2da53e60049242bbf389cedcd95dc0e6.ppt

- Количество слайдов: 63

Monitoring & Management System All materials and information contained in this presentation are Copyright 2001, MESON Fiber Optics, Inc. , One Technology Dr. , Hallstead, PA 18822. Phone: 570 -879 -4774, Fax: 570 -879 -4744, Email: tc@mesonfiberoptics. com

Monitoring & Management System All materials and information contained in this presentation are Copyright 2001, MESON Fiber Optics, Inc. , One Technology Dr. , Hallstead, PA 18822. Phone: 570 -879 -4774, Fax: 570 -879 -4744, Email: tc@mesonfiberoptics. com

FIBER OPTIC MONITORING & MANAGEMENT Important Points of Fibre. Guard Presentation: • Benefits of Optical Monitoring • Review of Fibre. Guard Modules • Water Detection • Enhanced Network Security and Intrusion Detection • Fibre. Guard and Other Technologies

FIBER OPTIC MONITORING & MANAGEMENT Important Points of Fibre. Guard Presentation: • Benefits of Optical Monitoring • Review of Fibre. Guard Modules • Water Detection • Enhanced Network Security and Intrusion Detection • Fibre. Guard and Other Technologies

FIBER OPTIC MONITORING & MANAGEMENT MESON Background: • Established in 1987 • Designer and Manufacturer of Fiber Optic Products: – – Installation, Termination, & Test Equipment LAN/WAN Connectivity Products Optical Multiplexing (WDM) Equipment Monitoring and Management = Fibre. Guard

FIBER OPTIC MONITORING & MANAGEMENT MESON Background: • Established in 1987 • Designer and Manufacturer of Fiber Optic Products: – – Installation, Termination, & Test Equipment LAN/WAN Connectivity Products Optical Multiplexing (WDM) Equipment Monitoring and Management = Fibre. Guard

FIBER OPTIC MONITORING & MANAGEMENT Monitoring and Management

FIBER OPTIC MONITORING & MANAGEMENT Monitoring and Management

FIBER OPTIC MONITORING & MANAGEMENT Advantages Of Optical Monitoring – – – – Reduce Network Downtime Automated Network Maintenance Track Optical Patterns & Trends (Degradation) Manage Optical Network Components Optional Connectivity Modules Proactively Switch to Backup Fibers Detection of Water Intrusion Detection of Network Tampering

FIBER OPTIC MONITORING & MANAGEMENT Advantages Of Optical Monitoring – – – – Reduce Network Downtime Automated Network Maintenance Track Optical Patterns & Trends (Degradation) Manage Optical Network Components Optional Connectivity Modules Proactively Switch to Backup Fibers Detection of Water Intrusion Detection of Network Tampering

FIBER OPTIC MONITORING & MANAGEMENT Reduce Network Downtime – Warns of Decreasing Optical Signal – View Real-time Optical Levels Network Operation Center • Resolve Technical Support Issues • Automated Routine Testing • Improve Customer Service – Tracks Degradation of Fiber • Plan for Repair of Trouble Backbones from

FIBER OPTIC MONITORING & MANAGEMENT Reduce Network Downtime – Warns of Decreasing Optical Signal – View Real-time Optical Levels Network Operation Center • Resolve Technical Support Issues • Automated Routine Testing • Improve Customer Service – Tracks Degradation of Fiber • Plan for Repair of Trouble Backbones from

FIBER OPTIC MONITORING & MANAGEMENT Automated Network Maintenance – Verify Optical Power Levels Without Disconnecting the Network Equipment – Answer These Questions: “Since the network was installed, when was the last time it was taken down for routine testing? ” “Has power loss already occurred since installation? ” THE NETWORK MAY ALREADY BE CLOSE TO FAILURE !

FIBER OPTIC MONITORING & MANAGEMENT Automated Network Maintenance – Verify Optical Power Levels Without Disconnecting the Network Equipment – Answer These Questions: “Since the network was installed, when was the last time it was taken down for routine testing? ” “Has power loss already occurred since installation? ” THE NETWORK MAY ALREADY BE CLOSE TO FAILURE !

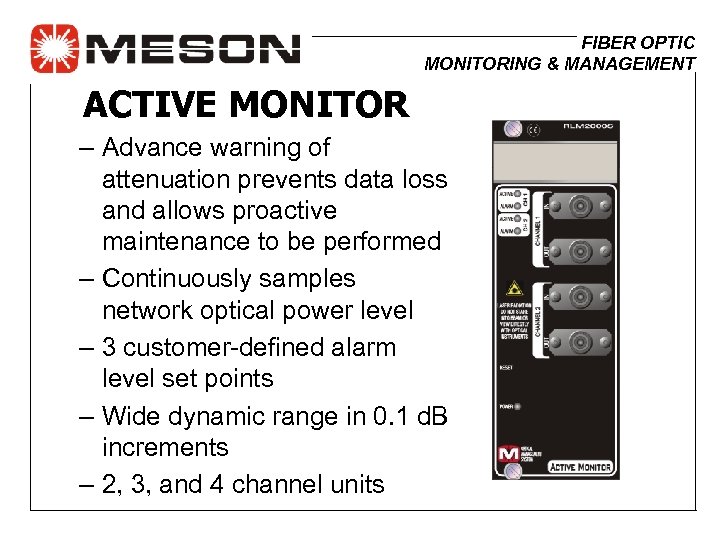

FIBER OPTIC MONITORING & MANAGEMENT ACTIVE MONITOR – Advance warning of attenuation prevents data loss and allows proactive maintenance to be performed – Continuously samples network optical power level – 3 customer-defined alarm level set points – Wide dynamic range in 0. 1 d. B increments – 2, 3, and 4 channel units

FIBER OPTIC MONITORING & MANAGEMENT ACTIVE MONITOR – Advance warning of attenuation prevents data loss and allows proactive maintenance to be performed – Continuously samples network optical power level – 3 customer-defined alarm level set points – Wide dynamic range in 0. 1 d. B increments – 2, 3, and 4 channel units

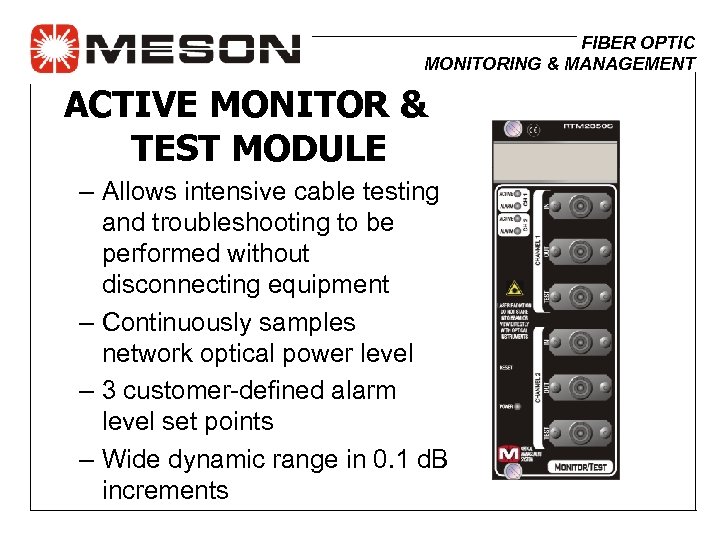

FIBER OPTIC MONITORING & MANAGEMENT ACTIVE MONITOR & TEST MODULE – Allows intensive cable testing and troubleshooting to be performed without disconnecting equipment – Continuously samples network optical power level – 3 customer-defined alarm level set points – Wide dynamic range in 0. 1 d. B increments

FIBER OPTIC MONITORING & MANAGEMENT ACTIVE MONITOR & TEST MODULE – Allows intensive cable testing and troubleshooting to be performed without disconnecting equipment – Continuously samples network optical power level – 3 customer-defined alarm level set points – Wide dynamic range in 0. 1 d. B increments

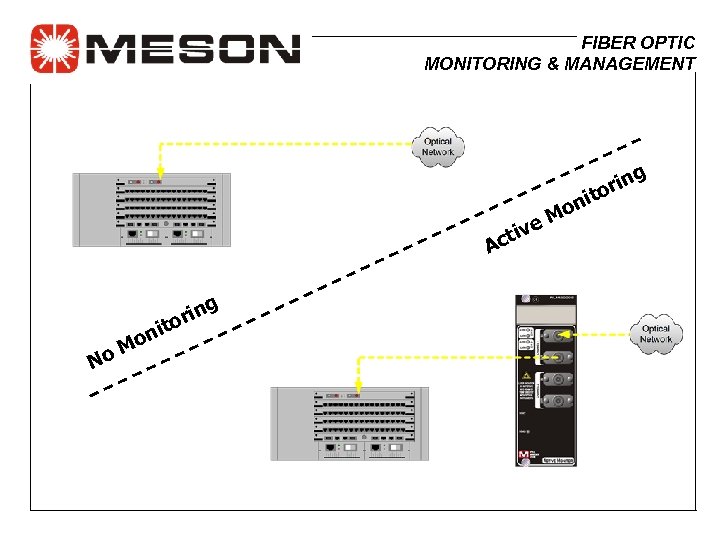

FIBER OPTIC MONITORING & MANAGEMENT g o n ori nit e. M tiv Ac i n ori t No n Mo g

FIBER OPTIC MONITORING & MANAGEMENT g o n ori nit e. M tiv Ac i n ori t No n Mo g

FIBER OPTIC MONITORING & MANAGEMENT Network Segmentation – Detects problems in customer equipment and fiber jumpers. – Differentiates “Customer” faults from “Network” faults – Eliminates the expense of unnecessary visits to the customer site. – Increases level of customer service

FIBER OPTIC MONITORING & MANAGEMENT Network Segmentation – Detects problems in customer equipment and fiber jumpers. – Differentiates “Customer” faults from “Network” faults – Eliminates the expense of unnecessary visits to the customer site. – Increases level of customer service

DIAGRAM - SEGMENTATION

DIAGRAM - SEGMENTATION

FIBER OPTIC MONITORING & MANAGEMENT Track Optical Trends – Power Level History Reporting – Graphical Analysis of Power over Time – Warns That Power Levels are Approaching the Receiver’s Minimum Sensitivity – Analysis of Fiber and Component Degradation

FIBER OPTIC MONITORING & MANAGEMENT Track Optical Trends – Power Level History Reporting – Graphical Analysis of Power over Time – Warns That Power Levels are Approaching the Receiver’s Minimum Sensitivity – Analysis of Fiber and Component Degradation

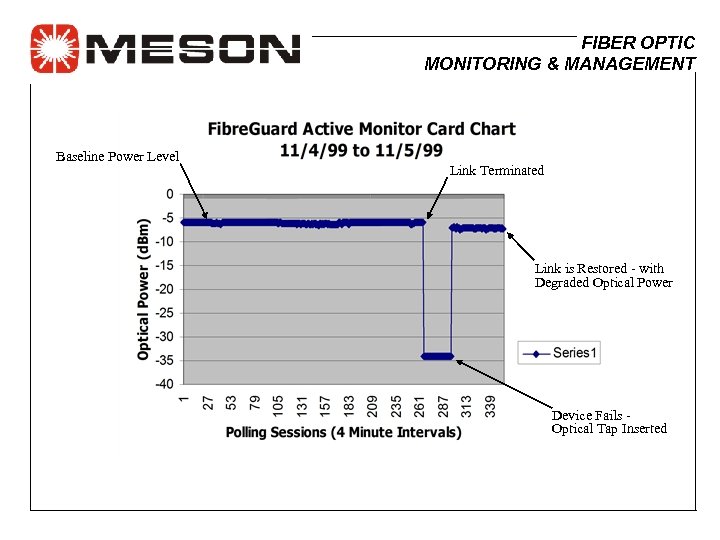

FIBER OPTIC MONITORING & MANAGEMENT Baseline Power Level Link Terminated Link is Restored - with Degraded Optical Power Device Fails Optical Tap Inserted

FIBER OPTIC MONITORING & MANAGEMENT Baseline Power Level Link Terminated Link is Restored - with Degraded Optical Power Device Fails Optical Tap Inserted

FIBER OPTIC MONITORING & MANAGEMENT Manage Optical Network Components – Locations of Equipment, Splices, etc. – Manufacturers, Model Numbers, etc. – Equipment Optical Specifications – Emergency Call-Out Information – Display of Maps / Documentation

FIBER OPTIC MONITORING & MANAGEMENT Manage Optical Network Components – Locations of Equipment, Splices, etc. – Manufacturers, Model Numbers, etc. – Equipment Optical Specifications – Emergency Call-Out Information – Display of Maps / Documentation

FIBER OPTIC MONITORING & MANAGEMENT Optical Switching – Disaster Recovery – Proactively Diverts Signal • Can Switch to Backup BEFORE Signal Loss Occurs • Prevent Network Outages – Use on Devices with no Redundancy • Fibre. Channel / Storage Area Networks (SAN’s) • Ethernet & FDDI / Local Area Networks – Use for Sites Not Protected by SONET Fabric – Allows for More Intensive Backbone Maintenance

FIBER OPTIC MONITORING & MANAGEMENT Optical Switching – Disaster Recovery – Proactively Diverts Signal • Can Switch to Backup BEFORE Signal Loss Occurs • Prevent Network Outages – Use on Devices with no Redundancy • Fibre. Channel / Storage Area Networks (SAN’s) • Ethernet & FDDI / Local Area Networks – Use for Sites Not Protected by SONET Fabric – Allows for More Intensive Backbone Maintenance

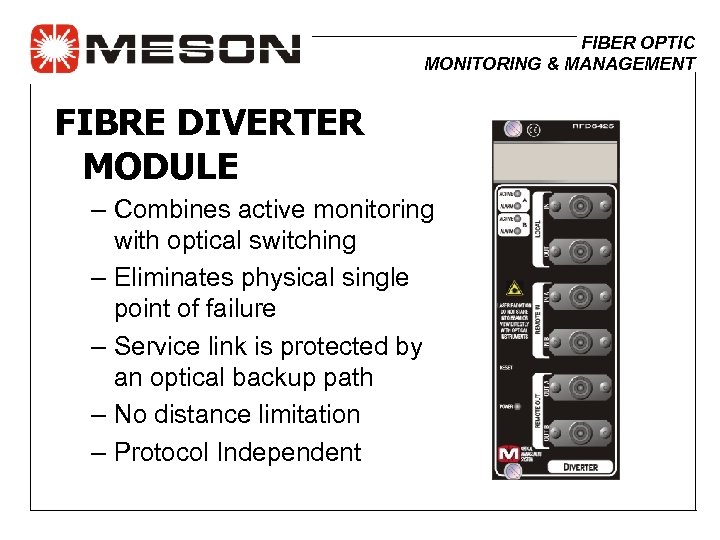

FIBER OPTIC MONITORING & MANAGEMENT FIBRE DIVERTER MODULE – Combines active monitoring with optical switching – Eliminates physical single point of failure – Service link is protected by an optical backup path – No distance limitation – Protocol Independent

FIBER OPTIC MONITORING & MANAGEMENT FIBRE DIVERTER MODULE – Combines active monitoring with optical switching – Eliminates physical single point of failure – Service link is protected by an optical backup path – No distance limitation – Protocol Independent

FIBER OPTIC MONITORING & MANAGEMENT The Fibre. Guard ‘System’

FIBER OPTIC MONITORING & MANAGEMENT The Fibre. Guard ‘System’

FIBER OPTIC MONITORING & MANAGEMENT How to Install Fibre. Guard Monitoring? – Mount Chassis Using 4 Screws – Connect Power Input – Connect Cable from Chassis to Software – Disconnect Fiber Input to Network Device and Connect to Monitor Card – Connect Fiber Cable from Monitor Card to Network Device – MONITORING IS STARTED !

FIBER OPTIC MONITORING & MANAGEMENT How to Install Fibre. Guard Monitoring? – Mount Chassis Using 4 Screws – Connect Power Input – Connect Cable from Chassis to Software – Disconnect Fiber Input to Network Device and Connect to Monitor Card – Connect Fiber Cable from Monitor Card to Network Device – MONITORING IS STARTED !

FIBER OPTIC MONITORING & MANAGEMENT Hardware Required: – Chassis – Power Supply – System Control Unit – User Modules Depending Upon Needs: • Monitor Cards • Optical Switching • Converters • Repeaters • WDM

FIBER OPTIC MONITORING & MANAGEMENT Hardware Required: – Chassis – Power Supply – System Control Unit – User Modules Depending Upon Needs: • Monitor Cards • Optical Switching • Converters • Repeaters • WDM

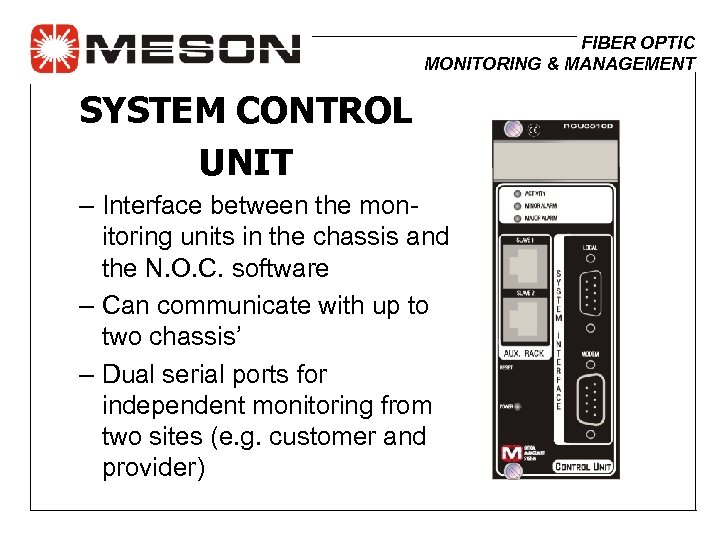

FIBER OPTIC MONITORING & MANAGEMENT SYSTEM CONTROL UNIT – Interface between the monitoring units in the chassis and the N. O. C. software – Can communicate with up to two chassis’ – Dual serial ports for independent monitoring from two sites (e. g. customer and provider)

FIBER OPTIC MONITORING & MANAGEMENT SYSTEM CONTROL UNIT – Interface between the monitoring units in the chassis and the N. O. C. software – Can communicate with up to two chassis’ – Dual serial ports for independent monitoring from two sites (e. g. customer and provider)

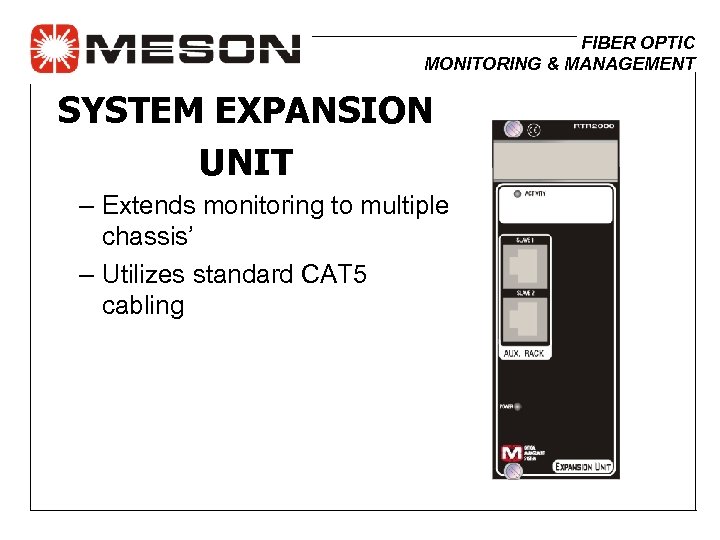

FIBER OPTIC MONITORING & MANAGEMENT SYSTEM EXPANSION UNIT – Extends monitoring to multiple chassis’ – Utilizes standard CAT 5 cabling

FIBER OPTIC MONITORING & MANAGEMENT SYSTEM EXPANSION UNIT – Extends monitoring to multiple chassis’ – Utilizes standard CAT 5 cabling

FIBER OPTIC MONITORING & MANAGEMENT Fibre. Guard is Much More than a Monitoring System: • Dark Fiber Monitoring • Active Network Cards – WDM / DWDM – LAN to WAN/MAN Connectivity – Repeaters – Amplifiers / Link Extenders • Water Detection • Enhanced Network Security

FIBER OPTIC MONITORING & MANAGEMENT Fibre. Guard is Much More than a Monitoring System: • Dark Fiber Monitoring • Active Network Cards – WDM / DWDM – LAN to WAN/MAN Connectivity – Repeaters – Amplifiers / Link Extenders • Water Detection • Enhanced Network Security

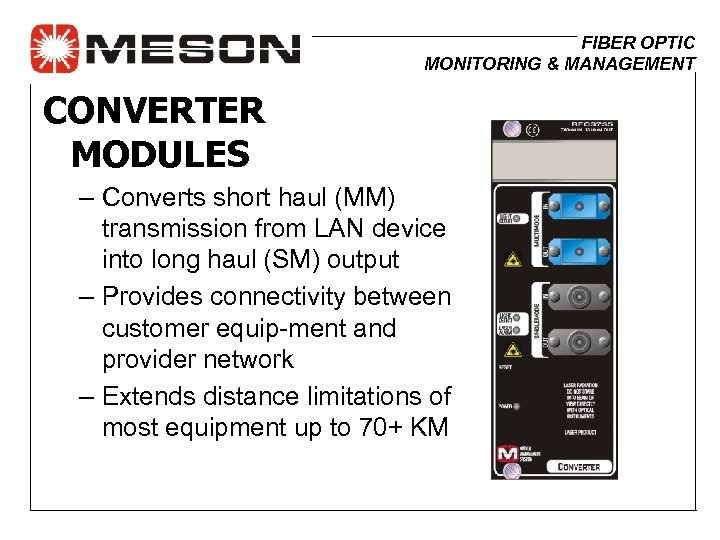

FIBER OPTIC MONITORING & MANAGEMENT CONVERTER MODULES – Converts short haul (MM) transmission from LAN device into long haul (SM) output – Provides connectivity between customer equip-ment and provider network – Extends distance limitations of most equipment up to 70+ KM

FIBER OPTIC MONITORING & MANAGEMENT CONVERTER MODULES – Converts short haul (MM) transmission from LAN device into long haul (SM) output – Provides connectivity between customer equip-ment and provider network – Extends distance limitations of most equipment up to 70+ KM

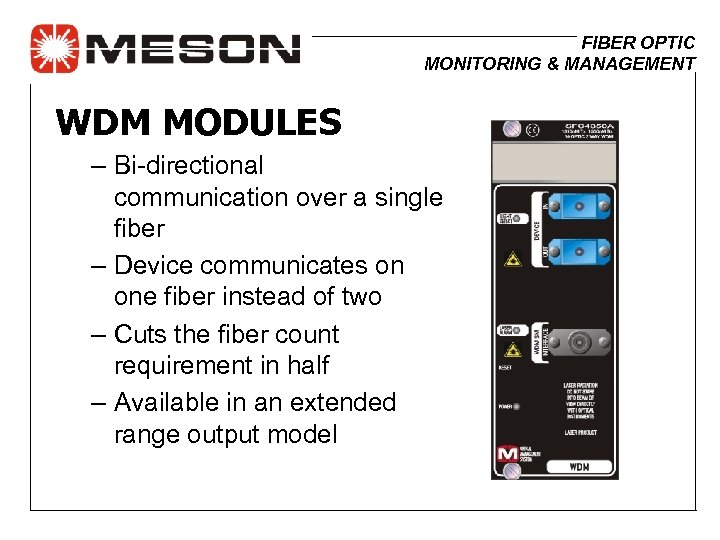

FIBER OPTIC MONITORING & MANAGEMENT WDM MODULES – Bi-directional communication over a single fiber – Device communicates on one fiber instead of two – Cuts the fiber count requirement in half – Available in an extended range output model

FIBER OPTIC MONITORING & MANAGEMENT WDM MODULES – Bi-directional communication over a single fiber – Device communicates on one fiber instead of two – Cuts the fiber count requirement in half – Available in an extended range output model

FIBER OPTIC MONITORING & MANAGEMENT REPEATER MODULE – Extends the distance between active network elements – Tested to 100+ KM – Protocol Independent

FIBER OPTIC MONITORING & MANAGEMENT REPEATER MODULE – Extends the distance between active network elements – Tested to 100+ KM – Protocol Independent

FIBER OPTIC MONITORING & MANAGEMENT The Fibre. Guard System can be Expanded for Resolution of Complex Network Problems: • Disaster Recovery • Equipment with narrow optical specifications (Such as SUN Microsystems SAN equipment. ) • Connectivity between Customer’s multimode equipment and Provider’s singlemode network

FIBER OPTIC MONITORING & MANAGEMENT The Fibre. Guard System can be Expanded for Resolution of Complex Network Problems: • Disaster Recovery • Equipment with narrow optical specifications (Such as SUN Microsystems SAN equipment. ) • Connectivity between Customer’s multimode equipment and Provider’s singlemode network

DIAGRAM - SWITCH, MONITOR, MM-SM

DIAGRAM - SWITCH, MONITOR, MM-SM

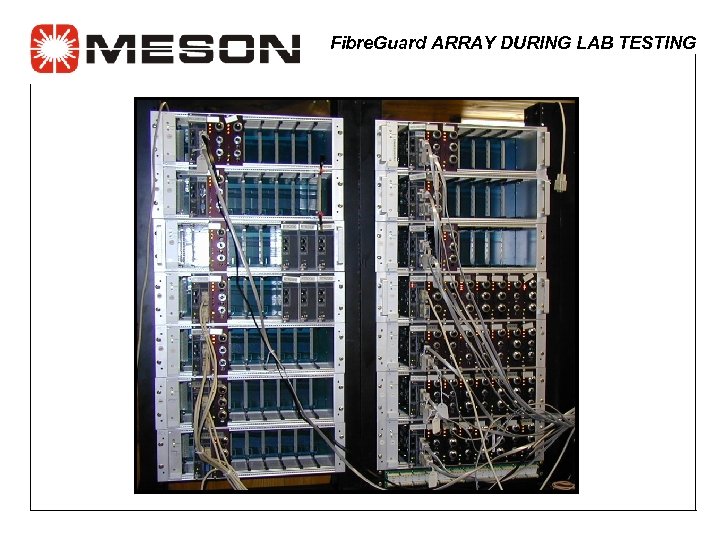

Fibre. Guard ARRAY DURING LAB TESTING

Fibre. Guard ARRAY DURING LAB TESTING

FIBER OPTIC MONITORING & MANAGEMENT Water Detection

FIBER OPTIC MONITORING & MANAGEMENT Water Detection

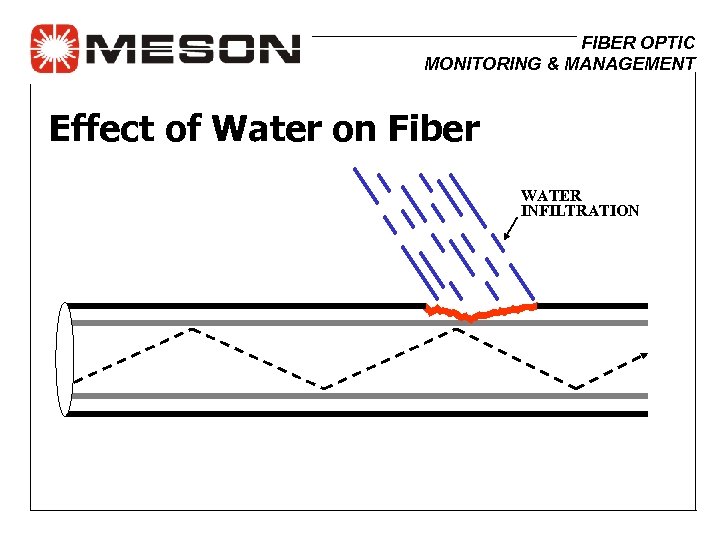

FIBER OPTIC MONITORING & MANAGEMENT How Does Water Effect Fiber? – Deteriorates Splices – Bonds Directly with Glass • Impurities in Water • By-product of Chemical Reaction with Strength Member – Resulting Change in the Fiber’s Refractive Property Allows Light to Escape – Situation Gets Worse Over Time Until Minimum Receiver Sensitivity is Reached and Network Fails

FIBER OPTIC MONITORING & MANAGEMENT How Does Water Effect Fiber? – Deteriorates Splices – Bonds Directly with Glass • Impurities in Water • By-product of Chemical Reaction with Strength Member – Resulting Change in the Fiber’s Refractive Property Allows Light to Escape – Situation Gets Worse Over Time Until Minimum Receiver Sensitivity is Reached and Network Fails

FIBER OPTIC MONITORING & MANAGEMENT Methods of Water Intrusion Into Splice Case – Improper Assembly During Installation – Cut or Break in Cable Jacket – Settling of Manhole or Splice Case

FIBER OPTIC MONITORING & MANAGEMENT Methods of Water Intrusion Into Splice Case – Improper Assembly During Installation – Cut or Break in Cable Jacket – Settling of Manhole or Splice Case

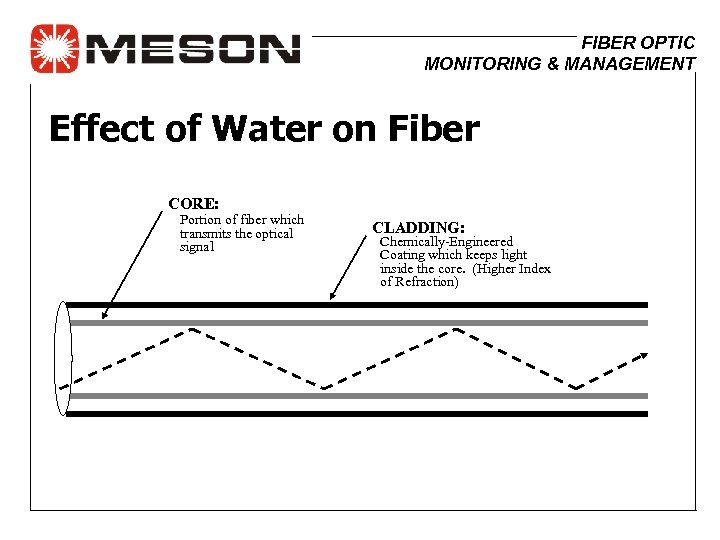

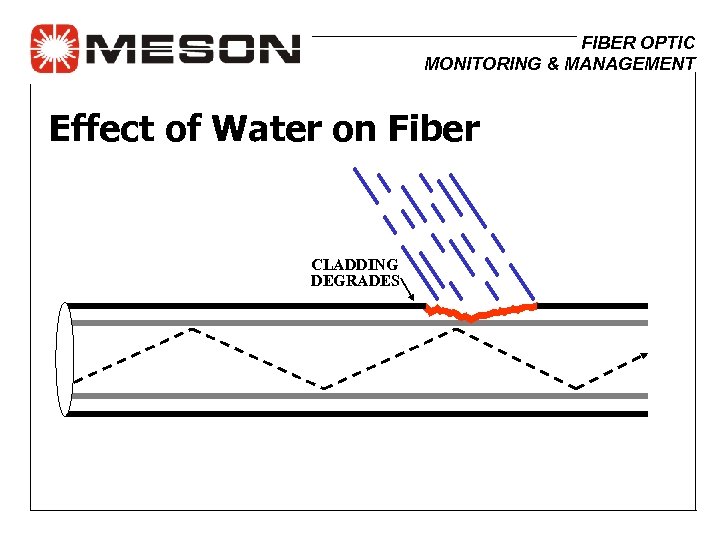

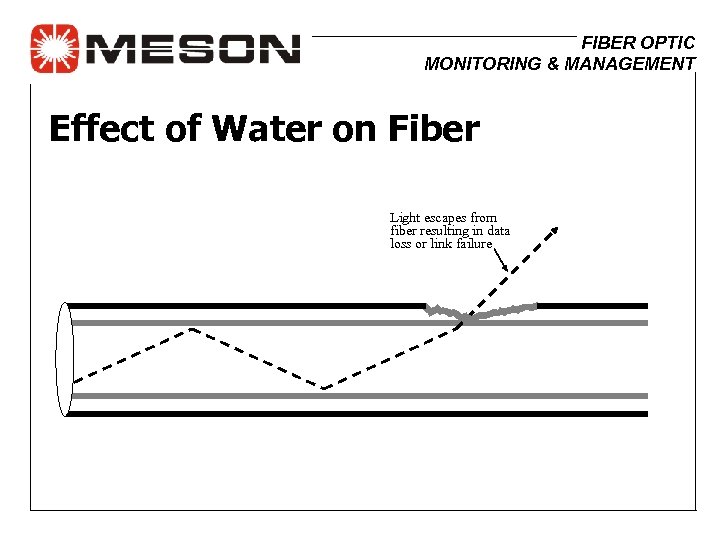

FIBER OPTIC MONITORING & MANAGEMENT Effect of Water on Fiber CORE: Portion of fiber which transmits the optical signal CLADDING: Chemically-Engineered Coating which keeps light inside the core. (Higher Index of Refraction)

FIBER OPTIC MONITORING & MANAGEMENT Effect of Water on Fiber CORE: Portion of fiber which transmits the optical signal CLADDING: Chemically-Engineered Coating which keeps light inside the core. (Higher Index of Refraction)

FIBER OPTIC MONITORING & MANAGEMENT Effect of Water on Fiber

FIBER OPTIC MONITORING & MANAGEMENT Effect of Water on Fiber

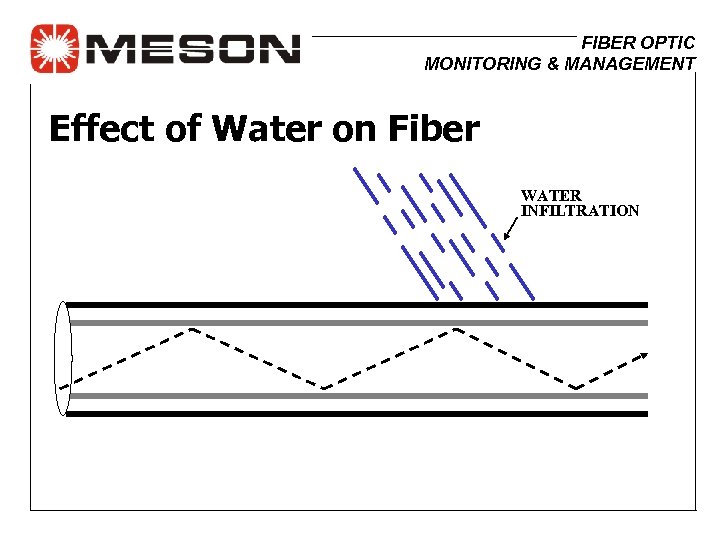

FIBER OPTIC MONITORING & MANAGEMENT Effect of Water on Fiber WATER INFILTRATION

FIBER OPTIC MONITORING & MANAGEMENT Effect of Water on Fiber WATER INFILTRATION

FIBER OPTIC MONITORING & MANAGEMENT Effect of Water on Fiber WATER INFILTRATION

FIBER OPTIC MONITORING & MANAGEMENT Effect of Water on Fiber WATER INFILTRATION

FIBER OPTIC MONITORING & MANAGEMENT Effect of Water on Fiber CLADDING DEGRADES

FIBER OPTIC MONITORING & MANAGEMENT Effect of Water on Fiber CLADDING DEGRADES

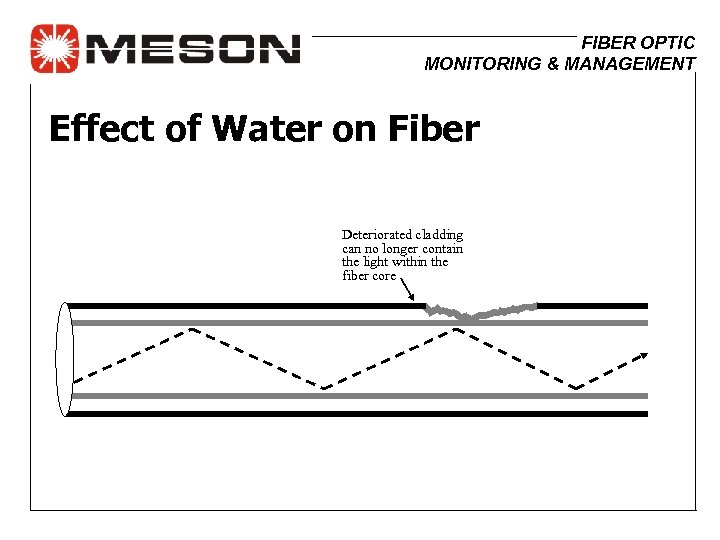

FIBER OPTIC MONITORING & MANAGEMENT Effect of Water on Fiber Deteriorated cladding can no longer contain the light within the fiber core

FIBER OPTIC MONITORING & MANAGEMENT Effect of Water on Fiber Deteriorated cladding can no longer contain the light within the fiber core

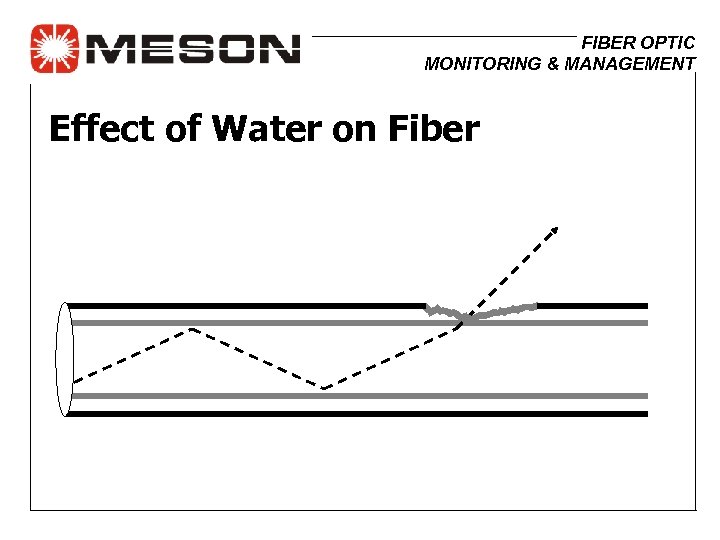

FIBER OPTIC MONITORING & MANAGEMENT Effect of Water on Fiber

FIBER OPTIC MONITORING & MANAGEMENT Effect of Water on Fiber

FIBER OPTIC MONITORING & MANAGEMENT Effect of Water on Fiber Light escapes from fiber resulting in data loss or link failure

FIBER OPTIC MONITORING & MANAGEMENT Effect of Water on Fiber Light escapes from fiber resulting in data loss or link failure

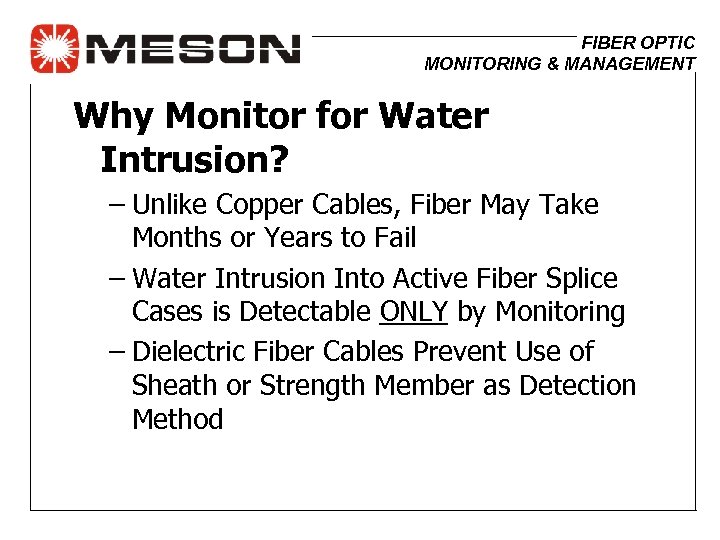

FIBER OPTIC MONITORING & MANAGEMENT Why Monitor for Water Intrusion? – Unlike Copper Cables, Fiber May Take Months or Years to Fail – Water Intrusion Into Active Fiber Splice Cases is Detectable ONLY by Monitoring – Dielectric Fiber Cables Prevent Use of Sheath or Strength Member as Detection Method

FIBER OPTIC MONITORING & MANAGEMENT Why Monitor for Water Intrusion? – Unlike Copper Cables, Fiber May Take Months or Years to Fail – Water Intrusion Into Active Fiber Splice Cases is Detectable ONLY by Monitoring – Dielectric Fiber Cables Prevent Use of Sheath or Strength Member as Detection Method

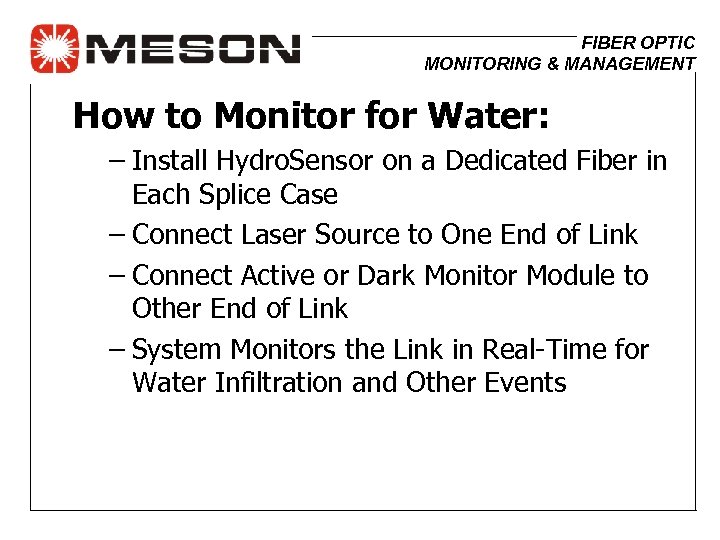

FIBER OPTIC MONITORING & MANAGEMENT How to Monitor for Water: – Install Hydro. Sensor on a Dedicated Fiber in Each Splice Case – Connect Laser Source to One End of Link – Connect Active or Dark Monitor Module to Other End of Link – System Monitors the Link in Real-Time for Water Infiltration and Other Events

FIBER OPTIC MONITORING & MANAGEMENT How to Monitor for Water: – Install Hydro. Sensor on a Dedicated Fiber in Each Splice Case – Connect Laser Source to One End of Link – Connect Active or Dark Monitor Module to Other End of Link – System Monitors the Link in Real-Time for Water Infiltration and Other Events

FIBER OPTIC MONITORING & MANAGEMENT Alternative : –Wait for link to fail and customers to call with service outage or disruption

FIBER OPTIC MONITORING & MANAGEMENT Alternative : –Wait for link to fail and customers to call with service outage or disruption

FIBER OPTIC MONITORING & MANAGEMENT Enhanced Security & Intrusion Detection

FIBER OPTIC MONITORING & MANAGEMENT Enhanced Security & Intrusion Detection

FIBER OPTIC MONITORING & MANAGEMENT SECURITY DEFINED: “The level to which a program or device is safe from unauthorized use. ” -American Heritage Dictionary

FIBER OPTIC MONITORING & MANAGEMENT SECURITY DEFINED: “The level to which a program or device is safe from unauthorized use. ” -American Heritage Dictionary

FIBER OPTIC MONITORING & MANAGEMENT Is There a Security Need? • Many Documented Network Attacks State of Minnesota - 1997, Defense Info. Systems Networks - 1998, U. S. Navy - 1998, NASA - 1998, Pentagon by Israeli Teenager - 1998, 3 U. S. Government Agencies by Chinese - 1999, plus many, many more, and unknown number undisclosed • Network is Vulnerable at the Physical Layer • PDD 62/63 Presidential Directive stating that all government and commercial computer systems should have secured information infrastructure by 2003. Directly addresses interconnected physical infrastructure vulnerabilities. • 120 Nations Have Information Warfare Programs Defense and information security experts estimation. Most prominent international espionage perpetrators against the U. S. : France, Germany, Israel, China, South Korea. This problem is equally apparent in the corporate world. • NSA Statement: “#1 Security issue is telecom and network security breaches”

FIBER OPTIC MONITORING & MANAGEMENT Is There a Security Need? • Many Documented Network Attacks State of Minnesota - 1997, Defense Info. Systems Networks - 1998, U. S. Navy - 1998, NASA - 1998, Pentagon by Israeli Teenager - 1998, 3 U. S. Government Agencies by Chinese - 1999, plus many, many more, and unknown number undisclosed • Network is Vulnerable at the Physical Layer • PDD 62/63 Presidential Directive stating that all government and commercial computer systems should have secured information infrastructure by 2003. Directly addresses interconnected physical infrastructure vulnerabilities. • 120 Nations Have Information Warfare Programs Defense and information security experts estimation. Most prominent international espionage perpetrators against the U. S. : France, Germany, Israel, China, South Korea. This problem is equally apparent in the corporate world. • NSA Statement: “#1 Security issue is telecom and network security breaches”

FIBER OPTIC MONITORING & MANAGEMENT The Myth: Fiber Is Untappable? – Network’s Physical Layer is Unprotected – Non-Intrusive Tap can be Placed in the Network Without Knowledge of N. O. C. – Passive ‘Y-Tap’ Can Be Inserted During Routine or Deliberate Outages Without Knowledge of N. O. C. – Commercially-available Fiber Identifiers Sample or ‘Tap’ the Network Without Detection

FIBER OPTIC MONITORING & MANAGEMENT The Myth: Fiber Is Untappable? – Network’s Physical Layer is Unprotected – Non-Intrusive Tap can be Placed in the Network Without Knowledge of N. O. C. – Passive ‘Y-Tap’ Can Be Inserted During Routine or Deliberate Outages Without Knowledge of N. O. C. – Commercially-available Fiber Identifiers Sample or ‘Tap’ the Network Without Detection

FIBER OPTIC MONITORING & MANAGEMENT Non-Intrusive Tap Demo Palm III Terminal Data Generator Fibre. Guard System Passive Tap & Printer

FIBER OPTIC MONITORING & MANAGEMENT Non-Intrusive Tap Demo Palm III Terminal Data Generator Fibre. Guard System Passive Tap & Printer

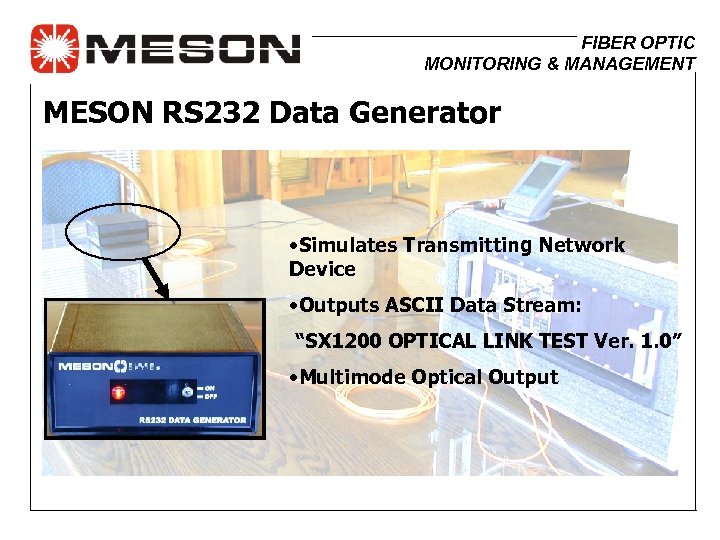

FIBER OPTIC MONITORING & MANAGEMENT MESON RS 232 Data Generator • Simulates Transmitting Network Device • Outputs ASCII Data Stream: “SX 1200 OPTICAL LINK TEST Ver. 1. 0” • Multimode Optical Output

FIBER OPTIC MONITORING & MANAGEMENT MESON RS 232 Data Generator • Simulates Transmitting Network Device • Outputs ASCII Data Stream: “SX 1200 OPTICAL LINK TEST Ver. 1. 0” • Multimode Optical Output

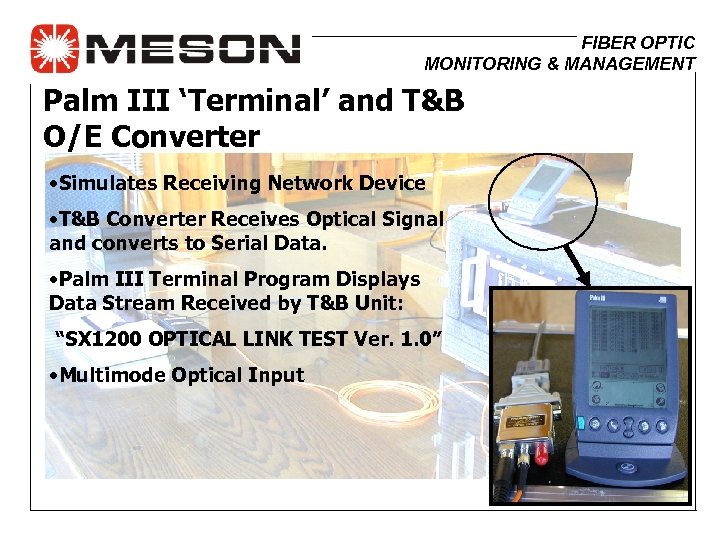

FIBER OPTIC MONITORING & MANAGEMENT Palm III ‘Terminal’ and T&B O/E Converter • Simulates Receiving Network Device • T&B Converter Receives Optical Signal and converts to Serial Data. • Palm III Terminal Program Displays Data Stream Received by T&B Unit: “SX 1200 OPTICAL LINK TEST Ver. 1. 0” • Multimode Optical Input

FIBER OPTIC MONITORING & MANAGEMENT Palm III ‘Terminal’ and T&B O/E Converter • Simulates Receiving Network Device • T&B Converter Receives Optical Signal and converts to Serial Data. • Palm III Terminal Program Displays Data Stream Received by T&B Unit: “SX 1200 OPTICAL LINK TEST Ver. 1. 0” • Multimode Optical Input

FIBER OPTIC MONITORING & MANAGEMENT MESON Non-Intrusive Tap & Line Printer • Passively Intercepts Transmitted Data • Does Not Disrupt Optical Signal to Receiver (T&B / Palm III Terminal) • Low-Loss Tap Constructed of Offthe-Shelf Components for Less Than $100 • Line Printer Outputs Data Stream Obtained by Tap • Without Monitoring, Tap is Undetectable

FIBER OPTIC MONITORING & MANAGEMENT MESON Non-Intrusive Tap & Line Printer • Passively Intercepts Transmitted Data • Does Not Disrupt Optical Signal to Receiver (T&B / Palm III Terminal) • Low-Loss Tap Constructed of Offthe-Shelf Components for Less Than $100 • Line Printer Outputs Data Stream Obtained by Tap • Without Monitoring, Tap is Undetectable

FIBER OPTIC MONITORING & MANAGEMENT Who is Implementing Security ? • Financial Institutions • Corporations (End-user) • Government • Education • Internet Service Providers • Medical Facilities • Utilities

FIBER OPTIC MONITORING & MANAGEMENT Who is Implementing Security ? • Financial Institutions • Corporations (End-user) • Government • Education • Internet Service Providers • Medical Facilities • Utilities

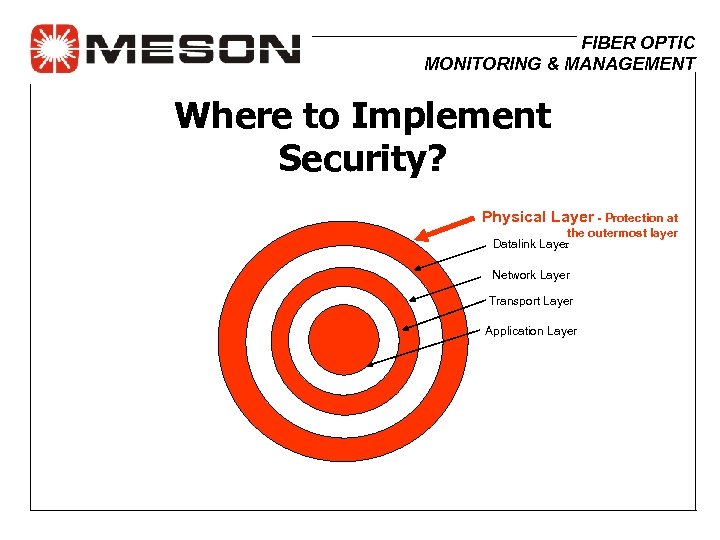

FIBER OPTIC MONITORING & MANAGEMENT Where to Implement Security? Physical Layer - Protection at the outermost layer Datalink Layer Network Layer Transport Layer Application Layer

FIBER OPTIC MONITORING & MANAGEMENT Where to Implement Security? Physical Layer - Protection at the outermost layer Datalink Layer Network Layer Transport Layer Application Layer

FIBER OPTIC MONITORING & MANAGEMENT THE SOLUTION – Senses Losses as Slight as 0. 1 d. B – ‘HIGH ALARM’ Monitors for Optical Injection – Measures Down to -45 d. Bm – Any Fiber Bend Readily Detected – Can Even ‘See’ Attenuation Caused by Fiber Identifiers and Similar Devices

FIBER OPTIC MONITORING & MANAGEMENT THE SOLUTION – Senses Losses as Slight as 0. 1 d. B – ‘HIGH ALARM’ Monitors for Optical Injection – Measures Down to -45 d. Bm – Any Fiber Bend Readily Detected – Can Even ‘See’ Attenuation Caused by Fiber Identifiers and Similar Devices

FIBER OPTIC MONITORING & MANAGEMENT THE SYSTEM’S ENHANCED SECURITY FEATURES ARE PART OF EACH ACTIVE MONITOR MODULE. THERE IS NO NEED TO PURCHASE ADDITIONAL EQUIPMENT OR SOFTWARE !

FIBER OPTIC MONITORING & MANAGEMENT THE SYSTEM’S ENHANCED SECURITY FEATURES ARE PART OF EACH ACTIVE MONITOR MODULE. THERE IS NO NEED TO PURCHASE ADDITIONAL EQUIPMENT OR SOFTWARE !

FIBER OPTIC MONITORING & MANAGEMENT Advantages of Fibre. Guard Versus OTDRbased Monitoring Systems • Monitors More of the Network • Monitors Faster • Can Detect Gradual Degradation More Effectively • Expands Easily • Costs LESS

FIBER OPTIC MONITORING & MANAGEMENT Advantages of Fibre. Guard Versus OTDRbased Monitoring Systems • Monitors More of the Network • Monitors Faster • Can Detect Gradual Degradation More Effectively • Expands Easily • Costs LESS

FIBER OPTIC MONITORING & MANAGEMENT Fibre. Guard - A Better Way to Monitored Not Monitored

FIBER OPTIC MONITORING & MANAGEMENT Fibre. Guard - A Better Way to Monitored Not Monitored

FIBER OPTIC MONITORING & MANAGEMENT Monitors Faster • Fibre. Guard Monitors in ‘Real-time’ • Readings are performed locally in module • Does not utilize an optical switch

FIBER OPTIC MONITORING & MANAGEMENT Monitors Faster • Fibre. Guard Monitors in ‘Real-time’ • Readings are performed locally in module • Does not utilize an optical switch

FIBER OPTIC MONITORING & MANAGEMENT Detects Degradation Better • Degradation and Gradual Attenuation is Often Not Recognized by an OTDR as a Failure • See Article in Outside Plant Magazine

FIBER OPTIC MONITORING & MANAGEMENT Detects Degradation Better • Degradation and Gradual Attenuation is Often Not Recognized by an OTDR as a Failure • See Article in Outside Plant Magazine

FIBER OPTIC MONITORING & MANAGEMENT Fibre. Guard has been Accepted and Recognized by: • Network Equipment Building Standards (NEBS) Certification • Underwriters Laboratory (UL) Safety Certification • U. S. Federal Communication Commission (FCC) 47 CFR Part 15 • Endorsed by U. S. National Security Agency (NSA) • Approved by Worldcom, SUN Microsystems, IBM, Compaq and others

FIBER OPTIC MONITORING & MANAGEMENT Fibre. Guard has been Accepted and Recognized by: • Network Equipment Building Standards (NEBS) Certification • Underwriters Laboratory (UL) Safety Certification • U. S. Federal Communication Commission (FCC) 47 CFR Part 15 • Endorsed by U. S. National Security Agency (NSA) • Approved by Worldcom, SUN Microsystems, IBM, Compaq and others

CUSTOMER LISTING • Bank Paribas • British Cabinet Office • Business Net • Citigroup • Credit Suisse • Deutsche-Morgan Grenfell • Energis Telecommunications • J. P. Morgan • London Clearing House • Fibrenet • Merrill Lynch • Gartmore Investments • MCI Worldcom • Metropolitan Fibre Systems • RABO Bank • Salomon Brothers • Warburgs

CUSTOMER LISTING • Bank Paribas • British Cabinet Office • Business Net • Citigroup • Credit Suisse • Deutsche-Morgan Grenfell • Energis Telecommunications • J. P. Morgan • London Clearing House • Fibrenet • Merrill Lynch • Gartmore Investments • MCI Worldcom • Metropolitan Fibre Systems • RABO Bank • Salomon Brothers • Warburgs

FIBER OPTIC MONITORING & MANAGEMENT Fibre. Guard: Your network’s best defense against damage and data loss due to intrusion, environmental, and accidental events…. . . …from MESON Fiber Optics !

FIBER OPTIC MONITORING & MANAGEMENT Fibre. Guard: Your network’s best defense against damage and data loss due to intrusion, environmental, and accidental events…. . . …from MESON Fiber Optics !