9d2d68fc387978b1b1bd10e0df272644.ppt

- Количество слайдов: 48

Modeling Inventory (Deterministic View) John H. Vande Vate Spring 2008 1 1

Modeling Inventory (Deterministic View) John H. Vande Vate Spring 2008 1 1

Types of Inventory • Deterministic Inventory – Pipeline Inventory: Inventory in transit – Cycle Inventory: • Goods accumulating for transit • Goods delivered and waiting for processing • Stochastic Inventory (later) 2 2

Types of Inventory • Deterministic Inventory – Pipeline Inventory: Inventory in transit – Cycle Inventory: • Goods accumulating for transit • Goods delivered and waiting for processing • Stochastic Inventory (later) 2 2

Illustrative Example • Develop a distribution strategy to minimize inventory and transportation costs • Purpose: – Outline issues covered in outbound logistics – The importance of transportation in the supply chain – Illustrate costs and investments – Always do a quick analysis first, then refine it. 3 3

Illustrative Example • Develop a distribution strategy to minimize inventory and transportation costs • Purpose: – Outline issues covered in outbound logistics – The importance of transportation in the supply chain – Illustrate costs and investments – Always do a quick analysis first, then refine it. 3 3

Overview • Products: – Computers: CPU, Monitor, Keyboard – Televisions: TV and Console • Stores – 100 across the US – Sell 10 TVs and 10 computers per day – 250 days/year 4 4

Overview • Products: – Computers: CPU, Monitor, Keyboard – Televisions: TV and Console • Stores – 100 across the US – Sell 10 TVs and 10 computers per day – 250 days/year 4 4

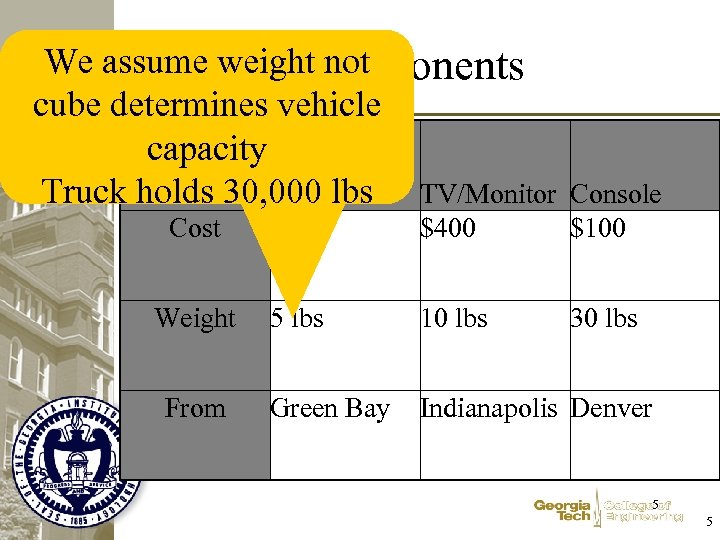

We assume weight not Components cube determines vehicle capacity Truck holds 30, 000 lbs TV/Monitor Computers Cost $300 $400 Console $100 Weight 5 lbs 10 lbs 30 lbs Green Bay Indianapolis Denver From 5 5

We assume weight not Components cube determines vehicle capacity Truck holds 30, 000 lbs TV/Monitor Computers Cost $300 $400 Console $100 Weight 5 lbs 10 lbs 30 lbs Green Bay Indianapolis Denver From 5 5

Current Situation • All direct shipments in full truckloads 6 6

Current Situation • All direct shipments in full truckloads 6 6

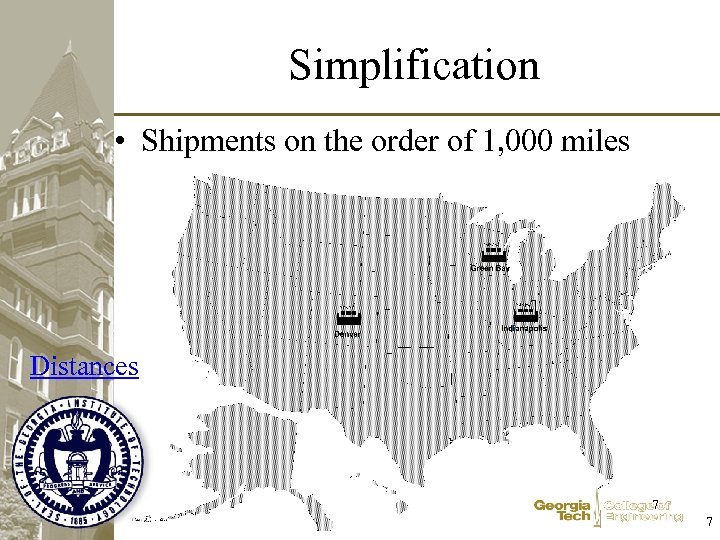

Simplification • Shipments on the order of 1, 000 miles Distances 7 7

Simplification • Shipments on the order of 1, 000 miles Distances 7 7

What Costs? • • • Transportation Pipeline inventory – inventory in transit Inventory at Plants Inventory at Stores Handling … 8 8

What Costs? • • • Transportation Pipeline inventory – inventory in transit Inventory at Plants Inventory at Stores Handling … 8 8

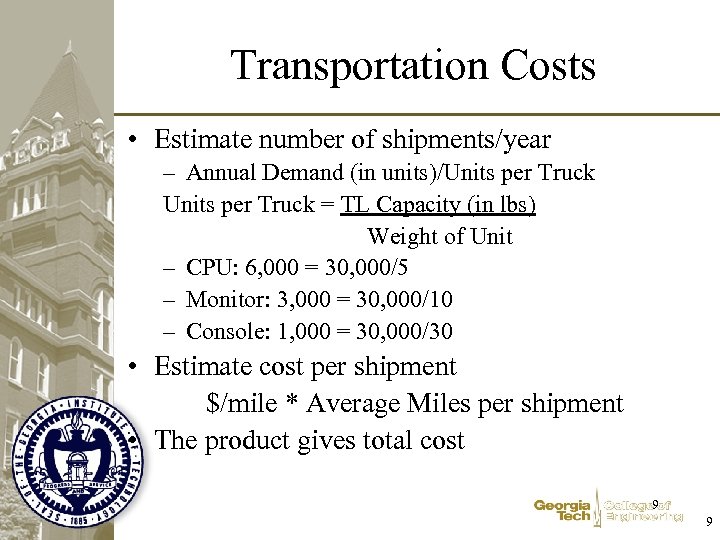

Transportation Costs • Estimate number of shipments/year – Annual Demand (in units)/Units per Truck = TL Capacity (in lbs) Weight of Unit – CPU: 6, 000 = 30, 000/5 – Monitor: 3, 000 = 30, 000/10 – Console: 1, 000 = 30, 000/30 • Estimate cost per shipment $/mile * Average Miles per shipment • The product gives total cost 9 9

Transportation Costs • Estimate number of shipments/year – Annual Demand (in units)/Units per Truck = TL Capacity (in lbs) Weight of Unit – CPU: 6, 000 = 30, 000/5 – Monitor: 3, 000 = 30, 000/10 – Console: 1, 000 = 30, 000/30 • Estimate cost per shipment $/mile * Average Miles per shipment • The product gives total cost 9 9

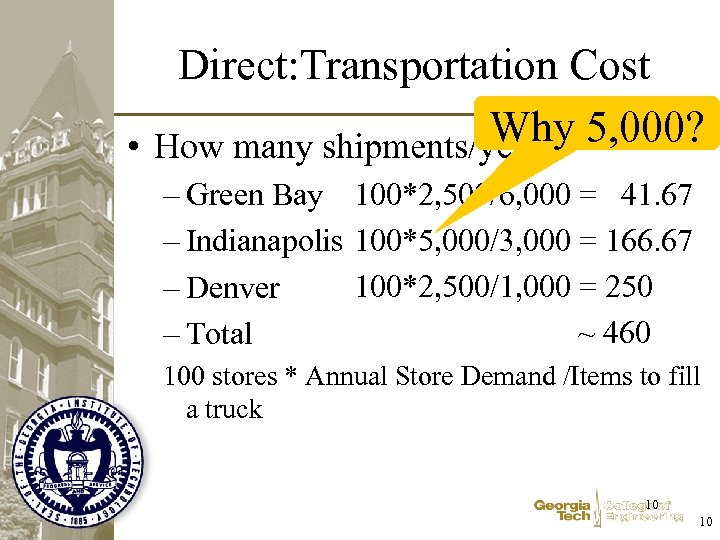

Direct: Transportation Cost Why 5, 000? • How many shipments/year? – Green Bay 100*2, 500/6, 000 = 41. 67 – Indianapolis 100*5, 000/3, 000 = 166. 67 100*2, 500/1, 000 = 250 – Denver ~ 460 – Total 100 stores * Annual Store Demand /Items to fill a truck 10 10

Direct: Transportation Cost Why 5, 000? • How many shipments/year? – Green Bay 100*2, 500/6, 000 = 41. 67 – Indianapolis 100*5, 000/3, 000 = 166. 67 100*2, 500/1, 000 = 250 – Denver ~ 460 – Total 100 stores * Annual Store Demand /Items to fill a truck 10 10

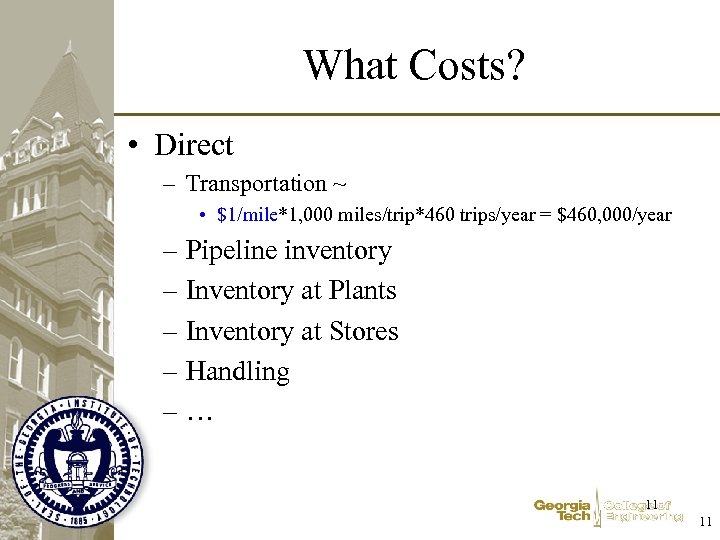

What Costs? • Direct – Transportation ~ • $1/mile*1, 000 miles/trip*460 trips/year = $460, 000/year – Pipeline inventory – Inventory at Plants – Inventory at Stores – Handling –… 11 11

What Costs? • Direct – Transportation ~ • $1/mile*1, 000 miles/trip*460 trips/year = $460, 000/year – Pipeline inventory – Inventory at Plants – Inventory at Stores – Handling –… 11 11

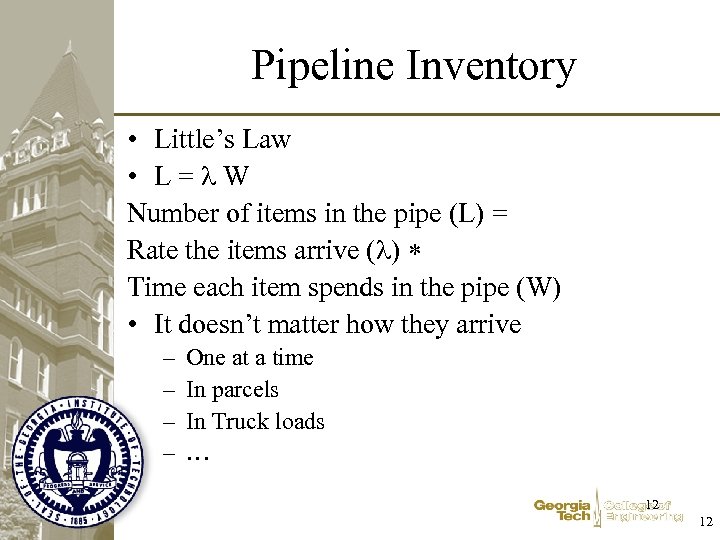

Pipeline Inventory • Little’s Law • L=l. W Number of items in the pipe (L) = Rate the items arrive (l) * Time each item spends in the pipe (W) • It doesn’t matter how they arrive – – One at a time In parcels In Truck loads … 12 12

Pipeline Inventory • Little’s Law • L=l. W Number of items in the pipe (L) = Rate the items arrive (l) * Time each item spends in the pipe (W) • It doesn’t matter how they arrive – – One at a time In parcels In Truck loads … 12 12

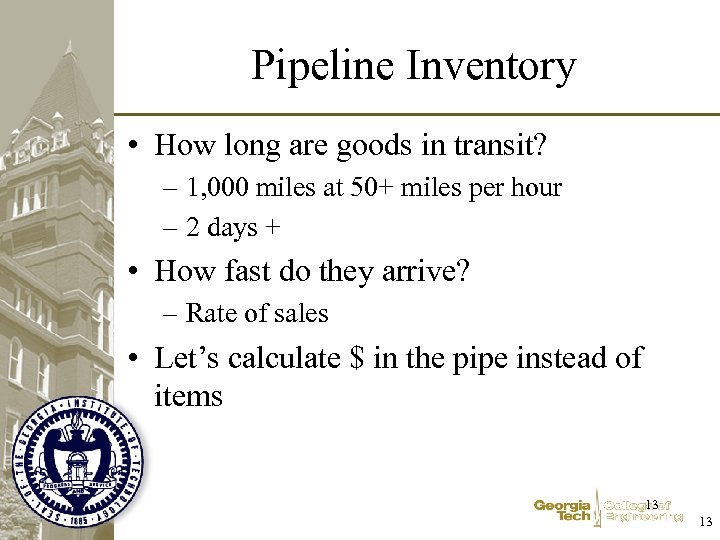

Pipeline Inventory • How long are goods in transit? – 1, 000 miles at 50+ miles per hour – 2 days + • How fast do they arrive? – Rate of sales • Let’s calculate $ in the pipe instead of items 13 13

Pipeline Inventory • How long are goods in transit? – 1, 000 miles at 50+ miles per hour – 2 days + • How fast do they arrive? – Rate of sales • Let’s calculate $ in the pipe instead of items 13 13

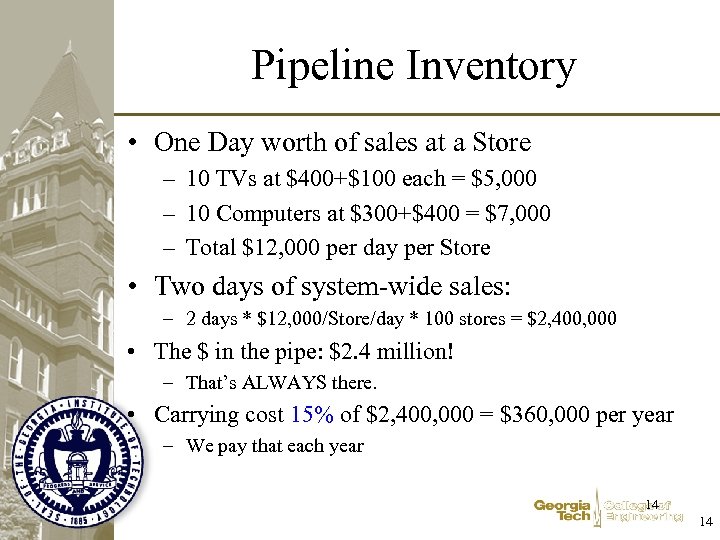

Pipeline Inventory • One Day worth of sales at a Store – 10 TVs at $400+$100 each = $5, 000 – 10 Computers at $300+$400 = $7, 000 – Total $12, 000 per day per Store • Two days of system-wide sales: – 2 days * $12, 000/Store/day * 100 stores = $2, 400, 000 • The $ in the pipe: $2. 4 million! – That’s ALWAYS there. • Carrying cost 15% of $2, 400, 000 = $360, 000 per year – We pay that each year 14 14

Pipeline Inventory • One Day worth of sales at a Store – 10 TVs at $400+$100 each = $5, 000 – 10 Computers at $300+$400 = $7, 000 – Total $12, 000 per day per Store • Two days of system-wide sales: – 2 days * $12, 000/Store/day * 100 stores = $2, 400, 000 • The $ in the pipe: $2. 4 million! – That’s ALWAYS there. • Carrying cost 15% of $2, 400, 000 = $360, 000 per year – We pay that each year 14 14

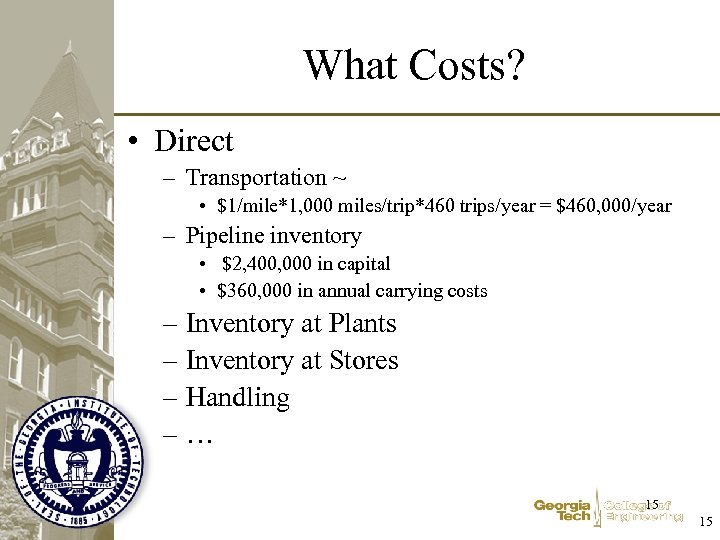

What Costs? • Direct – Transportation ~ • $1/mile*1, 000 miles/trip*460 trips/year = $460, 000/year – Pipeline inventory • $2, 400, 000 in capital • $360, 000 in annual carrying costs – Inventory at Plants – Inventory at Stores – Handling –… 15 15

What Costs? • Direct – Transportation ~ • $1/mile*1, 000 miles/trip*460 trips/year = $460, 000/year – Pipeline inventory • $2, 400, 000 in capital • $360, 000 in annual carrying costs – Inventory at Plants – Inventory at Stores – Handling –… 15 15

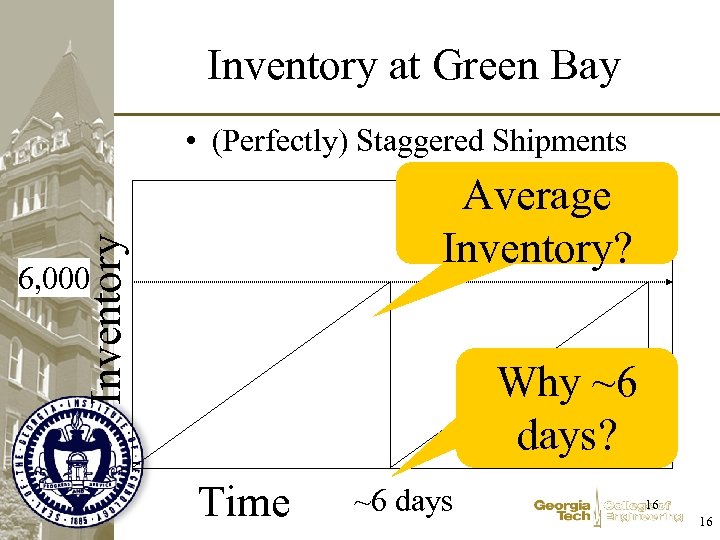

Inventory at Green Bay • (Perfectly) Staggered Shipments Inventory Average Inventory? 6, 000 Why ~6 days? Time ~6 days 16 16

Inventory at Green Bay • (Perfectly) Staggered Shipments Inventory Average Inventory? 6, 000 Why ~6 days? Time ~6 days 16 16

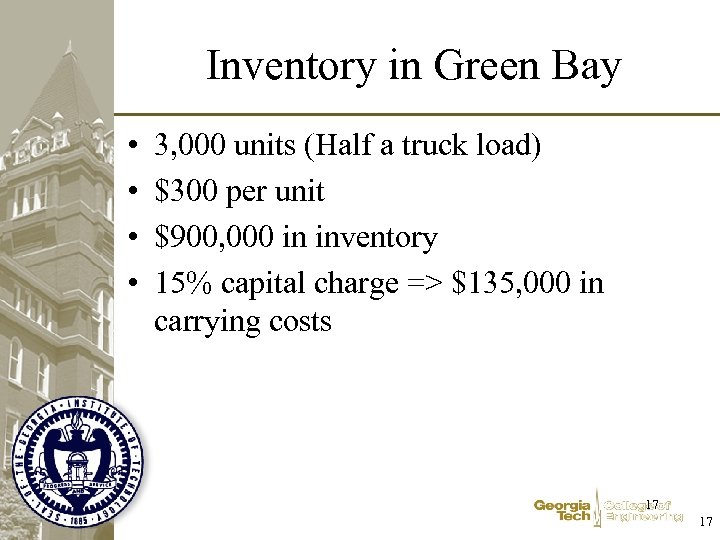

Inventory in Green Bay • • 3, 000 units (Half a truck load) $300 per unit $900, 000 in inventory 15% capital charge => $135, 000 in carrying costs 17 17

Inventory in Green Bay • • 3, 000 units (Half a truck load) $300 per unit $900, 000 in inventory 15% capital charge => $135, 000 in carrying costs 17 17

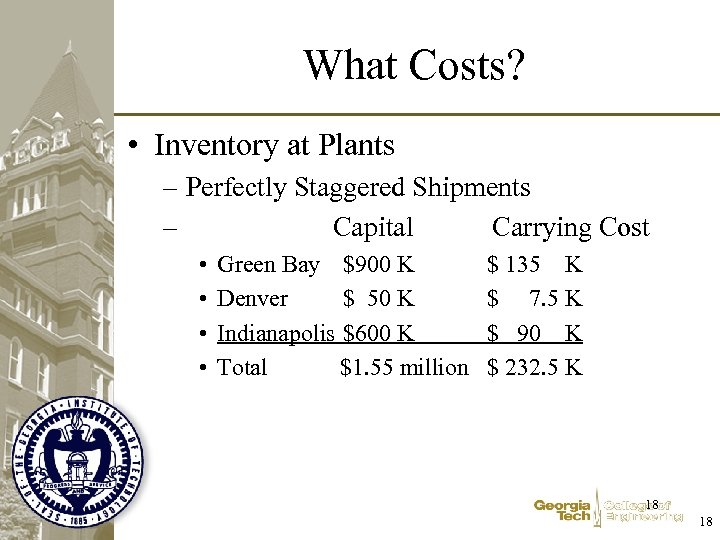

What Costs? • Inventory at Plants – Perfectly Staggered Shipments – Capital Carrying Cost • • Green Bay $900 K Denver $ 50 K Indianapolis $600 K Total $1. 55 million $ 135 K $ 7. 5 K $ 90 K $ 232. 5 K 18 18

What Costs? • Inventory at Plants – Perfectly Staggered Shipments – Capital Carrying Cost • • Green Bay $900 K Denver $ 50 K Indianapolis $600 K Total $1. 55 million $ 135 K $ 7. 5 K $ 90 K $ 232. 5 K 18 18

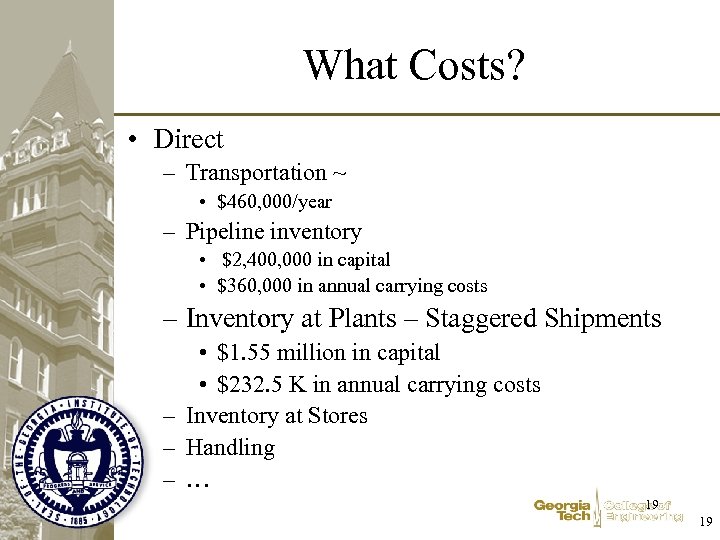

What Costs? • Direct – Transportation ~ • $460, 000/year – Pipeline inventory • $2, 400, 000 in capital • $360, 000 in annual carrying costs – Inventory at Plants – Staggered Shipments • $1. 55 million in capital • $232. 5 K in annual carrying costs – Inventory at Stores – Handling – … 19 19

What Costs? • Direct – Transportation ~ • $460, 000/year – Pipeline inventory • $2, 400, 000 in capital • $360, 000 in annual carrying costs – Inventory at Plants – Staggered Shipments • $1. 55 million in capital • $232. 5 K in annual carrying costs – Inventory at Stores – Handling – … 19 19

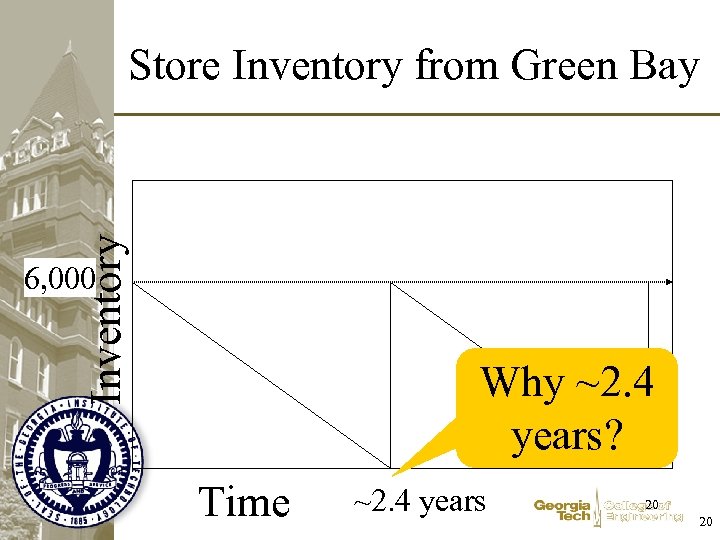

Inventory Store Inventory from Green Bay 6, 000 Why ~2. 4 years? Time ~2. 4 years 20 20

Inventory Store Inventory from Green Bay 6, 000 Why ~2. 4 years? Time ~2. 4 years 20 20

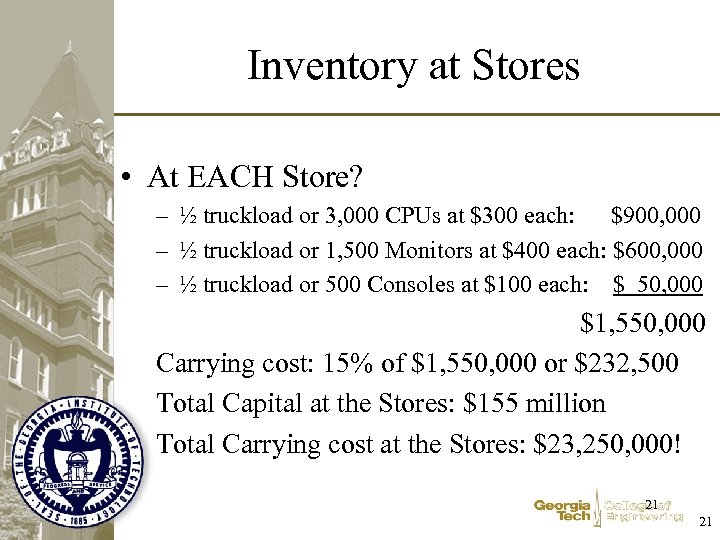

Inventory at Stores • At EACH Store? – ½ truckload or 3, 000 CPUs at $300 each: $900, 000 – ½ truckload or 1, 500 Monitors at $400 each: $600, 000 – ½ truckload or 500 Consoles at $100 each: $ 50, 000 $1, 550, 000 Carrying cost: 15% of $1, 550, 000 or $232, 500 Total Capital at the Stores: $155 million Total Carrying cost at the Stores: $23, 250, 000! 21 21

Inventory at Stores • At EACH Store? – ½ truckload or 3, 000 CPUs at $300 each: $900, 000 – ½ truckload or 1, 500 Monitors at $400 each: $600, 000 – ½ truckload or 500 Consoles at $100 each: $ 50, 000 $1, 550, 000 Carrying cost: 15% of $1, 550, 000 or $232, 500 Total Capital at the Stores: $155 million Total Carrying cost at the Stores: $23, 250, 000! 21 21

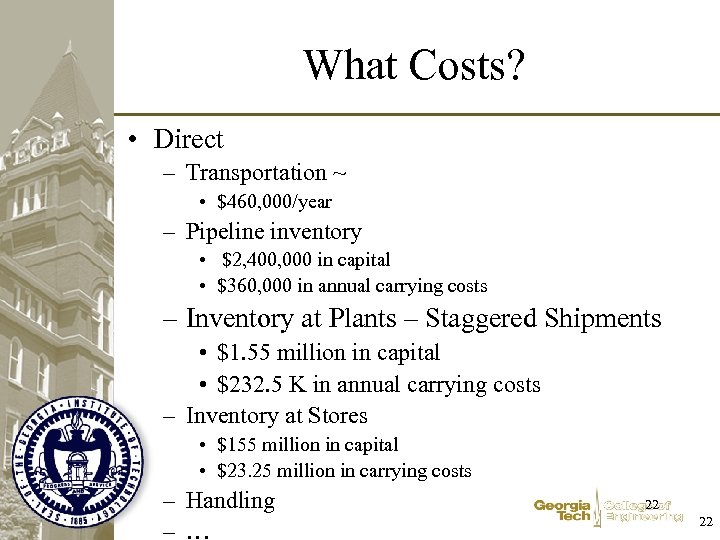

What Costs? • Direct – Transportation ~ • $460, 000/year – Pipeline inventory • $2, 400, 000 in capital • $360, 000 in annual carrying costs – Inventory at Plants – Staggered Shipments • $1. 55 million in capital • $232. 5 K in annual carrying costs – Inventory at Stores • $155 million in capital • $23. 25 million in carrying costs – Handling – … 22 22

What Costs? • Direct – Transportation ~ • $460, 000/year – Pipeline inventory • $2, 400, 000 in capital • $360, 000 in annual carrying costs – Inventory at Plants – Staggered Shipments • $1. 55 million in capital • $232. 5 K in annual carrying costs – Inventory at Stores • $155 million in capital • $23. 25 million in carrying costs – Handling – … 22 22

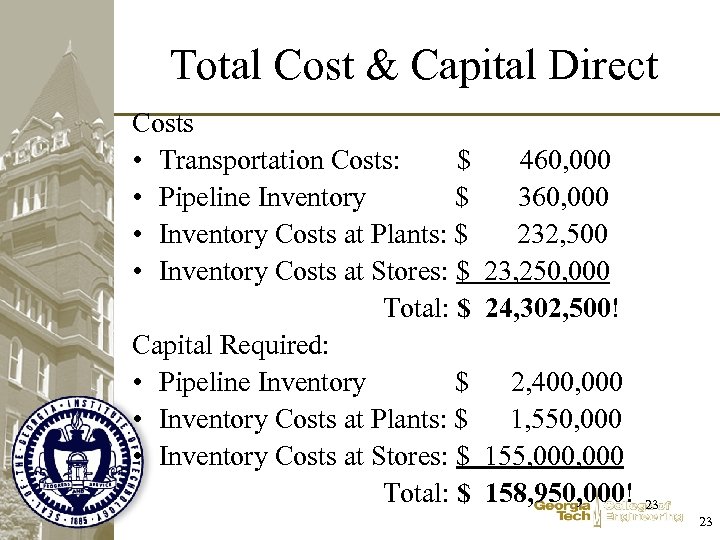

Total Cost & Capital Direct Costs • Transportation Costs: $ • Pipeline Inventory $ • Inventory Costs at Plants: $ • Inventory Costs at Stores: $ Total: $ Capital Required: • Pipeline Inventory $ • Inventory Costs at Plants: $ • Inventory Costs at Stores: $ Total: $ 460, 000 360, 000 232, 500 23, 250, 000 24, 302, 500! 2, 400, 000 1, 550, 000 155, 000 158, 950, 000! 23 23

Total Cost & Capital Direct Costs • Transportation Costs: $ • Pipeline Inventory $ • Inventory Costs at Plants: $ • Inventory Costs at Stores: $ Total: $ Capital Required: • Pipeline Inventory $ • Inventory Costs at Plants: $ • Inventory Costs at Stores: $ Total: $ 460, 000 360, 000 232, 500 23, 250, 000 24, 302, 500! 2, 400, 000 1, 550, 000 155, 000 158, 950, 000! 23 23

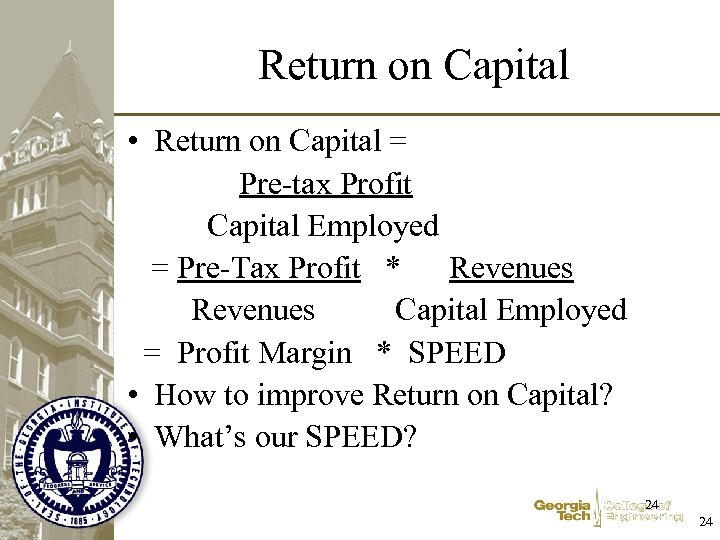

Return on Capital • Return on Capital = Pre-tax Profit Capital Employed = Pre-Tax Profit * Revenues Capital Employed = Profit Margin * SPEED • How to improve Return on Capital? • What’s our SPEED? 24 24

Return on Capital • Return on Capital = Pre-tax Profit Capital Employed = Pre-Tax Profit * Revenues Capital Employed = Profit Margin * SPEED • How to improve Return on Capital? • What’s our SPEED? 24 24

SPEED • Revenues: Well Cost of Goods, we don’t have selling prices…. • $12, 000/day per store • $1. 2 million per day • 250 days means $300 million • Capital Employed: $159 million (not counting the cost of the stores, the factories, and anything else we own) • Speed is 1. 89 = 300/159, i. e. , each year we generate $1. 89 in revenue for every $1 invested. 25 25

SPEED • Revenues: Well Cost of Goods, we don’t have selling prices…. • $12, 000/day per store • $1. 2 million per day • 250 days means $300 million • Capital Employed: $159 million (not counting the cost of the stores, the factories, and anything else we own) • Speed is 1. 89 = 300/159, i. e. , each year we generate $1. 89 in revenue for every $1 invested. 25 25

Your Job is… • As newly hired VP of SC, your job is to improve: – profitability and – capital utilization • Suggestions? 26 26

Your Job is… • As newly hired VP of SC, your job is to improve: – profitability and – capital utilization • Suggestions? 26 26

Consolidation • Strategy 2: Assemble Products in Indianapolis and distribute by truckload from there • What will happen to costs? – Transportation – Pipeline – At plants – At Indianapolis Warehouse/Cross Dock – At Stores 27 27

Consolidation • Strategy 2: Assemble Products in Indianapolis and distribute by truckload from there • What will happen to costs? – Transportation – Pipeline – At plants – At Indianapolis Warehouse/Cross Dock – At Stores 27 27

Via Indianapolis Facts 28 28

Via Indianapolis Facts 28 28

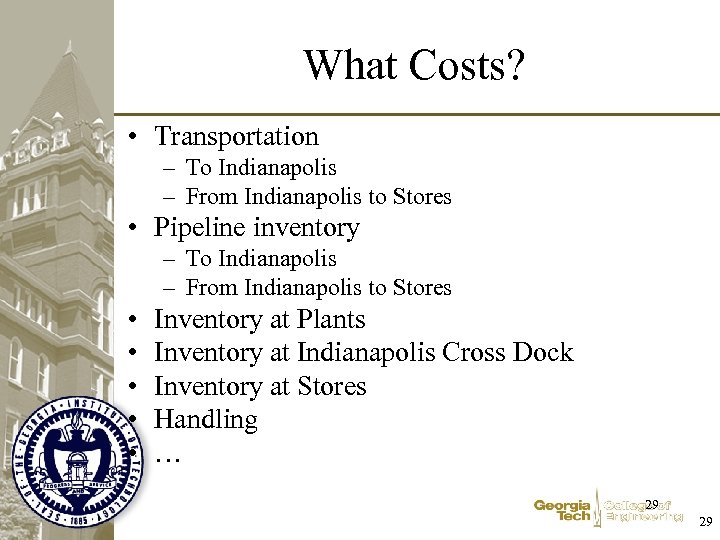

What Costs? • Transportation – To Indianapolis – From Indianapolis to Stores • Pipeline inventory – To Indianapolis – From Indianapolis to Stores • • • Inventory at Plants Inventory at Indianapolis Cross Dock Inventory at Stores Handling … 29 29

What Costs? • Transportation – To Indianapolis – From Indianapolis to Stores • Pipeline inventory – To Indianapolis – From Indianapolis to Stores • • • Inventory at Plants Inventory at Indianapolis Cross Dock Inventory at Stores Handling … 29 29

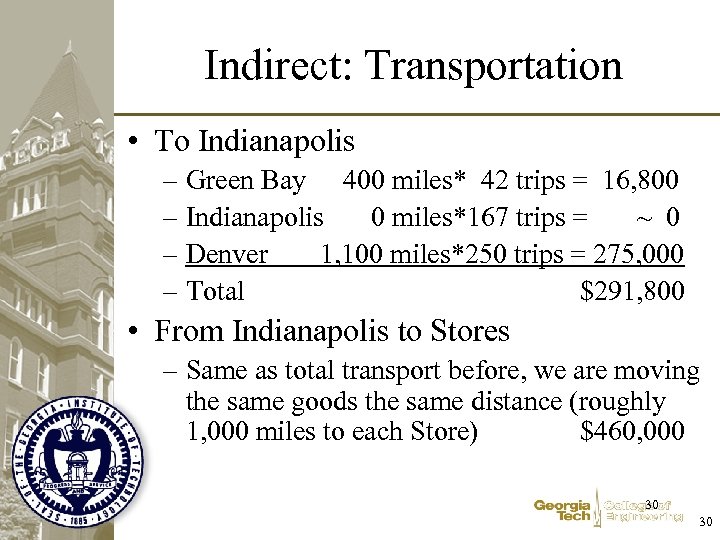

Indirect: Transportation • To Indianapolis – Green Bay 400 miles* 42 trips = 16, 800 – Indianapolis 0 miles*167 trips = ~ 0 – Denver 1, 100 miles*250 trips = 275, 000 – Total $291, 800 • From Indianapolis to Stores – Same as total transport before, we are moving the same goods the same distance (roughly 1, 000 miles to each Store) $460, 000 30 30

Indirect: Transportation • To Indianapolis – Green Bay 400 miles* 42 trips = 16, 800 – Indianapolis 0 miles*167 trips = ~ 0 – Denver 1, 100 miles*250 trips = 275, 000 – Total $291, 800 • From Indianapolis to Stores – Same as total transport before, we are moving the same goods the same distance (roughly 1, 000 miles to each Store) $460, 000 30 30

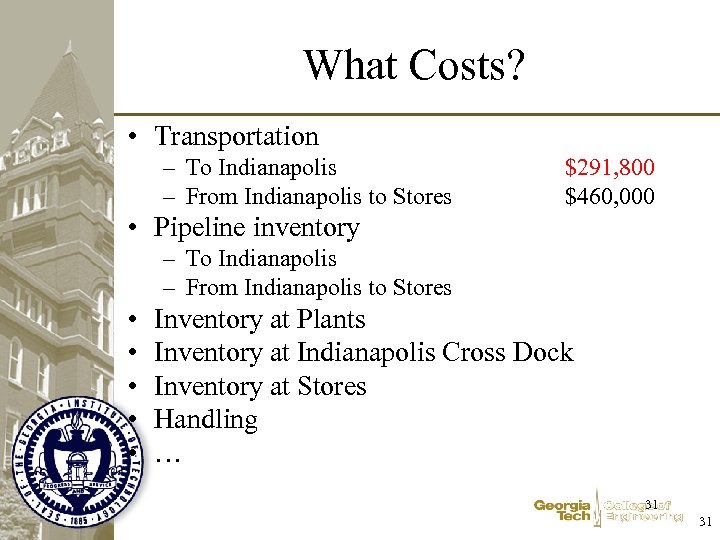

What Costs? • Transportation – To Indianapolis – From Indianapolis to Stores $291, 800 $460, 000 • Pipeline inventory – To Indianapolis – From Indianapolis to Stores • • • Inventory at Plants Inventory at Indianapolis Cross Dock Inventory at Stores Handling … 31 31

What Costs? • Transportation – To Indianapolis – From Indianapolis to Stores $291, 800 $460, 000 • Pipeline inventory – To Indianapolis – From Indianapolis to Stores • • • Inventory at Plants Inventory at Indianapolis Cross Dock Inventory at Stores Handling … 31 31

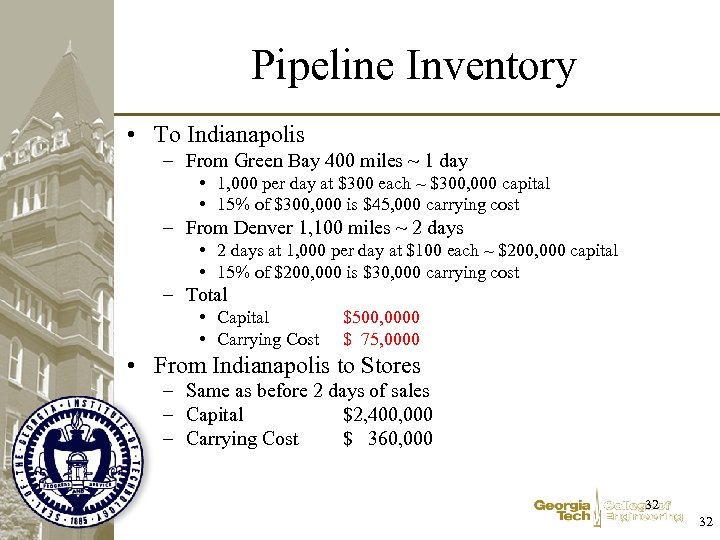

Pipeline Inventory • To Indianapolis – From Green Bay 400 miles ~ 1 day • 1, 000 per day at $300 each ~ $300, 000 capital • 15% of $300, 000 is $45, 000 carrying cost – From Denver 1, 100 miles ~ 2 days • 2 days at 1, 000 per day at $100 each ~ $200, 000 capital • 15% of $200, 000 is $30, 000 carrying cost – Total • Capital • Carrying Cost $500, 0000 $ 75, 0000 • From Indianapolis to Stores – Same as before 2 days of sales – Capital $2, 400, 000 – Carrying Cost $ 360, 000 32 32

Pipeline Inventory • To Indianapolis – From Green Bay 400 miles ~ 1 day • 1, 000 per day at $300 each ~ $300, 000 capital • 15% of $300, 000 is $45, 000 carrying cost – From Denver 1, 100 miles ~ 2 days • 2 days at 1, 000 per day at $100 each ~ $200, 000 capital • 15% of $200, 000 is $30, 000 carrying cost – Total • Capital • Carrying Cost $500, 0000 $ 75, 0000 • From Indianapolis to Stores – Same as before 2 days of sales – Capital $2, 400, 000 – Carrying Cost $ 360, 000 32 32

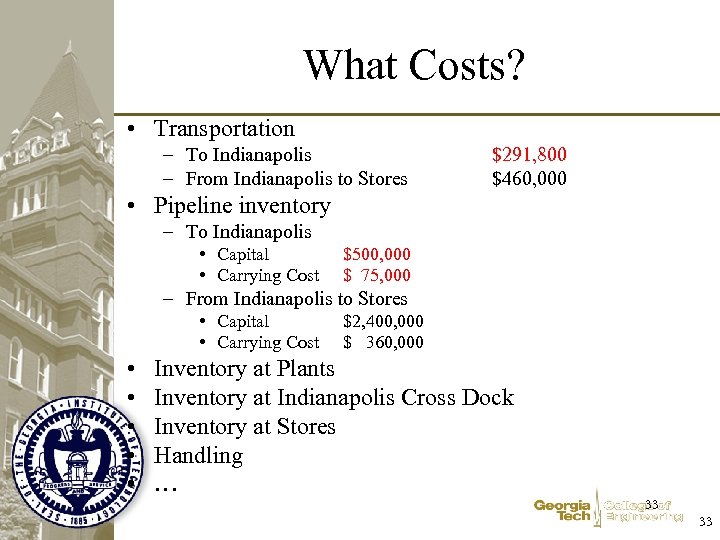

What Costs? • Transportation – To Indianapolis – From Indianapolis to Stores $291, 800 $460, 000 • Pipeline inventory – To Indianapolis • Capital • Carrying Cost $500, 000 $ 75, 000 – From Indianapolis to Stores • Capital • Carrying Cost • • • $2, 400, 000 $ 360, 000 Inventory at Plants Inventory at Indianapolis Cross Dock Inventory at Stores Handling … 33 33

What Costs? • Transportation – To Indianapolis – From Indianapolis to Stores $291, 800 $460, 000 • Pipeline inventory – To Indianapolis • Capital • Carrying Cost $500, 000 $ 75, 000 – From Indianapolis to Stores • Capital • Carrying Cost • • • $2, 400, 000 $ 360, 000 Inventory at Plants Inventory at Indianapolis Cross Dock Inventory at Stores Handling … 33 33

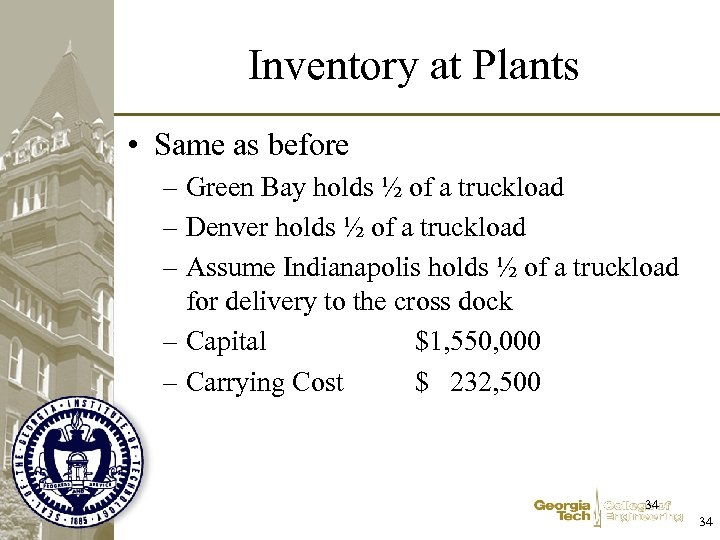

Inventory at Plants • Same as before – Green Bay holds ½ of a truckload – Denver holds ½ of a truckload – Assume Indianapolis holds ½ of a truckload for delivery to the cross dock – Capital $1, 550, 000 – Carrying Cost $ 232, 500 34 34

Inventory at Plants • Same as before – Green Bay holds ½ of a truckload – Denver holds ½ of a truckload – Assume Indianapolis holds ½ of a truckload for delivery to the cross dock – Capital $1, 550, 000 – Carrying Cost $ 232, 500 34 34

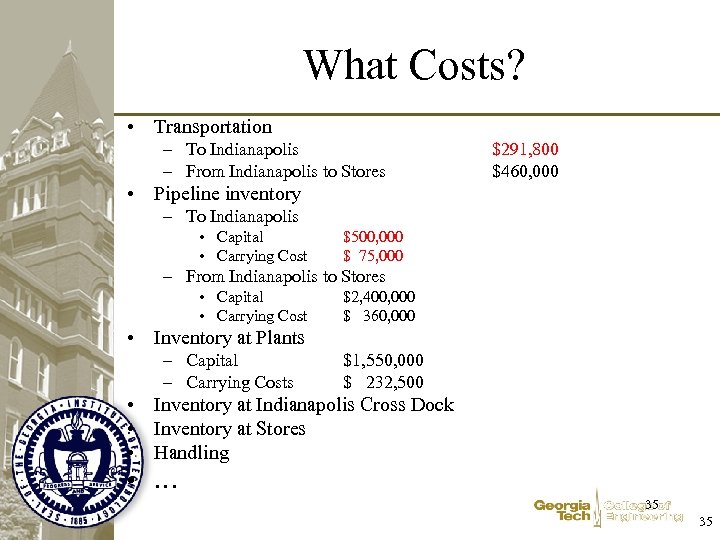

What Costs? • Transportation – To Indianapolis – From Indianapolis to Stores $291, 800 $460, 000 • Pipeline inventory – To Indianapolis • Capital • Carrying Cost $500, 000 $ 75, 000 – From Indianapolis to Stores • Capital • Carrying Cost $2, 400, 000 $ 360, 000 • Inventory at Plants – Capital – Carrying Costs $1, 550, 000 $ 232, 500 • Inventory at Indianapolis Cross Dock • Inventory at Stores • Handling • … 35 35

What Costs? • Transportation – To Indianapolis – From Indianapolis to Stores $291, 800 $460, 000 • Pipeline inventory – To Indianapolis • Capital • Carrying Cost $500, 000 $ 75, 000 – From Indianapolis to Stores • Capital • Carrying Cost $2, 400, 000 $ 360, 000 • Inventory at Plants – Capital – Carrying Costs $1, 550, 000 $ 232, 500 • Inventory at Indianapolis Cross Dock • Inventory at Stores • Handling • … 35 35

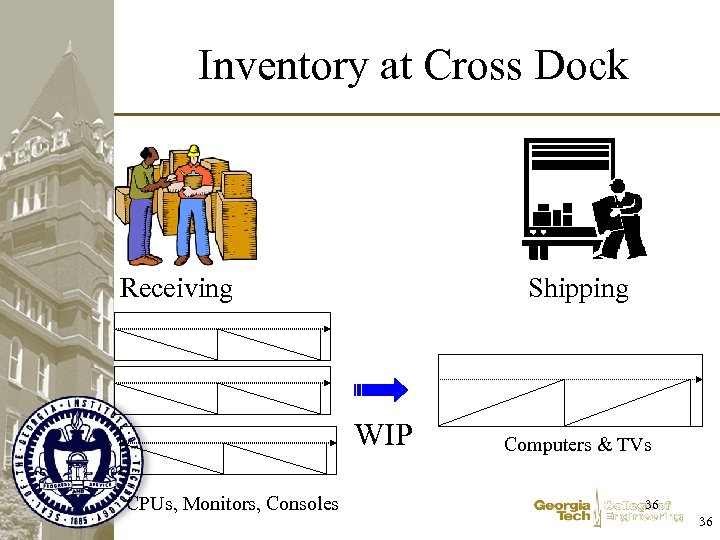

Inventory at Cross Dock Receiving Shipping WIP CPUs, Monitors, Consoles Computers & TVs 36 36

Inventory at Cross Dock Receiving Shipping WIP CPUs, Monitors, Consoles Computers & TVs 36 36

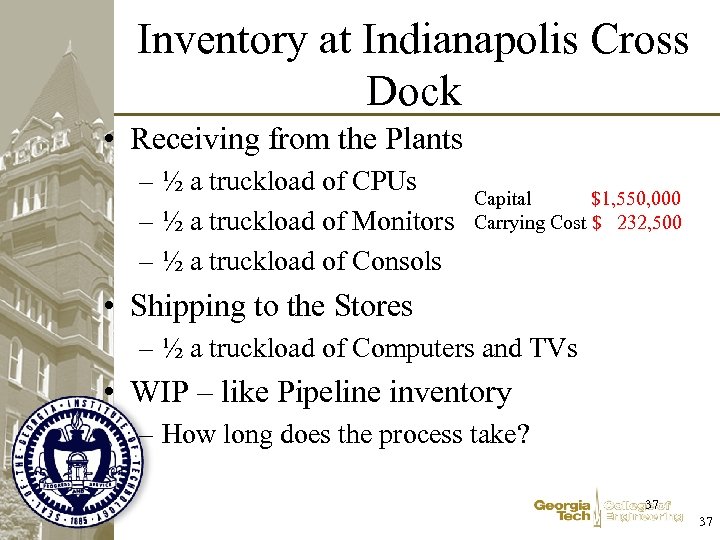

Inventory at Indianapolis Cross Dock • Receiving from the Plants – ½ a truckload of CPUs – ½ a truckload of Monitors – ½ a truckload of Consols Capital $1, 550, 000 Carrying Cost $ 232, 500 • Shipping to the Stores – ½ a truckload of Computers and TVs • WIP – like Pipeline inventory – How long does the process take? 37 37

Inventory at Indianapolis Cross Dock • Receiving from the Plants – ½ a truckload of CPUs – ½ a truckload of Monitors – ½ a truckload of Consols Capital $1, 550, 000 Carrying Cost $ 232, 500 • Shipping to the Stores – ½ a truckload of Computers and TVs • WIP – like Pipeline inventory – How long does the process take? 37 37

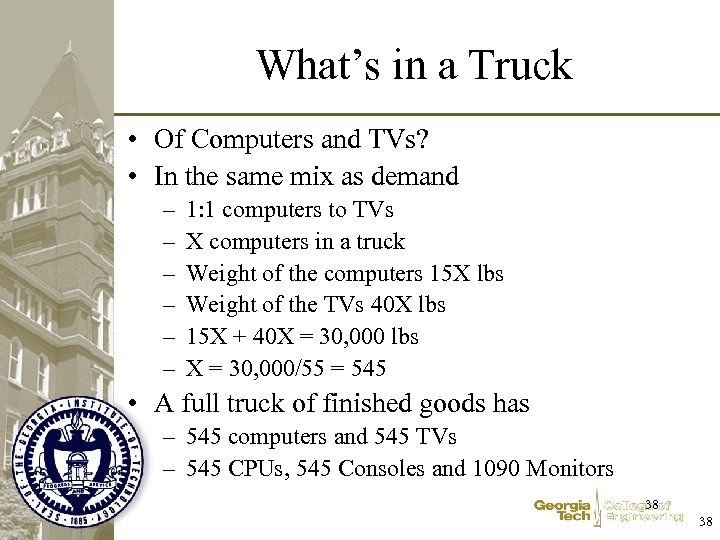

What’s in a Truck • Of Computers and TVs? • In the same mix as demand – – – 1: 1 computers to TVs X computers in a truck Weight of the computers 15 X lbs Weight of the TVs 40 X lbs 15 X + 40 X = 30, 000 lbs X = 30, 000/55 = 545 • A full truck of finished goods has – 545 computers and 545 TVs – 545 CPUs, 545 Consoles and 1090 Monitors 38 38

What’s in a Truck • Of Computers and TVs? • In the same mix as demand – – – 1: 1 computers to TVs X computers in a truck Weight of the computers 15 X lbs Weight of the TVs 40 X lbs 15 X + 40 X = 30, 000 lbs X = 30, 000/55 = 545 • A full truck of finished goods has – 545 computers and 545 TVs – 545 CPUs, 545 Consoles and 1090 Monitors 38 38

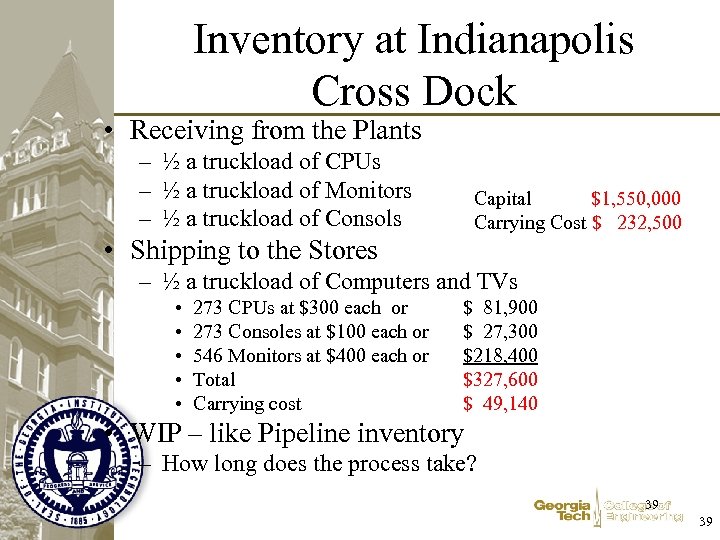

Inventory at Indianapolis Cross Dock • Receiving from the Plants – ½ a truckload of CPUs – ½ a truckload of Monitors – ½ a truckload of Consols Capital $1, 550, 000 Carrying Cost $ 232, 500 • Shipping to the Stores – ½ a truckload of Computers and TVs • • • 273 CPUs at $300 each or 273 Consoles at $100 each or 546 Monitors at $400 each or Total Carrying cost $ 81, 900 $ 27, 300 $218, 400 $327, 600 $ 49, 140 • WIP – like Pipeline inventory – How long does the process take? 39 39

Inventory at Indianapolis Cross Dock • Receiving from the Plants – ½ a truckload of CPUs – ½ a truckload of Monitors – ½ a truckload of Consols Capital $1, 550, 000 Carrying Cost $ 232, 500 • Shipping to the Stores – ½ a truckload of Computers and TVs • • • 273 CPUs at $300 each or 273 Consoles at $100 each or 546 Monitors at $400 each or Total Carrying cost $ 81, 900 $ 27, 300 $218, 400 $327, 600 $ 49, 140 • WIP – like Pipeline inventory – How long does the process take? 39 39

Inventory at Stores • Inventory at a Store: – Visited by truck 4. 6 times per year – Same as before – So inventory costs at Stores are the same as before, right? 40 40

Inventory at Stores • Inventory at a Store: – Visited by truck 4. 6 times per year – Same as before – So inventory costs at Stores are the same as before, right? 40 40

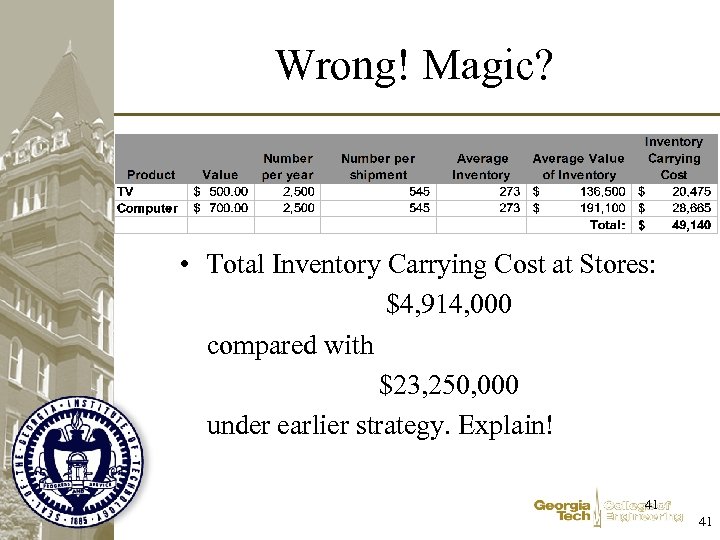

Wrong! Magic? • Total Inventory Carrying Cost at Stores: $4, 914, 000 compared with $23, 250, 000 under earlier strategy. Explain! 41 41

Wrong! Magic? • Total Inventory Carrying Cost at Stores: $4, 914, 000 compared with $23, 250, 000 under earlier strategy. Explain! 41 41

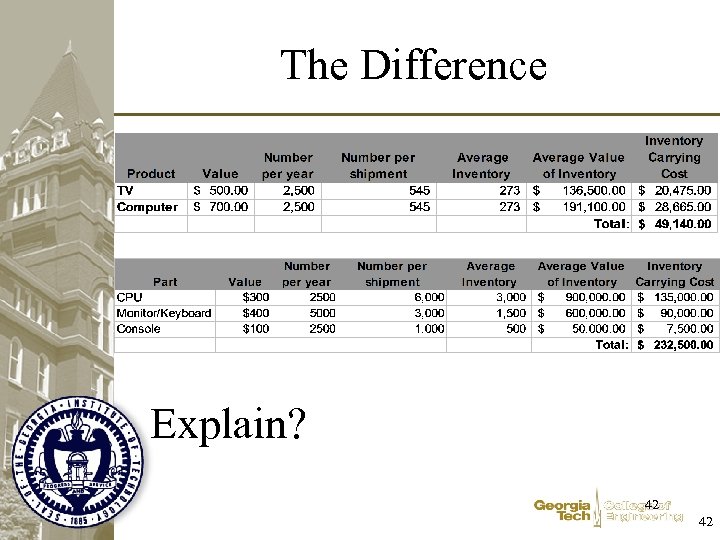

The Difference Explain? 42 42

The Difference Explain? 42 42

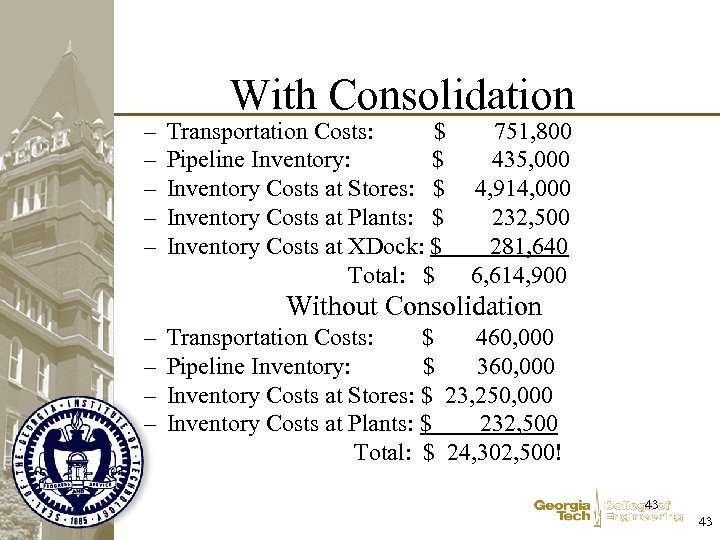

– – – With Consolidation Transportation Costs: $ Pipeline Inventory: $ Inventory Costs at Stores: $ Inventory Costs at Plants: $ Inventory Costs at XDock: $ Total: $ 751, 800 435, 000 4, 914, 000 232, 500 281, 640 6, 614, 900 Without Consolidation – – Transportation Costs: $ 460, 000 Pipeline Inventory: $ 360, 000 Inventory Costs at Stores: $ 23, 250, 000 Inventory Costs at Plants: $ 232, 500 Total: $ 24, 302, 500! 43 43

– – – With Consolidation Transportation Costs: $ Pipeline Inventory: $ Inventory Costs at Stores: $ Inventory Costs at Plants: $ Inventory Costs at XDock: $ Total: $ 751, 800 435, 000 4, 914, 000 232, 500 281, 640 6, 614, 900 Without Consolidation – – Transportation Costs: $ 460, 000 Pipeline Inventory: $ 360, 000 Inventory Costs at Stores: $ 23, 250, 000 Inventory Costs at Plants: $ 232, 500 Total: $ 24, 302, 500! 43 43

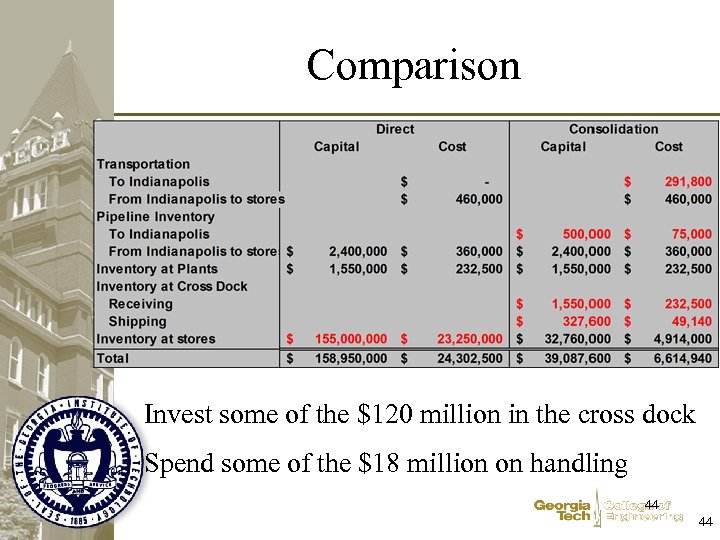

Comparison Invest some of the $120 million in the cross dock Spend some of the $18 million on handling 44 44

Comparison Invest some of the $120 million in the cross dock Spend some of the $18 million on handling 44 44

SPEED • With consolidation our SPEED (with the same caveats) is • $300 million/$39 million = 7. 69! • We generate $7. 69 in revenue for every $1 invested • That give us a lot more room to play with margin and still have a high return on capital 45 45

SPEED • With consolidation our SPEED (with the same caveats) is • $300 million/$39 million = 7. 69! • We generate $7. 69 in revenue for every $1 invested • That give us a lot more room to play with margin and still have a high return on capital 45 45

For Future Reference • Consolidation illustrates two situations – 1 -to-1 shipments • E. g. from Green Bay to Indianapolis XDock • Inventory at Green Bay Inventory of CPUs in Indianapolis – 1 -to-Many shipments • E. g. , from XDock to stores • Inventory at XDock Inventory at a SINGLE store • The point: Inventory at the origin of a 1 -to-Many system has a smaller impact than in a 1 -to-1 system…we will see this next time. 46 46

For Future Reference • Consolidation illustrates two situations – 1 -to-1 shipments • E. g. from Green Bay to Indianapolis XDock • Inventory at Green Bay Inventory of CPUs in Indianapolis – 1 -to-Many shipments • E. g. , from XDock to stores • Inventory at XDock Inventory at a SINGLE store • The point: Inventory at the origin of a 1 -to-Many system has a smaller impact than in a 1 -to-1 system…we will see this next time. 46 46

Summary • Deterministic Inventory – Pipeline – Cycle – WIP • • • Pipeline from Days in transit * Value/Day Cycle from half of shipment WIP like pipeline Value of consolidation Quick & Dirty analysis first 47 47

Summary • Deterministic Inventory – Pipeline – Cycle – WIP • • • Pipeline from Days in transit * Value/Day Cycle from half of shipment WIP like pipeline Value of consolidation Quick & Dirty analysis first 47 47

Deterministic Supply Chain Design • Next time: should we be shipping in full truckloads? • Later, how to reduce inventory in stores • Reducing inventory in stores is a powerful way to improve return on capital – Wal-Mart has more than 2, 300 supercenters in the US – Reducing inventory in each one by a mere $10 K frees $23 million in capital. 48 48

Deterministic Supply Chain Design • Next time: should we be shipping in full truckloads? • Later, how to reduce inventory in stores • Reducing inventory in stores is a powerful way to improve return on capital – Wal-Mart has more than 2, 300 supercenters in the US – Reducing inventory in each one by a mere $10 K frees $23 million in capital. 48 48