38878310f4ec2b653374a8f184f5a017.ppt

- Количество слайдов: 75

MTAT. 03. 231 Business Process Management (BPM) (for Masters of ETM) Lecture 3: Process Lifecycle Management Marlon Dumas marlon. dumas ät ut. ee

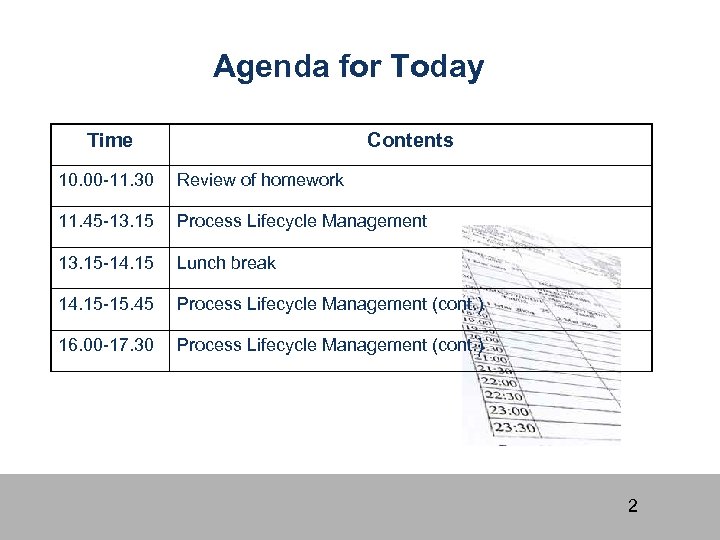

Agenda for Today Time Contents 10. 00 -11. 30 Review of homework 11. 45 -13. 15 Process Lifecycle Management 13. 15 -14. 15 Lunch break 14. 15 -15. 45 Process Lifecycle Management (cont. ) 16. 00 -17. 30 Process Lifecycle Management (cont. ) 2

Another View on Process Improvement

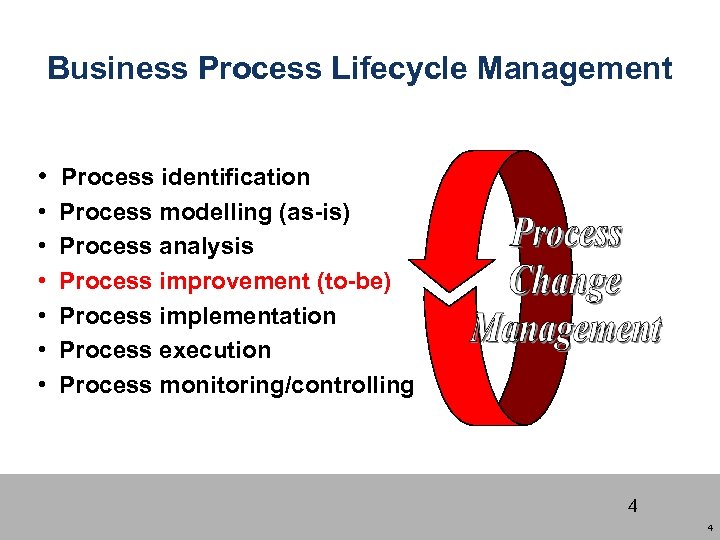

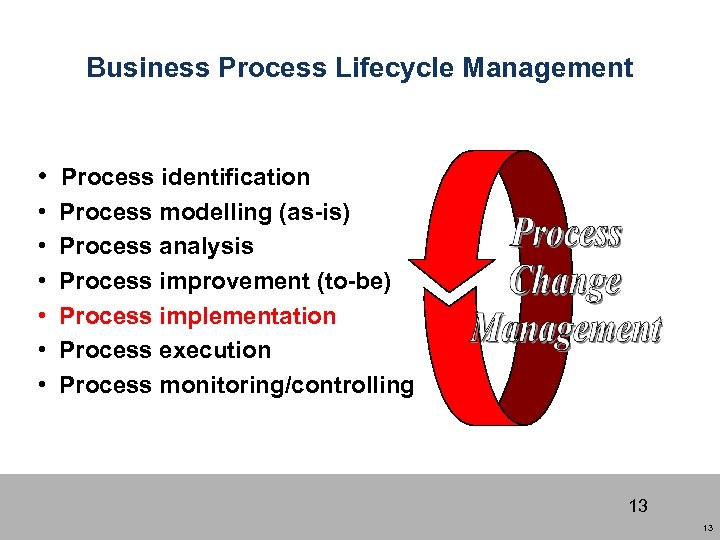

Business Process Lifecycle Management • Process identification • • • Process modelling (as-is) Process analysis Process improvement (to-be) Process implementation Process execution Process monitoring/controlling 4 4

Process Improvement - Object-oriented Approaches (1/2) • Elimination of object types – secondary objects (copies, reports) – e. g. prebilling • Elimination of objects – statistical checks in goods receipt or invoice verification • Substitution of objects – credit vouchers instead of invoices (Hammer: Ford) (Evaluated Receipt Settlement) • Digitalisation of objects – document management, EDM-systems – Microsoft‘s invoicing process © Michael Rosemann 5

Process Improvement - Object-oriented Approaches (2/2) • Harmonisation of objects – Unitisation – Logistical units (e. g. pallets) • Separation of objects – Differentiation of standard-cases and exceptions – Increased time-/cost-homogenity • Process oriented optimisation of objects – Design for process – Design of products meets needs of production, assembly, logistics and recycling © Michael Rosemann 6

Process Improvement - Function-oriented Approaches (1/2) • Elimination of functions – Lean Management-approach – Outsourcing • Integration of functions (unification) – Job Enlargement (horizontal compression) • Process Owner • Case manager / case worker – Job Enrichment (empowerment) • delegation of decisions © Michael Rosemann 7

Process Improvement - Function-oriented Approaches (2/2) • Change process direction – pull instead of push – Kanban, Just-in-time • Automation of functions – Basic idea of IT-use – Especially: Automation of control flow (workflow mgmt) • Parallel routing of functions – create ‚natural order‘ – delinearize processes e. g. simultaneous/concurrent engineering © Michael Rosemann 8

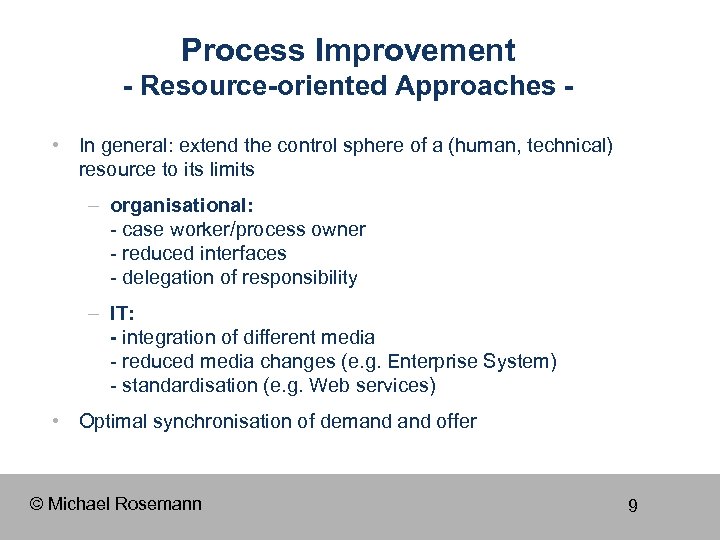

Process Improvement - Resource-oriented Approaches • In general: extend the control sphere of a (human, technical) resource to its limits – organisational: - case worker/process owner - reduced interfaces - delegation of responsibility – IT: - integration of different media - reduced media changes (e. g. Enterprise System) - standardisation (e. g. Web services) • Optimal synchronisation of demand offer © Michael Rosemann 9

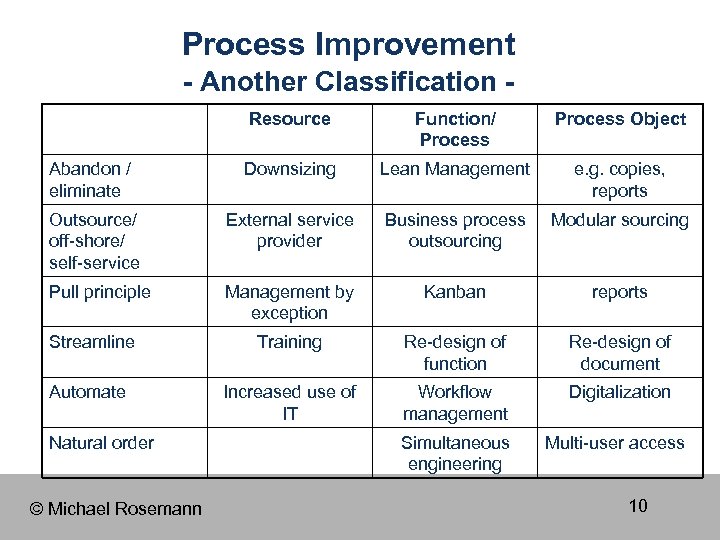

Process Improvement - Another Classification Resource Function/ Process Object Abandon / eliminate Downsizing Lean Management e. g. copies, reports Outsource/ off-shore/ self-service External service provider Business process outsourcing Modular sourcing Pull principle Management by exception Kanban reports Streamline Training Re-design of function Re-design of document Automate Increased use of IT Workflow management Digitalization Natural order © Michael Rosemann Simultaneous engineering Multi-user access 10

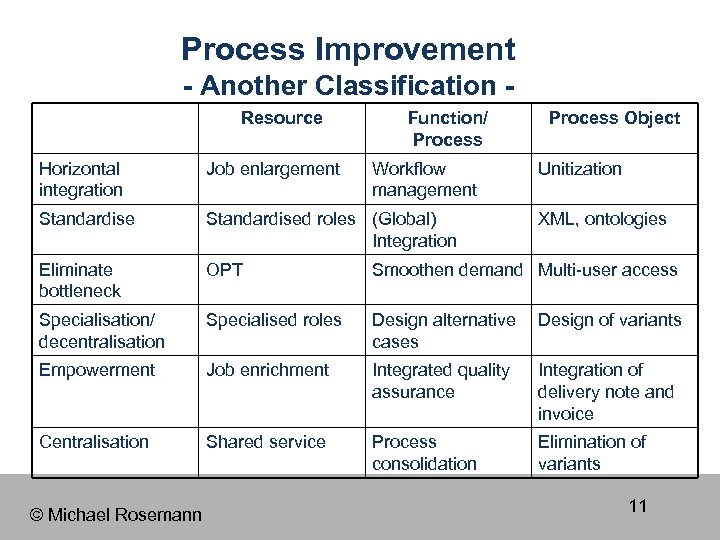

Process Improvement - Another Classification Resource Function/ Process Horizontal integration Job enlargement Standardised roles (Global) Integration Eliminate bottleneck OPT Smoothen demand Multi-user access Specialisation/ decentralisation Specialised roles Design alternative cases Design of variants Empowerment Job enrichment Integrated quality assurance Integration of delivery note and invoice Centralisation Shared service Process consolidation Elimination of variants © Michael Rosemann Workflow management Process Object Unitization XML, ontologies 11

Process Implementation

Business Process Lifecycle Management • Process identification • • • Process modelling (as-is) Process analysis Process improvement (to-be) Process implementation Process execution Process monitoring/controlling 13 13

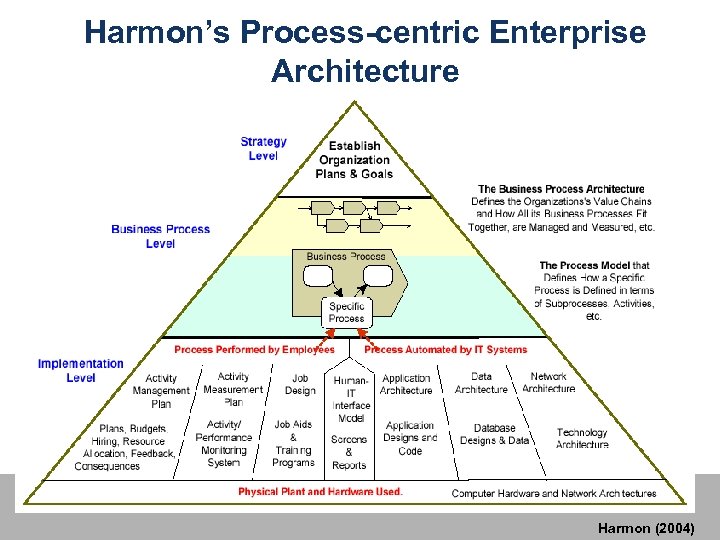

Harmon’s Process-centric Enterprise Architecture 14 Harmon (2004)

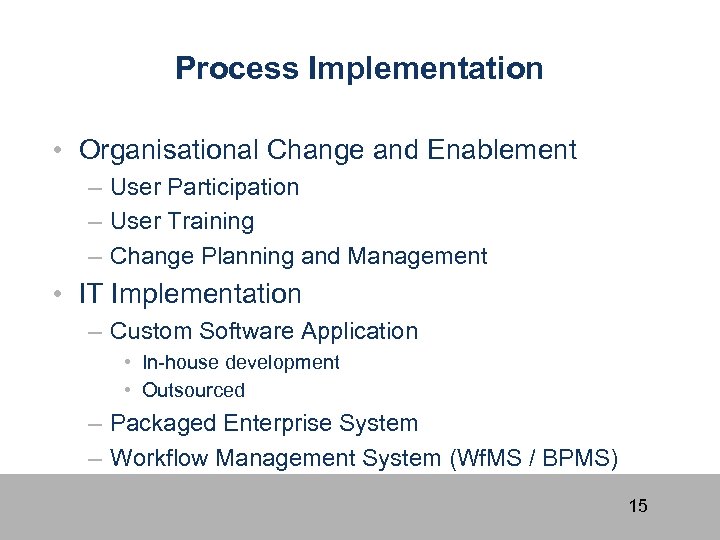

Process Implementation • Organisational Change and Enablement – User Participation – User Training – Change Planning and Management • IT Implementation – Custom Software Application • In-house development • Outsourced – Packaged Enterprise System – Workflow Management System (Wf. MS / BPMS) 15

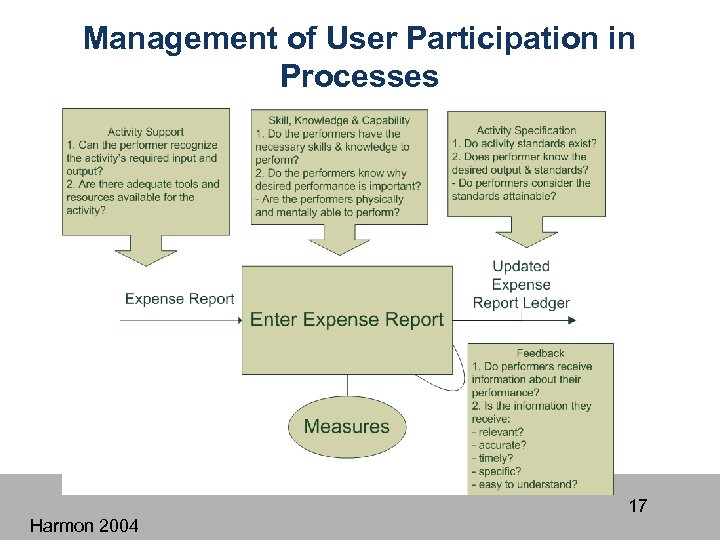

User Participation/Involvement 1. Buy-in, not only commitment 2. Select first processes carefully 3. Involve users and sponsors 4. Highlight business impact 5. Provide short-term benefits and long-term objectives 6. BPM must be in their self-interest 7. Proof of concept 8. Communicate (internal) success stories 9. Identify and coach BPM champion 10. Communication is different to consensus 16

Management of User Participation in Processes 17 Harmon 2004

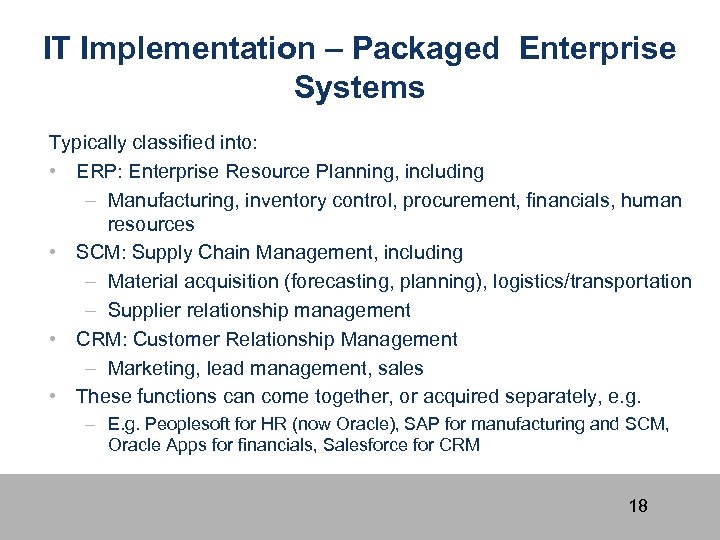

IT Implementation – Packaged Enterprise Systems Typically classified into: • ERP: Enterprise Resource Planning, including – Manufacturing, inventory control, procurement, financials, human resources • SCM: Supply Chain Management, including – Material acquisition (forecasting, planning), logistics/transportation – Supplier relationship management • CRM: Customer Relationship Management – Marketing, lead management, sales • These functions can come together, or acquired separately, e. g. – E. g. Peoplesoft for HR (now Oracle), SAP for manufacturing and SCM, Oracle Apps for financials, Salesforce for CRM 18

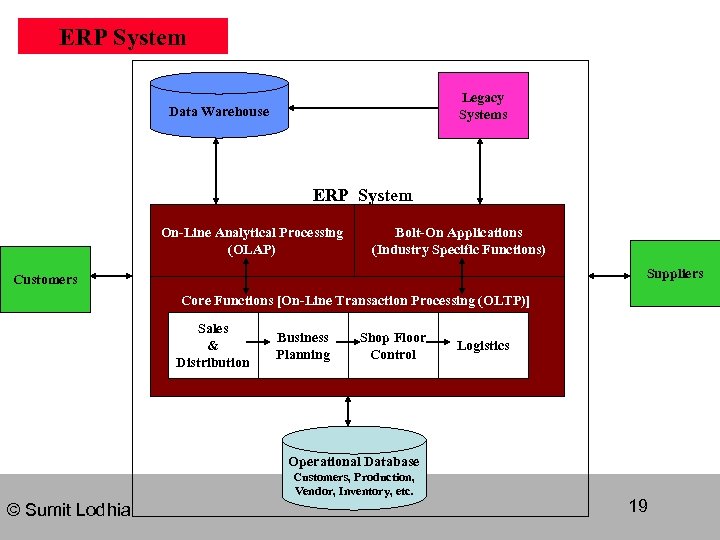

ERP System Legacy Systems Data Warehouse ERP System On-Line Analytical Processing (OLAP) Bolt-On Applications (Industry Specific Functions) Suppliers Customers Core Functions [On-Line Transaction Processing (OLTP)] Sales & Distribution Business Planning Shop Floor Control Logistics Operational Database Customers, Production, Vendor, Inventory, etc. © Sumit Lodhia 19

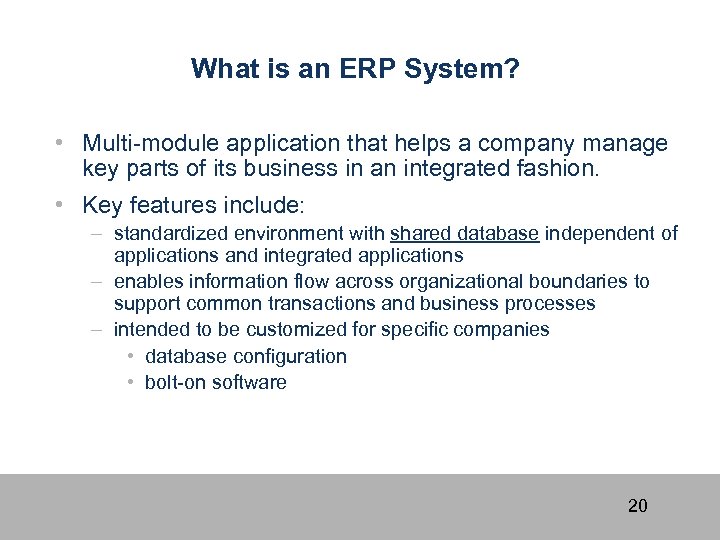

What is an ERP System? • Multi-module application that helps a company manage key parts of its business in an integrated fashion. • Key features include: – standardized environment with shared database independent of applications and integrated applications – enables information flow across organizational boundaries to support common transactions and business processes – intended to be customized for specific companies • database configuration • bolt-on software 20

Risks Associated with ERP Implementation • Pace of implementation – ‘Big Bang’--switch operations from legacy systems to ERP in a single event – ‘Phased-In’--independent ERP units installed over time, assimilated, and integrated • Opposition to change – user reluctance and inertia – need of upper management support • Choosing the wrong ERP – goodness of fit: no one ERP product is best for all industries – scalability: system’s ability to grow 21

Risks Associated with ERP Implementation … • High cost and cost overruns • training • testing and integration • database conversion • Disruptions to operations – ERP implementations usually involve major process changes – Need to align ERP-imposed processes with existing processes 22

Workflow Systems / BPM Systems • BPMN-based: Savvion, Lombardi, Biz. Agi • BPEL-based (Service-Oriented Architecture) – – Oracle SOA Suite Active. BPEL IBM Websphere Process Engine … • Microsoft: Biz. Talk, Windows Workflow Foundation • Community-based open-source: YAWL 23

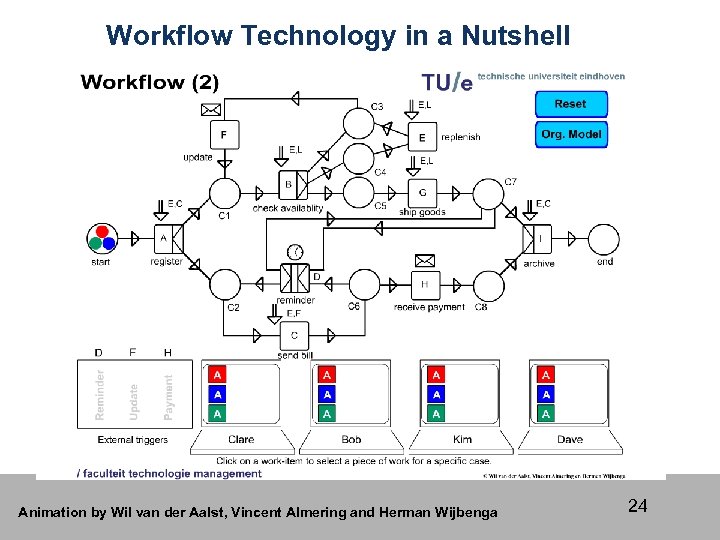

Workflow Technology in a Nutshell Animation by Wil van der Aalst, Vincent Almering and Herman Wijbenga 24

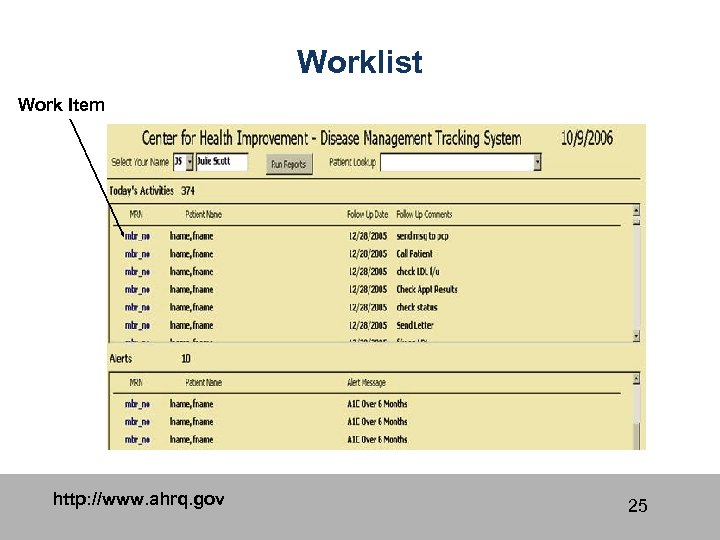

Worklist Work Item http: //www. ahrq. gov 25

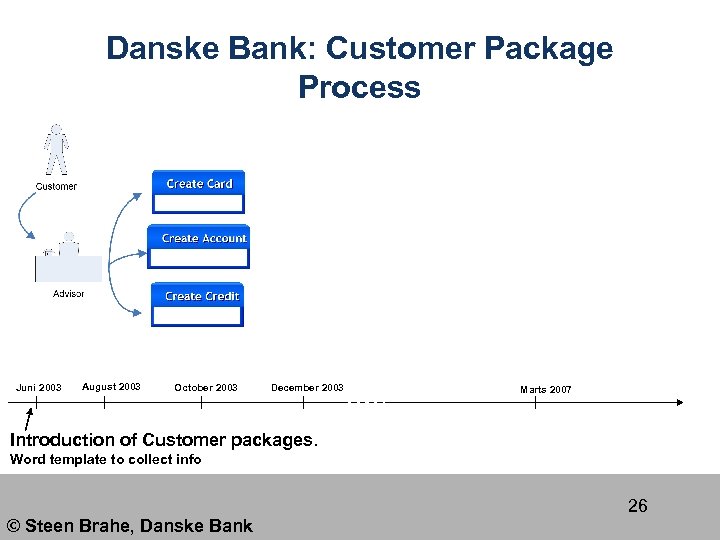

Danske Bank: Customer Package Process Juni 2003 August 2003 October 2003 December 2003 Marts 2007 Introduction of Customer packages. Word template to collect info 26 © Steen Brahe, Danske Bank

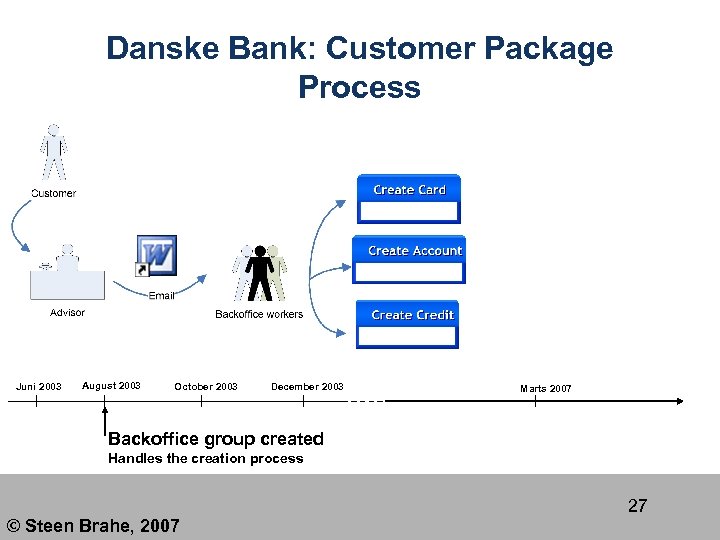

Danske Bank: Customer Package Process Juni 2003 August 2003 October 2003 December 2003 Marts 2007 Backoffice group created Handles the creation process 27 © Steen Brahe, 2007

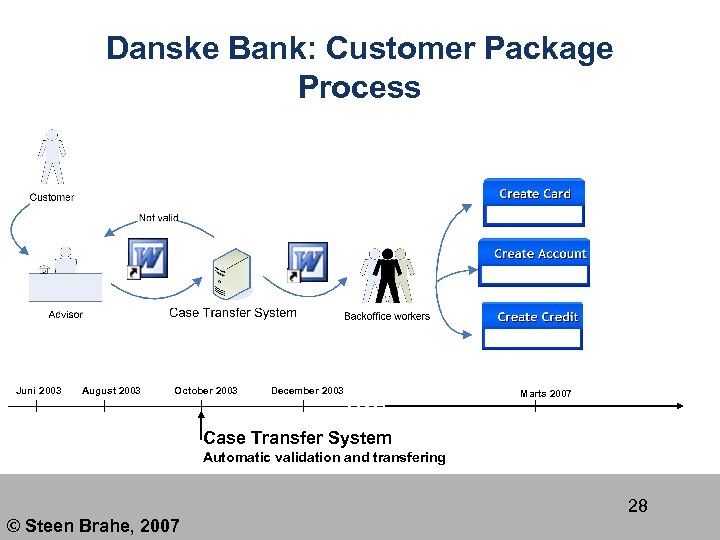

Danske Bank: Customer Package Process Juni 2003 August 2003 October 2003 December 2003 Marts 2007 Case Transfer System Automatic validation and transfering 28 © Steen Brahe, 2007

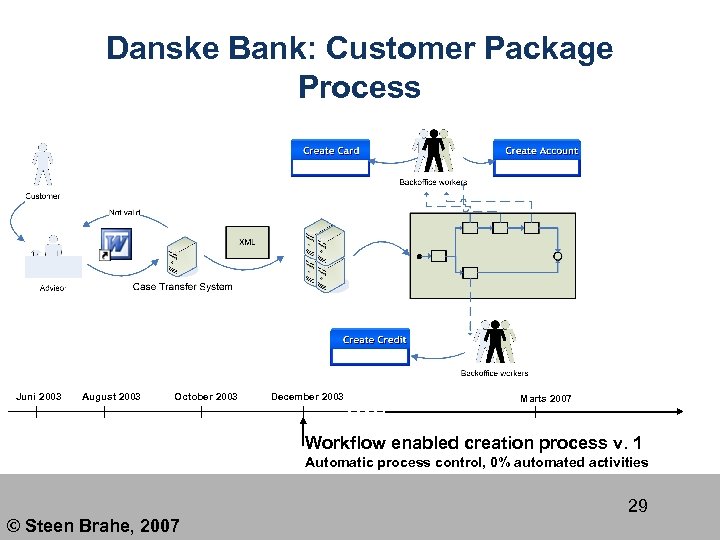

Danske Bank: Customer Package Process Juni 2003 August 2003 October 2003 December 2003 Marts 2007 Workflow enabled creation process v. 1 Automatic process control, 0% automated activities 29 © Steen Brahe, 2007

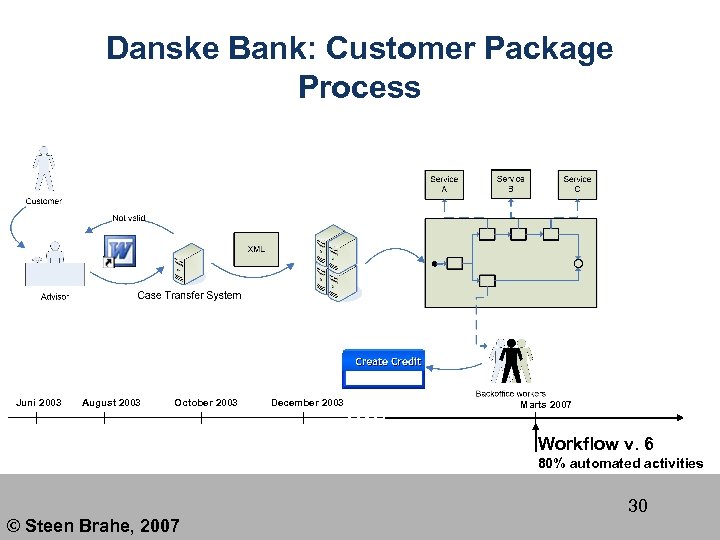

Danske Bank: Customer Package Process Juni 2003 August 2003 October 2003 December 2003 Marts 2007 Workflow v. 6 80% automated activities 30 © Steen Brahe, 2007

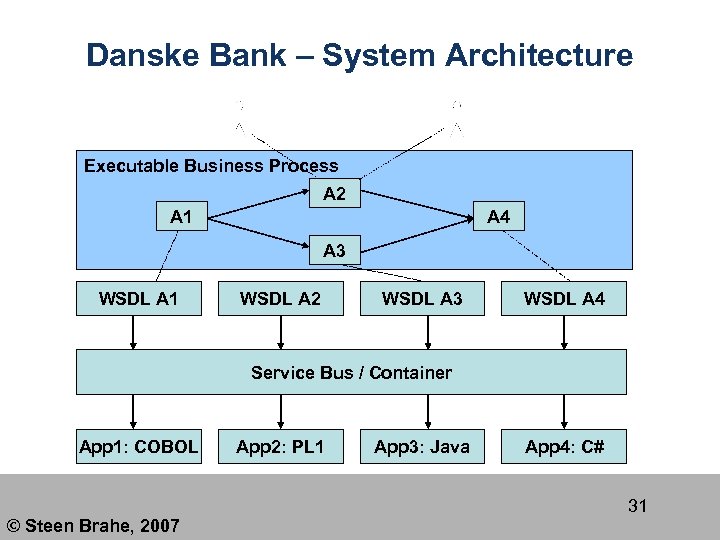

Danske Bank – System Architecture Executable Business Process A 2 A 1 A 4 A 3 WSDL A 1 WSDL A 2 WSDL A 3 WSDL A 4 Service Bus / Container App 1: COBOL App 2: PL 1 App 3: Java App 4: C# 31 © Steen Brahe, 2007

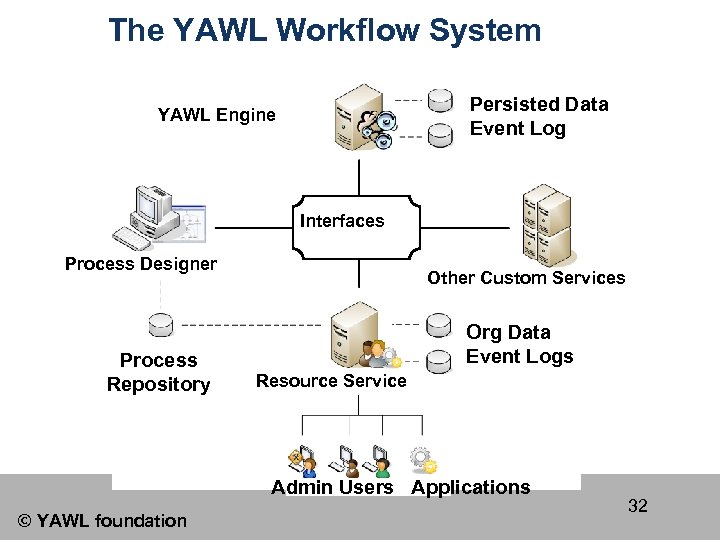

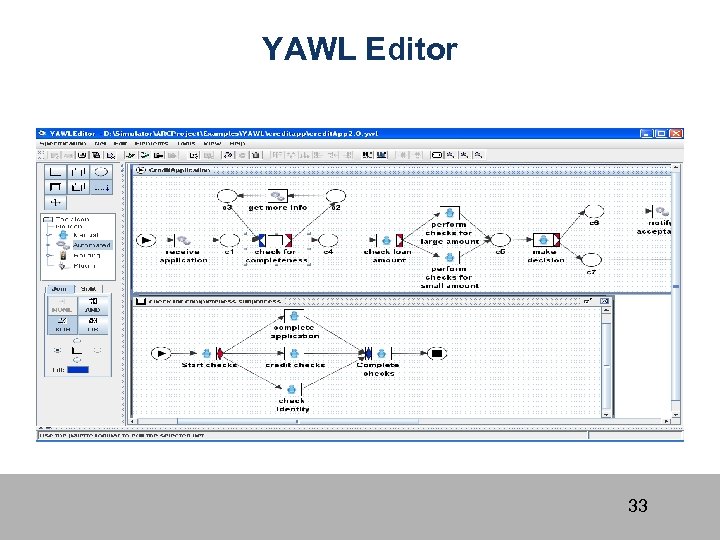

The YAWL Workflow System Persisted Data Event Log YAWL Engine Interfaces Process Designer Process Repository Other Custom Services Org Data Event Logs Resource Service Admin Users Applications © YAWL foundation 32

YAWL Editor 33

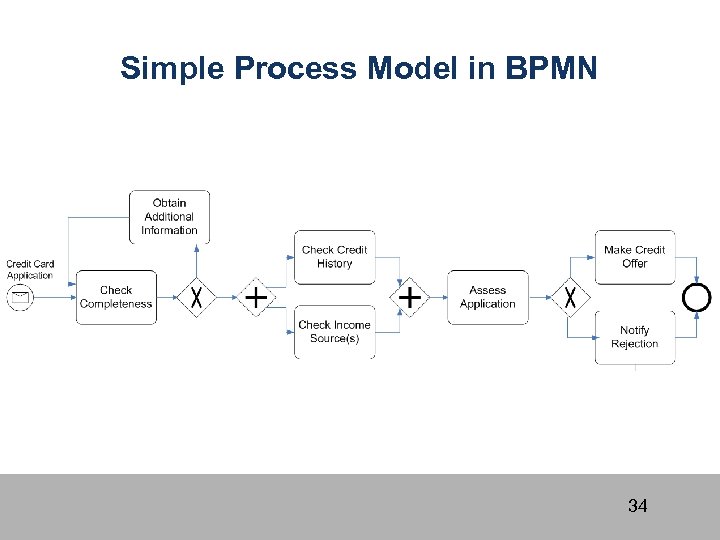

Simple Process Model in BPMN 34

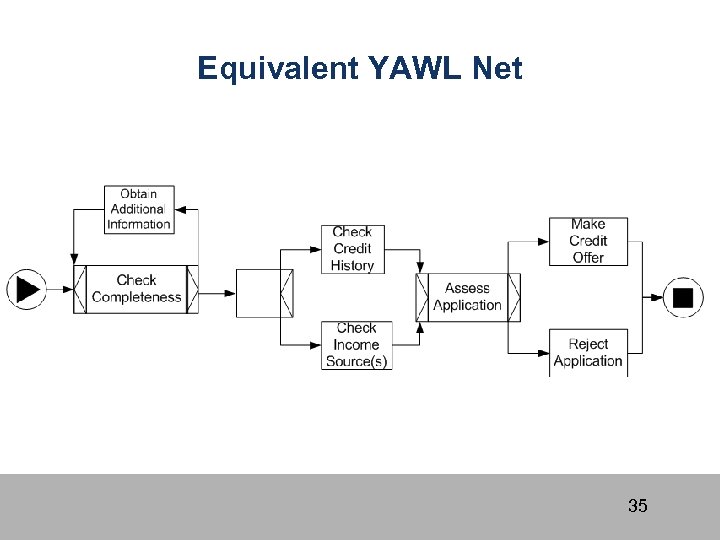

Equivalent YAWL Net 35

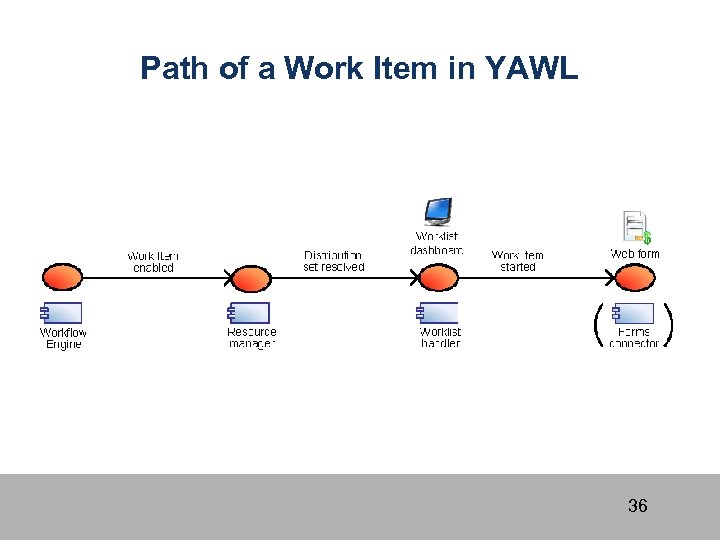

Path of a Work Item in YAWL 36

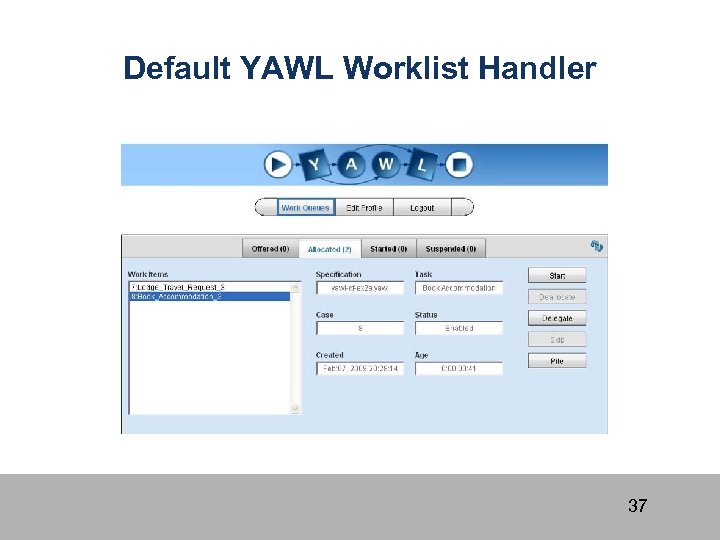

Default YAWL Worklist Handler 37

Process Monitoring & Controlling

Business Process Lifecycle Management • Process identification • • • Process modelling (as-is) Process analysis Process improvement (to-be) Process implementation Process execution Process monitoring/controlling 39 39

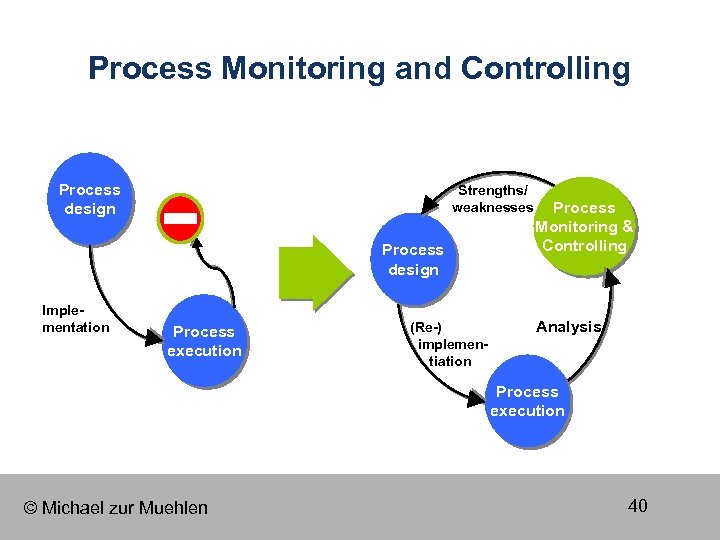

Process Monitoring and Controlling Process design Strengths/ weaknesses Process design Implementation Process execution (Re-) implementiation Process Monitoring & Controlling Analysis Process execution © Michael zur Muehlen 40

Process Monitoring • Technical Monitoring: - System performance measurement (response time, system-load, reliability, etc. ) • Organizational Monitoring: - Measurement of organizational efficiency Objective: enhanced transparency about the current process status (e. g. improvement of the response on customer requests) 41

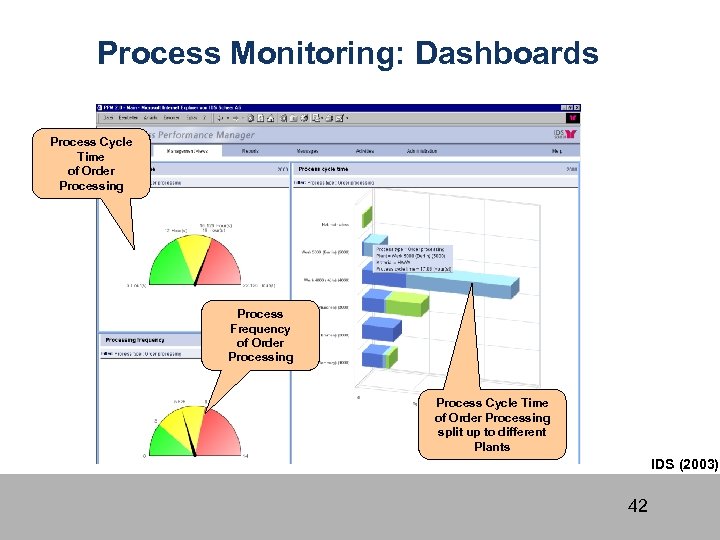

Process Monitoring: Dashboards Process Cycle Time of Order Processing Process Frequency of Order Processing Process Cycle Time of Order Processing split up to different Plants IDS (2003) 42

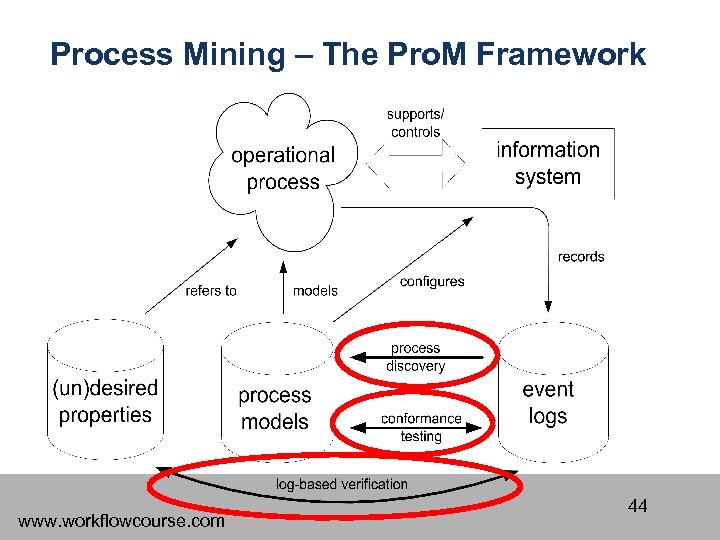

Process Mining – The Pro. M Framework www. workflowcourse. com 44

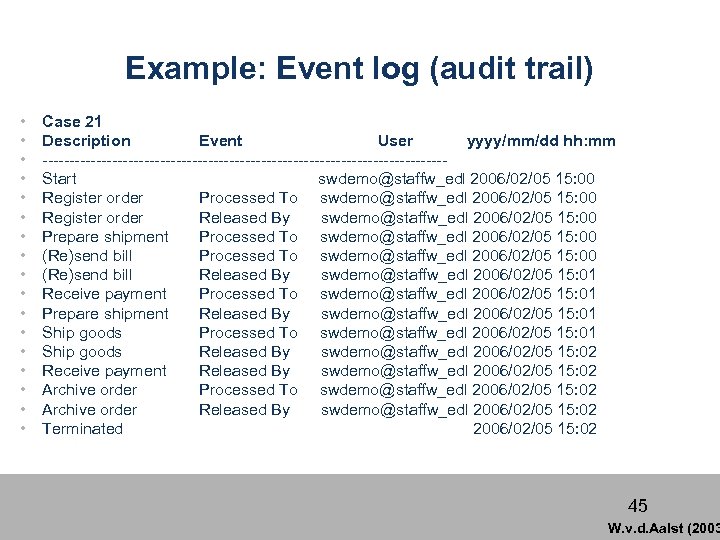

Example: Event log (audit trail) • • • • • Case 21 Description Event User yyyy/mm/dd hh: mm --------------------------------------Start swdemo@staffw_edl 2006/02/05 15: 00 Register order Processed To swdemo@staffw_edl 2006/02/05 15: 00 Register order Released By swdemo@staffw_edl 2006/02/05 15: 00 Prepare shipment Processed To swdemo@staffw_edl 2006/02/05 15: 00 (Re)send bill Released By swdemo@staffw_edl 2006/02/05 15: 01 Receive payment Processed To swdemo@staffw_edl 2006/02/05 15: 01 Prepare shipment Released By swdemo@staffw_edl 2006/02/05 15: 01 Ship goods Processed To swdemo@staffw_edl 2006/02/05 15: 01 Ship goods Released By swdemo@staffw_edl 2006/02/05 15: 02 Receive payment Released By swdemo@staffw_edl 2006/02/05 15: 02 Archive order Processed To swdemo@staffw_edl 2006/02/05 15: 02 Archive order Released By swdemo@staffw_edl 2006/02/05 15: 02 Terminated 2006/02/05 15: 02 45 W. v. d. Aalst (2003

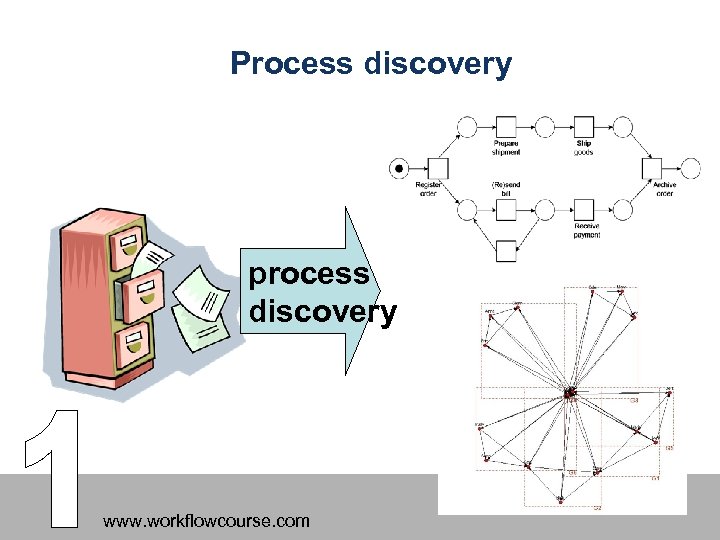

Process discovery process discovery www. workflowcourse. com 46

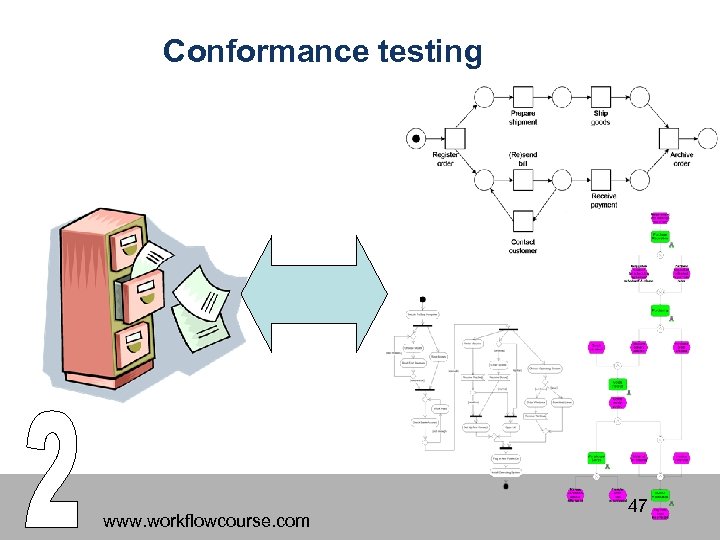

Conformance testing www. workflowcourse. com 47

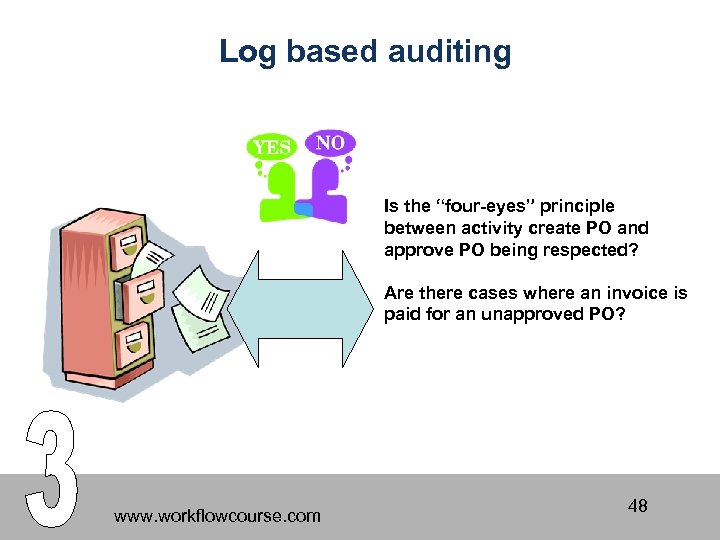

Log based auditing Is the “four-eyes” principle between activity create PO and approve PO being respected? Are there cases where an invoice is paid for an unapproved PO? www. workflowcourse. com 48

Pro. M Demo http: //www. processmining. org/ www. workflowcourse. com 49

Process Controlling • Collation and analysis of runtime data • Comparison of actual- and target data • Active impact on current process execution as well as future process modeling (target) Goal: Improvement of an enterprise‘s adaptability to changes in the environment and in the enterprise itself 50

Process Controlling Ø Objective: ü Establish a system for controlling the process and providing feedback to the people involved Establish Control Points • Control points are activities such as – Inspection, verification, auditing, measuring, counting… – Usually considered business value adding • Without control points and a control system the only way of assessing process performance is customer feedback Þ The process ends up in a reactive mode Þ Poor quality is discovered too late • Location of control points is determined by – Criticality – impact on customer satisfaction – Feasibility – physically and economically possible Laguna & Marklund 51

Process Controlling (cont. ) Develop and Implement Measurements • Involves answering the questions 1. What is to be measured and controlled (Ex. Fed. Ex)? 2. What is currently measured (available data)? 3. Can a business case be made for a new measurement system? 4. What is an adequate sampling method, sampling size & frequency? • Measurements should be meaningful, accurate and timely – Statistical and graphical tools needed to turn data into information. • Five measurement categories: Measures of… – – – Conformance (to given specifications) Response time (lead-time, cycle time) Service levels (degree of availability, service reliability) Repetition (frequency of recurring events such as rework) Cost (Quality, PAF, internal and external failure costs) Laguna & Marklund 52

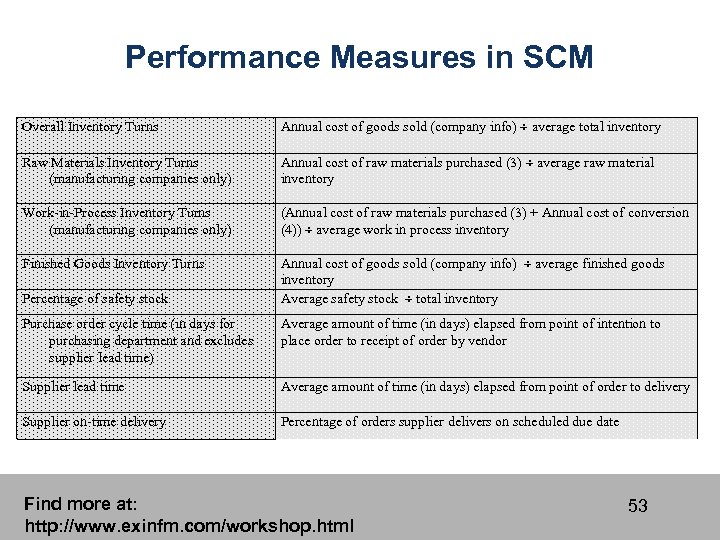

Performance Measures in SCM Overall Inventory Turns Annual cost of goods sold (company info) average total inventory Raw Materials Inventory Turns (manufacturing companies only) Annual cost of raw materials purchased (3) average raw material inventory Work-in-Process Inventory Turns (manufacturing companies only) (Annual cost of raw materials purchased (3) + Annual cost of conversion (4)) average work in process inventory Finished Goods Inventory Turns Annual cost of goods sold (company info) average finished goods inventory Average safety stock total inventory Percentage of safety stock Purchase order cycle time (in days for purchasing department and excludes supplier lead time) Average amount of time (in days) elapsed from point of intention to place order to receipt of order by vendor Supplier lead time Average amount of time (in days) elapsed from point of order to delivery Supplier on-time delivery Percentage of orders supplier delivers on scheduled due date Find more at: http: //www. exinfm. com/workshop. html 53

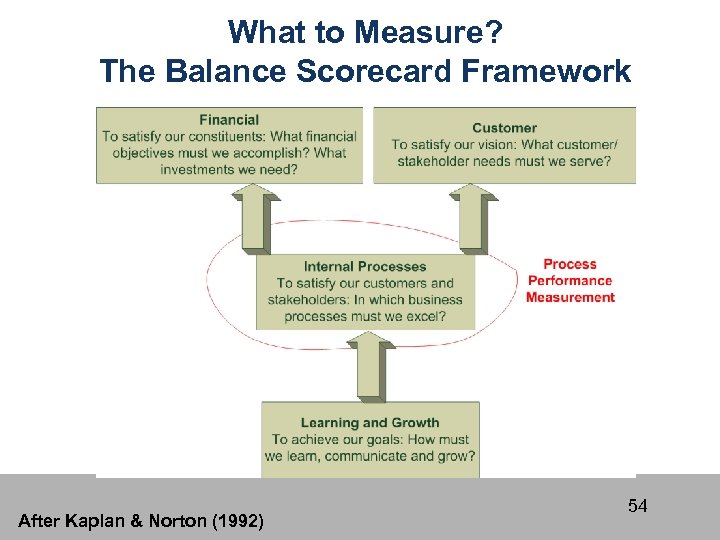

What to Measure? The Balance Scorecard Framework After Kaplan & Norton (1992) 54

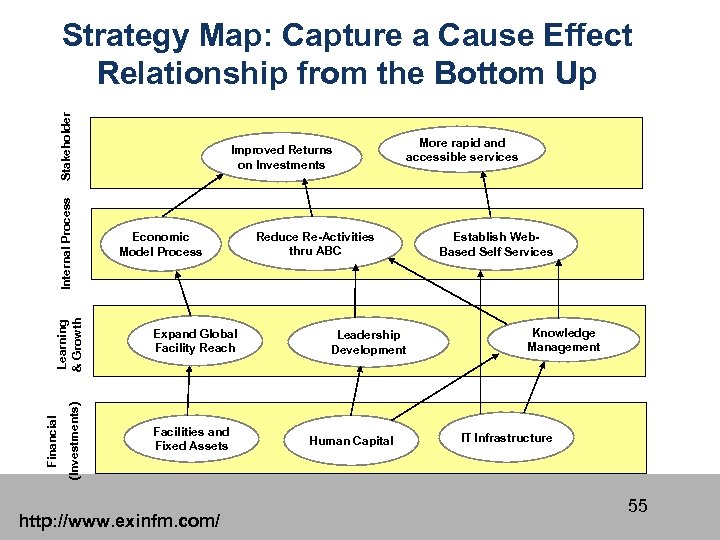

(Investments) Financial Learning & Growth Internal Process Stakeholder Strategy Map: Capture a Cause Effect Relationship from the Bottom Up Improved Returns on Investments Economic Model Process Expand Global Facility Reach Facilities and Fixed Assets http: //www. exinfm. com/ Reduce Re-Activities thru ABC Leadership Development Human Capital More rapid and accessible services Establish Web. Based Self Services Knowledge Management IT Infrastructure 55

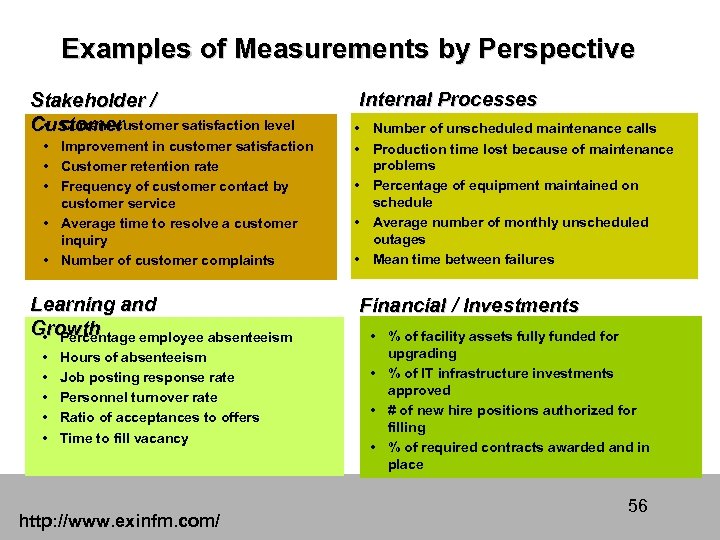

Examples of Measurements by Perspective Stakeholder / • Current customer satisfaction level Customer • Improvement in customer satisfaction • Customer retention rate • Frequency of customer contact by customer service • Average time to resolve a customer inquiry • Number of customer complaints Learning and Growth • Percentage employee absenteeism • • • Hours of absenteeism Job posting response rate Personnel turnover rate Ratio of acceptances to offers Time to fill vacancy http: //www. exinfm. com/ Internal Processes • Number of unscheduled maintenance calls • Production time lost because of maintenance problems • Percentage of equipment maintained on schedule • Average number of monthly unscheduled outages • Mean time between failures Financial / Investments • % of facility assets fully funded for upgrading • % of IT infrastructure investments approved • # of new hire positions authorized for filling • % of required contracts awarded and in place 56

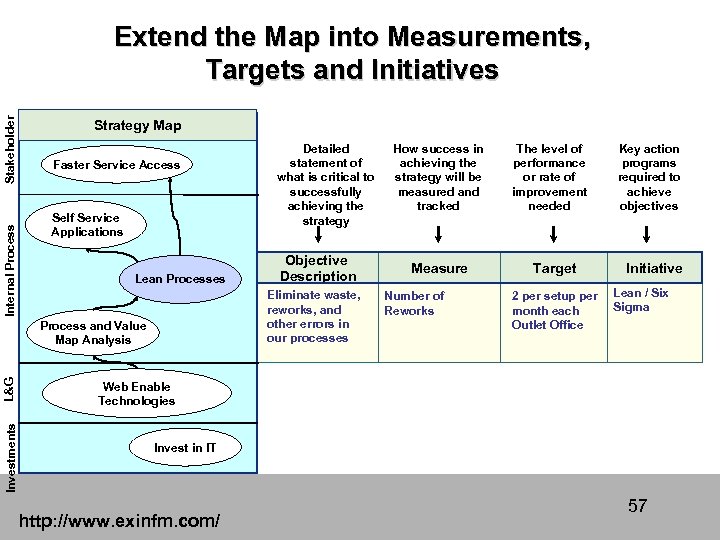

Internal Process Stakeholder Extend the Map into Measurements, Targets and Initiatives Strategy Map Faster Service Access Self Service Applications Lean Processes L&G Objective Description Eliminate waste, reworks, and other errors in our processes Process and Value Map Analysis Investments Detailed statement of what is critical to successfully achieving the strategy How success in achieving the strategy will be measured and tracked Measure Number of Reworks The level of performance or rate of improvement needed Target 2 per setup per month each Outlet Office Key action programs required to achieve objectives Initiative Lean / Six Sigma Web Enable Technologies Invest in IT http: //www. exinfm. com/ 57

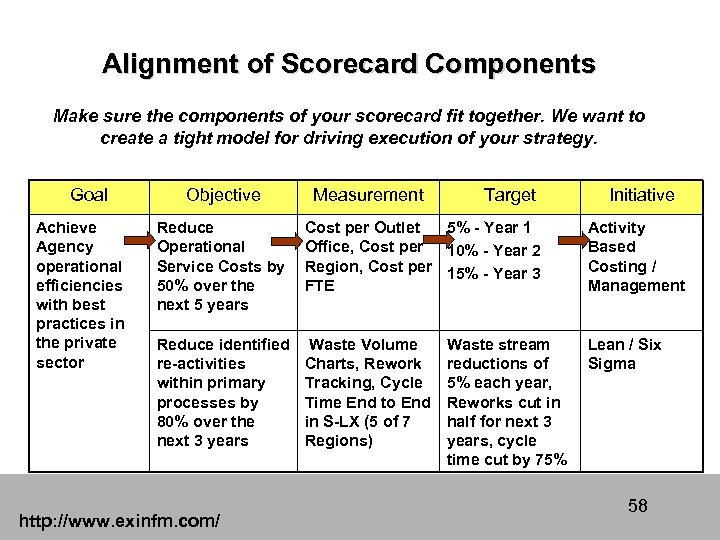

Alignment of Scorecard Components Make sure the components of your scorecard fit together. We want to create a tight model for driving execution of your strategy. Goal Achieve Agency operational efficiencies with best practices in the private sector Objective Measurement Target Initiative Reduce Operational Service Costs by 50% over the next 5 years Cost per Outlet 5% - Year 1 Office, Cost per 10% - Year 2 Region, Cost per 15% - Year 3 FTE Activity Based Costing / Management Reduce identified re-activities within primary processes by 80% over the next 3 years Waste Volume Charts, Rework Tracking, Cycle Time End to End in S-LX (5 of 7 Regions) Lean / Six Sigma http: //www. exinfm. com/ Waste stream reductions of 5% each year, Reworks cut in half for next 3 years, cycle time cut by 75% 58

Exercise • June 2009 exam, question 2 (Masters of ETM version) 59

Guidelines for Performance Measures • At least one measurement per objective. • Measurements define or explain objectives in quantifiable terms: Vague => We will improve customer service Precise => We will improve customer service by reducing response times by 30% by year end. • Measurements should drive change and encourage the right behavior. • Should be able to influence the outcome. http: //www. exinfm. com/ 60

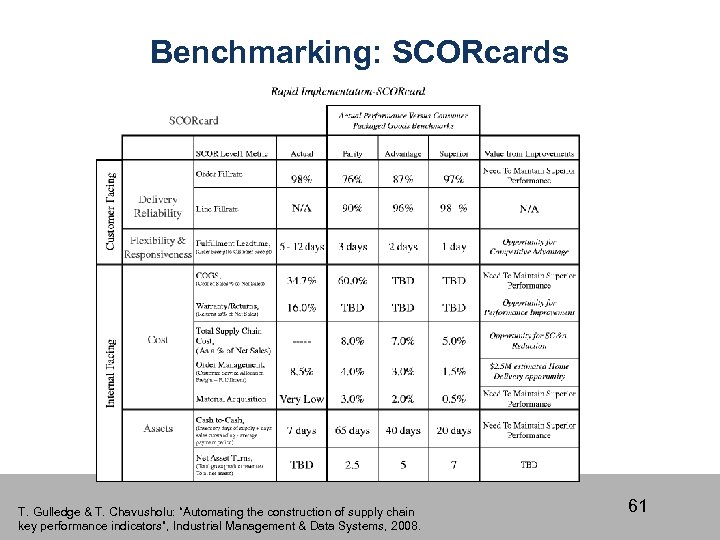

Benchmarking: SCORcards T. Gulledge & T. Chavusholu: “Automating the construction of supply chain key performance indicators”, Industrial Management & Data Systems, 2008. 61

Process Controlling (cont. ) Performing Feedback and Control • Important for stabilizing and improving the process • Objectives of control/corrective action are – Regulation to maintain a certain performance level – Improvement aiming at reducing variability or raising the average performance level (see for example Six Sigma) • Feedback is an important enabler for corrective action – People in the process need to understand how their actions affect the overall process and its performance – Feedback should be constructive and non-punitive • Constructive feedback – Makes people feel that they matter – Encourages involvement and commitment Laguna & Marklund 62

Six Sigma Quality Programs • Six Sigma is originally a company wide initiative at Motorola for breakthrough improvement in quality and productivity – Launched in 1987 • The ongoing success of Six Sigma programs has attracted a number of prestigious firms to adopt the approach – Ex. Ford, GE, AMEX, Honeywell, Nokia, Phillips, Samsung, J. P. Morgan, Maytag, Dupont… Ø Broad definition of Six Sigma programs “A company wide strategic initiative for process improvement in both manufacturing and service organizations with the clear objective of reducing costs and increasing revenues” – Fierce focus on bottom-line results Laguna & Marklund 63

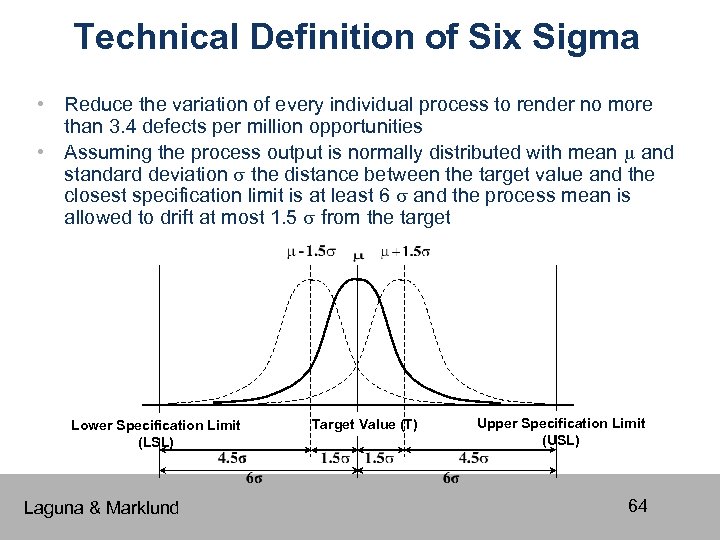

Technical Definition of Six Sigma • Reduce the variation of every individual process to render no more than 3. 4 defects per million opportunities • Assuming the process output is normally distributed with mean and standard deviation the distance between the target value and the closest specification limit is at least 6 and the process mean is allowed to drift at most 1. 5 from the target Lower Specification Limit (LSL) Laguna & Marklund Target Value (T) Upper Specification Limit (USL) 64

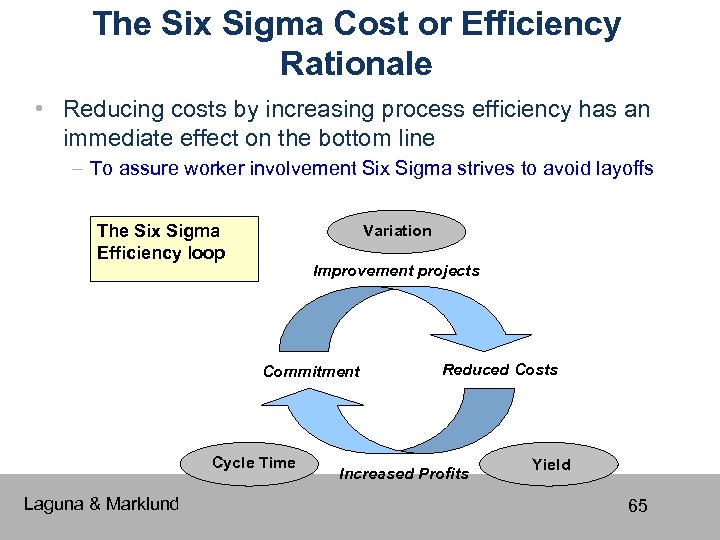

The Six Sigma Cost or Efficiency Rationale • Reducing costs by increasing process efficiency has an immediate effect on the bottom line – To assure worker involvement Six Sigma strives to avoid layoffs The Six Sigma Efficiency loop Variation Improvement projects Commitment Cycle Time Laguna & Marklund Reduced Costs Increased Profits Yield 65

The Six Sigma Cost or Efficiency Rationale • Based on the dimensions of variation, cycle time & yield Variation • Can be divided into two main types 1. Common cause or random variation 2. Special cause or non-random variation • Non-random variation – Relatively few identifiable root causes – First step in reducing the overall variation is to eliminate nonrandom variation by removing its root causes • Random variation – The result of many different causes – Inherent in the process and can only be affected by changing the process design Laguna & Marklund 66

The Six Sigma Cost or Efficiency Rationale Variation (cont. ) • Important concepts to understand the impact of variation – Dispersion – Predictability – Centering • Dispersion – Magnitude of variation in the measured process characteristics. • Predictability – Do the measured process characteristics belong to the same probability distribution over time? – For a predictable process, dispersion refers to the width of the pdf. • Centering – How well the process mean is aligned with the process target value Laguna & Marklund 67

The Six Sigma Cost or Efficiency Rationale Variation (cont. ) • • Ideally the process should be predictable, with low dispersion, and well centered Standard approach for reducing variability in Six Sigma programs 1. Eliminate special cause variation to reduce overall dispersion and improve predictability 2. Reduce dispersion of the predictable process 3. Center the process to the specified target • Six Sigma use traditional tools for quality and process control/analysis – Basic statistical tools for data analysis – The 7 QC tools Laguna & Marklund 68

The Six Sigma Cost or Efficiency Rationale Cycle time and Yield • Cycle time (lead-time, response time) – The time a job spends in the process • Yield (productivity) – Amount of output per unit of input or per unit time • Improvement in cycle time and yield follow the same tactic as for variation – Gain predictability, reduce dispersion and center to target • The target is usually broadly defined as – Minimize cycle time and Maximize yield • Six Sigma principle – Improvement in average cycle time and yield should not be made at the expense of increased variation Laguna & Marklund 69

The Six Sigma Revenue or Effectiveness Rationale • Determinants of the company’s revenues – Sales volume closely related to market share – Sales prices Þ Revenues contingent on how well the firm can satisfy the external customers’ desires Ø An important Six Sigma Success factor is the focus on internal and external customer requirements in every single improvement project Laguna & Marklund 70

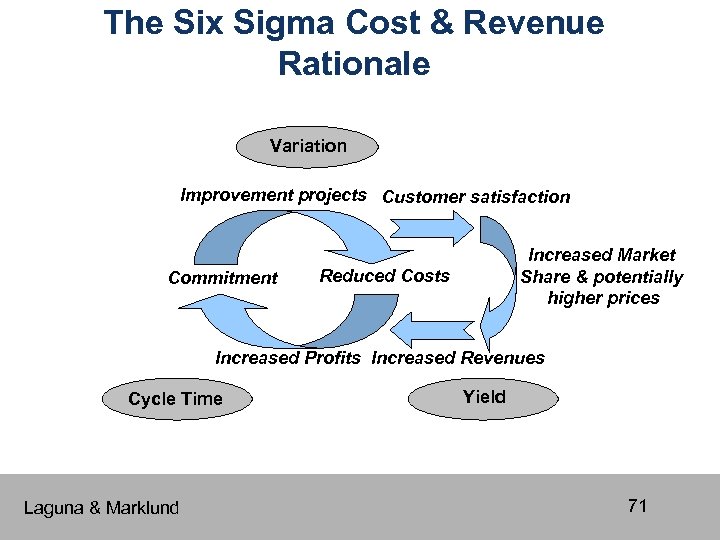

The Six Sigma Cost & Revenue Rationale Variation Improvement projects Customer satisfaction Commitment Increased Market Share & potentially higher prices Reduced Costs Increased Profits Increased Revenues Cycle Time Laguna & Marklund Yield 71

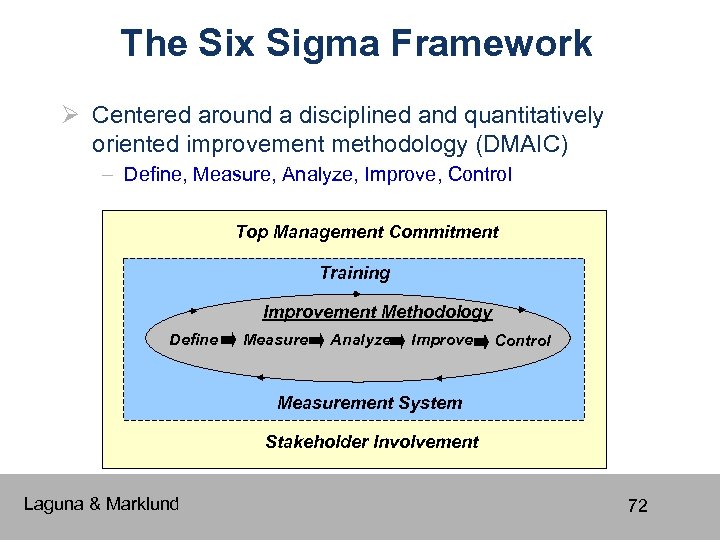

The Six Sigma Framework Ø Centered around a disciplined and quantitatively oriented improvement methodology (DMAIC) – Define, Measure, Analyze, Improve, Control Top Management Commitment Training Improvement Methodology Define Measure Analyze Improve Control Measurement System Stakeholder Involvement Laguna & Marklund 72

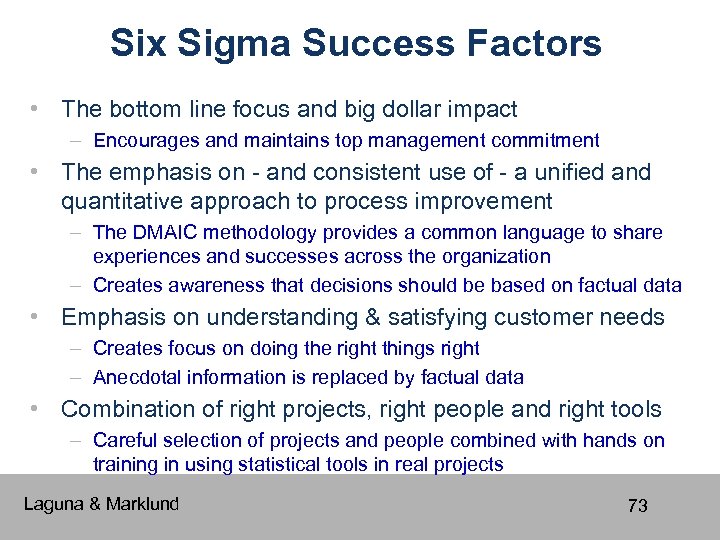

Six Sigma Success Factors • The bottom line focus and big dollar impact – Encourages and maintains top management commitment • The emphasis on - and consistent use of - a unified and quantitative approach to process improvement – The DMAIC methodology provides a common language to share experiences and successes across the organization – Creates awareness that decisions should be based on factual data • Emphasis on understanding & satisfying customer needs – Creates focus on doing the right things right – Anecdotal information is replaced by factual data • Combination of right projects, right people and right tools – Careful selection of projects and people combined with hands on training in using statistical tools in real projects Laguna & Marklund 73

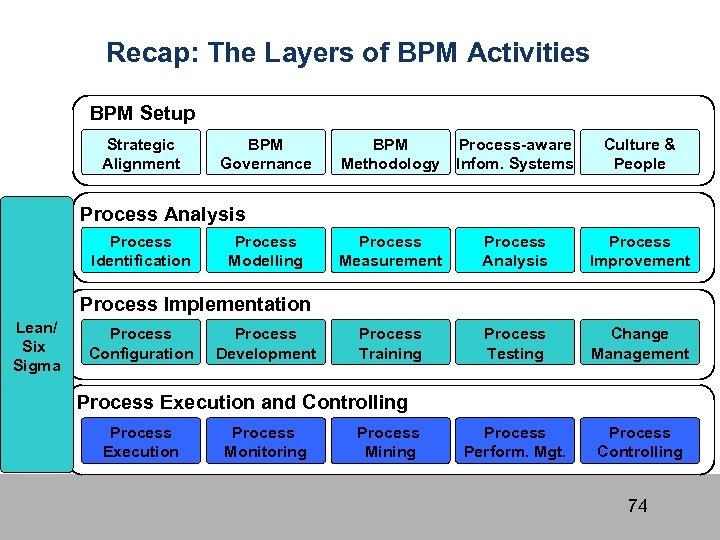

Recap: The Layers of BPM Activities BPM Setup Strategic Alignment BPM Governance BPM Process-aware Methodology Infom. Systems Culture & People Process Analysis Process Identification Process Modelling Process Measurement Process Analysis Process Improvement Process Training Process Testing Change Management Process Perform. Mgt. Process Controlling Process Implementation Lean/ Six Sigma Process Configuration Process Development Process Execution and Controlling Process Execution Process Monitoring Process Mining 74

Project (see project description on the course web page)

Readings • P. Harmon. Business Process Architecture and the Process-Centric Company, BPTrends Newsletter, March 2003. http: //tinyurl. com/c 88 rlp • P. Harmon. Business Processes at a New Company: What Do You Do First? . BPTrends Newsleter, October 2004. http: //tinyurl. com/cfckrf 76

38878310f4ec2b653374a8f184f5a017.ppt