a7e9bb9e815afe795fb041b1f7cb6b71.ppt

- Количество слайдов: 34

Model-Based Control for Automotive Cold Start Applications J. Karl Hedrick Carlos Zavala Pannag Sanketi Mechanical Engineering Dept. , University of California, Berkeley 2007 CHESS Winter Meeting

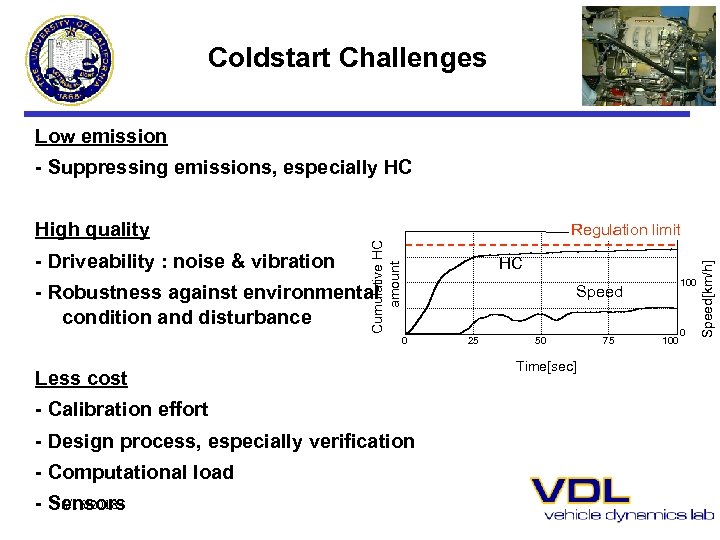

Coldstart Challenges Low emission - Suppressing emissions, especially HC HC - Robustness against environmental condition and disturbance 0 Less cost - Calibration effort - Design process, especially verification - Computational load 3/16/2018 - Sensors 100 Speed 25 50 Time[sec] 75 100 0 Speed[km/h] - Driveability : noise & vibration Regulation limit Cumulative HC amount High quality

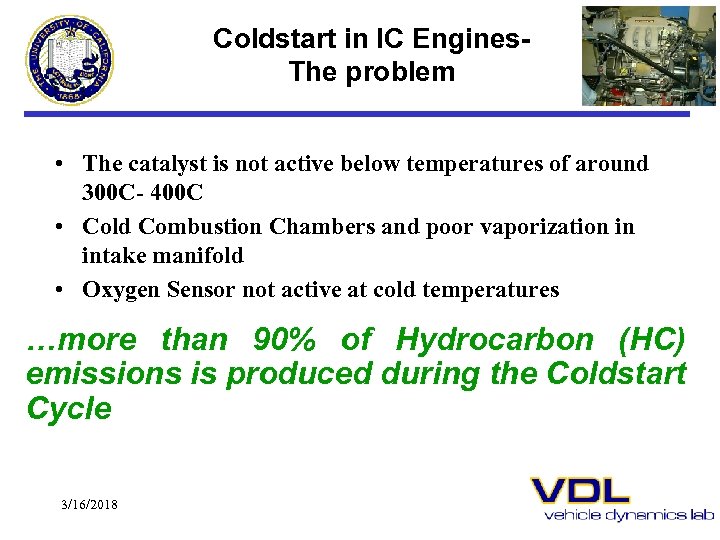

Coldstart in IC Engines. The problem • The catalyst is not active below temperatures of around 300 C- 400 C • Cold Combustion Chambers and poor vaporization in intake manifold • Oxygen Sensor not active at cold temperatures …more than 90% of Hydrocarbon (HC) emissions is produced during the Coldstart Cycle 3/16/2018

Model Based Approach to Emissions Reduction during Coldstart • Utilizes formal description of the engine to derive efficient ways of control. – Physical Models. Intuitive representation. – Black box models. Non-physical parameters. – Gray models. Combination of the two above • Motivation - improved control - efficient generation of software - software reusability 3/16/2018

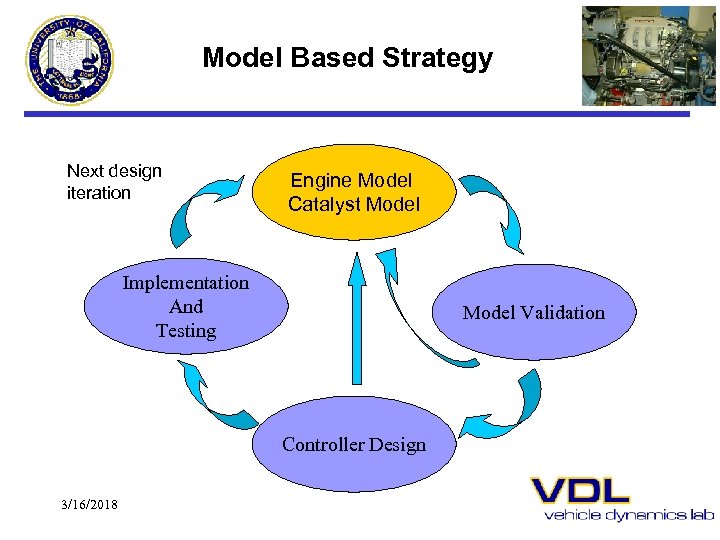

Model Based Strategy Next design iteration Engine Model Catalyst Model Implementation And Testing Model Validation Controller Design 3/16/2018

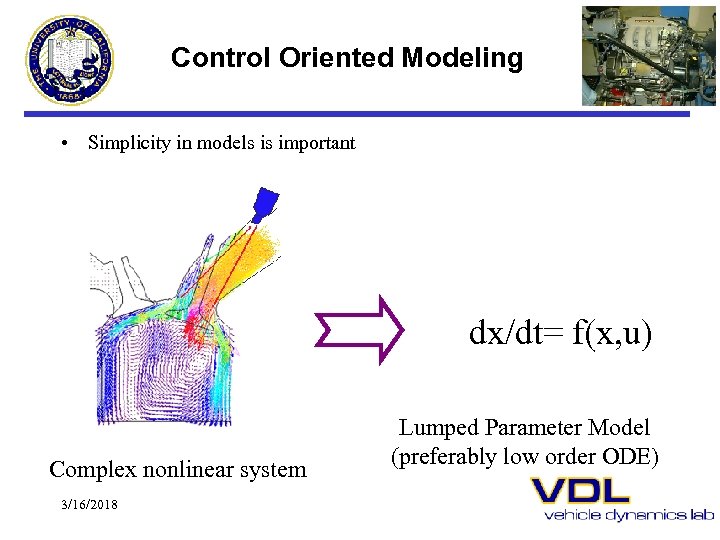

Control Oriented Modeling • Simplicity in models is important dx/dt= f(x, u) Complex nonlinear system 3/16/2018 Lumped Parameter Model (preferably low order ODE)

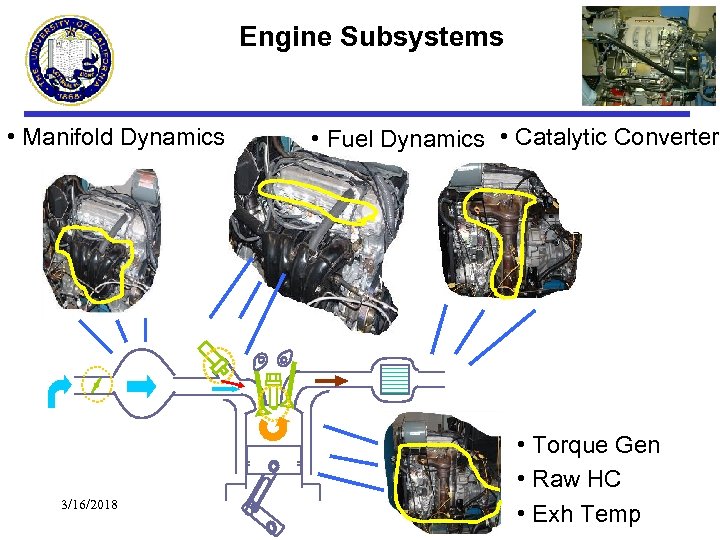

Engine Subsystems • Manifold Dynamics 3/16/2018 • Fuel Dynamics • Catalytic Converter • Torque Gen • Raw HC • Exh Temp

Engine Subsystems Modeling General Purpose Engine Modeling For control of air-fuel ratio, idle speed, models developed ~1980 • Combustion torque generation • Rotational dynamics and time delays • Actuator and sensor dynamics Cold Start Engine Modeling • Air and fuel dynamics • Catalytic converter dynamics • Engine thermal dynamics 3/16/2018

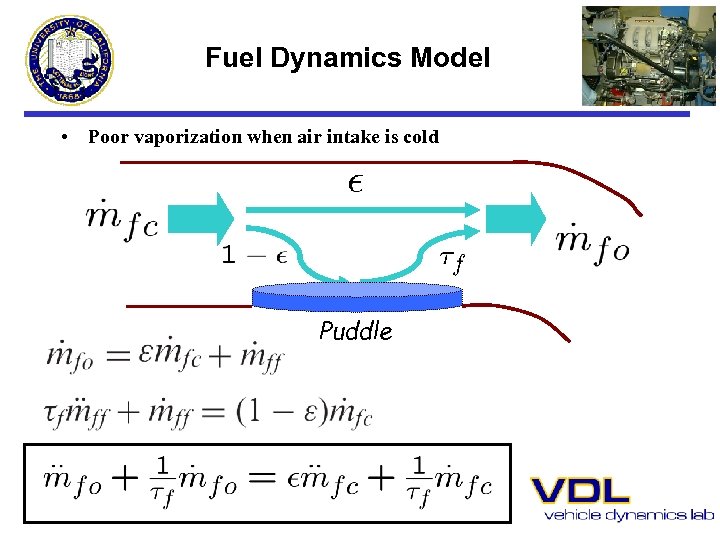

Fuel Dynamics Model • Poor vaporization when air intake is cold Puddle 3/16/2018

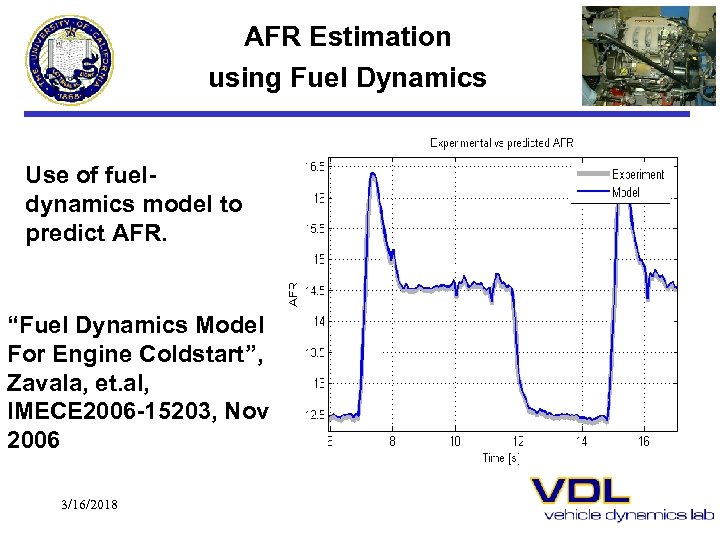

AFR Estimation using Fuel Dynamics Use of fueldynamics model to predict AFR. “Fuel Dynamics Model For Engine Coldstart”, Zavala, et. al, IMECE 2006 -15203, Nov. 2006 3/16/2018

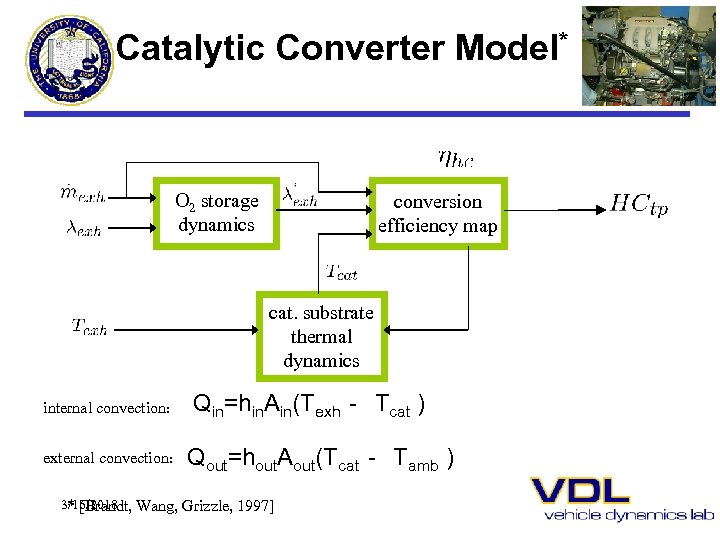

Catalytic Converter Model* O 2 storage dynamics conversion efficiency map cat. substrate thermal dynamics internal convection: external convection: Qin=hin. Ain(Texh - Tcat ) Qout=hout. Aout(Tcat - Tamb ) 3/16/2018 Wang, Grizzle, 1997] * [Brandt,

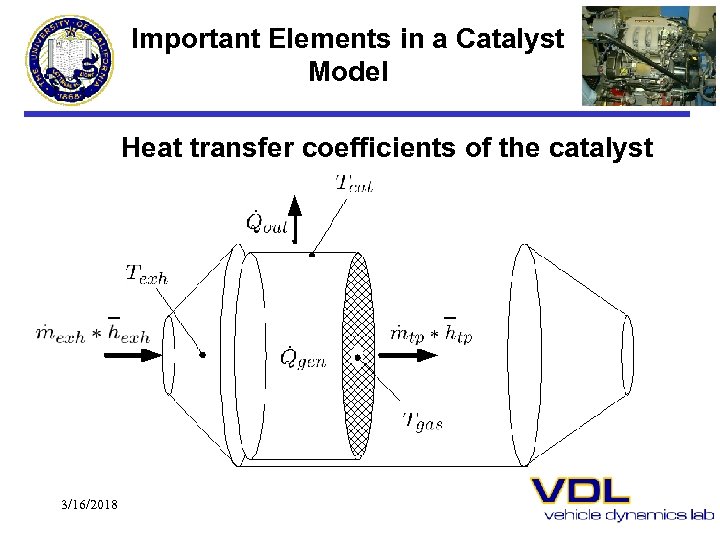

Important Elements in a Catalyst Model Heat transfer coefficients of the catalyst 3/16/2018

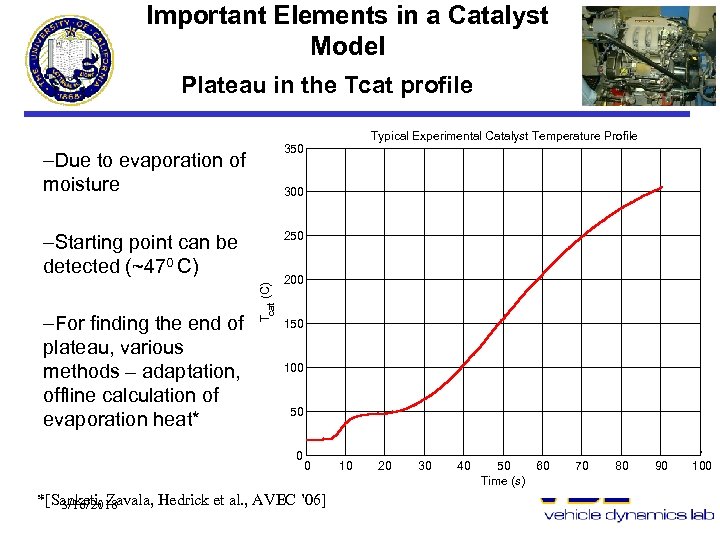

Important Elements in a Catalyst Model Plateau in the Tcat profile Typical Experimental Catalyst Temperature Profile 350 –Due to evaporation of moisture 300 250 –For finding the end of plateau, various methods – adaptation, offline calculation of evaporation heat* Tcat (C) –Starting point can be detected (~470 C) 200 150 100 50 0 0 *[Sanketi, Zavala, Hedrick et al. , AVEC ’ 06] 3/16/2018 10 20 30 40 50 60 Time (s) 70 80 90 100

Experimental plots of Catalyst 3/16/2018

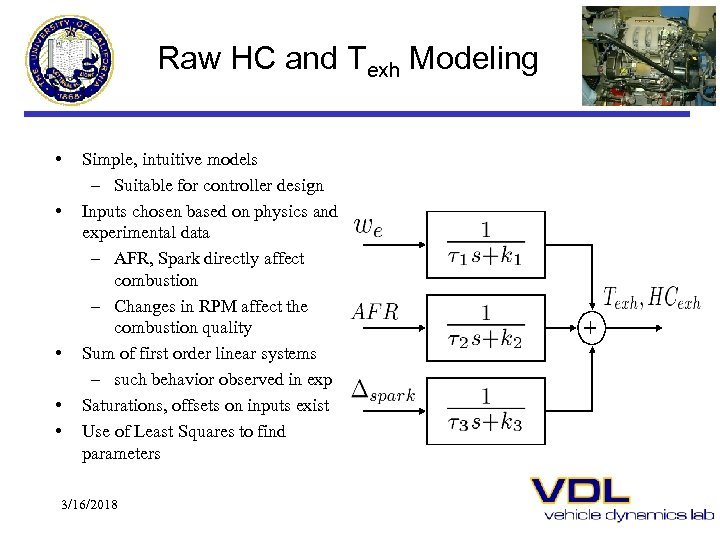

Raw HC and Texh Modeling • • • Simple, intuitive models – Suitable for controller design Inputs chosen based on physics and experimental data – AFR, Spark directly affect combustion – Changes in RPM affect the combustion quality Sum of first order linear systems – such behavior observed in exp Saturations, offsets on inputs exist Use of Least Squares to find parameters 3/16/2018

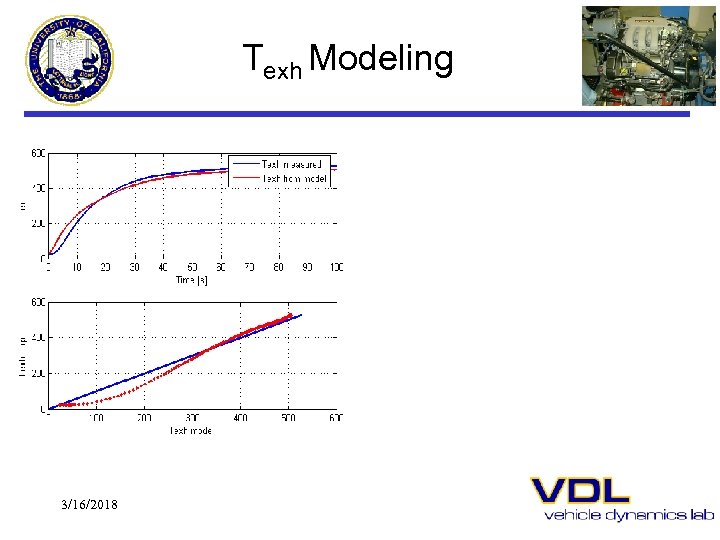

Texh Modeling 3/16/2018

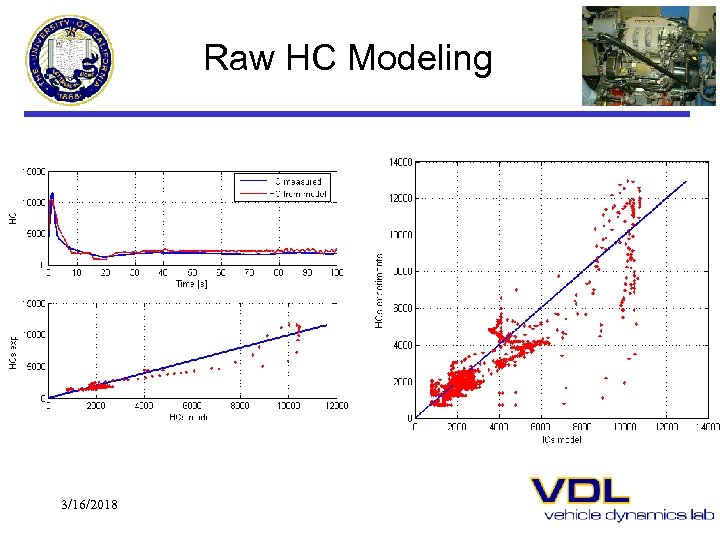

Raw HC Modeling 3/16/2018

Control Design Once the plant is defined, the synthesis of a controller should considered : – – – Performance requirements Uncertainty Nonlinearities Actuator bandwidth Sensor noise Disturbances 3/16/2018 u ? Plant y

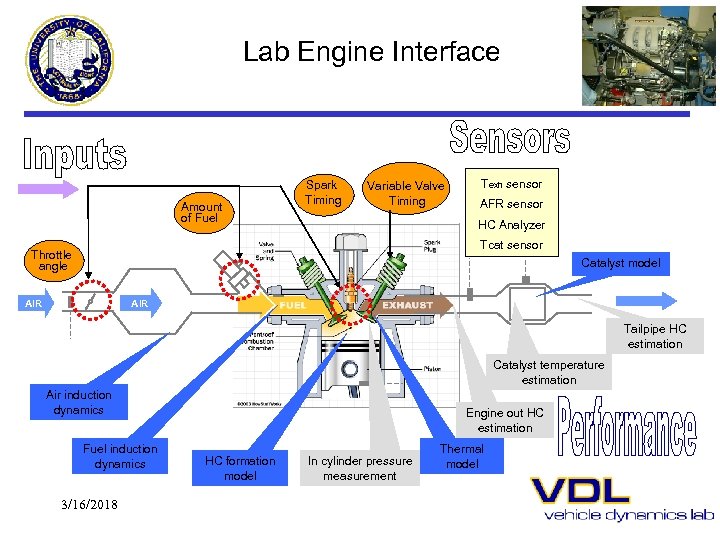

Lab Engine Interface Amount of Fuel Spark Timing Variable Valve Timing Texh sensor AFR sensor HC Analyzer Tcat sensor Throttle angle Catalyst model AIR Tailpipe HC estimation Catalyst temperature estimation Air induction dynamics Fuel induction dynamics 3/16/2018 Engine out HC estimation HC formation model In cylinder pressure measurement Thermal model

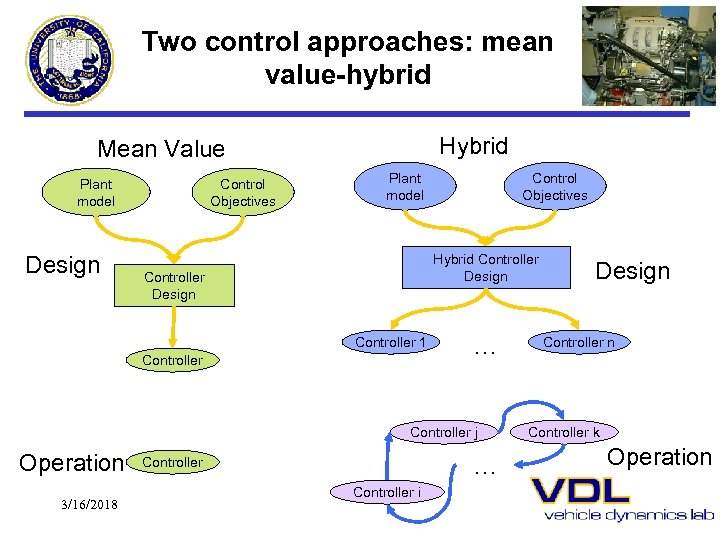

Two control approaches: mean value-hybrid Hybrid Mean Value Plant model Design Control Objectives Plant model Control Objectives Hybrid Controller Design Controller 1 Controller … Controller j Operation 3/16/2018 … Controller i Design Controller k Operation

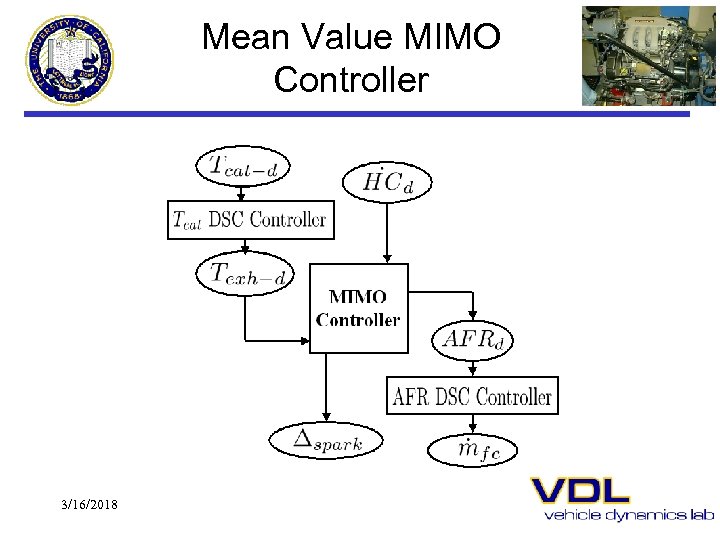

Mean Value MIMO Controller 3/16/2018

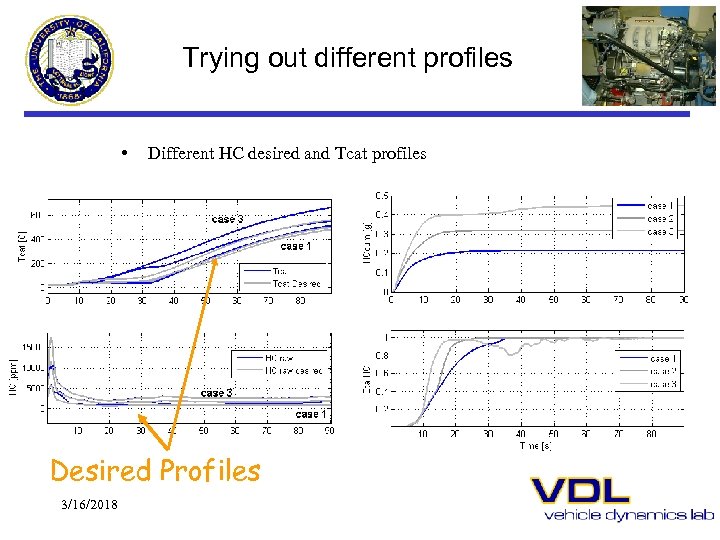

Trying out different profiles • Different HC desired and Tcat profiles Desired Profiles 3/16/2018

Model-Based Integration of Embedded Systems The complexity of automotive systems demands the use of more sophisticated tools for control software verification: • analysis of complex embedded systems • software assurance through modeling in all phases of software development process • Handling hybrid system analysis • Software timing analysis 3/16/2018

Why hybrid models? • Advantages – It accounts for continuous dynamics and discrete events. – It offers a more detailed description compared to mean-value models. • Disadvantages – No analytic solutions for stability analysis – More complicated than mean-value models. – Analysis tools still in development 3/16/2018

Engine Model • Mean Value models of Intake air flow and manifold air mass. (continuous dynamics). • Air and fuel flowing into cylinder calculated for each combustion cycle. (Discrete quantities). • Strokes of engine considered as discrete events using finite state machines (FSM: hybrid). • Torque and pollutants modeled for each combustion cycle. (continuous functions based on events: hybrid). 3/16/2018

Controller Verification of Hybrid Systems • Question of stability and evolution of the states • Model simulations cannot cover all possible trajectories inside a set • Reachability analysis – Tells you how your state space will behave with time starting given a set of initial conditions and bounds on inputs – Very useful in verifying the controller performance 3/16/2018

Example Hybrid Controller • Cumulative tailpipe HC function of both raw HC and catalyst efficiency • Trade off exists between the two objectives • A high level hybrid controller to exploit the trade-off 3/16/2018

Control Hierarchy The hybrid controller switches between the Tcat and HC dynamic surface controllers The Tcat and HC dynamic surface controllers use Texh and AFR respectively The low level Texh and AFR controllers use spark timing and fuel injection rate as the inputs respectively 3/16/2018

Hybrid Controller Modes Helps fast catalyst light-off 3/16/2018 Helps keep the raw emissions low

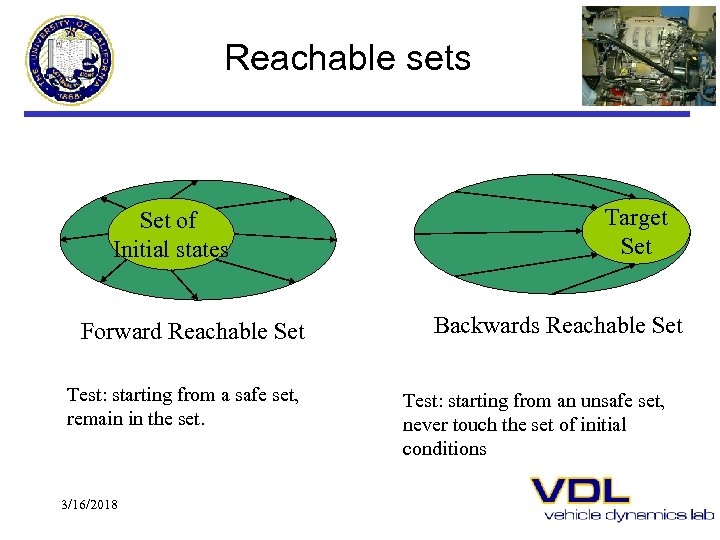

Reachable sets Set of Initial states Forward Reachable Set Test: starting from a safe set, remain in the set. 3/16/2018 Target Set Backwards Reachable Set Test: starting from an unsafe set, never touch the set of initial conditions

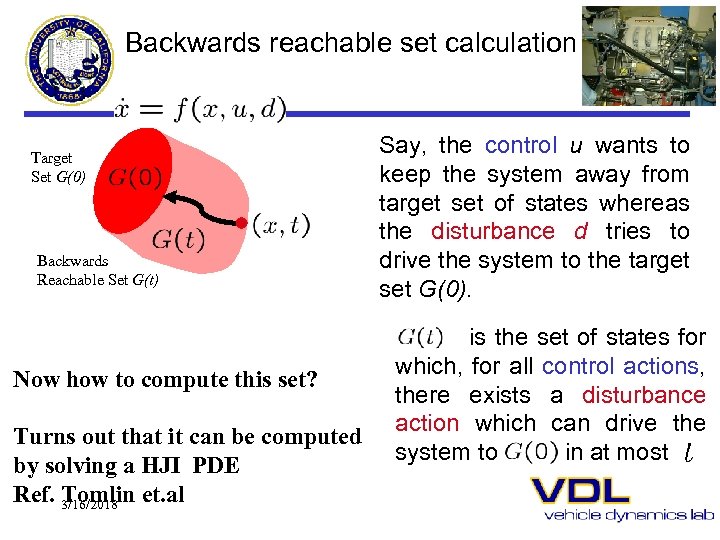

Backwards reachable set calculation Target Set G(0) Backwards Reachable Set G(t) Now how to compute this set? Turns out that it can be computed by solving a HJI PDE Ref. Tomlin et. al 3/16/2018 Say, the control u wants to keep the system away from target set of states whereas the disturbance d tries to drive the system to the target set G(0). is the set of states for which, for all control actions, there exists a disturbance action which can drive the system to in at most

![Reachability Analysis of Coldstart Controller* *[Sanketi, Zavala, Hedrick]- IJC, 2006 3/16/2018 Backwards Reachability Reachability Analysis of Coldstart Controller* *[Sanketi, Zavala, Hedrick]- IJC, 2006 3/16/2018 Backwards Reachability](https://present5.com/presentation/a7e9bb9e815afe795fb041b1f7cb6b71/image-32.jpg)

Reachability Analysis of Coldstart Controller* *[Sanketi, Zavala, Hedrick]- IJC, 2006 3/16/2018 Backwards Reachability

Conclusions • Hybrid modeling helped to achieve a more detailed description of engine operation • Hybrid control gave the chance to explore the tradeoff of hydrocarbon emissions level and catalyst light-off. • Hybrid modeling is a useful tool for coldstart analysis. 3/16/2018

Future of coldstart control • • • Fewer experiments for model validation. Closed-Loop control design Easy adaptation to new engines. Automated code generation. Automated software validation and verification. Use of AFR and HC production sensors and/or model based observers. 3/16/2018

a7e9bb9e815afe795fb041b1f7cb6b71.ppt