23d11771f0790db65315298d5af61315.ppt

- Количество слайдов: 36

Module 3 Electrical Hazards Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 1

Module 3 Electrical Hazards Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 1

Let’s start with a few case histories “An employee was electrocuted while using a grinder with a frayed cord. The employee was standing in water, wet-grinding stone countertops…” Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 2

Let’s start with a few case histories “An employee was electrocuted while using a grinder with a frayed cord. The employee was standing in water, wet-grinding stone countertops…” Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 2

“A maintenance employee was electrocuted while attempting to change a light fixture…” (no Lockout/Tagout) “An employee was electrocuted when he made contact with a piece of equipment being hoisted from an excavation. The arm of the backhoe hoisting the equipment contacted an overhead power line…” Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 3

“A maintenance employee was electrocuted while attempting to change a light fixture…” (no Lockout/Tagout) “An employee was electrocuted when he made contact with a piece of equipment being hoisted from an excavation. The arm of the backhoe hoisting the equipment contacted an overhead power line…” Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 3

Top Electrical Citations (FY 2005) Electrical, Wiring Design and Protection Elec. Wiring Methods, Components and Equipment, General Use Electrical, General Requirements Electrical, Safety-Related Work Practices, General Requirements Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 4 Source: Citation statistics from Federal OSHA data for OSHA fiscal year 2005

Top Electrical Citations (FY 2005) Electrical, Wiring Design and Protection Elec. Wiring Methods, Components and Equipment, General Use Electrical, General Requirements Electrical, Safety-Related Work Practices, General Requirements Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 4 Source: Citation statistics from Federal OSHA data for OSHA fiscal year 2005

Causes of Electrocution Fatalities • • • Contact with Overhead Power lines Contact with Live Circuits Not following Lock/Tagout procedures Poorly Maintained Extension Cords Defective Power Tools Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 5

Causes of Electrocution Fatalities • • • Contact with Overhead Power lines Contact with Live Circuits Not following Lock/Tagout procedures Poorly Maintained Extension Cords Defective Power Tools Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 5

Electrical Injuries There are three direct and two indirect types of electrical injuries: • Direct: ØElectrocution or death due to electrical shock ØElectrical shock ØBurns • Indirect: ØFalls ØFire Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 6

Electrical Injuries There are three direct and two indirect types of electrical injuries: • Direct: ØElectrocution or death due to electrical shock ØElectrical shock ØBurns • Indirect: ØFalls ØFire Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 6

Shock Severity • Severity of the shock depends on: – Path of current through the body – Amount of current flowing through the body (amps) – Duration of the shocking current through the body, • LOW VOLTAGE DOES NOT MEAN LOW HAZARD Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 7

Shock Severity • Severity of the shock depends on: – Path of current through the body – Amount of current flowing through the body (amps) – Duration of the shocking current through the body, • LOW VOLTAGE DOES NOT MEAN LOW HAZARD Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 7

Overhead Power Lines Hazard • Usually not insulated • Examples of equipment that can contact power lines: – – – – Crane Ladder Scaffold Backhoe Scissors lift Raised dump truck bed Aluminum paint roller Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 8

Overhead Power Lines Hazard • Usually not insulated • Examples of equipment that can contact power lines: – – – – Crane Ladder Scaffold Backhoe Scissors lift Raised dump truck bed Aluminum paint roller Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 8

It’s Your Job to Know! ü ü ü Know the hazards of electricity Know the equipment Use Safe Work Practices Inspect your PPE before each use Don’t work on energized circuits without permission Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 9

It’s Your Job to Know! ü ü ü Know the hazards of electricity Know the equipment Use Safe Work Practices Inspect your PPE before each use Don’t work on energized circuits without permission Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 9

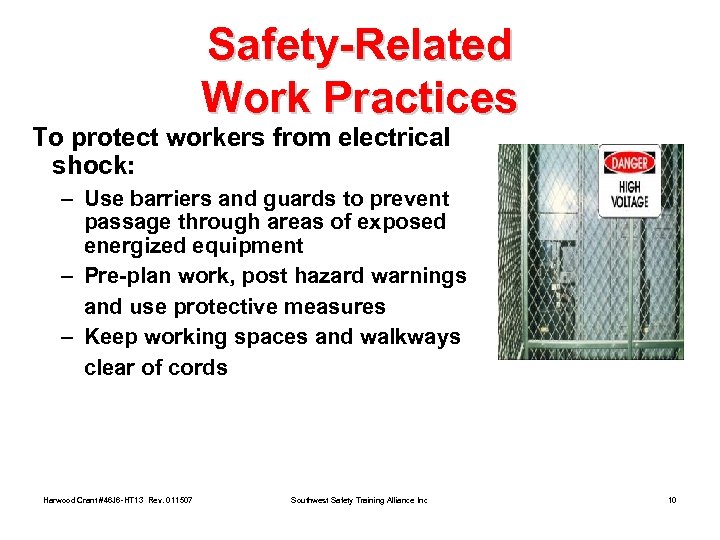

Safety-Related Work Practices To protect workers from electrical shock: – Use barriers and guards to prevent passage through areas of exposed energized equipment – Pre-plan work, post hazard warnings and use protective measures – Keep working spaces and walkways clear of cords Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 10

Safety-Related Work Practices To protect workers from electrical shock: – Use barriers and guards to prevent passage through areas of exposed energized equipment – Pre-plan work, post hazard warnings and use protective measures – Keep working spaces and walkways clear of cords Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 10

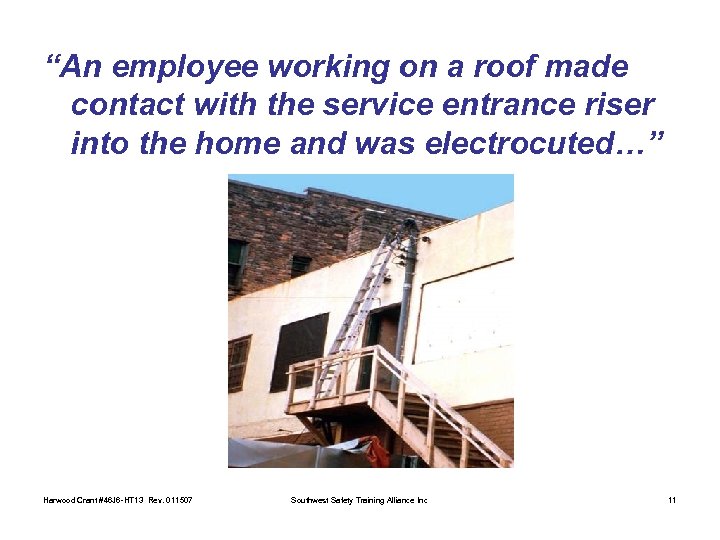

“An employee working on a roof made contact with the service entrance riser into the home and was electrocuted…” Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 11

“An employee working on a roof made contact with the service entrance riser into the home and was electrocuted…” Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 11

Caution • Special Training is required for work on electrical equipment. Such training is for Authorized Employees and it covers: – Safe Work Practices – Isolation of Electrical Sources – Test Equipment – Tools & PPE • Only Authorized Employees may conduct electrical work Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 12

Caution • Special Training is required for work on electrical equipment. Such training is for Authorized Employees and it covers: – Safe Work Practices – Isolation of Electrical Sources – Test Equipment – Tools & PPE • Only Authorized Employees may conduct electrical work Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 12

Control Devices Control circuit devices such as… – push buttons – selector switches – interlocks … may not be used as the sole means for de-energizing circuits or equipment. Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 13

Control Devices Control circuit devices such as… – push buttons – selector switches – interlocks … may not be used as the sole means for de-energizing circuits or equipment. Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 13

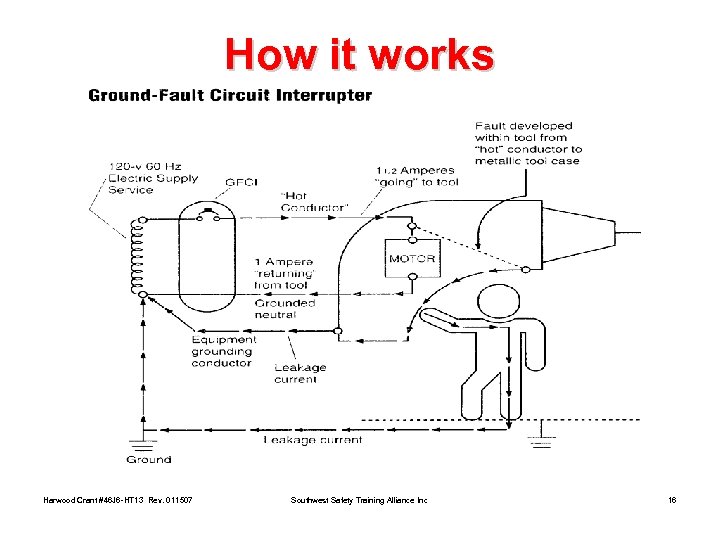

Control – Use GFCI (ground-fault circuit interrupter) • Protects you from shock • Detects difference in current between the black and white wires • If ground fault detected, GFCI shuts off electricity in 1/40 th of a second • Use GFCI’s on all 120 -volt, singlephase, 15 - and 20 -ampere receptacles, or have an assured equipment grounding conductor program. Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 14

Control – Use GFCI (ground-fault circuit interrupter) • Protects you from shock • Detects difference in current between the black and white wires • If ground fault detected, GFCI shuts off electricity in 1/40 th of a second • Use GFCI’s on all 120 -volt, singlephase, 15 - and 20 -ampere receptacles, or have an assured equipment grounding conductor program. Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 14

ELECTRICAL SAFETY Effects of Amount of AC Current ma=1/1000 th of an amp • 3 ma- painful shock which cause indirect accidents • 10 ma- muscle contraction. . . ”no let go” danger • 30 ma- lung paralysis- usually temporary • 50 ma- possible ventricular fibrillation (heart dysfunction, usually fatal) • 100 ma- certain ventricular fibrillation, fatal • 4 amps- heart paralysis, severe burns Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 15

ELECTRICAL SAFETY Effects of Amount of AC Current ma=1/1000 th of an amp • 3 ma- painful shock which cause indirect accidents • 10 ma- muscle contraction. . . ”no let go” danger • 30 ma- lung paralysis- usually temporary • 50 ma- possible ventricular fibrillation (heart dysfunction, usually fatal) • 100 ma- certain ventricular fibrillation, fatal • 4 amps- heart paralysis, severe burns Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 15

How it works Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 16

How it works Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 16

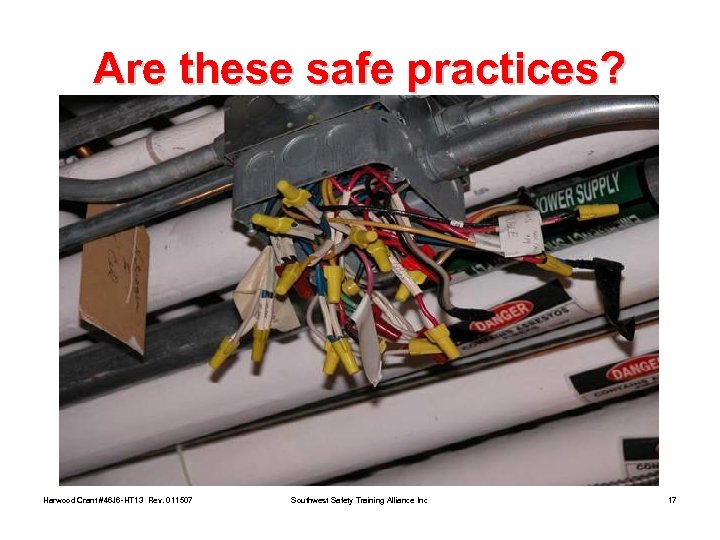

Are these safe practices? Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 17

Are these safe practices? Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 17

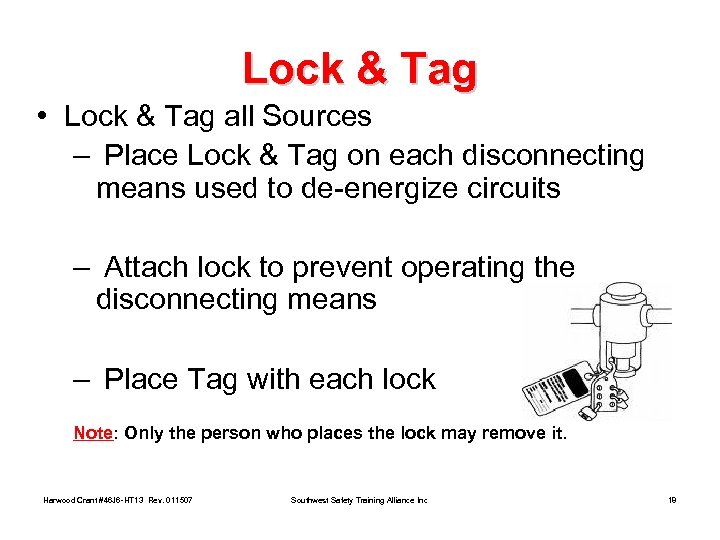

Lock & Tag • Lock & Tag all Sources – Place Lock & Tag on each disconnecting means used to de-energize circuits – Attach lock to prevent operating the disconnecting means – Place Tag with each lock Note: Only the person who places the lock may remove it. Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 18

Lock & Tag • Lock & Tag all Sources – Place Lock & Tag on each disconnecting means used to de-energize circuits – Attach lock to prevent operating the disconnecting means – Place Tag with each lock Note: Only the person who places the lock may remove it. Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 18

Lockout Devices Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 19

Lockout Devices Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 19

If a Lock cannot be applied… • A tag used without a lock must be supplemented by at least one additional safety measure that provides a level of safety equal to that of a lock. • Examples: – Removal of an isolating circuit element such as a fuse – Blocking of a controlling switch – Opening of an extra disconnecting device. Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 20

If a Lock cannot be applied… • A tag used without a lock must be supplemented by at least one additional safety measure that provides a level of safety equal to that of a lock. • Examples: – Removal of an isolating circuit element such as a fuse – Blocking of a controlling switch – Opening of an extra disconnecting device. Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 20

Tagout There many different kinds of tags and Lockout devices. Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 21

Tagout There many different kinds of tags and Lockout devices. Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 21

Release Stored Energy • Stored electric energy must be released before starting work. – Discharge all Capacitors – Short-Circuit & Ground all high capacitance elements Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 22

Release Stored Energy • Stored electric energy must be released before starting work. – Discharge all Capacitors – Short-Circuit & Ground all high capacitance elements Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 22

Is it “Dead”? • Verify System is Deenergized – Operate the equipment controls to check that equipment cannot be restarted. Use test equipment to test the circuits & electrical parts for voltage & current Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 23

Is it “Dead”? • Verify System is Deenergized – Operate the equipment controls to check that equipment cannot be restarted. Use test equipment to test the circuits & electrical parts for voltage & current Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 23

Alerting others of hazards v Use barricades to prevent or limit access to work areas with un-insulated energized conductors or circuit parts. v Use safety signs, safety symbols, or accident prevention tags to warn others about electrical hazards which may endanger them. v If signs and barricades do not provide sufficient warning and protection from electrical hazards, an attendant shall be stationed to warn and protect employees. Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 24

Alerting others of hazards v Use barricades to prevent or limit access to work areas with un-insulated energized conductors or circuit parts. v Use safety signs, safety symbols, or accident prevention tags to warn others about electrical hazards which may endanger them. v If signs and barricades do not provide sufficient warning and protection from electrical hazards, an attendant shall be stationed to warn and protect employees. Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 24

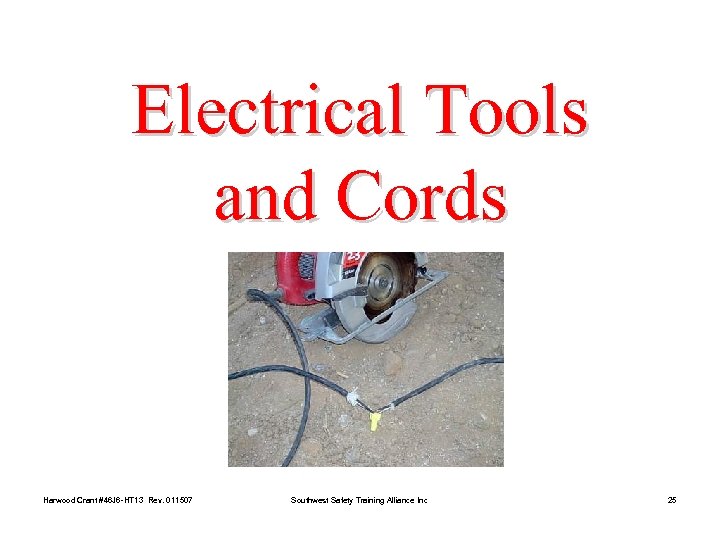

Electrical Tools and Cords Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 25

Electrical Tools and Cords Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 25

Portable Electric Tools & Cords • Portable equipment must be handled in a manner which will not cause damage. • Flexible electric cords connected to equipment may not be used for raising or lowering the equipment. • Flexible cords may not be fastened with staples or otherwise hung in such a fashion as could damage the outer jacket or insulation. Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 26

Portable Electric Tools & Cords • Portable equipment must be handled in a manner which will not cause damage. • Flexible electric cords connected to equipment may not be used for raising or lowering the equipment. • Flexible cords may not be fastened with staples or otherwise hung in such a fashion as could damage the outer jacket or insulation. Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 26

Tools & Equipment – Use insulated tools or handling equipment when working near exposed energized conductors or circuit parts. – Use fuse handling equipment to remove or install fuses when the fuse terminals are energized. – Ropes and handlines used near exposed energized parts must be nonconductive. Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 27

Tools & Equipment – Use insulated tools or handling equipment when working near exposed energized conductors or circuit parts. – Use fuse handling equipment to remove or install fuses when the fuse terminals are energized. – Ropes and handlines used near exposed energized parts must be nonconductive. Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 27

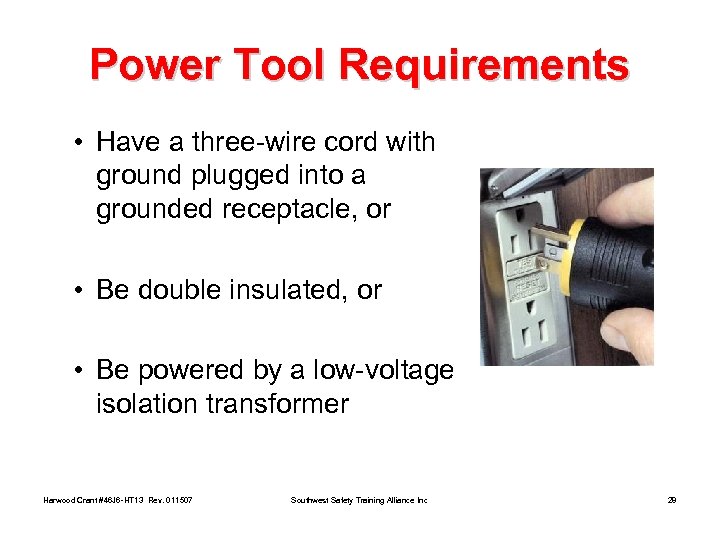

Power Tool Requirements • Have a three-wire cord with ground plugged into a grounded receptacle, or • Be double insulated, or • Be powered by a low-voltage isolation transformer Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 28

Power Tool Requirements • Have a three-wire cord with ground plugged into a grounded receptacle, or • Be double insulated, or • Be powered by a low-voltage isolation transformer Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 28

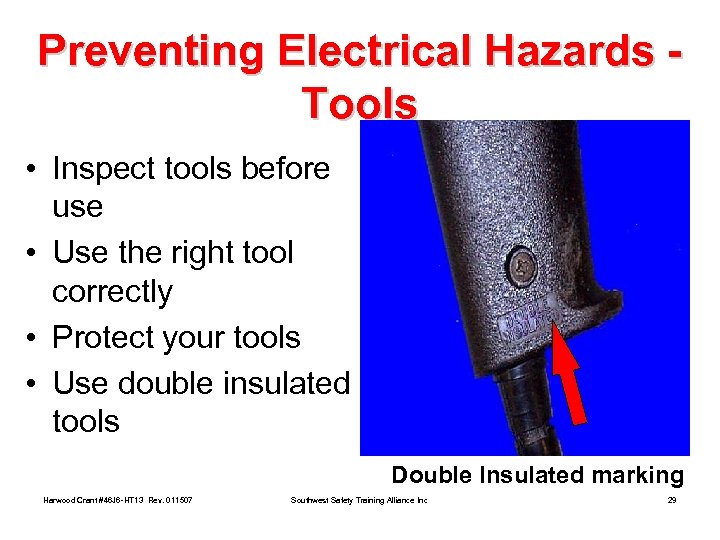

Preventing Electrical Hazards Tools • Inspect tools before use • Use the right tool correctly • Protect your tools • Use double insulated tools Double Insulated marking Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 29

Preventing Electrical Hazards Tools • Inspect tools before use • Use the right tool correctly • Protect your tools • Use double insulated tools Double Insulated marking Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 29

Any problems? Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 30

Any problems? Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 30

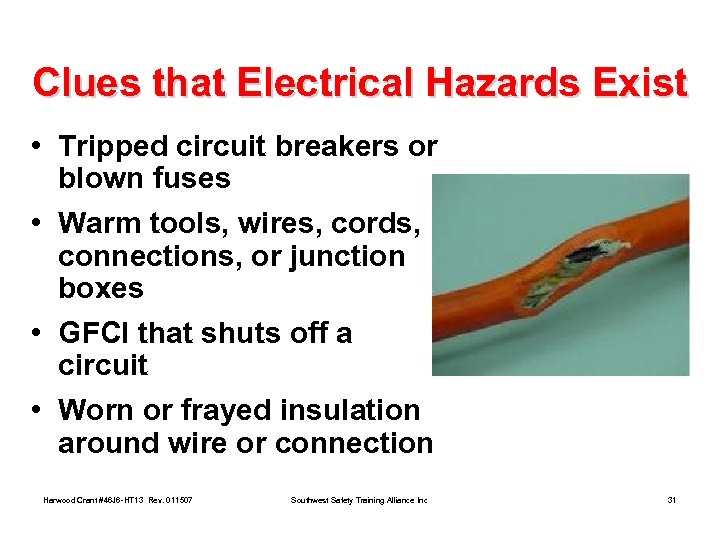

Clues that Electrical Hazards Exist • Tripped circuit breakers or blown fuses • Warm tools, wires, cords, connections, or junction boxes • GFCI that shuts off a circuit • Worn or frayed insulation around wire or connection Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 31

Clues that Electrical Hazards Exist • Tripped circuit breakers or blown fuses • Warm tools, wires, cords, connections, or junction boxes • GFCI that shuts off a circuit • Worn or frayed insulation around wire or connection Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 31

Beware of Old Wiring • Removal of expansion tank (hot water). • Old style knob electrical wiring. • Victim contacted frayed wiring. Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 32

Beware of Old Wiring • Removal of expansion tank (hot water). • Old style knob electrical wiring. • Victim contacted frayed wiring. Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 32

Wire Pulling • Avoid manual wire pulling and use a tugger or a handtool whenever possible • Communication between the puller and feeder to coordinate movements will make the job easier and safer. • Use lighter-weight tools. Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 33

Wire Pulling • Avoid manual wire pulling and use a tugger or a handtool whenever possible • Communication between the puller and feeder to coordinate movements will make the job easier and safer. • Use lighter-weight tools. Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 33

Reducing Body Strains • CHANGE BODY POSITIONS. • Working overhead, at floor level, or in cramped spaces forces the body into awkward postures. • To relieve muscle tension and improve circulation, change body positions, alternate tasks, and stretch throughout the day. Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 34

Reducing Body Strains • CHANGE BODY POSITIONS. • Working overhead, at floor level, or in cramped spaces forces the body into awkward postures. • To relieve muscle tension and improve circulation, change body positions, alternate tasks, and stretch throughout the day. Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 34

Summary Electrical equipment must be: – Listed and labeled – Free from hazards – Used in the proper manner If you use electrical tools you must: – Be protected from electrical shock – Use them in a comfortable position – Be provided with necessary safety equipment Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 35

Summary Electrical equipment must be: – Listed and labeled – Free from hazards – Used in the proper manner If you use electrical tools you must: – Be protected from electrical shock – Use them in a comfortable position – Be provided with necessary safety equipment Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 35

“A tree trimmer was electrocuted when he touched an overhead electrical line while descending a palm tree…” Always remember… It’s your life! “An employee was electrocuted while working on an A/C unit…” Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 36

“A tree trimmer was electrocuted when he touched an overhead electrical line while descending a palm tree…” Always remember… It’s your life! “An employee was electrocuted while working on an A/C unit…” Harwood Crant #46 J 6 -HT 13 Rev. 011507 Southwest Safety Training Alliance Inc 36