LV.ppt

- Количество слайдов: 12

Modifying of porous carbon electrode surface in glow discharge. Student: Tarasyuk G. M. Supervisor: Pisarev A. A.

Scope of supercapacitors: • Support the power supply in case of a voltage instability • Backup power disconnections energy • Alarm systems - run generators, emergency valves, cooling systems and ventilation. . • Portable electronics • Military industry Objective: development of the method of modification of electrode surface of a porous carbon supercapacitor to increase its capacity.

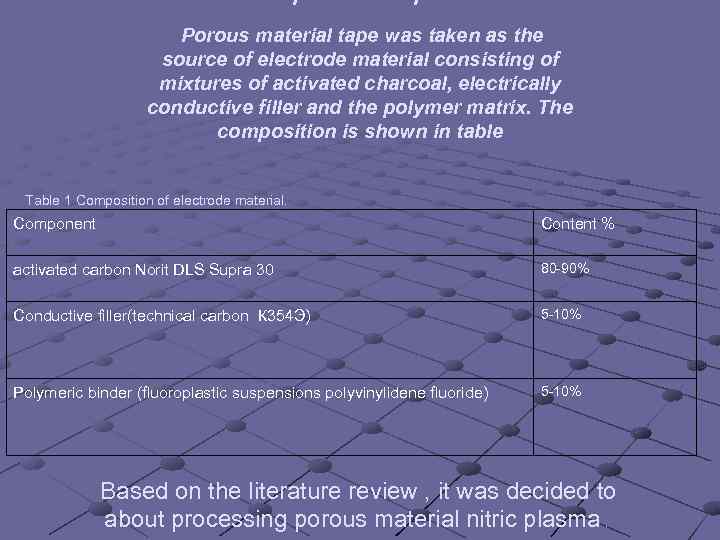

Description of experiments. Porous material tape was taken as the source of electrode material consisting of mixtures of activated charcoal, electrically conductive filler and the polymer matrix. The composition is shown in table Table 1 Composition of electrode material. Component Content % activated carbon Norit DLS Supra 30 80 -90% Conductive filler(technical carbon К 354 Э) 5 -10% Polymeric binder (fluoroplastic suspensions polyvinylidene fluoride) 5 -10% Based on the literature review , it was decided to about processing porous material nitric plasma.

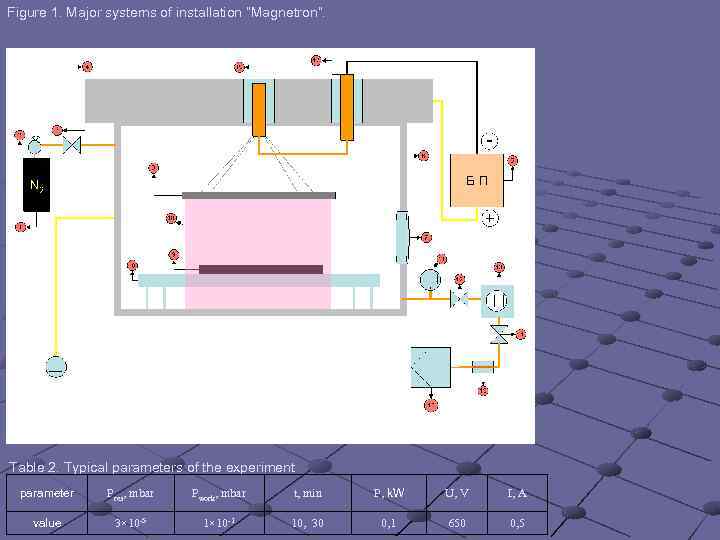

Figure 1. Major systems of installation “Magnetron”. Table 2. Typical parameters of the experiment parameter Pres, mbar Pwork, mbar t, min P, k. W U, V I, A value 3× 10 -5 1× 10 -1 10, 30 0, 1 650 0, 5

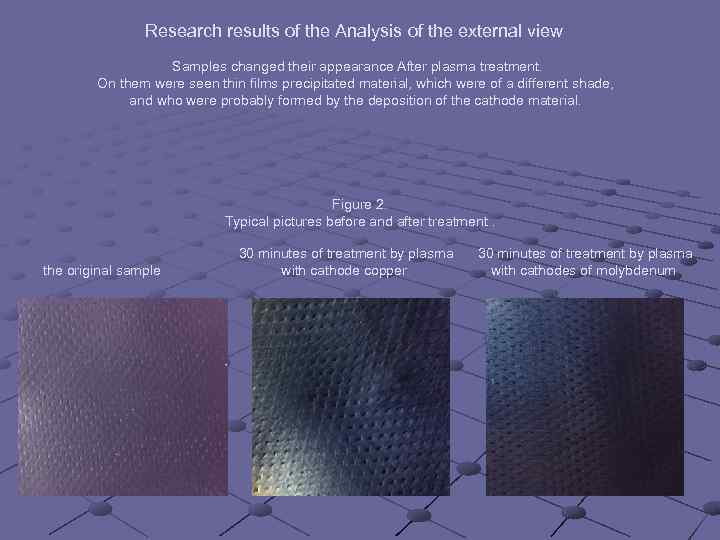

Research results of the Analysis of the external view Samples changed their appearance After plasma treatment. On them were seen thin films precipitated material, which were of a different shade, and who were probably formed by the deposition of the cathode material. Figure 2. Typical pictures before and after treatment. the original sample 30 minutes of treatment by plasma with cathode copper 30 minutes of treatment by plasma with cathodes of molybdenum

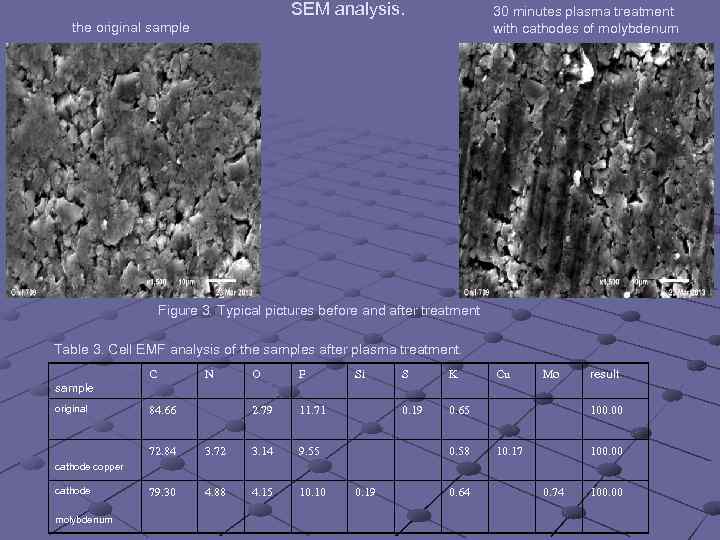

SEM analysis. the original sample 30 minutes plasma treatment with cathodes of molybdenum Figure 3. Typical pictures before and after treatment Table 3. Cell EMF analysis of the samples after plasma treatment. C N O F 2. 79 Si 11. 71 S K 0. 19 Cu Mo 0. 65 result sample original 84. 66 72. 84 3. 72 3. 14 9. 55 79. 30 4. 88 4. 15 10. 10 0. 58 100. 00 10. 17 100. 00 cathode copper cathode molybdenum 0. 19 0. 64 0. 74 100. 00

Testing electrodes in supercapacitors cell. . Figure 4. Assembly diagram of the test cell elementary supercapacitor.

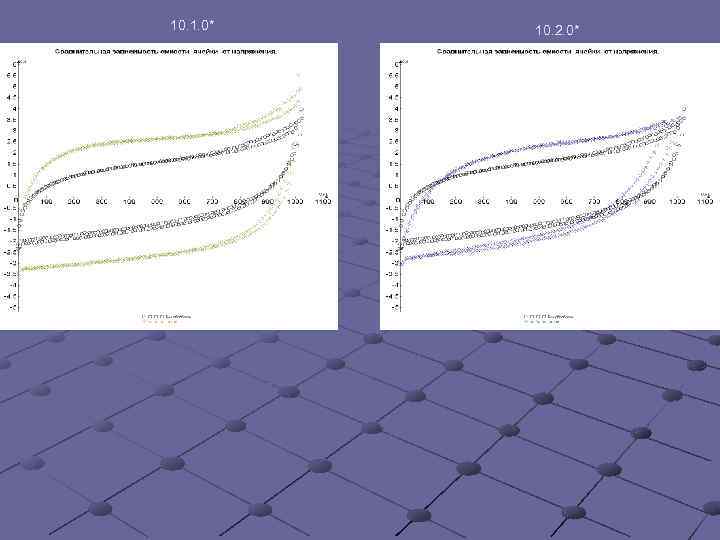

10. 1. 0* 10. 2. 0*

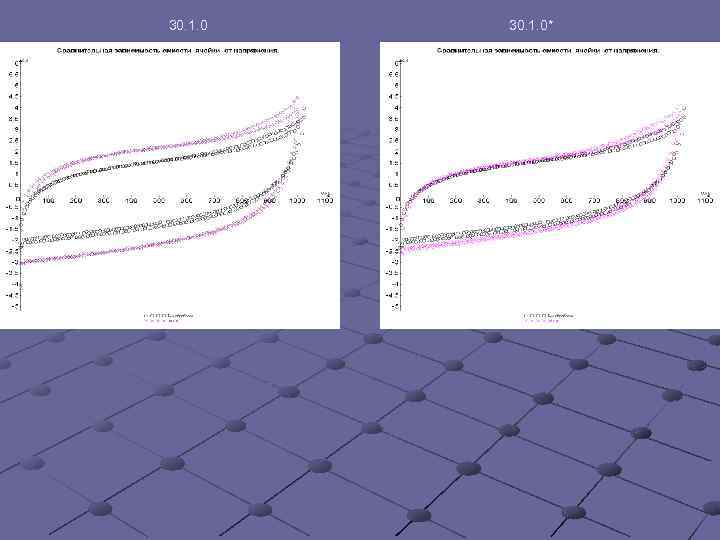

30. 1. 0*

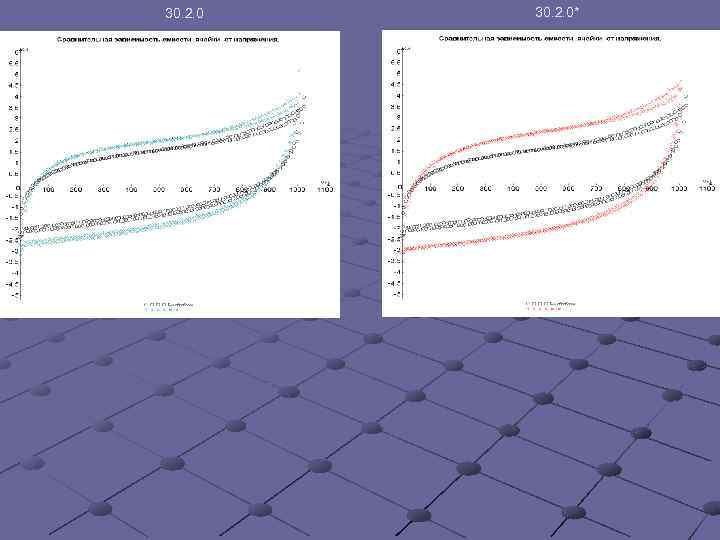

30. 2. 0*

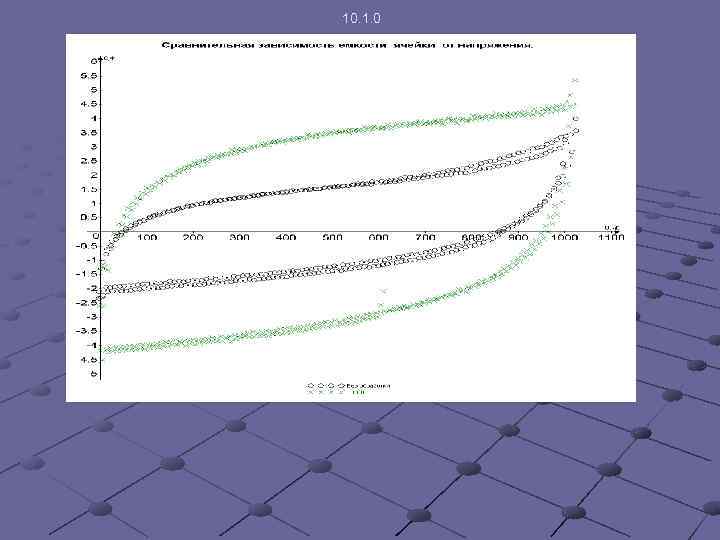

10. 1. 0

• Conclusions. • The literary review of plasma processing of porous materials. • The literary review by technical characteristics and technology of manufacturing of supercapacitors. • Upgrading to install Magnetron for the realization of this experiment. • Processed electrodes of a porous carbon nitrogen plasma of a glow discharge with the cathodes of copper and molybdenum in various time intervals. • Produced visual , SEM and EMF analyses of samples. • Collected elementary cell supercapacitor and received voltamperograms in the range of 0 -1 V were measured, and the capacitance was calculated • Processing of coal electrodes in nitric glow discharge plasma has led to increase of the capacity of elementary assembly with alkaline electrolyte. The best results are obtained with the minimum processing time (10 minutes) in the experiments. Capacity was doubled in the field of medium voltage (0. 5 V) and one and a half times in the area of working voltage of 1 V.

LV.ppt