0358d3f2300d1538b8cc1aef992910a6.ppt

- Количество слайдов: 40

NAVICP’s PBL Perspective NAVAL INVENTORY CONTROL POINT • Today’s Challenges • Response to Challenge • The PBL Solution • The PBL Process • Where We Are • Where We Need To Go • Take Aways Ready. Resourceful. Responsive! Presented to: LOG 235 B Class 17 November 2004 Larry Garvey Director, Supply Chain Solutions Division

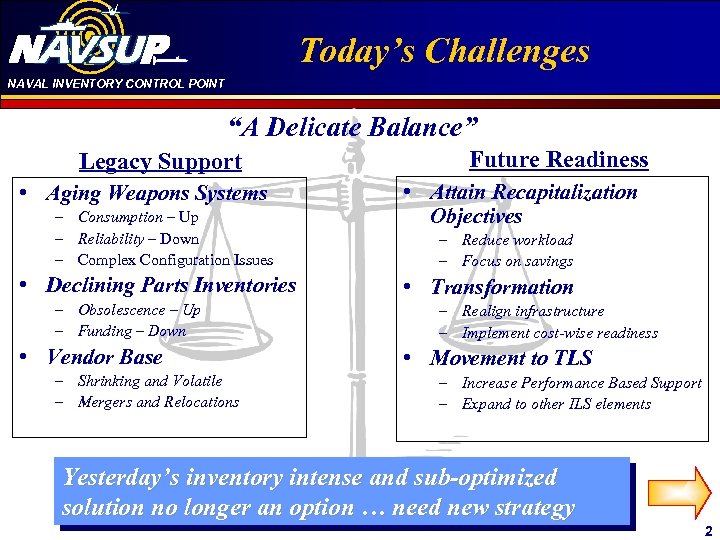

Click to edit Master title Today’s Challenges style NAVAL INVENTORY CONTROL POINT “A Delicate Balance” Legacy Support • Aging Weapons Systems – Consumption – Up – Reliability – Down – Complex Configuration Issues • Declining Parts Inventories – Obsolescence – Up – Funding – Down • Vendor Base – Shrinking and Volatile – Mergers and Relocations Future Readiness • Attain Recapitalization Objectives – Reduce workload – Focus on savings • Transformation – Realign infrastructure – Implement cost-wise readiness • Movement to TLS – Increase Performance Based Support – Expand to other ILS elements Yesterday’s inventory intense and sub-optimized solution no longer an option … need new strategy 2

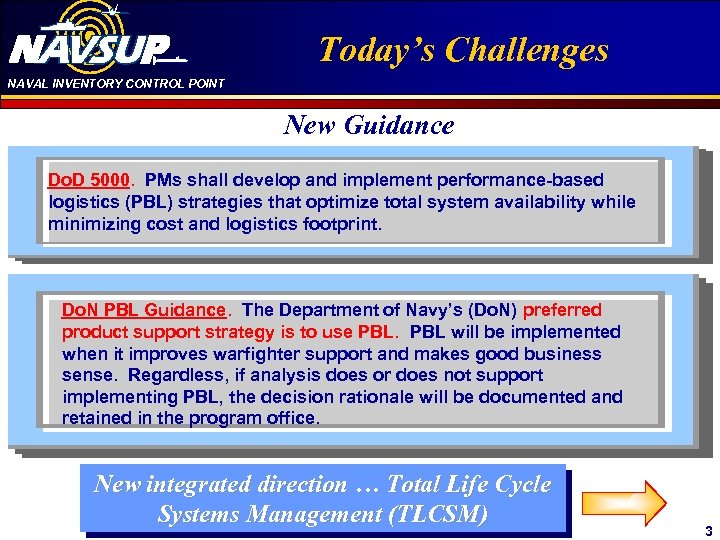

NAVAL INVENTORY CONTROL POINT Click to edit Master title Today’s Challenges style New Guidance Do. D 5000. PMs shall develop and implement performance-based logistics (PBL) strategies that optimize total system availability while minimizing cost and logistics footprint. Do. N PBL Guidance. The Department of Navy’s (Do. N) preferred product support strategy is to use PBL will be implemented when it improves warfighter support and makes good business sense. Regardless, if analysis does or does not support implementing PBL, the decision rationale will be documented and retained in the program office. New integrated direction … Total Life Cycle Systems Management (TLCSM) 3

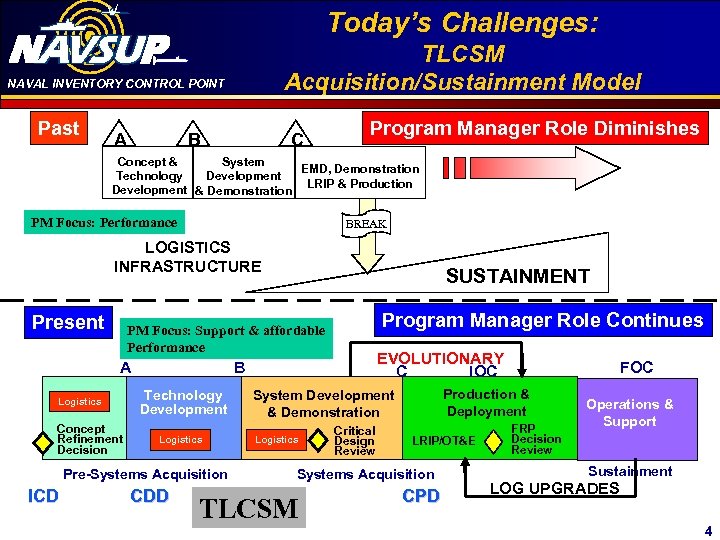

Today’s Challenges: Click to edit Master title TLCSM style Acquisition/Sustainment Model NAVAL INVENTORY CONTROL POINT Past A C B Program Manager Role Diminishes Concept & System EMD, Demonstration Technology Development LRIP & Production Development & Demonstration PM Focus: Performance BREAK LOGISTICS INFRASTRUCTURE Present Program Manager Role Continues PM Focus: Support & affordable Performance A Logistics Concept Refinement Decision EVOLUTIONARY IOC C B Technology Development Logistics Pre-Systems Acquisition ICD SUSTAINMENT CDD Production & Deployment System Development & Demonstration Logistics Critical Design Review LRIP/OT&E Systems Acquisition TLCSM FOC CPD FRP Decision Review Operations & Support Sustainment LOG UPGRADES 4

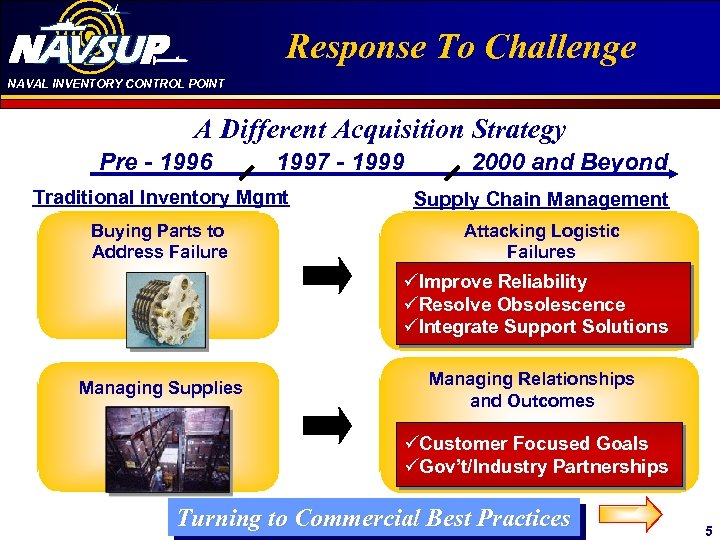

NAVAL INVENTORY CONTROL POINT Click to edit Master title Response To Challenge style A Different Acquisition Strategy Pre - 1996 1997 - 1999 2000 and Beyond Traditional Inventory Mgmt Supply Chain Management Buying Parts to Address Failure Attacking Logistic Failures üImprove Reliability üResolve Obsolescence üIntegrate Support Solutions Managing Supplies Managing Relationships and Outcomes üCustomer Focused Goals üGov’t/Industry Partnerships Turning to Commercial Best Practices 5

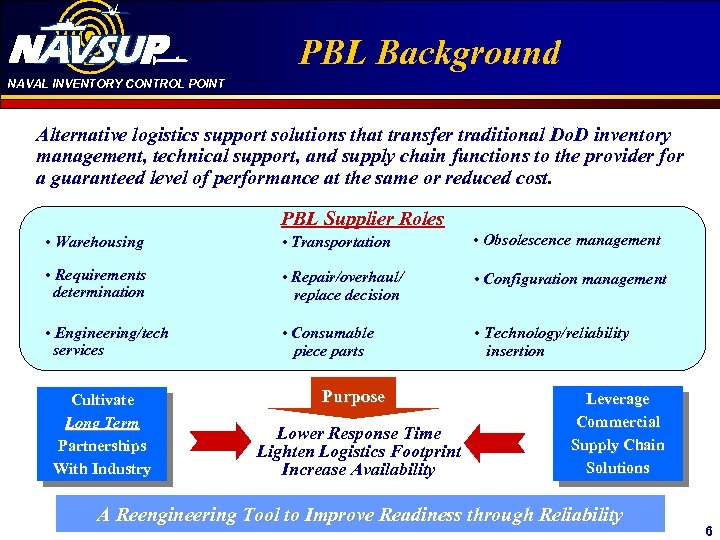

NAVAL INVENTORY CONTROL POINT Click to edit Master title PBL Background style Alternative logistics support solutions that transfer traditional Do. D inventory management, technical support, and supply chain functions to the provider for a guaranteed level of performance at the same or reduced cost. PBL Supplier Roles • Warehousing • Transportation • Obsolescence management • Requirements determination • Repair/overhaul/ replace decision • Configuration management • Engineering/tech services • Consumable piece parts • Technology/reliability insertion Cultivate Long Term Partnerships With Industry Purpose Lower Response Time Lighten Logistics Footprint Increase Availability Leverage Commercial Supply Chain Solutions A Reengineering Tool to Improve Readiness through Reliability 6

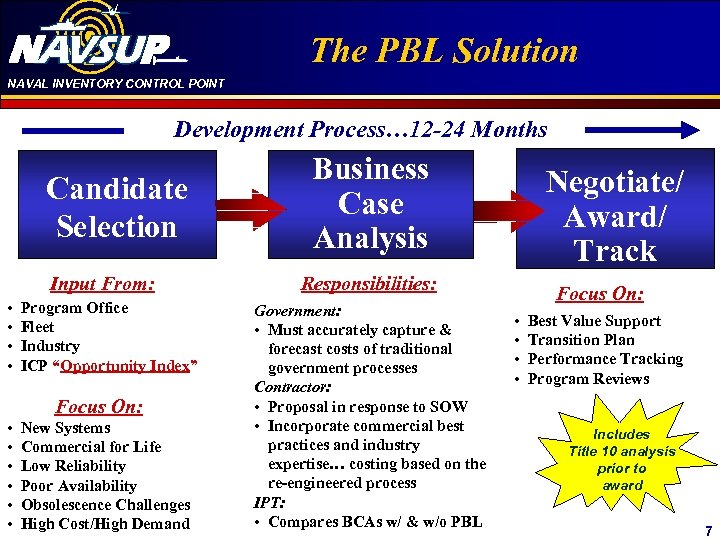

NAVAL INVENTORY CONTROL POINT Click to edit Master title The PBL Solution style Development Process… 12 -24 Months Candidate Selection Input From: • • Program Office Fleet Industry ICP “Opportunity Index” Focus On: • • • New Systems Commercial for Life Low Reliability Poor Availability Obsolescence Challenges High Cost/High Demand Business Case Analysis Negotiate/ Award/ Track Responsibilities: Government: • Must accurately capture & forecast costs of traditional government processes Contractor: • Proposal in response to SOW • Incorporate commercial best practices and industry expertise… costing based on the re-engineered process IPT: • Compares BCAs w/ & w/o PBL Focus On: • • Best Value Support Transition Plan Performance Tracking Program Reviews Includes Title 10 analysis prior to award 7

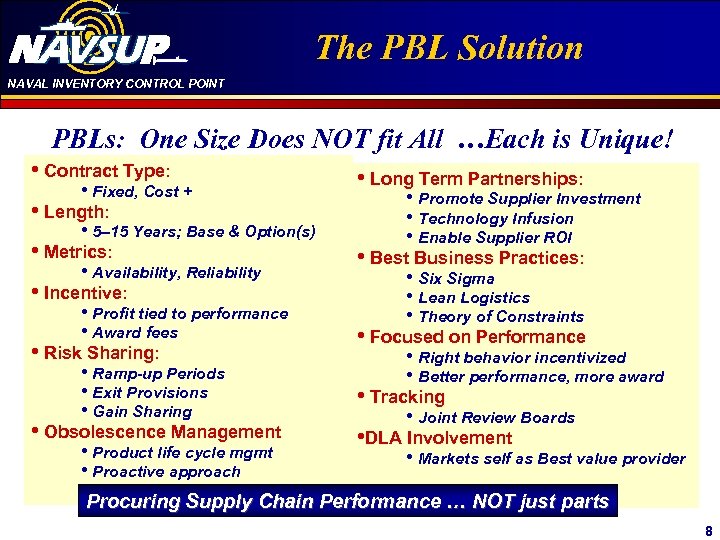

NAVAL INVENTORY CONTROL POINT Click to edit Master title The PBL Solution style PBLs: One Size Does NOT fit All …Each is Unique! • Contract Type: • Fixed, Cost + • Length: • 5– 15 Years; Base & Option(s) • Metrics: • Availability, Reliability • Incentive: • Profit tied to performance • Award fees • Risk Sharing: • Ramp-up Periods • Exit Provisions • Gain Sharing • Obsolescence Management • Long Term Partnerships: • Promote Supplier Investment • Technology Infusion • Enable Supplier ROI • Best Business Practices: • Six Sigma • Lean Logistics • Theory of Constraints • Focused on Performance • Right behavior incentivized • Better performance, more award • Tracking • Joint Review Boards • DLA Involvement • Product life cycle mgmt • Markets self as Best value provider • Proactive approach Procuring Supply Chain Performance … NOT just parts 8

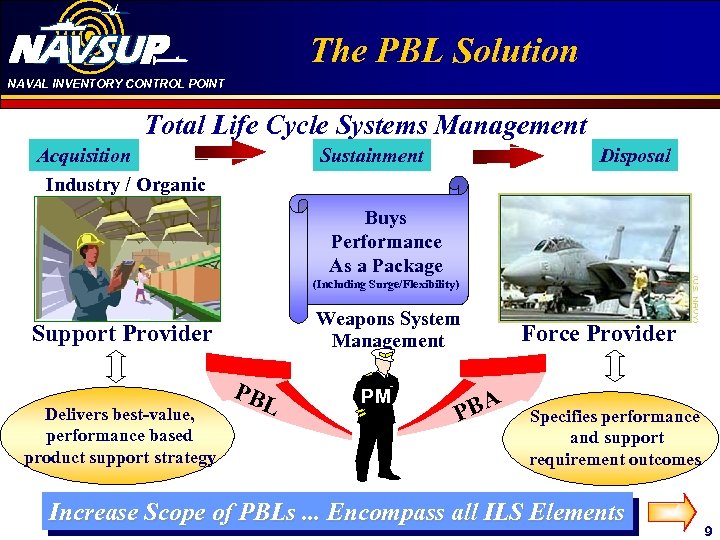

NAVAL INVENTORY CONTROL POINT Click to edit Master title The PBL Solution style Total Life Cycle Systems Management Acquisition Industry / Organic Sustainment Disposal Buys Performance As a Package (Including Surge/Flexibility) Weapons System Management Support Provider Delivers best-value, performance based product support strategy PB L PM A PB Force Provider Specifies performance and support requirement outcomes Increase Scope of PBLs. . . Encompass all ILS Elements 9

NAVAL INVENTORY CONTROL POINT Click to edit Master title The PBL Process Steps to Award style • The IPT • Key Issues • Notional Timeline • Critical Milestones • Scope of effort • Data Analysis • Contracting / Pricing • Business Case Analysis • Process Summary 10

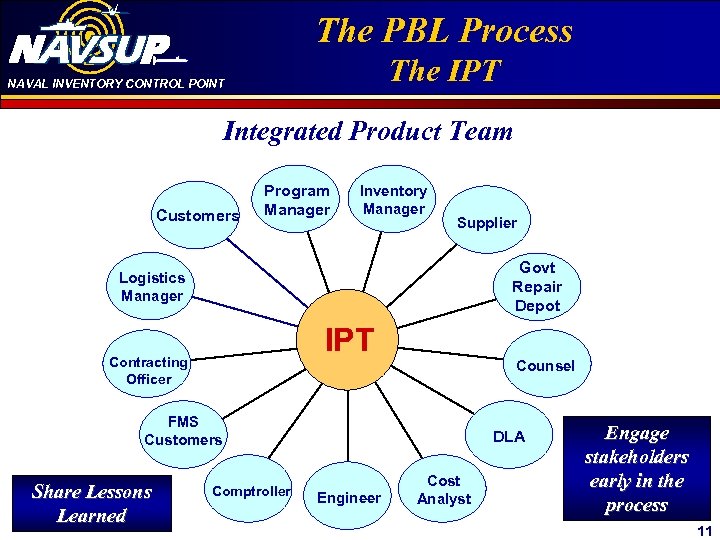

NAVAL INVENTORY CONTROL POINT Click to edit Master title The PBL Process Thestyle IPT Integrated Product Team Customers Program Manager Inventory Manager Supplier Govt Repair Depot Logistics Manager IPT Contracting Officer Counsel FMS Customers Share Lessons Learned Comptroller DLA Engineer Cost Analyst Engage stakeholders early in the process 11

NAVAL INVENTORY CONTROL POINT Click to edit Master title The PBL Process Key Issues style • Scope of Effort / Objectives – Universe of systems/components/NSNs – Intended ILS coverage • Financial Issues – Funding Streams … ties to scope of effort – Cash Flow • • • Metrics Core / Partnership Issues Transparency to Customer Configuration Control FMS / DLA / Interservice 12

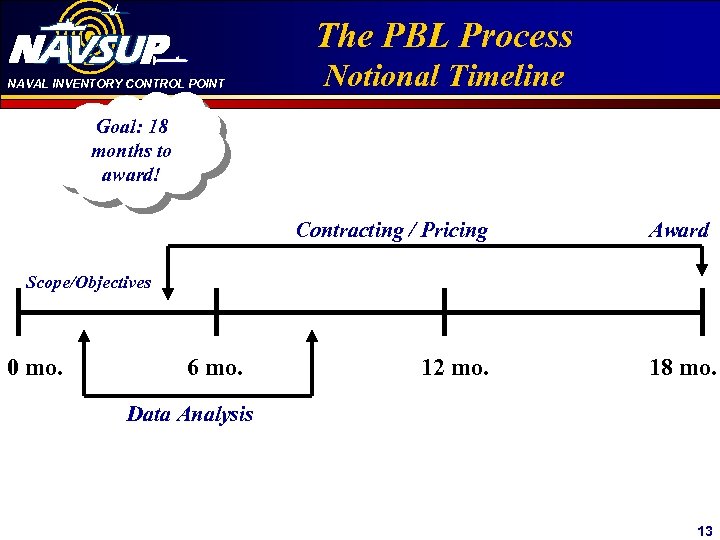

NAVAL INVENTORY CONTROL POINT Click to edit Master title The PBL Process Notionalstyle Timeline Goal: 18 months to award! Contracting / Pricing Award Scope/Objectives 0 mo. 6 mo. 12 mo. 18 mo. Data Analysis 13

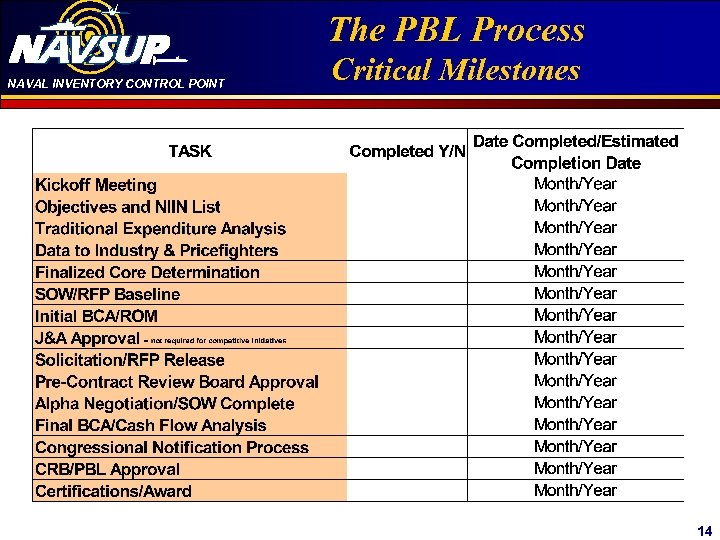

NAVAL INVENTORY CONTROL POINT Click to. PBL Process title The edit Master Critical style Milestones 14

NAVAL INVENTORY CONTROL POINT Click to edit Master title The PBL Process Scope of Effort style • Define scope • Develop clear understanding of expectations • Identify resources required for effort … does scope align with available funding? • Obtain commitment from resource sponsors… early and constant focus on affordability • Key Steps: – Identify PBL universe … what components or systems will be covered? – Establish Integrated Process Team (IPT)… all stakeholders must be included… ensure fleet buy-in – Develop draft Statement of Objectives / Statement of Work… attainable, realistic, and measurable metrics 15

NAVAL INVENTORY CONTROL POINT • • • Click to edit Master title The PBL Process Data Analysis style Gather relevant support data Provide baseline / historical data to industry Finalize Core determination Develop initial BCA / ROM … begin cash flow analysis Initiate Justification & Authorization (J&A) if required It is essential that Government and Industry discuss and understand program support data and baselines … consensus starting points in demand, reliability, flight hours, future program profiles, etc. are vital to valid comparisons in the BCA 16

NAVAL INVENTORY CONTROL POINT • • • Click to edit Master title The PBL Process Contracting/Pricing style Develop RFP Initiate Congressional Notification process Establish Alpha contracting team when applicable Finalize SOW / metrics / model contract Finalize contract pricing Complete BCA / cash flow analysis … obtain final PBL Board approval Entire process is a team effort … joint and expeditious resolution of issues at all milestones is essential to keep initiative on track to award … flexibility, innovation, and willingness to negotiate are key 17

NAVAL INVENTORY CONTROL POINT Click to. PBL Process title The edit Master Business Case Analysis style • Government: • Specifies desired results and outcome… not “how-to” • Must accurately capture & forecast costs of traditional government processes • Contractor: • Proposal in response to SOW • Can incorporate commercial best practices and industry expertise… costing based on the reengineered process Government and Industry not costing the same process • BCA is the primary tool for gauging traditional support vs. proposal: • • Comparison of government’s existing costs to contractor’s proposed costs of managing and supporting the system under PBL… improve support at break-even or better Determines affordability of concept and financial viability of PBL support • Critical that BCA stand up to audit… all assumptions must be justified and supportable Properly defined and understood scope of effort in SOW by both government and contractor members of IPT is critical… the scope is captured in the BCA 18

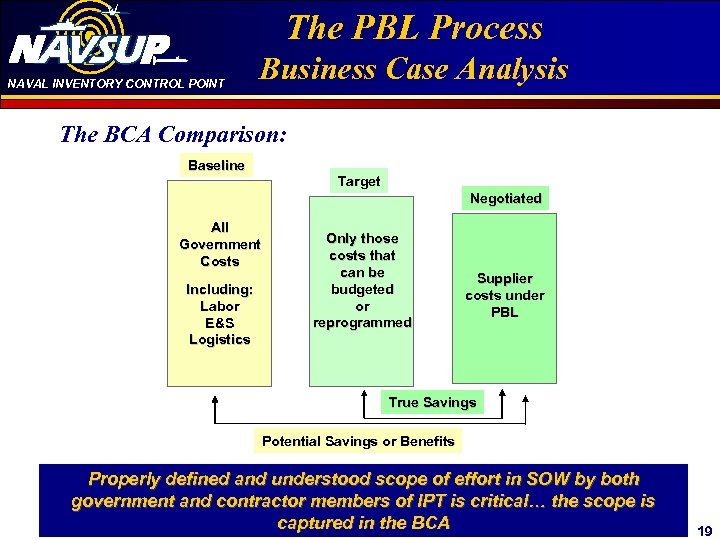

NAVAL INVENTORY CONTROL POINT Click PBL Process The to edit Master title Business Case Analysis style The BCA Comparison: Baseline Target Negotiated All Government Costs Including: Labor E&S Logistics Only those costs that can be budgeted or reprogrammed Supplier costs under PBL True Savings Potential Savings or Benefits Properly defined and understood scope of effort in SOW by both government and contractor members of IPT is critical… the scope is captured in the BCA 19

NAVAL INVENTORY CONTROL POINT Click to edit Master title The PBL Process Business Case Analysis style BCA Assumptions • PBL cannot “break the bank” and must be affordable within existing and planned funding levels • BCA can focus on the Navy Working Capital Fund (NWCF) environment or it can incorporate any “color of money” • • Any committed funding stream can be addressed in the BCA Commitments to directly fund the PBL contract and/or guarantees of “cuts” to traditional budgets are essential if these costs/savings are to be incorporated into the template… for example, costs for obsolescence management are only counted in the template if existing obsolescence budgets are committed to the PBL or are removed from existing budgets • Cost avoidances and intangible benefits are not included in the BCA “breakeven or better” comparison • Can be used to help “sell” the PBL initiative if below “break-even”… but only actual funding commitments or cuts to traditional budgets are part of the affordability analysis 20

NAVAL INVENTORY CONTROL POINT Click PBL Process The to edit Master title Summary style Key considerations from the outset: • Scope … definition of scope … mutual understanding of scope • Universe of items to be covered … understanding of current support posture and implications to desired performance requirements • Affordability … available funding … a direct impact on scope • Stakeholder concerns … Fleet / DLA / FMS / organic depots / Small Business / Interservice customers • Core determination • Cash flow 21

NAVAL INVENTORY CONTROL POINT Click to edit Master title Where We Are style Aviation Successes: F/A-18 E/F FIRST F 404 Engine H-60 Tip to Tail: GE Aircraft Engines • $750 M over 5 years • Awarded May 2001 • Over 100 systems • 131 suppliers: 15 K parts • Inventory management / warehousing / MIS / engineering • Reliability improvements • Teaming with 3 NADEPs • 85% availability vs 67% for F/A-18 C/D • $510 M contract with 5 -year base and five 1 -year options • Awarded July 2003 • $417 M with 5 -year base period • Partnership with NADEP • Awarded December 2003 Jacksonville … best • Partnership with 5 depots practices/technology insertion • Covers 540 NSNs • Covers 27 repairable components • Guaranteed availability 85% • Guaranteed 85% availability … pre • Obsolescence management -PBL SMA 55% • Inventory management • Repair process improvement • Requirements determination incentives • Obsolescence management • Inventory management/storage 22

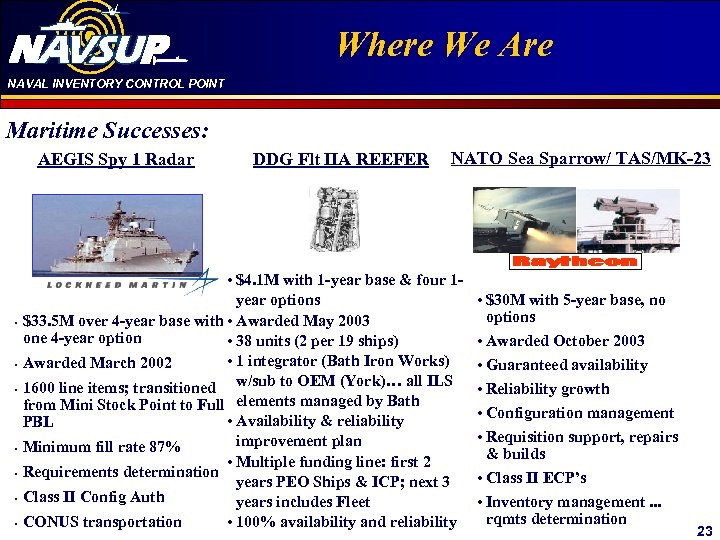

NAVAL INVENTORY CONTROL POINT Click to edit Master title Where We Are style Maritime Successes: AEGIS Spy 1 Radar • • DDG Flt IIA REEFER NATO Sea Sparrow/ TAS/MK-23 • $4. 1 M with 1 -year base & four 1 year options $33. 5 M over 4 -year base with • Awarded May 2003 one 4 -year option • 38 units (2 per 19 ships) • 1 integrator (Bath Iron Works) Awarded March 2002 1600 line items; transitioned w/sub to OEM (York)… all ILS from Mini Stock Point to Full elements managed by Bath • Availability & reliability PBL improvement plan Minimum fill rate 87% • Multiple funding line: first 2 Requirements determination years PEO Ships & ICP; next 3 Class II Config Auth years includes Fleet • 100% availability and reliability CONUS transportation • $30 M with 5 -year base, no options • Awarded October 2003 • Guaranteed availability • Reliability growth • Configuration management • Requisition support, repairs & builds • Class II ECP’s • Inventory management. . . rqmts determination 23

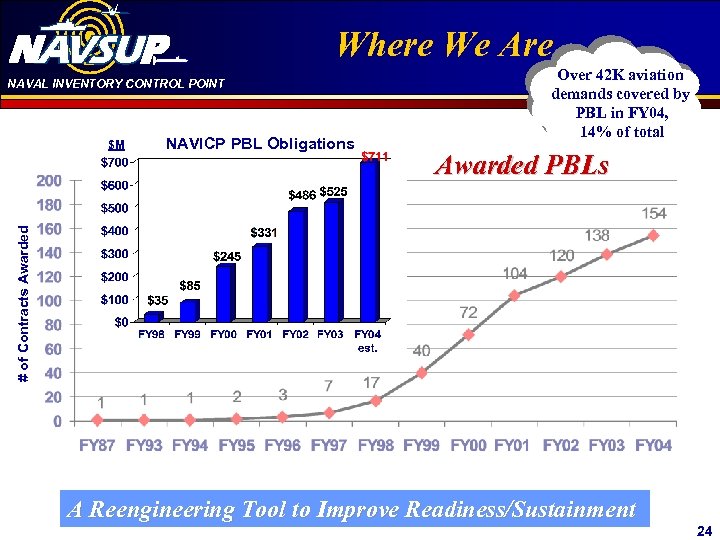

NAVAL INVENTORY CONTROL POINT NAVICP PBL Obligations Over 42 K aviation demands covered by PBL in FY 04, 14% of total Awarded PBLs # of Contracts Awarded $M Click to edit Master title Where We Are style A Reengineering Tool to Improve Readiness/Sustainment 24

NAVAL INVENTORY CONTROL POINT Click to edit Master title Where We Are style PBL Successes. . . A Sampling • F/A-18 SMS - availability was 65%. . . now 98% • CIWS - availability was 85%. . . now 95% • Tires - availability was 81%. . . now 98% • ARC - 210 Radio - availability was 70%. . . now 85% • AEGIS - availability was 85%. . . now 95% • APU - availability was 70%. . . now 90% • F-14 LANTIRN - availability was 73%. . . now 90% • H-60 Avionics - availability was 71%. . . now 85% • F/A-18 E/F FIRST - 85% availability. . . F/A-18 C/D 73% 25

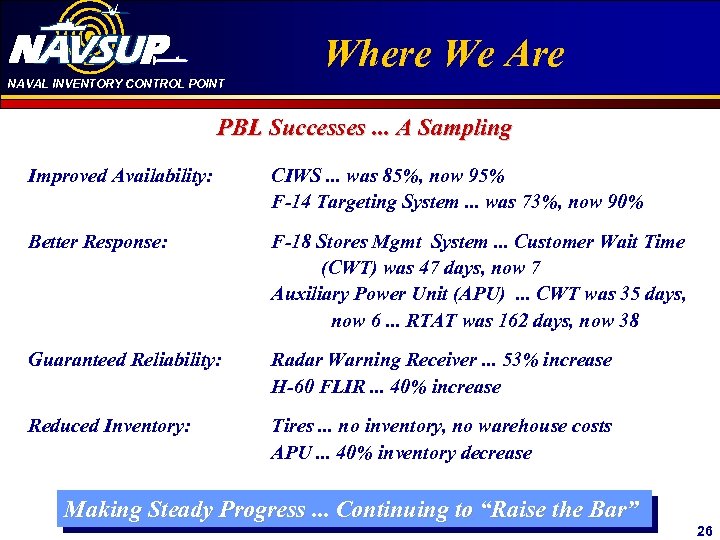

NAVAL INVENTORY CONTROL POINT Click to edit Master title Where We Are style PBL Successes. . . A Sampling Improved Availability: CIWS. . . was 85%, now 95% F-14 Targeting System. . . was 73%, now 90% Better Response: F-18 Stores Mgmt System. . . Customer Wait Time (CWT) was 47 days, now 7 Auxiliary Power Unit (APU). . . CWT was 35 days, now 6. . . RTAT was 162 days, now 38 Guaranteed Reliability: Radar Warning Receiver. . . 53% increase H-60 FLIR. . . 40% increase Reduced Inventory: Tires. . . no inventory, no warehouse costs APU. . . 40% inventory decrease Making Steady Progress. . . Continuing to “Raise the Bar” 26

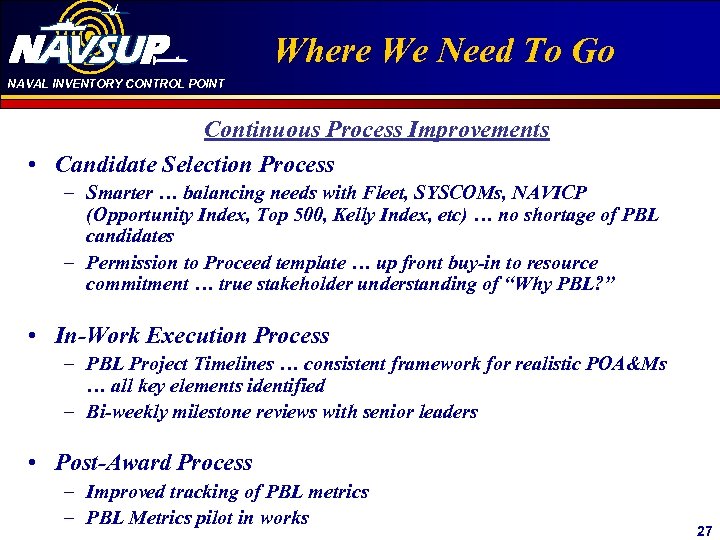

NAVAL INVENTORY CONTROL POINT Click to edit Master title Where We Need To Go style Continuous Process Improvements • Candidate Selection Process – Smarter … balancing needs with Fleet, SYSCOMs, NAVICP (Opportunity Index, Top 500, Kelly Index, etc) … no shortage of PBL candidates – Permission to Proceed template … up front buy-in to resource commitment … true stakeholder understanding of “Why PBL? ” • In-Work Execution Process – PBL Project Timelines … consistent framework for realistic POA&Ms … all key elements identified – Bi-weekly milestone reviews with senior leaders • Post-Award Process – Improved tracking of PBL metrics – PBL Metrics pilot in works 27

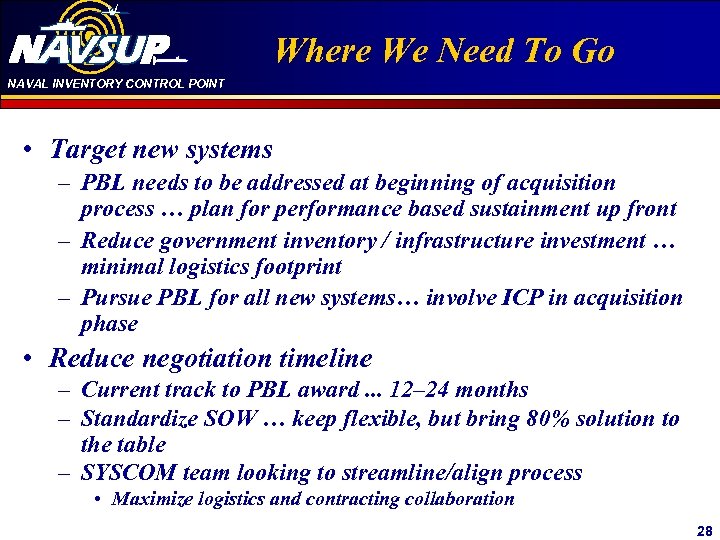

NAVAL INVENTORY CONTROL POINT Click to edit Master title Where We Need To Go style • Target new systems – PBL needs to be addressed at beginning of acquisition process … plan for performance based sustainment up front – Reduce government inventory / infrastructure investment … minimal logistics footprint – Pursue PBL for all new systems… involve ICP in acquisition phase • Reduce negotiation timeline – Current track to PBL award. . . 12– 24 months – Standardize SOW … keep flexible, but bring 80% solution to the table – SYSCOM team looking to streamline/align process • Maximize logistics and contracting collaboration 28

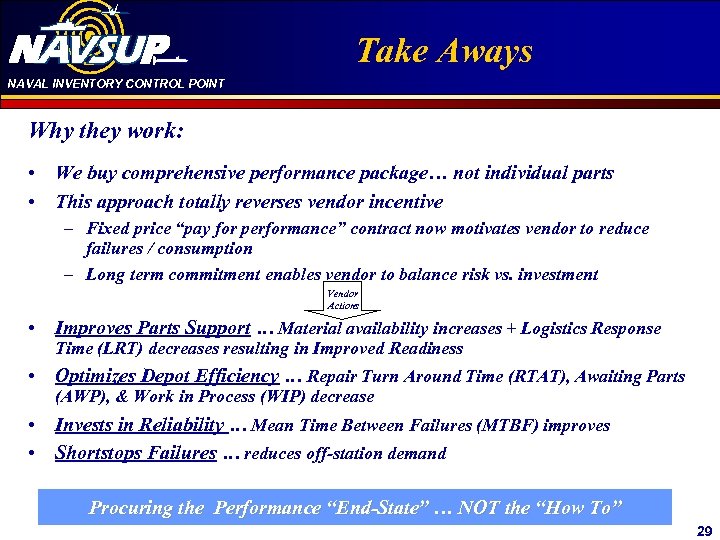

NAVAL INVENTORY CONTROL POINT Click to edit Master title Take Aways style Why they work: • We buy comprehensive performance package… not individual parts • This approach totally reverses vendor incentive – Fixed price “pay for performance” contract now motivates vendor to reduce failures / consumption – Long term commitment enables vendor to balance risk vs. investment Vendor Actions • Improves Parts Support … Material availability increases + Logistics Response Time (LRT) decreases resulting in Improved Readiness • Optimizes Depot Efficiency … Repair Turn Around Time (RTAT), Awaiting Parts (AWP), & Work in Process (WIP) decrease • Invests in Reliability … Mean Time Between Failures (MTBF) improves • Shortstops Failures … reduces off-station demand Procuring the Performance “End-State” … NOT the “How To” 29

NAVAL INVENTORY CONTROL POINT Click to edit Master title Take Aways style PBLs. . . • Proven approach to cost wise readiness – Vendor investments enhance legacy support – Vendor assumes risk for new systems • The solution to today's tough challenges – Vendor manages obsolescence – Vendor inserts technology – Vendor improves reliability • The "enabler" for future savings – Vendor performance opens the door to inventory / supply chain efficiencies – Vendor engagement as early as possible in the life cycle maximizes outyear potential 30

NAVAL INVENTORY CONTROL POINT Click to edit Master title Take Aways style Buying weapon system performance… buying optimized logistics support • Aggressive Growth … “Bigger”, “Broader” PBL • Early Involvement … TLCSM “cradle to grave” team approach • Accelerate Process … improve collaboration…beat 12 -24 mos. • Improve Reliability … cost-wise readiness • Public / Private Partnerships … they work … better output Acquisition Sustainment System acquisition linked with follow-on sustainment 31

NAVAL INVENTORY CONTROL POINT Click to edit Master title style Back Up 32

NAVAL INVENTORY CONTROL POINT Click to edit Master title Where We Are Partnerships style Why Partner? • OSD Policy • Satisfies Title 10 USC • Effective Use of Depot Expertise – Strike Proof, Skilled • Stable Depot Workload • Material Support • Sharing of Best Business Practices • Technology Insertion 33

NAVAL INVENTORY CONTROL POINT Click to edit Master title Where We Are Partnerships style Why Partner? • Reliability Improvements Encouraged • Reduces TAT, and Inventory Requirements • Defined Workshare • “Partners”, Not “Competitors” • Sharing vs. Maintaining Competitive Edge • Improved Readiness at Reduced Costs 34

NAVAL INVENTORY CONTROL POINT Click to edit Are Where We Master title FMS Clauses in PBL style • Requisition Processing – CLSSA requirements covered under PBL… traditional support commitment maintained… same delivery/availability metric as USN – DRP/Initial requirements filled as stock position permits • Notification of Configuration Changes • Potential CLIN for Repair of Repairables IPT must ensure that all elements of traditional FMS support will continue in PBL environment … PBL features, such as obsolescence management and reliability improvements, should improve FMS ROR support 35

NAVAL INVENTORY CONTROL POINT Click. Where We. Master title to edit Are FMS Customer Participation style • Potential that FMS Customers become full PBL participants using CLSSA RIRO procedures • To obtain full PBL coverage FMS Customers would need to provide the following (for Aviation initiatives): – – – Past flying hours Future flying hours Past demand data Past repair data Current configuration data • Funding procedures must be addressed • FMS Customers would receive same reliability improvement and availability performance metrics as USN • Unique FMS metrics are possible 36

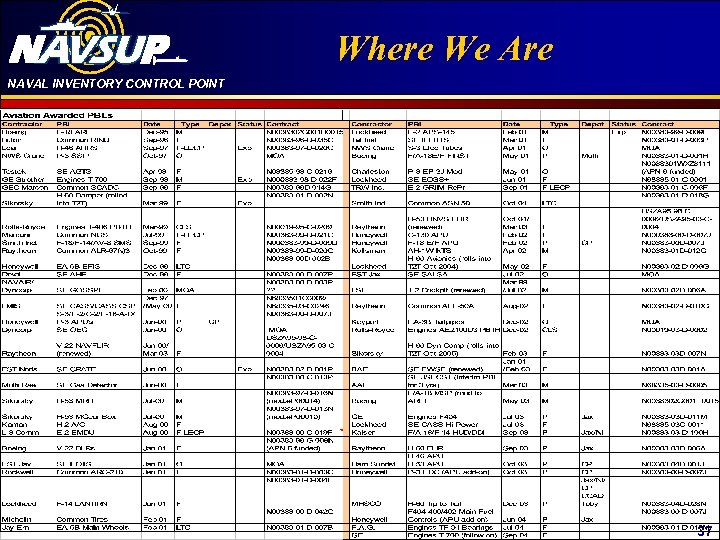

NAVAL INVENTORY CONTROL POINT Click to edit Master title Where We Are style 37

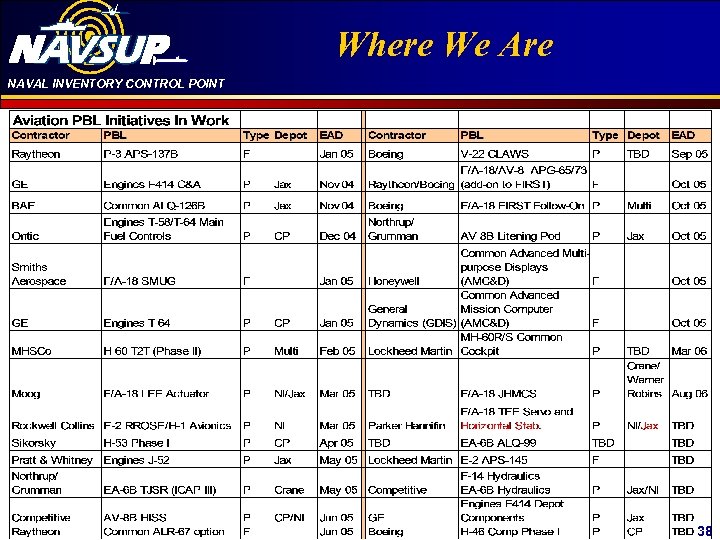

NAVAL INVENTORY CONTROL POINT Click to edit Master title Where We Are style 38

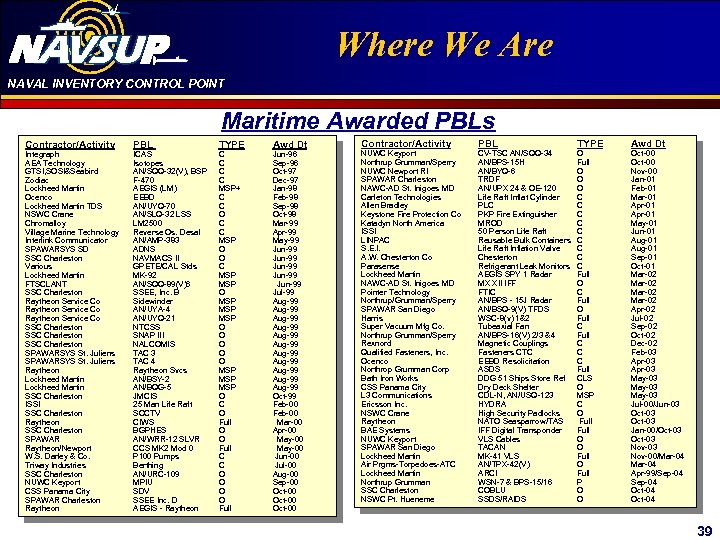

NAVAL INVENTORY CONTROL POINT Click to edit Master title Where We Are style Maritime Awarded PBLs Contractor/Activity Integraph AEA Technology GTSI, SOSI&Seabird Zodiac Lockheed Martin Ocenco Lockheed Martin TDS NSWC Crane Chromalloy Village Marine Technology Interlink Communicator SPAWARSYS SD SSC Charleston Various Lockheed Martin FTSCLANT SSC Charleston Raytheon Service Co SSC Charleston SPAWARSYS St. Juliens Raytheon Lockheed Martin SSC Charleston ISSI SSC Charleston Raytheon SSC Charleston SPAWAR Raytheon/Newport W. S. Darley & Co. Triway Industries SSC Charleston NUWC Keyport CSS Panama City SPAWAR Charleston Raytheon PBL ICAS Isotopes AN/SQQ-32(V), BSP F-470 AEGIS (LM) EEBD AN/UYQ-70 AN/SLQ-32 LSS LM 2500 Reverse Os. Desal AN/AMP-383 ADNS NAVMACS II GPETE/CAL Stds MK-92 AN/SQQ-89(V)6 SSEE, Inc. B Sidewinder AN/UYA-4 AN/UYQ-21 NTCSS SNAP III NALCOMIS TAC 3 TAC 4 Raytheon Svcs AN/BSY-2 AN/BQG-5 JMCIS 25 Man Life Raft SCCTV CIWS BGPHES AN/WRR-12 SLVR CCS MK 2 Mod 0 P 100 Pumps Berthing AN/URC-109 MPIU SDV SSEE Inc. D AEGIS - Raytheon TYPE C C MSP+ C C O C C MSP O O C MSP O MSP MSP O O O MSP MSP O C O Full O O Full C C O O Full Awd Dt Jun-96 Sep-96 Oct-97 Dec-97 Jan-98 Feb-98 Sep-98 Oct-98 Mar-99 Apr-99 May-99 Jun-99 Jun-99 Jul-99 Aug-99 Aug-99 Aug-99 Oct-99 Feb-00 Mar-00 Apr-00 May-00 Jun-00 Jul-00 Aug-00 Sep-00 Oct-00 Contractor/Activity NUWC Keyport Northrup Grumman/Sperry NUWC Newport RI SPAWAR Charleston NAWC-AD St. Inigoes MD Carleton Technologies Allen Bradley Keystone Fire Protection Co Katadyn North America ISSI LINPAC S. E. I. A. W. Chesterton Co Parasense Lockheed Martin NAWC-AD St. Inigoes MD Pointer Technology Northrup/Grumman/Sperry SPAWAR San Diego Harris Super Vacuum Mfg Co. Northrup Grumman/Sperry Rexnord Qualified Fasteners, Inc. Ocenco Northrop Grumman Corp Bath Iron Works CSS Panama City L 3 Communications Ericsson Inc. NSWC Crane Raytheon BAE Systems NUWC Keyport SPAWAR San Diego Lockheed Martin Air Prgms-Torpedoes-ATC Lockheed Martin Northrup Grumman SSC Charleston NSWC Pt. Hueneme PBL CV-TSC AN/SQQ-34 AN/BPS-15 H AN/BYQ-6 TRDF AN/UPX 24 & OE-120 Life Raft Inflat Cylinder PLC PKP Fire Extinguisher MROD 50 Person Life Raft Reusable Bulk Containers Life Raft Inflation Valve Chesterton Refrigerant Leak Monitors AEGIS SPY 1 Radar MX XII IFF FTIC AN/BPS - 15 J Radar AN/BSQ-9(V) TFDS WSC-8(v) 1&2 Tubeaxial Fan AN/BPS-16(V) 2/3 &4 Magnetic Couplings Fasteners CTC EEBD Resolicitation ASDS DDG 51 Ships Store Ref Dry Deck Shelter CDL-N, AN/USQ-123 HYDRA High Security Padlocks NATO Seasparrow/TAS IFF Digital Transponder VLS Cables TACAN MK-41 VLS AN/TPX-42(V) ARCI WSN-7 & BPS-15/16 COBLU SSDS/RAIDS TYPE O Full O O O C C C C C Full O Full C C C Full CLS O MSP C O Full O O Full P O O Awd Dt Oct-00 Nov-00 Jan-01 Feb-01 Mar-01 Apr-01 May-01 Jun-01 Aug-01 Sep-01 Oct-01 Mar-02 Apr-02 Jul-02 Sep-02 Oct-02 Dec-02 Feb-03 Apr-03 May-03 Jul-00/Jun-03 Oct-03 Jan-00/Oct-03 Nov-03 Nov-00/Mar-04 Apr-99/Sep-04 Oct-04 39

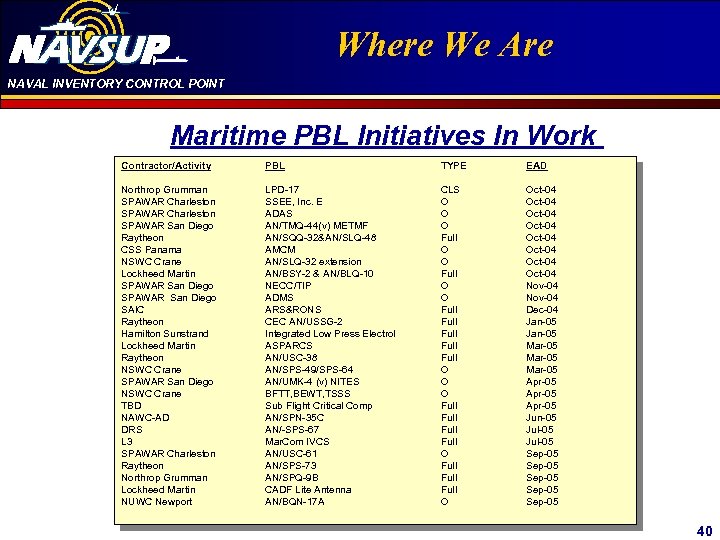

NAVAL INVENTORY CONTROL POINT Click to edit Master title Where We Are style Maritime PBL Initiatives In Work Contractor/Activity PBL TYPE EAD Northrop Grumman SPAWAR Charleston SPAWAR San Diego Raytheon CSS Panama NSWC Crane Lockheed Martin SPAWAR San Diego SAIC Raytheon Hamilton Sunstrand Lockheed Martin Raytheon NSWC Crane SPAWAR San Diego NSWC Crane TBD NAWC-AD DRS L 3 SPAWAR Charleston Raytheon Northrop Grumman Lockheed Martin NUWC Newport LPD-17 SSEE, Inc. E ADAS AN/TMQ-44(v) METMF AN/SQQ-32&AN/SLQ-48 AMCM AN/SLQ-32 extension AN/BSY-2 & AN/BLQ-10 NECC/TIP ADMS ARS&RONS CEC AN/USSG-2 Integrated Low Press Electrol ASPARCS AN/USC-38 AN/SPS-49/SPS-64 AN/UMK-4 (v) NITES BFTT, BEWT, TSSS Sub Flight Critical Comp AN/SPN-35 C AN/-SPS-67 Mar. Com IVCS AN/USC-61 AN/SPS-73 AN/SPQ-9 B CADF Lite Antenna AN/BQN-17 A CLS O O O Full Full O O O Full Full O Oct-04 Oct-04 Nov-04 Dec-04 Jan-05 Mar-05 Apr-05 Jun-05 Jul-05 Sep-05 Sep-05 40

0358d3f2300d1538b8cc1aef992910a6.ppt