173efe2b5103e12050e1fc629cd515b8.ppt

- Количество слайдов: 46

MUDLOGGING UNCONVENTIONAL GAS RESERVOIRS Bill Donovan, PE Donovan Brothers Incorporated Automated Mudlogging Systems Our Corporate Motto “WE DON’T PASS GAS” 1

Mudlogging Unconventional Gas Reservoirs OVERVIEW • • • Field study results Definitions and theory Resource comparison Mudlogging gas content Factors influencing mudlogging Calibrating the system 16/April/2007 © Donovan Brothers Inc. Automated Mudlogging Systems SM 2

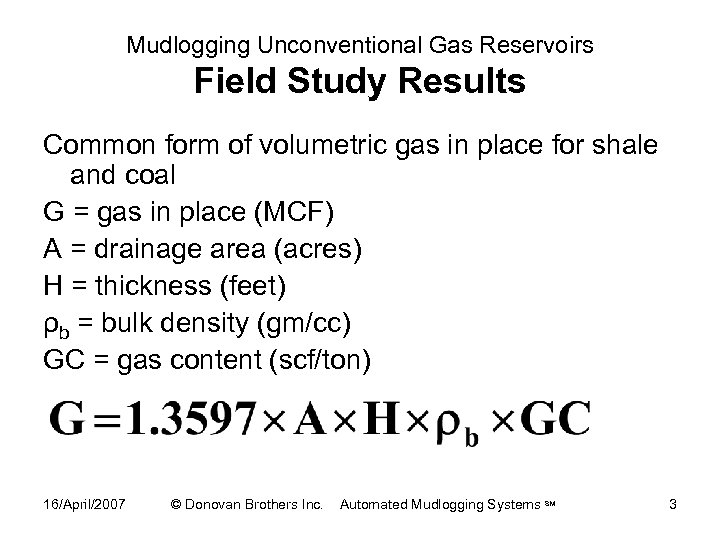

Mudlogging Unconventional Gas Reservoirs Field Study Results Common form of volumetric gas in place for shale and coal G = gas in place (MCF) A = drainage area (acres) H = thickness (feet) ρb = bulk density (gm/cc) GC = gas content (scf/ton) 16/April/2007 © Donovan Brothers Inc. Automated Mudlogging Systems SM 3

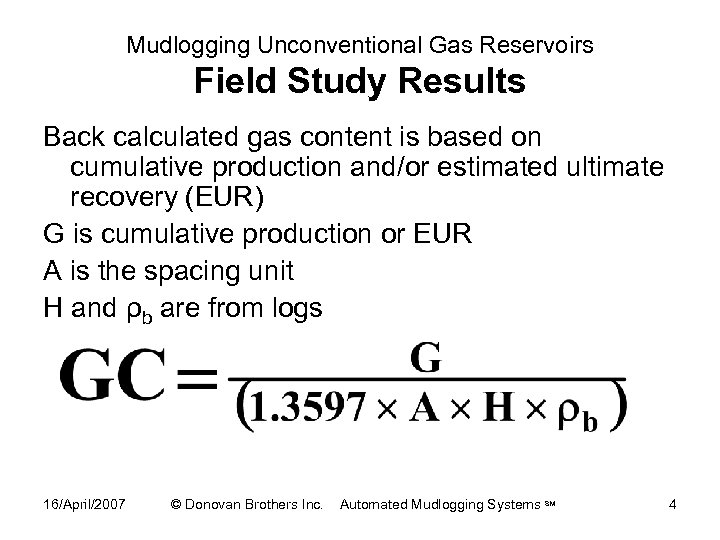

Mudlogging Unconventional Gas Reservoirs Field Study Results Back calculated gas content is based on cumulative production and/or estimated ultimate recovery (EUR) G is cumulative production or EUR A is the spacing unit H and ρb are from logs 16/April/2007 © Donovan Brothers Inc. Automated Mudlogging Systems SM 4

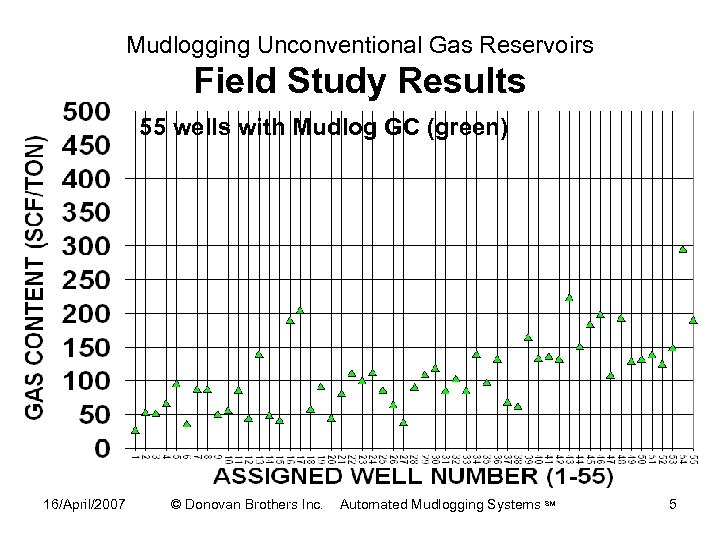

Mudlogging Unconventional Gas Reservoirs Field Study Results 55 wells with Mudlog GC (green) 16/April/2007 © Donovan Brothers Inc. Automated Mudlogging Systems SM 5

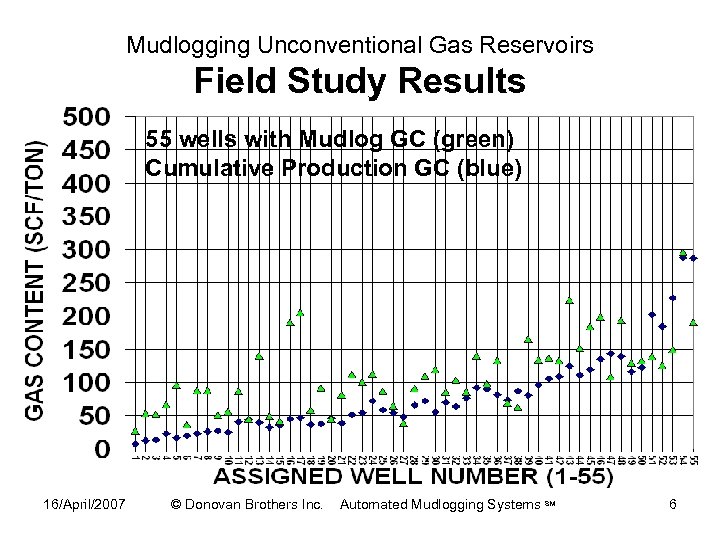

Mudlogging Unconventional Gas Reservoirs Field Study Results 55 wells with Mudlog GC (green) Cumulative Production GC (blue) 16/April/2007 © Donovan Brothers Inc. Automated Mudlogging Systems SM 6

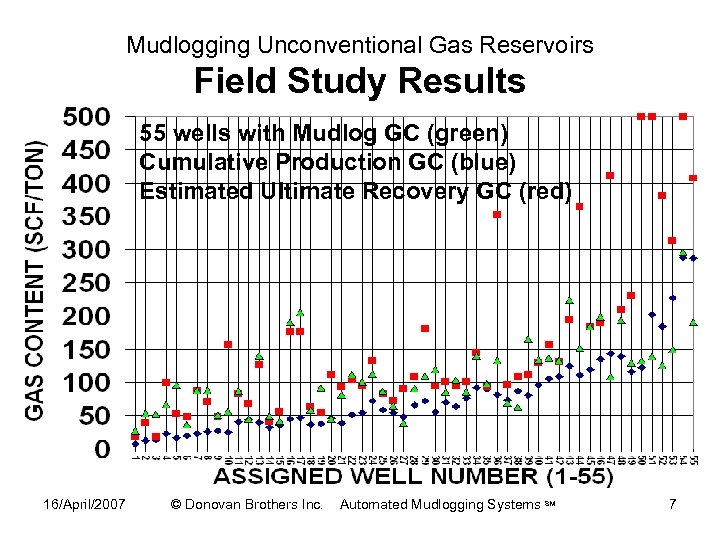

Mudlogging Unconventional Gas Reservoirs Field Study Results 55 wells with Mudlog GC (green) Cumulative Production GC (blue) Estimated Ultimate Recovery GC (red) 16/April/2007 © Donovan Brothers Inc. Automated Mudlogging Systems SM 7

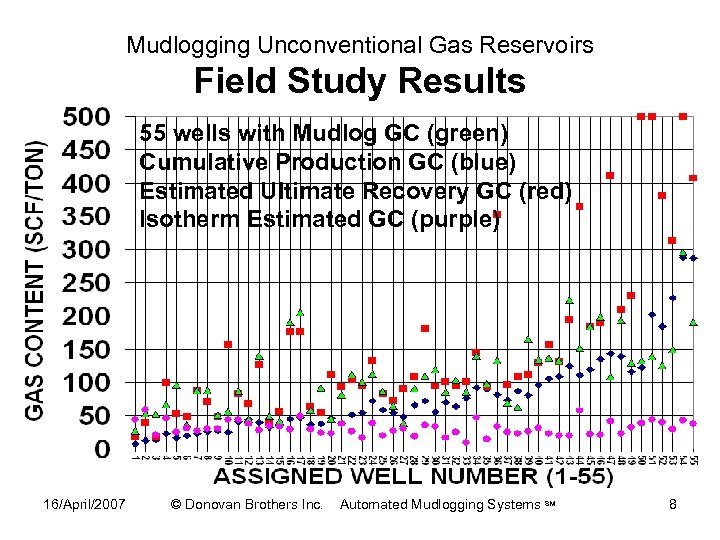

Mudlogging Unconventional Gas Reservoirs Field Study Results 55 wells with Mudlog GC (green) Cumulative Production GC (blue) Estimated Ultimate Recovery GC (red) Isotherm Estimated GC (purple) 16/April/2007 © Donovan Brothers Inc. Automated Mudlogging Systems SM 8

Mudlogging Unconventional Gas Reservoirs Definitions and Theory • Define mudlogging gas measurements Percent Equivalent Methane in Air (% EMA) and “Units EMA” • Explain why mudlogging is effective • Compare resources for different reservoirs 16/April/2007 © Donovan Brothers Inc. Automated Mudlogging Systems SM 9

Mudlogging Unconventional Gas Reservoirs Definitions and Theory EQUIVALENT METHANE IN AIR (% EMA) is a measure of methane in air at the measurement point (the mudlogging unit) expressed as a percent of methane in the air sample or expressed differently as 10, 000 parts per million methane by volume Calibrated and measured at the mudlogging unit, the whole system is not calibrated Although related to mudlogging gas content, % EMA is not a measure of gas in the formation Other hydrocarbon gases are presented as methane Typically 100 “Units EMA” equals 1% EMA 16/April/2007 © Donovan Brothers Inc. Automated Mudlogging Systems SM 10

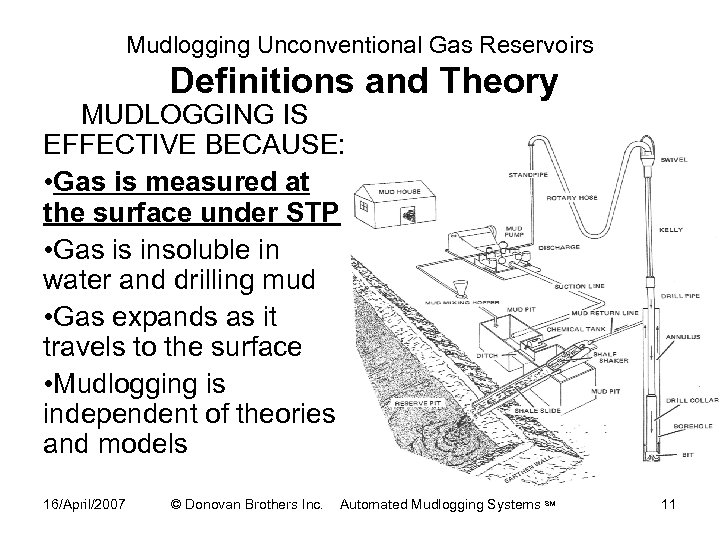

Mudlogging Unconventional Gas Reservoirs Definitions and Theory MUDLOGGING IS EFFECTIVE BECAUSE: • Gas is measured at the surface under STP • Gas is insoluble in water and drilling mud • Gas expands as it travels to the surface • Mudlogging is independent of theories and models 16/April/2007 © Donovan Brothers Inc. Automated Mudlogging Systems SM 11

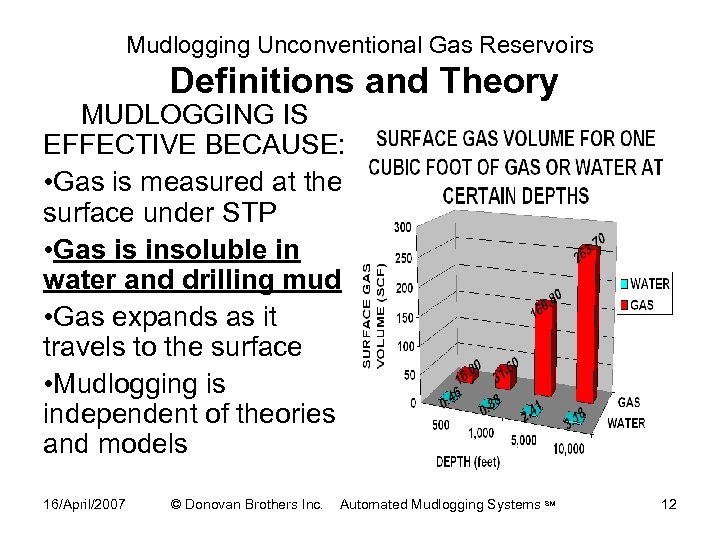

Mudlogging Unconventional Gas Reservoirs Definitions and Theory MUDLOGGING IS EFFECTIVE BECAUSE: • Gas is measured at the surface under STP • Gas is insoluble in water and drilling mud • Gas expands as it travels to the surface • Mudlogging is independent of theories and models 16/April/2007 © Donovan Brothers Inc. Automated Mudlogging Systems SM 12

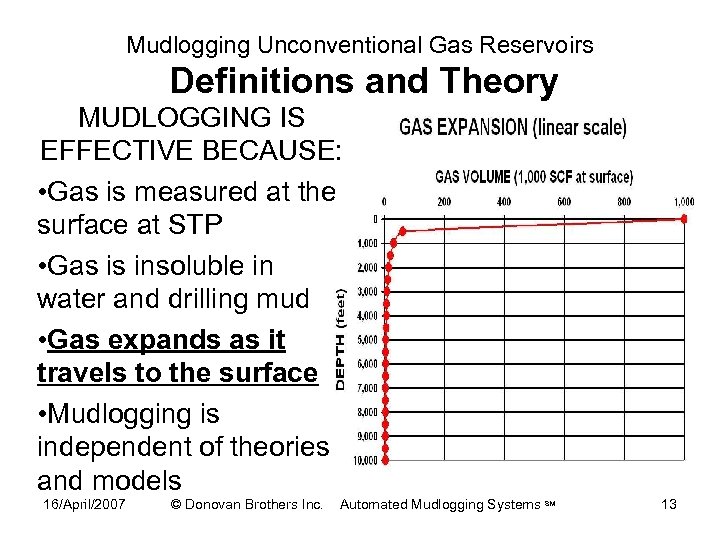

Mudlogging Unconventional Gas Reservoirs Definitions and Theory MUDLOGGING IS EFFECTIVE BECAUSE: • Gas is measured at the surface at STP • Gas is insoluble in water and drilling mud • Gas expands as it travels to the surface • Mudlogging is independent of theories and models 16/April/2007 © Donovan Brothers Inc. Automated Mudlogging Systems SM 13

Mudlogging Unconventional Gas Reservoirs Definitions and Theory MUDLOGGING IS EFFECTIVE BECAUSE: • Gas is measured at the surface at STP • Gas is insoluble in water and drilling mud • Gas expands as it travels to the surface • Mudlogging is independent of theories and models 16/April/2007 © Donovan Brothers Inc. Automated Mudlogging Systems SM 14

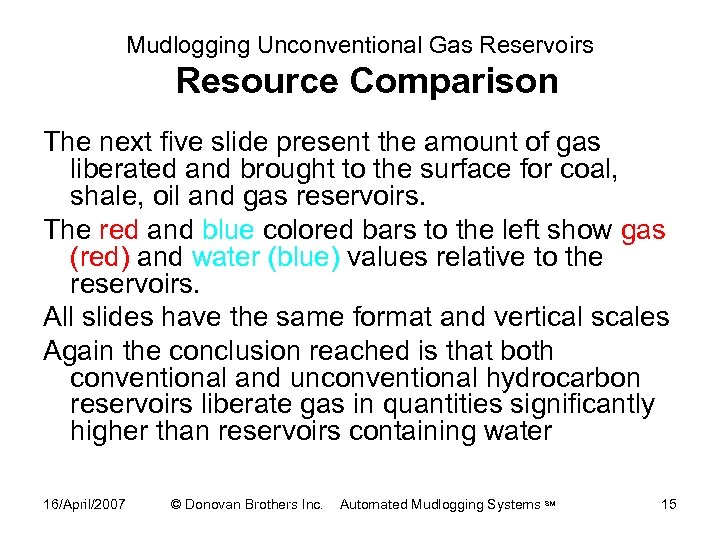

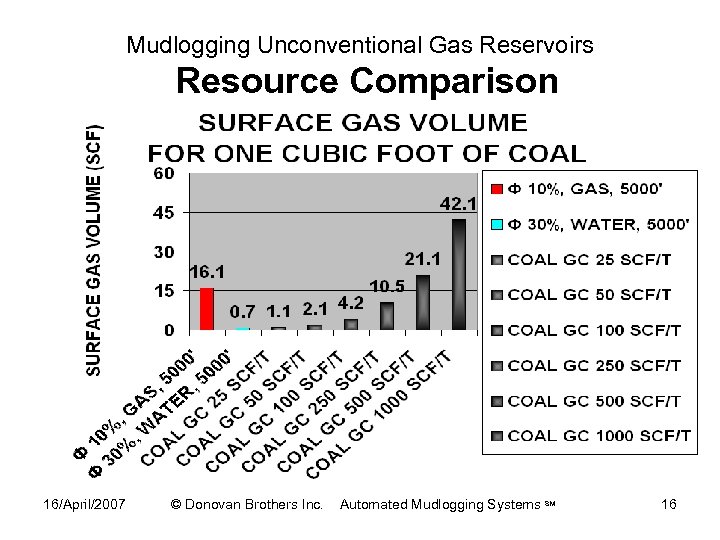

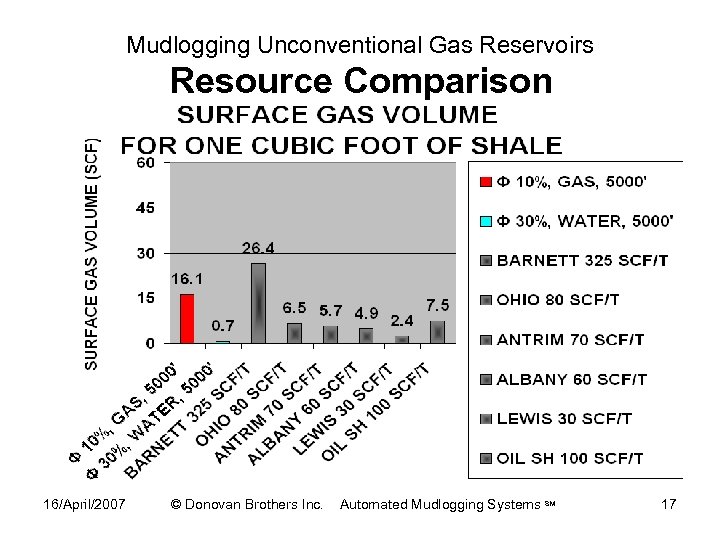

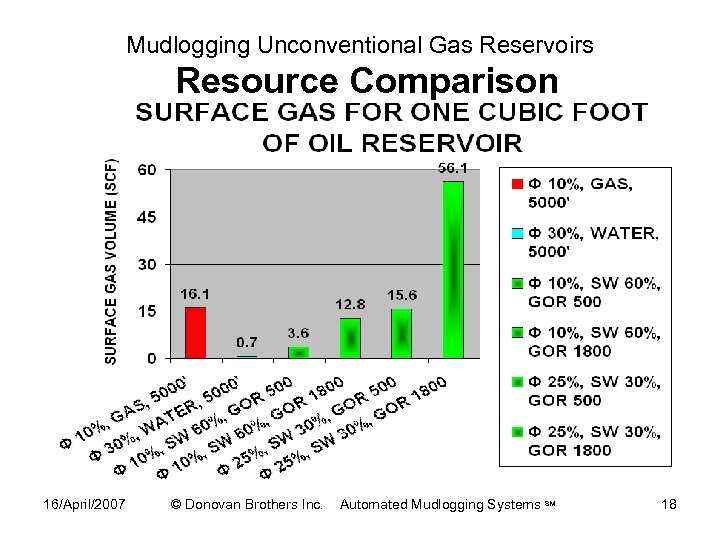

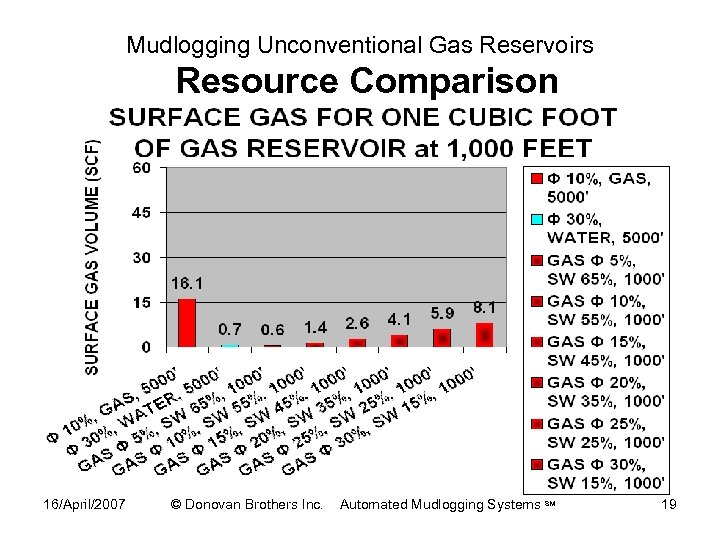

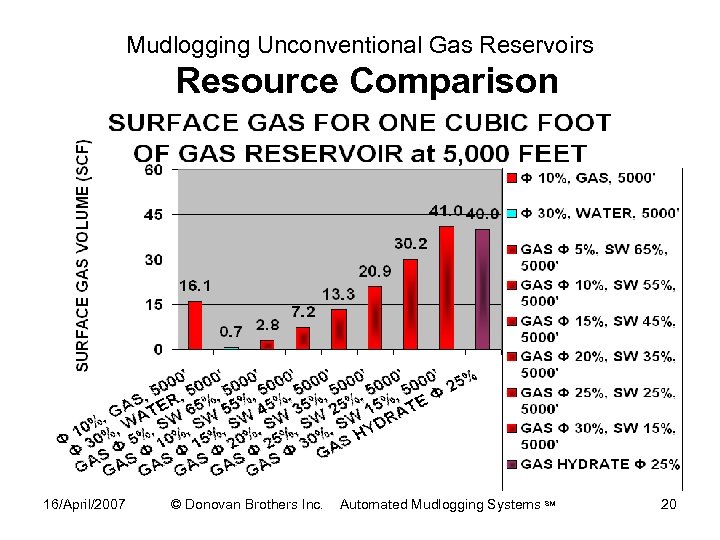

Mudlogging Unconventional Gas Reservoirs Resource Comparison The next five slide present the amount of gas liberated and brought to the surface for coal, shale, oil and gas reservoirs. The red and blue colored bars to the left show gas (red) and water (blue) values relative to the reservoirs. All slides have the same format and vertical scales Again the conclusion reached is that both conventional and unconventional hydrocarbon reservoirs liberate gas in quantities significantly higher than reservoirs containing water 16/April/2007 © Donovan Brothers Inc. Automated Mudlogging Systems SM 15

Mudlogging Unconventional Gas Reservoirs Resource Comparison 16/April/2007 © Donovan Brothers Inc. Automated Mudlogging Systems SM 16

Mudlogging Unconventional Gas Reservoirs Resource Comparison 16/April/2007 © Donovan Brothers Inc. Automated Mudlogging Systems SM 17

Mudlogging Unconventional Gas Reservoirs Resource Comparison 16/April/2007 © Donovan Brothers Inc. Automated Mudlogging Systems SM 18

Mudlogging Unconventional Gas Reservoirs Resource Comparison 16/April/2007 © Donovan Brothers Inc. Automated Mudlogging Systems SM 19

Mudlogging Unconventional Gas Reservoirs Resource Comparison 16/April/2007 © Donovan Brothers Inc. Automated Mudlogging Systems SM 20

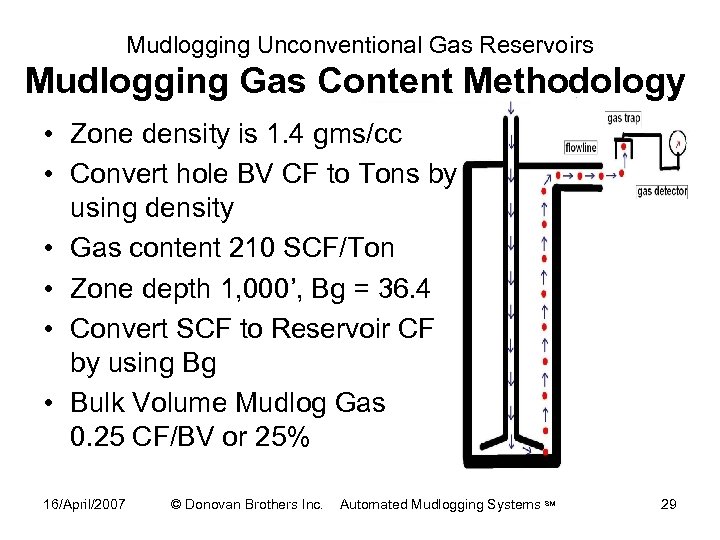

Mudlogging Unconventional Gas Reservoirs Mudlogging Gas Content Methodology The requirements to calculate gas volume liberated/bulk volume drilled, gas content and reservoir bulk volume mudlog gas are: • Data typically gathered while mudlogging • Calibrated calcium carbide lags to determine gas volumes liberated • Simple calculations using a spreadsheet and LAS files 16/April/2007 © Donovan Brothers Inc. Automated Mudlogging Systems SM 21

Mudlogging Unconventional Gas Reservoirs Mudlogging Gas Content Methodology • A measured amount of Calcium Carbide reacts with water to make determinable amount of acetylene gas: Ca. C 2 + H 20 = C 2 H 2 +Ca. O • Before mudlogging a calibration using both acetylene and methane establishes a relationship between the gases for the gas sensors in the mudlogging unit. • Before and after the zone of interest is drilled a known amount of Calcium Carbide (acetylene) is put in the drill string during connections and pumped to the surface. The peak gas value is recorded. • Using this data, a gas show in units EMA can be converted to SCF of gas liberated while drilling. 16/April/2007 © Donovan Brothers Inc. Automated Mudlogging Systems SM 22

Mudlogging Unconventional Gas Reservoirs Mudlogging Gas Content Methodology • If the hole volume is known, SCF/formation bulk volume (ft 3) can be calculated along with BCF/section or MCF/acre-foot. • If the formation density is known, SCF/T can be calculated. • If Bg, the gas expansion factor is known reservoir gas volume along with Bvg or reservoir gas porosity can be calculated. 16/April/2007 © Donovan Brothers Inc. Automated Mudlogging Systems SM 23

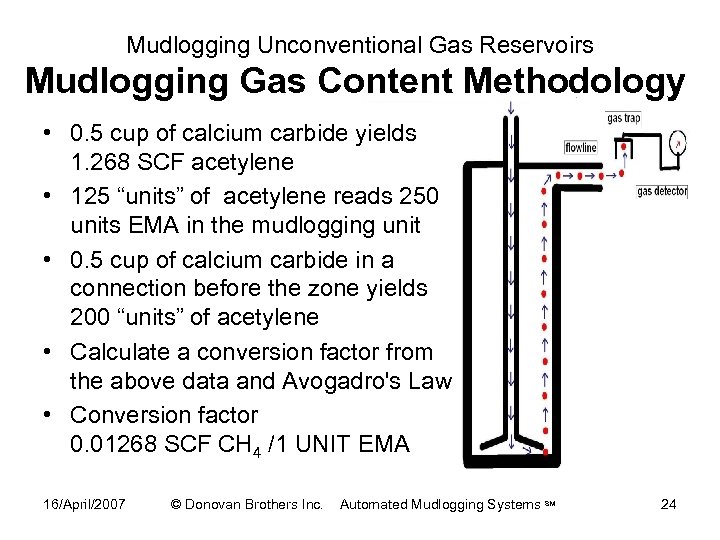

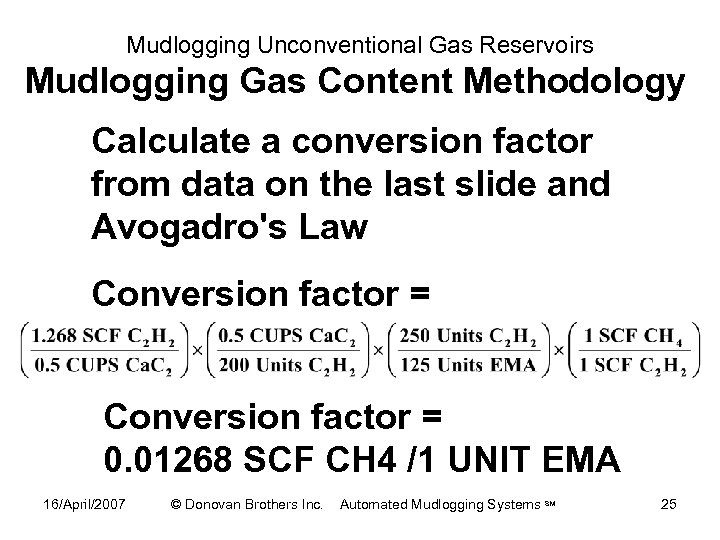

Mudlogging Unconventional Gas Reservoirs Mudlogging Gas Content Methodology • 0. 5 cup of calcium carbide yields 1. 268 SCF acetylene • 125 “units” of acetylene reads 250 units EMA in the mudlogging unit • 0. 5 cup of calcium carbide in a connection before the zone yields 200 “units” of acetylene • Calculate a conversion factor from the above data and Avogadro's Law • Conversion factor 0. 01268 SCF CH 4 /1 UNIT EMA 16/April/2007 © Donovan Brothers Inc. Automated Mudlogging Systems SM 24

Mudlogging Unconventional Gas Reservoirs Mudlogging Gas Content Methodology Calculate a conversion factor from data on the last slide and Avogadro's Law Conversion factor = 0. 01268 SCF CH 4 /1 UNIT EMA 16/April/2007 © Donovan Brothers Inc. Automated Mudlogging Systems SM 25

Mudlogging Unconventional Gas Reservoirs Mudlogging Gas Content Methodology • Gas reading in the zone 570 UNITS EMA/minute • Calculate gas liberated per minute in the zone by multiplying gas reading by the conversion factor • 570 UNITS EMA /minute X 0. 01268 SCF/UNIT EMA= 7. 23 SCF/Minute 16/April/2007 © Donovan Brothers Inc. Automated Mudlogging Systems SM 26

Mudlogging Unconventional Gas Reservoirs Mudlogging Gas Content Methodology • Penetration rate in the zone is 0. 5 minutes/foot • Hole diameter is 8. 5 inches • Calculate the hole bulk volume (BV) drilled per minute • Hole Volume/Minute = 0. 78813 BV Cubic Feet/Minute 16/April/2007 © Donovan Brothers Inc. Automated Mudlogging Systems SM 27

Mudlogging Unconventional Gas Reservoirs Mudlogging Gas Content Methodology • Divide the gas liberated per minute by the hole volume drilled per minute • 7. 23(SCF/Minute) / 0. 78813(BV CF/Minute) = 9. 17 SCF/BV CF • Conversion factors can be used to calculate BCF/Section foot or MCF/Acre foot 16/April/2007 © Donovan Brothers Inc. Automated Mudlogging Systems SM 28

Mudlogging Unconventional Gas Reservoirs Mudlogging Gas Content Methodology • Zone density is 1. 4 gms/cc • Convert hole BV CF to Tons by using density • Gas content 210 SCF/Ton • Zone depth 1, 000’, Bg = 36. 4 • Convert SCF to Reservoir CF by using Bg • Bulk Volume Mudlog Gas 0. 25 CF/BV or 25% 16/April/2007 © Donovan Brothers Inc. Automated Mudlogging Systems SM 29

Mudlogging Unconventional Gas Reservoirs Factors Influencing Mudlogging The factors which influence mudlogging can be grouped into two general categories: • Deterministic factors (hole size, drilling rate, etc. ) • Indeterminate factors (flushing, background gas, surface losses, gas trap performance) Carbide calibration accounts for all factors 16/April/2007 © Donovan Brothers Inc. Automated Mudlogging Systems SM 30

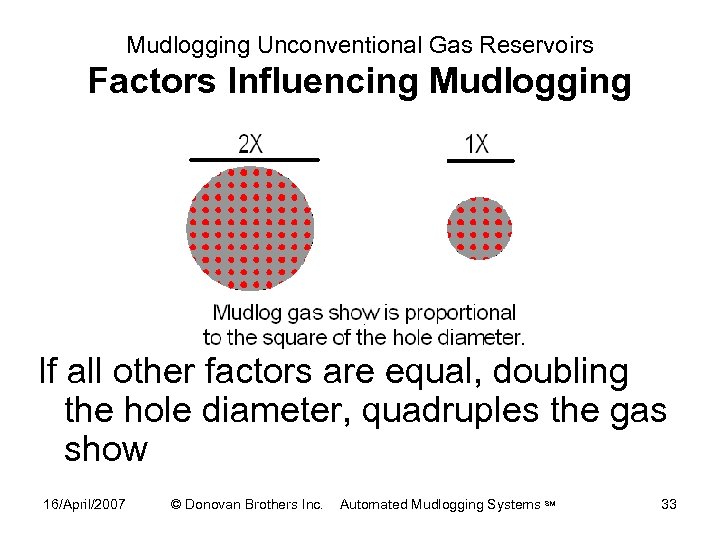

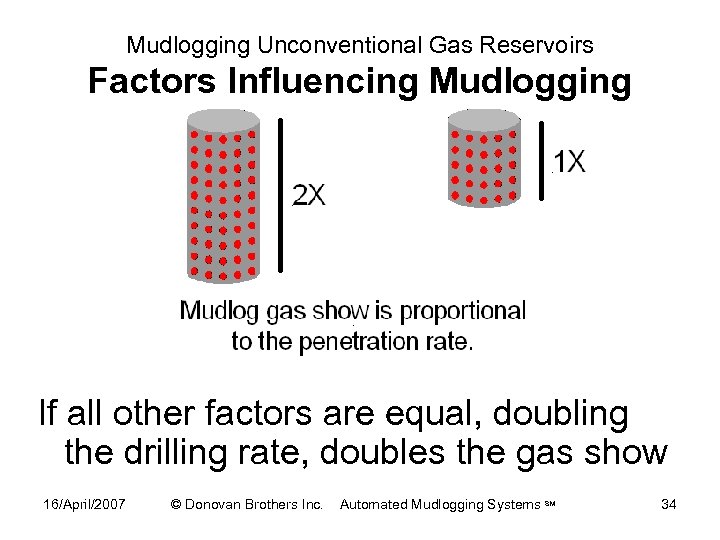

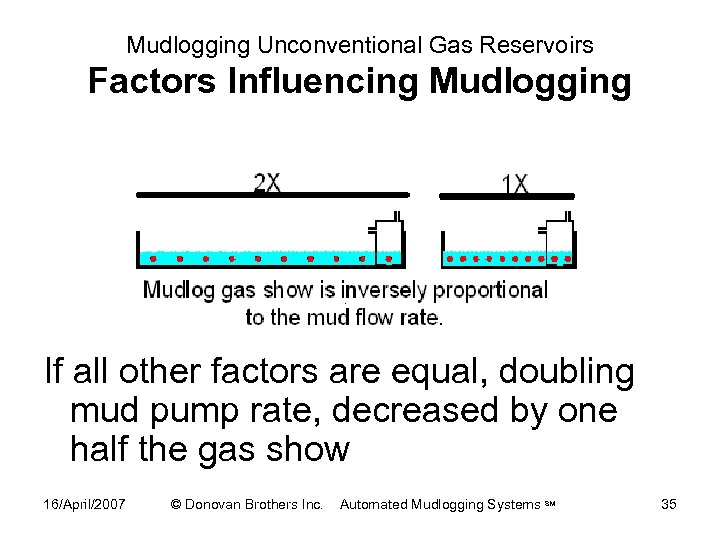

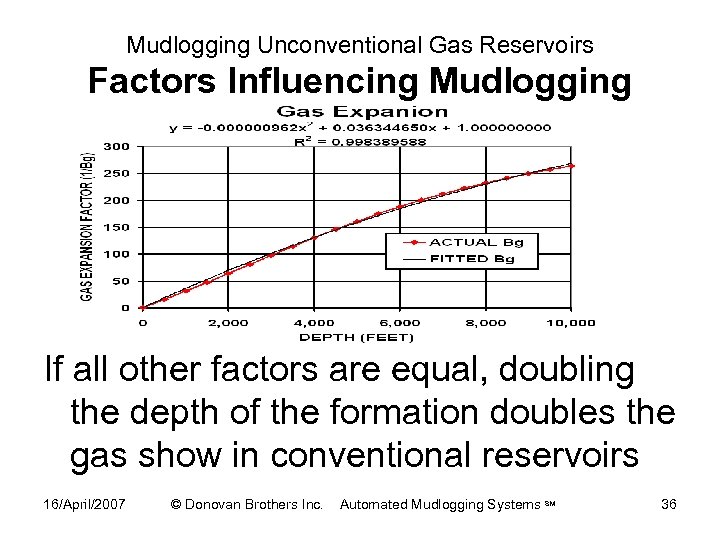

Mudlogging Unconventional Gas Reservoirs Factors Influencing Mudlogging Deterministic factors affecting mudlog gas are: • Gas in the formation • Hole size • Drilling rate • Mud pump rate • Gas expansion 16/April/2007 © Donovan Brothers Inc. Automated Mudlogging Systems SM 31

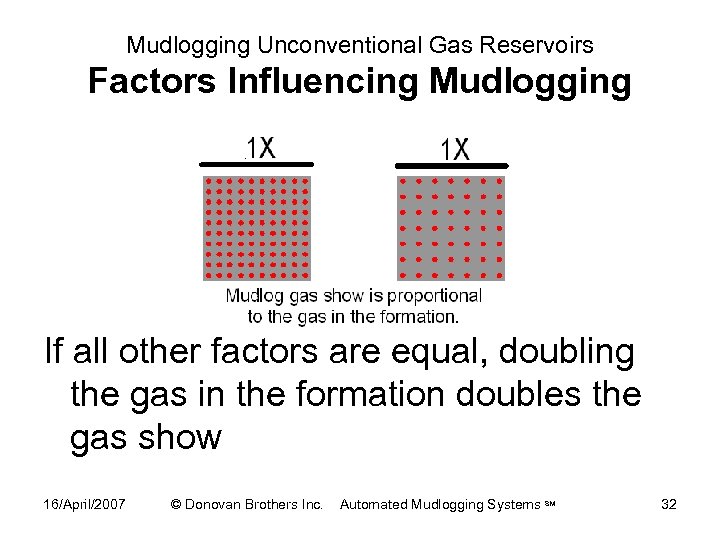

Mudlogging Unconventional Gas Reservoirs Factors Influencing Mudlogging If all other factors are equal, doubling the gas in the formation doubles the gas show 16/April/2007 © Donovan Brothers Inc. Automated Mudlogging Systems SM 32

Mudlogging Unconventional Gas Reservoirs Factors Influencing Mudlogging If all other factors are equal, doubling the hole diameter, quadruples the gas show 16/April/2007 © Donovan Brothers Inc. Automated Mudlogging Systems SM 33

Mudlogging Unconventional Gas Reservoirs Factors Influencing Mudlogging If all other factors are equal, doubling the drilling rate, doubles the gas show 16/April/2007 © Donovan Brothers Inc. Automated Mudlogging Systems SM 34

Mudlogging Unconventional Gas Reservoirs Factors Influencing Mudlogging If all other factors are equal, doubling mud pump rate, decreased by one half the gas show 16/April/2007 © Donovan Brothers Inc. Automated Mudlogging Systems SM 35

Mudlogging Unconventional Gas Reservoirs Factors Influencing Mudlogging If all other factors are equal, doubling the depth of the formation doubles the gas show in conventional reservoirs 16/April/2007 © Donovan Brothers Inc. Automated Mudlogging Systems SM 36

Mudlogging Unconventional Gas Reservoirs Factors Influencing Mudlogging Indeterminate factors are: • Recycled gas in the drilling mud (minor) • Contamination of mix water or mud chemicals (seldom) • Flushing or flowing in the formation being drilled (minor) • Flushing or flowing in the formations above the formation being drilled (minor) 16/April/2007 © Donovan Brothers Inc. Automated Mudlogging Systems SM 37

Mudlogging Unconventional Gas Reservoirs Factors Influencing Mudlogging More indeterminate factors are: • Cuttings not fully releasing gas (minor) • Surface losses (major) • Gas trap design (major) • Temperature (major) • Wind (seldom) • Miscalibrated sensors (seldom) 16/April/2007 © Donovan Brothers Inc. Automated Mudlogging Systems SM 38

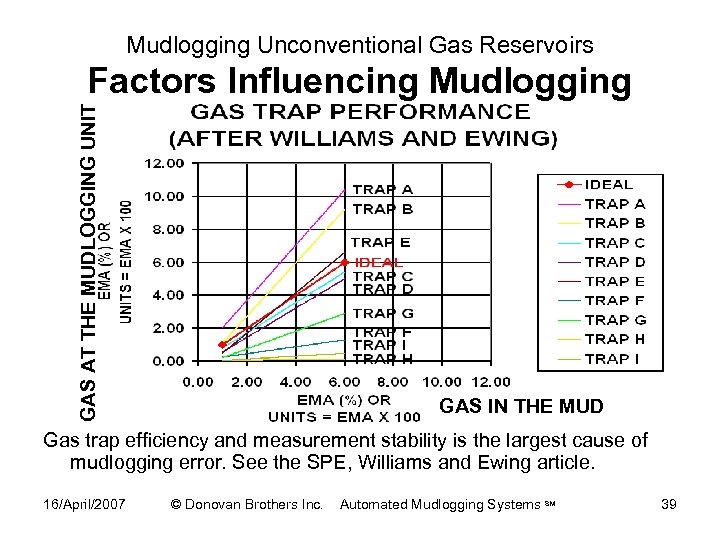

Mudlogging Unconventional Gas Reservoirs GAS AT THE MUDLOGGING UNIT Factors Influencing Mudlogging GAS IN THE MUD Gas trap efficiency and measurement stability is the largest cause of mudlogging error. See the SPE, Williams and Ewing article. 16/April/2007 © Donovan Brothers Inc. Automated Mudlogging Systems SM 39

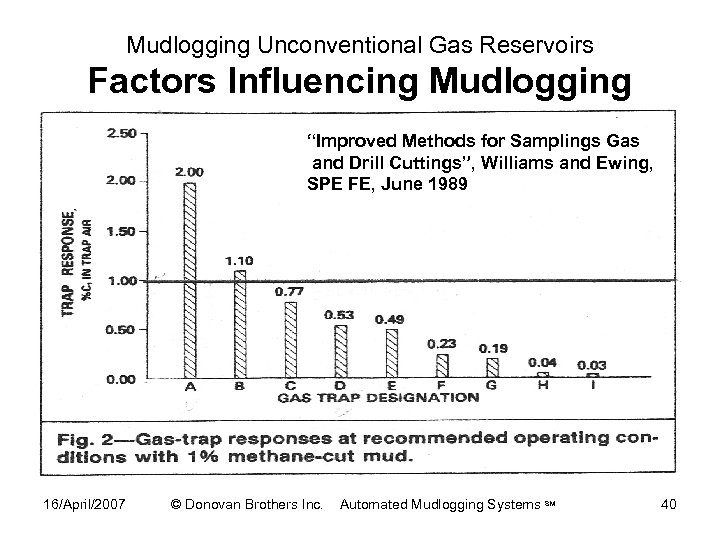

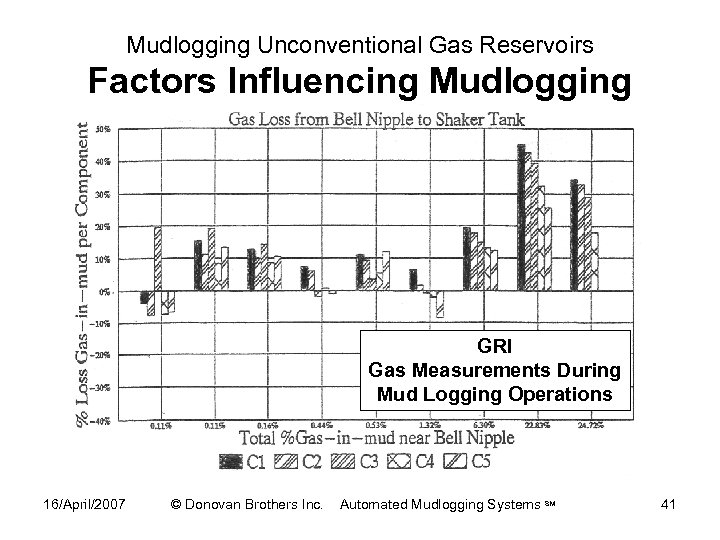

Mudlogging Unconventional Gas Reservoirs Factors Influencing Mudlogging “Improved Methods for Samplings Gas and Drill Cuttings”, Williams and Ewing, SPE FE, June 1989 16/April/2007 © Donovan Brothers Inc. Automated Mudlogging Systems SM 40

Mudlogging Unconventional Gas Reservoirs Factors Influencing Mudlogging GRI Gas Measurements During Mud Logging Operations 16/April/2007 © Donovan Brothers Inc. Automated Mudlogging Systems SM 41

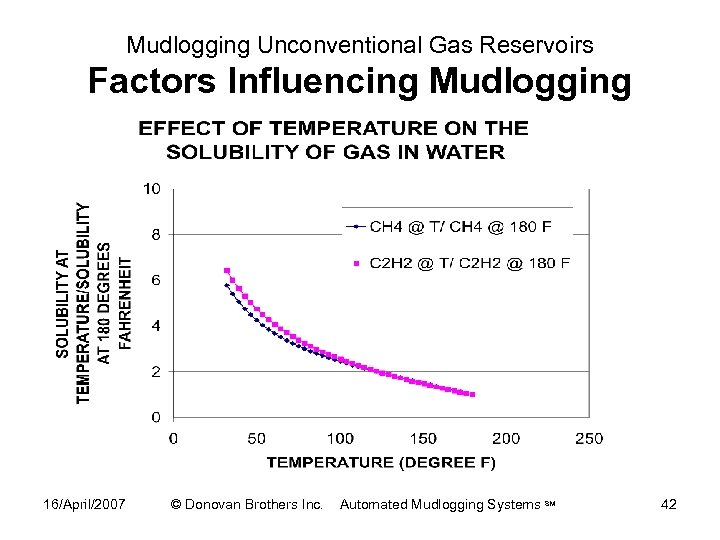

Mudlogging Unconventional Gas Reservoirs Factors Influencing Mudlogging 16/April/2007 © Donovan Brothers Inc. Automated Mudlogging Systems SM 42

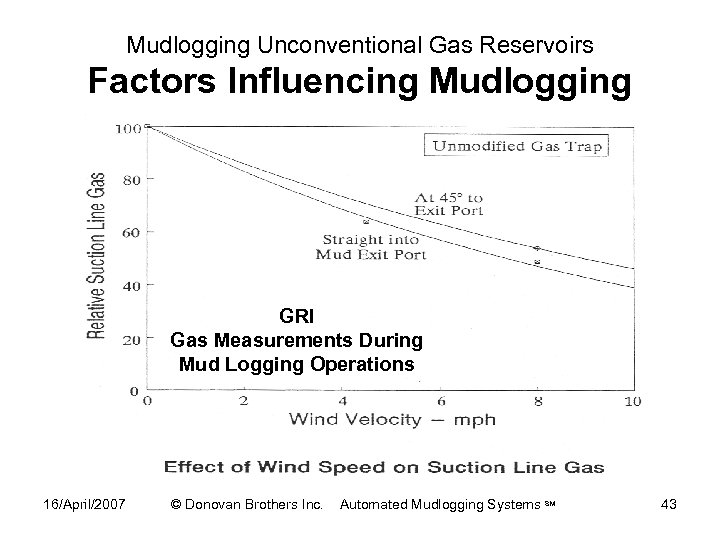

Mudlogging Unconventional Gas Reservoirs Factors Influencing Mudlogging GRI Gas Measurements During Mud Logging Operations 16/April/2007 © Donovan Brothers Inc. Automated Mudlogging Systems SM 43

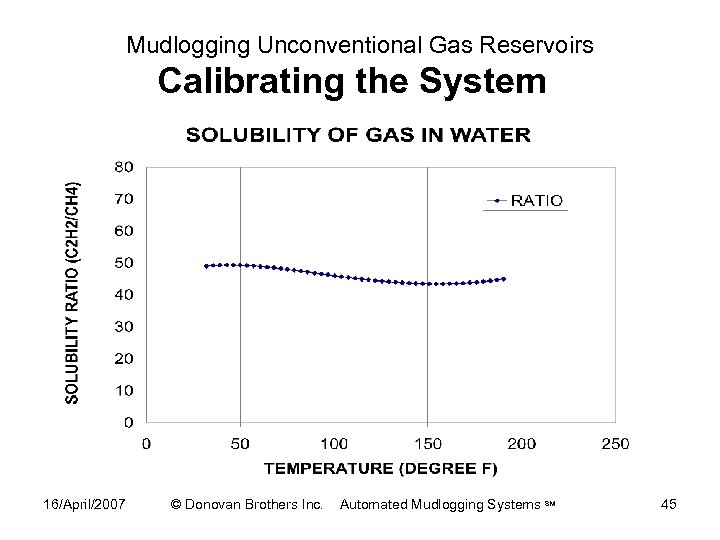

Mudlogging Unconventional Gas Reservoirs Factors Influencing Mudlogging Notice all the potential errors: • 100 units of gas in the mud could read as high as 200 units or as low as 3 units due to gas trap design • Gas losses as much as 40% due to loss in the flow line • Gas losses as much as 50% due to wind • A six fold change in methane solubility in water from 40ºF to 180ºF All of these losses can be normalized or compensated for by the use of calibrated carbide lagging. The next slide shows that acetylene behaves like methane over a wide range of conditions. If carbide lag results are consistent, it indicates good quality mudlogging 16/April/2007 © Donovan Brothers Inc. Automated Mudlogging Systems SM 44

Mudlogging Unconventional Gas Reservoirs Calibrating the System 16/April/2007 © Donovan Brothers Inc. Automated Mudlogging Systems SM 45

Mudlogging Unconventional Gas Reservoirs Mudlogging is an effective evaluation tool If you have questions or comments contact me Bill Donovan (303) 794 -7470 donovan@mudlogger. com www. mudlogger. com 16/April/2007 © Donovan Brothers Inc. Automated Mudlogging Systems SM 46

173efe2b5103e12050e1fc629cd515b8.ppt