b067d5c60a4a5778b6311d4b1b1bea96.ppt

- Количество слайдов: 38

MP-Series™ & TL-Series™ Electric Cylinders Insert Photo Here pyright © 2009 Rockwell Automation, Inc. All rights reserved. Flexible, controlled linear motion Product Marketing Linear Motion Solutions

MP-Series™ & TL-Series™ Electric Cylinders Insert Photo Here pyright © 2009 Rockwell Automation, Inc. All rights reserved. Flexible, controlled linear motion Product Marketing Linear Motion Solutions

Topics: Introduction to Electric Cylinders 1. Product Line Overview 2. Applications 3. Application Development, Setup & Programming 4. Commercial Information Copyright © 2009 Rockwell Automation, Inc. All rights reserved. 2

Topics: Introduction to Electric Cylinders 1. Product Line Overview 2. Applications 3. Application Development, Setup & Programming 4. Commercial Information Copyright © 2009 Rockwell Automation, Inc. All rights reserved. 2

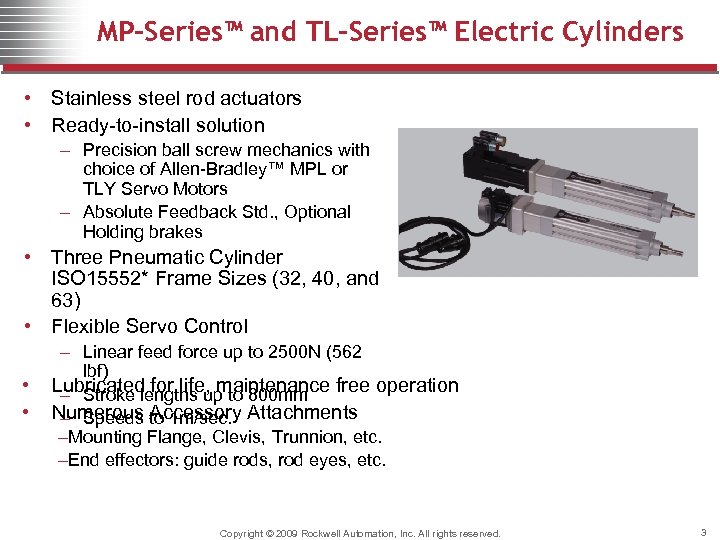

MP-Series™ and TL-Series™ Electric Cylinders • Stainless steel rod actuators • Ready-to-install solution – Precision ball screw mechanics with choice of Allen-Bradley™ MPL or TLY Servo Motors – Absolute Feedback Std. , Optional Holding brakes • Three Pneumatic Cylinder ISO 15552* Frame Sizes (32, 40, and 63) • Flexible Servo Control – Linear feed force up to 2500 N (562 lbf) • Lubricated for life, maintenance free operation – Stroke lengths up to 800 mm • Numerous Accessory Attachments – Speeds to 1 m/sec. –Mounting Flange, Clevis, Trunnion, etc. –End effectors: guide rods, rod eyes, etc. Copyright © 2009 Rockwell Automation, Inc. All rights reserved. 3

MP-Series™ and TL-Series™ Electric Cylinders • Stainless steel rod actuators • Ready-to-install solution – Precision ball screw mechanics with choice of Allen-Bradley™ MPL or TLY Servo Motors – Absolute Feedback Std. , Optional Holding brakes • Three Pneumatic Cylinder ISO 15552* Frame Sizes (32, 40, and 63) • Flexible Servo Control – Linear feed force up to 2500 N (562 lbf) • Lubricated for life, maintenance free operation – Stroke lengths up to 800 mm • Numerous Accessory Attachments – Speeds to 1 m/sec. –Mounting Flange, Clevis, Trunnion, etc. –End effectors: guide rods, rod eyes, etc. Copyright © 2009 Rockwell Automation, Inc. All rights reserved. 3

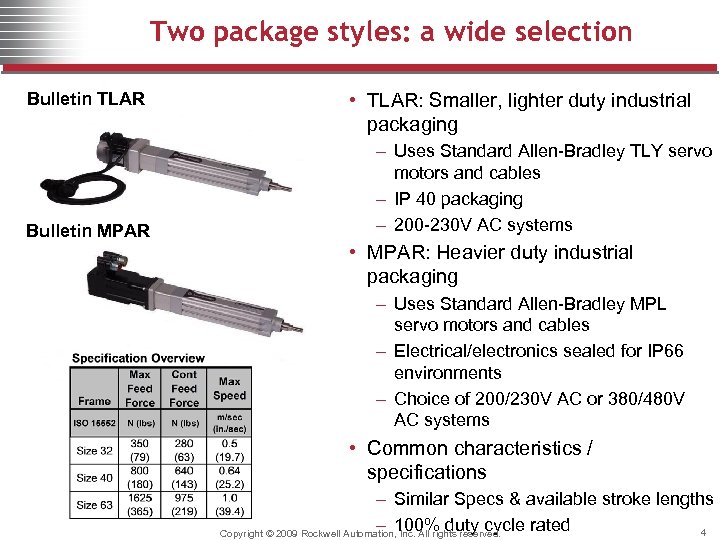

Two package styles: a wide selection Bulletin TLAR Bulletin MPAR • TLAR: Smaller, lighter duty industrial packaging – Uses Standard Allen-Bradley TLY servo motors and cables – IP 40 packaging – 200 -230 V AC systems • MPAR: Heavier duty industrial packaging – Uses Standard Allen-Bradley MPL servo motors and cables – Electrical/electronics sealed for IP 66 environments – Choice of 200/230 V AC or 380/480 V AC systems • Common characteristics / specifications – Similar Specs & available stroke lengths – 100% duty cycle rated 4 Copyright © 2009 Rockwell Automation, Inc. All rights reserved.

Two package styles: a wide selection Bulletin TLAR Bulletin MPAR • TLAR: Smaller, lighter duty industrial packaging – Uses Standard Allen-Bradley TLY servo motors and cables – IP 40 packaging – 200 -230 V AC systems • MPAR: Heavier duty industrial packaging – Uses Standard Allen-Bradley MPL servo motors and cables – Electrical/electronics sealed for IP 66 environments – Choice of 200/230 V AC or 380/480 V AC systems • Common characteristics / specifications – Similar Specs & available stroke lengths – 100% duty cycle rated 4 Copyright © 2009 Rockwell Automation, Inc. All rights reserved.

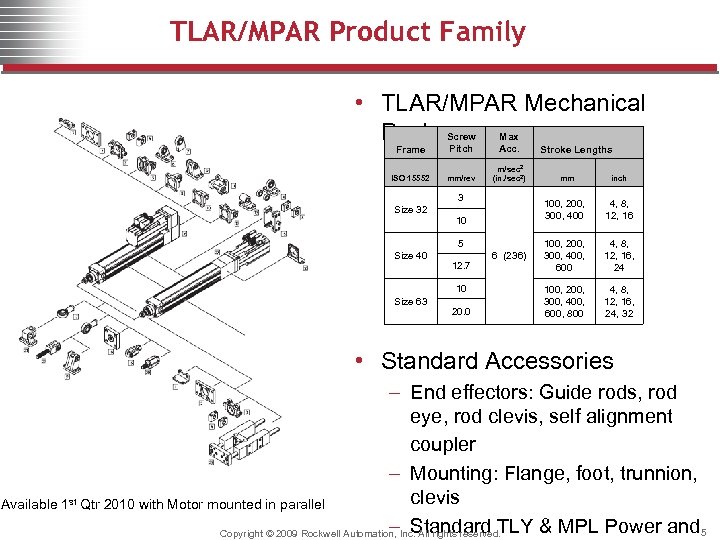

TLAR/MPAR Product Family • TLAR/MPAR Mechanical Package Max Screw Frame Pitch Acc. ISO 15552 mm/rev m/sec 2 (in. /sec 2) 10 5 Size 40 12. 7 10 Size 63 20. 0 6 (236) mm inch 100, 200, 300, 400 3 Size 32 Stroke Lengths 4, 8, 12, 16 100, 200, 300, 400, 600 4, 8, 12, 16, 24 100, 200, 300, 400, 600, 800 4, 8, 12, 16, 24, 32 • Standard Accessories – End effectors: Guide rods, rod eye, rod clevis, self alignment coupler – Mounting: Flange, foot, trunnion, clevis Available 1 st Qtr 2010 with Motor mounted in parallel – Standard TLY & MPL Power and 5 Copyright © 2009 Rockwell Automation, Inc. All rights reserved.

TLAR/MPAR Product Family • TLAR/MPAR Mechanical Package Max Screw Frame Pitch Acc. ISO 15552 mm/rev m/sec 2 (in. /sec 2) 10 5 Size 40 12. 7 10 Size 63 20. 0 6 (236) mm inch 100, 200, 300, 400 3 Size 32 Stroke Lengths 4, 8, 12, 16 100, 200, 300, 400, 600 4, 8, 12, 16, 24 100, 200, 300, 400, 600, 800 4, 8, 12, 16, 24, 32 • Standard Accessories – End effectors: Guide rods, rod eye, rod clevis, self alignment coupler – Mounting: Flange, foot, trunnion, clevis Available 1 st Qtr 2010 with Motor mounted in parallel – Standard TLY & MPL Power and 5 Copyright © 2009 Rockwell Automation, Inc. All rights reserved.

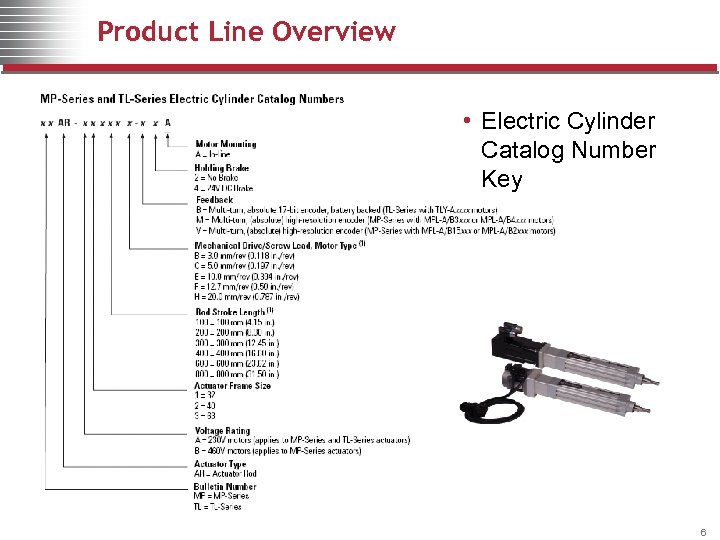

Product Line Overview • Electric Cylinder Catalog Number Key 6

Product Line Overview • Electric Cylinder Catalog Number Key 6

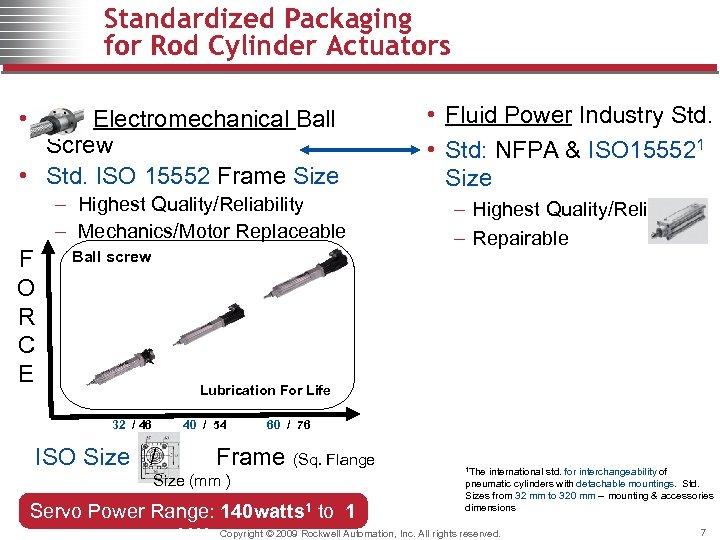

Standardized Packaging for Rod Cylinder Actuators • Electromechanical Ball Screw • Std. ISO 15552 Frame Size – Highest Quality/Reliability – Mechanics/Motor Replaceable F O R C E Ball screw • Fluid Power Industry Std. • Std: NFPA & ISO 155521 Size – Highest Quality/Reliability – Repairable Lubrication For Life 32 / 46 40 / 54 60 / 76 ISO Size / Frame (Sq. Flange Size (mm ) Servo Power Range: 140 watts 1 to 1 1 The international std. for interchangeability of pneumatic cylinders with detachable mountings. Std. Sizes from 32 mm to 320 mm -- mounting & accessories dimensions Copyright © 2009 Rockwell Automation, Inc. All rights reserved. 7

Standardized Packaging for Rod Cylinder Actuators • Electromechanical Ball Screw • Std. ISO 15552 Frame Size – Highest Quality/Reliability – Mechanics/Motor Replaceable F O R C E Ball screw • Fluid Power Industry Std. • Std: NFPA & ISO 155521 Size – Highest Quality/Reliability – Repairable Lubrication For Life 32 / 46 40 / 54 60 / 76 ISO Size / Frame (Sq. Flange Size (mm ) Servo Power Range: 140 watts 1 to 1 1 The international std. for interchangeability of pneumatic cylinders with detachable mountings. Std. Sizes from 32 mm to 320 mm -- mounting & accessories dimensions Copyright © 2009 Rockwell Automation, Inc. All rights reserved. 7

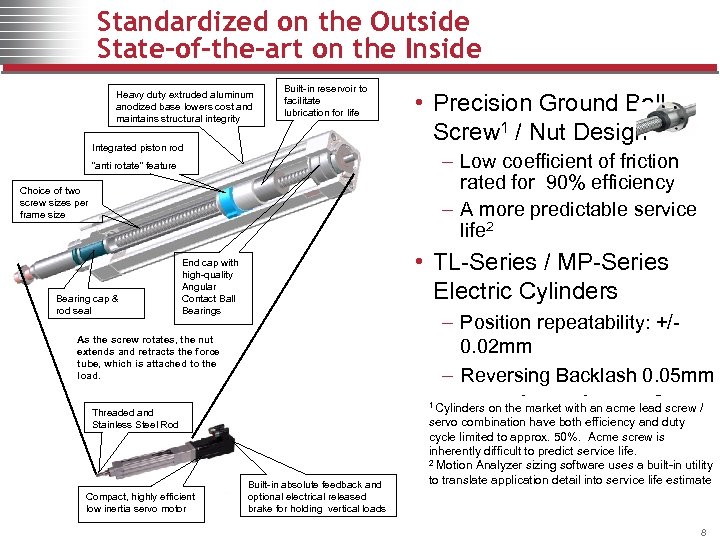

Standardized on the Outside State-of-the-art on the Inside Heavy duty extruded aluminum anodized base lowers cost and maintains structural integrity Built-in reservoir to facilitate lubrication for life Integrated piston rod • Precision Ground Ball Screw 1 / Nut Design – Low coefficient of friction rated for 90% efficiency – A more predictable service life 2 “anti rotate” feature Choice of two screw sizes per frame size Bearing cap & rod seal • TL-Series / MP-Series Electric Cylinders End cap with high-quality Angular Contact Ball Bearings As the screw rotates, the nut extends and retracts the force tube, which is attached to the load. 1 Threaded and Stainless Steel Rod Compact, highly efficient low inertia servo motor Built-in absolute feedback and optional electrical released brake for holding vertical loads – Position repeatability: +/- 0. 02 mm – Reversing Backlash 0. 05 mm – Rated for 100% Duty Cycle Cylinders on the market with an acme lead screw / servo combination have both efficiency and duty cycle limited to approx. 50%. Acme screw is inherently difficult to predict service life. 2 Motion Analyzer sizing software uses a built-in utility to translate application detail into service life estimate 8

Standardized on the Outside State-of-the-art on the Inside Heavy duty extruded aluminum anodized base lowers cost and maintains structural integrity Built-in reservoir to facilitate lubrication for life Integrated piston rod • Precision Ground Ball Screw 1 / Nut Design – Low coefficient of friction rated for 90% efficiency – A more predictable service life 2 “anti rotate” feature Choice of two screw sizes per frame size Bearing cap & rod seal • TL-Series / MP-Series Electric Cylinders End cap with high-quality Angular Contact Ball Bearings As the screw rotates, the nut extends and retracts the force tube, which is attached to the load. 1 Threaded and Stainless Steel Rod Compact, highly efficient low inertia servo motor Built-in absolute feedback and optional electrical released brake for holding vertical loads – Position repeatability: +/- 0. 02 mm – Reversing Backlash 0. 05 mm – Rated for 100% Duty Cycle Cylinders on the market with an acme lead screw / servo combination have both efficiency and duty cycle limited to approx. 50%. Acme screw is inherently difficult to predict service life. 2 Motion Analyzer sizing software uses a built-in utility to translate application detail into service life estimate 8

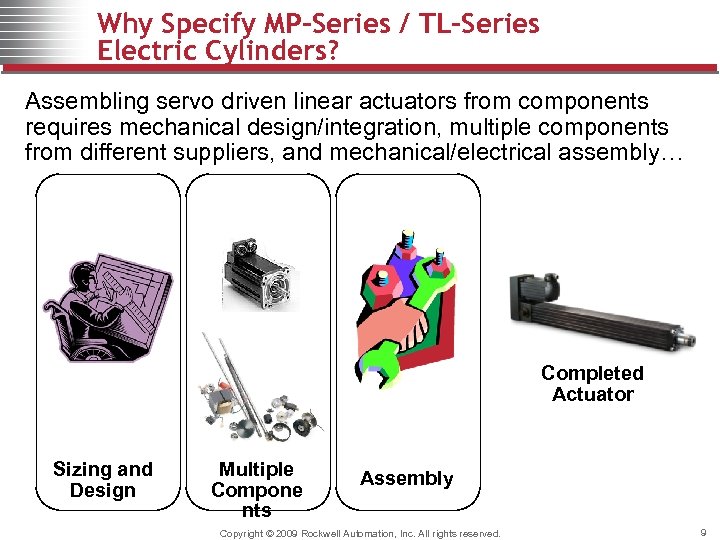

Why Specify MP-Series / TL-Series Electric Cylinders? Assembling servo driven linear actuators from components requires mechanical design/integration, multiple components from different suppliers, and mechanical/electrical assembly… Completed Actuator Sizing and Design Multiple Compone nts Assembly Copyright © 2009 Rockwell Automation, Inc. All rights reserved. 9

Why Specify MP-Series / TL-Series Electric Cylinders? Assembling servo driven linear actuators from components requires mechanical design/integration, multiple components from different suppliers, and mechanical/electrical assembly… Completed Actuator Sizing and Design Multiple Compone nts Assembly Copyright © 2009 Rockwell Automation, Inc. All rights reserved. 9

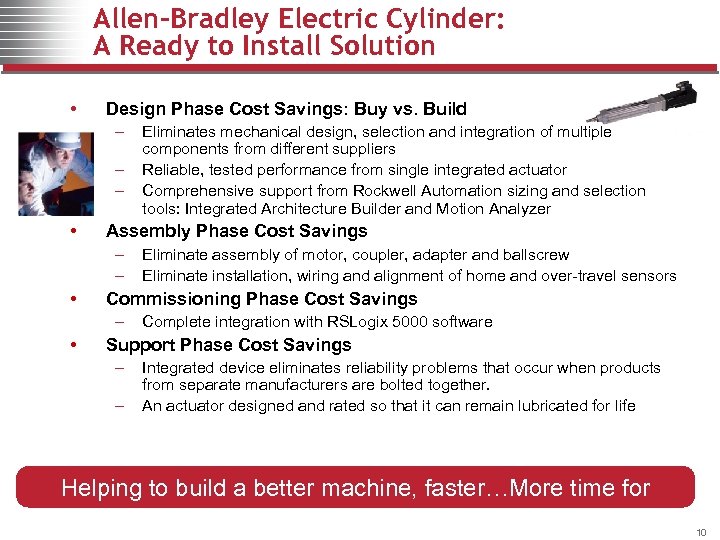

Allen-Bradley Electric Cylinder: A Ready to Install Solution • Design Phase Cost Savings: Buy vs. Build – – – • Assembly Phase Cost Savings – – • Eliminate assembly of motor, coupler, adapter and ballscrew Eliminate installation, wiring and alignment of home and over-travel sensors Commissioning Phase Cost Savings – • Eliminates mechanical design, selection and integration of multiple components from different suppliers Reliable, tested performance from single integrated actuator Comprehensive support from Rockwell Automation sizing and selection tools: Integrated Architecture Builder and Motion Analyzer Complete integration with RSLogix 5000 software Support Phase Cost Savings – – Integrated device eliminates reliability problems that occur when products from separate manufacturers are bolted together. An actuator designed and rated so that it can remain lubricated for life Helping to build a better machine, faster…More time for innovation 10

Allen-Bradley Electric Cylinder: A Ready to Install Solution • Design Phase Cost Savings: Buy vs. Build – – – • Assembly Phase Cost Savings – – • Eliminate assembly of motor, coupler, adapter and ballscrew Eliminate installation, wiring and alignment of home and over-travel sensors Commissioning Phase Cost Savings – • Eliminates mechanical design, selection and integration of multiple components from different suppliers Reliable, tested performance from single integrated actuator Comprehensive support from Rockwell Automation sizing and selection tools: Integrated Architecture Builder and Motion Analyzer Complete integration with RSLogix 5000 software Support Phase Cost Savings – – Integrated device eliminates reliability problems that occur when products from separate manufacturers are bolted together. An actuator designed and rated so that it can remain lubricated for life Helping to build a better machine, faster…More time for innovation 10

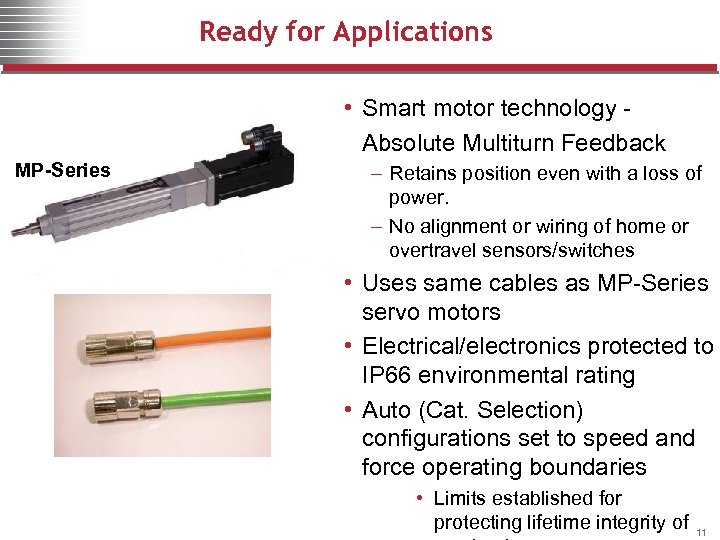

Ready for Applications • Smart motor technology - Absolute Multiturn Feedback MP-Series – Retains position even with a loss of power. – No alignment or wiring of home or overtravel sensors/switches • Uses same cables as MP-Series servo motors • Electrical/electronics protected to IP 66 environmental rating • Auto (Cat. Selection) configurations set to speed and force operating boundaries • Limits established for protecting lifetime integrity of 11

Ready for Applications • Smart motor technology - Absolute Multiturn Feedback MP-Series – Retains position even with a loss of power. – No alignment or wiring of home or overtravel sensors/switches • Uses same cables as MP-Series servo motors • Electrical/electronics protected to IP 66 environmental rating • Auto (Cat. Selection) configurations set to speed and force operating boundaries • Limits established for protecting lifetime integrity of 11

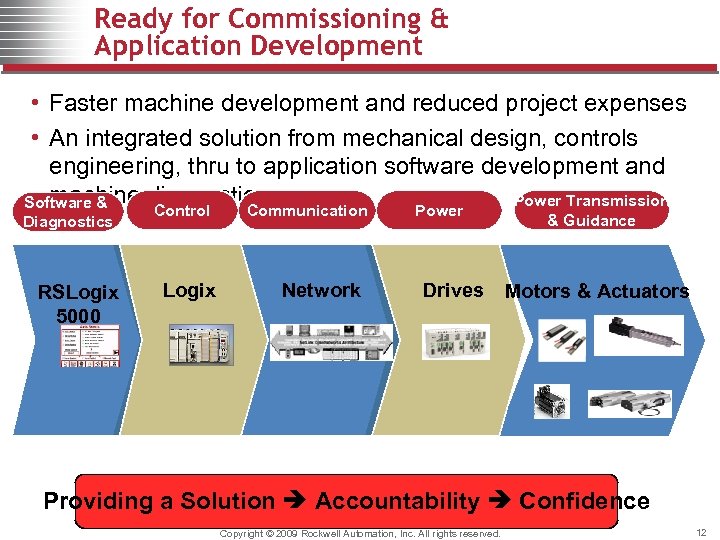

Ready for Commissioning & Application Development • Faster machine development and reduced project expenses • An integrated solution from mechanical design, controls engineering, thru to application software development and machine diagnostics Power Transmission Software & Diagnostics RSLogix 5000 Control Communication Logix Network Power Drives & Guidance Motors & Actuators Providing a Solution Accountability Confidence Copyright © 2009 Rockwell Automation, Inc. All rights reserved. 12

Ready for Commissioning & Application Development • Faster machine development and reduced project expenses • An integrated solution from mechanical design, controls engineering, thru to application software development and machine diagnostics Power Transmission Software & Diagnostics RSLogix 5000 Control Communication Logix Network Power Drives & Guidance Motors & Actuators Providing a Solution Accountability Confidence Copyright © 2009 Rockwell Automation, Inc. All rights reserved. 12

Topics: Introduction to Electric Cylinders 1. Product Line Overview 2. Applications 3. Application Development, Setup & Programming 4. Commercial Information Copyright © 2009 Rockwell Automation, Inc. All rights reserved. 13

Topics: Introduction to Electric Cylinders 1. Product Line Overview 2. Applications 3. Application Development, Setup & Programming 4. Commercial Information Copyright © 2009 Rockwell Automation, Inc. All rights reserved. 13

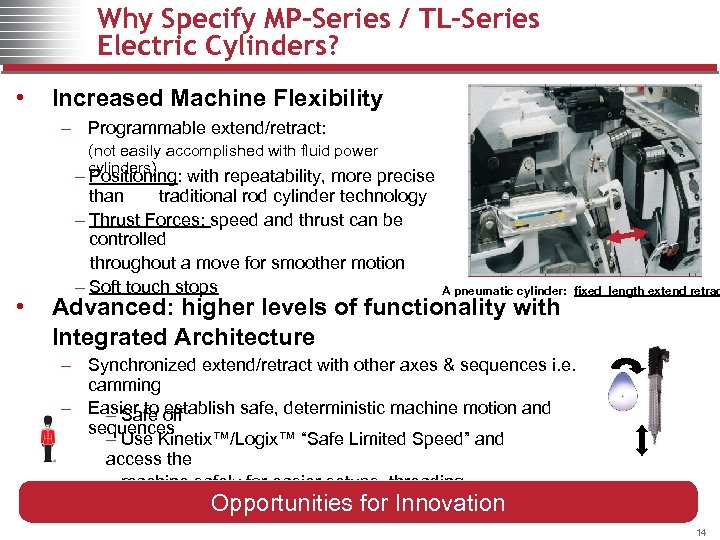

Why Specify MP-Series / TL-Series Electric Cylinders? • Increased Machine Flexibility – Programmable extend/retract: (not easily accomplished with fluid power cylinders) • – Positioning: with repeatability, more precise than traditional rod cylinder technology – Thrust Forces: speed and thrust can be controlled throughout a move for smoother motion – Soft touch stops A pneumatic cylinder: Advanced: higher levels of functionality with Integrated Architecture fixed length extend retrac – Synchronized extend/retract with other axes & sequences i. e. camming – Easier to establish safe, deterministic machine motion and – Safe off sequences – Use Kinetix™/Logix™ “Safe Limited Speed” and access the machine safely for easier setups, threading operations, etc. Opportunities for Innovation 14

Why Specify MP-Series / TL-Series Electric Cylinders? • Increased Machine Flexibility – Programmable extend/retract: (not easily accomplished with fluid power cylinders) • – Positioning: with repeatability, more precise than traditional rod cylinder technology – Thrust Forces: speed and thrust can be controlled throughout a move for smoother motion – Soft touch stops A pneumatic cylinder: Advanced: higher levels of functionality with Integrated Architecture fixed length extend retrac – Synchronized extend/retract with other axes & sequences i. e. camming – Easier to establish safe, deterministic machine motion and – Safe off sequences – Use Kinetix™/Logix™ “Safe Limited Speed” and access the machine safely for easier setups, threading operations, etc. Opportunities for Innovation 14

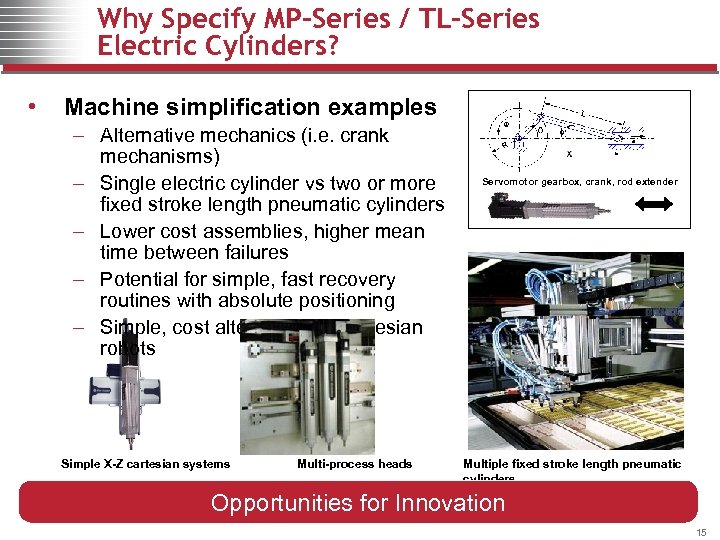

Why Specify MP-Series / TL-Series Electric Cylinders? • Machine simplification examples – Alternative mechanics (i. e. crank mechanisms) – Single electric cylinder vs two or more fixed stroke length pneumatic cylinders – Lower cost assemblies, higher mean time between failures – Potential for simple, fast recovery routines with absolute positioning – Simple, cost alternative for cartesian robots Simple X-Z cartesian systems Multi-process heads Servomotor gearbox, crank, rod extender Multiple fixed stroke length pneumatic cylinders Opportunities for Innovation 15

Why Specify MP-Series / TL-Series Electric Cylinders? • Machine simplification examples – Alternative mechanics (i. e. crank mechanisms) – Single electric cylinder vs two or more fixed stroke length pneumatic cylinders – Lower cost assemblies, higher mean time between failures – Potential for simple, fast recovery routines with absolute positioning – Simple, cost alternative for cartesian robots Simple X-Z cartesian systems Multi-process heads Servomotor gearbox, crank, rod extender Multiple fixed stroke length pneumatic cylinders Opportunities for Innovation 15

Why Specify MP-Series / TL-Series Electric Cylinders? • Energy efficient alternative to fluid power actuators – Compressed Air is the most expensive energy medium in a production facility. – About 88% of the TCO for pneumatics is not in the purchase price but in the operation and maintenance – Air leaks are often considered harmless and not taken seriously Reduce cost and maintenance through elimination of air compressors, filters and plumbing – • Clean, quiet, efficient operation 16

Why Specify MP-Series / TL-Series Electric Cylinders? • Energy efficient alternative to fluid power actuators – Compressed Air is the most expensive energy medium in a production facility. – About 88% of the TCO for pneumatics is not in the purchase price but in the operation and maintenance – Air leaks are often considered harmless and not taken seriously Reduce cost and maintenance through elimination of air compressors, filters and plumbing – • Clean, quiet, efficient operation 16

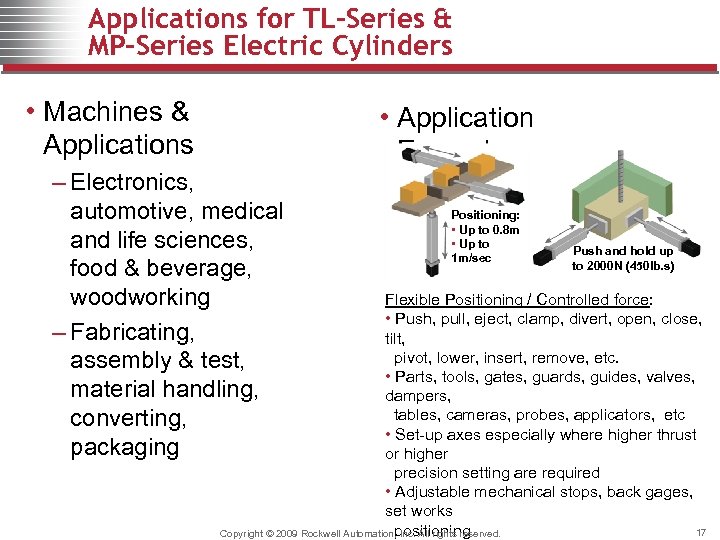

Applications for TL-Series & MP-Series Electric Cylinders • Machines & Applications • Application Examples – Electronics, automotive, medical and life sciences, food & beverage, woodworking – Fabricating, assembly & test, material handling, converting, packaging Positioning: • Up to 0. 8 m • Up to 1 m/sec Push and hold up to 2000 N (450 lb. s) Flexible Positioning / Controlled force: • Push, pull, eject, clamp, divert, open, close, tilt, pivot, lower, insert, remove, etc. • Parts, tools, gates, guards, guides, valves, dampers, tables, cameras, probes, applicators, etc • Set-up axes especially where higher thrust or higher precision setting are required • Adjustable mechanical stops, back gages, set works positioning 17 Copyright © 2009 Rockwell Automation, Inc. All rights reserved.

Applications for TL-Series & MP-Series Electric Cylinders • Machines & Applications • Application Examples – Electronics, automotive, medical and life sciences, food & beverage, woodworking – Fabricating, assembly & test, material handling, converting, packaging Positioning: • Up to 0. 8 m • Up to 1 m/sec Push and hold up to 2000 N (450 lb. s) Flexible Positioning / Controlled force: • Push, pull, eject, clamp, divert, open, close, tilt, pivot, lower, insert, remove, etc. • Parts, tools, gates, guards, guides, valves, dampers, tables, cameras, probes, applicators, etc • Set-up axes especially where higher thrust or higher precision setting are required • Adjustable mechanical stops, back gages, set works positioning 17 Copyright © 2009 Rockwell Automation, Inc. All rights reserved.

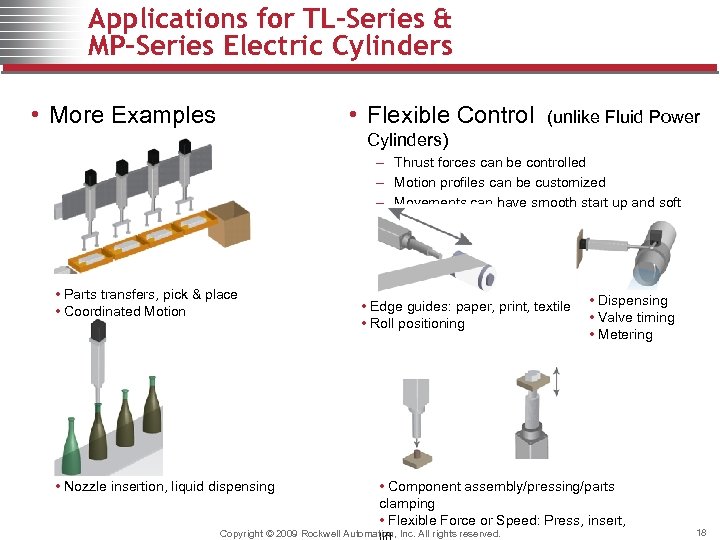

Applications for TL-Series & MP-Series Electric Cylinders • More Examples • Flexible Control (unlike Fluid Power Cylinders) – Thrust forces can be controlled – Motion profiles can be customized – Movements can have smooth start up and soft stops • Parts transfers, pick & place • Coordinated Motion • Nozzle insertion, liquid dispensing • Edge guides: paper, print, textile • Roll positioning • Dispensing • Valve timing • Metering • Component assembly/pressing/parts clamping • Flexible Force or Speed: Press, insert, Copyright © 2009 Rockwell Automation, Inc. All rights reserved. 18

Applications for TL-Series & MP-Series Electric Cylinders • More Examples • Flexible Control (unlike Fluid Power Cylinders) – Thrust forces can be controlled – Motion profiles can be customized – Movements can have smooth start up and soft stops • Parts transfers, pick & place • Coordinated Motion • Nozzle insertion, liquid dispensing • Edge guides: paper, print, textile • Roll positioning • Dispensing • Valve timing • Metering • Component assembly/pressing/parts clamping • Flexible Force or Speed: Press, insert, Copyright © 2009 Rockwell Automation, Inc. All rights reserved. 18

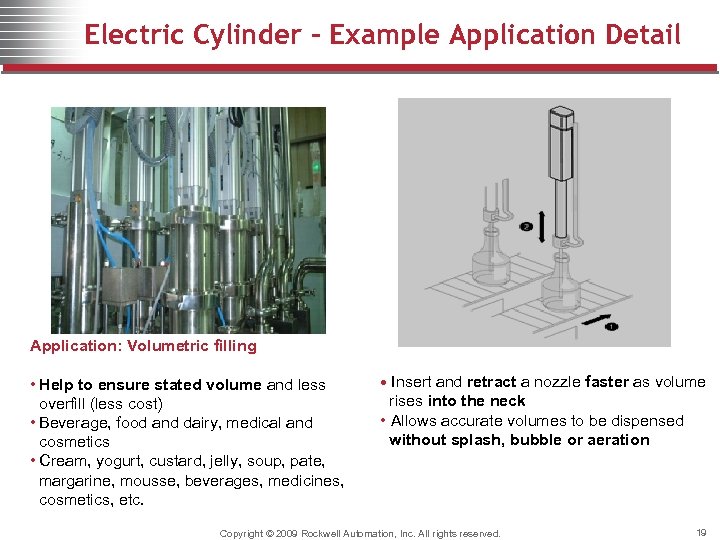

Electric Cylinder – Example Application Detail Application: Volumetric filling • Help to ensure stated volume and less overfill (less cost) • Beverage, food and dairy, medical and cosmetics • Cream, yogurt, custard, jelly, soup, pate, margarine, mousse, beverages, medicines, cosmetics, etc. • Insert and retract a nozzle faster as volume rises into the neck • Allows accurate volumes to be dispensed without splash, bubble or aeration Copyright © 2009 Rockwell Automation, Inc. All rights reserved. 19

Electric Cylinder – Example Application Detail Application: Volumetric filling • Help to ensure stated volume and less overfill (less cost) • Beverage, food and dairy, medical and cosmetics • Cream, yogurt, custard, jelly, soup, pate, margarine, mousse, beverages, medicines, cosmetics, etc. • Insert and retract a nozzle faster as volume rises into the neck • Allows accurate volumes to be dispensed without splash, bubble or aeration Copyright © 2009 Rockwell Automation, Inc. All rights reserved. 19

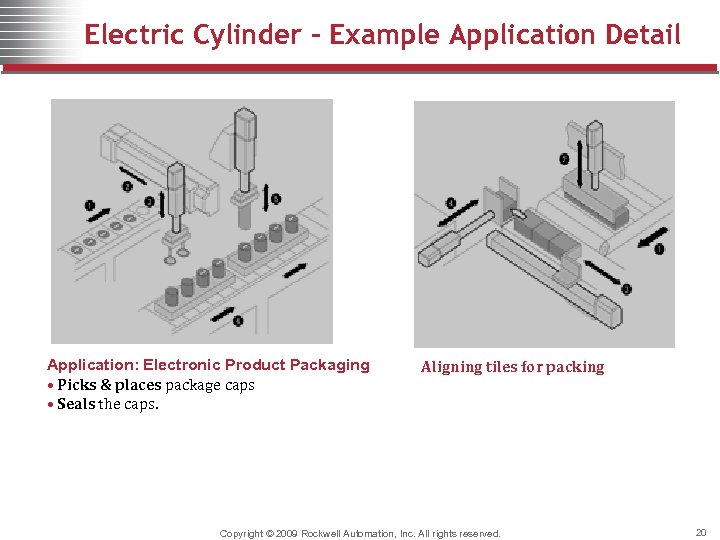

Electric Cylinder – Example Application Detail Application: Electronic Product Packaging • Picks & places package caps • Seals the caps. Aligning tiles for packing Copyright © 2009 Rockwell Automation, Inc. All rights reserved. 20

Electric Cylinder – Example Application Detail Application: Electronic Product Packaging • Picks & places package caps • Seals the caps. Aligning tiles for packing Copyright © 2009 Rockwell Automation, Inc. All rights reserved. 20

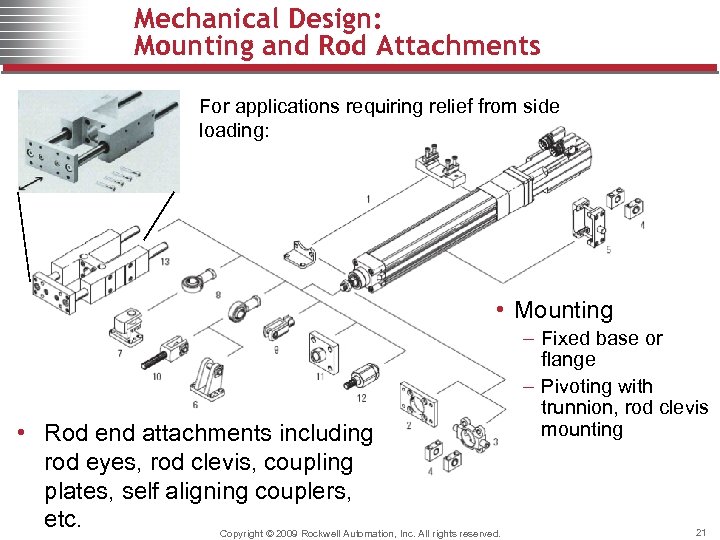

Mechanical Design: Mounting and Rod Attachments For applications requiring relief from side loading: • Mounting • Rod end attachments including rod eyes, rod clevis, coupling plates, self aligning couplers, etc. Copyright © 2009 Rockwell Automation, Inc. All rights reserved. – Fixed base or flange – Pivoting with trunnion, rod clevis mounting 21

Mechanical Design: Mounting and Rod Attachments For applications requiring relief from side loading: • Mounting • Rod end attachments including rod eyes, rod clevis, coupling plates, self aligning couplers, etc. Copyright © 2009 Rockwell Automation, Inc. All rights reserved. – Fixed base or flange – Pivoting with trunnion, rod clevis mounting 21

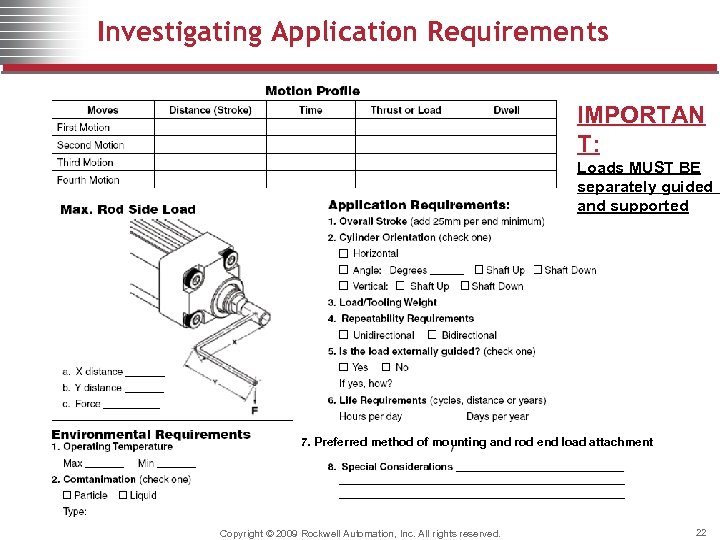

Investigating Application Requirements IMPORTAN T: Loads MUST BE separately guided and supported 7. Preferred method of mounting and rod end load attachment Copyright © 2009 Rockwell Automation, Inc. All rights reserved. 22

Investigating Application Requirements IMPORTAN T: Loads MUST BE separately guided and supported 7. Preferred method of mounting and rod end load attachment Copyright © 2009 Rockwell Automation, Inc. All rights reserved. 22

Topics: Introduction to Electric Cylinders 1. Product Line Overview 2. Applications 3. Application Development, Setup & Programming 4. Commercial Information Copyright © 2009 Rockwell Automation, Inc. All rights reserved. 23

Topics: Introduction to Electric Cylinders 1. Product Line Overview 2. Applications 3. Application Development, Setup & Programming 4. Commercial Information Copyright © 2009 Rockwell Automation, Inc. All rights reserved. 23

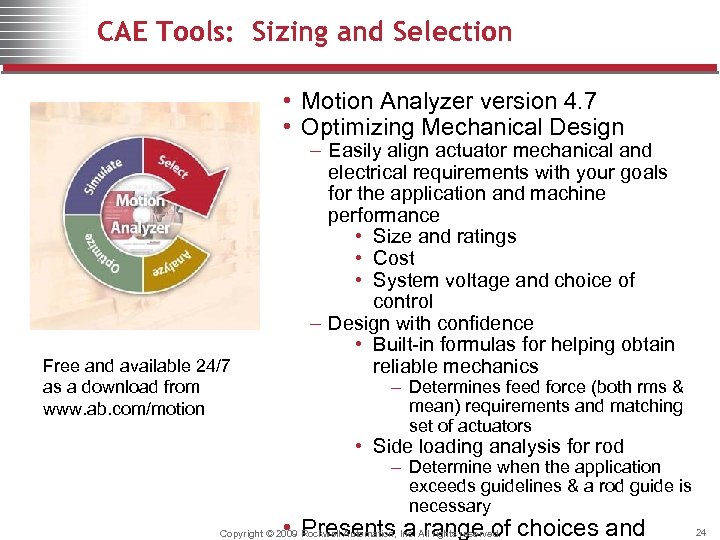

CAE Tools: Sizing and Selection • Motion Analyzer version 4. 7 • Optimizing Mechanical Design Free and available 24/7 as a download from www. ab. com/motion – Easily align actuator mechanical and electrical requirements with your goals for the application and machine performance • Size and ratings • Cost • System voltage and choice of control – Design with confidence • Built-in formulas for helping obtain reliable mechanics – Determines feed force (both rms & mean) requirements and matching set of actuators • Side loading analysis for rod – Determine when the application exceeds guidelines & a rod guide is necessary • Presents a range of choices and Copyright © 2009 Rockwell Automation, Inc. All rights reserved. 24

CAE Tools: Sizing and Selection • Motion Analyzer version 4. 7 • Optimizing Mechanical Design Free and available 24/7 as a download from www. ab. com/motion – Easily align actuator mechanical and electrical requirements with your goals for the application and machine performance • Size and ratings • Cost • System voltage and choice of control – Design with confidence • Built-in formulas for helping obtain reliable mechanics – Determines feed force (both rms & mean) requirements and matching set of actuators • Side loading analysis for rod – Determine when the application exceeds guidelines & a rod guide is necessary • Presents a range of choices and Copyright © 2009 Rockwell Automation, Inc. All rights reserved. 24

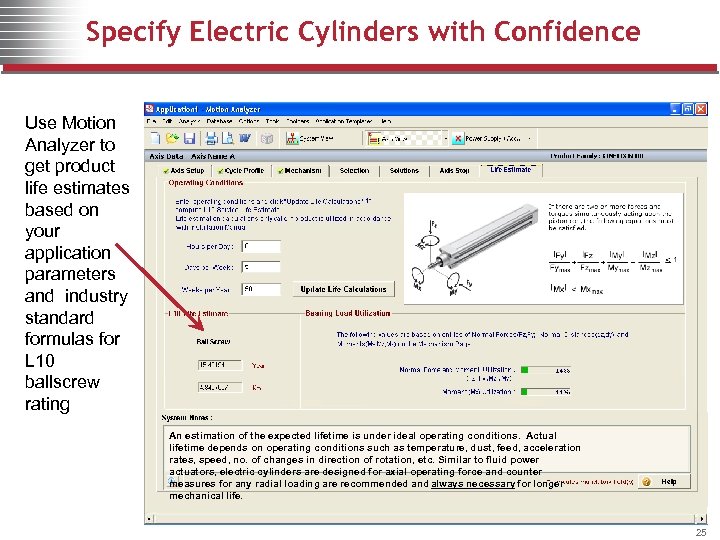

Specify Electric Cylinders with Confidence Use Motion Analyzer to get product life estimates based on your application parameters and industry standard formulas for L 10 ballscrew rating An estimation of the expected lifetime is under ideal operating conditions. Actual lifetime depends on operating conditions such as temperature, dust, feed, acceleration rates, speed, no. of changes in direction of rotation, etc. Similar to fluid power actuators, electric cylinders are designed for axial operating force and counter measures for any radial loading are recommended and always necessary for longer mechanical life. 25

Specify Electric Cylinders with Confidence Use Motion Analyzer to get product life estimates based on your application parameters and industry standard formulas for L 10 ballscrew rating An estimation of the expected lifetime is under ideal operating conditions. Actual lifetime depends on operating conditions such as temperature, dust, feed, acceleration rates, speed, no. of changes in direction of rotation, etc. Similar to fluid power actuators, electric cylinders are designed for axial operating force and counter measures for any radial loading are recommended and always necessary for longer mechanical life. 25

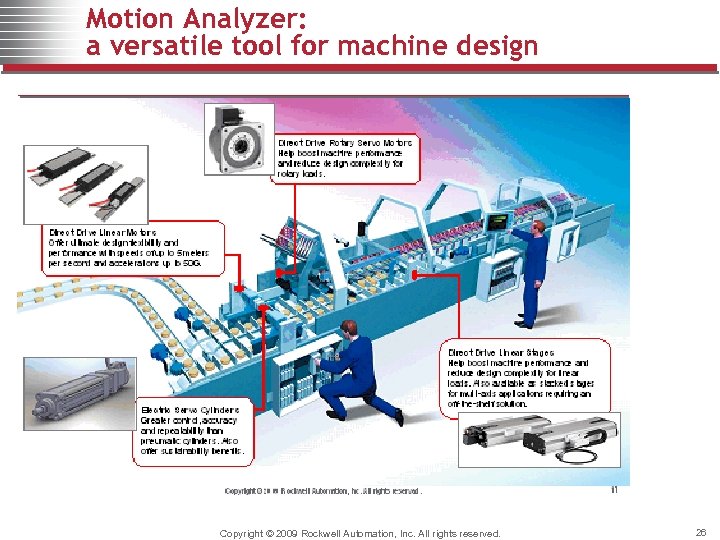

Motion Analyzer: a versatile tool for machine design Copyright © 2009 Rockwell Automation, Inc. All rights reserved. 26

Motion Analyzer: a versatile tool for machine design Copyright © 2009 Rockwell Automation, Inc. All rights reserved. 26

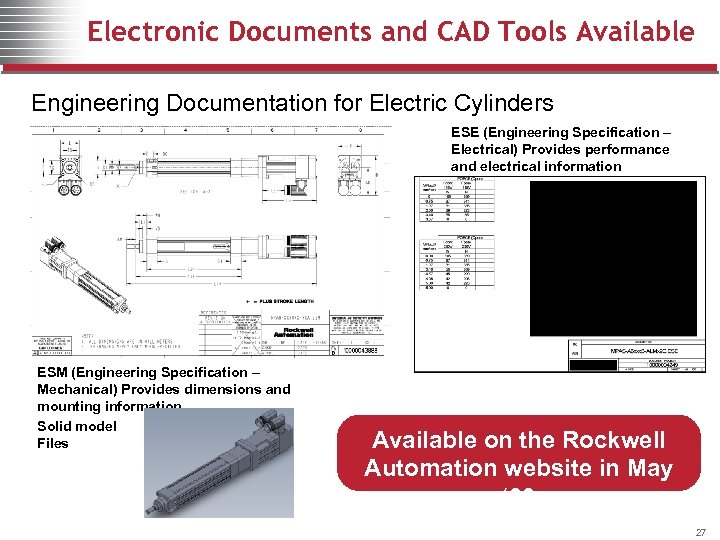

Electronic Documents and CAD Tools Available Engineering Documentation for Electric Cylinders ESE (Engineering Specification – Electrical) Provides performance and electrical information ESM (Engineering Specification – Mechanical) Provides dimensions and mounting information Solid model Files Available on the Rockwell Automation website in May ‘ 09 27

Electronic Documents and CAD Tools Available Engineering Documentation for Electric Cylinders ESE (Engineering Specification – Electrical) Provides performance and electrical information ESM (Engineering Specification – Mechanical) Provides dimensions and mounting information Solid model Files Available on the Rockwell Automation website in May ‘ 09 27

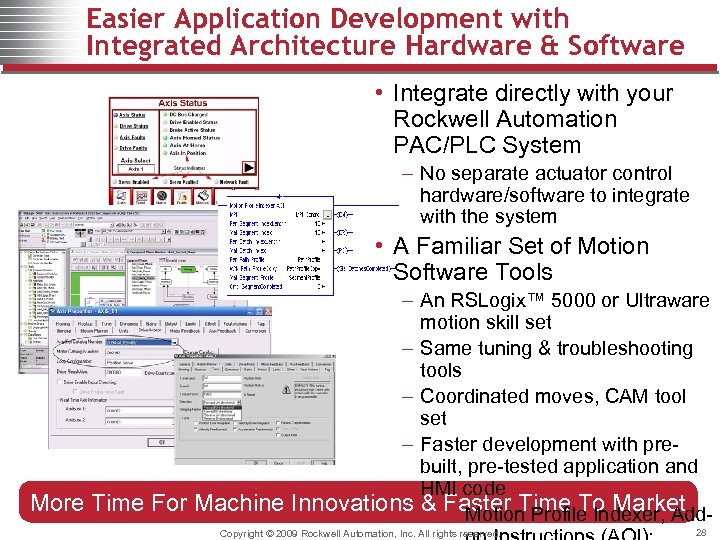

Easier Application Development with Integrated Architecture Hardware & Software • Integrate directly with your Rockwell Automation PAC/PLC System – No separate actuator control hardware/software to integrate with the system • A Familiar Set of Motion Software Tools – An RSLogix™ 5000 or Ultraware motion skill set – Same tuning & troubleshooting tools – Coordinated moves, CAM tool set – Faster development with prebuilt, pre-tested application and HMI code More Time For Machine Innovations & Faster Time To Market • Motion Profile Indexer, Add. Copyright © 2009 Rockwell Automation, Inc. All rights reserved. 28

Easier Application Development with Integrated Architecture Hardware & Software • Integrate directly with your Rockwell Automation PAC/PLC System – No separate actuator control hardware/software to integrate with the system • A Familiar Set of Motion Software Tools – An RSLogix™ 5000 or Ultraware motion skill set – Same tuning & troubleshooting tools – Coordinated moves, CAM tool set – Faster development with prebuilt, pre-tested application and HMI code More Time For Machine Innovations & Faster Time To Market • Motion Profile Indexer, Add. Copyright © 2009 Rockwell Automation, Inc. All rights reserved. 28

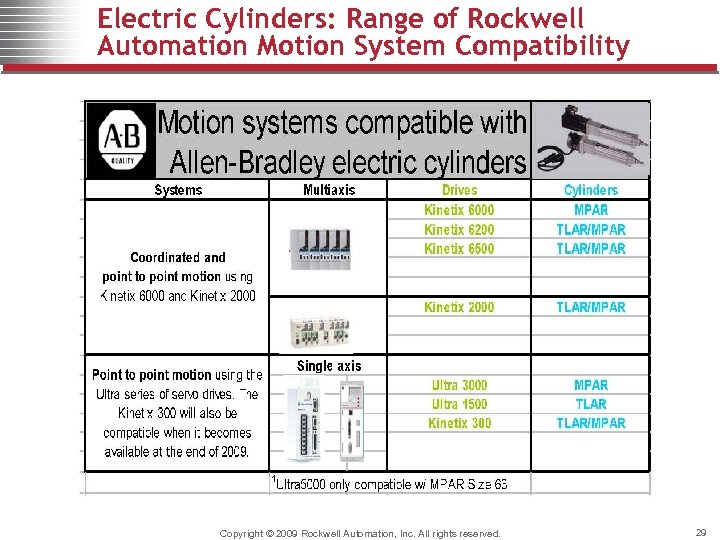

Electric Cylinders: Range of Rockwell Automation Motion System Compatibility Copyright © 2009 Rockwell Automation, Inc. All rights reserved. 29

Electric Cylinders: Range of Rockwell Automation Motion System Compatibility Copyright © 2009 Rockwell Automation, Inc. All rights reserved. 29

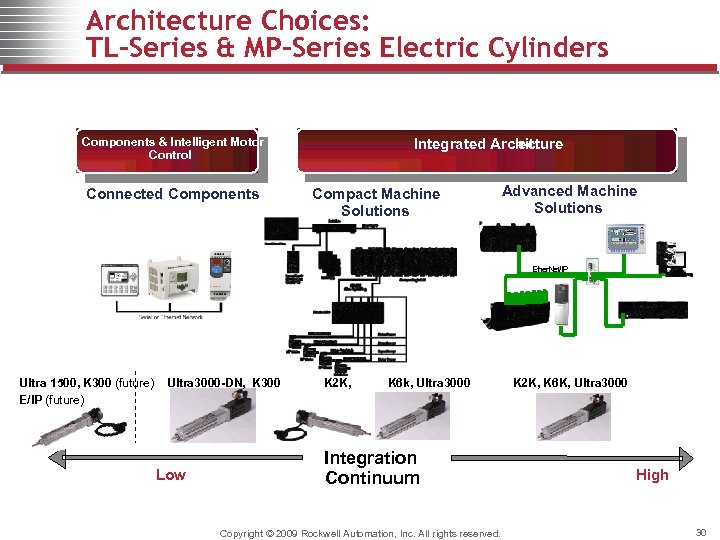

Architecture Choices: TL-Series & MP-Series Electric Cylinders Components & Intelligent Motor Control Connected Components Integrated Archit ecture Compact Machine Solutions Advanced Machine Solutions Ether. Net/IP Ultra 1500, K 300 (future) E/IP (future) Ultra 3000 -DN, K 300 Low K 2 K, K 6 k, Ultra 3000 Integration Continuum Copyright © 2009 Rockwell Automation, Inc. All rights reserved. K 2 K, K 6 K, Ultra 3000 High 30

Architecture Choices: TL-Series & MP-Series Electric Cylinders Components & Intelligent Motor Control Connected Components Integrated Archit ecture Compact Machine Solutions Advanced Machine Solutions Ether. Net/IP Ultra 1500, K 300 (future) E/IP (future) Ultra 3000 -DN, K 300 Low K 2 K, K 6 k, Ultra 3000 Integration Continuum Copyright © 2009 Rockwell Automation, Inc. All rights reserved. K 2 K, K 6 K, Ultra 3000 High 30

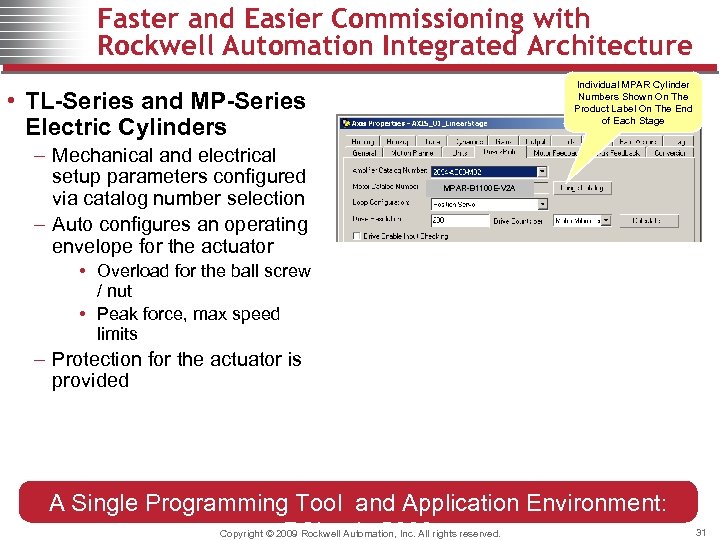

Faster and Easier Commissioning with Rockwell Automation Integrated Architecture Individual MPAR Cylinder Numbers Shown On The Product Label On The End of Each Stage • TL-Series and MP-Series Electric Cylinders – Mechanical and electrical setup parameters configured via catalog number selection – Auto configures an operating envelope for the actuator MPAR-B 1100 E-V 2 A • Overload for the ball screw / nut • Peak force, max speed limits – Protection for the actuator is provided A Single Programming Tool and Application Environment: Copyright © 2009 Rockwell Automation, Inc. All rights reserved. RSLogix 5000 31

Faster and Easier Commissioning with Rockwell Automation Integrated Architecture Individual MPAR Cylinder Numbers Shown On The Product Label On The End of Each Stage • TL-Series and MP-Series Electric Cylinders – Mechanical and electrical setup parameters configured via catalog number selection – Auto configures an operating envelope for the actuator MPAR-B 1100 E-V 2 A • Overload for the ball screw / nut • Peak force, max speed limits – Protection for the actuator is provided A Single Programming Tool and Application Environment: Copyright © 2009 Rockwell Automation, Inc. All rights reserved. RSLogix 5000 31

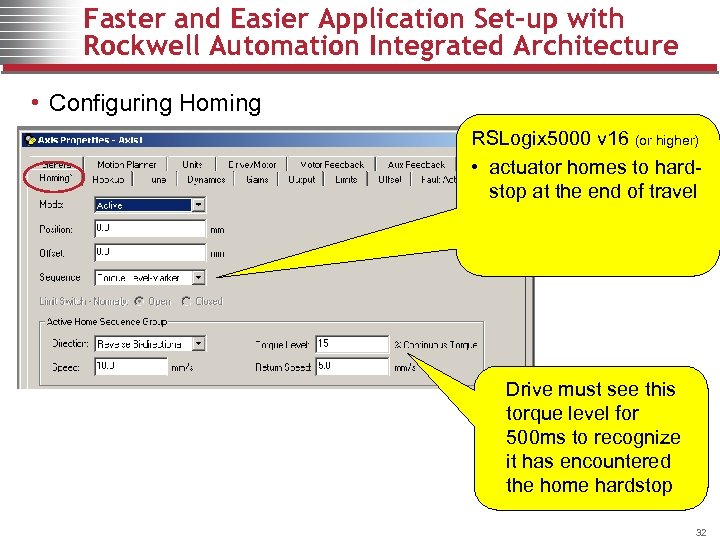

Faster and Easier Application Set-up with Rockwell Automation Integrated Architecture • Configuring Homing RSLogix 5000 v 16 (or higher) • actuator homes to hardstop at the end of travel Drive must see this torque level for 500 ms to recognize it has encountered the home hardstop 32

Faster and Easier Application Set-up with Rockwell Automation Integrated Architecture • Configuring Homing RSLogix 5000 v 16 (or higher) • actuator homes to hardstop at the end of travel Drive must see this torque level for 500 ms to recognize it has encountered the home hardstop 32

Topics: Introduction to Electric Cylinders 1. Product Line Overview 2. Applications 3. Application Development, Setup & Programming 4. Commercial Information Copyright © 2009 Rockwell Automation, Inc. All rights reserved. 33

Topics: Introduction to Electric Cylinders 1. Product Line Overview 2. Applications 3. Application Development, Setup & Programming 4. Commercial Information Copyright © 2009 Rockwell Automation, Inc. All rights reserved. 33

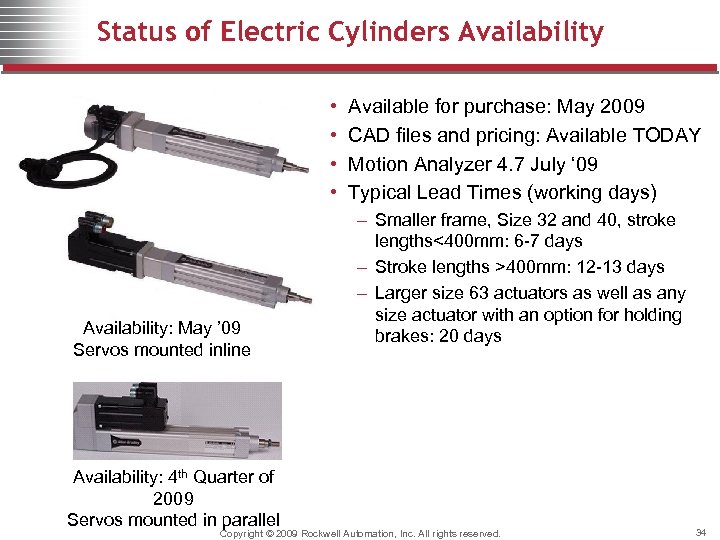

Status of Electric Cylinders Availability • • Availability: May ’ 09 Servos mounted inline Availability: 4 th Quarter of 2009 Servos mounted in parallel Available for purchase: May 2009 CAD files and pricing: Available TODAY Motion Analyzer 4. 7 July ‘ 09 Typical Lead Times (working days) – Smaller frame, Size 32 and 40, stroke lengths<400 mm: 6 -7 days – Stroke lengths >400 mm: 12 -13 days – Larger size 63 actuators as well as any size actuator with an option for holding brakes: 20 days Copyright © 2009 Rockwell Automation, Inc. All rights reserved. 34

Status of Electric Cylinders Availability • • Availability: May ’ 09 Servos mounted inline Availability: 4 th Quarter of 2009 Servos mounted in parallel Available for purchase: May 2009 CAD files and pricing: Available TODAY Motion Analyzer 4. 7 July ‘ 09 Typical Lead Times (working days) – Smaller frame, Size 32 and 40, stroke lengths<400 mm: 6 -7 days – Stroke lengths >400 mm: 12 -13 days – Larger size 63 actuators as well as any size actuator with an option for holding brakes: 20 days Copyright © 2009 Rockwell Automation, Inc. All rights reserved. 34

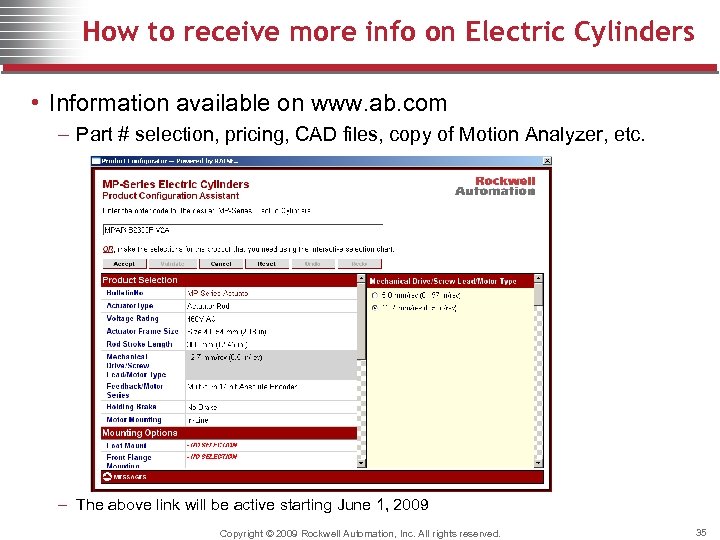

How to receive more info on Electric Cylinders • Information available on www. ab. com – Part # selection, pricing, CAD files, copy of Motion Analyzer, etc. – The above link will be active starting June 1, 2009 Copyright © 2009 Rockwell Automation, Inc. All rights reserved. 35

How to receive more info on Electric Cylinders • Information available on www. ab. com – Part # selection, pricing, CAD files, copy of Motion Analyzer, etc. – The above link will be active starting June 1, 2009 Copyright © 2009 Rockwell Automation, Inc. All rights reserved. 35

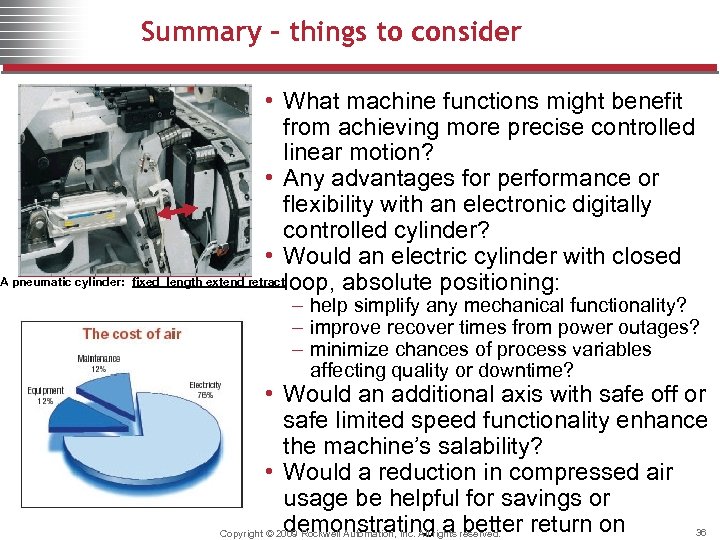

Summary – things to consider • What machine functions might benefit from achieving more precise controlled linear motion? • Any advantages for performance or flexibility with an electronic digitally controlled cylinder? • Would an electric cylinder with closed A pneumatic cylinder: fixed length extend retractloop, absolute positioning: – help simplify any mechanical functionality? – improve recover times from power outages? – minimize chances of process variables affecting quality or downtime? • Would an additional axis with safe off or safe limited speed functionality enhance the machine’s salability? • Would a reduction in compressed air usage be helpful for savings or demonstrating a better return on 36 Copyright © 2009 Rockwell Automation, Inc. All rights reserved.

Summary – things to consider • What machine functions might benefit from achieving more precise controlled linear motion? • Any advantages for performance or flexibility with an electronic digitally controlled cylinder? • Would an electric cylinder with closed A pneumatic cylinder: fixed length extend retractloop, absolute positioning: – help simplify any mechanical functionality? – improve recover times from power outages? – minimize chances of process variables affecting quality or downtime? • Would an additional axis with safe off or safe limited speed functionality enhance the machine’s salability? • Would a reduction in compressed air usage be helpful for savings or demonstrating a better return on 36 Copyright © 2009 Rockwell Automation, Inc. All rights reserved.

MP-Series & TL-Series Electric Cylinders Summary • Wide range of features − − − Precision ballscrews Stroke lengths up to 800 mm High resolution multi-turn absolute encoders 230 V AC and 460 V AC versions with optional holding brakes Field replaceable mechanics • Approvals − MP-Series, motors UL, c-UL Recognized, CE marked − TL-Series, motors CE marked • Allen-Bradley quality and support − Globally supported and built to order in USA (no more than 15 business day lead-time) − Fully supported by Rockwell Automation Integrated Architecture − Uses Allen-Bradley Bulletin 2090 motor power and feedback cables Copyright © 2009 Rockwell Automation, Inc. All rights reserved. 37

MP-Series & TL-Series Electric Cylinders Summary • Wide range of features − − − Precision ballscrews Stroke lengths up to 800 mm High resolution multi-turn absolute encoders 230 V AC and 460 V AC versions with optional holding brakes Field replaceable mechanics • Approvals − MP-Series, motors UL, c-UL Recognized, CE marked − TL-Series, motors CE marked • Allen-Bradley quality and support − Globally supported and built to order in USA (no more than 15 business day lead-time) − Fully supported by Rockwell Automation Integrated Architecture − Uses Allen-Bradley Bulletin 2090 motor power and feedback cables Copyright © 2009 Rockwell Automation, Inc. All rights reserved. 37

Electric Cylinder Applications Insert Photo Here pyright © 2009 Rockwell Automation, Inc. All rights reserved. Flexible, controlled linear motion

Electric Cylinder Applications Insert Photo Here pyright © 2009 Rockwell Automation, Inc. All rights reserved. Flexible, controlled linear motion