectiveness – % Good Removed – % Bad Removed • Working Area – Length – Width • Reliability – Mean Time to Failure • Speed – Pickles Per Minute • Portability – Size – Weight

8 Wants Metrics • Cost – Price • Effectiveness – % Good Removed – % Bad Removed • Working Area – Length – Width • Reliability – Mean Time to Failure • Speed – Pickles Per Minute • Portability – Size – Weight

9 Target Values

9 Target Values

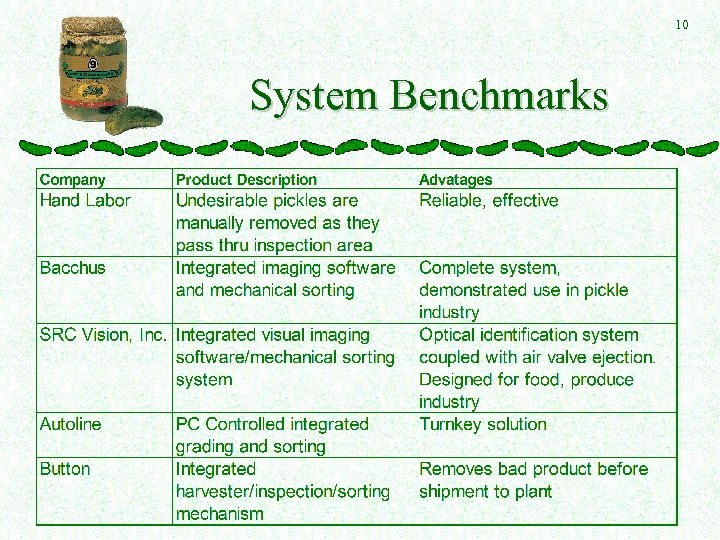

10 System Benchmarks

10 System Benchmarks

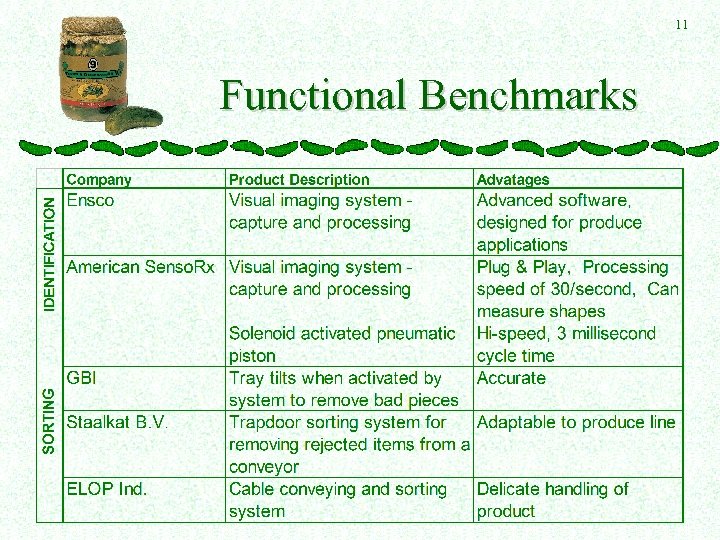

11 Functional Benchmarks

11 Functional Benchmarks

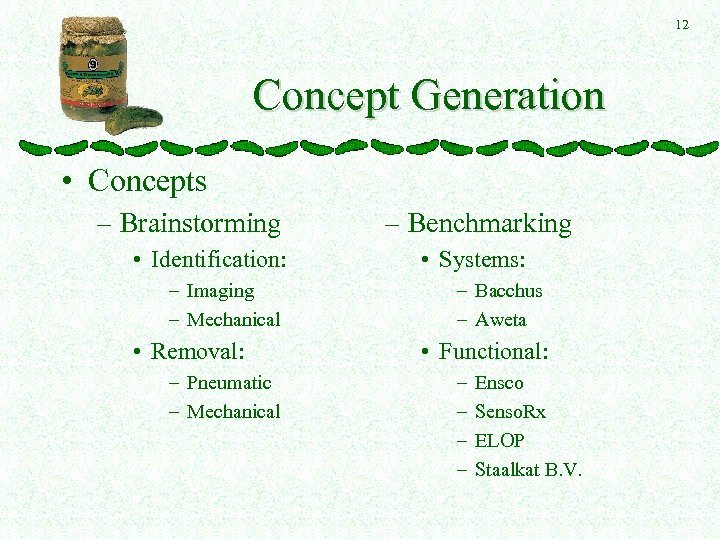

12 Concept Generation • Concepts – Brainstorming • Identification: – Imaging – Mechanical • Removal: – Pneumatic – Mechanical – Benchmarking • Systems: – Bacchus – Aweta • Functional: – – Ensco Senso. Rx ELOP Staalkat B. V.

12 Concept Generation • Concepts – Brainstorming • Identification: – Imaging – Mechanical • Removal: – Pneumatic – Mechanical – Benchmarking • Systems: – Bacchus – Aweta • Functional: – – Ensco Senso. Rx ELOP Staalkat B. V.

13 Concepts 1 Imaging system coupled to solenoid activated pneumatic piston. 2 Imaging system with a trap door removal system. 3 Imaging system which controls a robotic removal arm. 4 Tilted conveyor belt which separates good and bad pickles based on rolling characteristics.

13 Concepts 1 Imaging system coupled to solenoid activated pneumatic piston. 2 Imaging system with a trap door removal system. 3 Imaging system which controls a robotic removal arm. 4 Tilted conveyor belt which separates good and bad pickles based on rolling characteristics.

14 Concept Evaluation 1 - Imaging/Pneumatic System: • Most Promising; Is equally good with Effectiveness and Speed. Cost currently unknown. 2 - Imaging/Trap Door System: • Similar to system above, lags behind in Effectiveness and Speed. 3 - Imaging/Robotic Arm System: • Cost prohibitive if Speed Target Value is to be met. Also, more moving parts may decrease Reliability. 4 - Rolling Method: • Fails Effectiveness, Speed Metrics; Has been ruled out.

14 Concept Evaluation 1 - Imaging/Pneumatic System: • Most Promising; Is equally good with Effectiveness and Speed. Cost currently unknown. 2 - Imaging/Trap Door System: • Similar to system above, lags behind in Effectiveness and Speed. 3 - Imaging/Robotic Arm System: • Cost prohibitive if Speed Target Value is to be met. Also, more moving parts may decrease Reliability. 4 - Rolling Method: • Fails Effectiveness, Speed Metrics; Has been ruled out.

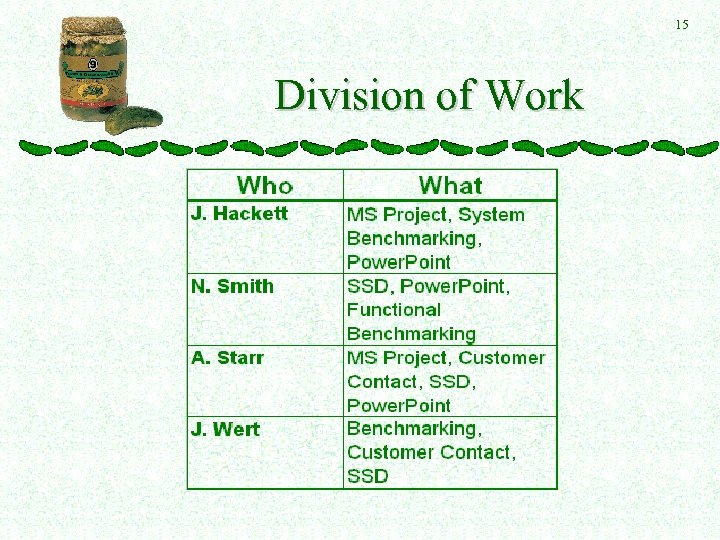

15 Division of Work

15 Division of Work

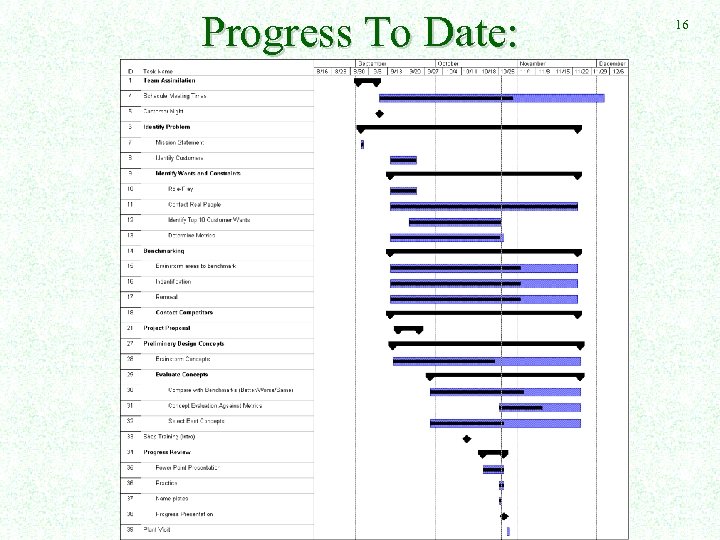

Progress To Date: 16

Progress To Date: 16

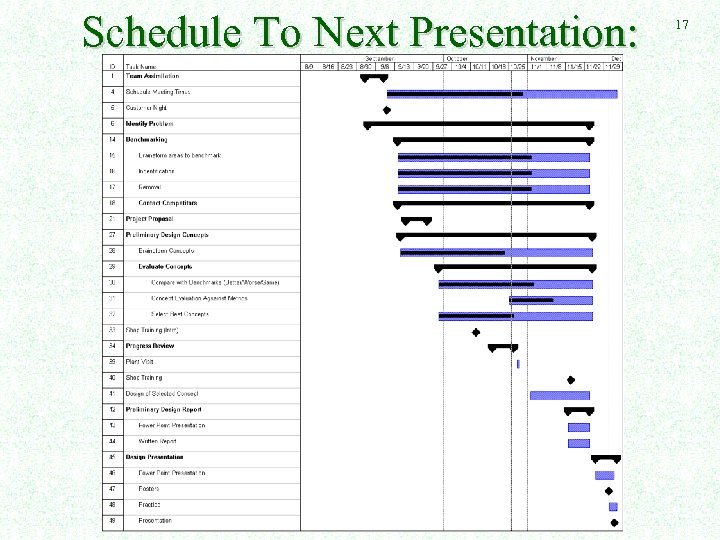

Schedule To Next Presentation: 17

Schedule To Next Presentation: 17

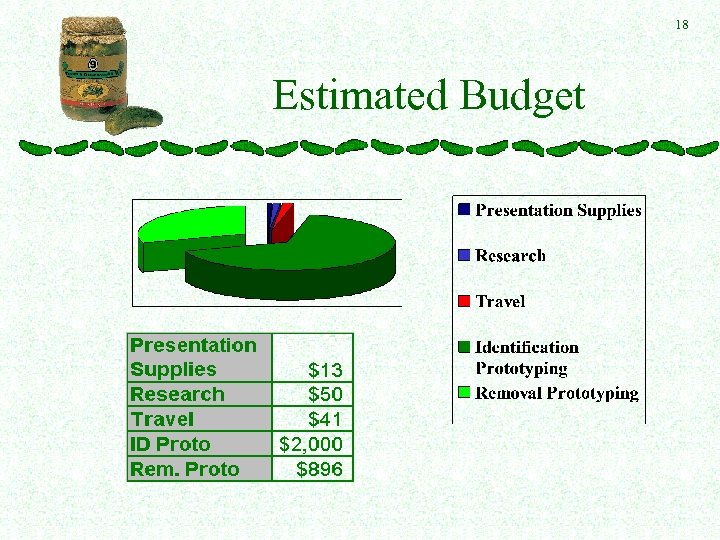

18 Estimated Budget

18 Estimated Budget

19 Closing Points • • Metrics Derived From Wants Benchmarks Evaluated Using Metrics Initial Concepts Evaluated Using Metrics Progress and Looking Ahead

19 Closing Points • • Metrics Derived From Wants Benchmarks Evaluated Using Metrics Initial Concepts Evaluated Using Metrics Progress and Looking Ahead