1efdb81884d36e61eac26e825032e399.ppt

- Количество слайдов: 56

National Center for Hydrogen Technology – Developing Strategic Technologies for Today and our Future Dr. Gerald H. Groenewold Director Mountain States Hydrogen Business Council 4 th Annual Hydrogen Implementation Conference – July 22– 24, 2008 © 2008 University of North Dakota Energy & Environmental Research Center. All rights reserved.

National Center for Hydrogen Technology – Developing Strategic Technologies for Today and our Future Dr. Gerald H. Groenewold Director Mountain States Hydrogen Business Council 4 th Annual Hydrogen Implementation Conference – July 22– 24, 2008 © 2008 University of North Dakota Energy & Environmental Research Center. All rights reserved.

Presentation Summary • Introduction to the EERC • The hydrogen opportunity • NCHT – Seizing the opportunity through Partnerships • CO 2 • Water • Moving forward

Presentation Summary • Introduction to the EERC • The hydrogen opportunity • NCHT – Seizing the opportunity through Partnerships • CO 2 • Water • Moving forward

What Does the EERC Do? • The EERC is recognized as one of the world's leading developers of: – Cleaner, more efficient and innovative energy technologies to guarantee clean, reliable energy supplies for the United States and the world. – Environmental technologies to protect and clean our air, water, and soil. • The EERC is a research, development, demonstration, and commercialization (RDD&C) center. • The EERC vigorously maintains a nonadvocacy position. • The EERC enhances any guarantee. • The EERC is NOT an academic enterprise.

What Does the EERC Do? • The EERC is recognized as one of the world's leading developers of: – Cleaner, more efficient and innovative energy technologies to guarantee clean, reliable energy supplies for the United States and the world. – Environmental technologies to protect and clean our air, water, and soil. • The EERC is a research, development, demonstration, and commercialization (RDD&C) center. • The EERC vigorously maintains a nonadvocacy position. • The EERC enhances any guarantee. • The EERC is NOT an academic enterprise.

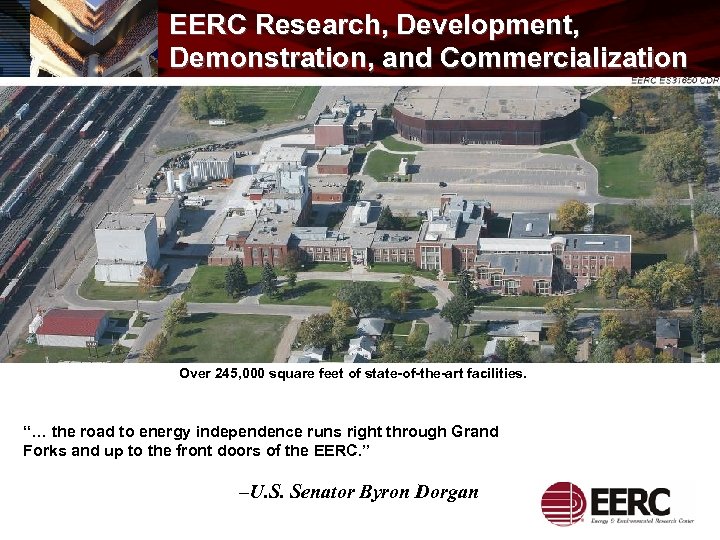

EERC Research, Development, Demonstration, and Commercialization Over 245, 000 square feet of state-of-the-art facilities. “… the road to energy independence runs right through Grand Forks and up to the front doors of the EERC. ” –U. S. Senator Byron Dorgan

EERC Research, Development, Demonstration, and Commercialization Over 245, 000 square feet of state-of-the-art facilities. “… the road to energy independence runs right through Grand Forks and up to the front doors of the EERC. ” –U. S. Senator Byron Dorgan

EERC Facilities

EERC Facilities

Providing Strategic Solutions to Real-World Problems The EERC provides practical, cost-effective solutions to today's most critical energy and environmental issues and challenges. Our research portfolio includes the following: • Clean coal technologies • Coalbed methane • Underground coal gasification • Emission control – SOx, NOx, air toxics, fine particulate, and CO 2 • Mercury measurement and control • CO 2 sequestration • Global climate change • Energy and water sustainability • Energy-efficient technologies • Distributed power generation – various fuels • Hydrogen technologies • • • Alternative fuels – Ethanol, biodiesel, biojet, and strategic fuels for the military Biomass Wind energy Water management Flood prevention Waste utilization Contaminant cleanup Advanced analytical technologies/extraction technologies Pesticides and neurological diseases

Providing Strategic Solutions to Real-World Problems The EERC provides practical, cost-effective solutions to today's most critical energy and environmental issues and challenges. Our research portfolio includes the following: • Clean coal technologies • Coalbed methane • Underground coal gasification • Emission control – SOx, NOx, air toxics, fine particulate, and CO 2 • Mercury measurement and control • CO 2 sequestration • Global climate change • Energy and water sustainability • Energy-efficient technologies • Distributed power generation – various fuels • Hydrogen technologies • • • Alternative fuels – Ethanol, biodiesel, biojet, and strategic fuels for the military Biomass Wind energy Water management Flood prevention Waste utilization Contaminant cleanup Advanced analytical technologies/extraction technologies Pesticides and neurological diseases

Invention vs. Innovation “Don’t invent something that nobody wants!” – Thomas Edison

Invention vs. Innovation “Don’t invent something that nobody wants!” – Thomas Edison

The EERC receives no state-appropriated funding for RDD&C that is not competitive.

The EERC receives no state-appropriated funding for RDD&C that is not competitive.

Willingness to Assume Risk

Willingness to Assume Risk

Worldwide Clients Since 1987, the EERC has had more than 1000 clients in all 50 states and 50 countries. Client Specs: • Government clients: 87 • Academia: 51 • International market: 129 • Private corporations: 750

Worldwide Clients Since 1987, the EERC has had more than 1000 clients in all 50 states and 50 countries. Client Specs: • Government clients: 87 • Academia: 51 • International market: 129 • Private corporations: 750

EERC Quick Facts • Total value of current EERC contract portfolio is $224 million. • The EERC had 443 active contracts in FY 08. • In FY 08, over 80% of contracts were with private sector partners. • Total employment of over 320 highly skilled scientists, engineers, and support personnel, with about 20 new open positions.

EERC Quick Facts • Total value of current EERC contract portfolio is $224 million. • The EERC had 443 active contracts in FY 08. • In FY 08, over 80% of contracts were with private sector partners. • Total employment of over 320 highly skilled scientists, engineers, and support personnel, with about 20 new open positions.

EERC Centers of Excellence The EERC’s Centers of Excellence are leading the world in providing expertise in scientifically advanced energy systems and the prevention and cleanup of air, water, and soil pollution. • • • Coal Utilization Technologies Center Emission Control Technologies Center The National Center for Hydrogen Technology Center for Climate Change and CO 2 Sequestration Center for Air Toxic Metals® (CATM®) Centers for Renewable Energy and Biomass Utilization Water Management Center National Alternative Fuels Laboratory® (NAFL®) Supercritical and Subcritical Extraction Technologies Center Coal Ash Research Center

EERC Centers of Excellence The EERC’s Centers of Excellence are leading the world in providing expertise in scientifically advanced energy systems and the prevention and cleanup of air, water, and soil pollution. • • • Coal Utilization Technologies Center Emission Control Technologies Center The National Center for Hydrogen Technology Center for Climate Change and CO 2 Sequestration Center for Air Toxic Metals® (CATM®) Centers for Renewable Energy and Biomass Utilization Water Management Center National Alternative Fuels Laboratory® (NAFL®) Supercritical and Subcritical Extraction Technologies Center Coal Ash Research Center

Ten Key Challenges/Issues Facing the Global Community 1. Population growth 2. Population growth 3. Population growth 4. Population growth 5. Population growth 6. Population growth 7. Population growth 8. Population growth 9. Population growth 10. Energy and water

Ten Key Challenges/Issues Facing the Global Community 1. Population growth 2. Population growth 3. Population growth 4. Population growth 5. Population growth 6. Population growth 7. Population growth 8. Population growth 9. Population growth 10. Energy and water

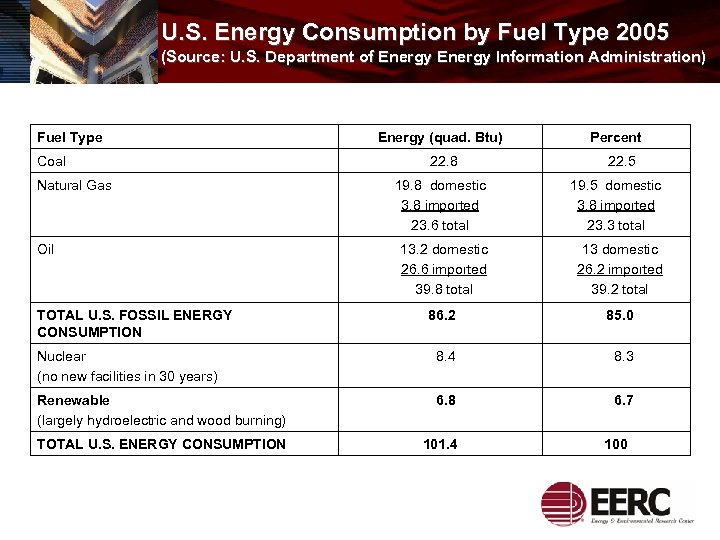

U. S. Energy Consumption by Fuel Type 2005 (Source: U. S. Department of Energy Information Administration) Fuel Type Energy (quad. Btu) Percent 22. 8 22. 5 Natural Gas 19. 8 domestic 3. 8 imported 23. 6 total 19. 5 domestic 3. 8 imported 23. 3 total Oil 13. 2 domestic 26. 6 imported 39. 8 total 13 domestic 26. 2 imported 39. 2 total TOTAL U. S. FOSSIL ENERGY CONSUMPTION 86. 2 85. 0 Nuclear (no new facilities in 30 years) 8. 4 8. 3 Renewable (largely hydroelectric and wood burning) 6. 8 6. 7 TOTAL U. S. ENERGY CONSUMPTION 101. 4 Coal 100

U. S. Energy Consumption by Fuel Type 2005 (Source: U. S. Department of Energy Information Administration) Fuel Type Energy (quad. Btu) Percent 22. 8 22. 5 Natural Gas 19. 8 domestic 3. 8 imported 23. 6 total 19. 5 domestic 3. 8 imported 23. 3 total Oil 13. 2 domestic 26. 6 imported 39. 8 total 13 domestic 26. 2 imported 39. 2 total TOTAL U. S. FOSSIL ENERGY CONSUMPTION 86. 2 85. 0 Nuclear (no new facilities in 30 years) 8. 4 8. 3 Renewable (largely hydroelectric and wood burning) 6. 8 6. 7 TOTAL U. S. ENERGY CONSUMPTION 101. 4 Coal 100

“Predictions are hard, especially about the future. ” – Yogi Berra

“Predictions are hard, especially about the future. ” – Yogi Berra

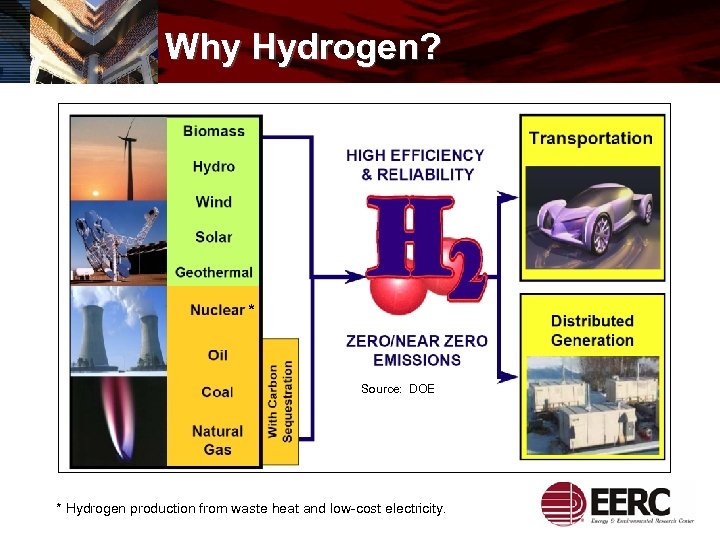

Why Hydrogen? * Source: : DOE * Hydrogen production from waste heat and low-cost electricity.

Why Hydrogen? * Source: : DOE * Hydrogen production from waste heat and low-cost electricity.

Hydrogen Production is Not New • Over 9 million tons of hydrogen is produced annually in the United States today. • The two primary hydrogen uses currently are for producing fertilizers and for hydrocracking petroleum. • The EERC is not reinventing the wheel; instead, we are working on better tires. – Hydrogen from renewable sources – Coal-to-hydrogen – Handling product impurities – Developing and demonstrating hydrogen uses – Etc.

Hydrogen Production is Not New • Over 9 million tons of hydrogen is produced annually in the United States today. • The two primary hydrogen uses currently are for producing fertilizers and for hydrocracking petroleum. • The EERC is not reinventing the wheel; instead, we are working on better tires. – Hydrogen from renewable sources – Coal-to-hydrogen – Handling product impurities – Developing and demonstrating hydrogen uses – Etc.

Hydrogen Economy Issues • • • Transportation issues – Hydrogen storage – Hydrogen production – Fuel cell cost Power generation and infrastructure issues – Difficulty in obtaining insurance – Codes and standards – Hydrogen delivery Public acceptance – Education and outreach “There is nothing more frightening than ignorance in action. ” — Mark Twain

Hydrogen Economy Issues • • • Transportation issues – Hydrogen storage – Hydrogen production – Fuel cell cost Power generation and infrastructure issues – Difficulty in obtaining insurance – Codes and standards – Hydrogen delivery Public acceptance – Education and outreach “There is nothing more frightening than ignorance in action. ” — Mark Twain

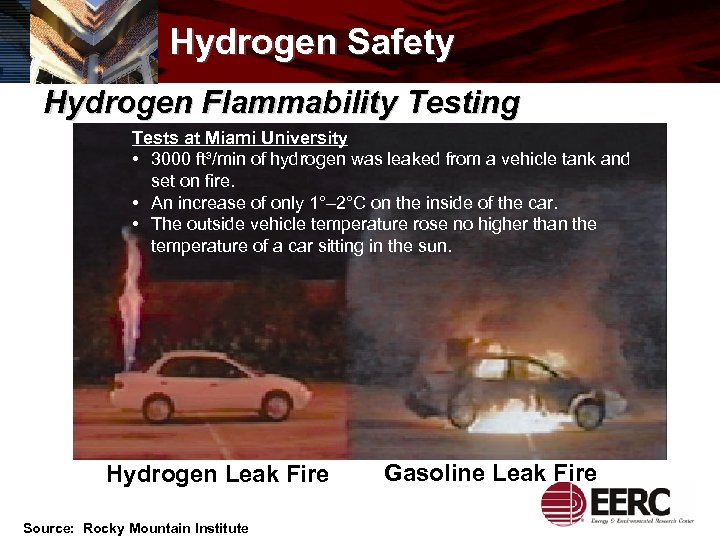

Hydrogen Safety Hydrogen Flammability Testing Tests at Miami University • 3000 ft³/min of hydrogen was leaked from a vehicle tank and set on fire. • An increase of only 1°– 2°C on the inside of the car. • The outside vehicle temperature rose no higher than the temperature of a car sitting in the sun. Hydrogen Leak Fire Source: Rocky Mountain Institute Gasoline Leak Fire

Hydrogen Safety Hydrogen Flammability Testing Tests at Miami University • 3000 ft³/min of hydrogen was leaked from a vehicle tank and set on fire. • An increase of only 1°– 2°C on the inside of the car. • The outside vehicle temperature rose no higher than the temperature of a car sitting in the sun. Hydrogen Leak Fire Source: Rocky Mountain Institute Gasoline Leak Fire

Evolution of the Hydrogen Economy The evolution of the hydrogen economy is not a paradigm shift—it is a fuel transition—analogous to the evolution to natural gas.

Evolution of the Hydrogen Economy The evolution of the hydrogen economy is not a paradigm shift—it is a fuel transition—analogous to the evolution to natural gas.

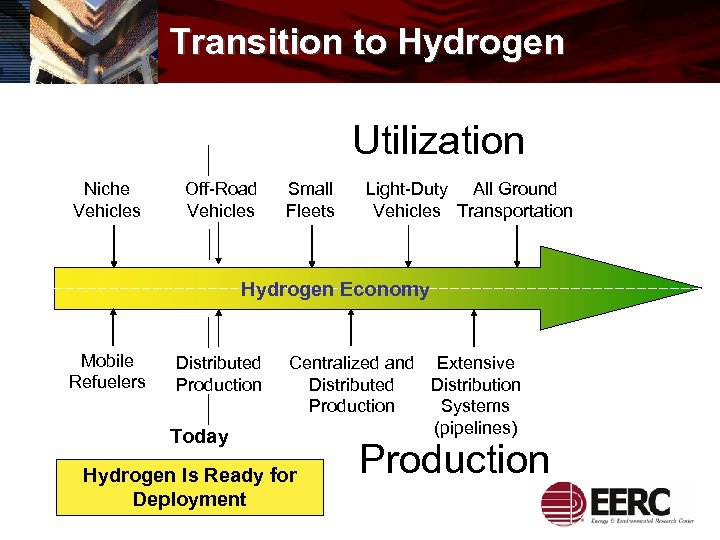

Transition to Hydrogen Utilization Niche Vehicles Off-Road Vehicles Small Fleets Light-Duty All Ground Vehicles Transportation Hydrogen Economy Mobile Refuelers Distributed Production Today Centralized and Extensive Distributed Distribution Production Systems (pipelines) Hydrogen Is Ready for Deployment Production

Transition to Hydrogen Utilization Niche Vehicles Off-Road Vehicles Small Fleets Light-Duty All Ground Vehicles Transportation Hydrogen Economy Mobile Refuelers Distributed Production Today Centralized and Extensive Distributed Distribution Production Systems (pipelines) Hydrogen Is Ready for Deployment Production

Natural Gas to Hydrogen • For hydrogen production from natural gas to replace even one-third of gasoline use for transportation, all of the natural gas currently used (6. 9 trillion cubic feet) for the generation of electricity in the United States would be required. 1 – Represents 30% of all natural gas usage – Results in the production of 46 billion kg of H 2 or the equivalent of 46 billion gallons of gas. 2 – In 2007, the United States consumed 142 billion gallons of finished motor gasoline. 1 • Currently, 8 billion kg of H 2 is produced in the United States each year, and about 95% of the hydrogen is derived from natural gas reforming. 3 1. Source: Energy Information Association (tonto. eia. doe. gov). 2. Life Cycle Assessment of Hydrogen Production via Natural Gas Steam Reforming, NREL, 2001. 3. U. S. Department of Energy, Fossil Energy (www. fossil. energy. gov)

Natural Gas to Hydrogen • For hydrogen production from natural gas to replace even one-third of gasoline use for transportation, all of the natural gas currently used (6. 9 trillion cubic feet) for the generation of electricity in the United States would be required. 1 – Represents 30% of all natural gas usage – Results in the production of 46 billion kg of H 2 or the equivalent of 46 billion gallons of gas. 2 – In 2007, the United States consumed 142 billion gallons of finished motor gasoline. 1 • Currently, 8 billion kg of H 2 is produced in the United States each year, and about 95% of the hydrogen is derived from natural gas reforming. 3 1. Source: Energy Information Association (tonto. eia. doe. gov). 2. Life Cycle Assessment of Hydrogen Production via Natural Gas Steam Reforming, NREL, 2001. 3. U. S. Department of Energy, Fossil Energy (www. fossil. energy. gov)

Coal-to-Hydrogen Opportunity Teamed with carbon management, coal-tohydrogen technology can help meet the main goals of a hydrogen economy (energy security, environmental benefits, and economic advantages). • Coal can be a cornerstone for the diverse hydrogen supply mix, with integration of hydrogen production into coproduction of power and synthetic fuels. • The United States has more than one-quarter of the world’s coal reserves, with a supply that will last over 250 years at current mining rates. • About 12% more coal would need to be mined and converted to hydrogen to serve one-third of the transportation demand. Tremendous opportunity to increase domestic energy supply without adding transmission capacity includes hydrogen, power, advanced tactical fuels for the military, fuels for energy markets, and specialty chemicals.

Coal-to-Hydrogen Opportunity Teamed with carbon management, coal-tohydrogen technology can help meet the main goals of a hydrogen economy (energy security, environmental benefits, and economic advantages). • Coal can be a cornerstone for the diverse hydrogen supply mix, with integration of hydrogen production into coproduction of power and synthetic fuels. • The United States has more than one-quarter of the world’s coal reserves, with a supply that will last over 250 years at current mining rates. • About 12% more coal would need to be mined and converted to hydrogen to serve one-third of the transportation demand. Tremendous opportunity to increase domestic energy supply without adding transmission capacity includes hydrogen, power, advanced tactical fuels for the military, fuels for energy markets, and specialty chemicals.

The United States Is Poised to Support a Hydrogen Economy Coal is the bridge to the hydrogen economy

The United States Is Poised to Support a Hydrogen Economy Coal is the bridge to the hydrogen economy

The National Center for Hydrogen Technology (NCHT) The EERC was designated in November 2004 as the National Center for Hydrogen Technology. The EERC has more than 50 years of experience with hydrogen production and fuel cell technologies.

The National Center for Hydrogen Technology (NCHT) The EERC was designated in November 2004 as the National Center for Hydrogen Technology. The EERC has more than 50 years of experience with hydrogen production and fuel cell technologies.

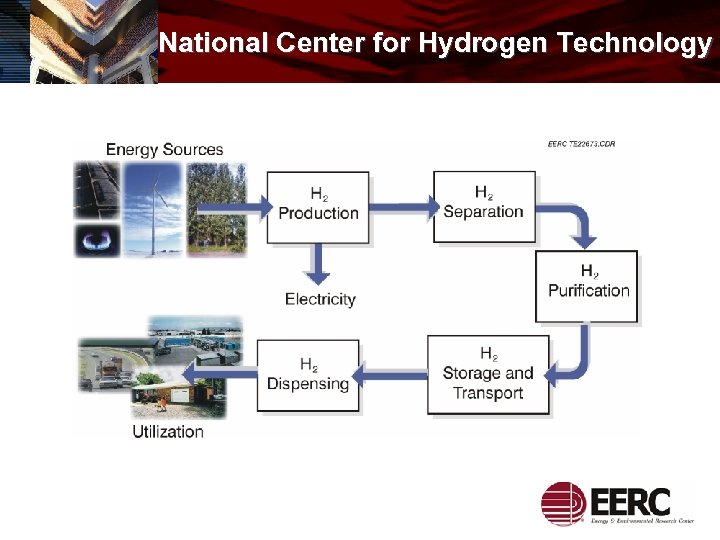

National Center for Hydrogen Technology

National Center for Hydrogen Technology

The National Center for Hydrogen Technology (NCHT) Current and pending contracts in the NCHT include nearly $60 million in funding for the following programmatic areas: • Hydrogen from coal • Hydrogen on demand • Battlefield hydrogen (JP-8) • Biomass-to-hydrogen program • Integrated hydrogen and ethanol production • Wind-to-hydrogen • Future. Gen • Materials for hydrogen utilization • Hydrogen fuel cell-powered vehicles The Market Must Pull Technology

The National Center for Hydrogen Technology (NCHT) Current and pending contracts in the NCHT include nearly $60 million in funding for the following programmatic areas: • Hydrogen from coal • Hydrogen on demand • Battlefield hydrogen (JP-8) • Biomass-to-hydrogen program • Integrated hydrogen and ethanol production • Wind-to-hydrogen • Future. Gen • Materials for hydrogen utilization • Hydrogen fuel cell-powered vehicles The Market Must Pull Technology

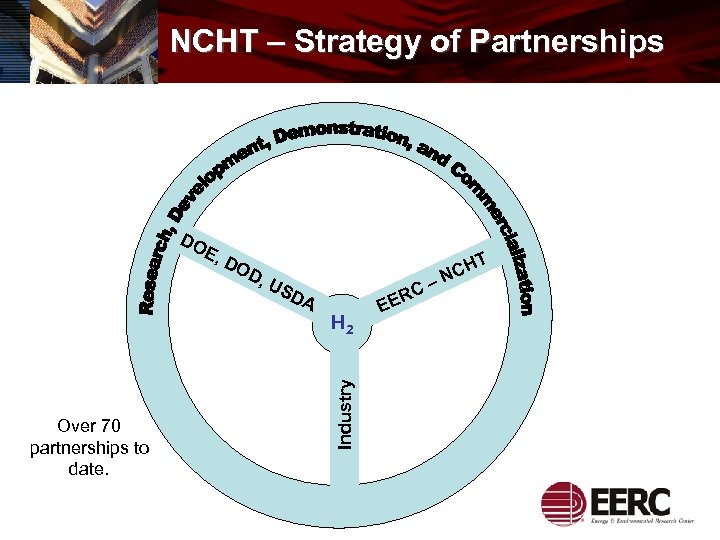

NCHT – Strategy of Partnerships DO E, DO D, US D A Over 70 partnerships to date. Industry H 2 C ER E – H NC T

NCHT – Strategy of Partnerships DO E, DO D, US D A Over 70 partnerships to date. Industry H 2 C ER E – H NC T

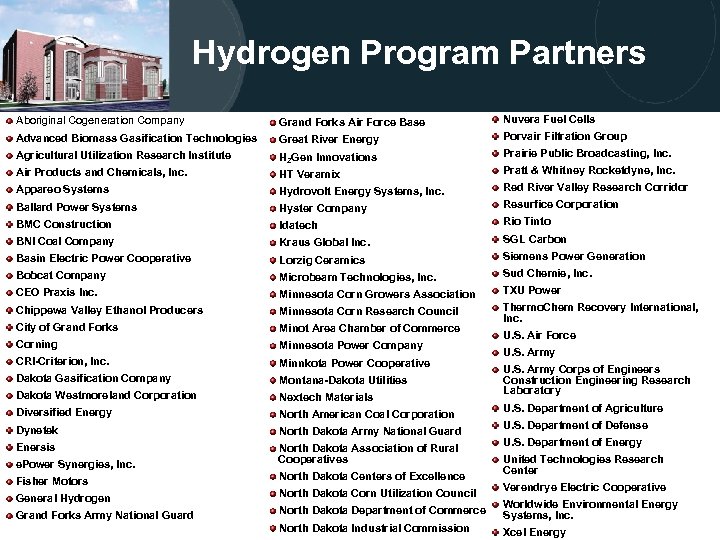

Hydrogen Program Partners Aboriginal Cogeneration Company Grand Forks Air Force Base Nuvera Fuel Cells Advanced Biomass Gasification Technologies Great River Energy Porvair Filtration Group Agricultural Utilization Research Institute H 2 Gen Innovations Prairie Public Broadcasting, Inc. Air Products and Chemicals, Inc. HT Veramix Pratt & Whitney Rocketdyne, Inc. Appareo Systems Hydrovolt Energy Systems, Inc. Red River Valley Research Corridor Ballard Power Systems Hyster Company Resurfice Corporation BMC Construction Idatech Rio Tinto BNI Coal Company Kraus Global Inc. SGL Carbon Basin Electric Power Cooperative Lorzig Ceramics Siemens Power Generation Bobcat Company Microbeam Technologies, Inc. Sud Chemie, Inc. CEO Praxis Inc. Minnesota Corn Growers Association TXU Power Chippewa Valley Ethanol Producers Minnesota Corn Research Council City of Grand Forks Minot Area Chamber of Commerce Thermo. Chem Recovery International, Inc. Corning Minnesota Power Company CRI-Criterion, Inc. Minnkota Power Cooperative Dakota Gasification Company Montana-Dakota Utilities Dakota Westmoreland Corporation Nextech Materials Diversified Energy North American Coal Corporation Dynetek North Dakota Army National Guard Enersis North Dakota Association of Rural Cooperatives e. Power Synergies, Inc. Fisher Motors General Hydrogen Grand Forks Army National Guard North Dakota Centers of Excellence North Dakota Corn Utilization Council U. S. Air Force U. S. Army Corps of Engineers Construction Engineering Research Laboratory U. S. Department of Agriculture U. S. Department of Defense U. S. Department of Energy United Technologies Research Center Verendrye Electric Cooperative North Dakota Department of Commerce Worldwide Environmental Energy Systems, Inc. North Dakota Industrial Commission Xcel Energy

Hydrogen Program Partners Aboriginal Cogeneration Company Grand Forks Air Force Base Nuvera Fuel Cells Advanced Biomass Gasification Technologies Great River Energy Porvair Filtration Group Agricultural Utilization Research Institute H 2 Gen Innovations Prairie Public Broadcasting, Inc. Air Products and Chemicals, Inc. HT Veramix Pratt & Whitney Rocketdyne, Inc. Appareo Systems Hydrovolt Energy Systems, Inc. Red River Valley Research Corridor Ballard Power Systems Hyster Company Resurfice Corporation BMC Construction Idatech Rio Tinto BNI Coal Company Kraus Global Inc. SGL Carbon Basin Electric Power Cooperative Lorzig Ceramics Siemens Power Generation Bobcat Company Microbeam Technologies, Inc. Sud Chemie, Inc. CEO Praxis Inc. Minnesota Corn Growers Association TXU Power Chippewa Valley Ethanol Producers Minnesota Corn Research Council City of Grand Forks Minot Area Chamber of Commerce Thermo. Chem Recovery International, Inc. Corning Minnesota Power Company CRI-Criterion, Inc. Minnkota Power Cooperative Dakota Gasification Company Montana-Dakota Utilities Dakota Westmoreland Corporation Nextech Materials Diversified Energy North American Coal Corporation Dynetek North Dakota Army National Guard Enersis North Dakota Association of Rural Cooperatives e. Power Synergies, Inc. Fisher Motors General Hydrogen Grand Forks Army National Guard North Dakota Centers of Excellence North Dakota Corn Utilization Council U. S. Air Force U. S. Army Corps of Engineers Construction Engineering Research Laboratory U. S. Department of Agriculture U. S. Department of Defense U. S. Department of Energy United Technologies Research Center Verendrye Electric Cooperative North Dakota Department of Commerce Worldwide Environmental Energy Systems, Inc. North Dakota Industrial Commission Xcel Energy

NCHT-Selected Projects

NCHT-Selected Projects

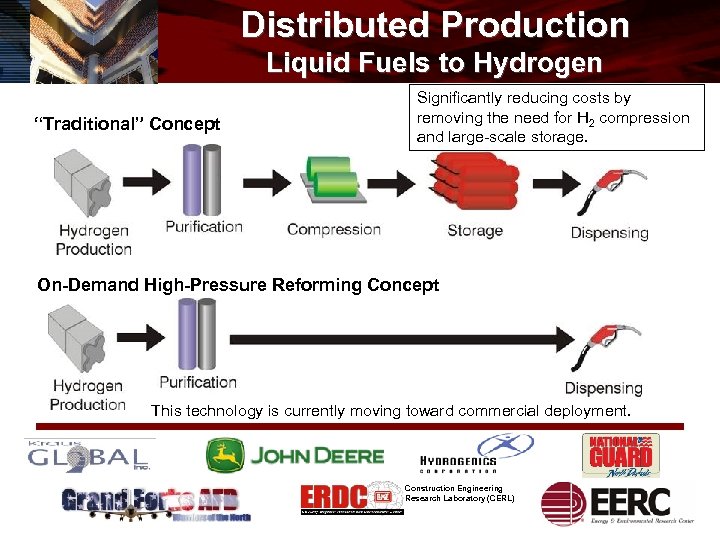

Distributed Production Liquid Fuels to Hydrogen “Traditional” Concept Significantly reducing costs by removing the need for H 2 compression and large-scale storage. On-Demand High-Pressure Reforming Concept This technology is currently moving toward commercial deployment. Construction Engineering Research Laboratory (CERL)

Distributed Production Liquid Fuels to Hydrogen “Traditional” Concept Significantly reducing costs by removing the need for H 2 compression and large-scale storage. On-Demand High-Pressure Reforming Concept This technology is currently moving toward commercial deployment. Construction Engineering Research Laboratory (CERL)

High-Pressure Hydrogen Purification Demonstrating a method for producing a high-purity hydrogen at ESA is very similar to the commercial extremely high pressures to take process known as pressure swing adsorption, except that the composite advantage of high-pressure is regenerated by passing a lowprocesses. voltage current through it. Electrical Swing Adsorption (ESA) • • Low-pressure ESA is being developed at Oak Ridge National Laboratory (ORNL) for purifying hydrogen gas streams. • The EERC is working with ORNL to develop ESA for high-pressure applications using high-density activated carbons.

High-Pressure Hydrogen Purification Demonstrating a method for producing a high-purity hydrogen at ESA is very similar to the commercial extremely high pressures to take process known as pressure swing adsorption, except that the composite advantage of high-pressure is regenerated by passing a lowprocesses. voltage current through it. Electrical Swing Adsorption (ESA) • • Low-pressure ESA is being developed at Oak Ridge National Laboratory (ORNL) for purifying hydrogen gas streams. • The EERC is working with ORNL to develop ESA for high-pressure applications using high-density activated carbons.

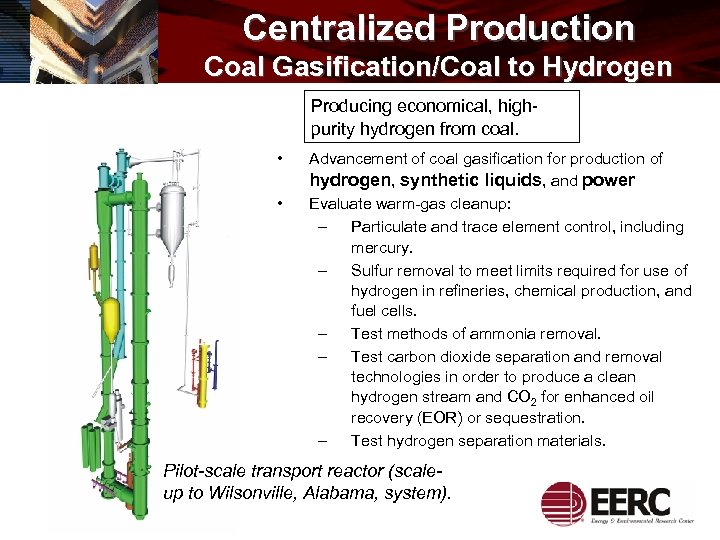

Centralized Production Coal Gasification/Coal to Hydrogen Producing economical, highpurity hydrogen from coal. • • Advancement of coal gasification for production of hydrogen, synthetic liquids, and power Evaluate warm-gas cleanup: – Particulate and trace element control, including mercury. – Sulfur removal to meet limits required for use of hydrogen in refineries, chemical production, and fuel cells. – Test methods of ammonia removal. – Test carbon dioxide separation and removal technologies in order to produce a clean hydrogen stream and CO 2 for enhanced oil recovery (EOR) or sequestration. – Test hydrogen separation materials. Pilot-scale transport reactor (scaleup to Wilsonville, Alabama, system).

Centralized Production Coal Gasification/Coal to Hydrogen Producing economical, highpurity hydrogen from coal. • • Advancement of coal gasification for production of hydrogen, synthetic liquids, and power Evaluate warm-gas cleanup: – Particulate and trace element control, including mercury. – Sulfur removal to meet limits required for use of hydrogen in refineries, chemical production, and fuel cells. – Test methods of ammonia removal. – Test carbon dioxide separation and removal technologies in order to produce a clean hydrogen stream and CO 2 for enhanced oil recovery (EOR) or sequestration. – Test hydrogen separation materials. Pilot-scale transport reactor (scaleup to Wilsonville, Alabama, system).

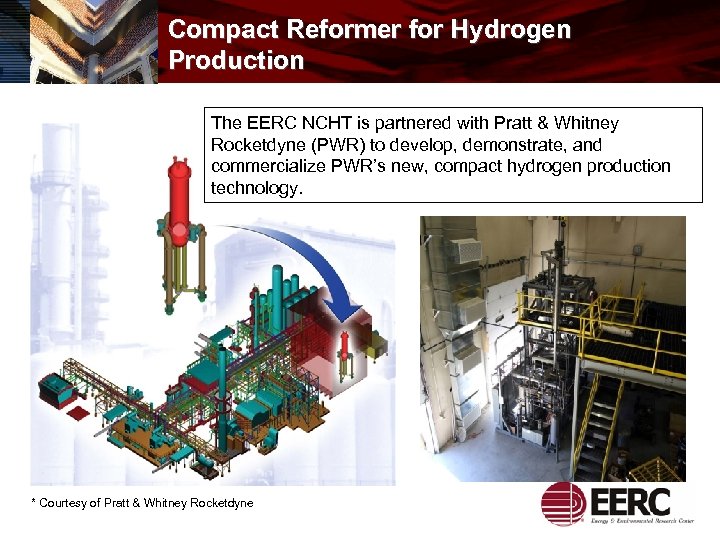

Compact Reformer for Hydrogen Production The EERC NCHT is partnered with Pratt & Whitney Rocketdyne (PWR) to develop, demonstrate, and commercialize PWR’s new, compact hydrogen production technology. * Courtesy of Pratt & Whitney Rocketdyne

Compact Reformer for Hydrogen Production The EERC NCHT is partnered with Pratt & Whitney Rocketdyne (PWR) to develop, demonstrate, and commercialize PWR’s new, compact hydrogen production technology. * Courtesy of Pratt & Whitney Rocketdyne

Wind-to-Hydrogen (W 2 H 2) Project • Wind-to-hydrogen demonstration in Minot, North Dakota • Twin 1. 2 -MW wind turbines • Stuart Energy electrolysis unit and filling station • Three IC hydrogen vehicles Evaluating and demonstrating intermittent hydrogen production from wind and integration with grid.

Wind-to-Hydrogen (W 2 H 2) Project • Wind-to-hydrogen demonstration in Minot, North Dakota • Twin 1. 2 -MW wind turbines • Stuart Energy electrolysis unit and filling station • Three IC hydrogen vehicles Evaluating and demonstrating intermittent hydrogen production from wind and integration with grid.

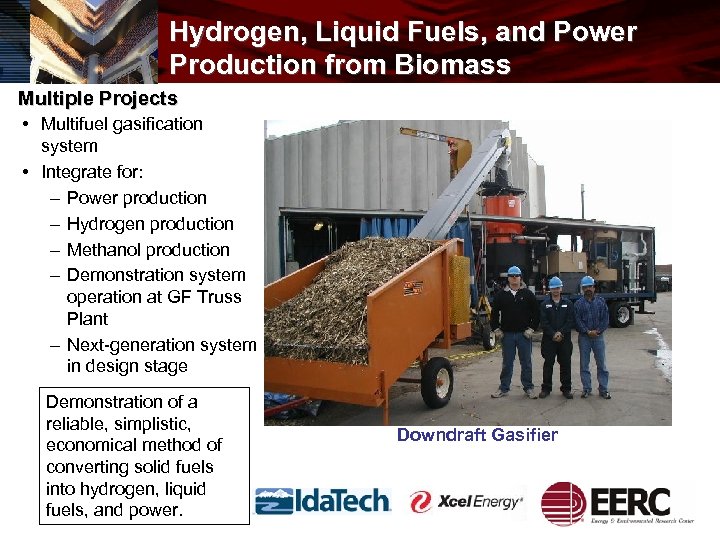

Hydrogen, Liquid Fuels, and Power Production from Biomass Multiple Projects • Multifuel gasification system • Integrate for: – Power production – Hydrogen production – Methanol production – Demonstration system operation at GF Truss Plant – Next-generation system in design stage Demonstration of a reliable, simplistic, economical method of converting solid fuels into hydrogen, liquid fuels, and power. Downdraft Gasifier

Hydrogen, Liquid Fuels, and Power Production from Biomass Multiple Projects • Multifuel gasification system • Integrate for: – Power production – Hydrogen production – Methanol production – Demonstration system operation at GF Truss Plant – Next-generation system in design stage Demonstration of a reliable, simplistic, economical method of converting solid fuels into hydrogen, liquid fuels, and power. Downdraft Gasifier

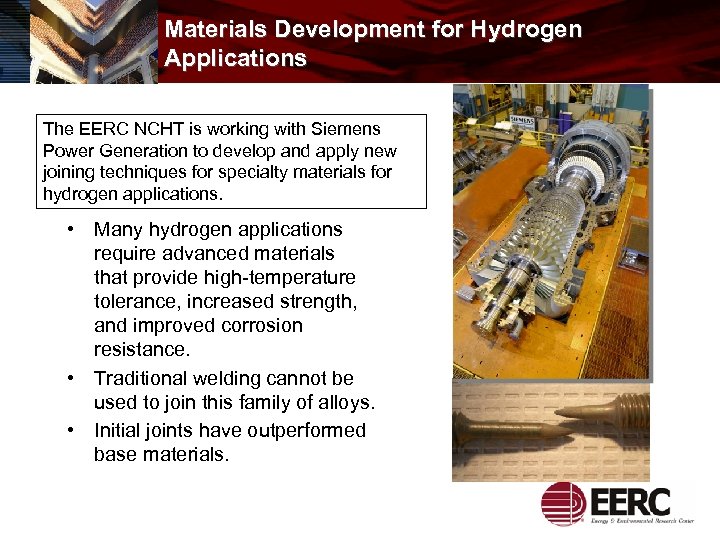

Materials Development for Hydrogen Applications The EERC NCHT is working with Siemens Power Generation to develop and apply new joining techniques for specialty materials for hydrogen applications. • Many hydrogen applications require advanced materials that provide high-temperature tolerance, increased strength, and improved corrosion resistance. • Traditional welding cannot be used to join this family of alloys. • Initial joints have outperformed base materials.

Materials Development for Hydrogen Applications The EERC NCHT is working with Siemens Power Generation to develop and apply new joining techniques for specialty materials for hydrogen applications. • Many hydrogen applications require advanced materials that provide high-temperature tolerance, increased strength, and improved corrosion resistance. • Traditional welding cannot be used to join this family of alloys. • Initial joints have outperformed base materials.

Hydrogen End-Use Demonstrations NCHT – Strategy includes integration of hydrogen end-use technology development and demonstration with hydrogen production and purification.

Hydrogen End-Use Demonstrations NCHT – Strategy includes integration of hydrogen end-use technology development and demonstration with hydrogen production and purification.

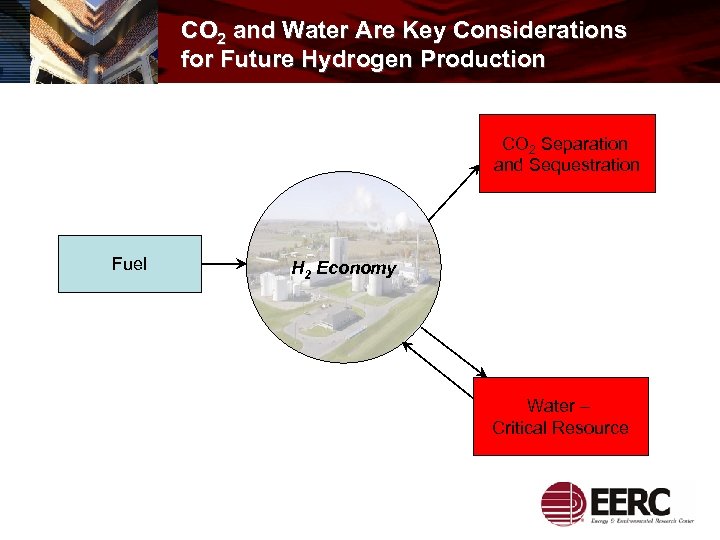

CO 2 and Water Are Key Considerations for Future Hydrogen Production CO 2 Separation and Sequestration Fuel H 2 Economy Water – Critical Resource

CO 2 and Water Are Key Considerations for Future Hydrogen Production CO 2 Separation and Sequestration Fuel H 2 Economy Water – Critical Resource

Carbon management (CO 2) is the gatekeeper for long-term fossil energy use: – Oil – Coal – Natural gas

Carbon management (CO 2) is the gatekeeper for long-term fossil energy use: – Oil – Coal – Natural gas

Major Opportunity • CO 2 is a resource, not a pollutant. • The use of sequestered CO 2 can enhance oil and gas production. • CO 2 is also a versatile solvent for many industrial applications.

Major Opportunity • CO 2 is a resource, not a pollutant. • The use of sequestered CO 2 can enhance oil and gas production. • CO 2 is also a versatile solvent for many industrial applications.

Center for Climate Change and CO 2 Sequestration • The EERC is one of the leading organizations selected by the U. S. Department of Energy (DOE) to determine the best ways to manage our country’s CO 2 emissions. • The EERC’s Plains CO 2 Reduction (PCOR) Partnership is the largest of seven lead organizations around the nation heading up an effort to meet the President’s Global Climate Change Initiative. • The EERC PCOR Partnership was awarded $67 million to advance commercialization of climate change technologies to capture and permanently store greenhouse gases. This award is the EERC’s largest single award to date.

Center for Climate Change and CO 2 Sequestration • The EERC is one of the leading organizations selected by the U. S. Department of Energy (DOE) to determine the best ways to manage our country’s CO 2 emissions. • The EERC’s Plains CO 2 Reduction (PCOR) Partnership is the largest of seven lead organizations around the nation heading up an effort to meet the President’s Global Climate Change Initiative. • The EERC PCOR Partnership was awarded $67 million to advance commercialization of climate change technologies to capture and permanently store greenhouse gases. This award is the EERC’s largest single award to date.

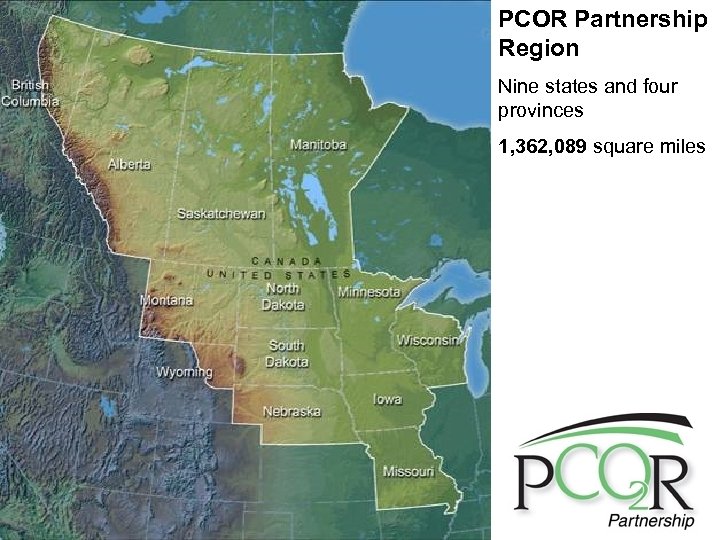

PCOR Partnership Region Nine states and four provinces 1, 362, 089 square miles

PCOR Partnership Region Nine states and four provinces 1, 362, 089 square miles

The PCOR Partnership has brought together the key stakeholders to make geologic CO 2 sequestration a viable option for carbon management in our region.

The PCOR Partnership has brought together the key stakeholders to make geologic CO 2 sequestration a viable option for carbon management in our region.

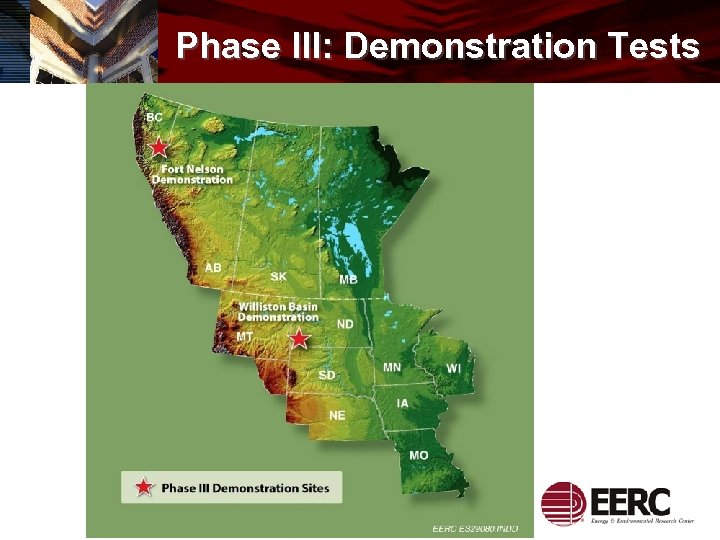

Phase III: Demonstration Tests

Phase III: Demonstration Tests

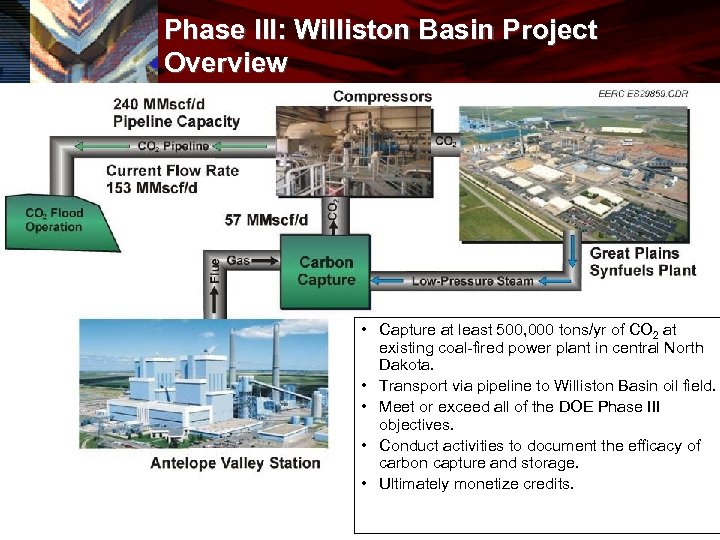

Phase III: Williston Basin Project Overview • Capture at least 500, 000 tons/yr of CO 2 at existing coal-fired power plant in central North Dakota. • Transport via pipeline to Williston Basin oil field. • Meet or exceed all of the DOE Phase III objectives. • Conduct activities to document the efficacy of carbon capture and storage. • Ultimately monetize credits.

Phase III: Williston Basin Project Overview • Capture at least 500, 000 tons/yr of CO 2 at existing coal-fired power plant in central North Dakota. • Transport via pipeline to Williston Basin oil field. • Meet or exceed all of the DOE Phase III objectives. • Conduct activities to document the efficacy of carbon capture and storage. • Ultimately monetize credits.

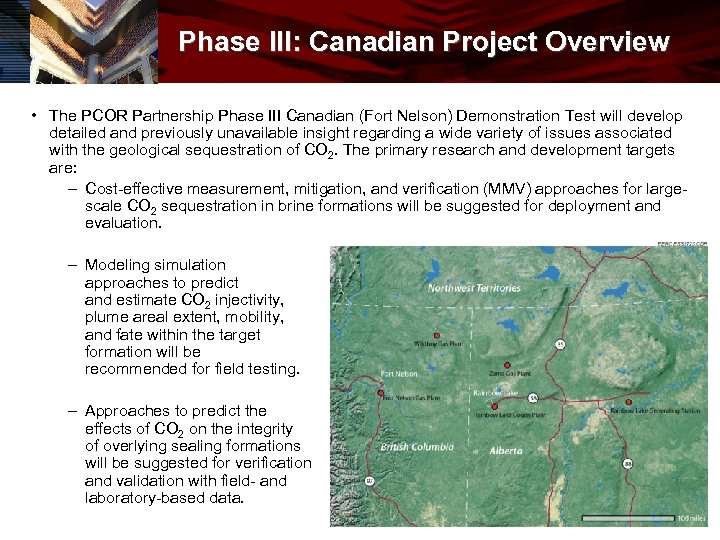

Phase III: Canadian Project Overview • The PCOR Partnership Phase III Canadian (Fort Nelson) Demonstration Test will develop detailed and previously unavailable insight regarding a wide variety of issues associated with the geological sequestration of CO 2. The primary research and development targets are: – Cost-effective measurement, mitigation, and verification (MMV) approaches for largescale CO 2 sequestration in brine formations will be suggested for deployment and evaluation. – Modeling simulation approaches to predict and estimate CO 2 injectivity, plume areal extent, mobility, and fate within the target formation will be recommended for field testing. – Approaches to predict the effects of CO 2 on the integrity of overlying sealing formations will be suggested for verification and validation with field- and laboratory-based data.

Phase III: Canadian Project Overview • The PCOR Partnership Phase III Canadian (Fort Nelson) Demonstration Test will develop detailed and previously unavailable insight regarding a wide variety of issues associated with the geological sequestration of CO 2. The primary research and development targets are: – Cost-effective measurement, mitigation, and verification (MMV) approaches for largescale CO 2 sequestration in brine formations will be suggested for deployment and evaluation. – Modeling simulation approaches to predict and estimate CO 2 injectivity, plume areal extent, mobility, and fate within the target formation will be recommended for field testing. – Approaches to predict the effects of CO 2 on the integrity of overlying sealing formations will be suggested for verification and validation with field- and laboratory-based data.

Water Management Center “Whiskey is for drinking, water is for fighting. ” – Mark Twain

Water Management Center “Whiskey is for drinking, water is for fighting. ” – Mark Twain

Energy and Water • Conventional coal power generation is second only to agriculture as the largest user of water in the United States: – 39% of all freshwater withdrawals in the United States • 131, 900 million gal/day of water is used. • All regions of the United States are vulnerable to water shortages. • Recent technology developments: – Flue gas water extraction – Dry and hybrid cooling systems Continued availability and efficient use of water resources are critical to the future growth of the energy industry.

Energy and Water • Conventional coal power generation is second only to agriculture as the largest user of water in the United States: – 39% of all freshwater withdrawals in the United States • 131, 900 million gal/day of water is used. • All regions of the United States are vulnerable to water shortages. • Recent technology developments: – Flue gas water extraction – Dry and hybrid cooling systems Continued availability and efficient use of water resources are critical to the future growth of the energy industry.

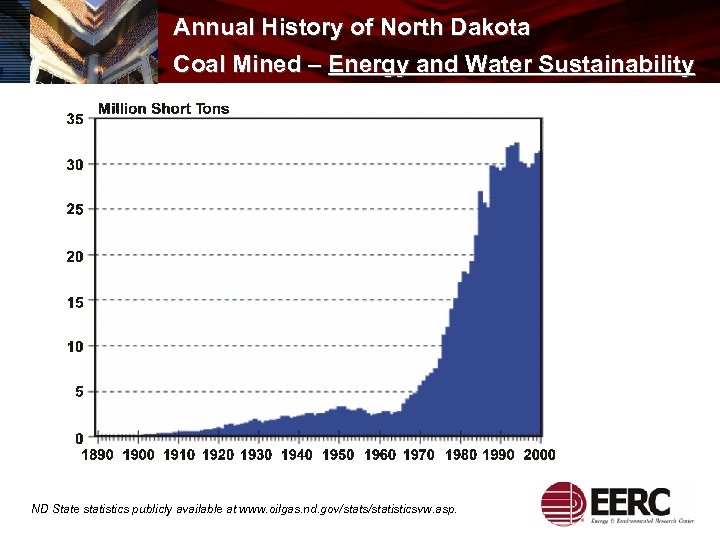

Annual History of North Dakota Coal Mined – Energy and Water Sustainability ND State statistics publicly available at www. oilgas. nd. gov/stats/statisticsvw. asp.

Annual History of North Dakota Coal Mined – Energy and Water Sustainability ND State statistics publicly available at www. oilgas. nd. gov/stats/statisticsvw. asp.

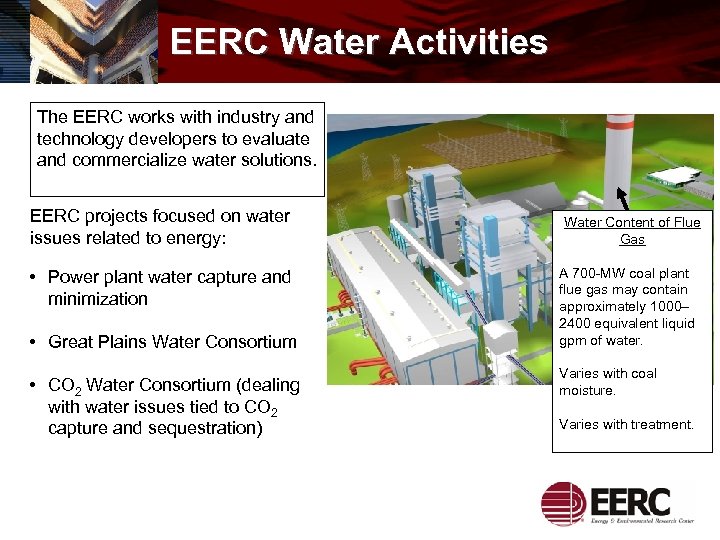

EERC Water Activities The EERC works with industry and technology developers to evaluate and commercialize water solutions. EERC projects focused on water issues related to energy: Water Content of Flue Gas • Great Plains Water Consortium A 700 -MW coal plant flue gas may contain approximately 1000– 2400 equivalent liquid gpm of water. • CO 2 Water Consortium (dealing with water issues tied to CO 2 capture and sequestration) Varies with coal moisture. Varies with treatment. • Power plant water capture and minimization

EERC Water Activities The EERC works with industry and technology developers to evaluate and commercialize water solutions. EERC projects focused on water issues related to energy: Water Content of Flue Gas • Great Plains Water Consortium A 700 -MW coal plant flue gas may contain approximately 1000– 2400 equivalent liquid gpm of water. • CO 2 Water Consortium (dealing with water issues tied to CO 2 capture and sequestration) Varies with coal moisture. Varies with treatment. • Power plant water capture and minimization

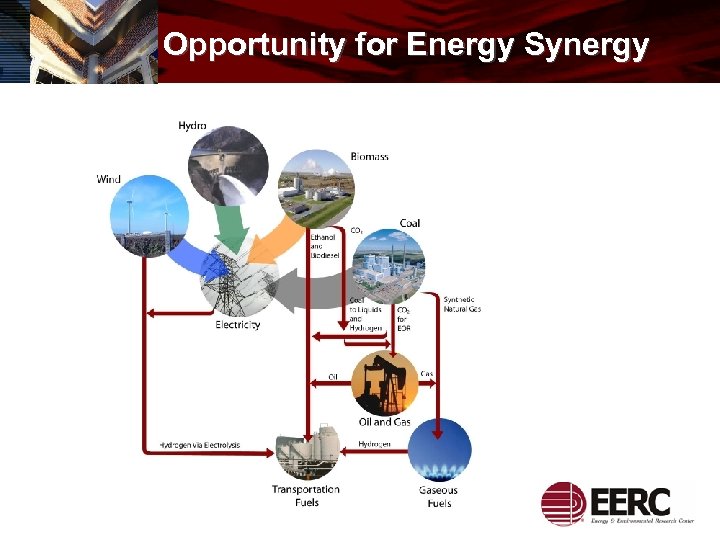

Opportunity for Energy Synergy

Opportunity for Energy Synergy

How Do We Get There (? ) from Here (? ) • • Technology investment Education of society Investment in logistics Infrastructure development • We need a national vision. • We need focused regional assessments and implementation plans for the future. • West and upper Midwest make up an ideal region for a diverse hydrogen supply system, starting with regional assessments and implementation plans.

How Do We Get There (? ) from Here (? ) • • Technology investment Education of society Investment in logistics Infrastructure development • We need a national vision. • We need focused regional assessments and implementation plans for the future. • West and upper Midwest make up an ideal region for a diverse hydrogen supply system, starting with regional assessments and implementation plans.

Critical Need • A dramatically enhanced education (not merely training) system which equips the global population with the knowledge and skills essential to understanding our increasingly technologically complex world. • A trained person is a worker; an educated person is a citizen.

Critical Need • A dramatically enhanced education (not merely training) system which equips the global population with the knowledge and skills essential to understanding our increasingly technologically complex world. • A trained person is a worker; an educated person is a citizen.

The Challenge “Human history more and more becomes a race between education and catastrophe. ” – H. G. Wells

The Challenge “Human history more and more becomes a race between education and catastrophe. ” – H. G. Wells

Contact Information Energy & Environmental Research Center University of North Dakota 15 North 23 rd Street, Stop 9018 Grand Forks, North Dakota 58202 -9018 World Wide Web: www. undeerc. org Telephone No. (701) 777 -5131 Fax No. (701) 777 -5181 Gerald H. Groenewold, Director ghg@undeerc. org

Contact Information Energy & Environmental Research Center University of North Dakota 15 North 23 rd Street, Stop 9018 Grand Forks, North Dakota 58202 -9018 World Wide Web: www. undeerc. org Telephone No. (701) 777 -5131 Fax No. (701) 777 -5181 Gerald H. Groenewold, Director ghg@undeerc. org