d0a9242391a2ea6464bc119e4f619a54.ppt

- Количество слайдов: 23

Modern Combined Cycle Power Plants – Improvement of a high efficient and clean technology O. Kreyenberg, H. Schütz, H. Friede Oct. 21, 2004 Siemens PG "Energy Efficiency in IPPC-installations" 21 and 22 October 2004 Vienna Modern Combined Cycle Power Plants – Power Generation Improvement of a high efficient and clean technology Authors: Schütz, Kreyenberg, Friede SPG

Agenda Market Drivers Reference Power Plant Product Overview - Steam Power Plant - Combined Cycle Power Plant Reference Power Plant Design Philosophy Design Targets References Oct. 21, 2004 Modern Combined Cycle Power Plants – Improvement of a high efficient and clean technology Power Generation 2 Authors: Schütz, Kreyenberg, Friede SPG

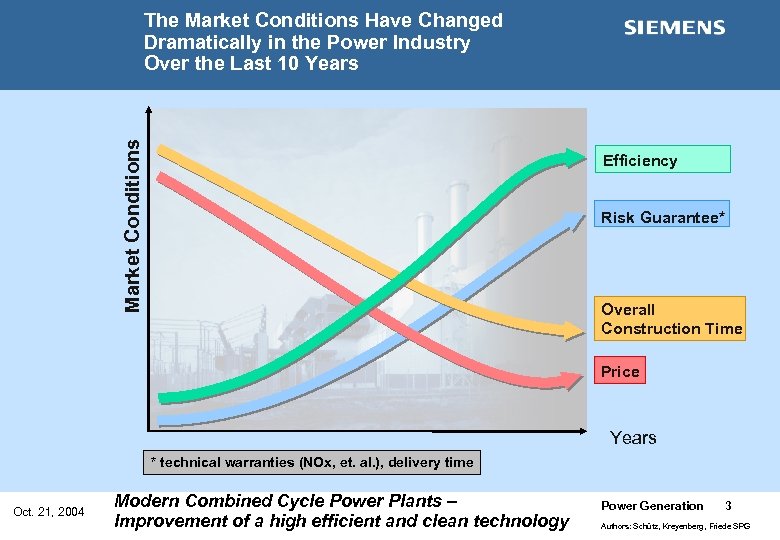

Market Conditions The Market Conditions Have Changed Dramatically in the Power Industry Over the Last 10 Years Efficiency Risk Guarantee* Overall Construction Time Price Years * technical warranties (NOx, et. al. ), delivery time Oct. 21, 2004 Modern Combined Cycle Power Plants – Improvement of a high efficient and clean technology Power Generation 3 Authors: Schütz, Kreyenberg, Friede SPG

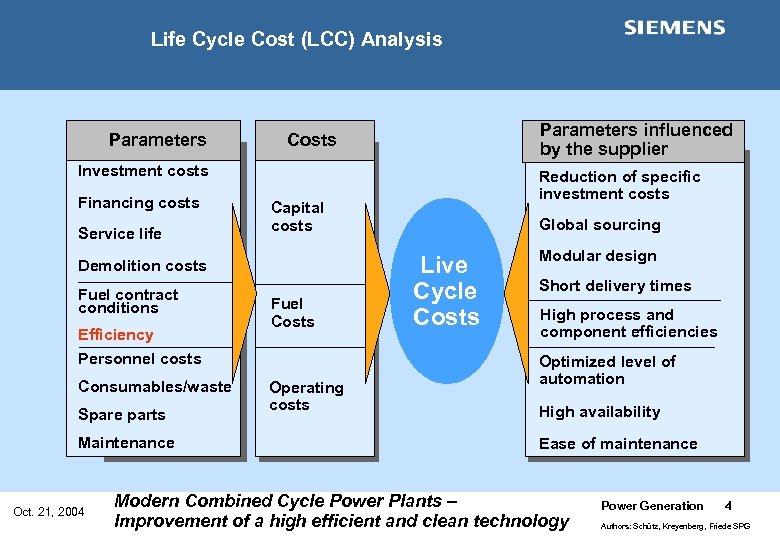

Life Cycle Cost (LCC) Analysis Parameters influenced by the supplier Costs Investment costs Financing costs Service life Capital costs Demolition costs Fuel contract conditions Efficiency Fuel Costs Personnel costs Consumables/waste Spare parts Maintenance Oct. 21, 2004 Reduction of specific investment costs Operating costs Global sourcing Live Cycle Costs Modular design Short delivery times High process and component efficiencies Optimized level of automation High availability Ease of maintenance Modern Combined Cycle Power Plants – Improvement of a high efficient and clean technology Power Generation 4 Authors: Schütz, Kreyenberg, Friede SPG

Reference Power Plant Product Overview Oct. 21, 2004 Modern Combined Cycle Power Plants – Improvement of a high efficient and clean technology Power Generation 5 Authors: Schütz, Kreyenberg, Friede SPG

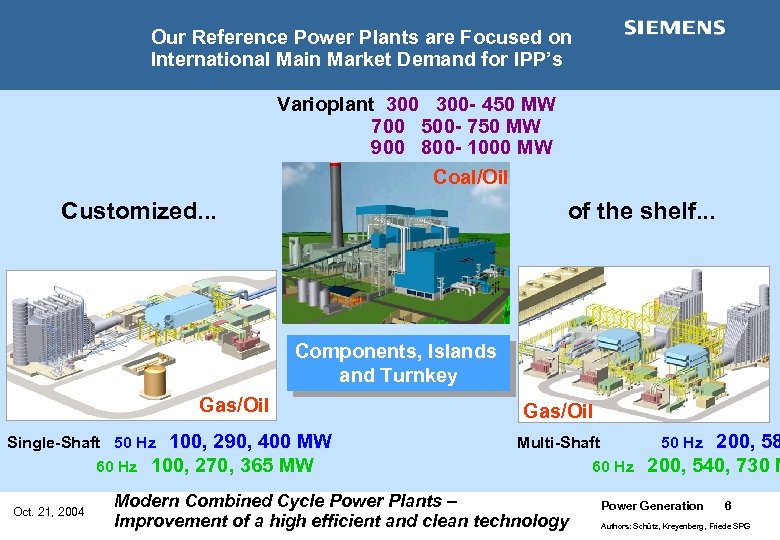

Our Reference Power Plants are Focused on International Main Market Demand for IPP’s Varioplant 300 - 450 MW 700 500 - 750 MW 900 800 - 1000 MW Coal/Oil Customized. . . of the shelf. . . Components, Islands and Turnkey Gas/Oil Single-Shaft 50 Hz 100, 290, 400 MW 60 Hz 100, 270, 365 MW Oct. 21, 2004 Gas/Oil Multi-Shaft 60 Hz Modern Combined Cycle Power Plants – Improvement of a high efficient and clean technology 200, 58 200, 540, 730 M 50 Hz Power Generation 6 Authors: Schütz, Kreyenberg, Friede SPG

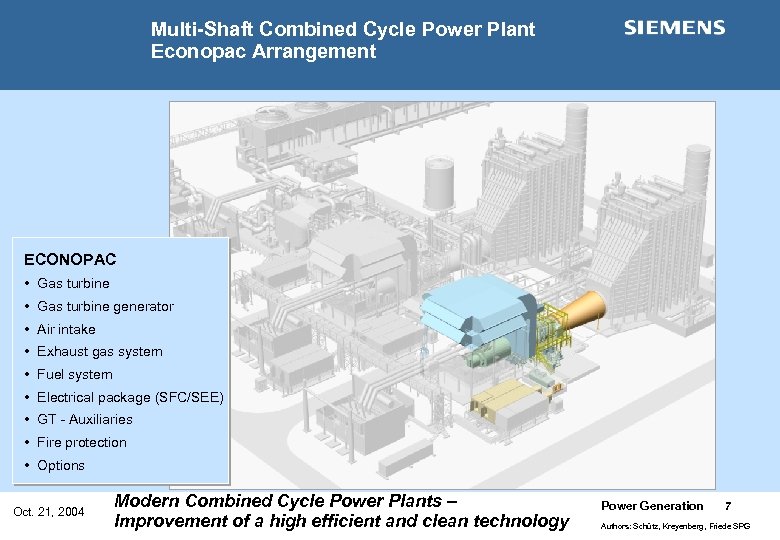

Multi-Shaft Combined Cycle Power Plant Econopac Arrangement ECONOPAC • Gas turbine generator • Air intake • Exhaust gas system • Fuel system • Electrical package (SFC/SEE) • GT - Auxiliaries • Fire protection • Options Oct. 21, 2004 Modern Combined Cycle Power Plants – Improvement of a high efficient and clean technology Power Generation 7 Authors: Schütz, Kreyenberg, Friede SPG

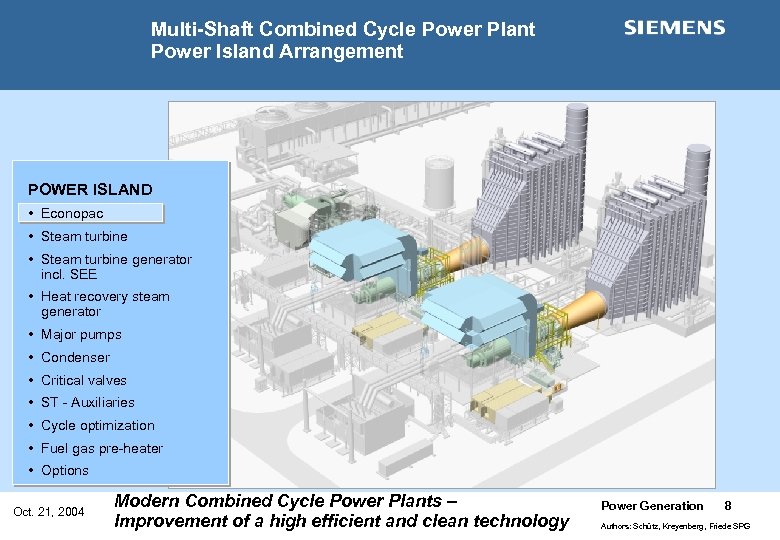

Multi-Shaft Combined Cycle Power Plant Power Island Arrangement POWER ISLAND • Econopac • Steam turbine generator incl. SEE • Heat recovery steam generator • Major pumps • Condenser • Critical valves • ST - Auxiliaries • Cycle optimization • Fuel gas pre-heater • Options Oct. 21, 2004 Modern Combined Cycle Power Plants – Improvement of a high efficient and clean technology Power Generation 8 Authors: Schütz, Kreyenberg, Friede SPG

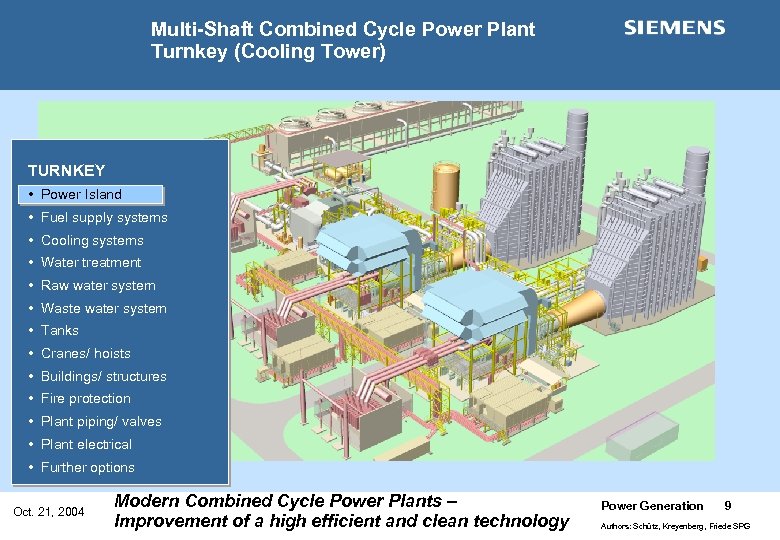

Multi-Shaft Combined Cycle Power Plant Turnkey (Cooling Tower) TURNKEY • Power Island • Fuel supply systems • Cooling systems • Water treatment • Raw water system • Waste water system • Tanks • Cranes/ hoists • Buildings/ structures • Fire protection • Plant piping/ valves • Plant electrical • Further options Oct. 21, 2004 Modern Combined Cycle Power Plants – Improvement of a high efficient and clean technology Power Generation 9 Authors: Schütz, Kreyenberg, Friede SPG

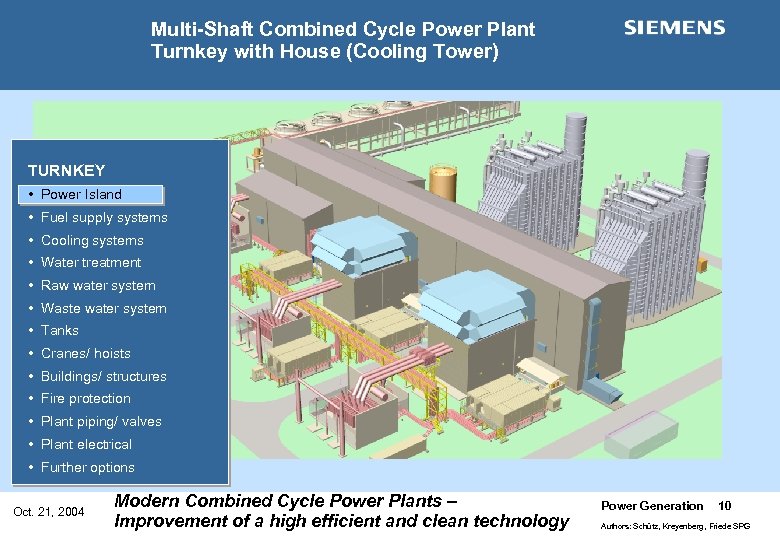

Multi-Shaft Combined Cycle Power Plant Turnkey with House (Cooling Tower) TURNKEY • Power Island • Fuel supply systems • Cooling systems • Water treatment • Raw water system • Waste water system • Tanks • Cranes/ hoists • Buildings/ structures • Fire protection • Plant piping/ valves • Plant electrical • Further options Oct. 21, 2004 Modern Combined Cycle Power Plants – Improvement of a high efficient and clean technology Power Generation 10 Authors: Schütz, Kreyenberg, Friede SPG

Reference Power Plant Design Philosophy Oct. 21, 2004 Modern Combined Cycle Power Plants – Improvement of a high efficient and clean technology Power Generation 11 Authors: Schütz, Kreyenberg, Friede SPG

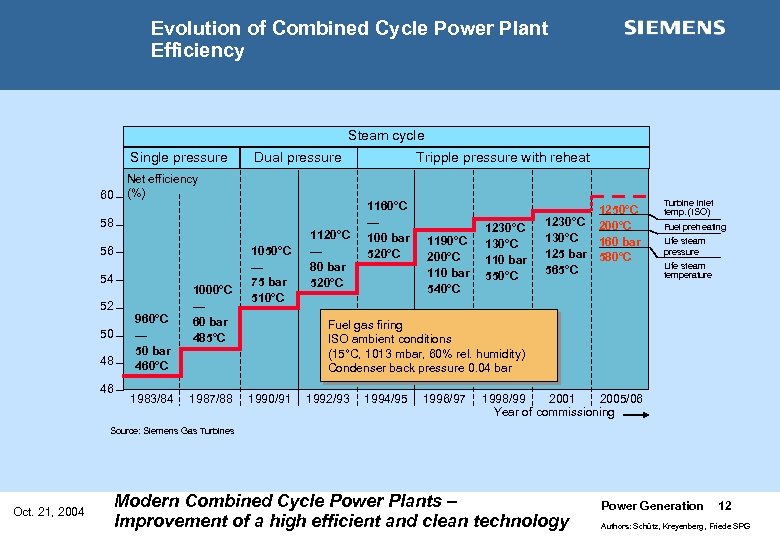

Evolution of Combined Cycle Power Plant Efficiency Steam cycle Single pressure 60 Dual pressure Net efficiency (%) 58 56 54 52 50 48 46 960°C — 50 bar 460°C 1983/84 1000°C — 60 bar 485°C 1987/88 1050°C — 75 bar 510°C 1120°C — 80 bar 520°C Tripple pressure with reheat 1160°C — 100 bar 520°C 1190°C 200°C 110 bar 540°C 1230°C 110 bar 550°C 1230°C 200°C 130°C 160 bar 125 bar 580°C 565°C Turbine inlet temp. (ISO) Fuel preheating Life steam pressure Life steam temperature Fuel gas firing ISO ambient conditions (15°C, 1013 mbar, 60% rel. humidity) Condenser back pressure 0. 04 bar 1990/91 1992/93 1994/95 1996/97 1998/99 2001 2005/06 Year of commissioning Source: Siemens Gas Turbines Oct. 21, 2004 Modern Combined Cycle Power Plants – Improvement of a high efficient and clean technology Power Generation 12 Authors: Schütz, Kreyenberg, Friede SPG

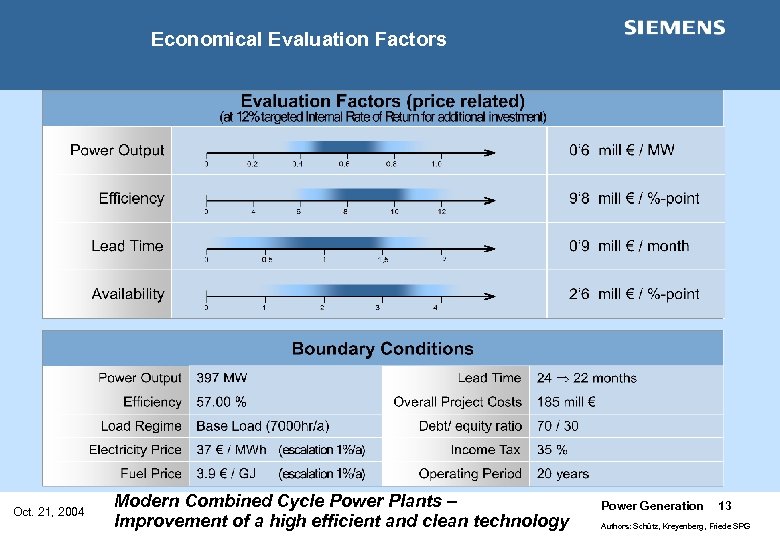

Economical Evaluation Factors Oct. 21, 2004 Modern Combined Cycle Power Plants – Improvement of a high efficient and clean technology Power Generation 13 Authors: Schütz, Kreyenberg, Friede SPG

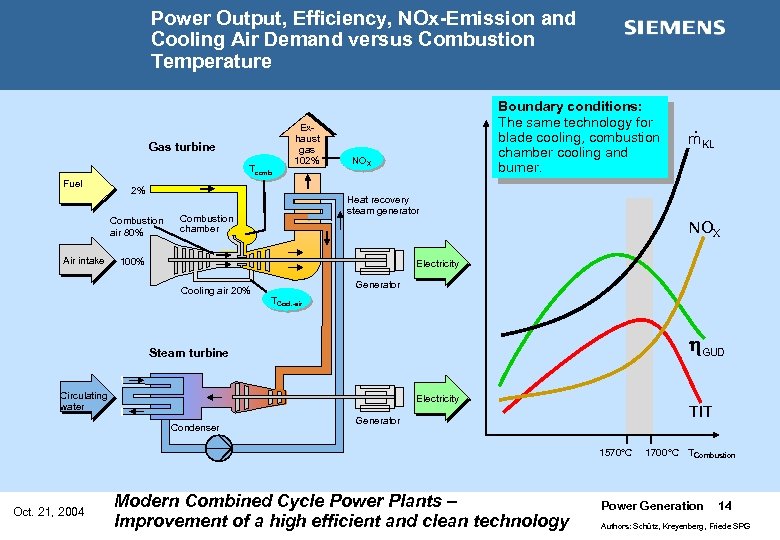

Power Output, Efficiency, NOx-Emission and Cooling Air Demand versus Combustion Temperature Gas turbine Tcomb. Fuel 2% Combustion air 80% Air intake Exhaust gas 102% Boundary conditions: The same technology for blade cooling, combustion chamber cooling and burner. NOX Heat recovery steam generator Combustion chamber NOX 100% Electricity Cooling air 20% Generator TCool. -air h. GUD Steam turbine Circulating water Electricity Condenser TIT Generator 1570°C Oct. 21, 2004 . m. KL Modern Combined Cycle Power Plants – Improvement of a high efficient and clean technology 1700°C TCombustion Power Generation 14 Authors: Schütz, Kreyenberg, Friede SPG

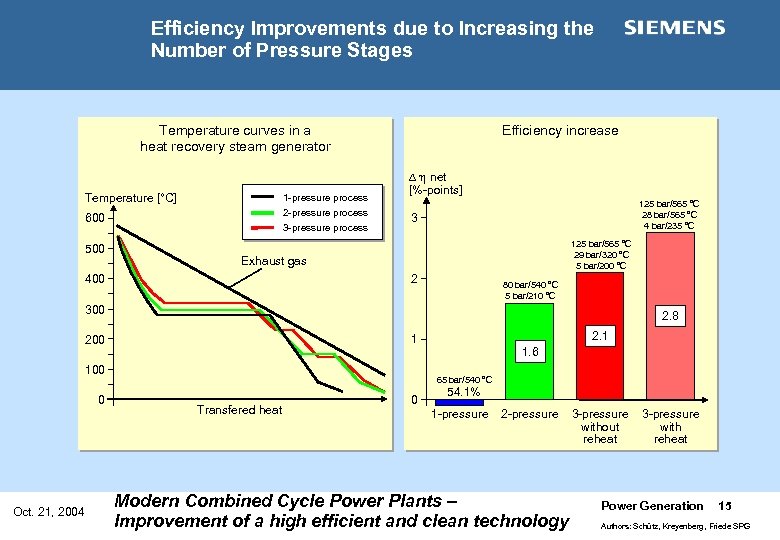

Efficiency Improvements due to Increasing the Number of Pressure Stages Temperature curves in a heat recovery steam generator Temperature [°C] 1 -pressure process 2 -pressure process 3 -pressure process 600 500 Efficiency increase D h net [%-points] 125 bar/565 °C 28 bar/565 °C 4 bar/235 °C 3 125 bar/565 °C 29 bar/320 °C 5 bar/200 °C Exhaust gas 400 2 80 bar/540 °C 5 bar/210 °C 300 2. 8 100 0 Oct. 21, 2004 2. 1 1 200 1. 6 65 bar/540 °C Transfered heat 0 54. 1% 1 -pressure 2 -pressure Modern Combined Cycle Power Plants – Improvement of a high efficient and clean technology 3 -pressure without reheat 3 -pressure with reheat Power Generation 15 Authors: Schütz, Kreyenberg, Friede SPG

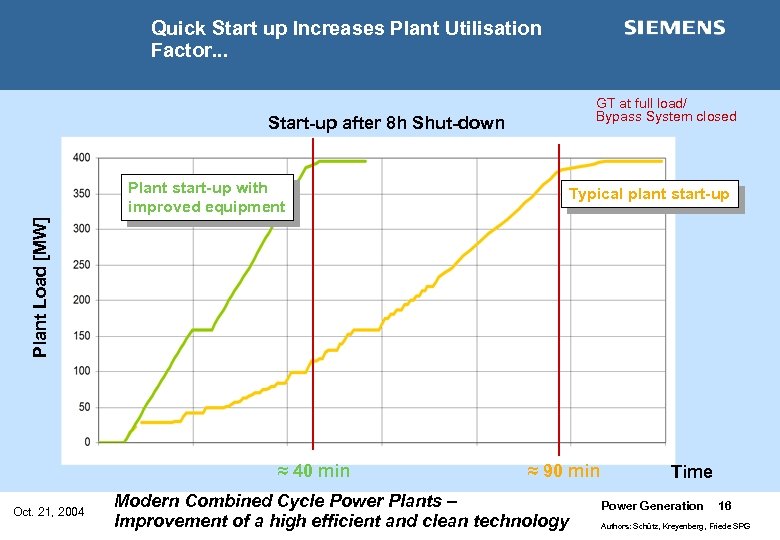

Quick Start up Increases Plant Utilisation Factor. . . GT at full load/ Bypass System closed Start-up after 8 h Shut-down Typical plant start-up Plant Load [MW] Plant start-up with improved equipment ≈ 40 min Oct. 21, 2004 ≈ 90 min Modern Combined Cycle Power Plants – Improvement of a high efficient and clean technology Time Power Generation 16 Authors: Schütz, Kreyenberg, Friede SPG

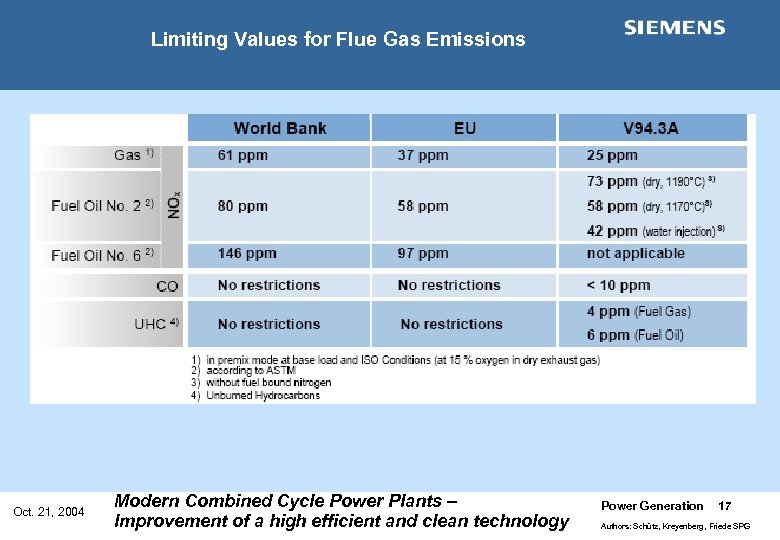

Limiting Values for Flue Gas Emissions Oct. 21, 2004 Modern Combined Cycle Power Plants – Improvement of a high efficient and clean technology Power Generation 17 Authors: Schütz, Kreyenberg, Friede SPG

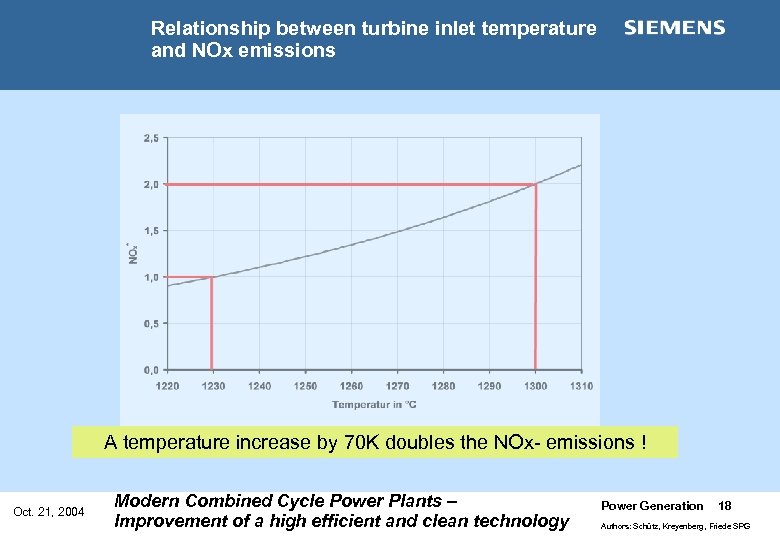

Relationship between turbine inlet temperature and NOx emissions A temperature increase by 70 K doubles the NOx- emissions ! Oct. 21, 2004 Modern Combined Cycle Power Plants – Improvement of a high efficient and clean technology Power Generation 18 Authors: Schütz, Kreyenberg, Friede SPG

Design Targets Oct. 21, 2004 Modern Combined Cycle Power Plants – Improvement of a high efficient and clean technology Power Generation 19 Authors: Schütz, Kreyenberg, Friede SPG

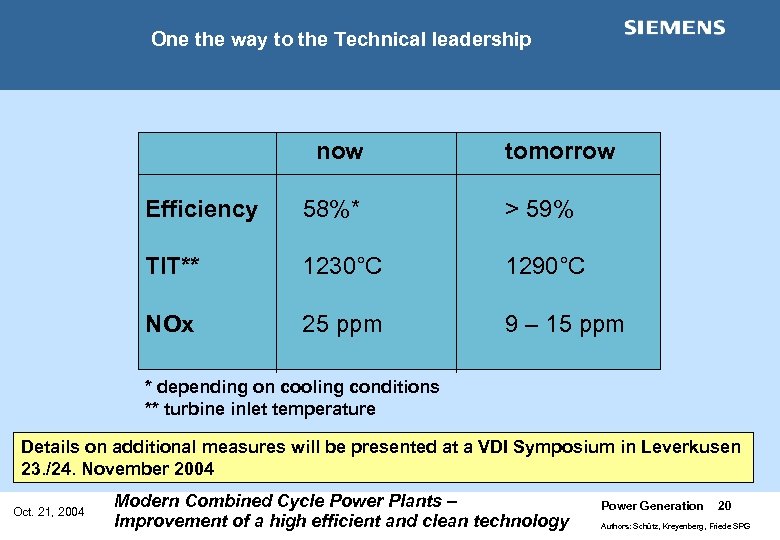

One the way to the Technical leadership now tomorrow Efficiency 58%* > 59% TIT** 1230°C 1290°C NOx 25 ppm 9 – 15 ppm * depending on cooling conditions ** turbine inlet temperature Details on additional measures will be presented at a VDI Symposium in Leverkusen 23. /24. November 2004 Oct. 21, 2004 Modern Combined Cycle Power Plants – Improvement of a high efficient and clean technology Power Generation 20 Authors: Schütz, Kreyenberg, Friede SPG

References Oct. 21, 2004 Modern Combined Cycle Power Plants – Improvement of a high efficient and clean technology Power Generation 21 Authors: Schütz, Kreyenberg, Friede SPG

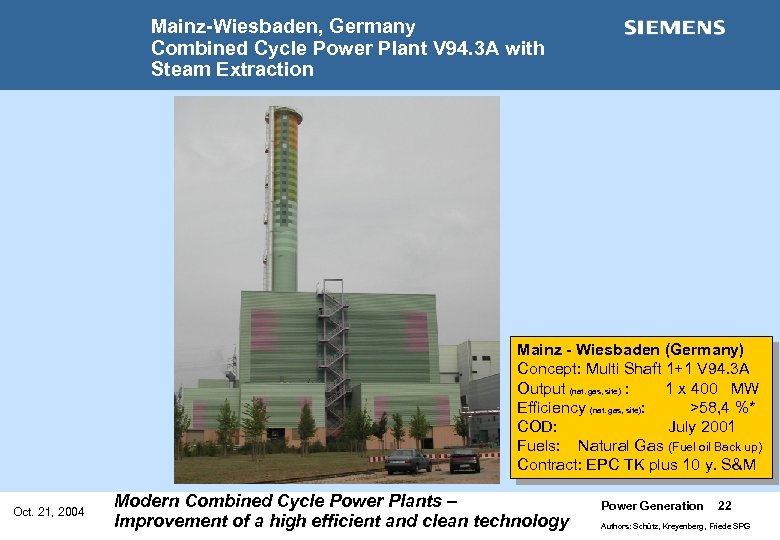

Mainz-Wiesbaden, Germany Combined Cycle Power Plant V 94. 3 A with Steam Extraction Mainz - Wiesbaden (Germany) Concept: Multi Shaft 1+1 V 94. 3 A Output (nat. gas, site) : 1 x 400 MW Efficiency (nat. gas, site): >58, 4 %* COD: July 2001 Fuels: Natural Gas (Fuel oil Back up) Contract: EPC TK plus 10 y. S&M Oct. 21, 2004 Modern Combined Cycle Power Plants – Improvement of a high efficient and clean technology Power Generation 22 Authors: Schütz, Kreyenberg, Friede SPG

Pulau Seraya, Singapore: 2 CC 1 S. V 94. 3 A The Most Efficient Plant in SEA Pulau Seraya (Singapore) Concept: Single Shaft 1 S. V 94. 3 A Output (nat. gas, site) : 2 x 367 MW Efficiency (nat. gas, site): >57. 2 % COD: November 2002 Fuels: Natural Gas (Fuel oil Back up) Contract: EPC TK plus 10 y. S&M Oct. 21, 2004 Modern Combined Cycle Power Plants – Improvement of a high efficient and clean technology Power Generation 23 Authors: Schütz, Kreyenberg, Friede SPG

d0a9242391a2ea6464bc119e4f619a54.ppt