31b526db2e45dac0b569891170666431.ppt

- Количество слайдов: 57

Mont Alto Projectile Project (M. A. P. P. ) BU Novel Magnetometers Flight Experiment Critical Design Review Penn State Mont Alto Boston University 12/17/2008 December 17, 2008 Rock. Sat CDR

Mont Alto Projectile Project (M. A. P. P. ) BU Novel Magnetometers Flight Experiment Critical Design Review Penn State Mont Alto Boston University 12/17/2008 December 17, 2008 Rock. Sat CDR

MAPP Team Kylie Flickinger – Mechanical Engineering Adam Kuhlman – Data Acquisition William K. Mc. Dannell Jr. – Software Chris Small – Strain Gauge Board Robert Stottlemyer – Team Leader Tim Svirbly – Test Equipment Development December 17, 2008 Rock. Sat CDR 2

MAPP Team Kylie Flickinger – Mechanical Engineering Adam Kuhlman – Data Acquisition William K. Mc. Dannell Jr. – Software Chris Small – Strain Gauge Board Robert Stottlemyer – Team Leader Tim Svirbly – Test Equipment Development December 17, 2008 Rock. Sat CDR 2

BU Mag Dog Team • • • Sensors – Aichi – Shawn Doria Sensors – Honeywell – John Gancarz Power – Tracy Thai Rabbit Controller – Andy Lee Mechanicals – Jim Thumber Software/Simulations/Analysis – TBD – Nanosat teams join after January 30 December 17, 2008 Rock. Sat CDR 3

BU Mag Dog Team • • • Sensors – Aichi – Shawn Doria Sensors – Honeywell – John Gancarz Power – Tracy Thai Rabbit Controller – Andy Lee Mechanicals – Jim Thumber Software/Simulations/Analysis – TBD – Nanosat teams join after January 30 December 17, 2008 Rock. Sat CDR 3

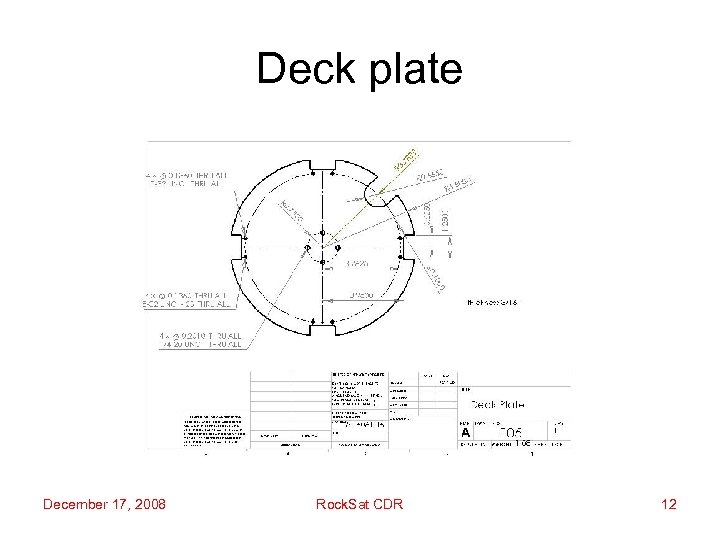

MAPP Science The purpose of this experiment is to investigate the mechanical stresses in an elastic structure during the flight of a sounding rocket. The structure proposed consists of a circular plate, the deck plate, which is supported by four longerons, which connect in turn to circular plates at either end of the longerons simulating a payload section of previous sounding rocket flights. A dummy mass is attached to the center of the deck plate. During the flight, dynamic loads in the axial and lateral directions will cause the deck plate to deflect. The resulting deformation will be measured at selected points using strain gauges connected to electronic boards to obtain time-varying voltage signals which in turn will be digitized and stored for later analysis. The obtained data will be compared to theoretical predictions. Careful preflight calibration of the entire data stream will be conducted. December 17, 2008 Rock. Sat CDR 4

MAPP Science The purpose of this experiment is to investigate the mechanical stresses in an elastic structure during the flight of a sounding rocket. The structure proposed consists of a circular plate, the deck plate, which is supported by four longerons, which connect in turn to circular plates at either end of the longerons simulating a payload section of previous sounding rocket flights. A dummy mass is attached to the center of the deck plate. During the flight, dynamic loads in the axial and lateral directions will cause the deck plate to deflect. The resulting deformation will be measured at selected points using strain gauges connected to electronic boards to obtain time-varying voltage signals which in turn will be digitized and stored for later analysis. The obtained data will be compared to theoretical predictions. Careful preflight calibration of the entire data stream will be conducted. December 17, 2008 Rock. Sat CDR 4

Novel Magnetometers Flight Experiment - Science • Design, assemble, and test two COTS, solid state 3 -axis magnetometers with controller, data storage and power: – Honeywell HMR 2003 - anisotropic magneto-resistance – Aichi Micro Intelligent AMI 302 - giant magneto-impedance • Compare directly the X, Y, Z flight readings of both sensors • Measure EMI from the chips’ bias straps (Honeywell) and bias coils (Aichi). • Honeywell device proposed for U. Colorado small satellite design (2003). We have found no other evidence of its use in space flight. • Aichi chip under study by US Navy for navigation of autonomous marine vehicles. We have found no record of the Aichi chip being used in space. December 17, 2008 Rock. Sat CDR 5

Novel Magnetometers Flight Experiment - Science • Design, assemble, and test two COTS, solid state 3 -axis magnetometers with controller, data storage and power: – Honeywell HMR 2003 - anisotropic magneto-resistance – Aichi Micro Intelligent AMI 302 - giant magneto-impedance • Compare directly the X, Y, Z flight readings of both sensors • Measure EMI from the chips’ bias straps (Honeywell) and bias coils (Aichi). • Honeywell device proposed for U. Colorado small satellite design (2003). We have found no other evidence of its use in space flight. • Aichi chip under study by US Navy for navigation of autonomous marine vehicles. We have found no record of the Aichi chip being used in space. December 17, 2008 Rock. Sat CDR 5

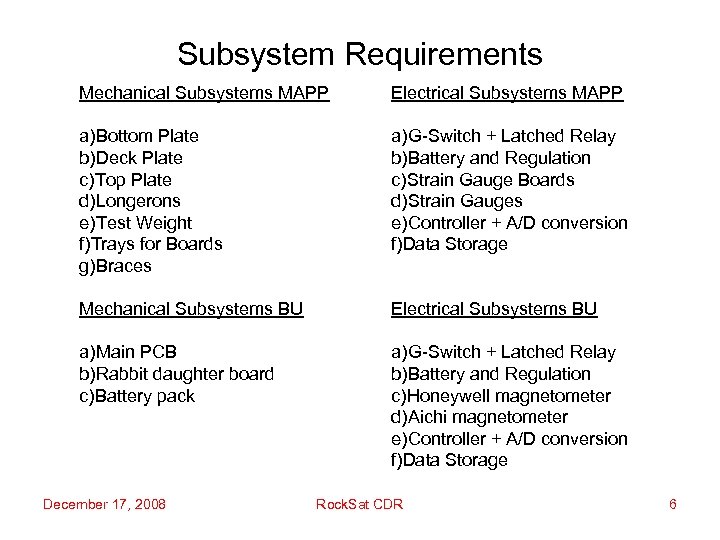

Subsystem Requirements Mechanical Subsystems MAPP Electrical Subsystems MAPP a)Bottom Plate b)Deck Plate c)Top Plate d)Longerons e)Test Weight f)Trays for Boards g)Braces a)G-Switch + Latched Relay b)Battery and Regulation c)Strain Gauge Boards d)Strain Gauges e)Controller + A/D conversion f)Data Storage Mechanical Subsystems BU Electrical Subsystems BU a)Main PCB b)Rabbit daughter board c)Battery pack a)G-Switch + Latched Relay b)Battery and Regulation c)Honeywell magnetometer d)Aichi magnetometer e)Controller + A/D conversion f)Data Storage December 17, 2008 Rock. Sat CDR 6

Subsystem Requirements Mechanical Subsystems MAPP Electrical Subsystems MAPP a)Bottom Plate b)Deck Plate c)Top Plate d)Longerons e)Test Weight f)Trays for Boards g)Braces a)G-Switch + Latched Relay b)Battery and Regulation c)Strain Gauge Boards d)Strain Gauges e)Controller + A/D conversion f)Data Storage Mechanical Subsystems BU Electrical Subsystems BU a)Main PCB b)Rabbit daughter board c)Battery pack a)G-Switch + Latched Relay b)Battery and Regulation c)Honeywell magnetometer d)Aichi magnetometer e)Controller + A/D conversion f)Data Storage December 17, 2008 Rock. Sat CDR 6

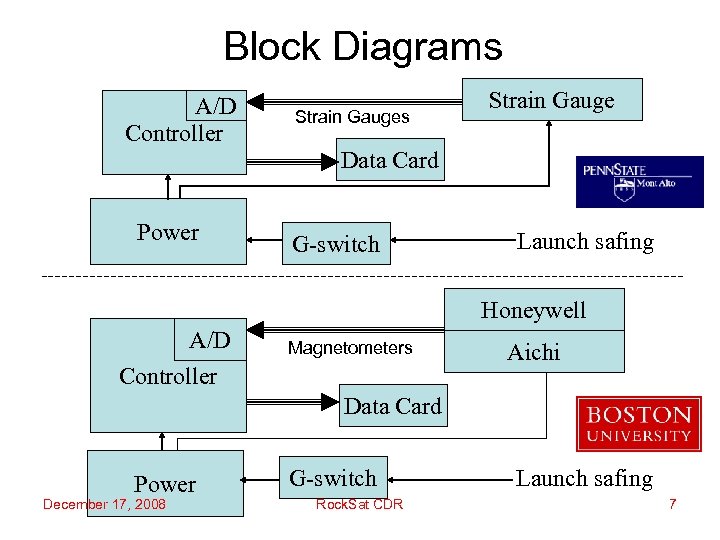

Block Diagrams A/D Controller Strain Gauges Strain Gauge Data Card Power G-switch Launch safing Honeywell A/D Magnetometers Controller Aichi Data Card Power December 17, 2008 G-switch Rock. Sat CDR Launch safing 7

Block Diagrams A/D Controller Strain Gauges Strain Gauge Data Card Power G-switch Launch safing Honeywell A/D Magnetometers Controller Aichi Data Card Power December 17, 2008 G-switch Rock. Sat CDR Launch safing 7

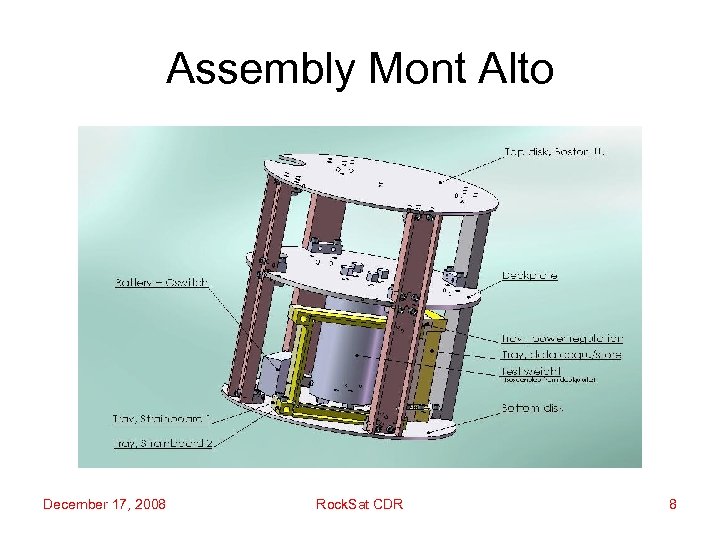

Assembly Mont Alto December 17, 2008 Rock. Sat CDR 8

Assembly Mont Alto December 17, 2008 Rock. Sat CDR 8

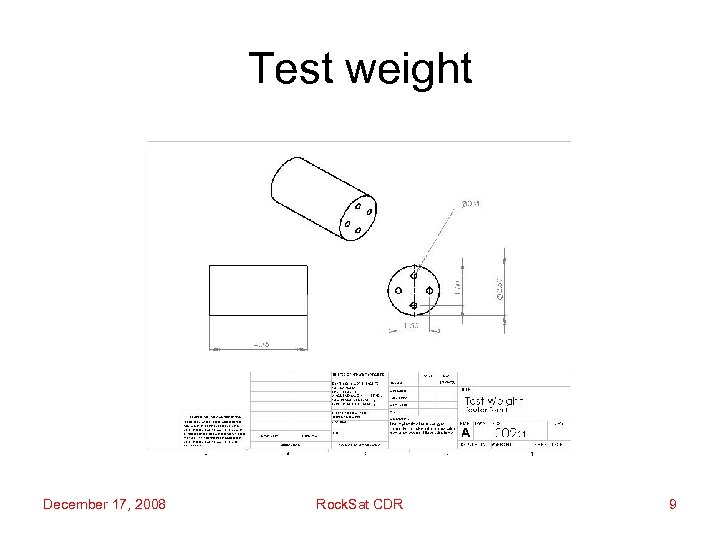

Test weight December 17, 2008 Rock. Sat CDR 9

Test weight December 17, 2008 Rock. Sat CDR 9

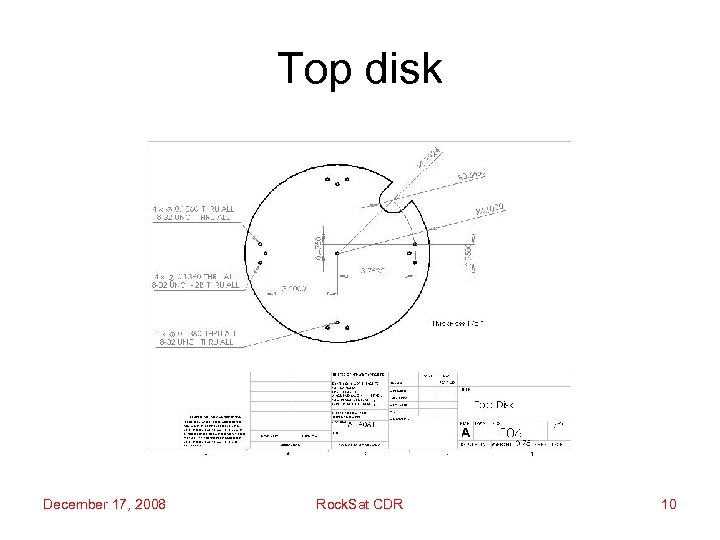

Top disk December 17, 2008 Rock. Sat CDR 10

Top disk December 17, 2008 Rock. Sat CDR 10

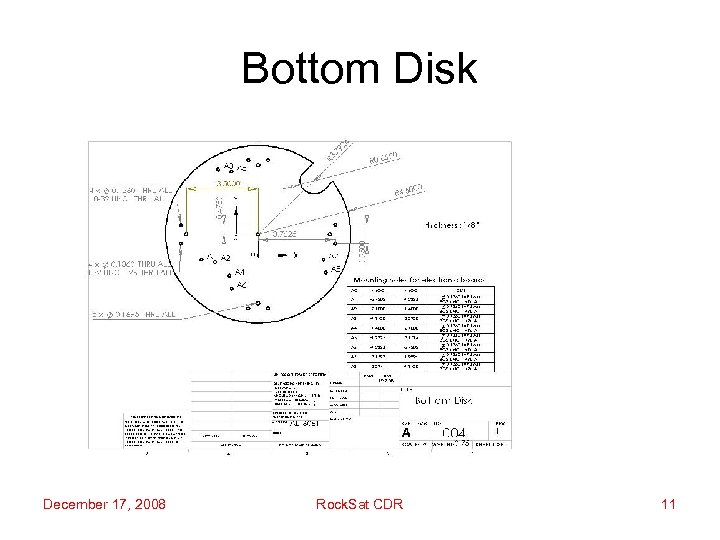

Bottom Disk December 17, 2008 Rock. Sat CDR 11

Bottom Disk December 17, 2008 Rock. Sat CDR 11

Deck plate December 17, 2008 Rock. Sat CDR 12

Deck plate December 17, 2008 Rock. Sat CDR 12

MAPP Strain Gauges • After testing in Solid. Works, we determined that the deck plate would not deform enough for the strain boards that we built for the USERS program to amplify the signal enough to get meaningful data using metal strain gauges. After research, we decided to use semi-conductor strain gauges, which have a gauge factor of ~60 times that of a metal foil strain gauge. We will implement them in a configuration that would both double signal output and reduce concerns about temperature sensitivity. Using this configuration should allow us to use our boards from the USERS program with only minor changes. December 17, 2008 Rock. Sat CDR 13

MAPP Strain Gauges • After testing in Solid. Works, we determined that the deck plate would not deform enough for the strain boards that we built for the USERS program to amplify the signal enough to get meaningful data using metal strain gauges. After research, we decided to use semi-conductor strain gauges, which have a gauge factor of ~60 times that of a metal foil strain gauge. We will implement them in a configuration that would both double signal output and reduce concerns about temperature sensitivity. Using this configuration should allow us to use our boards from the USERS program with only minor changes. December 17, 2008 Rock. Sat CDR 13

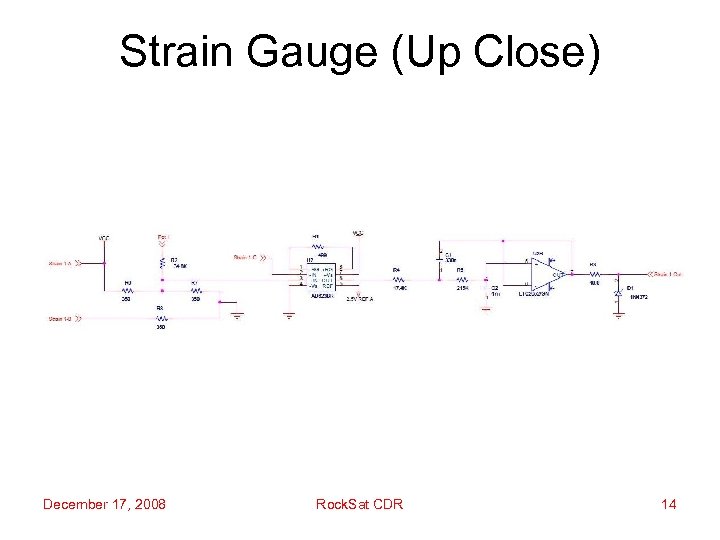

Strain Gauge (Up Close) December 17, 2008 Rock. Sat CDR 14

Strain Gauge (Up Close) December 17, 2008 Rock. Sat CDR 14

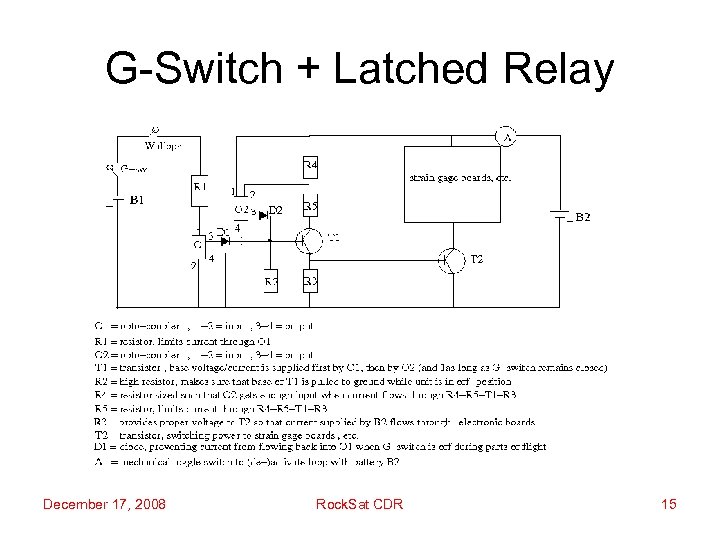

G-Switch + Latched Relay December 17, 2008 Rock. Sat CDR 15

G-Switch + Latched Relay December 17, 2008 Rock. Sat CDR 15

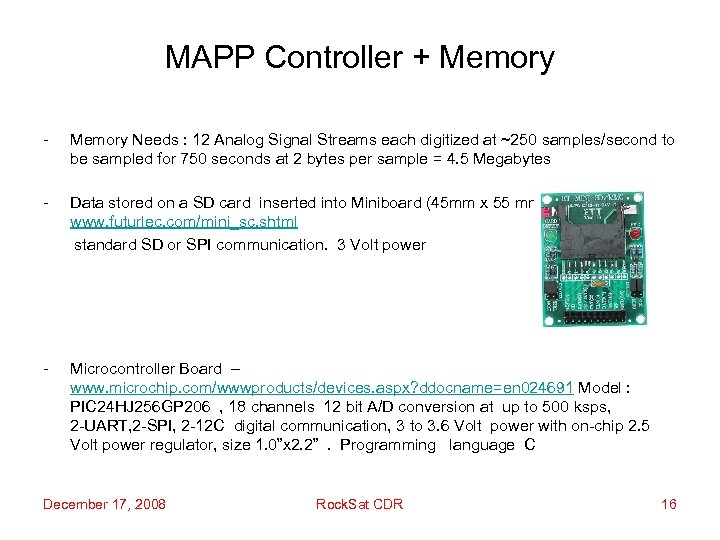

MAPP Controller + Memory - Memory Needs : 12 Analog Signal Streams each digitized at ~250 samples/second to be sampled for 750 seconds at 2 bytes per sample = 4. 5 Megabytes - Data stored on a SD card inserted into Miniboard (45 mm x 55 mm) - www. futurlec. com/mini_sc. shtml standard SD or SPI communication. 3 Volt power - Microcontroller Board – www. microchip. com/wwwproducts/devices. aspx? ddocname=en 024691 Model : PIC 24 HJ 256 GP 206 , 18 channels 12 bit A/D conversion at up to 500 ksps, 2 -UART, 2 -SPI, 2 -12 C digital communication, 3 to 3. 6 Volt power with on-chip 2. 5 Volt power regulator, size 1. 0”x 2. 2” . Programming language C December 17, 2008 Rock. Sat CDR 16

MAPP Controller + Memory - Memory Needs : 12 Analog Signal Streams each digitized at ~250 samples/second to be sampled for 750 seconds at 2 bytes per sample = 4. 5 Megabytes - Data stored on a SD card inserted into Miniboard (45 mm x 55 mm) - www. futurlec. com/mini_sc. shtml standard SD or SPI communication. 3 Volt power - Microcontroller Board – www. microchip. com/wwwproducts/devices. aspx? ddocname=en 024691 Model : PIC 24 HJ 256 GP 206 , 18 channels 12 bit A/D conversion at up to 500 ksps, 2 -UART, 2 -SPI, 2 -12 C digital communication, 3 to 3. 6 Volt power with on-chip 2. 5 Volt power regulator, size 1. 0”x 2. 2” . Programming language C December 17, 2008 Rock. Sat CDR 16

Special Requirements • MAPP Special Requirements – Shift in center of mass along length axis on rocket • BU Special Requirements – Minimize magnetic materials and fields December 17, 2008 Rock. Sat CDR 17

Special Requirements • MAPP Special Requirements – Shift in center of mass along length axis on rocket • BU Special Requirements – Minimize magnetic materials and fields December 17, 2008 Rock. Sat CDR 17

MAPP Commands and Sensors - Always On – Triggered by the G-Switch - Turned off by microcontroller before splash down - 12 Analog Signal Streams each digitized at ~250 samples/second to be sampled for 750 seconds at 2 bytes per sample = 4. 5 Megabytes - Data stored on a SD card Miniboard (45 mm x 55 mm) - www. futurlec. com/mini_sc. shtml - Microcontroller Board (protopic 28) – 1. 0” x 2. 2” – www. microchip. com/wwwproducts/devices. aspx? ddocname=en 024 691 Model : PIC 24 HJ 256 GP 206 , 18 channels A/D conversion, on-chip 2. 5 Volt power regulator - Strain Gauge: Vishay or Semiconductor (to be decided) - Data Acquisition Controlled by Microcontroller initiated by power on December 17, 2008 Rock. Sat CDR 18

MAPP Commands and Sensors - Always On – Triggered by the G-Switch - Turned off by microcontroller before splash down - 12 Analog Signal Streams each digitized at ~250 samples/second to be sampled for 750 seconds at 2 bytes per sample = 4. 5 Megabytes - Data stored on a SD card Miniboard (45 mm x 55 mm) - www. futurlec. com/mini_sc. shtml - Microcontroller Board (protopic 28) – 1. 0” x 2. 2” – www. microchip. com/wwwproducts/devices. aspx? ddocname=en 024 691 Model : PIC 24 HJ 256 GP 206 , 18 channels A/D conversion, on-chip 2. 5 Volt power regulator - Strain Gauge: Vishay or Semiconductor (to be decided) - Data Acquisition Controlled by Microcontroller initiated by power on December 17, 2008 Rock. Sat CDR 18

MAPP Test Plans • Mechanical Stress Distribution - Solid. Works Thin Plate Theory Static Force Rig (similar to the one we used for USERS) - G-Switch and Latched Relay - Spring loaded launch in a controlled setting Ensure compliance with no-volts requirement when integrated with power supply - Strain Gauges - Temperature sensitivity Circuitry and Signal Strength – simple beam test Compare to metal foil strain gauges Calibration - Data Acquisition/Storage - Store and retrieve data - All electronics: Burn in period December 17, 2008 Rock. Sat CDR 19

MAPP Test Plans • Mechanical Stress Distribution - Solid. Works Thin Plate Theory Static Force Rig (similar to the one we used for USERS) - G-Switch and Latched Relay - Spring loaded launch in a controlled setting Ensure compliance with no-volts requirement when integrated with power supply - Strain Gauges - Temperature sensitivity Circuitry and Signal Strength – simple beam test Compare to metal foil strain gauges Calibration - Data Acquisition/Storage - Store and retrieve data - All electronics: Burn in period December 17, 2008 Rock. Sat CDR 19

• • • MAPP Timeline By the end of fall semester (12/19/08) – Critical design review completed – Begin ordering parts – Wrap up design phase Over Christmas Break (12/19/08 – 01/12/09) – Continue ordering parts – Begin planning build phase Beginning of Spring Semester (01/12/09) – Meet to plan build phase – Take an inventory of parts • Between (01/12/09 – 03/15/09) Build Phase • Manufacture circuit board for data collection • Alter strain gauge boards • Manufacture testing rigs—Static force rig like we used for USERS, Spring mechanism to test G-Switch • Manufacture G-switch • Manufacture plates, longerons, alter dummy weight from USERS, braces, and housing for battery and g-switch. • Between (3/15/09 – 4/25/09) Testing Phase • Test performance of Semiconductor Strain Gauges—Compare to metal foil strain gauges. Also test temperature drift. – Static force rig similar to the one we used for testing for the USERS project • Test performance of G-Switch and power supply – see that it meets launch safing no volts requirements. – Use spring mechanism to test the performance of the “ball and tube” part of the G-Switch • Test performance of Data Acquisition unit • Burn in period for electronics Preliminary Integration Phase (4/25/09 – 5/3/09) • Assemble structure • Attach strain gauges to test points in structure • Integrate electronic components—manufacture wire harnesses • Have structure ready to install in can Finals week (5/4/09 – 5/8/09) See you in June! Launch at Wallops • • • December 17, 2008 Rock. Sat CDR 20

• • • MAPP Timeline By the end of fall semester (12/19/08) – Critical design review completed – Begin ordering parts – Wrap up design phase Over Christmas Break (12/19/08 – 01/12/09) – Continue ordering parts – Begin planning build phase Beginning of Spring Semester (01/12/09) – Meet to plan build phase – Take an inventory of parts • Between (01/12/09 – 03/15/09) Build Phase • Manufacture circuit board for data collection • Alter strain gauge boards • Manufacture testing rigs—Static force rig like we used for USERS, Spring mechanism to test G-Switch • Manufacture G-switch • Manufacture plates, longerons, alter dummy weight from USERS, braces, and housing for battery and g-switch. • Between (3/15/09 – 4/25/09) Testing Phase • Test performance of Semiconductor Strain Gauges—Compare to metal foil strain gauges. Also test temperature drift. – Static force rig similar to the one we used for testing for the USERS project • Test performance of G-Switch and power supply – see that it meets launch safing no volts requirements. – Use spring mechanism to test the performance of the “ball and tube” part of the G-Switch • Test performance of Data Acquisition unit • Burn in period for electronics Preliminary Integration Phase (4/25/09 – 5/3/09) • Assemble structure • Attach strain gauges to test points in structure • Integrate electronic components—manufacture wire harnesses • Have structure ready to install in can Finals week (5/4/09 – 5/8/09) See you in June! Launch at Wallops • • • December 17, 2008 Rock. Sat CDR 20

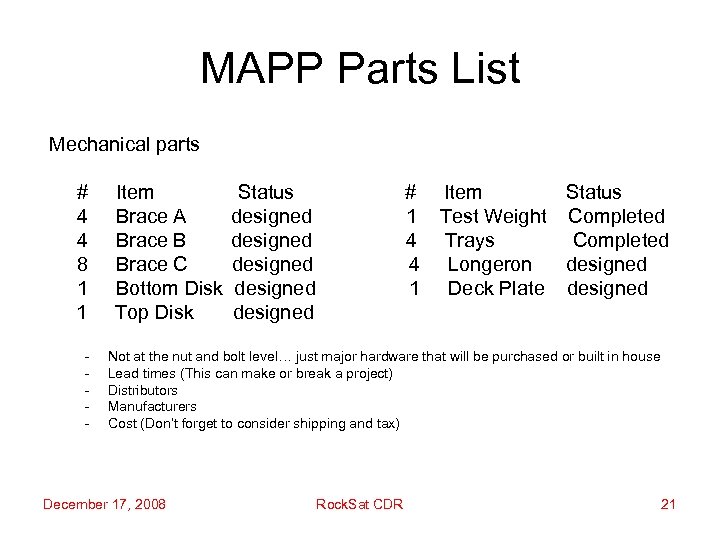

MAPP Parts List Mechanical parts # Item Status 4 Brace A designed 1 Test Weight Completed 4 Brace B designed 4 Trays Completed 8 Brace C designed 4 Longeron designed 1 Bottom Disk designed 1 Deck Plate designed 1 Top Disk designed - Not at the nut and bolt level… just major hardware that will be purchased or built in house Lead times (This can make or break a project) Distributors Manufacturers Cost (Don’t forget to consider shipping and tax) December 17, 2008 Rock. Sat CDR 21

MAPP Parts List Mechanical parts # Item Status 4 Brace A designed 1 Test Weight Completed 4 Brace B designed 4 Trays Completed 8 Brace C designed 4 Longeron designed 1 Bottom Disk designed 1 Deck Plate designed 1 Top Disk designed - Not at the nut and bolt level… just major hardware that will be purchased or built in house Lead times (This can make or break a project) Distributors Manufacturers Cost (Don’t forget to consider shipping and tax) December 17, 2008 Rock. Sat CDR 21

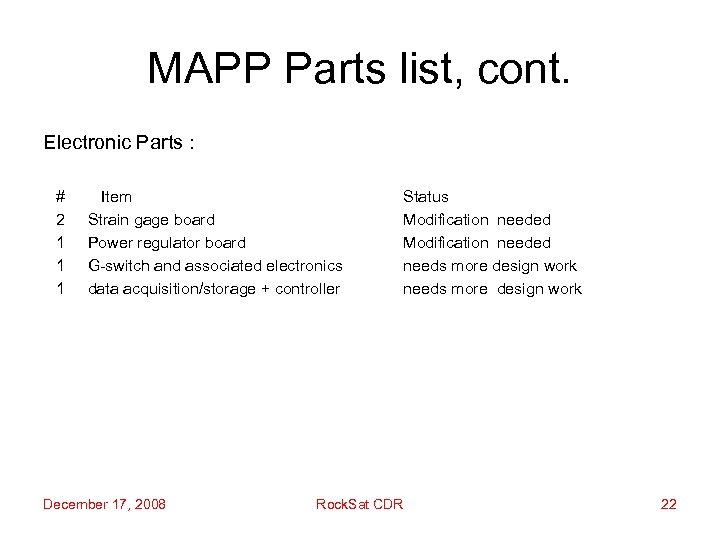

MAPP Parts list, cont. Electronic Parts : # Item 2 Strain gage board 1 Power regulator board 1 G-switch and associated electronics 1 data acquisition/storage + controller December 17, 2008 Status Modification needed needs more design work Rock. Sat CDR 22

MAPP Parts list, cont. Electronic Parts : # Item 2 Strain gage board 1 Power regulator board 1 G-switch and associated electronics 1 data acquisition/storage + controller December 17, 2008 Status Modification needed needs more design work Rock. Sat CDR 22

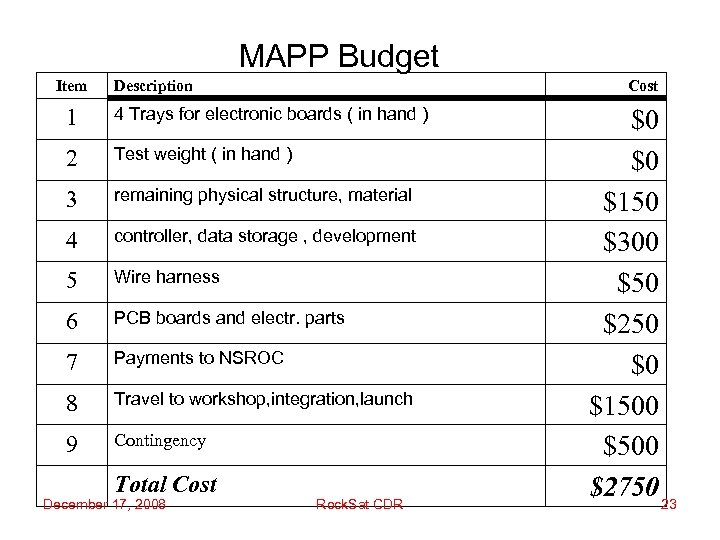

MAPP Budget Item Description Cost 1 4 Trays for electronic boards ( in hand ) 2 Test weight ( in hand ) 3 remaining physical structure, material 4 controller, data storage , development 5 Wire harness 6 PCB boards and electr. parts 7 Payments to NSROC 8 Travel to workshop, integration, launch 9 Contingency Total Cost December 17, 2008 Rock. Sat CDR $0 $0 $150 $300 $50 $250 $0 $1500 $2750 23

MAPP Budget Item Description Cost 1 4 Trays for electronic boards ( in hand ) 2 Test weight ( in hand ) 3 remaining physical structure, material 4 controller, data storage , development 5 Wire harness 6 PCB boards and electr. parts 7 Payments to NSROC 8 Travel to workshop, integration, launch 9 Contingency Total Cost December 17, 2008 Rock. Sat CDR $0 $0 $150 $300 $50 $250 $0 $1500 $2750 23

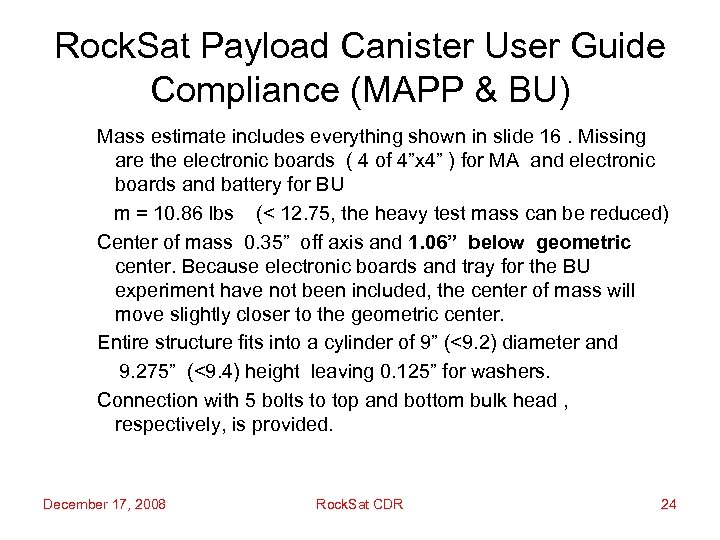

Rock. Sat Payload Canister User Guide Compliance (MAPP & BU) Mass estimate includes everything shown in slide 16. Missing are the electronic boards ( 4 of 4”x 4” ) for MA and electronic boards and battery for BU m = 10. 86 lbs (< 12. 75, the heavy test mass can be reduced) Center of mass 0. 35” off axis and 1. 06” below geometric center. Because electronic boards and tray for the BU experiment have not been included, the center of mass will move slightly closer to the geometric center. Entire structure fits into a cylinder of 9” (<9. 2) diameter and 9. 275” (<9. 4) height leaving 0. 125” for washers. Connection with 5 bolts to top and bottom bulk head , respectively, is provided. December 17, 2008 Rock. Sat CDR 24

Rock. Sat Payload Canister User Guide Compliance (MAPP & BU) Mass estimate includes everything shown in slide 16. Missing are the electronic boards ( 4 of 4”x 4” ) for MA and electronic boards and battery for BU m = 10. 86 lbs (< 12. 75, the heavy test mass can be reduced) Center of mass 0. 35” off axis and 1. 06” below geometric center. Because electronic boards and tray for the BU experiment have not been included, the center of mass will move slightly closer to the geometric center. Entire structure fits into a cylinder of 9” (<9. 2) diameter and 9. 275” (<9. 4) height leaving 0. 125” for washers. Connection with 5 bolts to top and bottom bulk head , respectively, is provided. December 17, 2008 Rock. Sat CDR 24

Rock. Sat Payload Canister User Guide Compliance– cont. - Payload Activation a battery , a G-switch, and shorting wires to Wallops shorting plug form a complete loop with electric current flowing only if both the G-switch and shorting plug are in closed position simultaneously. Once current is flowing a circuit consisting of a second battery (ies) and all electronic boards is activated using a solid-state latched relay and switch transistor. This second loop maintains itself even when the G-switch subsequently falls back into its open position (during ballistic flight phase). December 17, 2008 Rock. Sat CDR 25

Rock. Sat Payload Canister User Guide Compliance– cont. - Payload Activation a battery , a G-switch, and shorting wires to Wallops shorting plug form a complete loop with electric current flowing only if both the G-switch and shorting plug are in closed position simultaneously. Once current is flowing a circuit consisting of a second battery (ies) and all electronic boards is activated using a solid-state latched relay and switch transistor. This second loop maintains itself even when the G-switch subsequently falls back into its open position (during ballistic flight phase). December 17, 2008 Rock. Sat CDR 25

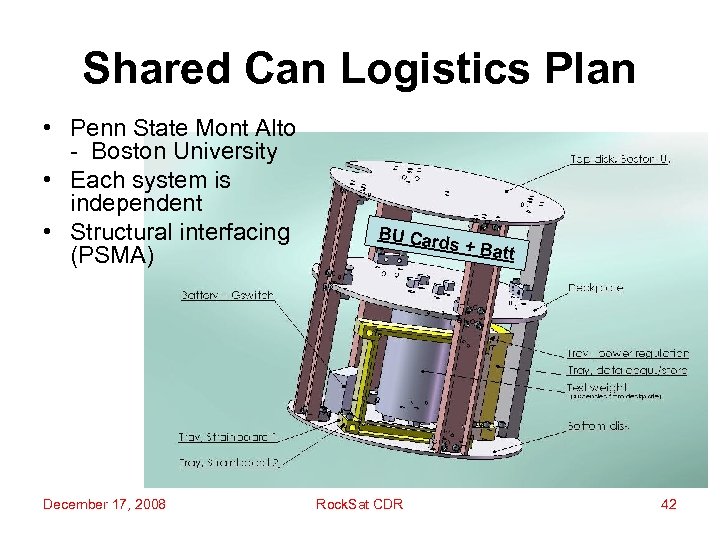

Shared Can Logistics Plan o Boston University (Mike Ruane) o Penn State Mont Alto (Zig Herzog) Sharing mechanical structure but independent power supply, controller, data acquisition, and data storage. Possibility of future sharing of these items is not excluded. December 17, 2008 Rock. Sat CDR 26

Shared Can Logistics Plan o Boston University (Mike Ruane) o Penn State Mont Alto (Zig Herzog) Sharing mechanical structure but independent power supply, controller, data acquisition, and data storage. Possibility of future sharing of these items is not excluded. December 17, 2008 Rock. Sat CDR 26

Team Management Dr. Siegfried Herzog Penn State University at Mont Alto Assistant Professor of Mechanical Engineering 1 Campus Drive Mont Alto, PA 17237 Tel (717)-749 -6209 Fax (717)-749 -6069 E-Mail: hgn@psu. edu Dr. Michael Ruane Professor, ECE Dept. , Boston University 8 St. Mary's Street, Boston, MA 02215 Phone: 617 -353 -3256 617 -353 -6440 fax E-Mail: mfr@bu. edu December 17, 2008 Rock. Sat CDR 27

Team Management Dr. Siegfried Herzog Penn State University at Mont Alto Assistant Professor of Mechanical Engineering 1 Campus Drive Mont Alto, PA 17237 Tel (717)-749 -6209 Fax (717)-749 -6069 E-Mail: hgn@psu. edu Dr. Michael Ruane Professor, ECE Dept. , Boston University 8 St. Mary's Street, Boston, MA 02215 Phone: 617 -353 -3256 617 -353 -6440 fax E-Mail: mfr@bu. edu December 17, 2008 Rock. Sat CDR 27

MAPP Conclusions - Lab space available - Students are nervous but excited - We have some previous experience with the USERS program and can re-use some parts - We aim to finish by the end of April (end of the spring semester) - Looking forward to beach time! December 17, 2008 Rock. Sat CDR 28

MAPP Conclusions - Lab space available - Students are nervous but excited - We have some previous experience with the USERS program and can re-use some parts - We aim to finish by the end of April (end of the spring semester) - Looking forward to beach time! December 17, 2008 Rock. Sat CDR 28

BU Subsystems • • Sensor 1 Aichi Sensor 2 Honeywell Power (Battery + Regulation) Controller – Sequencing of sensors – Data A/D conversion – Storage to SD card December 17, 2008 Rock. Sat CDR 29

BU Subsystems • • Sensor 1 Aichi Sensor 2 Honeywell Power (Battery + Regulation) Controller – Sequencing of sensors – Data A/D conversion – Storage to SD card December 17, 2008 Rock. Sat CDR 29

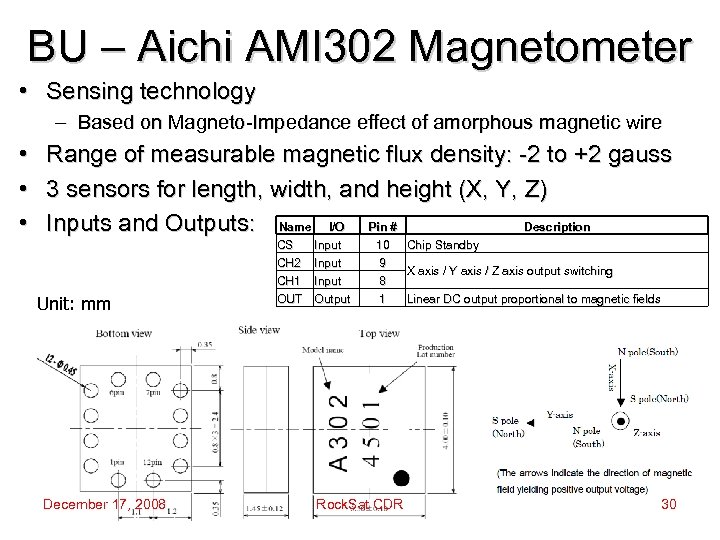

BU – Aichi AMI 302 Magnetometer • Sensing technology – Based on Magneto-Impedance effect of amorphous magnetic wire • • • Range of measurable magnetic flux density: -2 to +2 gauss 3 sensors for length, width, and height (X, Y, Z) Description Inputs and Outputs: Name I/O Pin # Unit: mm December 17, 2008 CS CH 2 CH 1 OUT Input Output 10 9 8 1 Rock. Sat CDR Chip Standby X axis / Y axis / Z axis output switching Linear DC output proportional to magnetic fields 30

BU – Aichi AMI 302 Magnetometer • Sensing technology – Based on Magneto-Impedance effect of amorphous magnetic wire • • • Range of measurable magnetic flux density: -2 to +2 gauss 3 sensors for length, width, and height (X, Y, Z) Description Inputs and Outputs: Name I/O Pin # Unit: mm December 17, 2008 CS CH 2 CH 1 OUT Input Output 10 9 8 1 Rock. Sat CDR Chip Standby X axis / Y axis / Z axis output switching Linear DC output proportional to magnetic fields 30

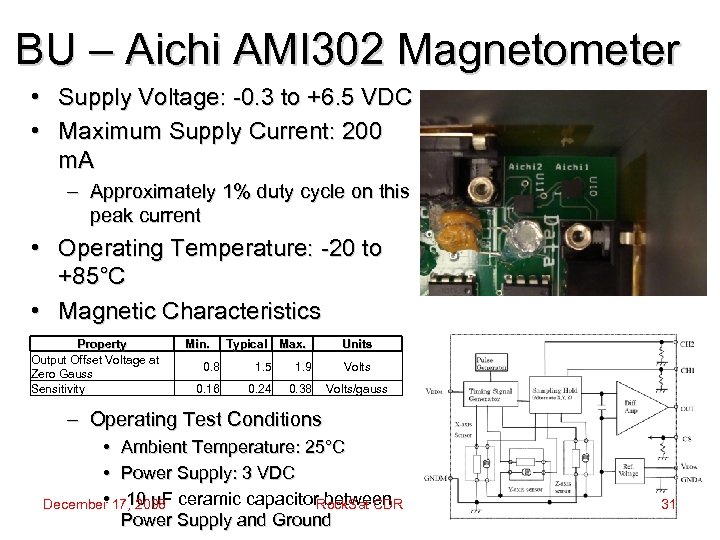

BU – Aichi AMI 302 Magnetometer • Supply Voltage: -0. 3 to +6. 5 VDC • Maximum Supply Current: 200 m. A – Approximately 1% duty cycle on this peak current • Operating Temperature: -20 to +85°C • Magnetic Characteristics Property Output Offset Voltage at Zero Gauss Sensitivity Min. Typical Max. Units 0. 8 1. 5 1. 9 Volts 0. 16 0. 24 0. 38 Volts/gauss – Operating Test Conditions • Ambient Temperature: 25°C • Power Supply: 3 VDC • 10 μF December 17, 2008 ceramic capacitor between Rock. Sat CDR Power Supply and Ground 31

BU – Aichi AMI 302 Magnetometer • Supply Voltage: -0. 3 to +6. 5 VDC • Maximum Supply Current: 200 m. A – Approximately 1% duty cycle on this peak current • Operating Temperature: -20 to +85°C • Magnetic Characteristics Property Output Offset Voltage at Zero Gauss Sensitivity Min. Typical Max. Units 0. 8 1. 5 1. 9 Volts 0. 16 0. 24 0. 38 Volts/gauss – Operating Test Conditions • Ambient Temperature: 25°C • Power Supply: 3 VDC • 10 μF December 17, 2008 ceramic capacitor between Rock. Sat CDR Power Supply and Ground 31

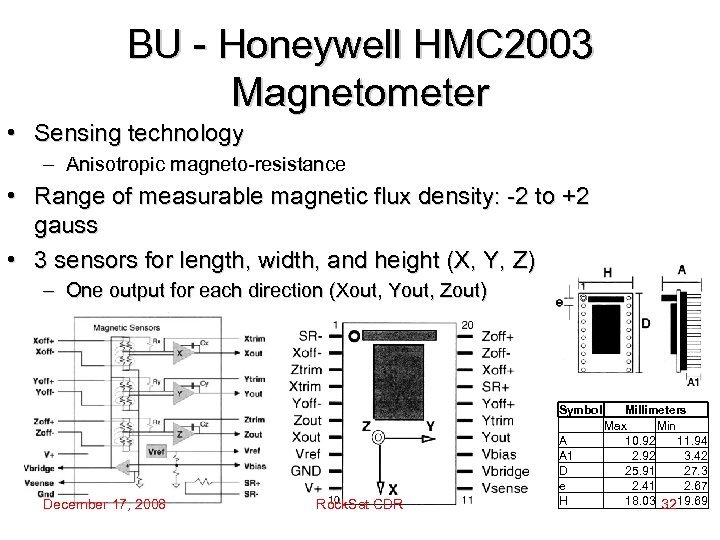

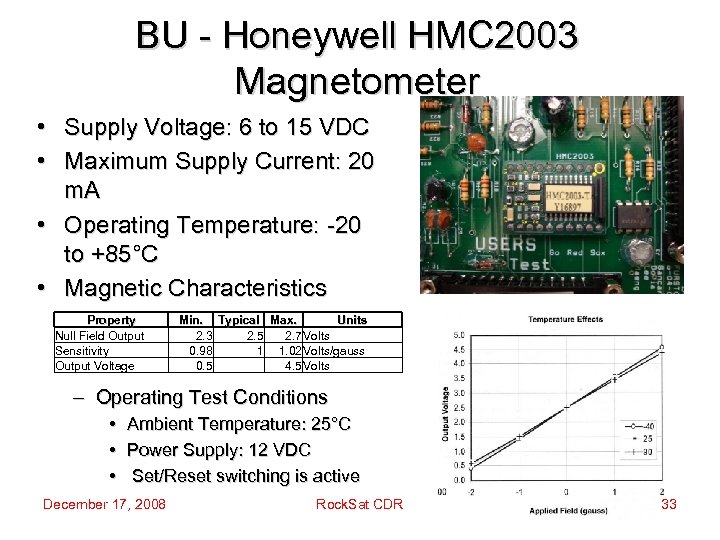

BU - Honeywell HMC 2003 Magnetometer • Sensing technology – Anisotropic magneto-resistance • Range of measurable magnetic flux density: -2 to +2 gauss • 3 sensors for length, width, and height (X, Y, Z) – One output for each direction (Xout, Yout, Zout) Symbol December 17, 2008 Rock. Sat CDR A A 1 D e H Millimeters Max Min 10. 92 11. 94 2. 92 3. 42 25. 91 27. 3 2. 41 2. 67 18. 03 32 19. 69

BU - Honeywell HMC 2003 Magnetometer • Sensing technology – Anisotropic magneto-resistance • Range of measurable magnetic flux density: -2 to +2 gauss • 3 sensors for length, width, and height (X, Y, Z) – One output for each direction (Xout, Yout, Zout) Symbol December 17, 2008 Rock. Sat CDR A A 1 D e H Millimeters Max Min 10. 92 11. 94 2. 92 3. 42 25. 91 27. 3 2. 41 2. 67 18. 03 32 19. 69

BU - Honeywell HMC 2003 Magnetometer • Supply Voltage: 6 to 15 VDC • Maximum Supply Current: 20 m. A • Operating Temperature: -20 to +85°C • Magnetic Characteristics Property Null Field Output Sensitivity Output Voltage Min. Typical Max. Units 2. 3 2. 5 2. 7 Volts 0. 98 1 1. 02 Volts/gauss 0. 5 4. 5 Volts – Operating Test Conditions • • • Ambient Temperature: 25°C Power Supply: 12 VDC Set/Reset switching is active December 17, 2008 Rock. Sat CDR 33

BU - Honeywell HMC 2003 Magnetometer • Supply Voltage: 6 to 15 VDC • Maximum Supply Current: 20 m. A • Operating Temperature: -20 to +85°C • Magnetic Characteristics Property Null Field Output Sensitivity Output Voltage Min. Typical Max. Units 2. 3 2. 5 2. 7 Volts 0. 98 1 1. 02 Volts/gauss 0. 5 4. 5 Volts – Operating Test Conditions • • • Ambient Temperature: 25°C Power Supply: 12 VDC Set/Reset switching is active December 17, 2008 Rock. Sat CDR 33

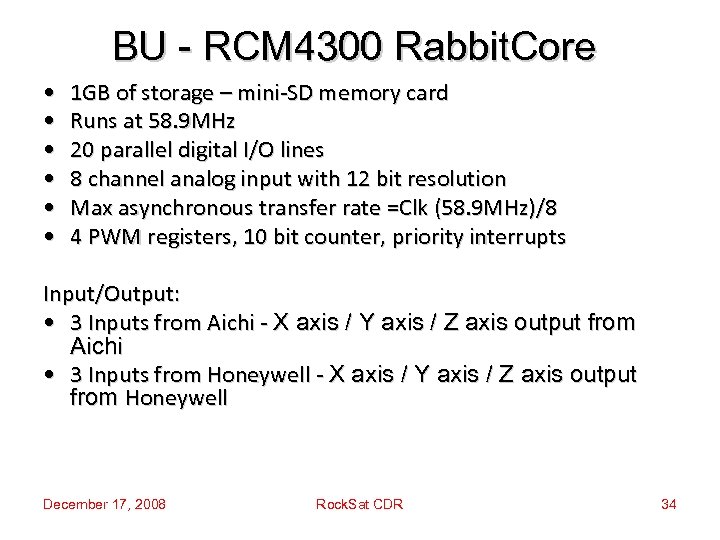

BU - RCM 4300 Rabbit. Core • • • 1 GB of storage – mini-SD memory card Runs at 58. 9 MHz 20 parallel digital I/O lines 8 channel analog input with 12 bit resolution Max asynchronous transfer rate =Clk (58. 9 MHz)/8 4 PWM registers, 10 bit counter, priority interrupts Input/Output: • 3 Inputs from Aichi - X axis / Y axis / Z axis output from Aichi • 3 Inputs from Honeywell - X axis / Y axis / Z axis output from Honeywell December 17, 2008 Rock. Sat CDR 34

BU - RCM 4300 Rabbit. Core • • • 1 GB of storage – mini-SD memory card Runs at 58. 9 MHz 20 parallel digital I/O lines 8 channel analog input with 12 bit resolution Max asynchronous transfer rate =Clk (58. 9 MHz)/8 4 PWM registers, 10 bit counter, priority interrupts Input/Output: • 3 Inputs from Aichi - X axis / Y axis / Z axis output from Aichi • 3 Inputs from Honeywell - X axis / Y axis / Z axis output from Honeywell December 17, 2008 Rock. Sat CDR 34

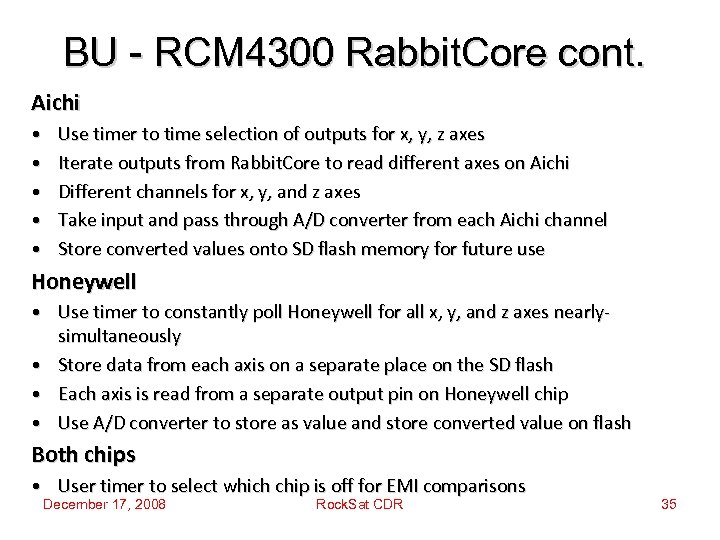

BU - RCM 4300 Rabbit. Core cont. Aichi • • • Use timer to time selection of outputs for x, y, z axes Iterate outputs from Rabbit. Core to read different axes on Aichi Different channels for x, y, and z axes Take input and pass through A/D converter from each Aichi channel Store converted values onto SD flash memory for future use Honeywell • Use timer to constantly poll Honeywell for all x, y, and z axes nearlysimultaneously • Store data from each axis on a separate place on the SD flash • Each axis is read from a separate output pin on Honeywell chip • Use A/D converter to store as value and store converted value on flash Both chips • User timer to select which chip is off for EMI comparisons December 17, 2008 Rock. Sat CDR 35

BU - RCM 4300 Rabbit. Core cont. Aichi • • • Use timer to time selection of outputs for x, y, z axes Iterate outputs from Rabbit. Core to read different axes on Aichi Different channels for x, y, and z axes Take input and pass through A/D converter from each Aichi channel Store converted values onto SD flash memory for future use Honeywell • Use timer to constantly poll Honeywell for all x, y, and z axes nearlysimultaneously • Store data from each axis on a separate place on the SD flash • Each axis is read from a separate output pin on Honeywell chip • Use A/D converter to store as value and store converted value on flash Both chips • User timer to select which chip is off for EMI comparisons December 17, 2008 Rock. Sat CDR 35

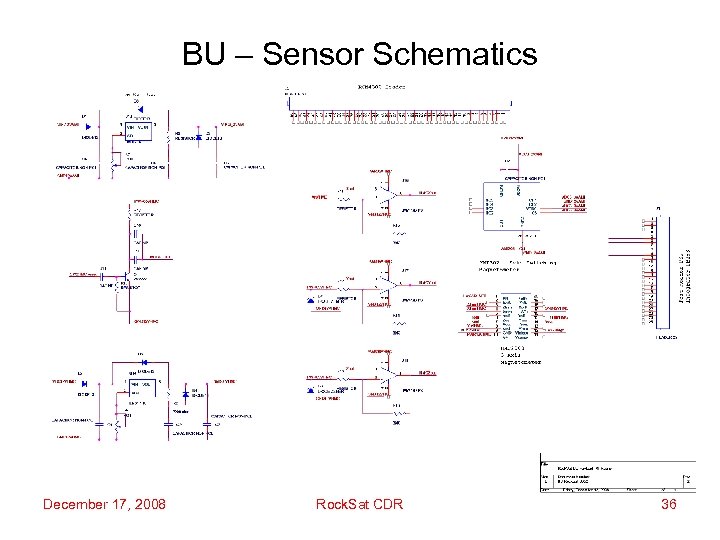

BU – Sensor Schematics December 17, 2008 Rock. Sat CDR 36

BU – Sensor Schematics December 17, 2008 Rock. Sat CDR 36

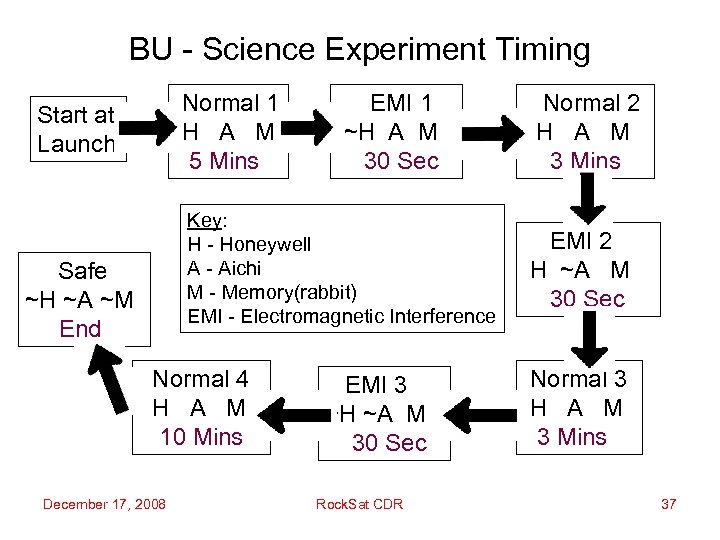

BU - Science Experiment Timing Normal 1 H A M 5 Mins Start at Launch EMI 1 ~H A M 30 Sec Key: H - Honeywell A - Aichi M - Memory(rabbit) EMI - Electromagnetic Interference Safe ~H ~A ~M End Normal 4 H A M 10 Mins December 17, 2008 EMI 3 ~H ~A M 30 Sec Rock. Sat CDR Normal 2 H A M 3 Mins EMI 2 H ~A M 30 Sec Normal 3 H A M 3 Mins 37

BU - Science Experiment Timing Normal 1 H A M 5 Mins Start at Launch EMI 1 ~H A M 30 Sec Key: H - Honeywell A - Aichi M - Memory(rabbit) EMI - Electromagnetic Interference Safe ~H ~A ~M End Normal 4 H A M 10 Mins December 17, 2008 EMI 3 ~H ~A M 30 Sec Rock. Sat CDR Normal 2 H A M 3 Mins EMI 2 H ~A M 30 Sec Normal 3 H A M 3 Mins 37

BU - Data Flows • • 2 sensors, 4 data sources, housekeeping 12 b/sample on Rabbit RCM 4300 Slow change in Earth’s field over flight Changes from spin of rocket (<10 Hz) Sample 10 pts/cycle or 100 Sa/s Estimated flight 22. 5 min or 1350 s 135 k Sa x 4 x 12 b/Sa = 6. 48 Mb = 0. 8 MB Well within low-end SD card capacities December 17, 2008 Rock. Sat CDR 38

BU - Data Flows • • 2 sensors, 4 data sources, housekeeping 12 b/sample on Rabbit RCM 4300 Slow change in Earth’s field over flight Changes from spin of rocket (<10 Hz) Sample 10 pts/cycle or 100 Sa/s Estimated flight 22. 5 min or 1350 s 135 k Sa x 4 x 12 b/Sa = 6. 48 Mb = 0. 8 MB Well within low-end SD card capacities December 17, 2008 Rock. Sat CDR 38

BU Testing Plans • Electrical systems operation – Timing test for sequencing – DAQ test with sensors – SD card storage and retrieval • Sensor operation – Earth field testing – Helmholz coil testing of boards • Power operation – Charging/discharging – Voltage regulation and distribution December 17, 2008 Rock. Sat CDR 39

BU Testing Plans • Electrical systems operation – Timing test for sequencing – DAQ test with sensors – SD card storage and retrieval • Sensor operation – Earth field testing – Helmholz coil testing of boards • Power operation – Charging/discharging – Voltage regulation and distribution December 17, 2008 Rock. Sat CDR 39

BU - Parts & Vendors • Aichi AMI 302 (3 on hand from Aichi; two week order time) • Honeywell (2 on hand; distributors; 2 week order time) • PCB fab - turnaround (5 business days) • PCB Assembly for Aichi (10 business days) • Rabbit Core 4300 (Dev kit on hand) • Miscellaneous Digi. Key/Newark parts December 17, 2008 Rock. Sat CDR 40

BU - Parts & Vendors • Aichi AMI 302 (3 on hand from Aichi; two week order time) • Honeywell (2 on hand; distributors; 2 week order time) • PCB fab - turnaround (5 business days) • PCB Assembly for Aichi (10 business days) • Rabbit Core 4300 (Dev kit on hand) • Miscellaneous Digi. Key/Newark parts December 17, 2008 Rock. Sat CDR 40

BU - Rock. Sat Payload Canister User Guide Compliance • • • Sensor PCB ~15 cm x 2 cm; < 150 g Rabbit PCB ~ 5 cm x 8 cm x 1 cm; <100 g Battery ~ 6 cm x 10 cm x 2 cm; <150 g (Easily reside in ½ canister or even ¼ height) Will follow G-switch and Rocket wire protocol Independent of MAPP system except CG December 17, 2008 Rock. Sat CDR 41

BU - Rock. Sat Payload Canister User Guide Compliance • • • Sensor PCB ~15 cm x 2 cm; < 150 g Rabbit PCB ~ 5 cm x 8 cm x 1 cm; <100 g Battery ~ 6 cm x 10 cm x 2 cm; <150 g (Easily reside in ½ canister or even ¼ height) Will follow G-switch and Rocket wire protocol Independent of MAPP system except CG December 17, 2008 Rock. Sat CDR 41

Shared Can Logistics Plan • Penn State Mont Alto - Boston University • Each system is independent • Structural interfacing (PSMA) December 17, 2008 BU Car ds + Ba Rock. Sat CDR tt 42

Shared Can Logistics Plan • Penn State Mont Alto - Boston University • Each system is independent • Structural interfacing (PSMA) December 17, 2008 BU Car ds + Ba Rock. Sat CDR tt 42

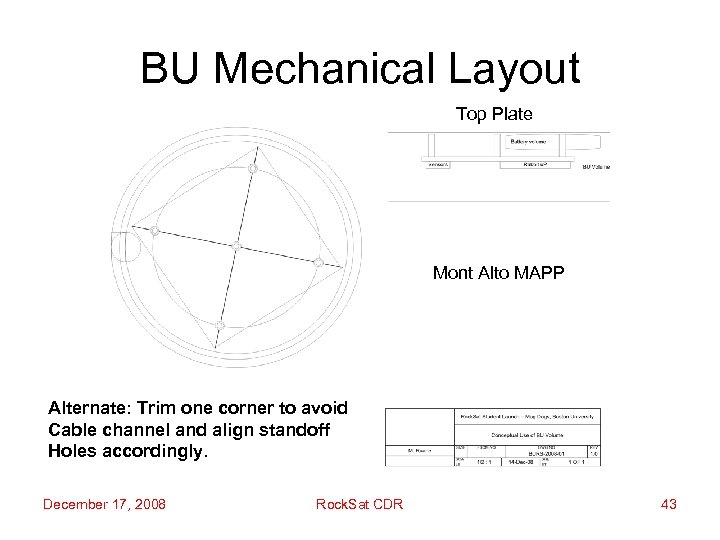

BU Mechanical Layout Top Plate Mont Alto MAPP Alternate: Trim one corner to avoid Cable channel and align standoff Holes accordingly. December 17, 2008 Rock. Sat CDR 43

BU Mechanical Layout Top Plate Mont Alto MAPP Alternate: Trim one corner to avoid Cable channel and align standoff Holes accordingly. December 17, 2008 Rock. Sat CDR 43

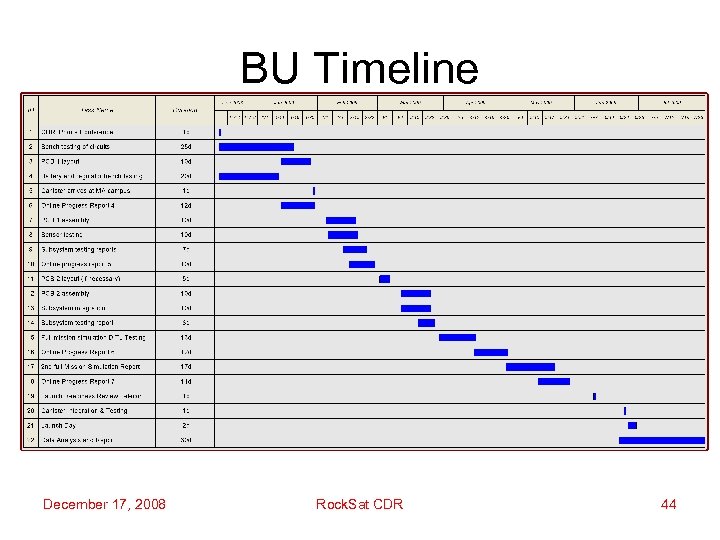

BU Timeline December 17, 2008 Rock. Sat CDR 44

BU Timeline December 17, 2008 Rock. Sat CDR 44

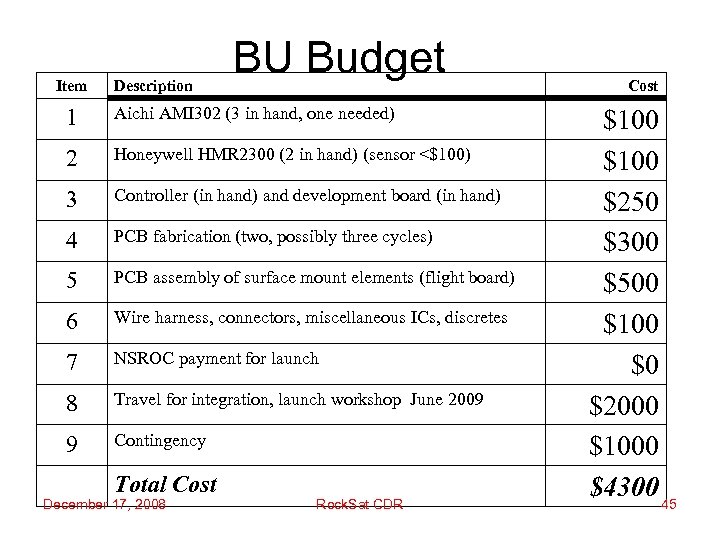

Item Description BU Budget 1 Aichi AMI 302 (3 in hand, one needed) 2 Honeywell HMR 2300 (2 in hand) (sensor <$100) 3 Controller (in hand) and development board (in hand) 4 PCB fabrication (two, possibly three cycles) 5 PCB assembly of surface mount elements (flight board) 6 Wire harness, connectors, miscellaneous ICs, discretes 7 NSROC payment for launch 8 Travel for integration, launch workshop June 2009 9 Contingency Total Cost December 17, 2008 Rock. Sat CDR Cost $100 $250 $300 $500 $100 $0 $2000 $1000 $4300 45

Item Description BU Budget 1 Aichi AMI 302 (3 in hand, one needed) 2 Honeywell HMR 2300 (2 in hand) (sensor <$100) 3 Controller (in hand) and development board (in hand) 4 PCB fabrication (two, possibly three cycles) 5 PCB assembly of surface mount elements (flight board) 6 Wire harness, connectors, miscellaneous ICs, discretes 7 NSROC payment for launch 8 Travel for integration, launch workshop June 2009 9 Contingency Total Cost December 17, 2008 Rock. Sat CDR Cost $100 $250 $300 $500 $100 $0 $2000 $1000 $4300 45

• BU Conclusions – BU Mag Dogs Team is closing out its semester and catching up to the Rock. Sat schedule – We have an enthusiastic group of students, a lab space for work, and a Nanosat team becoming available in January – Our experiment is building on a sensor board from USERS and a microcontroller DAQ system December 17, 2008 Rock. Sat CDR 46

• BU Conclusions – BU Mag Dogs Team is closing out its semester and catching up to the Rock. Sat schedule – We have an enthusiastic group of students, a lab space for work, and a Nanosat team becoming available in January – Our experiment is building on a sensor board from USERS and a microcontroller DAQ system December 17, 2008 Rock. Sat CDR 46

Appendices – Backup Slides December 17, 2008 Rock. Sat CDR 47

Appendices – Backup Slides December 17, 2008 Rock. Sat CDR 47

Management Dr. Michael Ruane Professor, ECE Dept. , Boston University 8 St. Mary's Street, Boston, MA 02215 Phone: 617 -353 -3256 617 -353 -6440 fax E-Mail: mfr@bu. edu Dr. Siegfried Herzog Penn State University at Mont Alto Assistant Professor of Mechanical Engineering 1 Campus Drive Mont Alto, PA 17237 Tel (717)-749 -6209 Fax (717)-749 -6069 E-Mail: hgn@psu. edu December 17, 2008 Rock. Sat CDR 48

Management Dr. Michael Ruane Professor, ECE Dept. , Boston University 8 St. Mary's Street, Boston, MA 02215 Phone: 617 -353 -3256 617 -353 -6440 fax E-Mail: mfr@bu. edu Dr. Siegfried Herzog Penn State University at Mont Alto Assistant Professor of Mechanical Engineering 1 Campus Drive Mont Alto, PA 17237 Tel (717)-749 -6209 Fax (717)-749 -6069 E-Mail: hgn@psu. edu December 17, 2008 Rock. Sat CDR 48

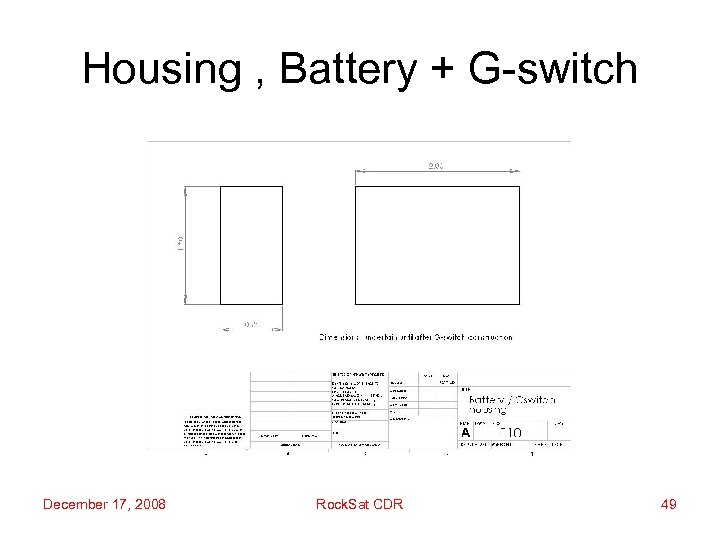

Housing , Battery + G-switch December 17, 2008 Rock. Sat CDR 49

Housing , Battery + G-switch December 17, 2008 Rock. Sat CDR 49

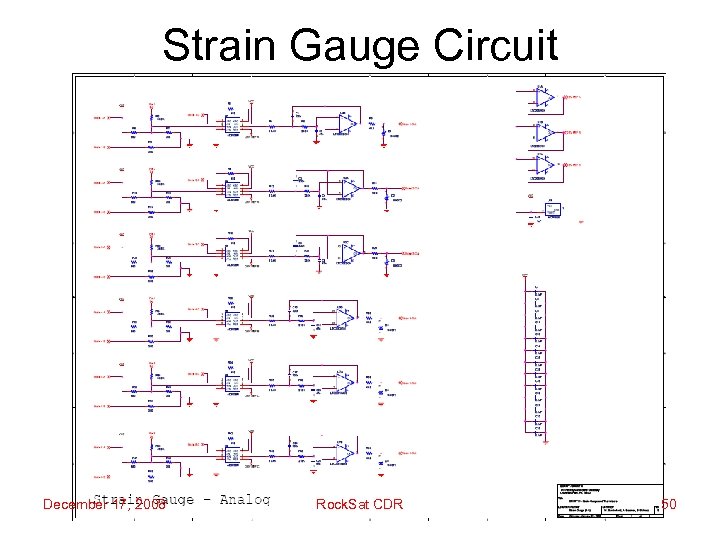

Strain Gauge Circuit December 17, 2008 Rock. Sat CDR 50

Strain Gauge Circuit December 17, 2008 Rock. Sat CDR 50

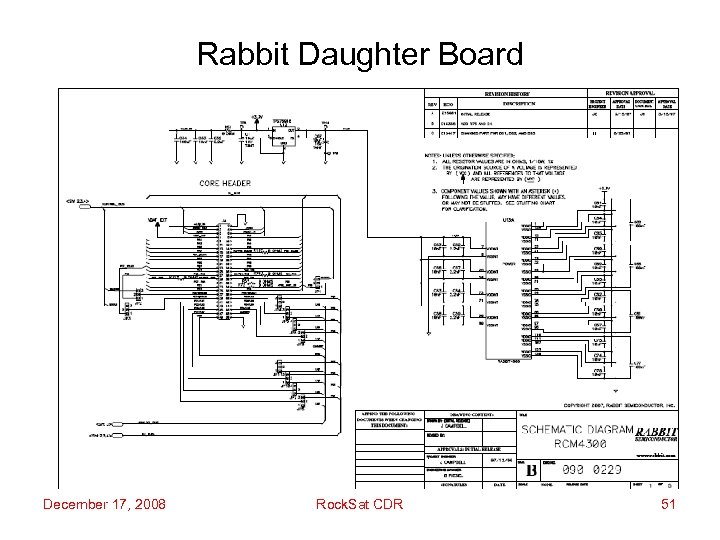

Rabbit Daughter Board December 17, 2008 Rock. Sat CDR 51

Rabbit Daughter Board December 17, 2008 Rock. Sat CDR 51

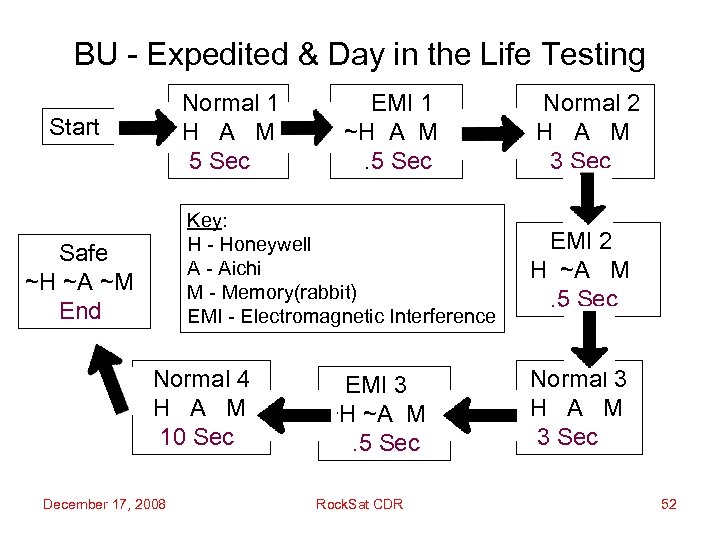

BU - Expedited & Day in the Life Testing Normal 1 H A M 5 Sec Start EMI 1 ~H A M . 5 Sec Key: H - Honeywell A - Aichi M - Memory(rabbit) EMI - Electromagnetic Interference Safe ~H ~A ~M End Normal 4 H A M 10 Sec December 17, 2008 EMI 3 ~H ~A M . 5 Sec Rock. Sat CDR Normal 2 H A M 3 Sec EMI 2 H ~A M . 5 Sec Normal 3 H A M 3 Sec 52

BU - Expedited & Day in the Life Testing Normal 1 H A M 5 Sec Start EMI 1 ~H A M . 5 Sec Key: H - Honeywell A - Aichi M - Memory(rabbit) EMI - Electromagnetic Interference Safe ~H ~A ~M End Normal 4 H A M 10 Sec December 17, 2008 EMI 3 ~H ~A M . 5 Sec Rock. Sat CDR Normal 2 H A M 3 Sec EMI 2 H ~A M . 5 Sec Normal 3 H A M 3 Sec 52

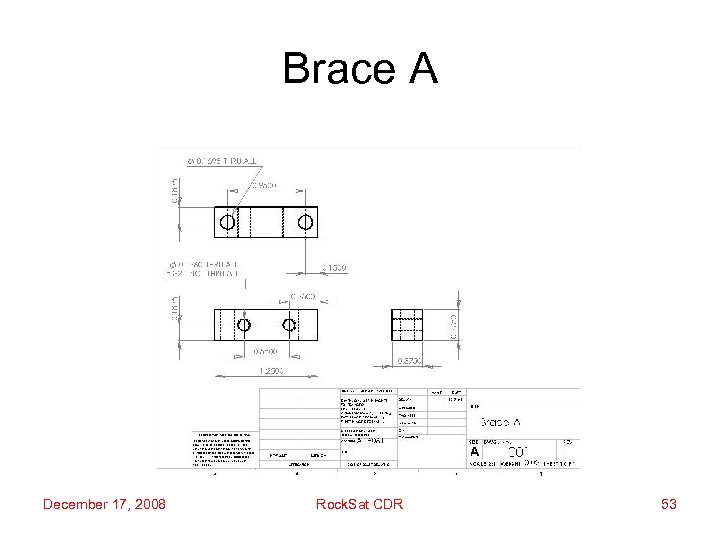

Brace A December 17, 2008 Rock. Sat CDR 53

Brace A December 17, 2008 Rock. Sat CDR 53

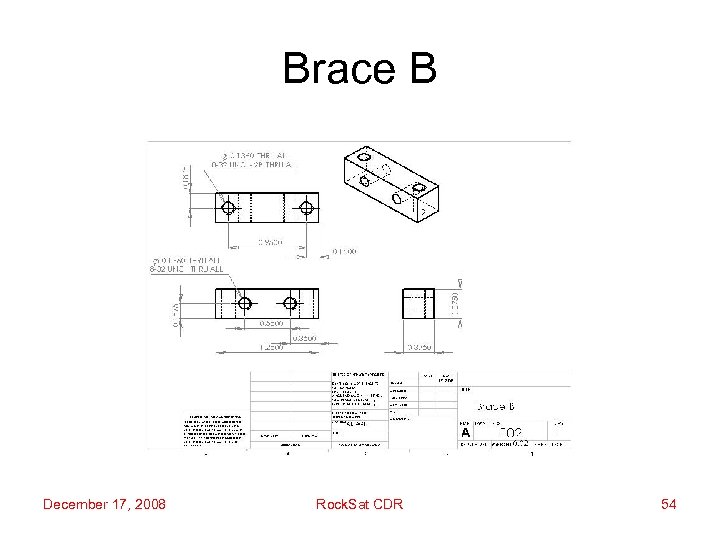

Brace B December 17, 2008 Rock. Sat CDR 54

Brace B December 17, 2008 Rock. Sat CDR 54

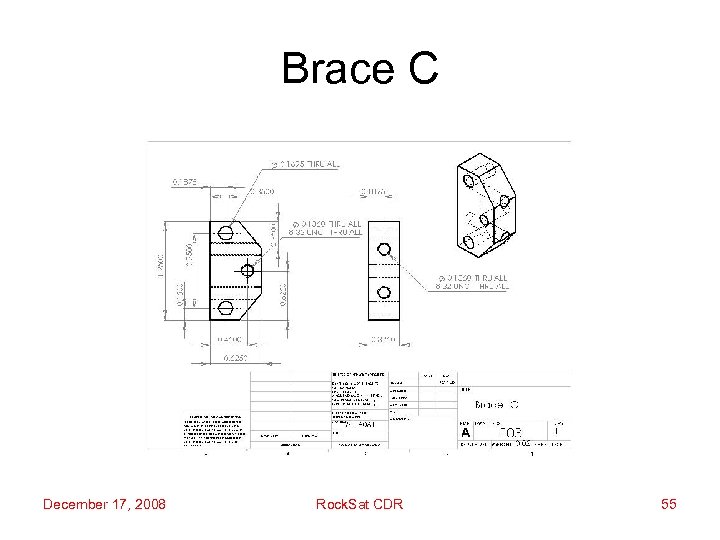

Brace C December 17, 2008 Rock. Sat CDR 55

Brace C December 17, 2008 Rock. Sat CDR 55

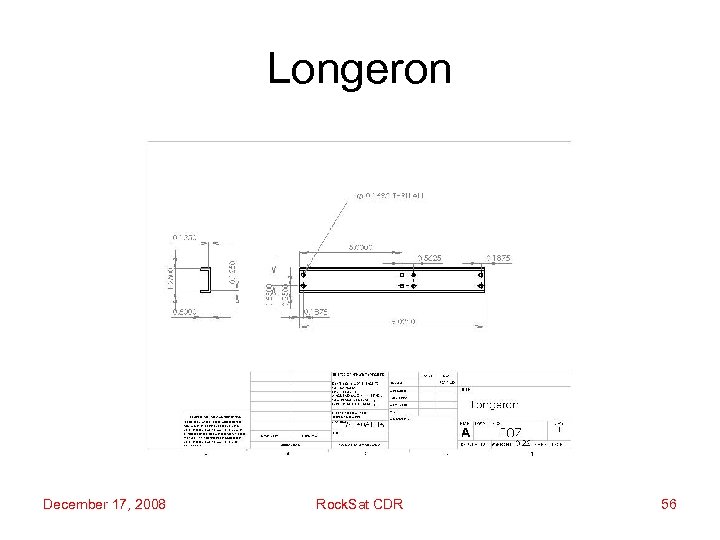

Longeron December 17, 2008 Rock. Sat CDR 56

Longeron December 17, 2008 Rock. Sat CDR 56

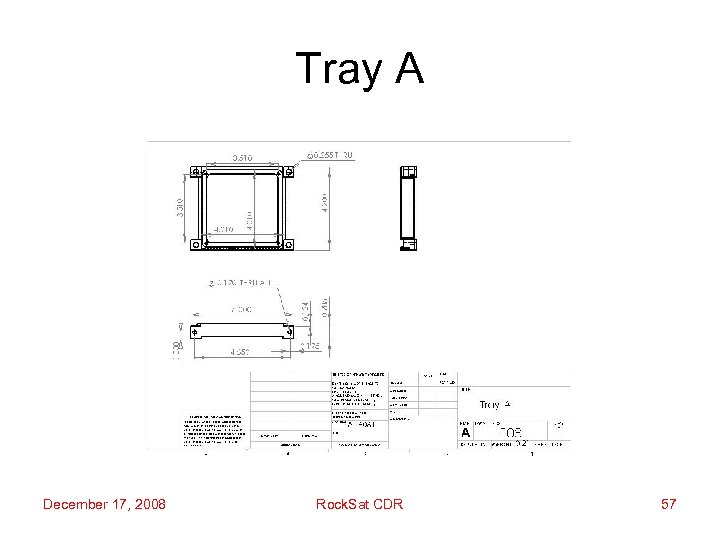

Tray A December 17, 2008 Rock. Sat CDR 57

Tray A December 17, 2008 Rock. Sat CDR 57