6a8de09593401cfadd87ee949cd59440.ppt

- Количество слайдов: 39

Multi-layer Protection Strategy for Manufacturing Facilities Vasilis Fthenakis National Photovoltaic EH&S Assistance Center Brookhaven National Laboratory SSA 2001 Annual Symposium New Orleans, LA

Multi-layer Protection Strategy for Manufacturing Facilities Vasilis Fthenakis National Photovoltaic EH&S Assistance Center Brookhaven National Laboratory SSA 2001 Annual Symposium New Orleans, LA

National Photovoltaic EH&S Assistance Center www. pv. bnl. gov ä Preserve safe & environmentally friendly facilities – (S&E audits, SAR, HAZOP, FTA) ä Identify/characterize potential EH&S hazards before full-scale commercialization of new technologies, processes & materials – (Si, x-Si, a-Si, Cd. Te, CIS, CGS, Ga. As, Zn. P) ä ä End-of-Life PV module recycling feasibility (with DOE-SBIR) Pb-free solder technology transfer Toxicology of new materials e. g. , Cd. Te, CIS, CGS, (with NIEHS) Integrated energy-environmental-economic market penetration & CO 2 reduction forecasts (MARKAL model)

National Photovoltaic EH&S Assistance Center www. pv. bnl. gov ä Preserve safe & environmentally friendly facilities – (S&E audits, SAR, HAZOP, FTA) ä Identify/characterize potential EH&S hazards before full-scale commercialization of new technologies, processes & materials – (Si, x-Si, a-Si, Cd. Te, CIS, CGS, Ga. As, Zn. P) ä ä End-of-Life PV module recycling feasibility (with DOE-SBIR) Pb-free solder technology transfer Toxicology of new materials e. g. , Cd. Te, CIS, CGS, (with NIEHS) Integrated energy-environmental-economic market penetration & CO 2 reduction forecasts (MARKAL model)

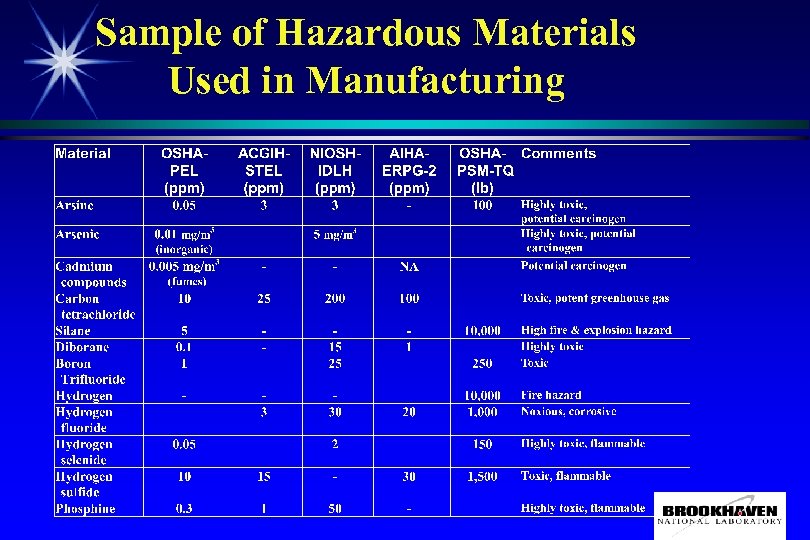

Sample of Hazardous Materials Used in Manufacturing

Sample of Hazardous Materials Used in Manufacturing

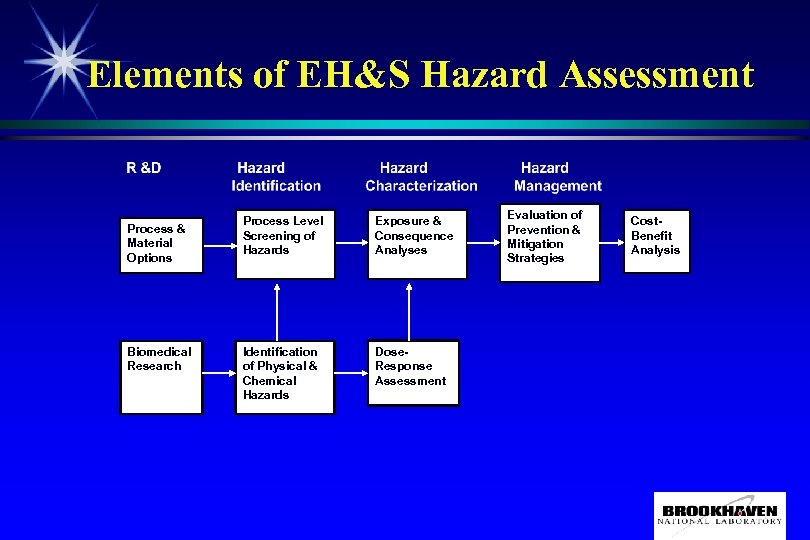

Elements of EH&S Hazard Assessment Process & Material Options Biomedical Research Process Level Screening of Hazards Exposure & Consequence Analyses Identification of Physical & Chemical Hazards Dose. Response Assessment Evaluation of Prevention & Mitigation Strategies Cost. Benefit Analysis

Elements of EH&S Hazard Assessment Process & Material Options Biomedical Research Process Level Screening of Hazards Exposure & Consequence Analyses Identification of Physical & Chemical Hazards Dose. Response Assessment Evaluation of Prevention & Mitigation Strategies Cost. Benefit Analysis

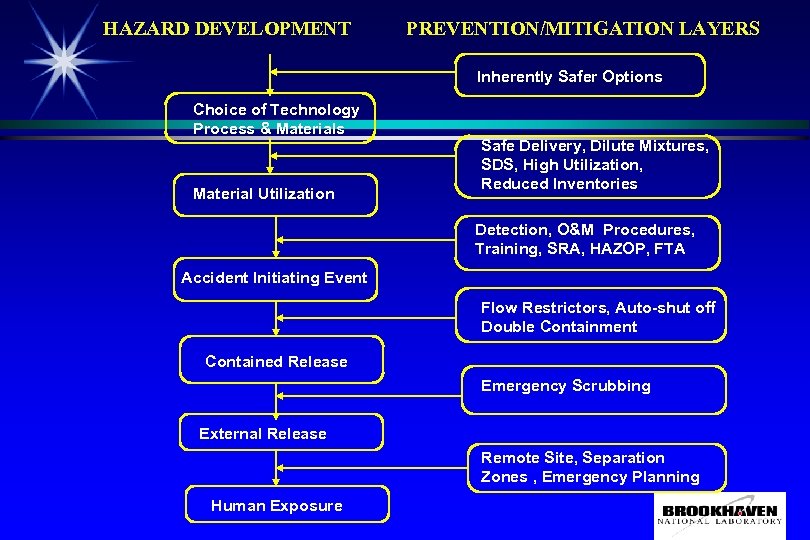

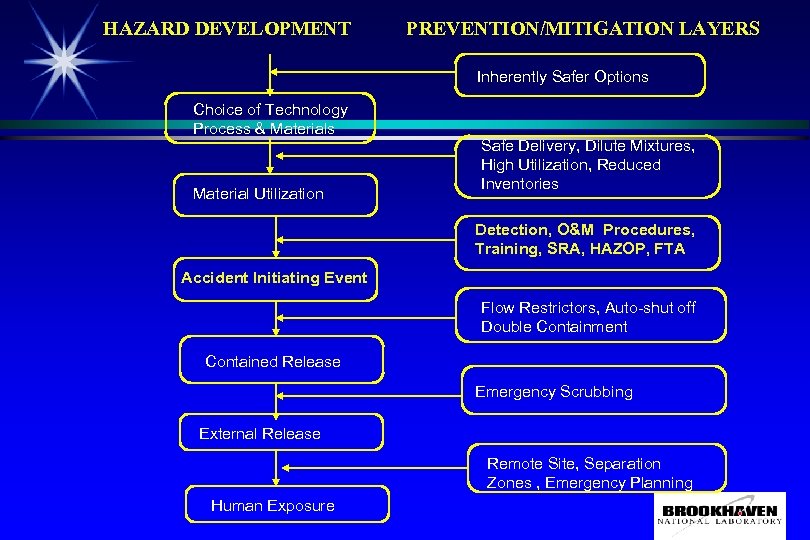

HAZARD DEVELOPMENT PREVENTION/MITIGATION LAYERS Inherently Safer Options Choice of Technology Process & Materials Material Utilization Safe Delivery, Dilute Mixtures, SDS, High Utilization, Reduced Inventories Detection, O&M Procedures, Training, SRA, HAZOP, FTA Accident Initiating Event Flow Restrictors, Auto-shut off Double Containment Contained Release Emergency Scrubbing External Release Remote Site, Separation Zones , Emergency Planning Human Exposure

HAZARD DEVELOPMENT PREVENTION/MITIGATION LAYERS Inherently Safer Options Choice of Technology Process & Materials Material Utilization Safe Delivery, Dilute Mixtures, SDS, High Utilization, Reduced Inventories Detection, O&M Procedures, Training, SRA, HAZOP, FTA Accident Initiating Event Flow Restrictors, Auto-shut off Double Containment Contained Release Emergency Scrubbing External Release Remote Site, Separation Zones , Emergency Planning Human Exposure

Defense in Depth

Defense in Depth

Selection of Technology, Processes and Materials Technologies and processes that do not require the use of large quantities of hazardous materials; especially important for new technologies Consider: • Type & form of material used • Utilization rate • Process emissions • Life-cycle If a hazardous material must be used, then try safer forms and minimum quantities.

Selection of Technology, Processes and Materials Technologies and processes that do not require the use of large quantities of hazardous materials; especially important for new technologies Consider: • Type & form of material used • Utilization rate • Process emissions • Life-cycle If a hazardous material must be used, then try safer forms and minimum quantities.

Safer Material Utilization • Substitution (use safer materials or environmentally more benign ones) • Attenuation (use a safer, less mobile form of a hazardous material) • Intensification (reduce the quantity of a hazardous material in process and storage) • Dilution (reduce its concentration) • Point-of-use generation Alternatives need careful evaluation

Safer Material Utilization • Substitution (use safer materials or environmentally more benign ones) • Attenuation (use a safer, less mobile form of a hazardous material) • Intensification (reduce the quantity of a hazardous material in process and storage) • Dilution (reduce its concentration) • Point-of-use generation Alternatives need careful evaluation

Material Substitution Examples • Wet etching with plasma etching • Wet wafer cleaning with gas-phase cleaning • Silane (in epitaxial Si and Si 3 N 4 deposition) with organosilanes and chlorosilanes • As. H 3 & PH 3, with TBA & TBP • As. H 3, PH 3 & H 2 Se, with solid As, P, & Se compounds

Material Substitution Examples • Wet etching with plasma etching • Wet wafer cleaning with gas-phase cleaning • Silane (in epitaxial Si and Si 3 N 4 deposition) with organosilanes and chlorosilanes • As. H 3 & PH 3, with TBA & TBP • As. H 3, PH 3 & H 2 Se, with solid As, P, & Se compounds

Safer Material Forms • Subatmospheric pressure gas sources (As. H 3, PH 3, BF 3) • VAC -Internally pressure regulated sources (Si. H 4) ‡ Twofold benefit; it reduces the probability for an explosion and the overpressure resulting from one • For hazardous solid materials (e. g. , Cd compounds) using the material in pelleted form instead of a fine (respirable size) powder, reduces the severity of exposure.

Safer Material Forms • Subatmospheric pressure gas sources (As. H 3, PH 3, BF 3) • VAC -Internally pressure regulated sources (Si. H 4) ‡ Twofold benefit; it reduces the probability for an explosion and the overpressure resulting from one • For hazardous solid materials (e. g. , Cd compounds) using the material in pelleted form instead of a fine (respirable size) powder, reduces the severity of exposure.

Dilution • Wafer cleaning processes that do not require concentrated chemical solutions • Diluted inorganic hydrides reduce consequences of leaks. • For toxic gases (e. g. , PH 3, B 2 H 6), is a trade-off between frequency and maximum consequences of an incident. • For explosive gases, the benefit of dilution is twofold; it reduces the probability for an explosion and the overpressure resulting from one. • Productivity issues

Dilution • Wafer cleaning processes that do not require concentrated chemical solutions • Diluted inorganic hydrides reduce consequences of leaks. • For toxic gases (e. g. , PH 3, B 2 H 6), is a trade-off between frequency and maximum consequences of an incident. • For explosive gases, the benefit of dilution is twofold; it reduces the probability for an explosion and the overpressure resulting from one. • Productivity issues

Reduced Quantities on Site • High rate of material use & strict control of inventories. • Deposition processes that use materials more efficiently: (Hot-wire deposition vs. plasma-discharge deposition in a-Si; Electrodeposition vs. spray pyrolysis in Cd. Te and Cd. S deposition). • Higher material utilization rates offers safety advantages and lower costs; processes with low efficiency will have to be improved or unused materials be captured, purified, and reused.

Reduced Quantities on Site • High rate of material use & strict control of inventories. • Deposition processes that use materials more efficiently: (Hot-wire deposition vs. plasma-discharge deposition in a-Si; Electrodeposition vs. spray pyrolysis in Cd. Te and Cd. S deposition). • Higher material utilization rates offers safety advantages and lower costs; processes with low efficiency will have to be improved or unused materials be captured, purified, and reused.

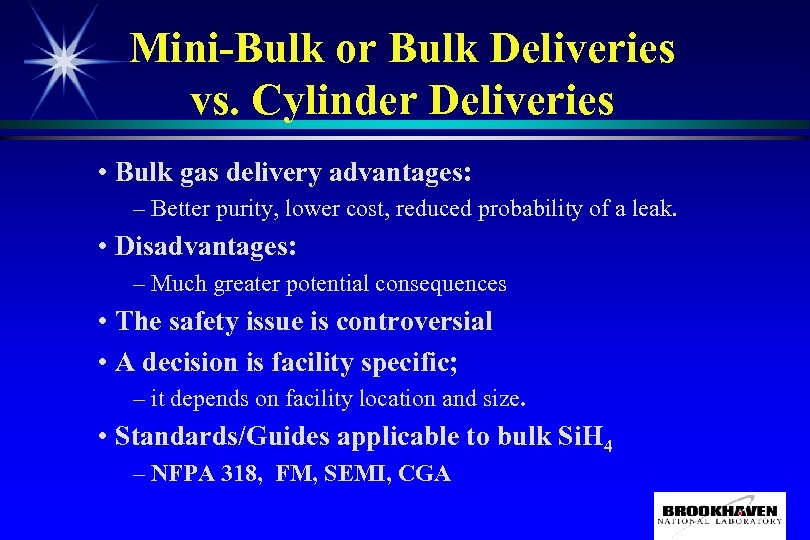

Mini-Bulk or Bulk Deliveries vs. Cylinder Deliveries • Bulk gas delivery advantages: – Better purity, lower cost, reduced probability of a leak. • Disadvantages: – Much greater potential consequences • The safety issue is controversial • A decision is facility specific; – it depends on facility location and size. • Standards/Guides applicable to bulk Si. H 4 – NFPA 318, FM, SEMI, CGA

Mini-Bulk or Bulk Deliveries vs. Cylinder Deliveries • Bulk gas delivery advantages: – Better purity, lower cost, reduced probability of a leak. • Disadvantages: – Much greater potential consequences • The safety issue is controversial • A decision is facility specific; – it depends on facility location and size. • Standards/Guides applicable to bulk Si. H 4 – NFPA 318, FM, SEMI, CGA

HAZARD DEVELOPMENT PREVENTION/MITIGATION LAYERS Inherently Safer Options Choice of Technology Process & Materials Material Utilization Safe Delivery, Dilute Mixtures, High Utilization, Reduced Inventories Detection, O&M Procedures, Training, SRA, HAZOP, FTA Accident Initiating Event Flow Restrictors, Auto-shut off Double Containment Contained Release Emergency Scrubbing External Release Remote Site, Separation Zones , Emergency Planning Human Exposure

HAZARD DEVELOPMENT PREVENTION/MITIGATION LAYERS Inherently Safer Options Choice of Technology Process & Materials Material Utilization Safe Delivery, Dilute Mixtures, High Utilization, Reduced Inventories Detection, O&M Procedures, Training, SRA, HAZOP, FTA Accident Initiating Event Flow Restrictors, Auto-shut off Double Containment Contained Release Emergency Scrubbing External Release Remote Site, Separation Zones , Emergency Planning Human Exposure

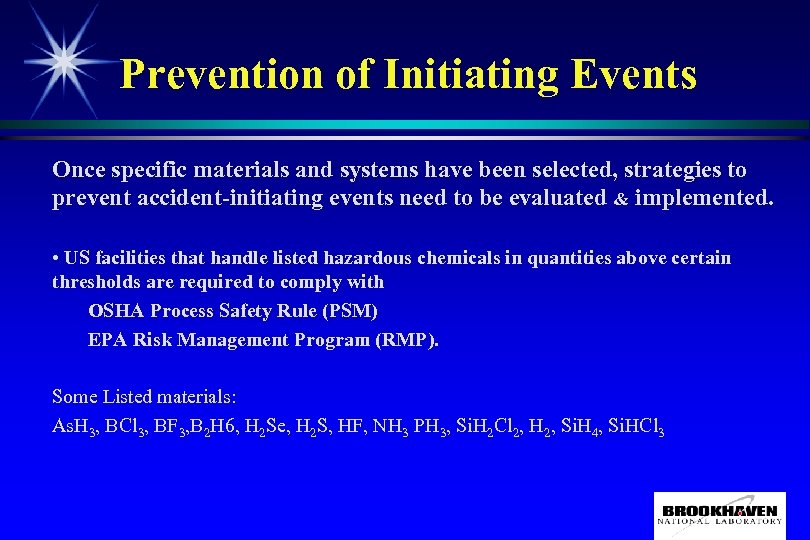

Prevention of Initiating Events Once specific materials and systems have been selected, strategies to prevent accident-initiating events need to be evaluated & implemented. • US facilities that handle listed hazardous chemicals in quantities above certain thresholds are required to comply with OSHA Process Safety Rule (PSM) EPA Risk Management Program (RMP). Some Listed materials: As. H 3, BCl 3, BF 3, B 2 H 6, H 2 Se, H 2 S, HF, NH 3 PH 3, Si. H 2 Cl 2, H 2, Si. H 4, Si. HCl 3

Prevention of Initiating Events Once specific materials and systems have been selected, strategies to prevent accident-initiating events need to be evaluated & implemented. • US facilities that handle listed hazardous chemicals in quantities above certain thresholds are required to comply with OSHA Process Safety Rule (PSM) EPA Risk Management Program (RMP). Some Listed materials: As. H 3, BCl 3, BF 3, B 2 H 6, H 2 Se, H 2 S, HF, NH 3 PH 3, Si. H 2 Cl 2, H 2, Si. H 4, Si. HCl 3

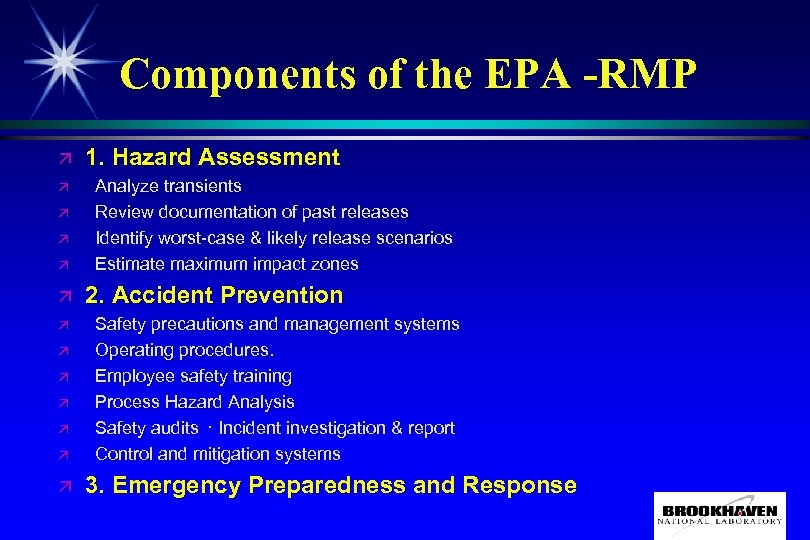

Components of the EPA -RMP ä ä ä ä 1. Hazard Assessment Analyze transients Review documentation of past releases Identify worst-case & likely release scenarios Estimate maximum impact zones 2. Accident Prevention Safety precautions and management systems Operating procedures. Employee safety training Process Hazard Analysis Safety audits · Incident investigation & report Control and mitigation systems 3. Emergency Preparedness and Response

Components of the EPA -RMP ä ä ä ä 1. Hazard Assessment Analyze transients Review documentation of past releases Identify worst-case & likely release scenarios Estimate maximum impact zones 2. Accident Prevention Safety precautions and management systems Operating procedures. Employee safety training Process Hazard Analysis Safety audits · Incident investigation & report Control and mitigation systems 3. Emergency Preparedness and Response

Prevention of Initiating Events ä Be Proactive! ä Conduct Process Hazard Analysis (PHA) even when it is not required. ä PHA must be formal & rigorous. ä PHA focus on equipment, instrumentation, utilities, human action, external factors that may impact a process & cause an accident initiating event. ä Example: SAR conducted proactively as a result of a selfappraisal at NREL

Prevention of Initiating Events ä Be Proactive! ä Conduct Process Hazard Analysis (PHA) even when it is not required. ä PHA must be formal & rigorous. ä PHA focus on equipment, instrumentation, utilities, human action, external factors that may impact a process & cause an accident initiating event. ä Example: SAR conducted proactively as a result of a selfappraisal at NREL

Safety Analysis Review (SAR) –Reviewed operations –Identified 30 potential accident-initiating events –Characterized risks –Implemented administrative and engineering controls to ensure safe operation, e. g. • Control systems to avoid cross-contamination, elimination of single-point failures, safeguards against process deviations and monitoring systems. • Safe operating & maintenance procedures & training.

Safety Analysis Review (SAR) –Reviewed operations –Identified 30 potential accident-initiating events –Characterized risks –Implemented administrative and engineering controls to ensure safe operation, e. g. • Control systems to avoid cross-contamination, elimination of single-point failures, safeguards against process deviations and monitoring systems. • Safe operating & maintenance procedures & training.

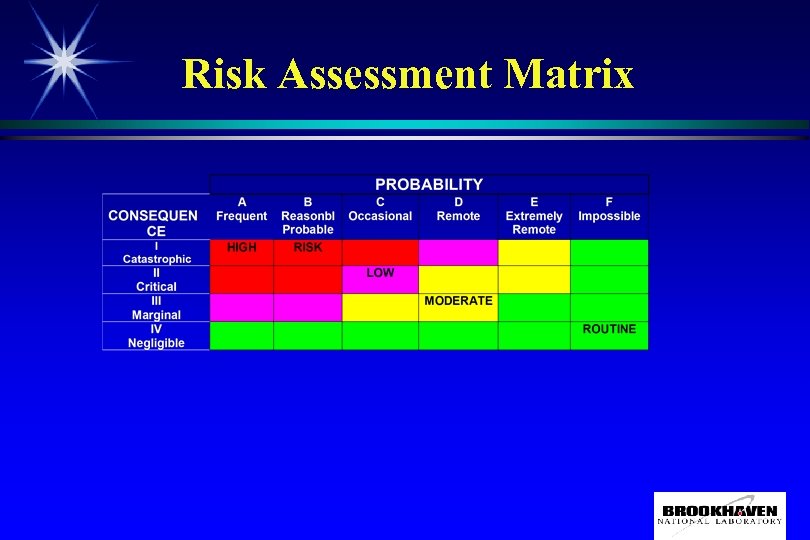

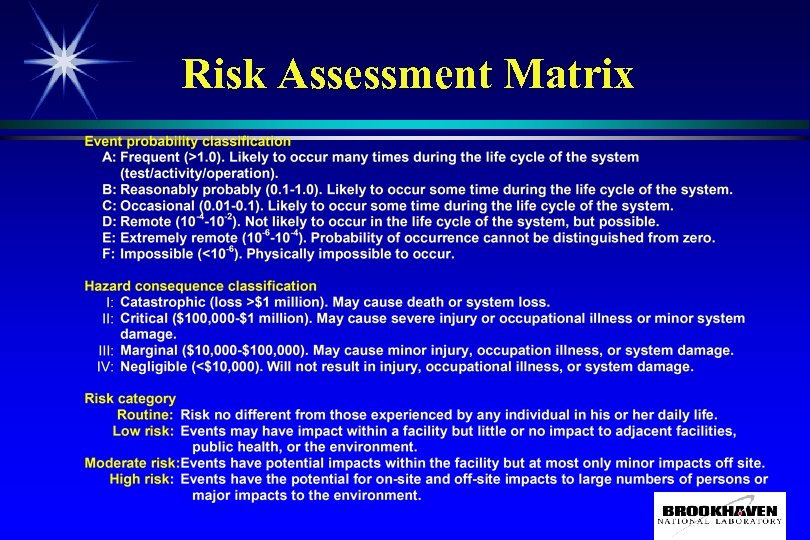

Risk Assessment Matrix

Risk Assessment Matrix

Risk Assessment Matrix

Risk Assessment Matrix

Prevention Layers Failed!

Prevention Layers Failed!

Prevention/Minimization of Releases • Implement safety options to suppress a hazard when an accidentinitiating event occurs • Prevention options to enhance the safety of compressed-gas cylinder systems: a) Continuous monitoring, early detection b) System integrity, fail-proof design c) Outside storage or indoors explosion-proof banker d) Remotely operated cylinder valves e) Automated purging f) Flow restrictors g) Double containment e) Redundancy of critical systems

Prevention/Minimization of Releases • Implement safety options to suppress a hazard when an accidentinitiating event occurs • Prevention options to enhance the safety of compressed-gas cylinder systems: a) Continuous monitoring, early detection b) System integrity, fail-proof design c) Outside storage or indoors explosion-proof banker d) Remotely operated cylinder valves e) Automated purging f) Flow restrictors g) Double containment e) Redundancy of critical systems

System Integrity Operational hazards are greatly reduced by certain features that improve the system's integrity, e. g. , • properly designed, constructed, and vented enclosures, • welded piping joints, • ventilation system back-up, • alarms and interlocks for process chambers.

System Integrity Operational hazards are greatly reduced by certain features that improve the system's integrity, e. g. , • properly designed, constructed, and vented enclosures, • welded piping joints, • ventilation system back-up, • alarms and interlocks for process chambers.

Outside Storage • Outside storage bunkers for toxic and pyrophoric gases reduce occupational risks associated with accidental releases.

Outside Storage • Outside storage bunkers for toxic and pyrophoric gases reduce occupational risks associated with accidental releases.

Indoors Bunkers • Silane cylinders can be kept indoors in explosionproof bunkers (with relief through the ceiling); however, this is an expensive option.

Indoors Bunkers • Silane cylinders can be kept indoors in explosionproof bunkers (with relief through the ceiling); however, this is an expensive option.

Remote Operation • Remotely operated cylinder valves enhance safety by separating workers from hazards and allowing for remote shutdown in an emergency.

Remote Operation • Remotely operated cylinder valves enhance safety by separating workers from hazards and allowing for remote shutdown in an emergency.

Automated Purging • Manual purging is demanding on the operator. • Automated purge systems reduce actions needed to complete a purge procedure, and reduce potential for human errors.

Automated Purging • Manual purging is demanding on the operator. • Automated purge systems reduce actions needed to complete a purge procedure, and reduce potential for human errors.

Continuous Toxic Gas Monitoring Systems • Integrate toxic-gas detection into gas-handling systems and process tools for early warning and source & process shut down • Set audible and visible alarms at 1/2 TLV

Continuous Toxic Gas Monitoring Systems • Integrate toxic-gas detection into gas-handling systems and process tools for early warning and source & process shut down • Set audible and visible alarms at 1/2 TLV

Flow Restrictors • Flow-restricting orifices (RFO) in cylinder valves for highly toxic and pyrophoric gases (e. g. , As. H 3, PH 3, Si. H 4). • RFO can reduce the flow out of an open cylindervalve up to 100 times; they provide superb passive flow-reduction.

Flow Restrictors • Flow-restricting orifices (RFO) in cylinder valves for highly toxic and pyrophoric gases (e. g. , As. H 3, PH 3, Si. H 4). • RFO can reduce the flow out of an open cylindervalve up to 100 times; they provide superb passive flow-reduction.

Double Containment • Double co-axial distribution lines and raceways. • Double-wall storage. • Secondary enclosures to contain toxic emissions and divert to pollution-control equipment.

Double Containment • Double co-axial distribution lines and raceways. • Double-wall storage. • Secondary enclosures to contain toxic emissions and divert to pollution-control equipment.

Redundancy in Critical Systems

Redundancy in Critical Systems

Redundancy in Critical Systems • If a hazard analysis identifies accidents that can be caused by the failure of a single component, redundant components should be installed • Examples of critical components: Flow-regulators, valves, exhaust fans, pumps, compressors. • Redundant systems must be completely independent • Examine conditions which may adversely affect a given layer of defense at the same time that they produce a safety challenge to that layer (Such conditions in complex systems can be studied with Fault Tree Analysis)

Redundancy in Critical Systems • If a hazard analysis identifies accidents that can be caused by the failure of a single component, redundant components should be installed • Examples of critical components: Flow-regulators, valves, exhaust fans, pumps, compressors. • Redundant systems must be completely independent • Examine conditions which may adversely affect a given layer of defense at the same time that they produce a safety challenge to that layer (Such conditions in complex systems can be studied with Fault Tree Analysis)

Control and Minimization of Releases to the Environment • SCBA, spill control, safety equipment for quick response in all areas where there is potential for an accidental release. • Accidental release containment and control equipment (e. g. , wet or dry scrubbers)

Control and Minimization of Releases to the Environment • SCBA, spill control, safety equipment for quick response in all areas where there is potential for an accidental release. • Accidental release containment and control equipment (e. g. , wet or dry scrubbers)

Prevention and Minimization of Human Exposures • Remote location, exclusion zones • Early warning systems • Emergency preparedness and response programs • Medical preparedness

Prevention and Minimization of Human Exposures • Remote location, exclusion zones • Early warning systems • Emergency preparedness and response programs • Medical preparedness

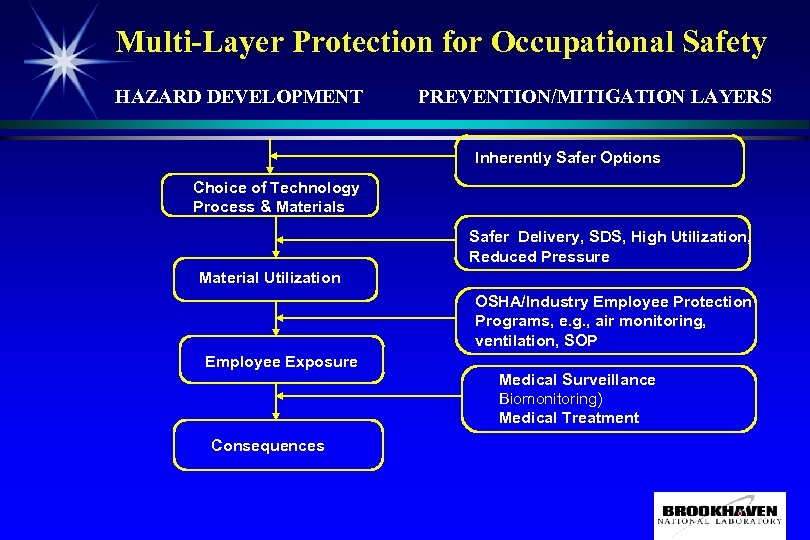

Multi-Layer Protection for Occupational Safety HAZARD DEVELOPMENT PREVENTION/MITIGATION LAYERS Inherently Safer Options Choice of Technology Process & Materials Safer Delivery, SDS, High Utilization, Reduced Pressure Material Utilization OSHA/Industry Employee Protection Programs, e. g. , air monitoring, ventilation, SOP Employee Exposure Medical Surveillance Biomonitoring) Medical Treatment Consequences

Multi-Layer Protection for Occupational Safety HAZARD DEVELOPMENT PREVENTION/MITIGATION LAYERS Inherently Safer Options Choice of Technology Process & Materials Safer Delivery, SDS, High Utilization, Reduced Pressure Material Utilization OSHA/Industry Employee Protection Programs, e. g. , air monitoring, ventilation, SOP Employee Exposure Medical Surveillance Biomonitoring) Medical Treatment Consequences

CONCLUSION • Accidental releases of hazardous gases and vapors can cause occupational hazards. • Prevent and minimize accidental releases of hazardous gases by choosing safer technologies, processes, and materials, using materials more efficiently and in safer forms. • Use safety systems and procedures to reduce risks that could not be avoided with process and material selections. • A systematic approach assists management to minimize EH&S risks

CONCLUSION • Accidental releases of hazardous gases and vapors can cause occupational hazards. • Prevent and minimize accidental releases of hazardous gases by choosing safer technologies, processes, and materials, using materials more efficiently and in safer forms. • Use safety systems and procedures to reduce risks that could not be avoided with process and material selections. • A systematic approach assists management to minimize EH&S risks

We are all partners in EH&S ! Working together means winning together www. pv. bnl. gov

We are all partners in EH&S ! Working together means winning together www. pv. bnl. gov

Point-of-use Generation ä Point-of-use generation of hazardous materials reduces the hazards of both transportation and storage on-site. ä e. g. , Bell Labs on-demand arsine generators give better purity than compressed-gas cylinders

Point-of-use Generation ä Point-of-use generation of hazardous materials reduces the hazards of both transportation and storage on-site. ä e. g. , Bell Labs on-demand arsine generators give better purity than compressed-gas cylinders

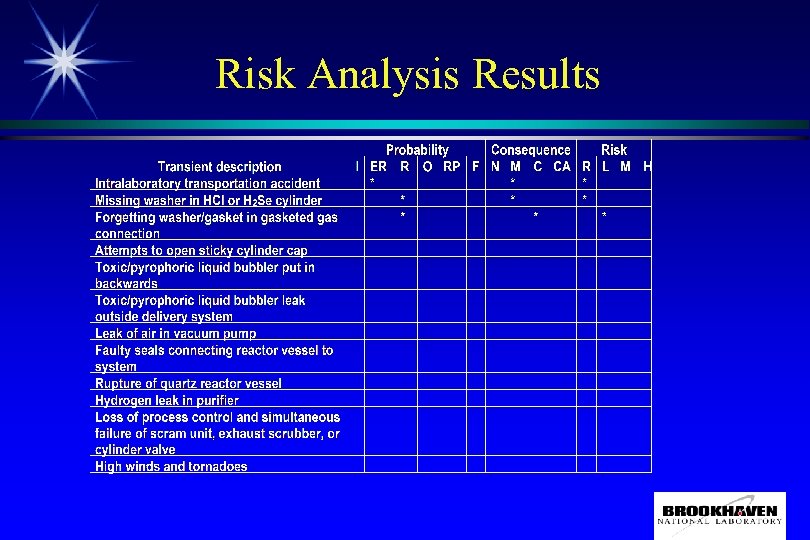

Risk Analysis Results

Risk Analysis Results