f9c7911dc36add0045213e323e2cc235.ppt

- Количество слайдов: 22

Multiport Calibration ATE Architecture, Design and Support

What We Do Solve challenging high-speed and microwave measurement problems, providing customers with accurate, reliable, and repeatable data

Fixturing Calibration & Error Correction Reference Plane Positioning

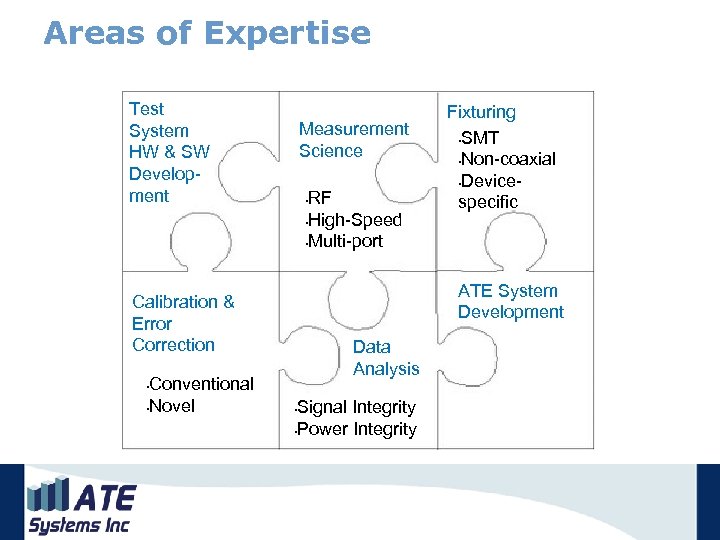

Areas of Expertise Test System HW & SW Development Measurement Science RF • High-Speed • Multi-port • ATE System Development Calibration & Error Correction Conventional • Novel Fixturing • SMT • Non-coaxial • Devicespecific Data Analysis • Signal Integrity • Power Integrity •

Company Philosophy Simultaneously make measurement systems: Accurate Fast Simple

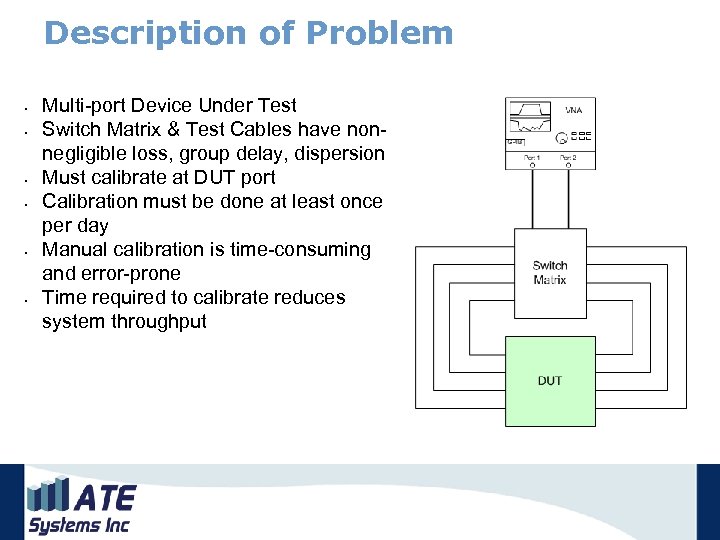

Description of Problem • • • Multi-port Device Under Test Switch Matrix & Test Cables have nonnegligible loss, group delay, dispersion Must calibrate at DUT port Calibration must be done at least once per day Manual calibration is time-consuming and error-prone Time required to calibrate reduces system throughput

Why It Matters • • Poor (or no) calibration results in poor measurement accuracy Poor accuracy causes Bad parts to pass through, or Good parts to be scrapped Both represent real costs through Higher-level system failures & customer relations issues, or Increased material costs due to scrapage Time required for calibration takes away from system throughput and must be minimized to reduce cost per tested part

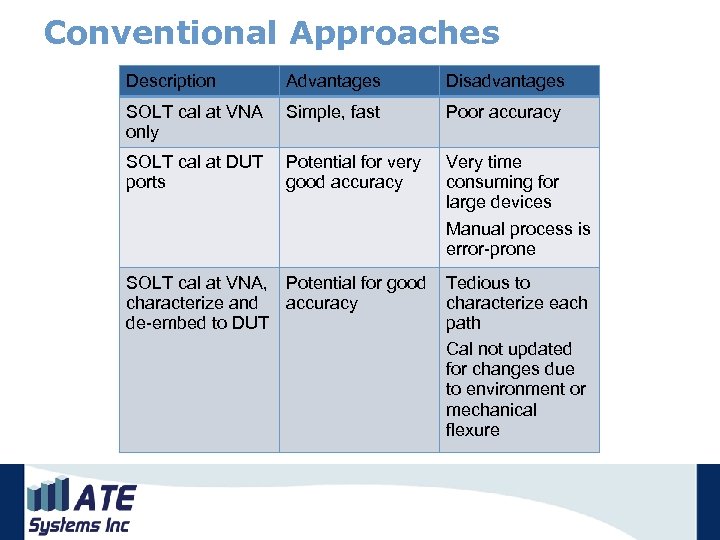

Conventional Approaches Description Advantages Disadvantages SOLT cal at VNA only Simple, fast Poor accuracy SOLT cal at DUT ports Potential for very good accuracy Very time consuming for large devices Manual process is error-prone SOLT cal at VNA, Potential for good characterize and accuracy de-embed to DUT Tedious to characterize each path Cal not updated for changes due to environment or mechanical flexure

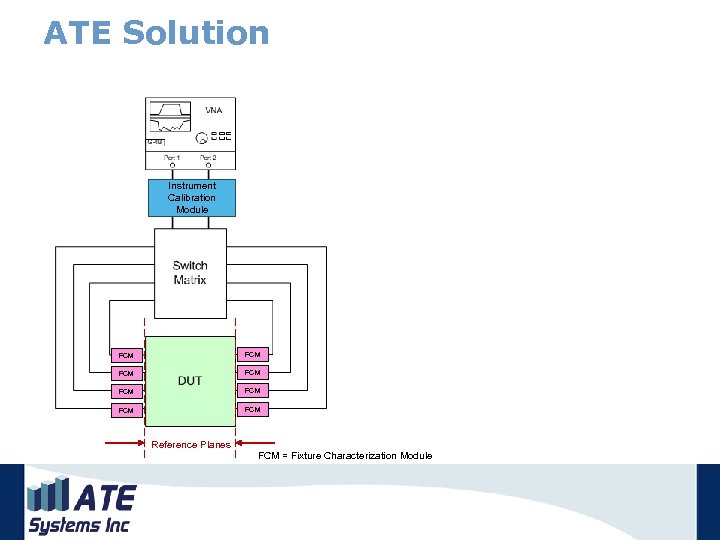

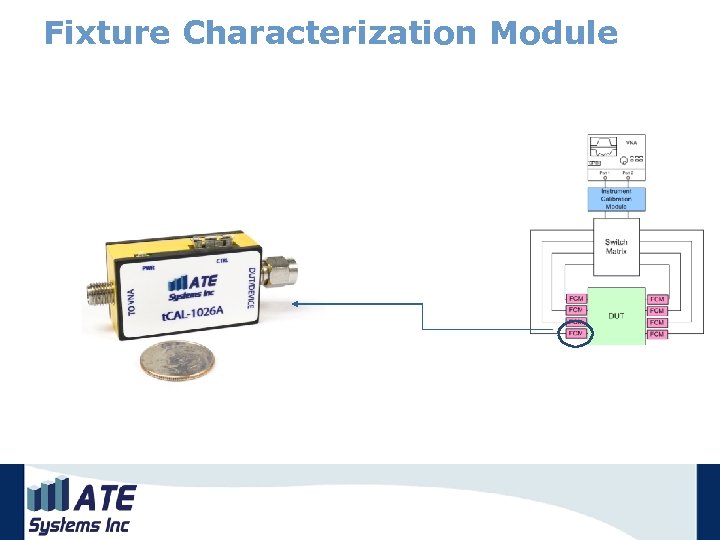

ATE Solution 1 Calibrate at VNA test ports 2 Automatically characterize interconnect path in situ Instrument Calibration Module Calibration can be done with DUT connected 3 Measure DUT Measurement done with cal modules connected FCM FCM Reference Planes 4 Automatically de-embed interconnect and display data at DUT reference plane FCM = Fixture Characterization Module

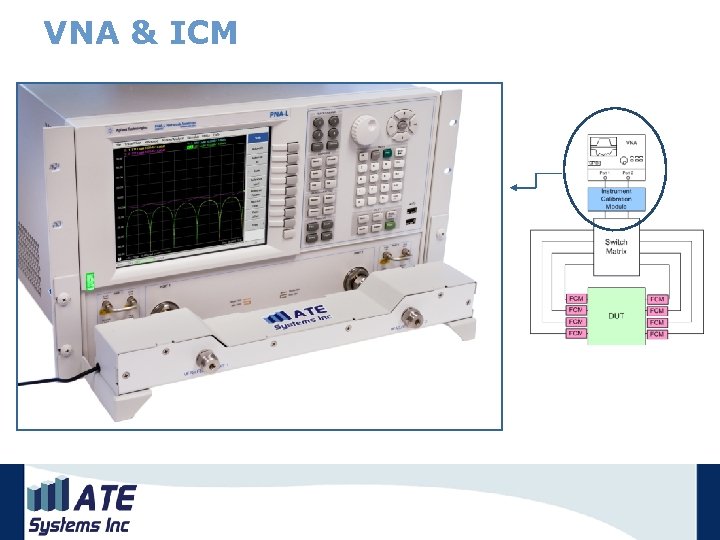

VNA & ICM

Fixture Characterization Module

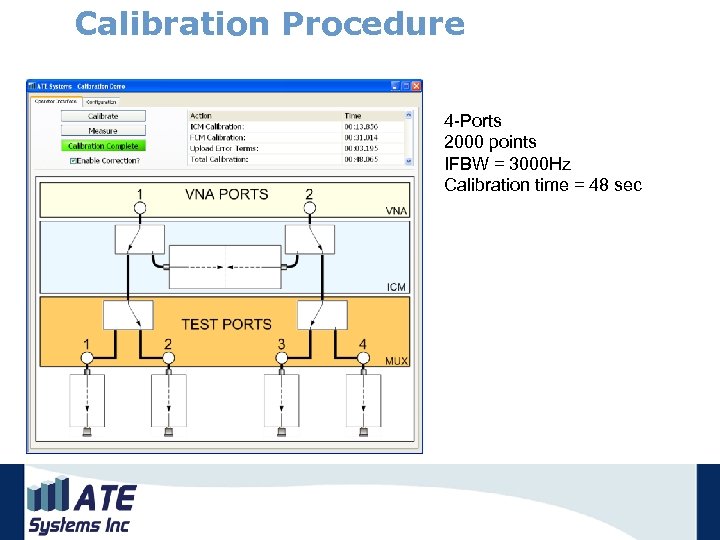

Calibration Procedure 4 -Ports 2000 points IFBW = 3000 Hz Calibration time = 48 sec

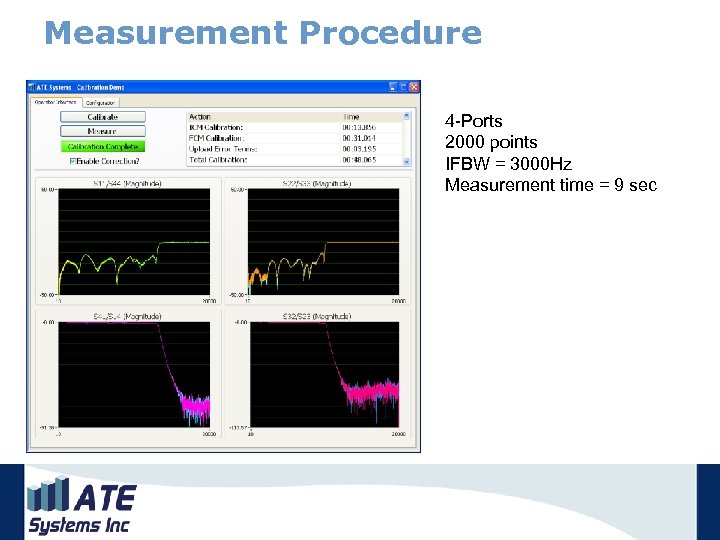

Measurement Procedure 4 -Ports 2000 points IFBW = 3000 Hz Measurement time = 9 sec

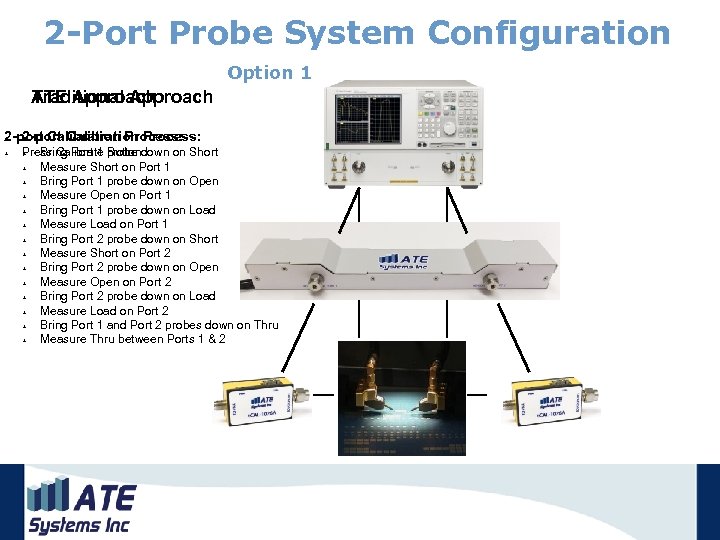

2 -Port Probe System Configuration Option 1 Traditional Approach ATE Approach 2 -port Calibration Process: Press Calibrate probe down on Short Bring Port 1 Button Measure Short on Port 1 Bring Port 1 probe down on Open Measure Open on Port 1 Bring Port 1 probe down on Load Measure Load on Port 1 Bring Port 2 probe down on Short Measure Short on Port 2 Bring Port 2 probe down on Open Measure Open on Port 2 Bring Port 2 probe down on Load Measure Load on Port 2 Bring Port 1 and Port 2 probes down on Thru Measure Thru between Ports 1 & 2

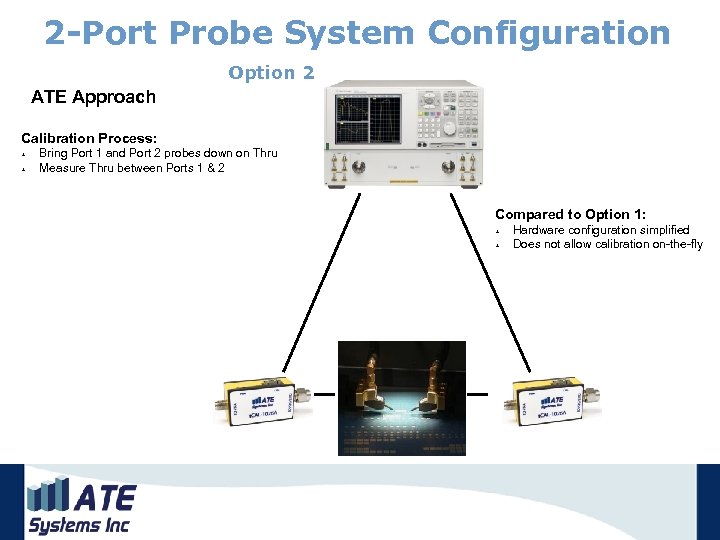

2 -Port Probe System Configuration Option 2 ATE Approach Calibration Process: Bring Port 1 and Port 2 probes down on Thru Measure Thru between Ports 1 & 2 Compared to Option 1: Hardware configuration simplified Does not allow calibration on-the-fly

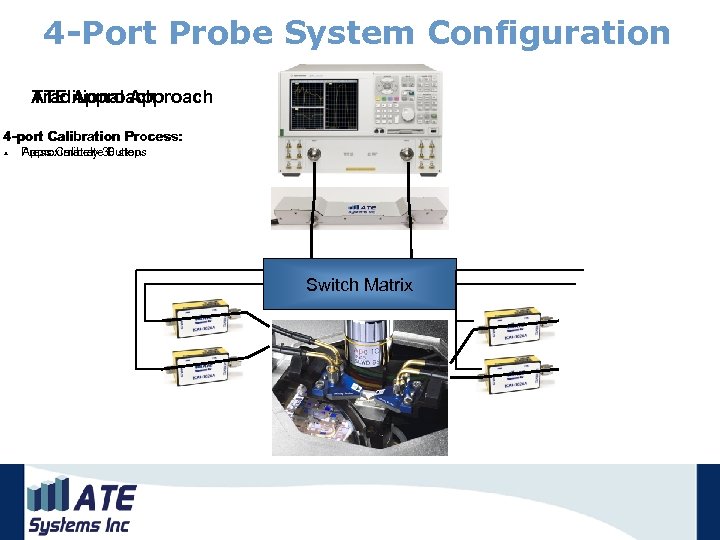

4 -Port Probe System Configuration Traditional Approach ATE Approach 4 -port Calibration Process: Press Calibrate 30 steps Approximately Button Switch Matrix

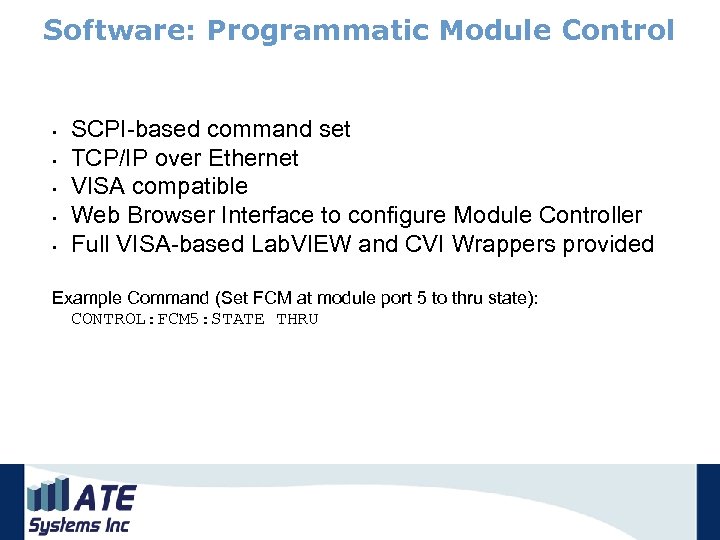

Software: Programmatic Module Control • • • SCPI-based command set TCP/IP over Ethernet VISA compatible Web Browser Interface to configure Module Controller Full VISA-based Lab. VIEW and CVI Wrappers provided Example Command (Set FCM at module port 5 to thru state): CONTROL: FCM 5: STATE THRU

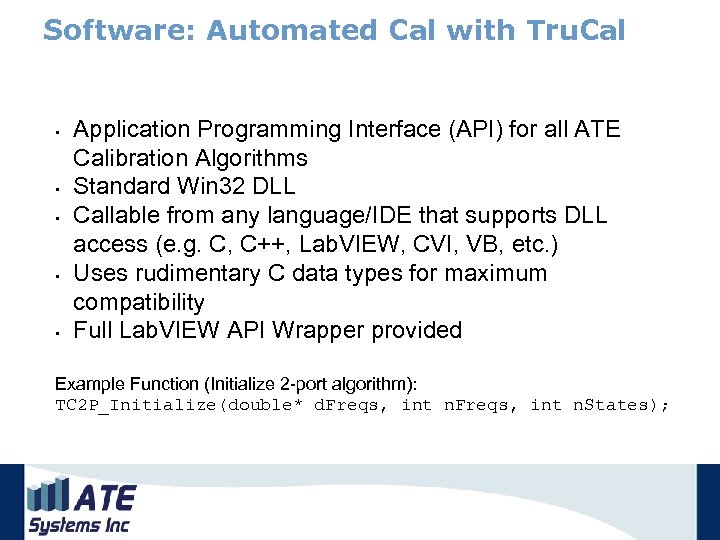

Software: Automated Cal with Tru. Cal • • • Application Programming Interface (API) for all ATE Calibration Algorithms Standard Win 32 DLL Callable from any language/IDE that supports DLL access (e. g. C, C++, Lab. VIEW, CVI, VB, etc. ) Uses rudimentary C data types for maximum compatibility Full Lab. VIEW API Wrapper provided Example Function (Initialize 2 -port algorithm): TC 2 P_Initialize(double* d. Freqs, int n. States);

Characteristics: Automated • • In situ calibration allows system to be calibrated without removing DUT and connecting standards No manual, error-prone operations Fast calibration improves system availability Non-intrusive calibration allows it to be done more frequently

Characteristics: Accurate • • • Calibration transfer standards have TRL-level accuracy In situ calibration removes inaccuracies resulting from test cable performance with flexure of conventional cal methodologies Fast calibration facilitates more frequent calibration as needed

Characteristics: Cost-Effective • • • Improved accuracy avoids costs associated with shipping bad material resulting in high-level system failure and customer dissatisfaction Improved accuracy avoids scrapping good material just when it has the maximum value-added, reducing manufacturing cost Increased system up-time reduces cost per tested part by being able to test more devices in a shift

Contact information For more information please contact us at: ATE Systems, Inc. 85 Rangeway Road North Billerica, MA 01862 Phone: +1 -978 -362 -1850 email: info@atesystems. com http: //www. atesystems. com

f9c7911dc36add0045213e323e2cc235.ppt