cdb0ef11cfba316f5f3104a5b784538a.ppt

- Количество слайдов: 23

Multidisciplinary Engineering Senior Design 06421 Automated Plasma Generator Test System Preliminary Design Review 11/11/05 Project Sponsor: MKS, ENI Incorporated Team Members: John Dullea Christine Kuss Megan Suflita Team Mentor: Dr. Ferat Sahin Acknowledgements: Dr. Paul Steibitz, Advisor Kate Gleason College of Engineering Rochester Institute of Technology

Multidisciplinary Engineering Senior Design 06421 Automated Plasma Generator Test System Preliminary Design Review 11/11/05 Project Sponsor: MKS, ENI Incorporated Team Members: John Dullea Christine Kuss Megan Suflita Team Mentor: Dr. Ferat Sahin Acknowledgements: Dr. Paul Steibitz, Advisor Kate Gleason College of Engineering Rochester Institute of Technology

Project Background n n n Narrow band HF RF amplifier Parallel devices with controller Subcomponents of 3700 Watt amplifier

Project Background n n n Narrow band HF RF amplifier Parallel devices with controller Subcomponents of 3700 Watt amplifier

Current Situation n n Tedious to test Time consuming Resource consuming Interpolation issues Result analysis is time consuming

Current Situation n n Tedious to test Time consuming Resource consuming Interpolation issues Result analysis is time consuming

Software Capabilities n Lab. VIEW code n n n Collect necessary data Perform calculations Generate graphs Fully automated Required tests

Software Capabilities n Lab. VIEW code n n n Collect necessary data Perform calculations Generate graphs Fully automated Required tests

Needs Assessment n Customer’s Needs n n n Automated in Lab. VIEW Graphical User Interface will be provided Ability to vary input parameters Ability to perform safety checks and take measurements Potential for destructive testing Our Needs n n n Access to MKS facility, equipment, and technical support Defined work area at MKS Results of past tests for comparison

Needs Assessment n Customer’s Needs n n n Automated in Lab. VIEW Graphical User Interface will be provided Ability to vary input parameters Ability to perform safety checks and take measurements Potential for destructive testing Our Needs n n n Access to MKS facility, equipment, and technical support Defined work area at MKS Results of past tests for comparison

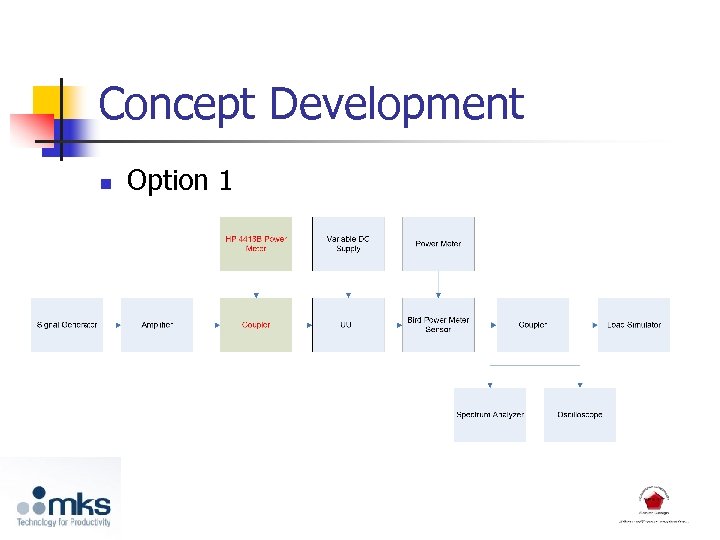

Concept Development n Option 1

Concept Development n Option 1

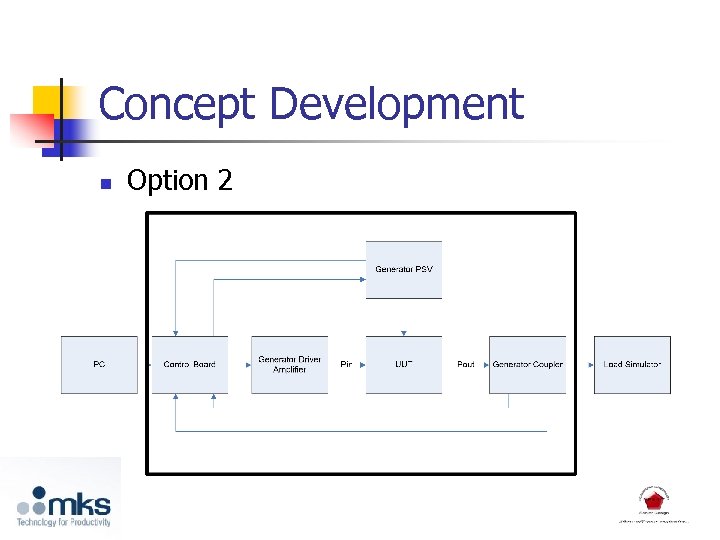

Concept Development n Option 2

Concept Development n Option 2

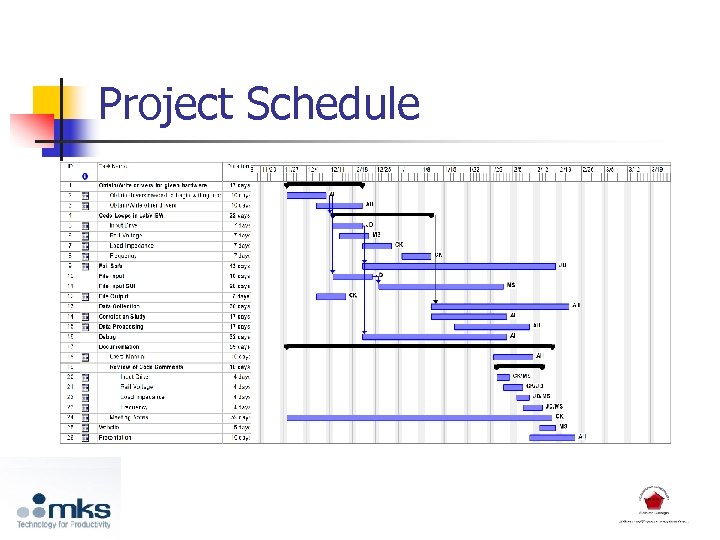

Project Schedule

Project Schedule

Key Requirements & Critical Parameters n n n Repeatable Data Safety Checks Fully Automated

Key Requirements & Critical Parameters n n n Repeatable Data Safety Checks Fully Automated

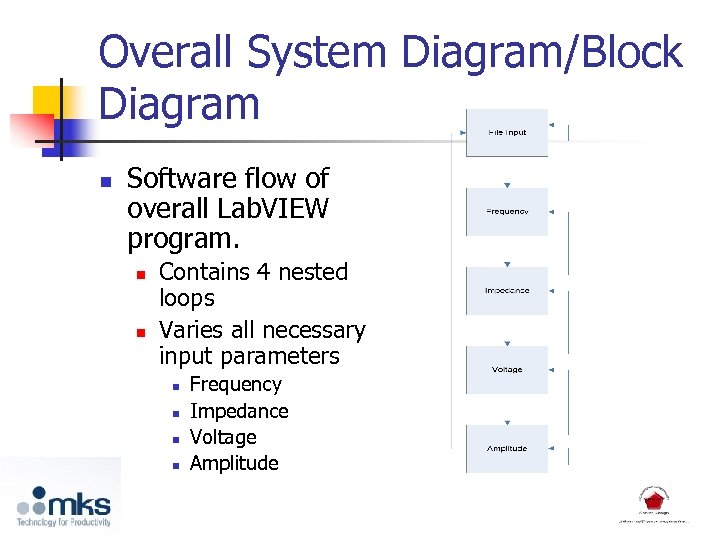

Overall System Diagram/Block Diagram n Software flow of overall Lab. VIEW program. n n Contains 4 nested loops Varies all necessary input parameters n n Frequency Impedance Voltage Amplitude

Overall System Diagram/Block Diagram n Software flow of overall Lab. VIEW program. n n Contains 4 nested loops Varies all necessary input parameters n n Frequency Impedance Voltage Amplitude

Analysis & Synthesis of Design n Project based upon generic platform n n Easily adaptable for future considerations Easily interchangeable with similar units Customer specifications met Integration of existing code

Analysis & Synthesis of Design n Project based upon generic platform n n Easily adaptable for future considerations Easily interchangeable with similar units Customer specifications met Integration of existing code

BOM & Costs n n All equipment provided by MKS Equipment list n n n n Tektronix Digital Scope Bird Power Meter Bird Power Sensor Agilent Power Meter Agilent Power Sensor ENI Load Simulator & RS 232 Cable ENI Matchwork Controller ENI Fiber Optic Converter Agilent Spectrum Analyzer Dell PC Agilent Signal Generator Keithey Scanning Card 4 RF Cables, DC Power Cable, & 6 GPIB Cables Power Supply

BOM & Costs n n All equipment provided by MKS Equipment list n n n n Tektronix Digital Scope Bird Power Meter Bird Power Sensor Agilent Power Meter Agilent Power Sensor ENI Load Simulator & RS 232 Cable ENI Matchwork Controller ENI Fiber Optic Converter Agilent Spectrum Analyzer Dell PC Agilent Signal Generator Keithey Scanning Card 4 RF Cables, DC Power Cable, & 6 GPIB Cables Power Supply

Anticipated Design Challenges/Risk n n n Difficulty integrating software blocks Creating user-friendly interface that is easily interpreted UUT safety and control systems Stability of amplifier signal Debugging of code

Anticipated Design Challenges/Risk n n n Difficulty integrating software blocks Creating user-friendly interface that is easily interpreted UUT safety and control systems Stability of amplifier signal Debugging of code

SD II Project Plan n n Automated Tests Correlation Study Corrective Actions MKS onsite verifications

SD II Project Plan n n Automated Tests Correlation Study Corrective Actions MKS onsite verifications

Deliverables n n n Lab. VIEW code User manual On site training

Deliverables n n n Lab. VIEW code User manual On site training

Questions

Questions

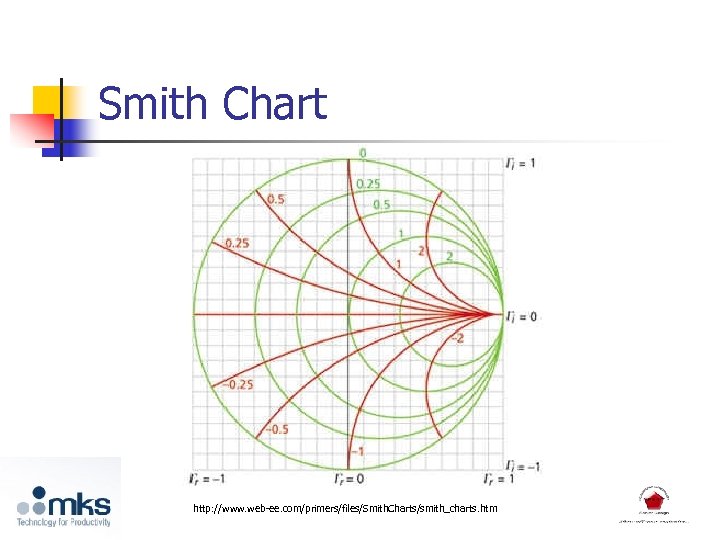

Smith Chart http: //www. web-ee. com/primers/files/Smith. Charts/smith_charts. htm

Smith Chart http: //www. web-ee. com/primers/files/Smith. Charts/smith_charts. htm

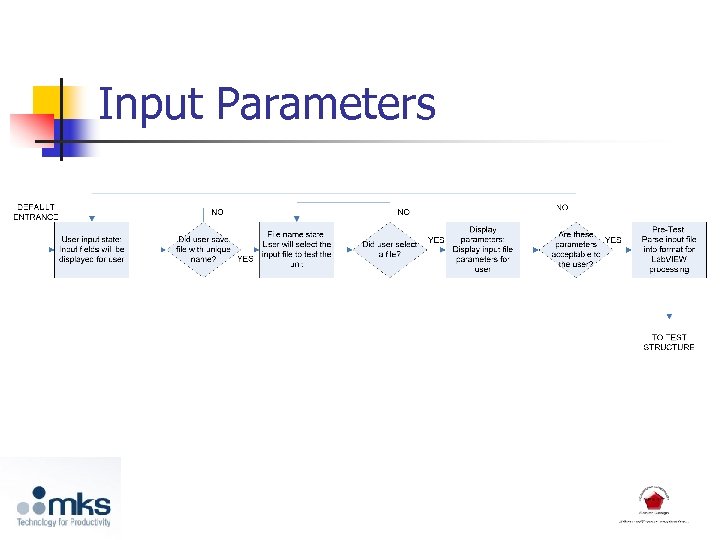

Input Parameters

Input Parameters

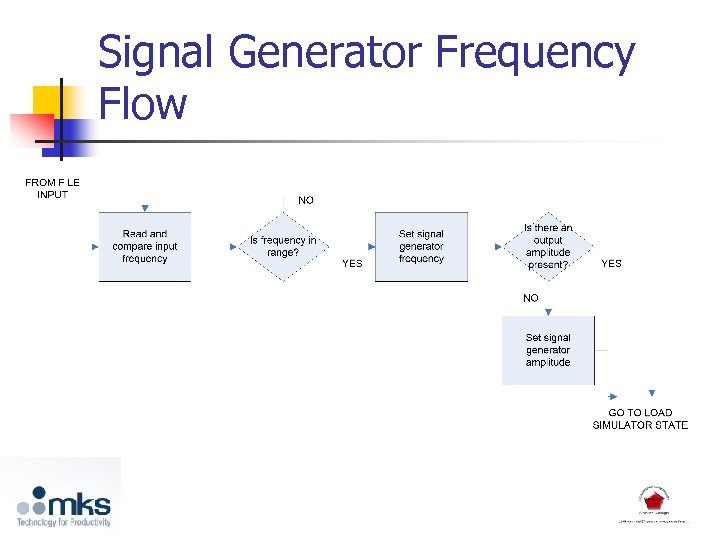

Signal Generator Frequency Flow

Signal Generator Frequency Flow

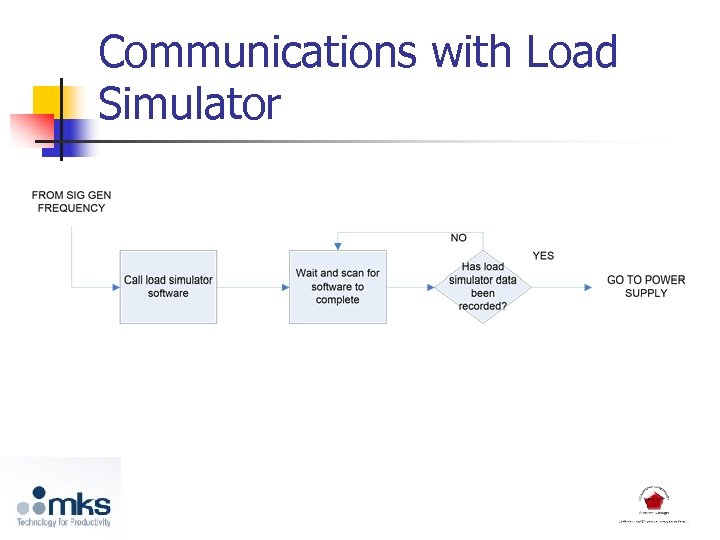

Communications with Load Simulator

Communications with Load Simulator

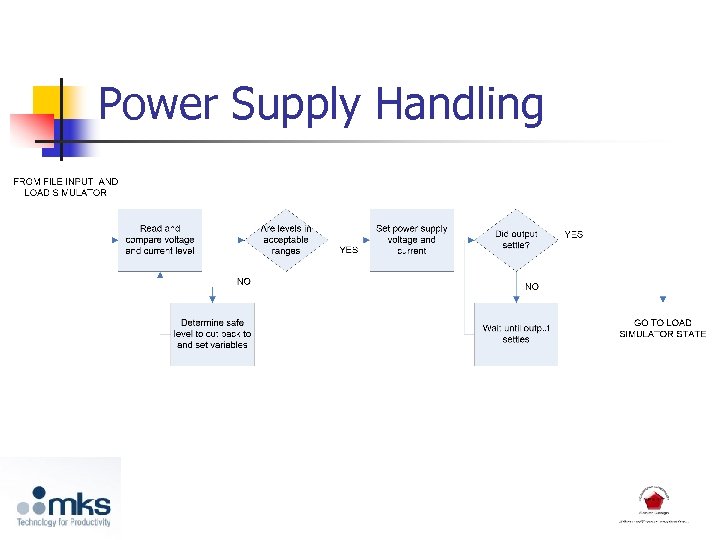

Power Supply Handling

Power Supply Handling

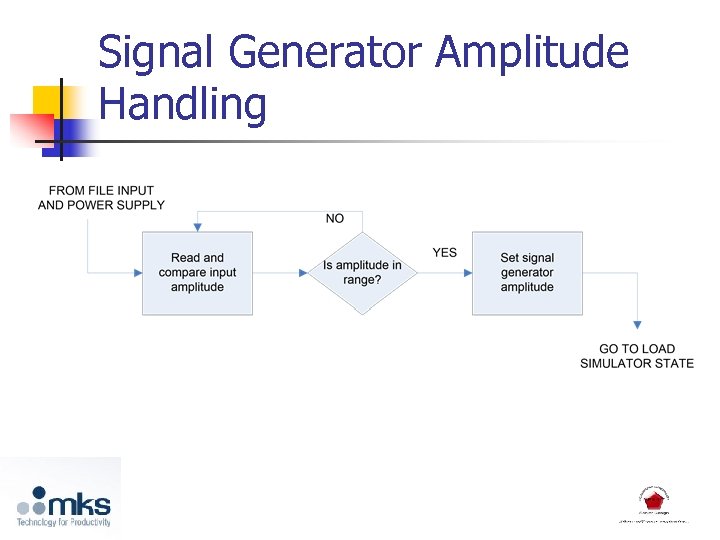

Signal Generator Amplitude Handling

Signal Generator Amplitude Handling

Cost – Benefit Analysis n Assumptions n n n n For manual testing a technician requires 3 days for completion Technician gets paid $15/hour. Automated program can complete task in 24 hours with 1 hour set up. ($15)*(8 hrs/day)*(3 days) = $360 ($15)*(1 hr) = $15 A cost difference of $345 per test 3 tests * $360 = $1080 3 tests can be completed with the automatic test system in the same time that 1 test can be completed manually

Cost – Benefit Analysis n Assumptions n n n n For manual testing a technician requires 3 days for completion Technician gets paid $15/hour. Automated program can complete task in 24 hours with 1 hour set up. ($15)*(8 hrs/day)*(3 days) = $360 ($15)*(1 hr) = $15 A cost difference of $345 per test 3 tests * $360 = $1080 3 tests can be completed with the automatic test system in the same time that 1 test can be completed manually